A Systems Engineering Approach to Decarbonizing Mining: Analyzing Electrification and CO2 Emission Reduction Scenarios for Copper Mining Haulage Systems

Abstract

1. Introduction

- Electrification of waste and ore haulage by replacing the diesel fleet with an electric overland conveyor system in an open-pit copper mine in Canada with 12 years of life-of-mine (LOM).

- Decarbonization potential of electric overland conveyor system-based waste and ore haulage in different jurisdictions with various grid emission factors.

- It provides a systematic approach to quantifying the evaluation of decarbonization alternatives. It considers the costs, energy, and carbon savings of low-carbon technology alternatives at various stages of the mine life cycle with different mining characteristics.

- It Integrates market, policy, local, and climate-related risks and opportunities into the business-as-usual and electrification option analyses.

- It allows mapping the complex mining system holistically, time-efficiently, and cost-effectively to provide cost-effective improvement options by addressing highly interdependent operational and process subsystems of mining operations.

1.1. Overview of Copper Demand and Supply

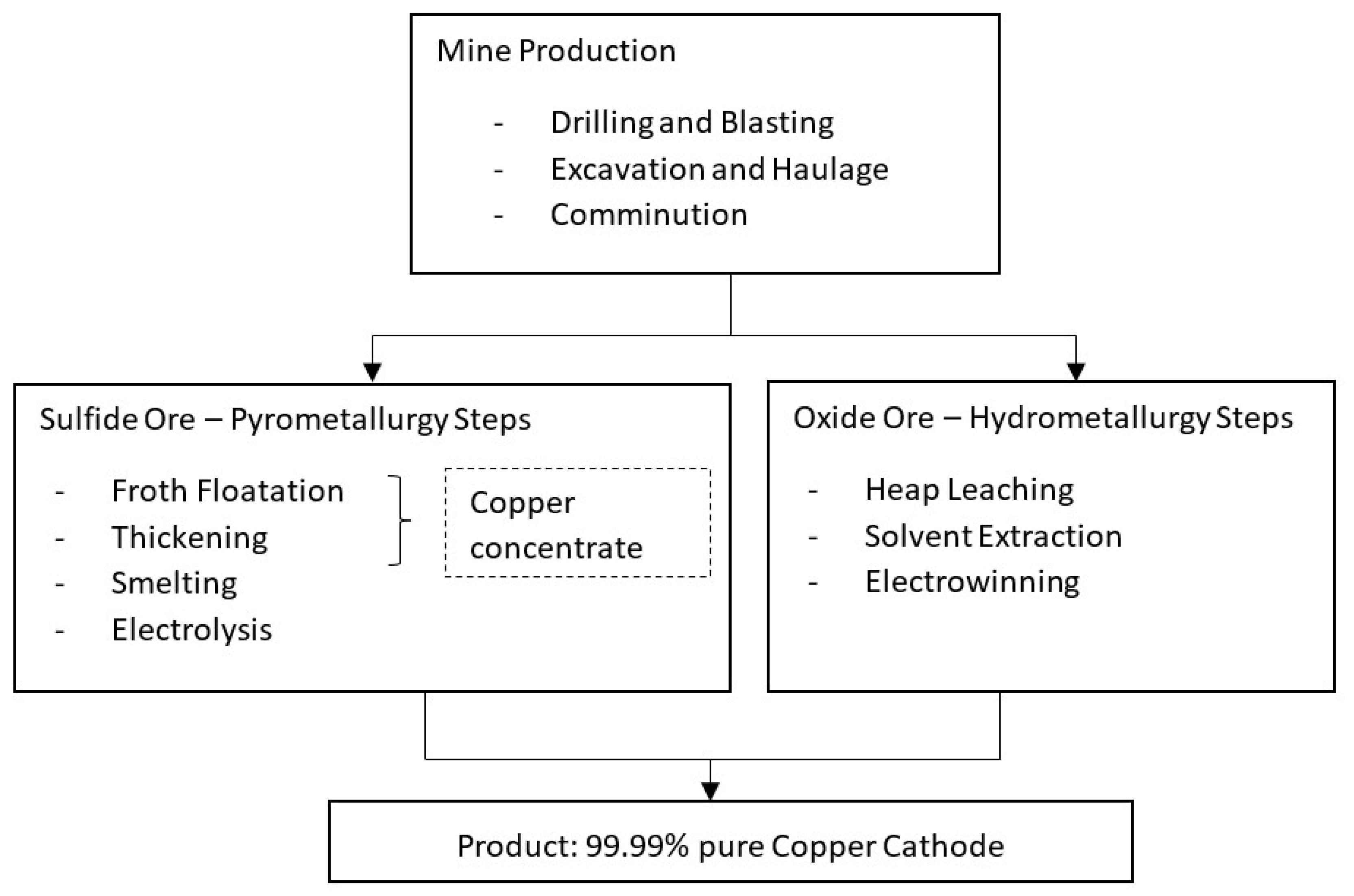

1.2. Surface Copper Mining and Beneficiation Systems

1.3. System Dynamics Modeling (SDM)

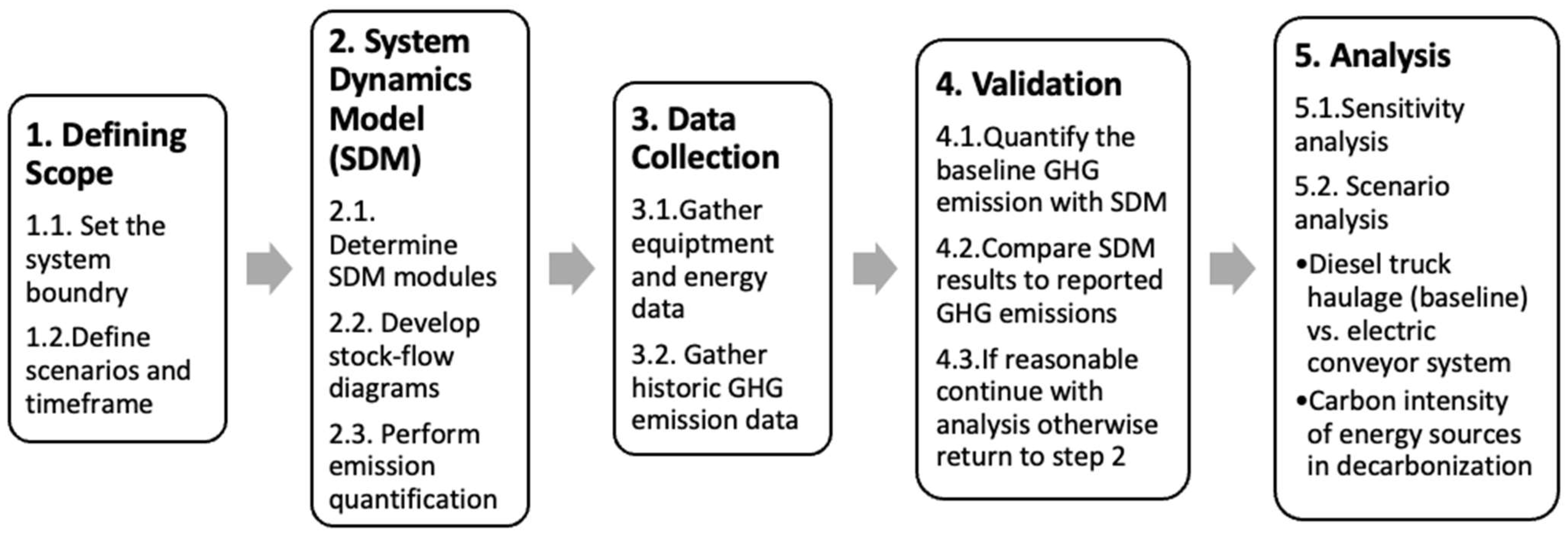

2. Materials and Methods

3. Implementation of the Methodology to an Open-Pit Copper Mining Operation

3.1. Defining Scope

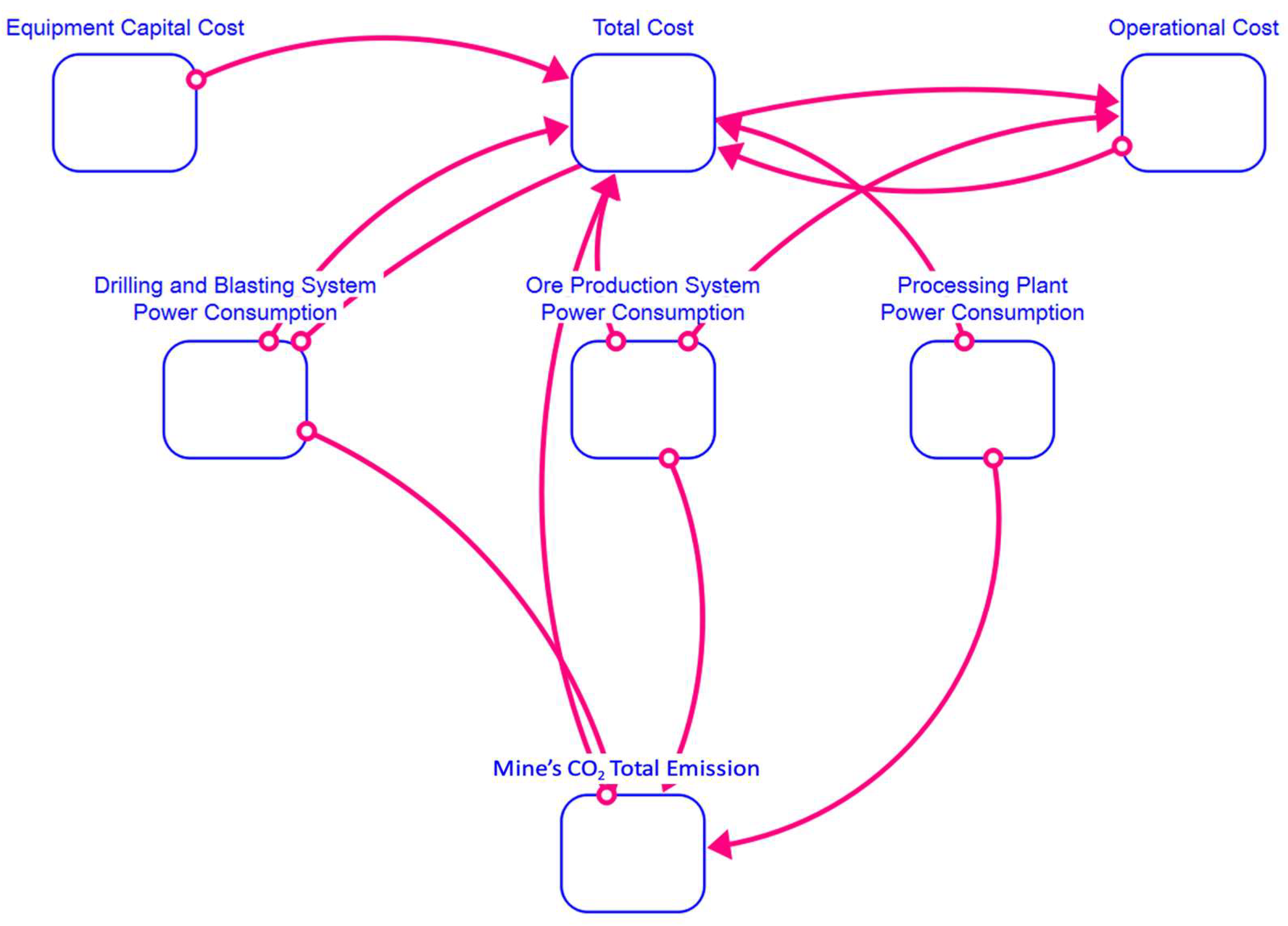

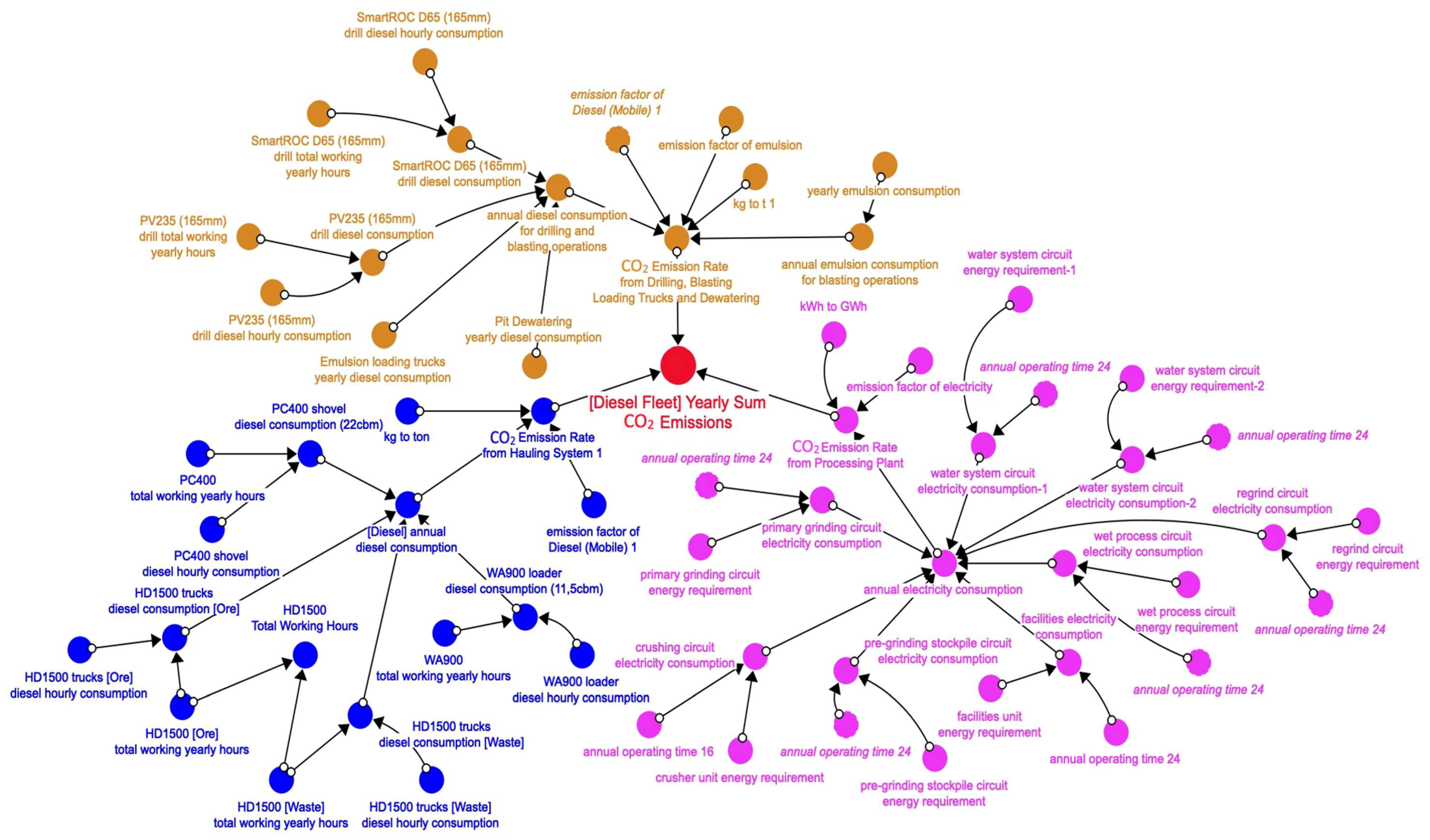

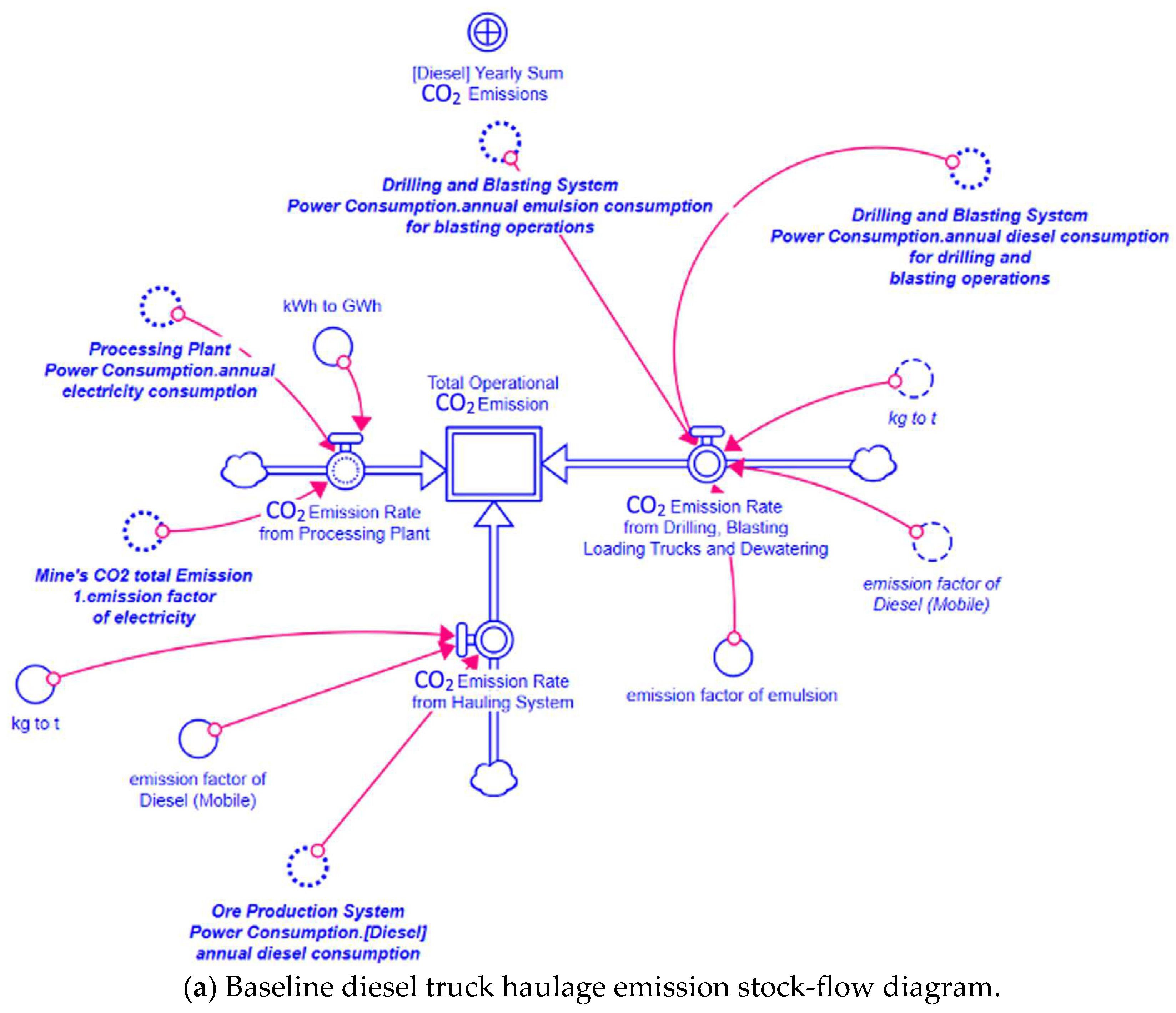

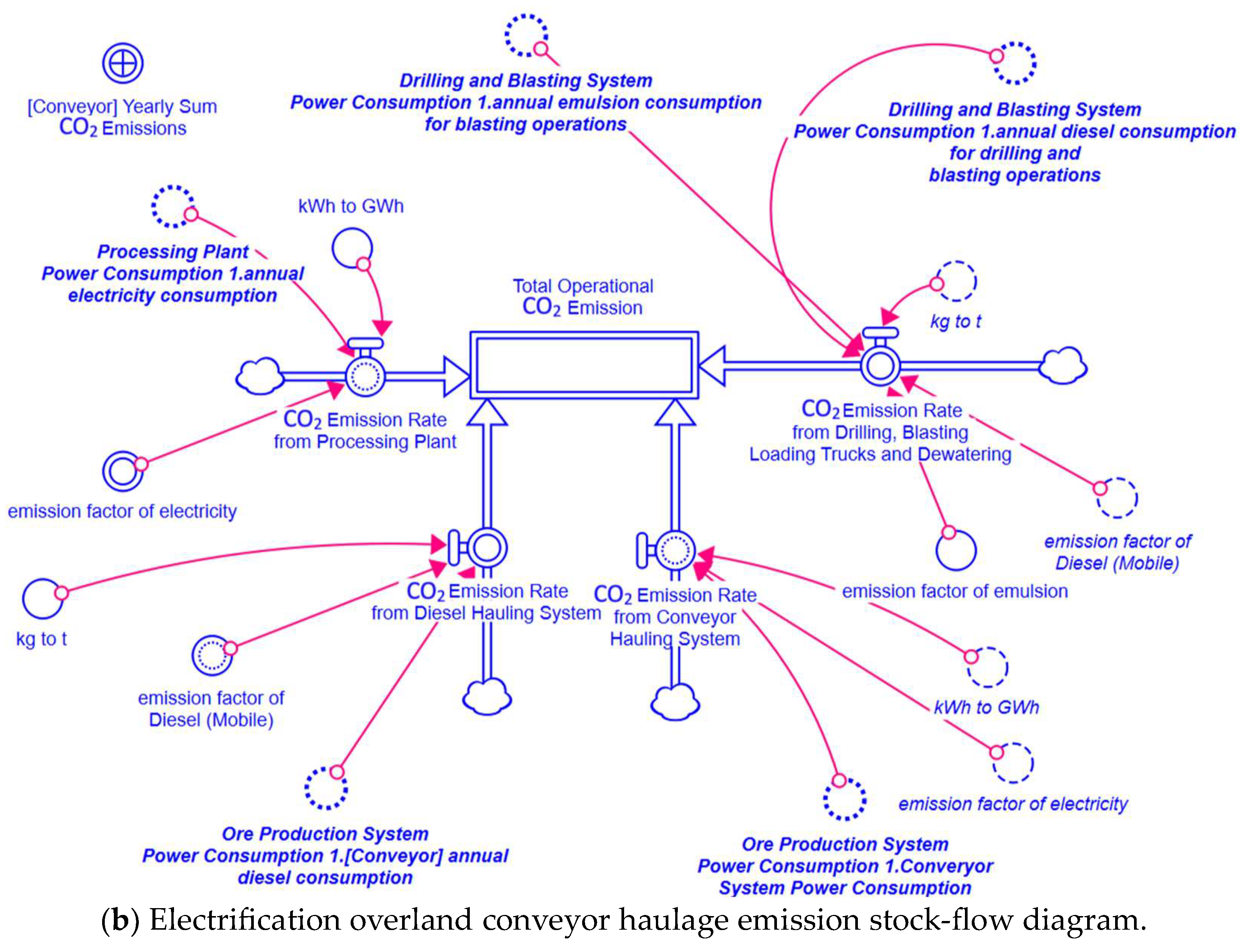

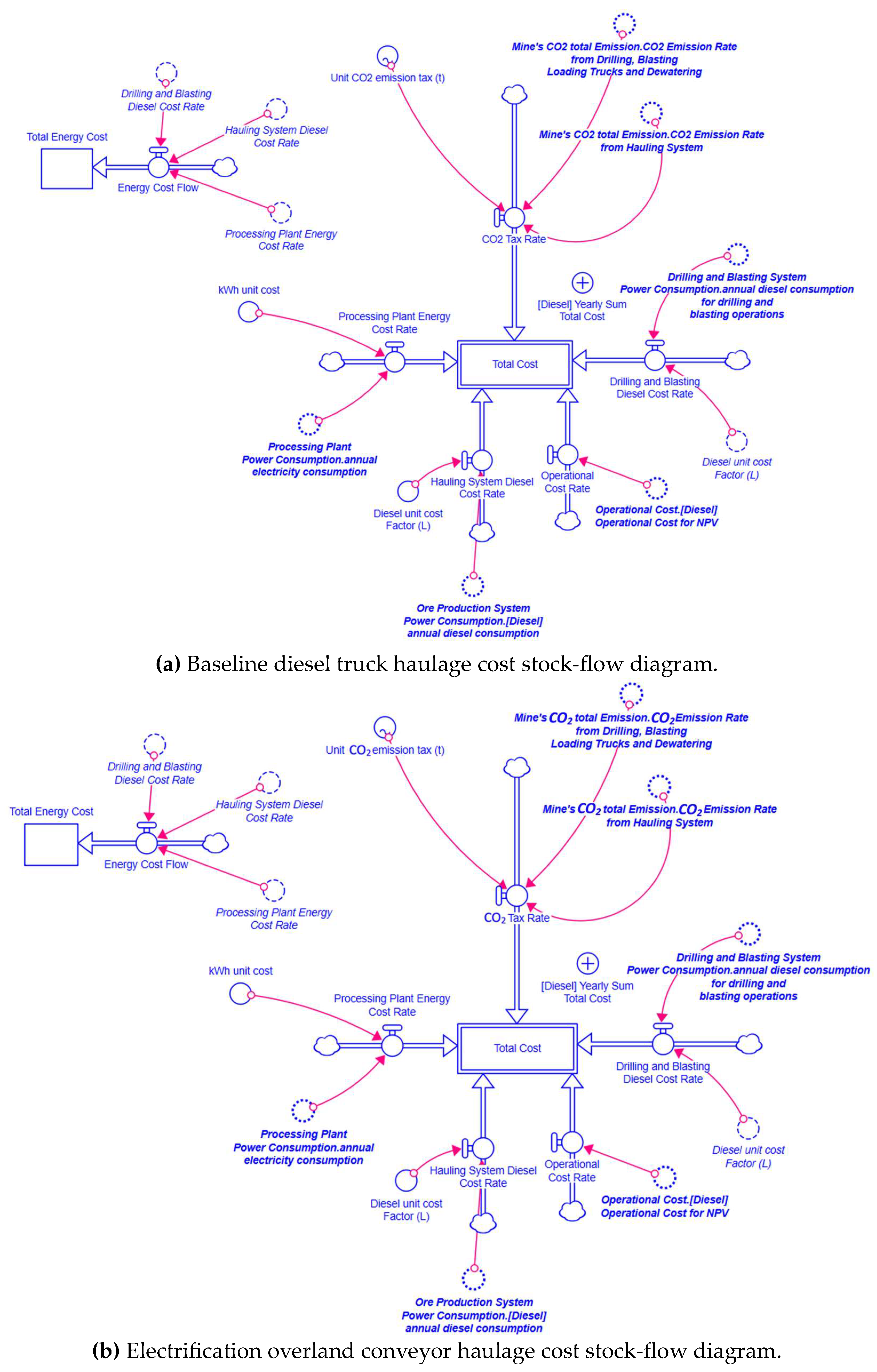

3.2. System Dynamics Model (SDM)

- As the baseline case, the diesel truck haulage activity is modeled based on in-pit and ex-pit activities. The open-pit development starts with the movement of overburden material closer to the waste dump site, and the travel distance and average grade of the haulage roads will increase as the pit gets deeper. In this regard, the average haulage distance is assumed to be 1000 m at the beginning of the project, and it is increased by 10% annually over LOM in the model. The assumption is used for ore and waste haulage activity within the pit in the model.

- The ex-pit distance for ore and waste haulage is different. The ex-pit haulage distance of ore material is kept constant as the pit exit location and process plant location, specifically the crusher, will be the same during LOM. The ex-pit ore haulage is assumed to be 1500 m during LOM. However, the ex-pit waste material haulage distance is assumed to be 4000 m from the exit of the pit to the waste dump site, and a 5% increase in distance due to the high change of the waste dump site is included for the baseline calculations.

- The in-pit haulage activities are kept the same for the electrification case as the baseline diesel truck case. The ex-pit distance of the conveyor haulage is assumed to be 5000 m to reflect the system’s cost and energy consumption due to inflexible route selection requirements and extension needs as the waste stockpile area extends over time. The conveyor’s capacity is calculated to deliver the work required at the mine’s peak production years.

3.3. Data Collection

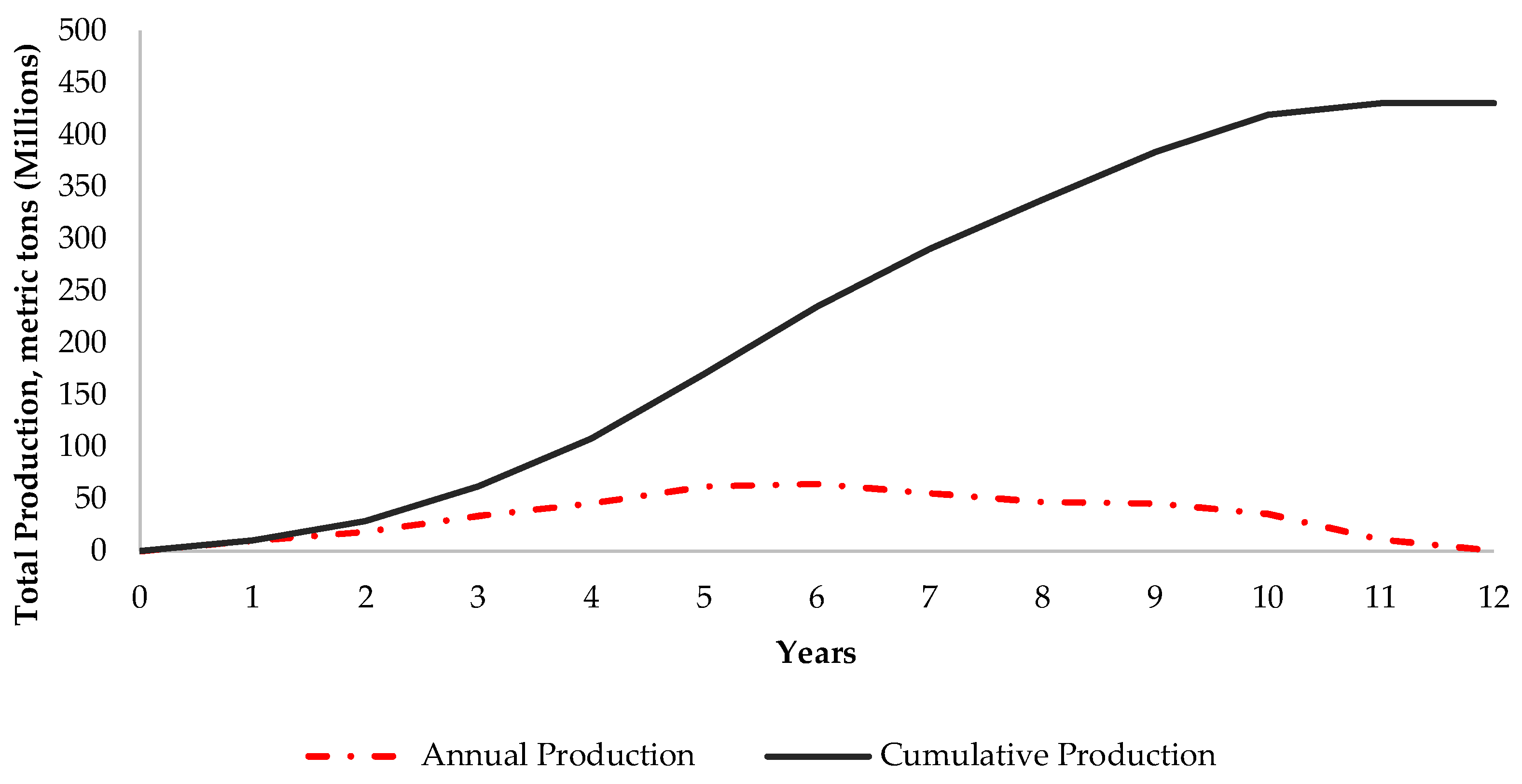

- The considered open-pit copper mine has 12 years of LOM. The first year is preproduction, where only overburden (waste) material is excavated and hauled. Ore production and waste rock haulage start in Year 2. The total production is 430.5 million tonnes (Figure 8), 391 million tonnes of which are waste material and 39.5 million tonnes of ore. The overall stripping ratio is 1:10.

- The mine operates two 12-h daily shifts for 365 days with a 12-year life-of-mine (LOM). However, 7500 h per year of active truck and shovel/loader operational time is used in the model due to operational and mechanical efficiency limitations in an operating mine based on the authors’ expertise. The number of non-haulage and process plant equipment is assumed to be the same in both cases. The costs and emissions from these processes are assumed to be the same in both cases and included in the analysis.

- The average annual ROM ore is 3.3 million tonnes, and hauled waste is 32.5 million tonnes. The overall stripping ratio of 10:1 results in hauling 10 tonnes of waste material for mining one tonne of ore.

- The mill and crusher operation times are assumed to be 12 h per shift for 365 days a year and 16 h per day for 365 days a year, and there will be a stockpile to control the grade and feed the mill continuously. It is assumed that the processing plant will start operating at the beginning of the third year to feed enough ore to the stockpile and the mill.

- The baseline case includes shovel and truck production with 150 tonnes of haulage trucks with a fuel consumption of 95 L (diesel) per hour. Due to the significant difference in total waste production year over year after Year 6, it is assumed that leasing haulage trucks for a specific period during the peak production years is feasible. It is calculated that 44 haulage trucks are needed in the peak production year. The cost analysis considers the purchased 34 trucks and the leased rest of the haulage trucks. The number of trucks leased is eight in year 5, 10 in Year 6, and five in Year 7. Mine operates with the owned trucks in the other years. Truck working hours are calculated based on prioritizing the shovels and loaders, not waiting.

- The mine has two 22-cubic-meter hydraulic shovels and three 11.5-cubic meter Front-End Loaders (FELs). The loading equipment loads ore and waste material to 150-ton diesel haulage trucks.

- The model includes auxiliary mining equipment in addition to the main diesel production equipment: three dozers, two graders, five 165 mm drills, an emulsion, and a water truck.

- The processing plant has an annual capacity of 3.7 Mt and an assumed overall mechanical availability of 86%. The model includes comminution, froth flotation, thickener, conveyors and pumps, and pit dewatering.

- The electrification case includes an overland conveyor system to haul waste material from the exit of the pit near the process plant location to the waste dump site. The overland conveyor requires a crusher in a loading station. As the loading station is an ex-pit asset, it is assumed that 150-t diesel truck utilization is required to haul material from production faces to the crusher. The loading station mainly has a crusher and a feeder. The main crusher has a capacity of 5000 tonnes per hour, and a secondary crusher with a capacity of 3000 tonnes per hour is added to the feeding system starting from Year-4 to Year-10. A 150-kW feeder and discharger are used in the system, and an additional 100-kW feeder is used for Year-4 to Year-10 in the loading station.

- It is assumed that the waste dump site accepts all waste material. Even though storing waste material when ore starts to be produced requires a special facility to avoid acid mine generation, it is assumed that the waste material can be dumped in a single waste dump site in the mine for this study.

- The electricity consumption of the pumps for dewatering the pit starts in Year 1, and the process plant water system electricity consumption starts in Year 3, with the plant starting to process fed ore.

- The data used to calculate costs in the model are listed in Table 4, and all the monetary information in this study is in Canadian dollars.

- Carbon tax rates are only calculated for diesel equipment.

3.4. Validation

3.5. Analysis

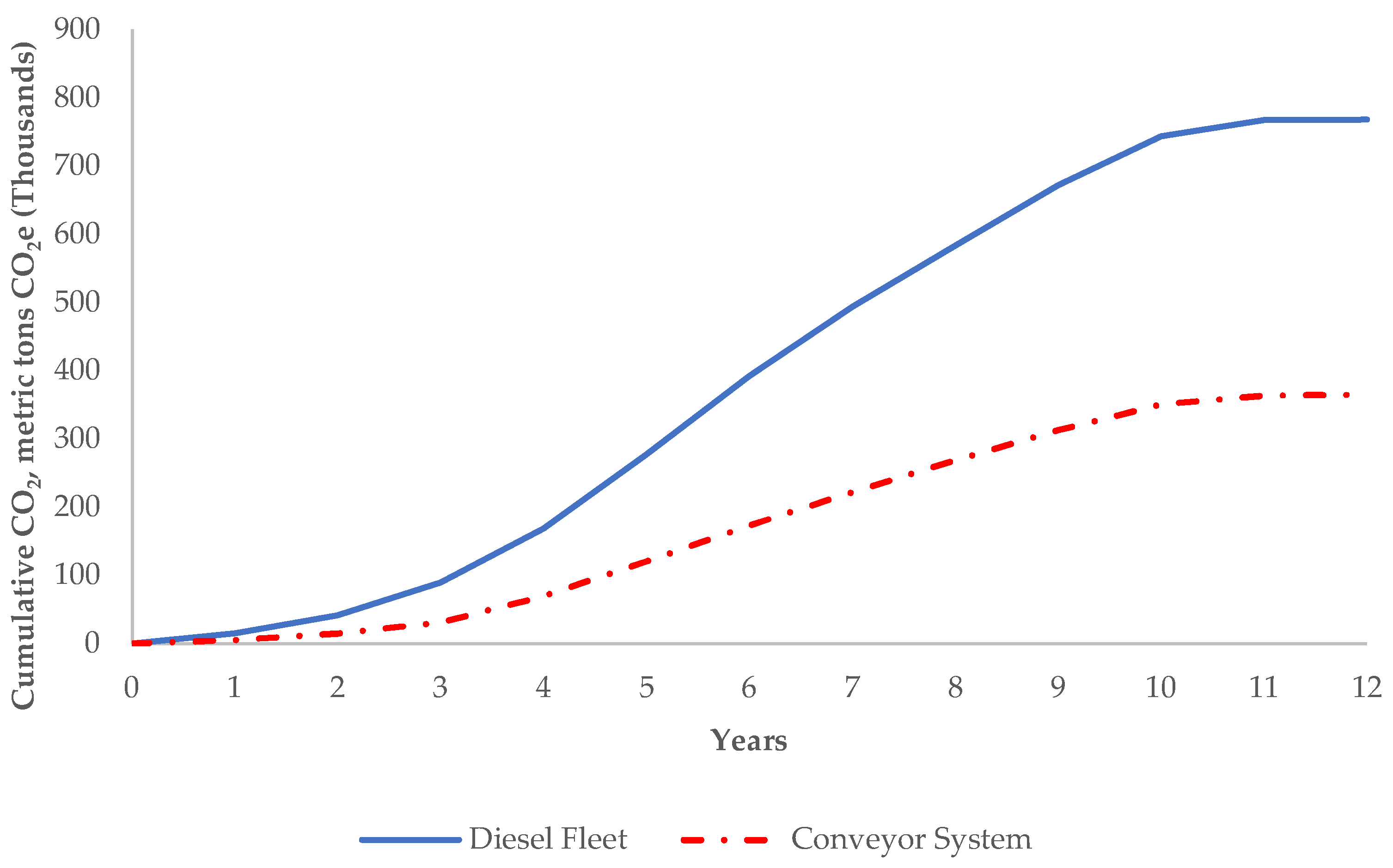

- Change in GHG footprint of material movement based on diesel and electric equipment cases.

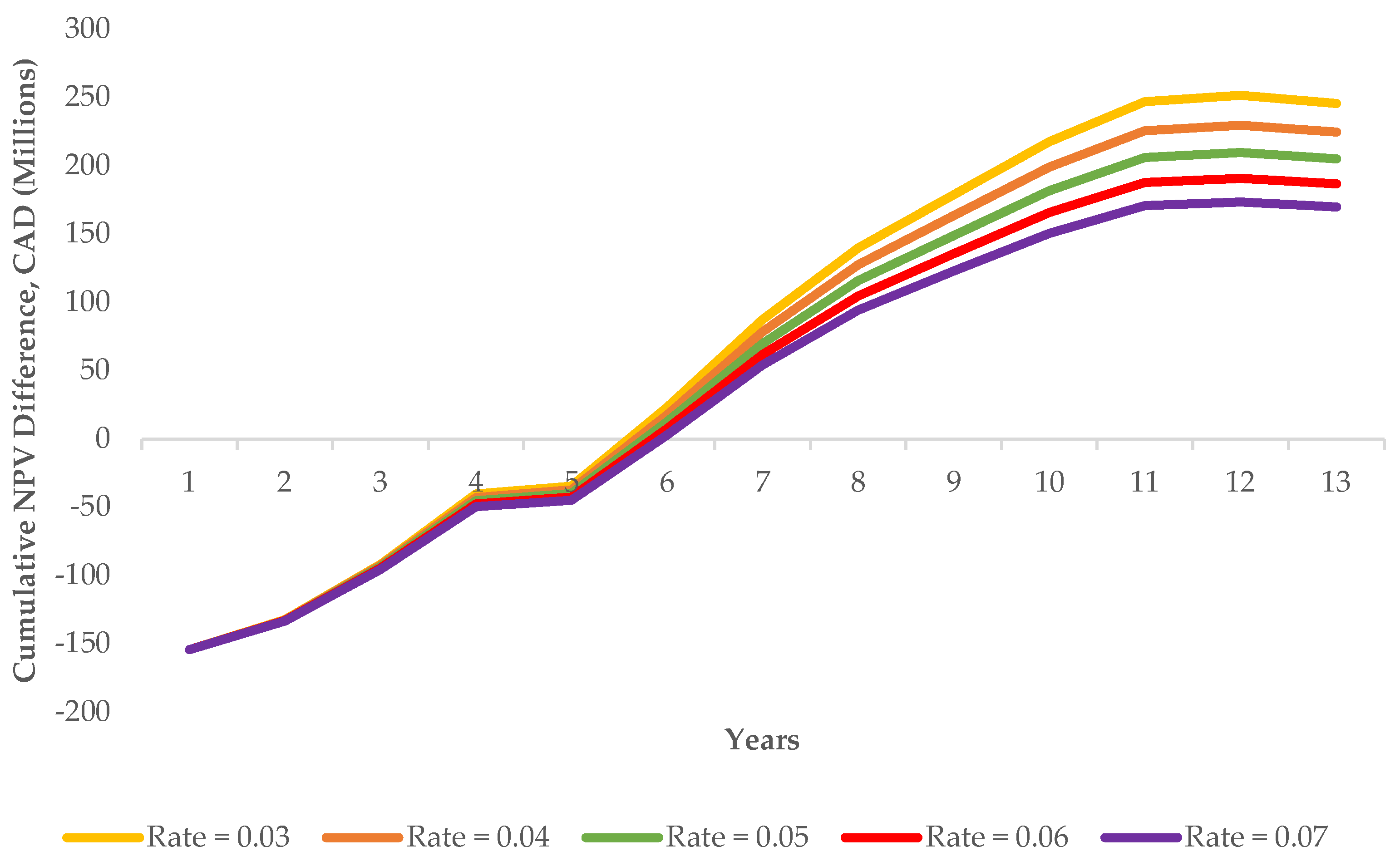

- Cost of switching diesel haulage to an electric alternative.

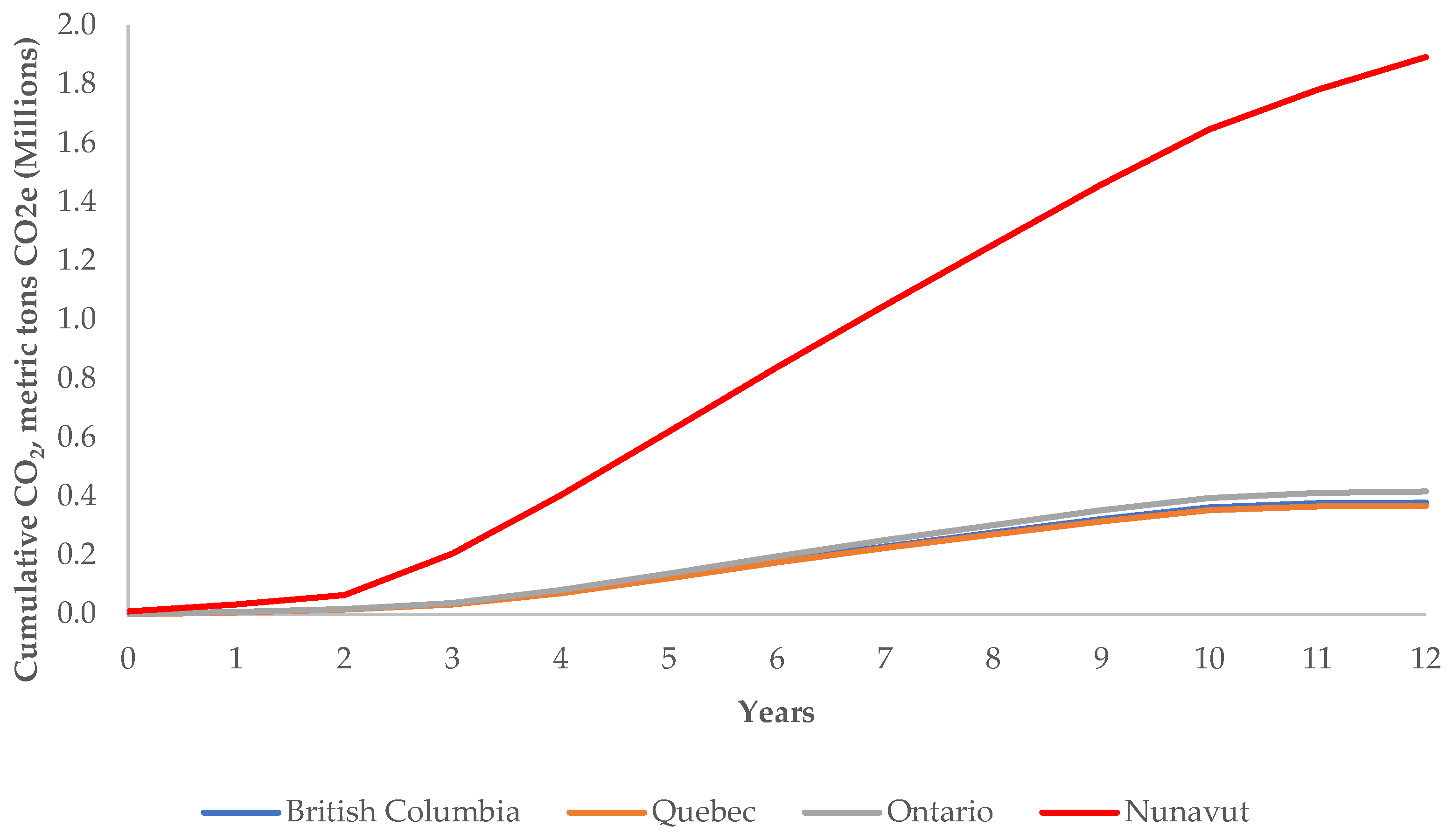

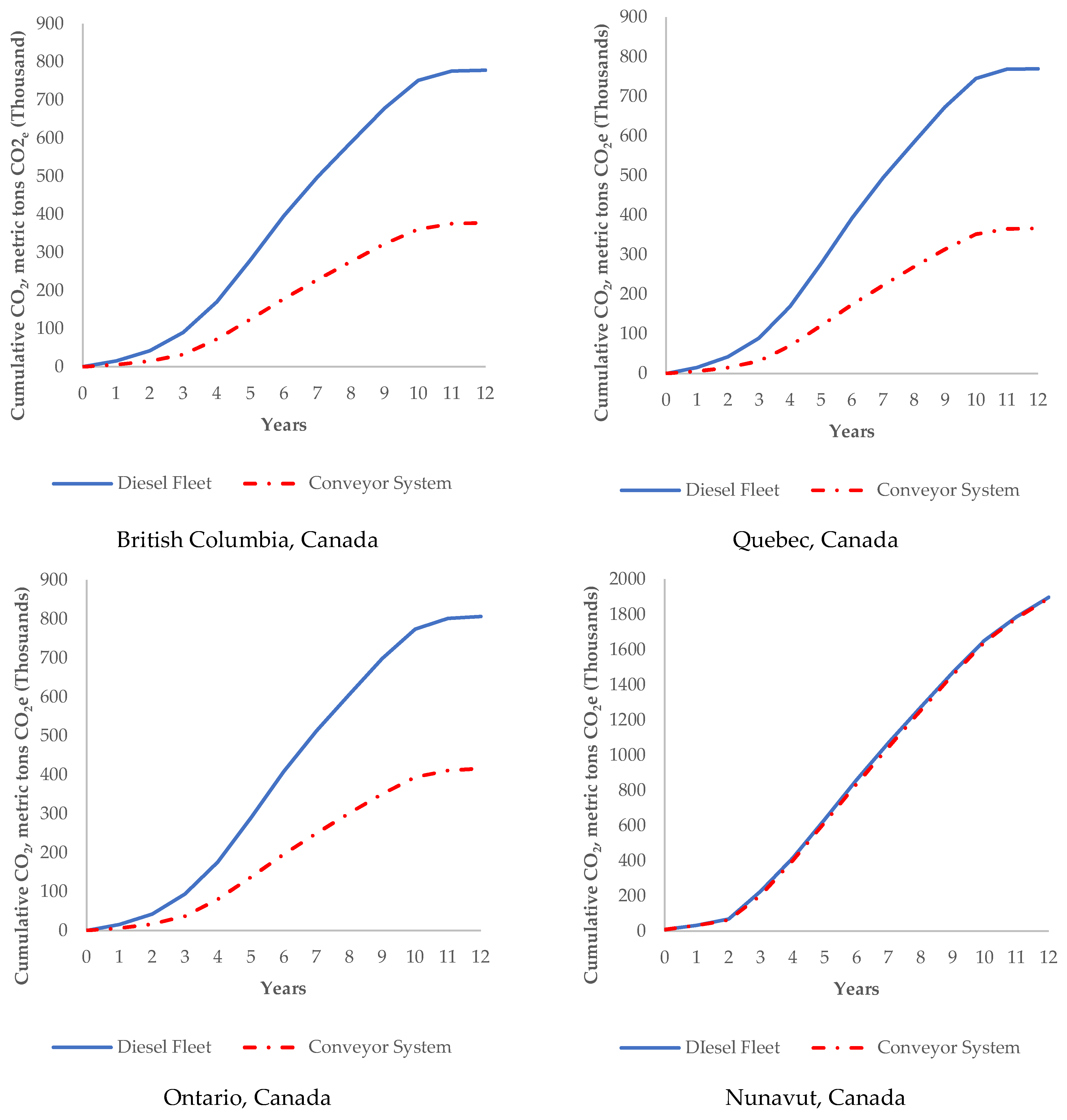

- Impact of the carbon intensity of power sources in GHG reduction in various jurisdictions.

3.5.1. Sensitivity Analysis

3.5.2. Scenario Analysis

- Impact of electrification of a haulage system on CO2e emissions in an open-pit copper mine

- Cost of switching diesel haulage to an electric alternative

- Impact of the carbon intensity of an energy source on CO2e emissions in an open-pit copper mine

4. Results and Discussion

5. Conclusions

- It is essential for governments to promote the development of low-carbon power generation, enhance clean technology integration, and boost energy efficiency.

- It is important for mining companies to consider energy-efficient options such as modifying process elements like reducing grinding, implementing dry stacking, utilizing high-pressure grinding rolls, incorporating a SAG mill for fine grinding rather than a ball mill, and using on-demand ventilation for underground operations.

- Minerals and metals with low carbon intensity should be priced differently from those produced using energy and carbon-intensive methods and those with higher environmental and social impacts.

- Additional research should prioritize technologies such as in-pit crushing and conveying autonomous equipment, alternative fuels, low-carbon on-site power generation and storage, and the seamless integration of these technologies by reducing uncertainty and risks through digital platforms like digital twins.

- Educators and consultants should prioritize the core aspects of mining engineering, such as mine design, process design, resource estimation, and project valuation, in relation to energy and carbon intensity. They should also consider environmental and social impacts before the feasibility study phase of a mining project to reduce additional costs in the development and production phases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Legge, H.; Müller-Falcke, C.; Nauclér, T.; Östgren, E. Creating the Zero-Carbon Mine. 2021. Available online: https://www.mckinsey.com/industries/metals-and-mining/our-insights/creating-the-zero-carbon-mine (accessed on 14 March 2022).

- Azadi, M.; Northey, S.A.; Ali, S.H.; Edraki, M. Transparency on greenhouse gas emissions from mining to enable climate change mitigation. Nat. Geosci. 2020, 13, 100–104. [Google Scholar] [CrossRef]

- Delevingne, L.; Glazener, W.; Grégoir, L.; Henderson, K. Climate Risk and Decarbonization: What Every Mining CEO Needs to Know. 2020. Available online: https://www.mckinsey.com/business-functions/sustainability/our-insights/climate-risk-and-decarbonization-what-every-mining-ceo-needs-to-know (accessed on 14 March 2022).

- Heinrich, L.; Koschinsky, A.; Markus, T.; Singh, P. Quantifying the fuel consumption, greenhouse gas emissions and air pollution of a potential commercial manganese nodule mining operation. Mar. Policy 2020, 114, 103678. [Google Scholar] [CrossRef]

- Barrick. Barrick Updates Its Evolving Emissions Reduction Target. 2021. Available online: https://www.barrick.com/English/news/news-details/2021/barrick-updates-its-evolving-emissions-reduction-target/default.aspx (accessed on 8 March 2022).

- BHP. Climate Transition Action Plan. 2021. Available online: https://www.bhp.com/-/media/documents/investors/annual-reports/2021/210914_bhpclimatetransitionactionplan2021.pdf (accessed on 8 March 2022).

- Copper Alliance. 2021. Available online: https://sustainablecopper.org/best-practice-indicator/climate-action/ (accessed on 8 March 2022).

- Freeport-MecMoran. 2022 Climate Report. 2023. Available online: https://www.fcx.com/sites/fcx/files/documents/sustainability/2022-Climate-Report.pdf (accessed on 8 January 2024).

- Newmont. Newmont Corporation Climate Strategy Report. 2021. Available online: https://s24.q4cdn.com/382246808/files/doc_downloads/sustainability/2020-report/Newmont-Climate-Strategy-Report.pdf (accessed on 8 March 2022).

- Rio Tinto. Climate Change Report. 2022. Available online: https://www.riotinto.com/en/sustainability/climate-change (accessed on 8 March 2022).

- Purhamadani, E.; Bagherpour, R.; Tudeshki, H. Energy consumption in open-pit mining operations relying on reduced energy consumption for haulage using in-pit crusher systems. J. Clean. Prod. 2020, 291, 125228. [Google Scholar] [CrossRef]

- International Energy Association (IEA). The Role of Critical World Energy Outlook Special Report Minerals in Clean Energy Transitions. 2022. Available online: https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions/the-state-of-play (accessed on 8 November 2023).

- Duzgun, H. The Integration of Systems Engineering and Data Analytics for Enhancing the Resiliency and Transparency of Mineral Supply Chains. In Proceedings of the Critical Minerals Symposium, Golden, CO, USA, 21–22 September 2023. [Google Scholar]

- Coalition for Energy Efficient Comminution (CEEC). Mining Energy Consumption 2021. 2021. Available online: https://www.ceecthefuture.org/resources?task=download&file=publication_file&id=3701 (accessed on 9 February 2024).

- OECD. ESG Investing and Climate Transition: Market Practices, Issues and Policy Considerations. Paris. 2021. Available online: https://www.oecd.org/finance/ESG-investing-and-climate-transition-Market-practices-issues-and-policy-considerations.pdf (accessed on 3 March 2022).

- Feng, Y.; Liu, Q.; Li, Y.; Yang, J.; Dong, Z. Energy efficiency and CO2 emission comparison of alternative powertrain solutions for mining haul truck using integrated design and control optimization. J. Clean. Prod. 2022, 370, 133568. [Google Scholar] [CrossRef]

- Bulk, A.; Shoukas, G.; Faramarzi, R. Industrial Conveyor Motor Performance Evaluation. ComEd Energy Efficiency Program National Renewable Energy Laboratory. 2021. Available online: https://www.nrel.gov/docs/fy21osti/80051.pdf (accessed on 15 January 2024).

- The International Copper Association. Copper—The Pathway to Net Zero. 2023. Available online: https://copperalliance.org/wp-content/uploads/2023/03/ICA-GlobalDecar-202301-English-Final-singlepgs.pdf (accessed on 8 November 2023).

- Natural Resources of Canada (NRCAN). Copper Facts. 2023. Available online: https://natural-resources.canada.ca/our-natural-resources/minerals-mining/minerals-metals-facts/copper-facts/20506 (accessed on 8 December 2023).

- World Bank (WB). Minerals for Climate Action—The Mineral Intensity of the Clean Energy Transition. 2020. Available online: https://pubdocs.worldbank.org/en/961711588875536384/Minerals-for-Climate-Action-The-Mineral-Intensity-of-the-Clean-Energy-Transition.pdf (accessed on 10 December 2023).

- Natural Resources of Canada (NRCAN). Critical Minerals List. 2021. Available online: https://natural-resources.canada.ca/sites/nrcan/files/mineralsmetals/pdf/Critical_Minerals_List_2021-EN.pdf (accessed on 1 February 2024).

- International Energy Association (IEA). Critical Minerals List 2021. 2022. Available online: https://www.iea.org/policies/15698-critical-minerals-list-2021 (accessed on 1 February 2024).

- The United States Department of Energy (DOE). What Are Critical Materials and Critical Minerals? 2023. Available online: https://www.energy.gov/cmm/what-are-critical-materials-and-critical-minerals#:~:text=Critical%20materials%20for%20energy%20(%E2%80%9Cthe,silicon%2C%20silicon%20carbide%20and%20terbium (accessed on 1 February 2024).

- International Copper Study Group. World Copper Factbook 2023. 2023. Available online: https://icsg.org/copper-factbook/ (accessed on 15 January 2024).

- Chesnokov, Y.N.; Lisienko, V.G.; Holod, S.I.; Anufriev, V.P.; Lapteva, A.V. Estimation of CO2-Equivalent Emission under the Copper Fire Refining Process. IOP Conf. Ser. Earth Environ. Sci. 2017, 72, 012013. [Google Scholar] [CrossRef]

- Sparshott, E.; Walls, M. Copper Miners Go Underground. Wall Str. J. 2009. Available online: https://www.wsj.com/articles/SB10001424052748704201404574589941445376718 (accessed on 14 January 2024).

- Cooper Development Association, n.d. Mining Methods. Available online: https://copper.org/education/copper-production/2.html (accessed on 30 January 2024).

- Yearworth, M. A Brief Introduction to System Dynamics Modelling; University of Bristol: Bristol, UK, 2014; p. 15. Available online: https://www.grounded.systems/wp-content/uploads/2015/02/SD-Introduction-MY-241014.pdf (accessed on 10 June 2023).

- Li, Q.; Zhang, W.; Li, H. CO2 emission trends of China’s primary aluminum industry: A scenario analysis using systems dynamics model. Energy Policy 2017, 105, 225–235. [Google Scholar] [CrossRef]

- Aranoglu, F.; Flamand, T.; Duzgun, S. Analysis of Artisanal and Small-Scale Gold Mining in Peru under Climate Impacts Using System Dynamics Modeling. Sustainability 2022, 14, 7390. [Google Scholar] [CrossRef]

- Einhäupl, P.; Van Acker, K.; Peremans, H.; Van Passel, S. The conceptualization of societal impacts of landfill mining—A system dynamics approach. J. Clean. Prod. 2021, 296, 126351. [Google Scholar] [CrossRef]

- Aranoglu, F.; Flamand, T.; Duzgun, S.; Martinez, G.; Smith, N. Integrated System Dynamics Modeling and Optimization for Artisanal and Small-scale Gold Supply Chains. IISE Trans. 2024, 1–19. [Google Scholar] [CrossRef]

- Dai, S.S.; Li, L.H.; Xu, H.G.; Pan, X.L.; Li, X.M. A system dynamics approach for water resources policy analysis in arid land: A model for Manas River Basin. J. Arid Land 2013, 5, 118–131. [Google Scholar] [CrossRef]

- McAvoy, S.; Grant, T.; Smith, C.; Bontinck, P. Combining Life Cycle Assessment and System Dynamics to improve impact assessment: A systematic review. J. Clean. Prod. 2021, 315, 128060. [Google Scholar] [CrossRef]

- Phan, T.D.; Bertone, E.; Stewart, R.A. Critical review of system dynamics modelling applications for water resources planning and management. Clean. Environ. Syst. 2021, 2, 100031. [Google Scholar] [CrossRef]

- Jiang, H.; Simonovic, S.P.; Yu, Z.; Wang, W. A system dynamics simulation approach for environmentally friendly operation of a reservoir system. J. Hydrol. 2020, 587, 124971. [Google Scholar] [CrossRef]

- Sun, L.; Niu, D.; Wang, K.; Xu, X. Sustainable development pathways of hydropower in China: Interdisciplinary qualitative analysis and scenario-based system dynamics quantitative modelling. J. Clean. Prod. 2021, 287, 125528. [Google Scholar] [CrossRef]

- Sverdrup, H.U.; Ragnarsdottir, K.V.; Koca, D. On modelling the global copper mining rates, market supply, copper price and the end of copper reserves. Resour. Conserv. Recycl. 2014, 87, 158–174. [Google Scholar] [CrossRef]

- Tian, Y.; Govindan, K.; Zhu, Q. A system dynamics model based on evolutionary game theory for green supply chain management diffusion among Chinese manufacturers. J. Clean. Prod. 2014, 80, 96–105. [Google Scholar] [CrossRef]

- Dace, E.; Bazbauers, G.; Berzina, A.; Davidsen, P.I. System dynamics model for analyzing effects of eco-design policy on packaging waste management system. Resour. Conserv. Recycl. 2014, 87, 175–190. [Google Scholar] [CrossRef]

- Dehghan, H.; Amin-Naseri, M.R.; Nahavandi, N. A system dynamics model to analyze future electricity supply and demand in Iran under alternative pricing policies. Util. Policy 2021, 69, 101165. [Google Scholar] [CrossRef]

- Li, J.; Nian, V.; Jiao, J. Diffusion and benefits evaluation of electric vehicles under policy interventions based on a multiagent system dynamics model. Appl. Energy 2022, 309, 118430. [Google Scholar] [CrossRef]

- Xiao, S.; Dong, H.; Geng, Y.; Tian, X.; Liu, C.; Li, H. Policy impacts on Municipal Solid Waste management in Shanghai: A system dynamics model analysis. J. Clean. Prod. 2020, 262, 121366. [Google Scholar] [CrossRef]

- Ye, F.; Xiong, X.; Li, L.; Li, Y. Measuring the effectiveness of the Chinese Certified Emission Reduction scheme in mitigating CO2 emissions: A system dynamics approach. J. Clean. Prod. 2021, 294, 125355. [Google Scholar] [CrossRef]

- Ansari, N.; Seifi, A. A system dynamics model for analyzing energy consumption and CO2 emission in Iranian cement industry under various production and export scenarios. Energy Policy 2013, 58, 75–89. [Google Scholar] [CrossRef]

- Datola, G.; Bottero, M.; de Angelis, E.; Romagnoli, F. Operationalizing resilience: A methodological framework for assessing urban resilience through System Dynamics Model. Ecol. Model. 2022, 465, 109851. [Google Scholar] [CrossRef]

- Liu, X.; Mao, G.; Ren, J.; Li, R.Y.M.; Guo, J.; Zhang, L. How might China achieve its 2020 emissions target? A scenario analysis of energy consumption and CO2 emissions using the system dynamics model. J. Clean. Prod. 2015, 103, 401–410. [Google Scholar] [CrossRef]

- Stasinopoulos, P.; Shiwakoti, N.; Beining, M. Use-stage life cycle greenhouse gas emissions of the transition to an autonomous vehicle fleet: A System Dynamics approach. J. Clean. Prod. 2021, 278, 123447. [Google Scholar] [CrossRef]

- Tseng, C.H.; Chen, L.L.; Su, S.M. Development of a system dynamics model for dioxin flow and its application to the energy sector. Heliyon 2021, 7, e08361. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Li, X.; Ma, L.; Li, Z. Using system dynamics to analyse key factors influencing China’s energy-related CO2 emissions and emission reduction scenarios. J. Clean. Prod. 2021, 320, 128811. [Google Scholar] [CrossRef]

- Ahmad, S.; Mat Tahar, R.; Muhammad-Sukki, F.; Munir, A.B.; Abdul Rahim, R. Application of system dynamics approach in electricity sector modelling: A review. Renew. Sustain. Energy Rev. 2016, 56, 29–37. [Google Scholar] [CrossRef]

- Environment and Climate Change Canada (ECCC). Emission Factors and Reference Values: Version 1.0. 2022. Available online: https://publications.gc.ca/collections/collection_2022/eccc/En84-294-2022-eng.pdf (accessed on 5 June 2023).

| Variable | Notation | Unit | Description |

|---|---|---|---|

| Activity data | AD | L or kWh | The total amount of fuel consumption as a result of an activity, e.g., haulage |

| Emission factor | EF | kg/L, kg/kWh, g/kWh | The emission factor of the fuel type used |

| CO2e emissions | ECO2 | tonnes | The total amount of CO2e emissions from |

| Conversion factor | cf | Kg to t, kWh to GWh, g to tonne |

| Parameter | Value | Unit | |

|---|---|---|---|

| Life of Mine (LOM) | 12 | Year | |

| Total Production | 430.5 | Tonne | |

| Overall Stripping Ratio | 1:10 | Tonne:Tonne | |

| Operating Hours | 7500 | Hours/Year | |

| Average Run of Mine (ROM) | 3.3 | Million Tonnes/Year | |

| Number of Haulage Trucks at Peak Production Year | 44 | Count | |

| Capacity of Haulage Truck | 150 | Tonne | |

| Fuel Consumption of Haulage Trucks | 95 | Liter/Hour | |

| Number of Hydraulic Shovels | 2 | Count | |

| Capacity of Hydraulic Shovels | 22 | Cubic-meter | |

| Number of Front-End Loaders (FELs) | 3 | Count | |

| Capacity of Front-End Loaders (FELs) | 11.5 | Cubic-meter | |

| Capacity of Processing Plant | 3.7 | Million Tonnes/Year | |

| Mechanical Availability of Processing Plant | 86 | % | |

| Waste Rock Crushing Plant | Main Crusher Capacity | 5000 | Tonnes/Hour |

| Secondary Crusher Capacity | 3000 | Tonnes/Hour | |

| Unit | Emission Factor | |

|---|---|---|

| Grid electricity, Quebec, Canada | tCO2e/GWh | 1.9 |

| Grid electricity, British Columbia, Canada | tCO2e/GWh | 7.8 |

| Grid electricity, Ontario, Canada | tCO2e/GWh | 28 |

| Grid electricity, Nunavut, Canada | tCO2e/GWh | 800 |

| Diesel Emission Factor (off-road heavy mobile equipment) | kg CO2e/L | 2.786 |

| Emulsion Emission Factor | kg CO2e/ton | 170 |

| ANFO Emission Factor | kg CO2e/ton | 189 |

| Item | Unit | Cost (Canadian Dollar) |

|---|---|---|

| Grid electricity cost | $/kWh | 0.06 |

| Diesel Cost | $/L | 1.28 |

| Carbon tax, first five years | $/tCO2 | 75 |

| Carbon tax, Year-6 to Year-12 | $/tCO2 | 100 |

| 150-t truck CAPEX | $ | 3,500,000 |

| 150-t truck (lease) | $/year | 875,000 |

| The conveyor system (construction, conveyor and discharge) CAPEX | $ | 130,000,000 |

| Loading station (two crushers, feeder, construction) CAPEX | $ | 38,000,000 |

| 150-t truck non-fuel operational cost, including maintenance, parts, tires, oil/lubricants | $/hour | 143 |

| Conveyor system non-electricity operational cost, including maintenance, parts etc. | $/year | 5,400,000 |

| The inflation rate | % | 3 |

| Net Present Value discount rate | % | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aydogdu, K.; Duzgun, S.; Yaylaci, E.D.; Aranoglu, F. A Systems Engineering Approach to Decarbonizing Mining: Analyzing Electrification and CO2 Emission Reduction Scenarios for Copper Mining Haulage Systems. Sustainability 2024, 16, 6232. https://doi.org/10.3390/su16146232

Aydogdu K, Duzgun S, Yaylaci ED, Aranoglu F. A Systems Engineering Approach to Decarbonizing Mining: Analyzing Electrification and CO2 Emission Reduction Scenarios for Copper Mining Haulage Systems. Sustainability. 2024; 16(14):6232. https://doi.org/10.3390/su16146232

Chicago/Turabian StyleAydogdu, Kemalcan, Sebnem Duzgun, Evren Deniz Yaylaci, and Fatih Aranoglu. 2024. "A Systems Engineering Approach to Decarbonizing Mining: Analyzing Electrification and CO2 Emission Reduction Scenarios for Copper Mining Haulage Systems" Sustainability 16, no. 14: 6232. https://doi.org/10.3390/su16146232

APA StyleAydogdu, K., Duzgun, S., Yaylaci, E. D., & Aranoglu, F. (2024). A Systems Engineering Approach to Decarbonizing Mining: Analyzing Electrification and CO2 Emission Reduction Scenarios for Copper Mining Haulage Systems. Sustainability, 16(14), 6232. https://doi.org/10.3390/su16146232