Recycling Clay Waste from Excavation, Demolition, and Construction: Trends and Challenges

Abstract

:1. Introduction

2. Methodology

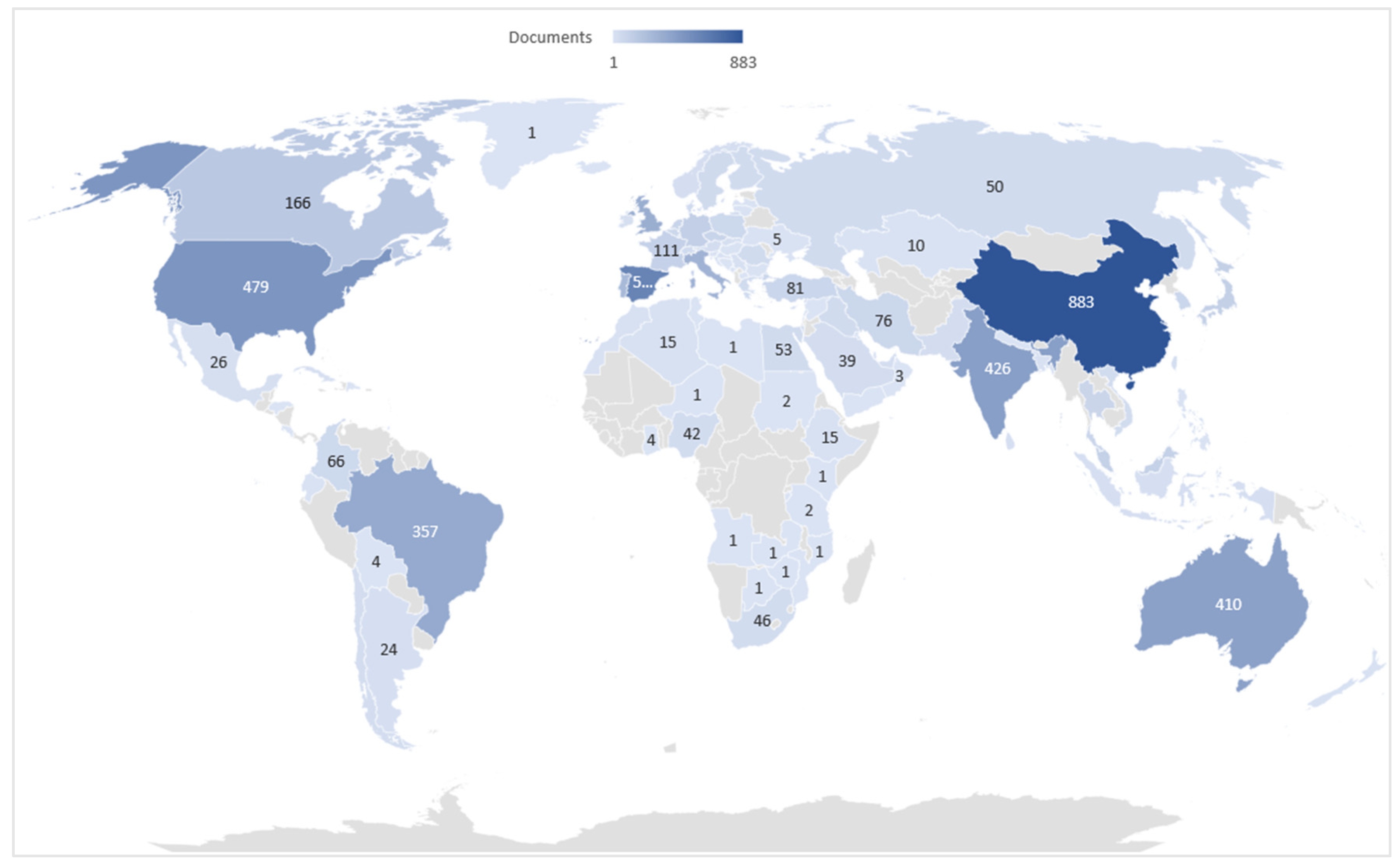

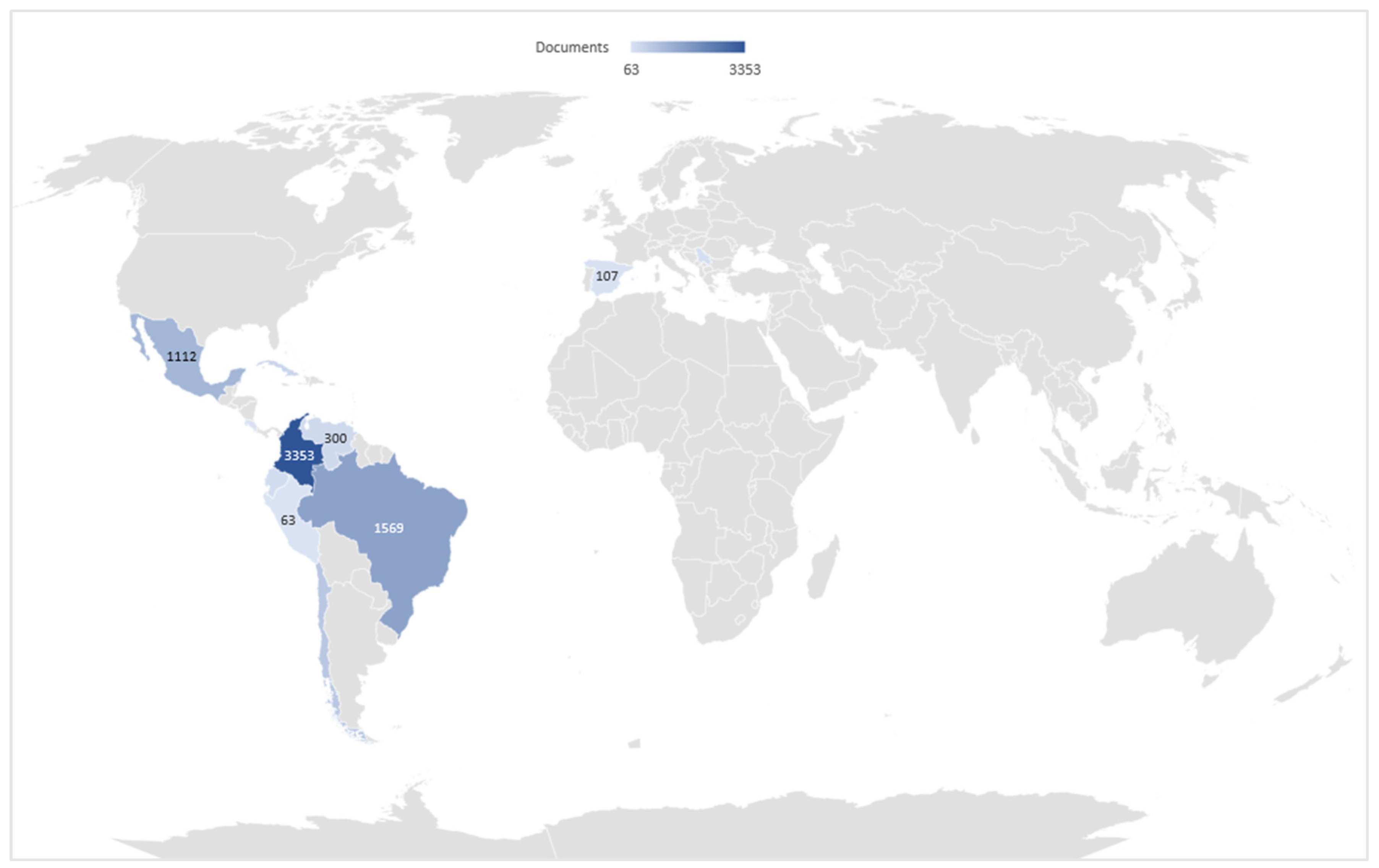

- Data collection: Metadata were obtained from the keywords ‘waste clay’ and ‘demolition and construction waste’, filtering for only scientific publications and excluding review articles, books, and other publications.

- Data processing: R Studio, Excel, and Power BI were applied, with parameters used for a descriptive analysis over time.

- Visualization, analysis, and interpretation of data: We used maps, boxes, bar charts, and ring graphs, which are presented as plots in this manuscript in Figures 2–7.

3. Results

3.1. Marginal Waste and Its Applications

3.1.1. Applications in Hydraulic Concrete

3.1.2. Applications in Precast and 3D Printing

3.1.3. Water Purification

3.1.4. Soil Fertility

3.1.5. Pigments and Paints

3.1.6. Food Packaging and Storage

3.1.7. Ceramic White Goods

4. Conclusions

5. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kaufman, Y.J.; Fraser, R.S.; Ferrare, R.A. Satellite Measurements of Large-Scale Air Pollution: Methods. J. Geophys. Res. Atmos. 1990, 95, 9895–9909. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H.; Gosling, S.N.; Kummu, M.; Flörke, M.; Pfister, S.; Hanasaki, N.; Wada, Y.; Zhang, X.; Zheng, C.; et al. Water scarcity assessments in the past, present, and future. Earth’s Future 2017, 5, 545–559. [Google Scholar] [CrossRef] [PubMed]

- Mahasenan, N.; Smith, S.; Humphreys, K. Greenhouse Gas Control Technologies-6th International Conference; Proceeding; Elsevier: Kyoto, Japan, 2003. [Google Scholar]

- Grantz, D.A.; Garner, J.H.B.; Johnson, D.W. Ecological effects of particulate matter. Environ. Int. 2003, 29, 213–239. [Google Scholar] [CrossRef]

- Werkheiser, I.; Piso, Z. People Work to Sustain Systems: A Framework for Understanding Sustainability. J. Water Resour. Plan. Manag. 2015, 141, A4015002. [Google Scholar] [CrossRef]

- Ismail, Z.; Ali, S.; Zulfiqar, A.; El-Serehy, H.A. Impact of cement industries on potentially toxic elements’ contamination and other characteristics of topsoil: A case study. Environ. Pollut. Bioavailab. 2023, 35, 550–568. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Summary for Policymakers Global Resources Outlook 2024 Bend the Trend; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar]

- United Nations. Paris Agreement; United Nations: New York, NY, USA, 2015. [Google Scholar]

- United Nations Environment Programme. Global Status Report for Buildings and Construction. In Global Alliance for Buildings and Construction; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar] [CrossRef]

- Colorado, H.A.; Muñoz, A.; Monteiro, S.N. Circular Economy of Construction and Demolition Waste: A Case Study of Colombia. Sustainability 2022, 14, 7225. [Google Scholar] [CrossRef]

- ASTM D5681-23; Standard Terminology for Waste and Waste Management. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- United Nations Environment Programme. Global Resources Outlook; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar]

- PIARC. Review of Practices Using Marginal and Secondary Materials in Rural and Industrial Areas; Comité Técnico AIPCR Geotecnia y Carreteras sin Pavimentar: La Défense, France, 2019. [Google Scholar]

- Gaspar, T.A.V.; Jacobsz, S.W.; Heymann, G.; Toll, D.G.; Gens, A.; Osman, A.S. The mechanical properties of a high plasticity expansive clay. Eng. Geol. 2022, 303, 106647. [Google Scholar] [CrossRef]

- PIARC. Design and Construction of Earth-Structures 2B/Treatment of Materials Technical, 2021R02B/EN; World Road Association (PIARC): Paris, France, 2021; Volume 1, Available online: http://www.piarc.org (accessed on 1 May 2024).

- Doudou, S.; McTeer, J.; Wickham, S.; Thied, R.; Woodcock, R.; Turner, T.; Hamblin, C.; Buckley, M.; Walsh, C. Optimised Management of Orphan Wastes in the UK. In Proceedings of the ASME 2013 15th International Conference on Environmental Remediation and Radioactive Waste Management, Brussels, Belgium, 8–12 September 2013. [Google Scholar] [CrossRef]

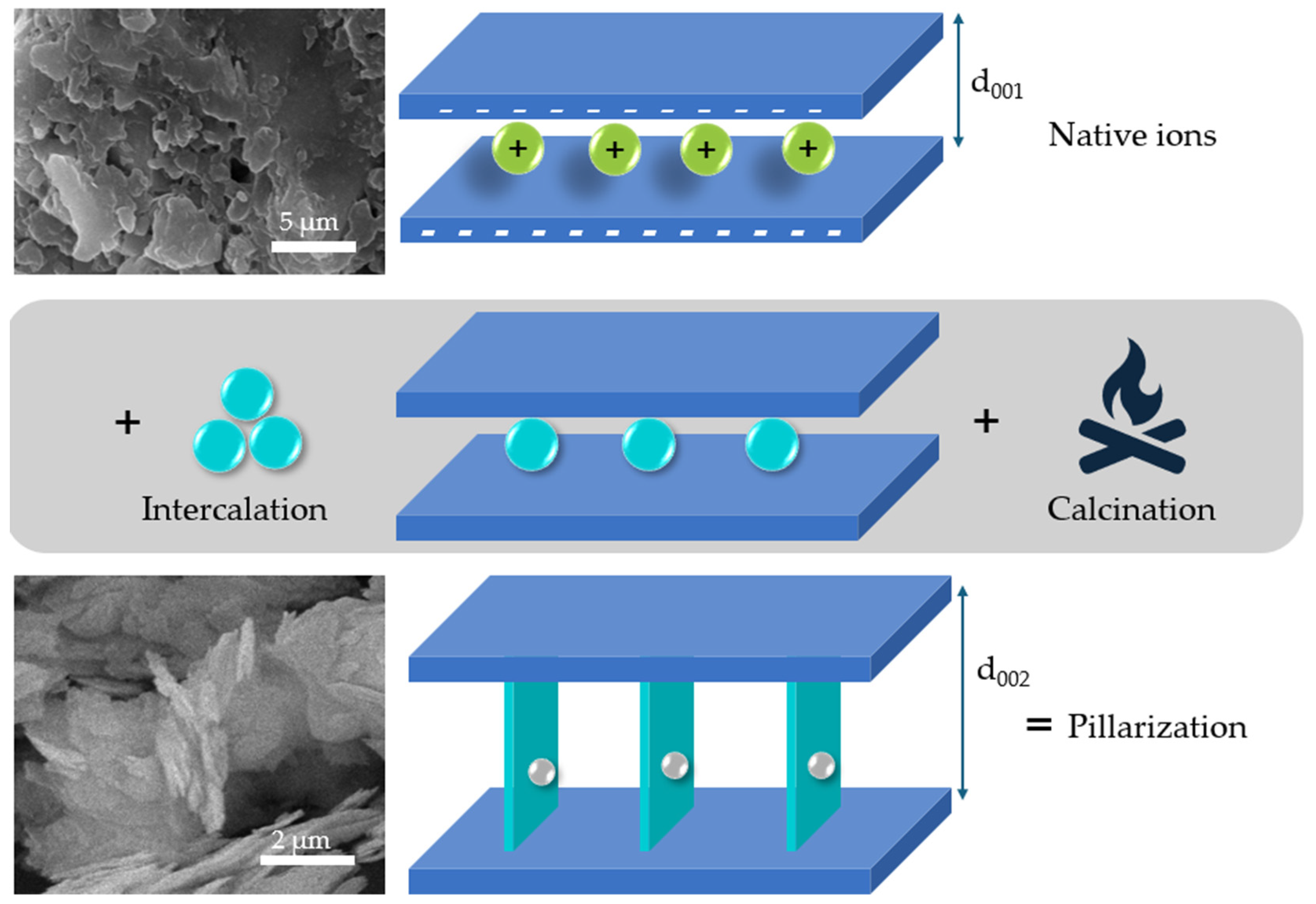

- Rodríguez, M.; Bussi, J.; De León, M.A. Application of pillared raw clay-base catalysts and natural solar radiation for water decontamination by the photo-Fenton process. Sep. Purif. Technol. 2021, 259, 118167. [Google Scholar] [CrossRef]

- Mohammed, S. Processing, effect and reactivity assessment of artificial pozzolans obtained from clays and clay wastes: A review. Constr. Build. Mater. 2017, 140, 10–19. [Google Scholar] [CrossRef]

- Selvasofia, S.D.A.; Sarojini, E.; Moulica, G.; Thomas, S.; Tharani, M.; Saravanakumar, P.; Kumar, P.M. Study on the mechanical properties of the nanoconcrete using nano-TiO2 and nanoclay. Mater. Today Proc. 2021, 50, 1319–1325. [Google Scholar] [CrossRef]

- Gil, A.; Vicente, M.A. Progress and perspectives on pillared clays applied in energetic and environmental remediation processes. Curr. Opin. Green Sustain. Chem. 2020, 21, 56–63. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Papatzani, S. Effect of nanosilica and montmorillonite nanoclay particles on cement hydration and microstructure. Mater. Sci. Technol. 2016, 32, 138–153. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Karayannis, V.G.; Karapanagioti, H.K.; Domopoulou, A.E.; Komilis, D.P. Stabilization/Solidification of Hazardous Metals from Solid Wastes into Ceramics. Waste Biomass Valorization 2017, 8, 1863–1874. [Google Scholar] [CrossRef]

- Florez, R.; Colorado, H.A.; Alajo, A.; Giraldo, C.H. The material characterization and gamma attenuation properties of Portland cement-Fe3O4 composites for potential dry cask applications. Prog. Nucl. Energy 2019, 111, 65–73. [Google Scholar] [CrossRef]

- García, L.C.H.; Salamanca, N.F.L. Resilient Module Soil-Cement Prediction based on Setting Temperature. Ing. Investig. 2020, 40, 7–13. [Google Scholar] [CrossRef]

- Luciano, A.; Cutaia, L.; Altamura, P.; Penalvo, E. Critical issues hindering a widespread construction and demolition waste (CDW) recycling practice in EU countries and actions to undertake: The stakeholder’s perspective. Sustain. Chem. Pharm. 2022, 29, 100745. [Google Scholar] [CrossRef]

- Johnston, C.T. Clay mineral–water interactions. Dev. Clay Sci. 2018, 9, 89–124. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Alonso-Azcárate, J. What is clay? A new definition of “clay” based on plasticity and its impact on the most widespread soil classification systems. Appl. Clay Sci. 2018, 161, 57–63. [Google Scholar] [CrossRef]

- Singh, N.B. Clays and Clay Minerals in the Construction Industry. Minerals 2022, 12, 301. [Google Scholar] [CrossRef]

- Carretero, M.I.; Pozo, M. Clay and non-clay minerals in the pharmaceutical industry. Part I. Excipients and medical applications. Appl. Clay Sci. 2009, 46, 73–80. [Google Scholar] [CrossRef]

- Yang, X.; Wei, G.; Wu, P.; Liu, P.; Liang, X.; Chu, W. Controlling oxygen vacancies of CoMn2O4 by loading on planar and tubular clay minerals and its application for boosted PMS activation. J. Hazard. Mater. 2022, 436, 129060. [Google Scholar] [CrossRef] [PubMed]

- Fang, L.; Wang, L.; Zhou, T.; Liu, L.; Zhou, J.; Li, M. Preparation and characterization of Fe,Co,Si-pillared montmorillonites with aminosilanes as silicon pillars precursor. Appl. Clay Sci. 2017, 141, 88–94. [Google Scholar] [CrossRef]

- Najafi, H.; Farajfaed, S.; Zolgharnian, S.; Mosavi Mirak, S.H.; Asasian-Kolur, N.; Sharifian, S. A comprehensive study on modified-pillared clays as an adsorbent in wastewater treatment processes. Process Saf. Environ. Prot. 2021, 147, 8–36. [Google Scholar] [CrossRef]

- Asgari, M.; Vitale, G.; Sundararaj, U. Synthesis and characterization of a novel nickel pillared–clay catalyst: In-situ carbon nanotube–clay hybrid nanofiller from Ni-PILC. Appl. Clay Sci. 2021, 205, 106064. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Lehnend, J.; Preston, F. Making Concrete Change Innovation in Low-Carbon Cement and Concrete, Cambridge; The Royal Institute of International Affairs: Tokyo, Japan, 2018; Available online: https://www.chathamhouse.org (accessed on 1 May 2024).

- Khalid, U.; Liao, C.; Ye, G.-L.; Yadav, S.K. Sustainable improvement of soft marine clay using low cement content: A multi-scale experimental investigation. Constr. Build. Mater. 2018, 191, 469–480. [Google Scholar] [CrossRef]

- Ding, M.; Yu, R.; Feng, Y.; Wang, S.; Zhou, F.; Shui, Z.; Gao, X.; He, Y.; Chen, L. Possibility and advantages of producing an ultra-high performance concrete (UHPC) with ultra-low cement content. Constr. Build. Mater. 2021, 273, 122023. [Google Scholar] [CrossRef]

- Zapata, J.F.; Azevedo, A.; Fontes, C.; Monteiro, S.N.; Colorado, H.A. Environmental impact and sustainability of calcium aluminate cements. Sustainability 2022, 14, 2751. [Google Scholar] [CrossRef]

- Zhang, B.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A scientometric analysis approach to analyze the present research on recycled aggregate concrete. J. Build. Eng. 2022, 46, 103679. [Google Scholar] [CrossRef]

- Galetakis, M.; Soultana, A. A review on the utilisation of quarry and ornamental stone industry fine by-products in the construction sector. Constr. Build. Mater. 2016, 102, 769–781. [Google Scholar] [CrossRef]

- De Carvalho Gomes, S.; Zhou, J.L.; Li, W.; Long, G. Progress in manufacture and properties of construction materials incorporating water treatment sludge: A review. Resour. Conserv. Recycl. 2019, 145, 148–159. [Google Scholar] [CrossRef]

- Ray, S.; Haque, M.; Ahmed, T.; Mita, A.F.; Saikat, H.; Alom, M. Predicting the strength of concrete made with stone dust and nylon fiber using artificial neural network. Heliyon 2022, 8, e09129. [Google Scholar] [CrossRef] [PubMed]

- Likes, L.; Markandeya, A.; Haider, M.; Bollinger, D.; McCloy, J.S.; Nassiri, S. Recycled concrete and brick powders as supplements to Portland cement for more sustainable concrete. J. Clean. Prod. 2022, 364, 132651. [Google Scholar] [CrossRef]

- Al-Salami, A.E.; Morsy, M.S.; Taha, S.; Shoukry, H. Physico-mechanical characteristics of blended white cement pastes containing thermally activated ultrafine nano clays. Constr. Build. Mater. 2013, 47, 138–145. [Google Scholar] [CrossRef]

- Mikyskova, E.; Dousova, B.; Mikysek, P.; Lhotka, M.; Kolousek, D. Equilibrium, kinetic and thermodynamic study of Pb2+ removal from aqueous solution by waste brick dust. Colloids Surf. A Physicochem. Eng. Asp. 2022, 634, 127939. [Google Scholar] [CrossRef]

- D’Elia, A.; Pinto, D.; Eramo, G.; Giannossa, L.C.; Ventruti, G.; Laviano, R. Effects of processing on the mineralogy and solubility of carbonate-rich clays for alkaline activation purpose: Mechanical, thermal activation in red/ox atmosphere and their combination. Appl. Clay Sci. 2018, 152, 9–21. [Google Scholar] [CrossRef]

- España, V.A.A.; Sarkar, B.; Biswas, B.; Rusmin, R.; Naidu, R. Environmental applications of thermally modified and acid activated clay minerals: Current status of the art. Environ. Technol. Innov. 2019, 13, 383–397. [Google Scholar] [CrossRef]

- Padilla-Ortega, E.; Medellín-Castillo, N.; Robledo-Cabrera, A. Comparative study of the effect of structural arrangement of clays in the thermal activation: Evaluation of their adsorption capacity to remove Cd(II). J. Environ. Chem. Eng. 2020, 8, 103850. [Google Scholar] [CrossRef]

- Li, L.G.; Lin, Z.H.; Chen, G.M.; Kwan, A.K.H. Reutilizing clay brick dust as paste substitution to produce environment-friendly durable mortar. J. Clean. Prod. 2020, 274, 122787. [Google Scholar] [CrossRef]

- Hachemi, S.; Khattab, M.; Benzetta, H. The effects of recycled brick and water/cement ratios on the physical and mechanical performance of recycled aggregates concrete. Innov. Infrastruct. Solut. 2022, 7, 270. [Google Scholar] [CrossRef]

- Sun, Y.; Yu, R.; Wang, S.; Zhou, Y.; Zeng, M.; Hu, F.; Shui, Z.; Rao, B.; Yuan, S.; Luo, Z.; et al. Development of a novel eco-efficient LC2 conceptual cement based ultra-high performance concrete (UHPC) incorporating limestone powder and calcined clay tailings: Design and performances. J. Clean. Prod. 2021, 315, 128236. [Google Scholar] [CrossRef]

- Sinkhonde, D.; Onchiri, R.O.; Oyawa, W.O.; Mwero, J.N. Response surface methodology-based optimisation of cost and compressive strength of rubberised concrete incorporating burnt clay brick powder. Heliyon 2021, 7, e08565. [Google Scholar] [CrossRef] [PubMed]

- Sinkhonde, D.; Onchiri, R.O.; Oyawa, W.O.; Mwero, J.N. A study on mechanical properties of rubberised concrete containing burnt clay powder. Heliyon 2022, 8, e09614. [Google Scholar] [CrossRef] [PubMed]

- Mitrović, A.; Zdujić, M. Preparation of pozzolanic addition by mechanical treatment of kaolin clay. Int. J. Miner. Process. 2014, 132, 59–66. [Google Scholar] [CrossRef]

- Mansour, A.M.; Al Biajawi, M.I. The effect of the addition of metakaolin on the fresh and hardened properties of blended cement products: A review. Mater. Today Proc. 2022, 66, 2811–2817. [Google Scholar] [CrossRef]

- Supit, S.W.M.; Olivia, M. Compressive strength and sulfate resistance of metakaolin-based geopolymer mortar with different ratio of alkaline activator. Mater. Today Proc. 2022, 66, 2776–2779. [Google Scholar] [CrossRef]

- Kaur, L. Mixed influence of steel fiber (SF) and metakaolin (MK) incorporation on mechanical properties of concrete. Mater. Today Proc. 2022, 65, 3449–3452. [Google Scholar] [CrossRef]

- Chand, G.; Kumar, A.; Ram, S. Comparative study of metakaolin, pumice powder and silica fume in producing treated sustainable recycled coarse aggregate concrete by adopting two-stage mixing. Clean. Eng. Technol. 2022, 9, 100528. [Google Scholar] [CrossRef]

- Li, R.; Lei, L.; Plank, J. Impact of metakaolin content and fineness on the behavior of calcined clay blended cements admixed with HPEG PCE superplasticizer. Cem. Concr. Compos. 2022, 133, 104654. [Google Scholar] [CrossRef]

- Singh, S.B.; Murugan, M. Effect of metakaolin on the properties of pervious concrete. Constr. Build. Mater. 2022, 346, 128476. [Google Scholar] [CrossRef]

- Khankhaje, E.; Kim, T.; Jang, H.; Kim, C.-S.; Kim, J.; Rafieizonooz, M. A review of utilization of industrial waste materials as cement replacement in pervious concrete: An alternative approach to sustainable pervious concrete production. Heliyon 2024, 10, e26188. [Google Scholar] [CrossRef]

- Khan, M.; McNally, C. Recent developments on low carbon 3D printing concrete: Revolutionizing construction through innovative technology. Clean. Mater. 2024, 12, 100251. [Google Scholar] [CrossRef]

- Junaid, M.F.; Rehman, Z.U.; Kuruc, M.; Medveď, I.; Bačinskas, D.; Čurpek, J.; Čekon, M.; Ijaz, N.; Ansari, W.S. Lightweight concrete from a perspective of sustainable reuse of waste byproducts. Constr. Build. Mater. 2022, 319, 126061. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Başaran, B.; Aksoylu, C.; Karalar, M.; Martins, C.H. Mechanical behavior in terms of shear and bending performance of reinforced concrete beam using waste fire clay as replacement of aggregate. Case Stud. Constr. Mater. 2023, 18, e02104. [Google Scholar] [CrossRef]

- Fakhri, R.S.; Dawood, E.T. Limestone powder, calcined clay and slag as quaternary blended cement used for green concrete production. J. Build. Eng. 2023, 79, 107644. [Google Scholar] [CrossRef]

- Rodriguez-Morales, J.; Burciaga-Diaz, O.; Gomez-Zamorano, L.Y.; Escalante-Garcia, J.I. Transforming construction and demolition waste concrete as a precursor in sustainable cementitious materials: An innovative recycling approach. Resour. Conserv. Recycl. 2024, 204, 107474. [Google Scholar] [CrossRef]

- Maaze, M.R.; Shrivastava, S. Development of framework in the selection and reuse of concrete waste and brick waste powder as pozzolanic material in cement concrete application using analytical hierarchy process technique. Constr. Build. Mater. 2023, 393, 132056. [Google Scholar] [CrossRef]

- Negm, A.A.; El Nemr, A.; Elgabbas, F.; Khalaf, M.A. High and normal strength concrete using grounded vitrified clay pipe (GVCP). Clean. Mater. 2022, 5, 100107. [Google Scholar] [CrossRef]

- Dai, T.; Liu, T.; Zheng, T.; Fang, C.; Zheng, S.; Lei, G. Effect of waste clay brick powder on microstructure and properties in blended oil well cement pastes at HTHP conditions. Geoenergy Sci. Eng. 2024, 237, 212823. [Google Scholar] [CrossRef]

- Murali, G.; Wong, L.S.; Ramkumar, V.; Abid, S.R.; Karthik, S. From waste to resource recycled lime sludge: Sustainable low clinker cementitious binder, a comprehensive study on hydration, strength of concrete. J. Build. Eng. 2024, 86, 108935. [Google Scholar] [CrossRef]

- Balestra, C.E.T.; Garcez, L.R.; da Silva, L.C.; Veit, M.T.; Jubanski, E.; Nakano, A.Y.; Pietrobelli, M.H.; Schneider, R.; Gil, M.A.R. Contribution to low-carbon cement studies: Effects of silica fume, fly ash, sugarcane bagasse ash and acai stone ash incorporation in quaternary blended limestone-calcined clay cement concretes. Environ. Dev. 2023, 45, 100792. [Google Scholar] [CrossRef]

- Wu, H.; Hu, R.; Yang, D.; Ma, Z. Micro-macro characterizations of mortar containing construction waste fines as replacement of cement and sand: A comparative study. Constr. Build. Mater. 2023, 383, 131328. [Google Scholar] [CrossRef]

- Wu, H.; Gao, J.; Liu, C.; Guo, Z.; Luo, X. Reusing waste clay brick powder for low-carbon cement concrete and alkali-activated concrete: A critical review. J. Clean. Prod. 2024, 449, 141755. [Google Scholar] [CrossRef]

- Bonet-Martínez, E.; Pérez-Villarejo, L.; Eliche-Quesada, D.; Castro, E. Manufacture of Sustainable Clay Bricks Using Waste from Secondary Aluminum Recycling as Raw Material. Materials 2018, 11, 2439. [Google Scholar] [CrossRef]

- Obeng, E.; Essandoh, H.M.K.; Akodwaa-Boadi, K.; Taylor, T.S.; Kusi, I.; Appiah-Effah, E. Recycled clay bricks and palm kernel shell as constructed wetland substrate for wastewater treatment: An engineered closed circuit circular economy approach. Environ. Technol. Innov. 2023, 32, 103324. [Google Scholar] [CrossRef]

- ASTM C1272-21; Standard Specification for Heavy Vehicular Paving Brick. ASTM International: West Conshohocken, PA, USA, 2021; pp. 1–4. [CrossRef]

- ASTM C62-17; Standard Specification for Building Brick (Solid Masonry Units Made from Clay or Shale). ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–4. [CrossRef]

- Lesovik, V.; Volodchenko, A.; Fediuk, R.; Amran, Y.H.M.; Timokhin, R. Enhancing performances of clay masonry materials based on nanosize mine waste. Constr. Build. Mater. 2021, 269, 121333. [Google Scholar] [CrossRef]

- Aneke, F.I.; Shabangu, C. Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud. Constr. Mater. 2021, 14, e00515. [Google Scholar] [CrossRef]

- de la Casa, J.A.; Romero, I.; Jiménez, J.; Castro, E. Fired clay masonry units production incorporating two-phase olive mill waste (alperujo). Ceram. Int. 2012, 38, 5027–5037. [Google Scholar] [CrossRef]

- Ulugöl, H.; Kul, A.; Yıldırım, G.; Şahmaran, M.; Aldemir, A.; Figueira, D.; Ashour, A. Mechanical and microstructural characterization of geopolymers from assorted construction and demolition waste-based masonry and glass. J. Clean. Prod. 2021, 280, 124358. [Google Scholar] [CrossRef]

- Gencel, O.; Kazmi, S.M.S.; Munir, M.J.; Sutcu, M.; Erdogmus, E.; Yaras, A. Feasibility of using clay-free bricks manufactured from water treatment sludge, glass, and marble wastes: An exploratory study. Constr. Build. Mater. 2021, 298, 123843. [Google Scholar] [CrossRef]

- Dodoo-Arhin, D.; Konadu, D.S.; Annan, E.; Buabeng, F.P.; Yaya, A.; Agyei-Tuffour, B. Fabrication and Characterisation of Ghanaian Bauxite Red Mud-Clay Composite Bricks for Construction Applications. Am. J. Mater. Sci. 2013, 3, 110–119. [Google Scholar] [CrossRef]

- Revelo, C.F.; Colorado, H.A. 3D printing of kaolinite clay ceramics using the Direct Ink Writing (DIW) technique. Ceram. Int. 2018, 44, 5673–5682. [Google Scholar] [CrossRef]

- Vergara, L.A.; Perez, J.F.; Colorado, H.A. 3D printing of ordinary Portland cement with waste wood derived biochar obtained from gasification. Case Stud. Constr. Mater. 2023, 18, e02117. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.; De Schutter, G.; Van Tittelboom, K. Extrusion-based concrete 3D printing from a material perspective: A state-of-the-art review. Cem. Concr. Compos. 2020, 115, 103855. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, Z.; Zhang, X.; Chen, Z. 3D printing concrete structures: State of the art, challenges, and opportunities. Constr. Build. Mater. 2023, 405, 133364. [Google Scholar] [CrossRef]

- Miao, Y.; Wang, G.; Gong, H.; Sheng, M.; Jing, J.; Lu, J.; Liu, M. Direct ink writing of SiOC ceramics with microwave absorption properties. Ceram. Int. 2023, 49, 12710–12724. [Google Scholar] [CrossRef]

- Chen, Y.; Jansen, K.; Zhang, H.; Rodriguez, C.R.; Gan, Y.; Çopuroğlu, O.; Schlangen, E. Effect of printing parameters on interlayer bond strength of 3D printed limestone-calcined clay-based cementitious materials: An experimental and numerical study. Constr. Build. Mater. 2020, 262, 120094. [Google Scholar] [CrossRef]

- Hou, S.; Xiao, J.; Duan, Z.; Ma, G. Fresh properties of 3D printed mortar with recycled powder. Constr. Build. Mater. 2021, 309, 125186. [Google Scholar] [CrossRef]

- Revelo, C.F.; Colorado, H.A. 3D printing of kaolinite clay with small additions of lime, fly ash and talc ceramic powders. Process. Appl. Ceram. 2019, 13, 287–299. [Google Scholar] [CrossRef]

- Chen, Y.; He, S.; Zhang, Y.; Wan, Z.; Çopuroğlu, O.; Schlangen, E. 3D printing of calcined clay-limestone-based cementitious materials. Cem. Concr. Res. 2021, 149, 106553. [Google Scholar] [CrossRef]

- Ordoñez, E.; Monteiro, S.N.; Colorado, H.A. Valorization of a hazardous waste with 3D-printing: Combination of kaolin clay and electric arc furnace dust from the steel making industry. Mater. Des. 2022, 217, 110617. [Google Scholar] [CrossRef]

- Ihekweme, G.O.; Shondo, J.N.; Orisekeh, K.I.; Kalu-Uka, G.M.; Nwuzor, I.C.; Onwualu, A.P. Characterization of certain Nigerian clay minerals for water purification and other industrial applications. Heliyon 2020, 6, e03783. [Google Scholar] [CrossRef]

- Adams, F.V.; Peter, A.; Joseph, I.V.; Sylvester, O.P.; Mulaba-Bafubiandi, A.F. Purification of crude oil contaminated water using fly ash/clay. J. Water Process Eng. 2019, 30, 100471. [Google Scholar] [CrossRef]

- Brown, K.; Mendoza, M.; Tinsley, T.; Bee-DiGregorio, M.Y.; Bible, M.; Brooks, J.L.; Colorado, M.; Esenther, J.; Farag, A.; Gill, R.; et al. Polyvinyl alcohol-montmorillonite composites for water purification: Analysis of clay mineral cation exchange and composite particle synthesis. Polyhedron 2021, 205, 115297. [Google Scholar] [CrossRef] [PubMed]

- Nir, S.; Brook, I.; Anavi, Y.; Ryskin, M.; Ari, J.B.; Huterer, R.S.; Etkin, H.; Zadaka-Amir, D.; Shuali, U. Water purification from perchlorate by a micelle–clay complex: Laboratory and pilot experiments. Appl. Clay Sci. 2015, 114, 151–156. [Google Scholar] [CrossRef]

- Gatica, J.M.; Gómez, D.M.; Harti, S.; Vidal, H. Clay honeycomb monoliths for water purification: Modulating methylene blue adsorption through controlled activation via natural coal templating. Appl. Surf. Sci. 2013, 277, 242–248. [Google Scholar] [CrossRef]

- Seçilmiş, Ş.S.; Yanık, D.K.; Fadiloğlu, S.; Göğüş, F. A comparative study on performance of industrial and microwave techniques for sunflower oil bleaching process. Food Chem. 2021, 365, 130488. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, Y.; Oshita, K.; Takaoka, M.; Wang, Q.; Sheng, C.; Lin, Z. Liquefied dimethyl ether based multi-stage extraction for high efficient oil recovery from spent bleaching clay. Waste Manag. 2021, 136, 204–212. [Google Scholar] [CrossRef]

- Wan, Z.; Wang, S.; Li, Z.; Yi, W.; Zhang, A.; Li, Y.; Zhang, P. Co-pyrolysis of lignin and spent bleaching clay: Insight into the catalytic characteristic and hydrogen supply of spent bleaching clay. J. Anal. Appl. Pyrolysis 2022, 163, 105491. [Google Scholar] [CrossRef]

- Sapawe, N.; Hanafi, M.F. Analysis of the pyrolysis products from spent bleaching clay. Mater. Today Proc. 2018, 5, 21940–21947. [Google Scholar] [CrossRef]

- Khankhasaeva, S.T.; Badmaeva, S.V. Removal of p-aminobenzenesulfanilamide from water solutions by catalytic photo-oxidation over Fe-pillared clay. Water Res. 2020, 185, 116212. [Google Scholar] [CrossRef] [PubMed]

- Hacıosmanoğlu, G.G.; Mejías, C.; Martín, J.; Santos, J.L.; Aparicio, I.; Alonso, E. Antibiotic adsorption by natural and modified clay minerals as designer adsorbents for wastewater treatment: A comprehensive review. J. Environ. Manag. 2022, 317, 115397. [Google Scholar] [CrossRef] [PubMed]

- Vicente, M.A.; Gil, A.; Bergaya, F. Pillared Clays and Clay Minerals. In Developments in Clay Science; Elsevier Ltd.: Amsterdam, The Netherlands, 2013; Volume 5, pp. 523–557. [Google Scholar] [CrossRef]

- Chauhan, T.; Udayakumar, M.; Shehab, M.A.; Kristály, F.; Leskó, A.K.; Ek, M.; Wahlqvist, D.; Tóth, P.; Hernadi, K.; Németh, Z. Synthesis, characterization, and challenges faced during the preparation of zirconium pillared clays. Arab. J. Chem. 2022, 15, 103706. [Google Scholar] [CrossRef]

- Reimbaeva, S.M.; Massalimova, B.K.; Kalmakhanova, M.S. New pillared clays prepared from different deposits of Kazakhstan. Mater. Today Proc. 2020, 31, 607–610. [Google Scholar] [CrossRef]

- Chauhan, M.; Saini, V.K.; Suthar, S. Enhancement in selective adsorption and removal efficiency of natural clay by intercalation of Zr-pillars into its layered nanostructure. J. Clean. Prod. 2020, 258, 120686. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, S.; Zhang, T.; Xu, M.; Zhao, J.; Zeng, M.; Sun, K.; Feng, R.; Yang, Z.; Zhang, P.; et al. Positron annihilation study of chitosan and its derived carbon/pillared montmorillonite clay stabilized Pd species nanocomposites. Polym. Test. 2022, 114, 107689. [Google Scholar] [CrossRef]

- Khan, M.I.; Almesfer, M.K.; Danish, M.; Ali, I.H.; Shoukry, H.; Patel, R.; Gardy, J.; Nizami, A.S.; Rehan, M. Potential of Saudi natural clay as an effective adsorbent in heavy metals removal from wastewater. Desalination Water Treat. 2019, 158, 140–151. [Google Scholar] [CrossRef]

- Marczak, D.; Lejcuś, K.; Kulczycki, G.; Misiewicz, J. Towards circular economy: Sustainable soil additives from natural waste fibres to improve water retention and soil fertility. Sci. Total Environ. 2022, 844, 157169. [Google Scholar] [CrossRef]

- Santos, R.P.; Tubino, R. Potential evaluation of the use of construction and demolition waste (CDW) in the recovery of degraded soils by mining in Brazil. Resour. Conserv. Recycl. Adv. 2021, 12, 200060. [Google Scholar] [CrossRef]

- Lord, R.; Sakrabani, R. Ten-year legacy of organic carbon in non-agricultural (brownfield) soils restored using green waste compost exceeds 4 per mille per annum: Benefits and trade-offs of a circular economy approach. Sci. Total Environ. 2019, 686, 1057–1068. [Google Scholar] [CrossRef]

- Dubey, P.K.; Singh, A.; Chaurasia, R.; Pandey, K.K.; Bundela, A.K.; Singh, G.S.; Abhilash, P.C. Animal manures and plant residue-based amendments for sustainable rice-wheat production and soil fertility improvement in eastern Uttar Pradesh, North India. Ecol. Eng. 2022, 177, 106551. [Google Scholar] [CrossRef]

- Soinne, H.; Keskinen, R.; Heikkinen, J.; Hyväluoma, J.; Uusitalo, R.; Peltoniemi, K.; Velmala, S.; Pennanen, T.; Fritze, H.; Kaseva, J.; et al. Are there environmental or agricultural benefits in using forest residue biochar in boreal agricultural clay soil? Sci. Total Environ. 2020, 731, 138955. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Zhang, J. Maya blue pigments derived from clay minerals. In Nanomaterials from Clay Minerals: A New Approach to Green Functional Materials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 627–661. [Google Scholar] [CrossRef]

- Jiang, J.; Ayaz, T.; Jiang, Z.; Lei, M. Green Remediation of Heavy Metal Polluted Water and Soil Using Clay Minerals: A Review. IOP Conf. Ser. Earth Environ. Sci. 2021, 632, 052079. [Google Scholar] [CrossRef]

- Carrillo, A.M.; Urruchurto, C.M.; Carriazo, J.G.; Moreno, R.A.; Molina, R.A. Structural and textural characterization of a Colombian Halloysite. Mex. J. Chem. Eng. 2014, 13, 563–570. [Google Scholar]

- Yang, X.; Cai, J.; Chen, L.; Cao, X.; Liu, H.; Liu, M. Green detergent made of halloysite nanotubes. Chem. Eng. J. 2021, 425, 130623. [Google Scholar] [CrossRef]

- Akbarinezhad, E.; Ebrahimi, M.; Sharif, F.; Ghanbarzadeh, A. Evaluating protection performance of zinc rich epoxy paints modified with polyaniline and polyaniline-clay nanocomposite. Prog. Org. Coat. 2014, 77, 1299–1308. [Google Scholar] [CrossRef]

- Lopes, M.M.S.; Pedroti, L.G.; de Oliveira, A.F.; Ribeiro, J.C.L.; de Carvalho, J.M.F.; de Carvalho, A.F.; Cardoso, F.d.P.; Nalon, G.H.; de Lima, G.E.S. Optimization of performance of sustainable paints using granite waste through the variation of particle size and pH. J. Clean. Prod. 2021, 326, 129418. [Google Scholar] [CrossRef]

- Tressmann, D.M.G.A.; Pedroti, L.G.; de Carvalho, A.F.; Ribeiro, J.C.L.; Cardoso, F.d.P.; Lopes, M.M.S.; de Oliveira, A.F.; Ferreira, S.O. Research into the use of marble waste as mineral filler in soil pigment-based paints and as an active pigment in waterborne paints. Constr. Build. Mater. 2020, 241, 117976. [Google Scholar] [CrossRef]

- Lopes, M.M.S.; Alvarenga, R.d.C.S.S.; Pedroti, L.G.; Ribeiro, J.C.L.; de Carvalho, A.F.; Cardoso, F.d.P.; Mendes, B.C. Influence of the incorporation of granite waste on the hiding power and abrasion resistance of soil pigment-based paints. Constr. Build. Mater. 2019, 205, 463–474. [Google Scholar] [CrossRef]

- Cheikh, D.; Majdoub, H.; Darder, M. An overview of clay-polymer nanocomposites containing bioactive compounds for food packaging applications. Appl. Clay Sci. 2022, 216, 106335. [Google Scholar] [CrossRef]

- Karimlou, M.M.; Tavakol, M.R.; Tooski, M.Y. Experimental study of the effect of clay nanoparticles on the strength of hybrid sandwich panels under quasi-static loading. Aerosp. Sci. Technol. 2022, 121, 107313. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Ponce, A.G.; Alvarez, V.A. Nano-clays from natural and modified montmorillonite with and without added blueberry extract for active and intelligent food nanopackaging materials. Mater. Chem. Phys. 2017, 194, 283–292. [Google Scholar] [CrossRef]

- Maisanaba, S.; Llana-Ruíz-Cabello, M.; Pichardo, S.; Prieto, A.I.; Cameán, A.M.; Jordá-Beneyto, M.; Jos, Á. Toxicological assessment of two silane-modified clay minerals with potential use as food contact materials in human hepatoma cells and Salmonella typhimurium strains. Appl. Clay Sci. 2017, 150, 98–105. [Google Scholar] [CrossRef]

- Wu, X.; Ji, F.; Zhang, X.; Wang, F.; Feng, F.; Lu, Q.; Zhao, S.; Zhang, Y.; Wang, C.; Huang, F.; et al. Geochemical evidence reveals a long-distance trade of white pottery in Neolithic China 5000 years ago. J. Archaeol. Sci. Rep. 2022, 44, 103533. [Google Scholar] [CrossRef]

- Bahtli, T.; Erdem, Y. The use of foundry waste sand from investment casting in the production of porcelain tiles. Ceram. Int. 2022, 48, 27967–27972. [Google Scholar] [CrossRef]

- Conte, S.; Zanelli, C.; Molinari, C.; Guarini, G.; Dondi, M. Glassy wastes as feldspar substitutes in porcelain stoneware tiles: Thermal behaviour and effect on sintering process. Mater. Chem. Phys. 2020, 256, 123613. [Google Scholar] [CrossRef]

- de Sousa, I.V.; Nieves, L.J.J.; Dal-Bó, A.G.; Bernardin, A.M. Valorization of porcelain tile polishing residue in the production of cellular ceramics. Clean. Eng. Technol. 2022, 6, 100381. [Google Scholar] [CrossRef]

- de Souza, B.N.; Bó, M.D.; Hotza, D.; Fredel, M.C. Chemical modification of porcelain tile surface to optimize flexural strength and Weibull modulus through the ion exchange process. J. Build. Eng. 2022, 56, 104735. [Google Scholar] [CrossRef]

- Tarhan, B.; Tarhan, M.; Aydin, T. Reusing sanitaryware waste products in glazed porcelain tile production. Ceram. Int. 2017, 43, 3107–3112. [Google Scholar] [CrossRef]

- Li, L.; Jiang, T.; Chen, B.; Zhou, M.; Chen, C. Overall utilization of vanadium–titanium magnetite tailings to prepare lightweight foam ceramics. Process Saf. Environ. Prot. 2020, 139, 305–314. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, W.; Xu, J.; Ding, J.; Wang, Q.; Wang, A. Solid-phase oxalic acid leaching of natural red palygorskite-rich clay: A solvent-free way to change color and properties. Appl. Clay Sci. 2020, 198, 105848. [Google Scholar] [CrossRef]

| Layer Type | Group | Subgroup | |

|---|---|---|---|

| T:O | 1:1 | Rectorite | |

| Kaolinite | |||

| Halloysite | |||

| Serpentine | |||

| Chrysotile | |||

| T:O:T | 2:1 | Smectite | Montmorillonite |

| Laponite | |||

| Illite | |||

| Hectorite | |||

| Bentonite | |||

| Vermiculite | Vermiculite | ||

| Pyrophyllite Talc | Pyrophyllite | ||

| Talc | |||

| Mica | Muscovite | ||

| Paragonite | |||

| Brittle Mica | Margarita | ||

| Clintonite | |||

| Kinoshitalite | |||

| T:O:T:O | 2:1:1 | Chlorite | Donbassite |

| Sudoite | |||

| Chamosite | |||

| Reference | Research Location | Residue Used in the Mixture | Optimal Dosage | Main Findings | |

|---|---|---|---|---|---|

| [63] | South Korea | FA | Fly ash | 10−30% | GGBS increases permeability and reduces compressive strength due to the lower cementitious material content. |

| MK | Metakaolin | 20% | |||

| SF | Silica fume | 10% | |||

| GGBS | Ground granulated blast | 30% | |||

| FSD | Fine sawdust | - | |||

| [64] | Dublin, Ireland | GGBD | Ground granulated blast furnace slag | 30% | GGBS possesses a smaller particle size in comparison to cement, thereby improving the workability of the concrete mixture. |

| [65] | Bratislava, Slovakia | FRCA | Fine recycled coarse aggregate | 30% | The presence of good interfacial bonding between FRCA and the cement paste favors increased compressive strength. |

| [66] | Konya, Turkey | WFC | Waste of fireclay | 20% | As the stirrup spacing decreases, the stirrups dominate the behavior, and as the stirrup spacing increases, WFC determines the bending behavior in the beams. |

| [67] | Nineveh, Iraq | LMP | Limestone power | 10% | The slump properties of fresh concrete are decreased, so a higher dose of superplasticizer is needed. |

| SS | Steel slag | 10% | |||

| CC | Calcined clay | 10% | |||

| [68] | Coahuila, Mexico | PHC | Pulverized hardened concrete | 45% | CaCO3 and Ca(OH)2 from the recycled concrete and the Portland cement release Ca ionic species, which reacted with the sodium silicate, forming amorphous cementitious compounds such as calcium silicate hydrates and calcium modified silica gel, stable under water. |

| [2] | Nanjing, China | GGBS | Ground granulated blast | 20% | GGBS provides more active silicon and active aluminum than Portland cement, promoting the generation of CSH and CASH. |

| [69] | Jaipur, India | FA | Fly ash | 20% | TGA presents pozzolanic activity in FA, CWP, and BWP at 28 days of 0.92, 0.75, and 0.81 compared to Portland cement. |

| CWP | Concrete waste powder | ||||

| BWP | Brick waste powder | ||||

| [70] | Cairo, Egypt | GVCP | Grounded vitrified clay pipe | 20% | Slump shows a reduction in value of 15%; a superplasticizer must be used. |

| [71] | Huei, China | CBP | Clay brick powder | 25–50% | Main hydration product is xonoltite, which effectively refines the pore structure and improves its high-temperature resistance. |

| [72] | Selangor, Malaysia | RLS | Recycled lime sludge | 15% | Incorporation of LS and CC in the mixture prompts additional hydration reactions and, after 28 days, the matrix exhibits a reduction in pore size and increased density. |

| CC | Calcined clay | 30% | |||

| [73] | Toledo, Brazil | SCA | Acai stone ash | 10% | The concrete shows negligible reinforcement corrosion risk, with resistivity values above 100 kΩ cm. |

| CC | Calcined clay | ||||

| [74] | Nanjing, China | WBF | Waste brick fines | 10% | WCF as a cement replacement raises water absorption and water porosity of mortar, and WBF causes a water porosity decline. |

| WCF | Waste concrete fines | 10% | |||

| [75] | China and others. | CBP | Clay brick powder | 15% | CBP mixture as a cement replacement decreases the heat of hydration; the smaller the particle size, the longer the curing time. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández García, L.C.; Monteiro, S.N.; Lopera, H.A.C. Recycling Clay Waste from Excavation, Demolition, and Construction: Trends and Challenges. Sustainability 2024, 16, 6265. https://doi.org/10.3390/su16146265

Hernández García LC, Monteiro SN, Lopera HAC. Recycling Clay Waste from Excavation, Demolition, and Construction: Trends and Challenges. Sustainability. 2024; 16(14):6265. https://doi.org/10.3390/su16146265

Chicago/Turabian StyleHernández García, Liliana Carolina, Sergio Neves Monteiro, and Henry A. Colorado Lopera. 2024. "Recycling Clay Waste from Excavation, Demolition, and Construction: Trends and Challenges" Sustainability 16, no. 14: 6265. https://doi.org/10.3390/su16146265

APA StyleHernández García, L. C., Monteiro, S. N., & Lopera, H. A. C. (2024). Recycling Clay Waste from Excavation, Demolition, and Construction: Trends and Challenges. Sustainability, 16(14), 6265. https://doi.org/10.3390/su16146265