Basalt Fibers versus Plant Fibers: The Effect of Fiber-Reinforced Red Clay on Shear Strength and Thermophysical Properties under Freeze–Thaw Conditions

Abstract

:1. Introduction

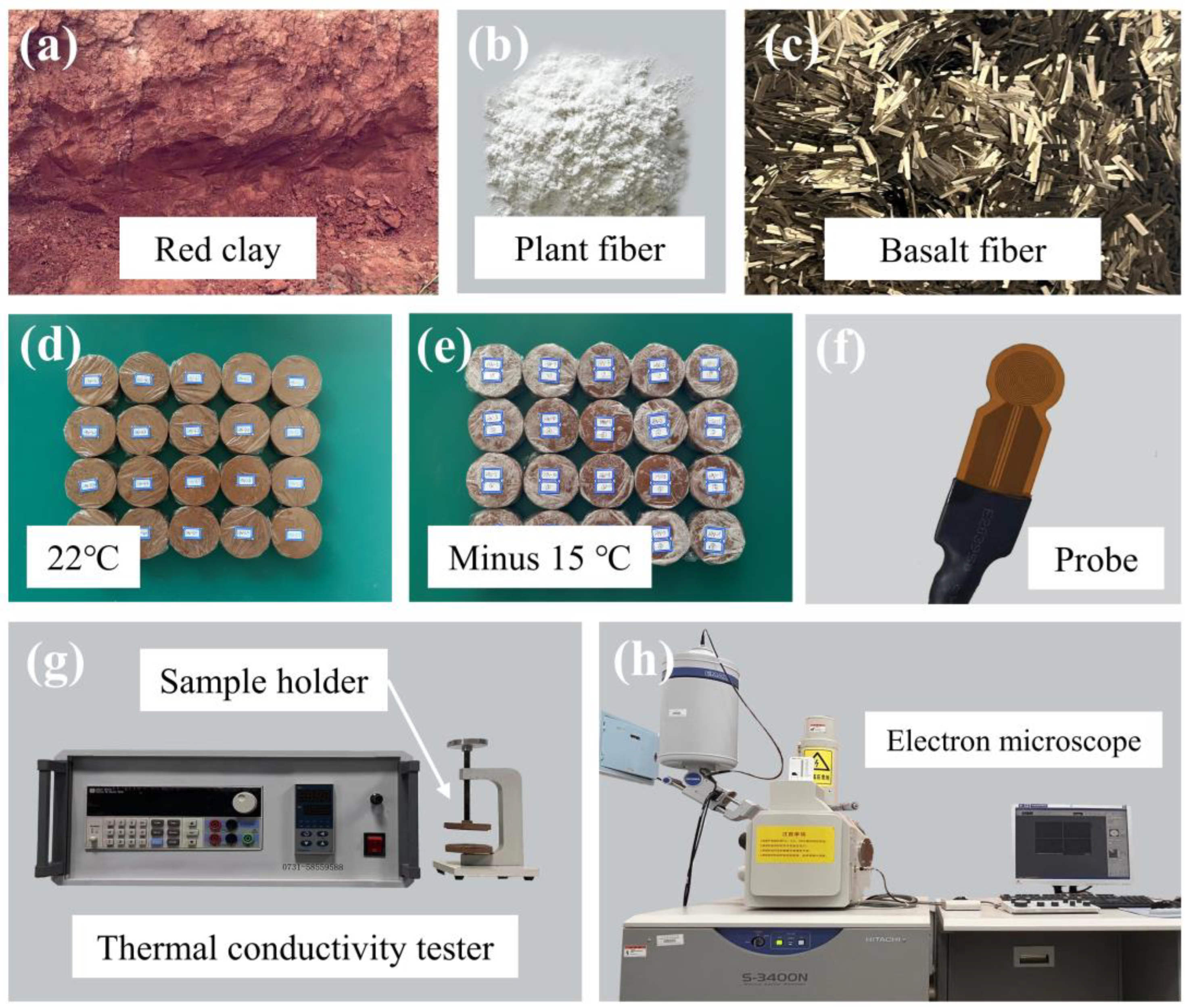

2. Materials and Experimental Methods

2.1. Materials

2.2. Shear Strength Test

2.2.1. Experimental Program

2.2.2. Specimen Preparation

2.2.3. Experimental Process

2.3. Thermophysical Property Test

2.3.1. Experimental Instruments and Principles

2.3.2. Experimental Program

2.3.3. Experimental Steps

2.4. XRD and SEM Test

3. Results and Discussions

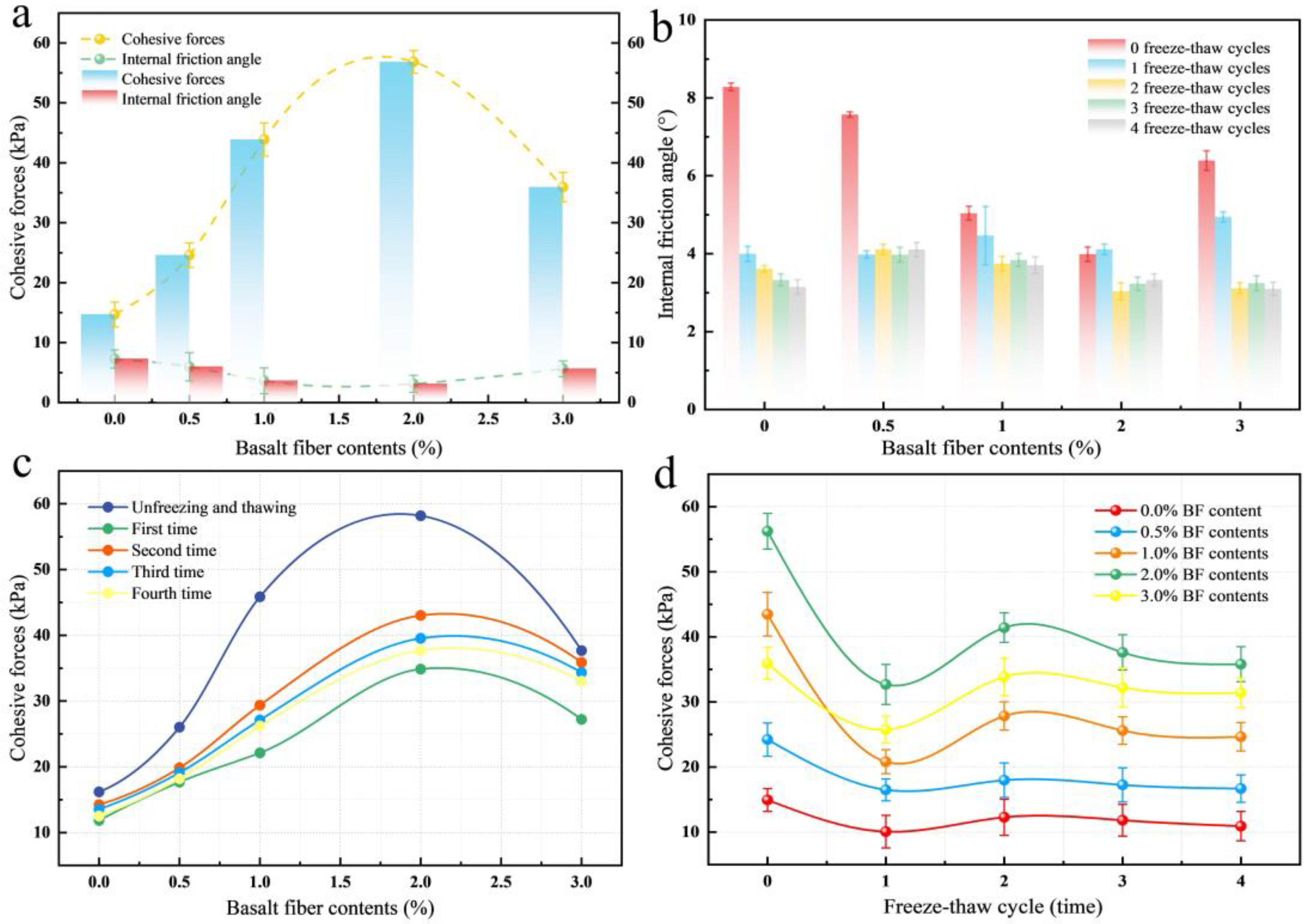

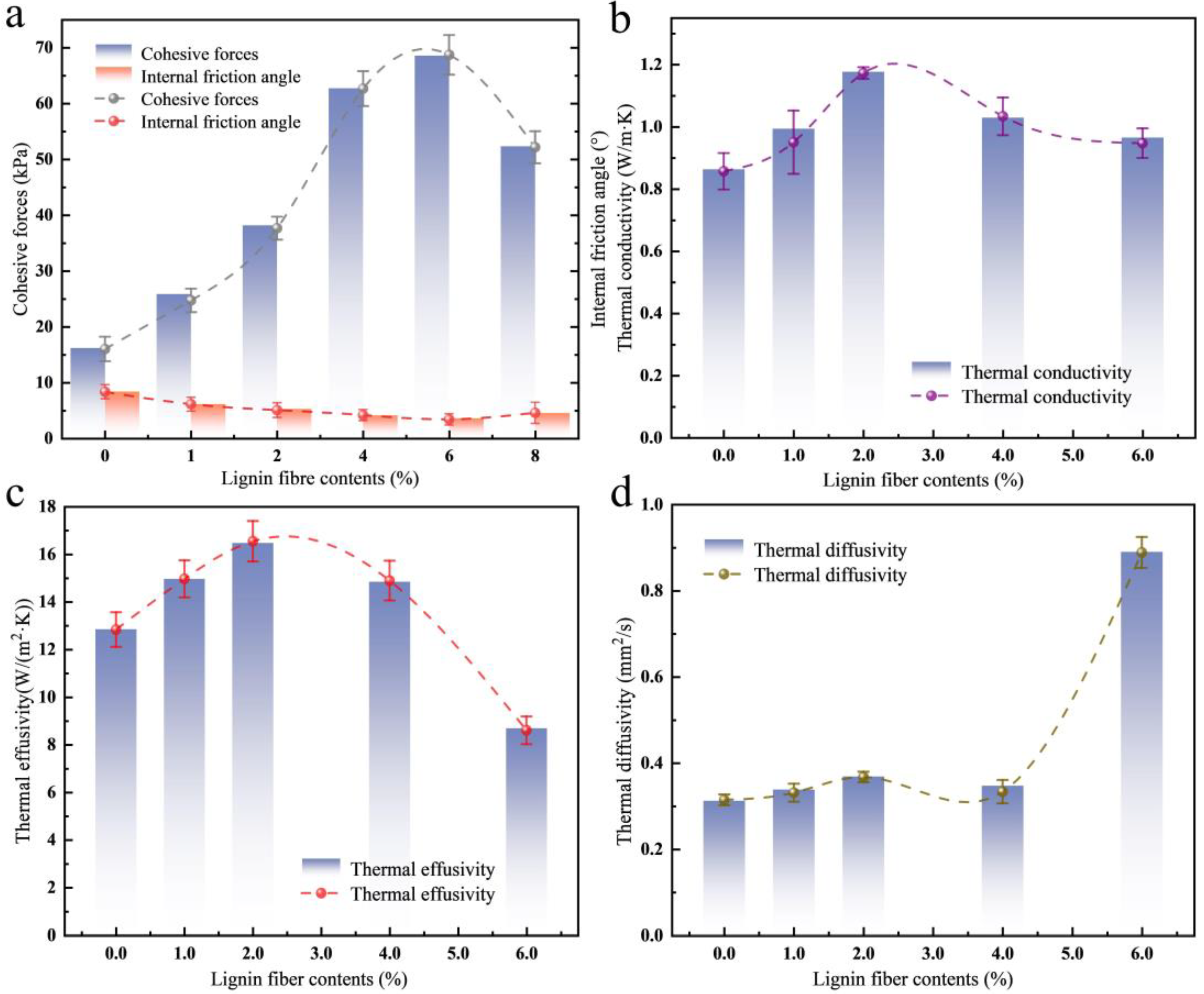

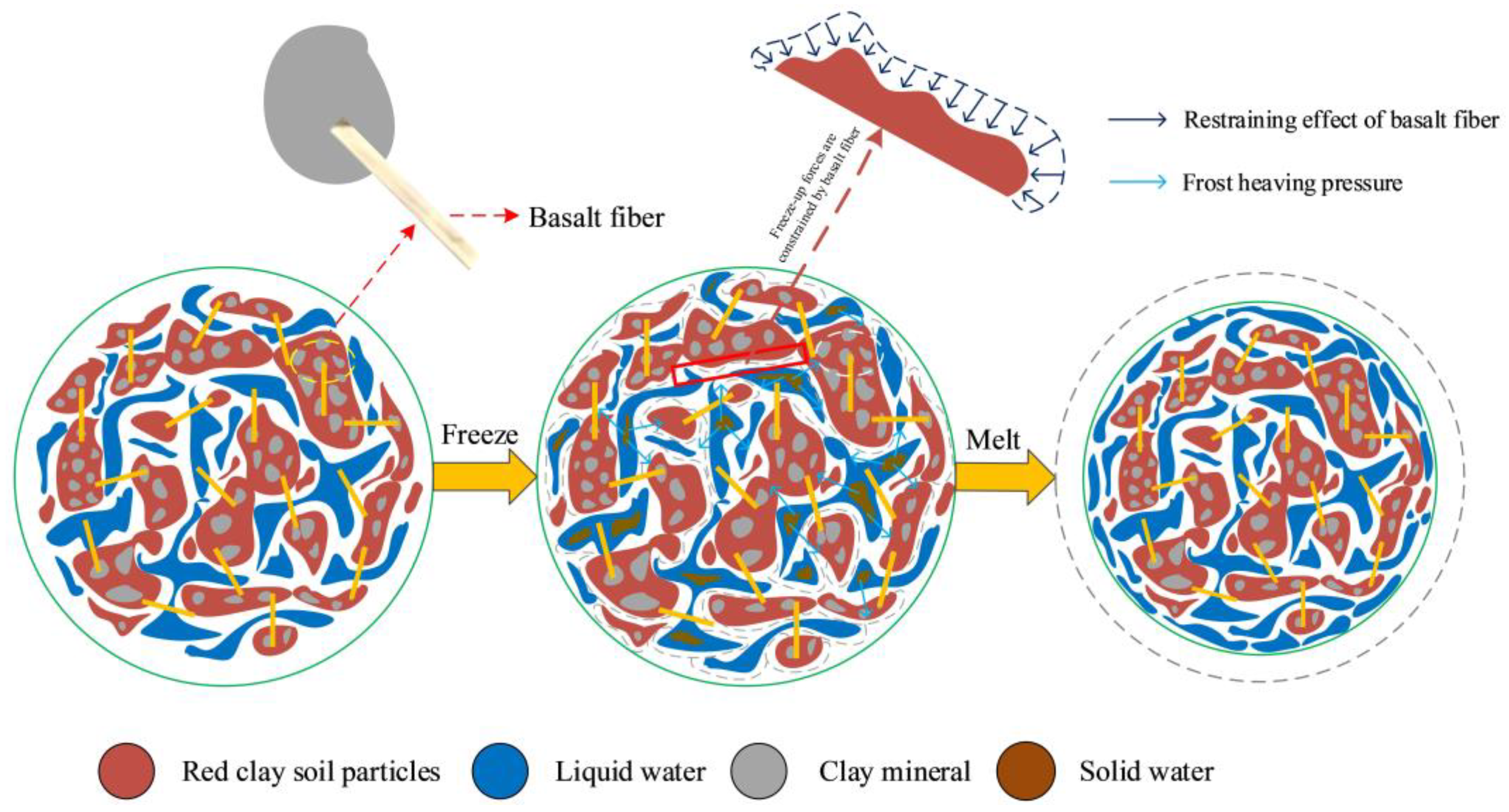

3.1. Effect of BF Content and Number of Freeze–Thaw Cycles on Shear Strength

3.2. XRD Whole Rock Mineral Analyses

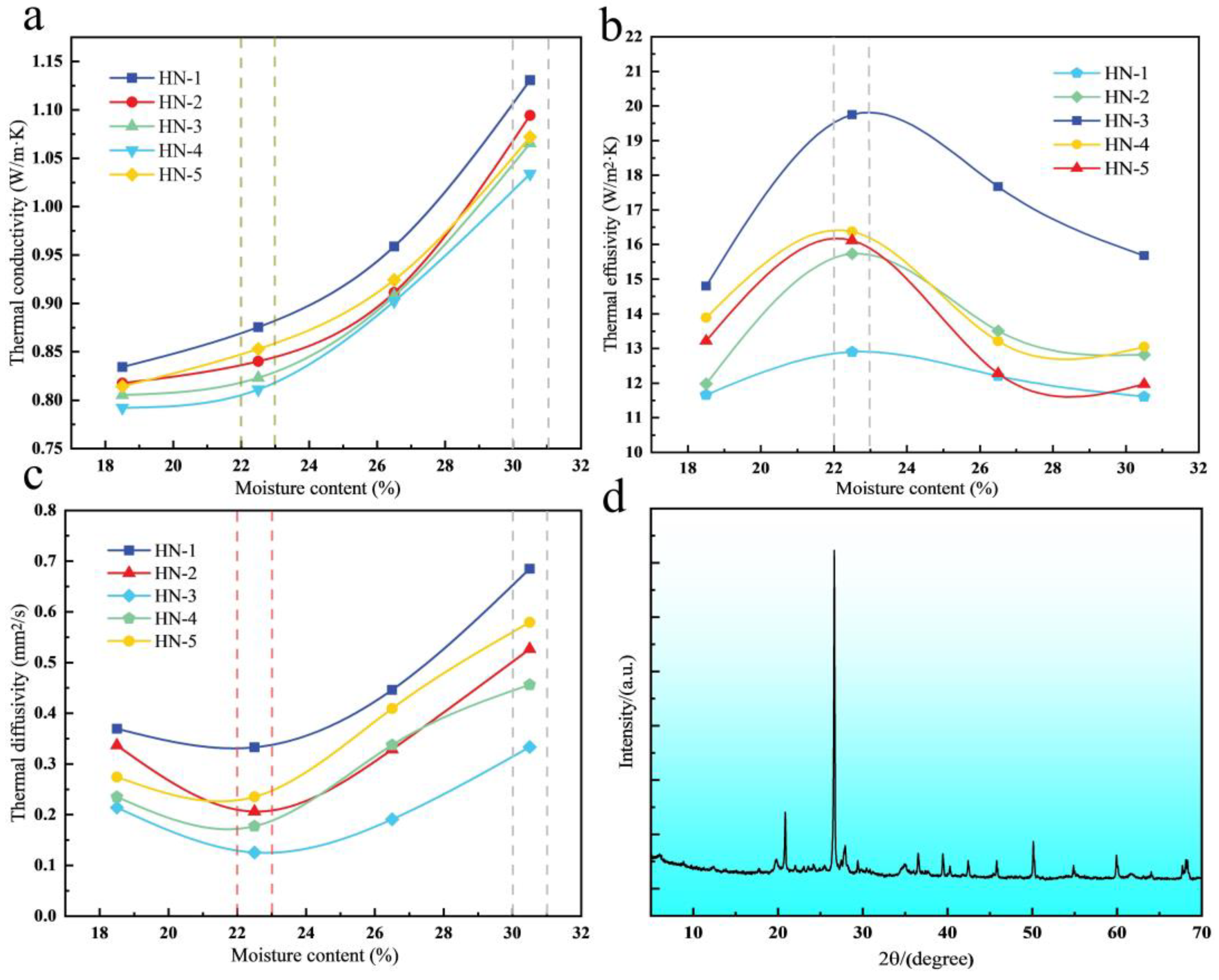

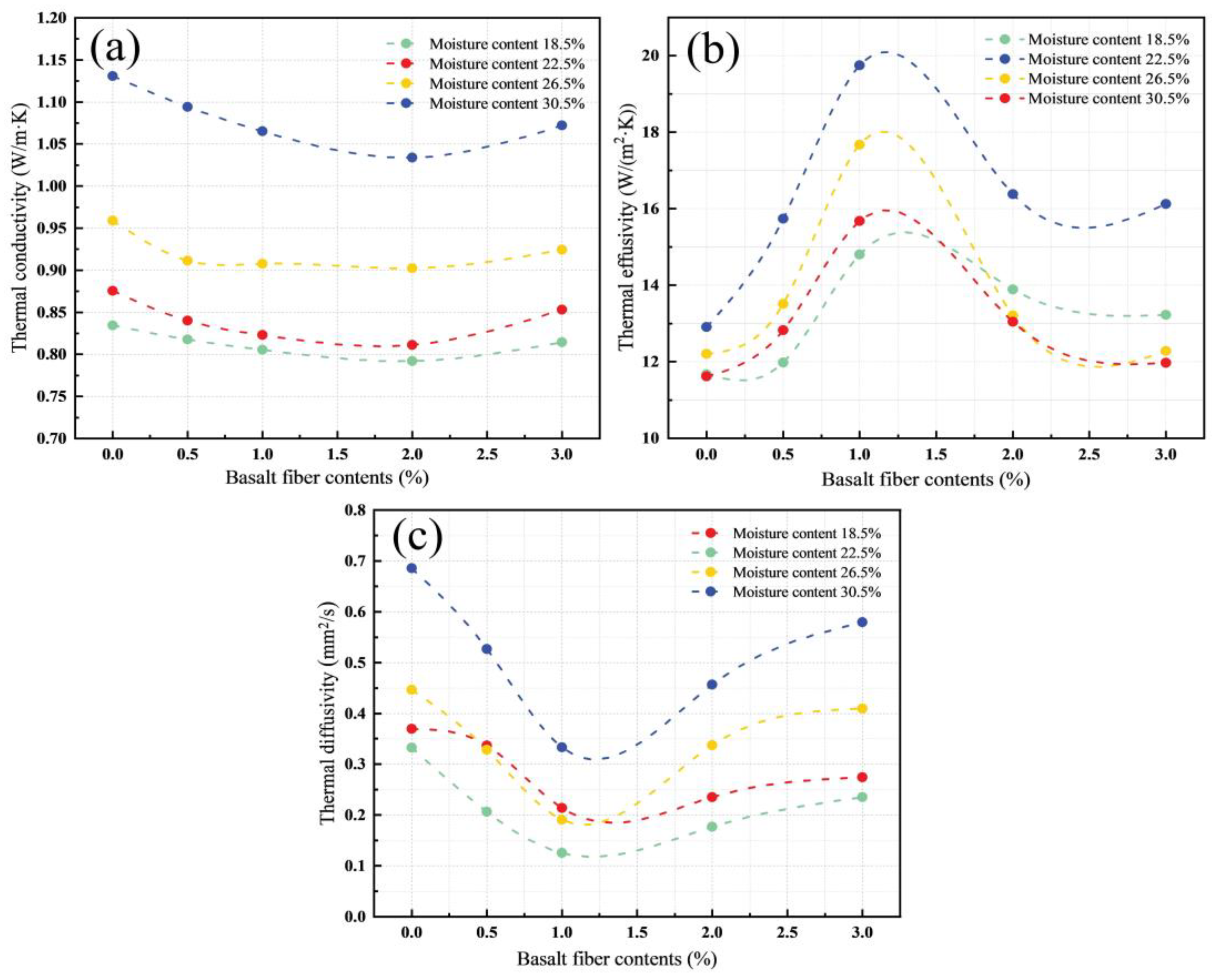

3.3. Effect of Moisture Content and BF Blending on Thermal Conductivity Properties

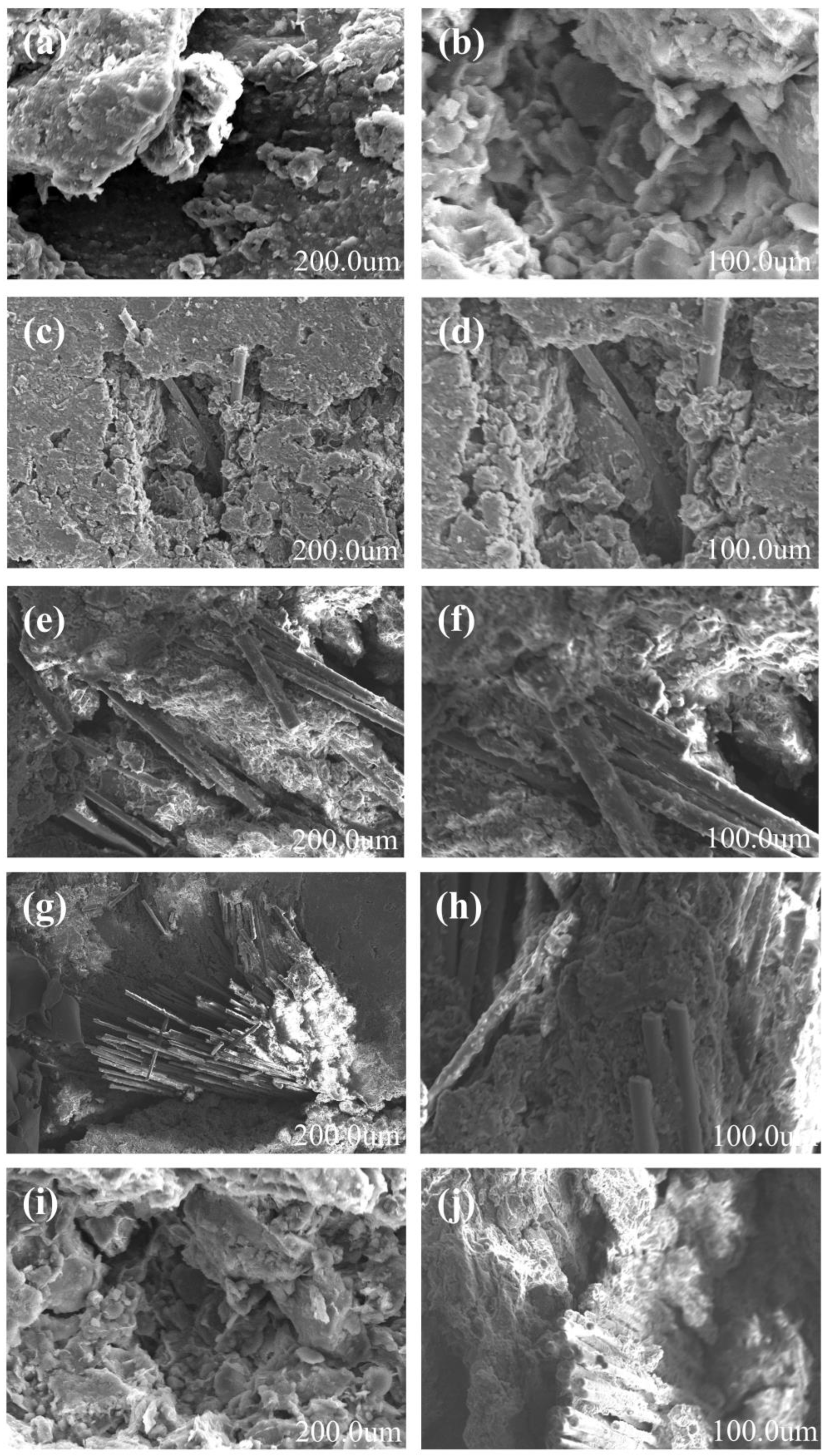

3.4. Electron Microscope Scanning and Analysis

3.5. Comparison with LF Improved RC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gava, O.; Bartolini, F.; Venturi, F.; Brunori, G.; Pardossi, A. Improving Policy Evidence Base for Agricultural Sustainability and Food Security: A Content Analysis of Life Cycle Assessment Research. Sustainability 2020, 12, 1033. [Google Scholar] [CrossRef]

- Bartolini, F.; Vergamini, D. Trade-Offs and Synergies between Ecosystem Services Provided by Different Rural Landscape. Agronomy 2023, 13, 977. [Google Scholar] [CrossRef]

- Al-Khoury, R. Computational Modeling of Shallow Geothermal Systems; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Raos, S.; Hranić, J.; Rajšl, I. Multi-criteria Decision-making Method for Evaluation of Investment in Enhanced Geothermal Systems Projects. Energy AI 2024, 17, 100390. [Google Scholar] [CrossRef]

- Alsaleh, M.; Abdul-Rahim, A. The impacts of intellectual capital, market size, and intellectual property factors in geothermal power exploration. Energy Explor. Exploit. 2024, 42, 1241–1266. [Google Scholar] [CrossRef]

- Kiran, R.; Rajak, V.; Upadhyay, R.; Kumar, A. Comparative techno-economic assessment of superhot rock and conventional geothermal energy feasibility for decarbonizing India. Geothermics 2024, 122, 103078. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Y.; Xia, C.; Yang, Y. Tunnel heating system using geothermal energy and its construction method. Mod. Tunn. Technol. 2015, 52, 170–176. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M. Thermodynamic aspects of renewables and sustainable development. Renew. Sustain. Energy Rev. 2005, 9, 169–189. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E. Plain and ultrafine fly ashes mortars for environmentally friendly construction materials. Sustainability 2018, 10, 874. [Google Scholar] [CrossRef]

- Rosen, M.; Koohi-Fayegh, S. Geothermal Energy: Sustainable Heating and Cooling Using the Ground; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Delaleux, F.; Py, X.; Olives, R.; Dominguez, A. Enhancement of geothermal borehole heat exchangers performances by improvement of bentonite grouts conductivity. Appl. Therm. Eng. 2012, 33, 92–99. [Google Scholar] [CrossRef]

- Lee, C.; Lee, K.; Choi, H.; Choi, H. Characteristics of thermally-enhanced bentonite grouts for geothermal heat exchanger in South Korea. Sci. China Ser. E Technol. Sci. 2010, 53, 123–128. [Google Scholar] [CrossRef]

- Gao, L.; Hu, G.; Xu, N.; Fu, J.; Xiang, C. Advances in research on engineering properties of basalt fiber. Chin. J. Undergr. Space Eng. 2014, 10, 1749–1754. [Google Scholar]

- Frydrych, M.; Hýsek, Š.; Fridrichová, L.; Le Van, S.; Herclík, M.; Pechočiaková, M.; Le Chi, H.; Louda, P. Impact of Flax and Basalt Fiber Reinforcement on Selected Properties of Geopolymer Composites. Sustainability 2019, 12, 118. [Google Scholar] [CrossRef]

- Wei, C.; Guo, R. Properties and Application of basalt fiber. J. Text. Sci. Eng. 2019, 36, 89–94. [Google Scholar]

- Gao, L.; Hu, G.; Yang, C.; Xiang, C.; Fu, J.; Xu, N. Shear strength characteristics of basalt fiber-reinforced clay. Chin. J. Geotech. Eng. 2016, 38, 231–237. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Rangappa, M.; Siengchin, S. Basalt fibers: An environmentally acceptable and sustainable green material for polymer composites. Constr. Build. Mater. 2024, 436, 136834. [Google Scholar] [CrossRef]

- Dong, J.; Liu, Y.; Yuan, S.; Li, K.; Zhang, F.; Guang, Z.; Chai, H.; Wang, Q. Mechanical behavior and impact resistance of rubberized concrete enhanced by basalt fiber-epoxy resin composite. Constr. Build. Mater. 2024, 435, 136836. [Google Scholar] [CrossRef]

- Lv, J.; Han, W.; Zheng, J.; Lin, S.; Yuan, S. Effects of basalt fiber and rubber particles on the mechanical properties and impact resistance of concrete. Structures 2024, 65, 106677. [Google Scholar] [CrossRef]

- Hassan, R.; Yousif, R. Shear performance and strength of reinforced concrete non-prismatic beams with basalt fiber reinforced polymer rebars. Structures 2024, 65, 106571. [Google Scholar] [CrossRef]

- Zhu, R.; Wang, Y.; Huang, Y.; Zhang, W.; Xing, W.; Zhou, F. Freeze-thawing characteristics and microscopic mechanism of expansive soil treated with lignin fibers. Trans. Chin. Soc. Agric. Eng. 2024, 40, 263–272. [Google Scholar] [CrossRef]

- Jamei, M.; Villard, P.; Guiras, H. Shear Failure Criterion Based on Experimental and Modeling Results for Fiber-Reinforced Clay. Int. J. Geomech. 2013, 13, 882–893. [Google Scholar] [CrossRef]

- Li, J.; Hao, J.; Chen, W. Advances in Study of Fiber Reinforced Soil. World Sci-Tech RD 2015, 37, 319–325. [Google Scholar] [CrossRef]

- Fatahi, B.; Fatahi, B.; Le, T.; Khabbaz, H. Small-strain properties of soft clay treated with fiber and cement. Geosynth. Int. 2013, 20, 286–300. [Google Scholar] [CrossRef]

- Li, J.; Tang, C.; Wang, Y.; Shi, B.; Pei, X. Single fiber pullout tests on interfacial shear strength of wave-shape fiber-reinforced soils. Chin. J. Geotech. Eng. 2014, 36, 1696–1704. [Google Scholar] [CrossRef]

- Cristelo, N.; Cunha, M.; Dias, M.; Gomes, A.; Miranda, T.; Araújo, N. Influence of discrete fiber reinforcement on the uniaxial compression response and seismic wave velocity of a cement-stabilised sandy-clay. Geotext. Geomembr. 2015, 43, 1–13. [Google Scholar] [CrossRef]

- Ple, O.; Lê, T. Effect of polypropylene fiber-reinforcement on the mechanical behavior of silty clay. Geotext. Geomembr. 2012, 32, 111–116. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, C.; Li, J.; Liu, B.; Tang, W.; Zhu, K. Shear strength characteristics of fiber-reinforced unsaturated cohesive soils. Chin. J. Geotech. Eng. 2013, 35, 1933–1939. [Google Scholar]

- Niu, L.; Wu, Z.; Xu, L.; Bi, S.; Huang, Z. Effect of different fibers on soil mechanical properties and mechanism analysis. J. Chang. River Sci. Res. Inst. 2024, 1–8. [Google Scholar]

- Wei, L.; Yang, G.; Shang, J.; Chai, S. Compressive properties and crack evolution characteristics of fiber reinforced soil under freeze-thaw cycling. China Civ. Eng. J. 2024, 57, 81–91. [Google Scholar] [CrossRef]

- Wei, L.; Chai, S.; Xue, M.; Wang, P.; Li, F. Evaluation of freeze-thaw durability of fiber reinforced soil by shear performances and structural damage. Chin. J. Rock Mech. Eng. 2022, 41, 3453–3463. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, Q.; Wang, K. Research on Highway Subgrade Soil Modified by Basalt Powder and Fiber. Highway 2022, 67, 15–21. [Google Scholar]

- Tiwari, N.; Satyam, N.; Singh, K. Effect of curing on micro-physical performance of polypropylene fiber reinforced and silica fume stabilized expansive soil under freezing thawing cycles. Sci. Rep. 2020, 10, 7624. [Google Scholar] [CrossRef]

- Almajed, A.; Srirama, D.; Moghal, A. Response surface method analysis of chemically stabilized fiber-reinforced soil. Materials 2021, 14, 1535. [Google Scholar] [CrossRef]

- Shaker, A.; Al-Shamrani, M.; Moghal, A.; Vydehi, K. Effect of confining conditions on the hydraulic conductivity behavior of fiber-reinforced lime blended semiarid soil. Materials 2021, 14, 3120. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.; Li, Y.; Wang, C.; Ye, Z. Experimental study on mechanical properties of coir fiber reinforced lime improved Soil mechanics. Adv. Eng. Sci. 2024, 1–14. [Google Scholar] [CrossRef]

- Wei, L.; Chao, S.; Zhang, L.; Li, Y. Compressive and tensile properties of three fiber-lime-soils under freeze-thaw cycle. Rock Soil Mech. 2022, 43, 3241–3248+3280. [Google Scholar] [CrossRef]

- Jiang, X.; Liu, J.; Li, M.; Dong, C.; Yao, H.; Huang, R. Study on the Shear Strength Characteristics and Reinforcement Mechanism of Palm Fiber Reinforced Soil. Chin. Q. Mech. 2024, 45, 274–285. [Google Scholar] [CrossRef]

- Wu, R.; Xiang, Q.; Yang, G.; Wu, Z. Study on shear characteristics of shaoxing unsaturated clay reinforced with polypropylene fibers. Chin. Q. Mech. 2023, 44, 172–180. [Google Scholar] [CrossRef]

- Tang, Y.; Wu, R.; Yang, G. Experimental study on shear strength characteristics of unsaturated silty clay in east zhejiang grand canal. Chin. Q. Mech. 2021, 42, 360–369. [Google Scholar] [CrossRef]

- Xiong, Y.; Deng, H.; Peng, M.; Qi, Y.; Li, T. Shear properties of loess reinforced with four synthetic fibers. J. Yangtze River Sci. Res. Inst. 2022, 39, 122–126+133. [Google Scholar] [CrossRef]

- Niu, W.; Liu, J.; Zheng, Y.; Ren, Z. Experimental Study on Strain Rate Effect of Basalt Fiber-reinforced Soil. J. Basic Sci. Eng. 2024, 32, 850–859. [Google Scholar] [CrossRef]

- Fan, X.; Ji, H.; Jiang, S.; Qiu, C.; Ding, F.; Yuan, G. Strength characteristics of solidified silt using combination method of basalt fibre-lime-volcanic ash. J. Railw. Sci. Eng. 2023, 20, 4613–4624. [Google Scholar] [CrossRef]

- Chai, S.; Zhang, L.; Wei, L.; Tian, M. Compressive properties and microstructure of saline soil added fiber and lime under freezing thawing cycles. Hydrogeol. Eng. Geol. 2022, 49, 96–105. [Google Scholar] [CrossRef]

- Zhang, J.; Lv, Z.; Li, X.; Zheng, J.; Sheng, G.; Li, Q. Durability study of polypropylene fibers on enzyme-induced carbonate precipitation cured sandy soil under dry-wet cycling. Acta Mater. Compos. Sin. 2024, 1–12. [Google Scholar] [CrossRef]

- Liu, T. Experimental investigation on the static and dynamic characteristics of silty clay reinforced with basalt fiber. J. Railw. Sci. Eng. 2020, 17, 1734–1742. [Google Scholar] [CrossRef]

- Qu, J.; Hu, C.; Zhao, C. Shear strength experimental study on basalt fiber and nano slilca reinforced Shanghai clay. J. Water Resour. Water Eng. 2017, 28, 186–192. [Google Scholar]

- Mohamad, A.; Shadi, N.; Salah, S. Drained Triaxial Response of Natural Clay Reinforced with Natural Hemp Fibers. Int. J. Geomech. 2024, 24, 04024123. [Google Scholar] [CrossRef]

- Salimi, M.; Payan, M.; Hosseinpour, I.; Arabani, M.; Ranjbar, Z. Effect of glass fiber (GF) on the mechanical properties and freeze-thaw (F-T) durability of lime-nanoclay (NC)-stabilized marl clayey soil. Constr. Build. Mater. 2024, 416, 135227. [Google Scholar] [CrossRef]

- Wang, J.; Hughes, P.; Augarde, C. Towards a predictive model of the shear strength behaviour of fibre reinforced clay. European J. Environ. Civ. Eng. 2024, 28, 380–400. [Google Scholar] [CrossRef]

- Tao, G.; Guo, E.; Yuan, J.; Chen, Q.; Nimbalkar, S. Permeability and Cracking of Compacted Clay Liner Improved by Nano-SiO2 and Sisal Fiber. KSCE J. Civ. Eng. 2023, 27, 5109–5122. [Google Scholar] [CrossRef]

- Mohamad, H.; Ala, A.; Abdullah, E.; Arrieta, B. Mechanical properties of alluvium clay treated with cement and carbon fiber: Relationships among strength, stiffness, and durability. Int. J. Pavement Eng. 2023, 24, 2094928. [Google Scholar] [CrossRef]

- Wang, H.; Li, D.; Xia, M.; Li, X. Study on thermal conductivity of improved soil under different freezing temperatures. PLoS ONE 2023, 18, e0292560. [Google Scholar] [CrossRef]

- Xu, J.; Hu, H.; Zheng, Z. The influence of compactness and moisture content on the thermal conductivity of unsaturated soil. J. Geotech. Eng. 2020, 42, 244–248. [Google Scholar] [CrossRef]

- Salomone, L.; Kovacs, W.; Kusuda, T. Thermal performance of fine-grained soils. J. Geotech. Eng. 1984, 110, 359–374. [Google Scholar] [CrossRef]

- Nikiforova, T.; Savytskyi, M.; Limam, K.; Bosschaerts, W.; Belarbi, R. Methods and results of experimental researches of thermal conductivity of soils. Energy Procedia 2013, 42, 775–783. [Google Scholar] [CrossRef]

- Ye, W.; Dong, X.; Yang, G.; Chen, Q.; Peng, R.; Liu, K. Experimental study on the influence of moisture content and dry density on thermal parameters of loess. Geotech. Mech. 2017, 38, 656–662. [Google Scholar] [CrossRef]

- Dong, X.; Ye, W.; Yang, G.; Wu, D.; Shen, Y.; Liu, H. Experimental study on the effect of temperature on thermal parameters of loess. Geotech. Mech. 2017, 38, 2888–2894+2900. [Google Scholar] [CrossRef]

- Tang, S.; Yin, L.; Yang, Q.; Ke, X. Thermal conductivity and predictive modeling of microencapsulated phase change materials for improved silt sands. China Powder Sci. Technol. 2024, 30, 112–123. [Google Scholar] [CrossRef]

- Feng, Z.; Li, D.; Jia, Z.; Wang, Z.; Xia, M.; Qin, Z.; He, J. Experimental study on thermal conductivity of red clay improved by copper-tail ore. Sci. Technol. Eng. 2024, 24, 308–319. [Google Scholar] [CrossRef]

- Dong, C.; Lin, C.; Zhang, Y.; Sun, X.; Huang, Y. Study on the thermal parameters and mechanical properties of lignin fiber improved loess in cold and arid areas. J. Arid Land Resour. Environ. 2022, 36, 119–126. [Google Scholar] [CrossRef]

- Wang, L.; Song, X.; Huang, M.; Wang, M. Influence factors and prediction method of thermal conductivity for dispersive clay. J. Hydraul. Eng. 2023, 54, 311–322. [Google Scholar] [CrossRef]

- Kuila, C.; Maji, A.; Phadikar, U.; Mallisetty, P.; Murmu, N.; Kuila, T. Bio-inspired basalt fiber reinforced epoxy laminates with wasted egg shell derived CaCO3 for improved thermal and mechanical properties. Polym. Compos. 2024, 45, 215–226. [Google Scholar] [CrossRef]

- Aziz, E.; Imad, M.; Yousra, L.; Hassane, S.; Houssame, L. Enhancing the mechanical and thermal insulation properties of clay-based construction materials with neutral carbon footprint through the use of Doum fibers. Mater. Chem. Phys. 2024, 314, 128774. [Google Scholar] [CrossRef]

- Yassine, C.; Najma, L.; Mohammed, G. Thermal performance and energy efficiency of the composite clay and hemp fibers. J. Build. Eng. 2023, 73, 106810. [Google Scholar] [CrossRef]

- Sayouba, S.; Kayaba, H.; Téré, D.; Souleymane, S.; Oumar, S.; Jean, K.; Antoine, B. Formulation and Thermomechanical Characterization of Earth-based Biosourced Composites: Cases of Clay-Hibiscus cannabinus L.Fiber, Clay-sawdust and Clay- Oryza sativa Husk. Asian J. Phys. Chem. Sci. 2023, 11, 30–44. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Test Methods. China Standard Press: Beijing, China, 2019.

- Li, G.; Chen, L.; Zheng, J.; Jie, Y. Experimental study on fiber-reinforced cohesive soil. J. Hydraul. Eng. 1995, 6, 31–36. [Google Scholar]

- Lv, H.; Zeng, Z.; Yin, G.; Zhao, Y. Analysis of mineral composition of Red Clay in Guangxi. J. Eng. Geol. 2012, 20, 651–656. [Google Scholar]

- Tang, C.; Shi, B.; Gu, K. Microstructural research on interfacial interactions between fiber reinforcement and soil. J. Eng. Geol. 2011, 19, 610–614. [Google Scholar]

| Soil Sample | ωP (%) | ωL (%) | ωopt (%) | ρdmax (g/cm3) | Gs |

|---|---|---|---|---|---|

| RC | 25.7 | 44.7 | 18.1 | 1.72 | 2.62 |

| Materials | ρ (g/cm3) | E (GPa) | Rm (N/tex) | ε (%) | L (mm) | D (μm) |

|---|---|---|---|---|---|---|

| BF | 2.94 | 96.82 | 0.41 | 2.83 | 6 | 17 |

| Materials | L (mm) | D (μm) | PH | ω (%) | T (°C) | Ash (%) |

|---|---|---|---|---|---|---|

| LF | 1 ± 0.5 | 40 | 7.0 ± 0.5 | <5 | 220 | 18 ± 2 |

| Serial Number | BF Content (%) | Mass Moisture Content (%) |

|---|---|---|

| HN-1 | 0 | 18.5, 22.5, 26.5, 30.5 |

| HN-2 | 0.5 | 18.5, 22.5, 26.5, 30.5 |

| HN-3 | 1.0 | 18.5, 22.5, 26.5, 30.5 |

| HN-4 | 2.0 | 18.5, 22.5, 26.5, 30.5 |

| HN-5 | 3.0 | 18.5, 22.5, 26.5, 30.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.; Yuan, J.; Wang, F.; He, Q.; Huang, B.; Kong, L.; Huang, Z. Basalt Fibers versus Plant Fibers: The Effect of Fiber-Reinforced Red Clay on Shear Strength and Thermophysical Properties under Freeze–Thaw Conditions. Sustainability 2024, 16, 6440. https://doi.org/10.3390/su16156440

Wu T, Yuan J, Wang F, He Q, Huang B, Kong L, Huang Z. Basalt Fibers versus Plant Fibers: The Effect of Fiber-Reinforced Red Clay on Shear Strength and Thermophysical Properties under Freeze–Thaw Conditions. Sustainability. 2024; 16(15):6440. https://doi.org/10.3390/su16156440

Chicago/Turabian StyleWu, Tunasheng, Junhong Yuan, Feng Wang, Qiansheng He, Baoyu Huang, Linghong Kong, and Zhan Huang. 2024. "Basalt Fibers versus Plant Fibers: The Effect of Fiber-Reinforced Red Clay on Shear Strength and Thermophysical Properties under Freeze–Thaw Conditions" Sustainability 16, no. 15: 6440. https://doi.org/10.3390/su16156440