Management of the Municipal Waste Stream: Waste into Energy in the Context of a Circular Economy—Economic and Technological Aspects for a Selected Region in Poland

Abstract

:1. Introduction

2. Literature Review

2.1. Technical Aspects

2.2. Economic Conditions

2.3. Managing Waste Disposal

- Natural environment protection by decreasing the risks of soil, water, and air pollution [55];

- Using waste as a source of resources, including valuable elements [56], resulting in its independence from resource extraction. The above factors contribute to resource protection, while meeting the condition of the circular economy, the establishment of which provides further synergistic benefits, including a reduced demand for primary raw materials, energy saving, and reduced greenhouse gas emissions [54];

- Energy recovery, e.g., through the thermal treatment of waste [57] or its gasification;

- Economic benefits, as the recycling and waste treatment industry creates jobs, stimulates the economy, and contributes to lowering the external effects (by-products) of industrial production;

- Reducing waste management costs by reducing the amount of waste in landfills [60];

- Stimulating public awareness of waste issues and the cooperation between different stakeholders, governments, local authorities, businesses, local communities, and citizens, to implement sustainable waste management practices, which ultimately contribute to a higher quality of life.

- The protection of human health and the environment;

- No risks to water, air, soil, plants, or animals;

- Does not cause a nuisance through noise or odors; and

- Does not adversely affect the countryside or places of special interest [62].

- Define the system through its scopes, i.e., scale, timeframe, and boundaries, but also define the goals of the system in environmental, social, and economic dimensions, taking into account local conditions. The authors of the concept also highlighted the need for clear and precise definitions of the key terms that stakeholders will use within the system;

- Identify the environmental impact of planned activities;

- Identify stakeholders and their concerns about the system, and determine the method of communicating with them;

- Identify system performance indicators taking into account environmental, financial, regulatory, social, and stakeholder expectations;

- Select the best program option based on the above factors [77].

- Determining the specific goals as well as the time and measures to achieve them;

- Implementation;

- Systematic data collection.

- Diagnosing whether the goals specified at the planning stage are achieved and the reasons for the possible failures in the area;

- Evaluating the goals achieved from the perspective of requirements;

- Determining the challenges of the system.

- Introducing changes by defining the manner of the existing program’s modification;

- Planning and implementing new action plans under the system;

- Goal reviews and modifications;

- Changes in other planning-stage elements;

- Iteratively moving through all the stages of the management framework to improve the system [73].

3. Materials and Methods

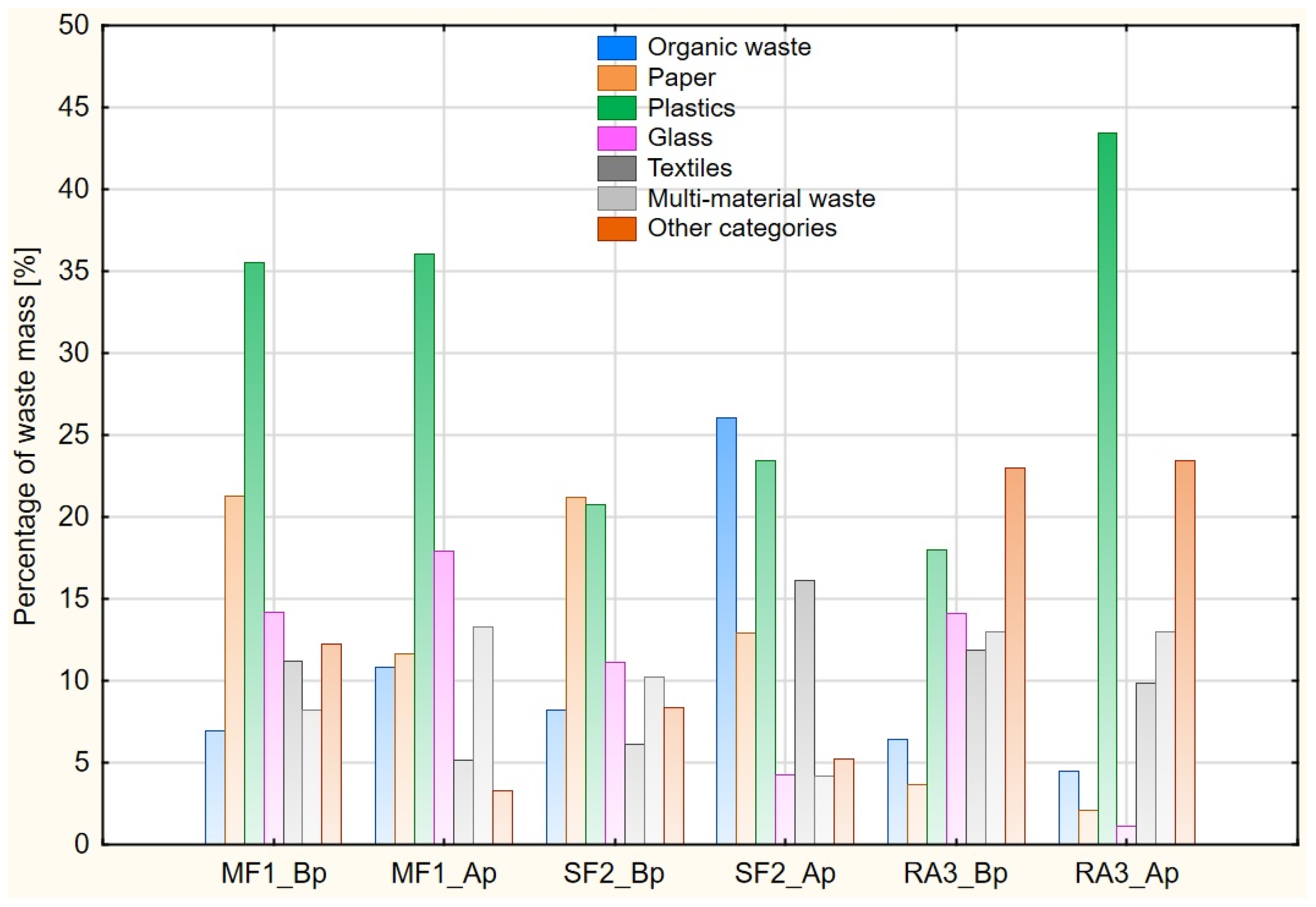

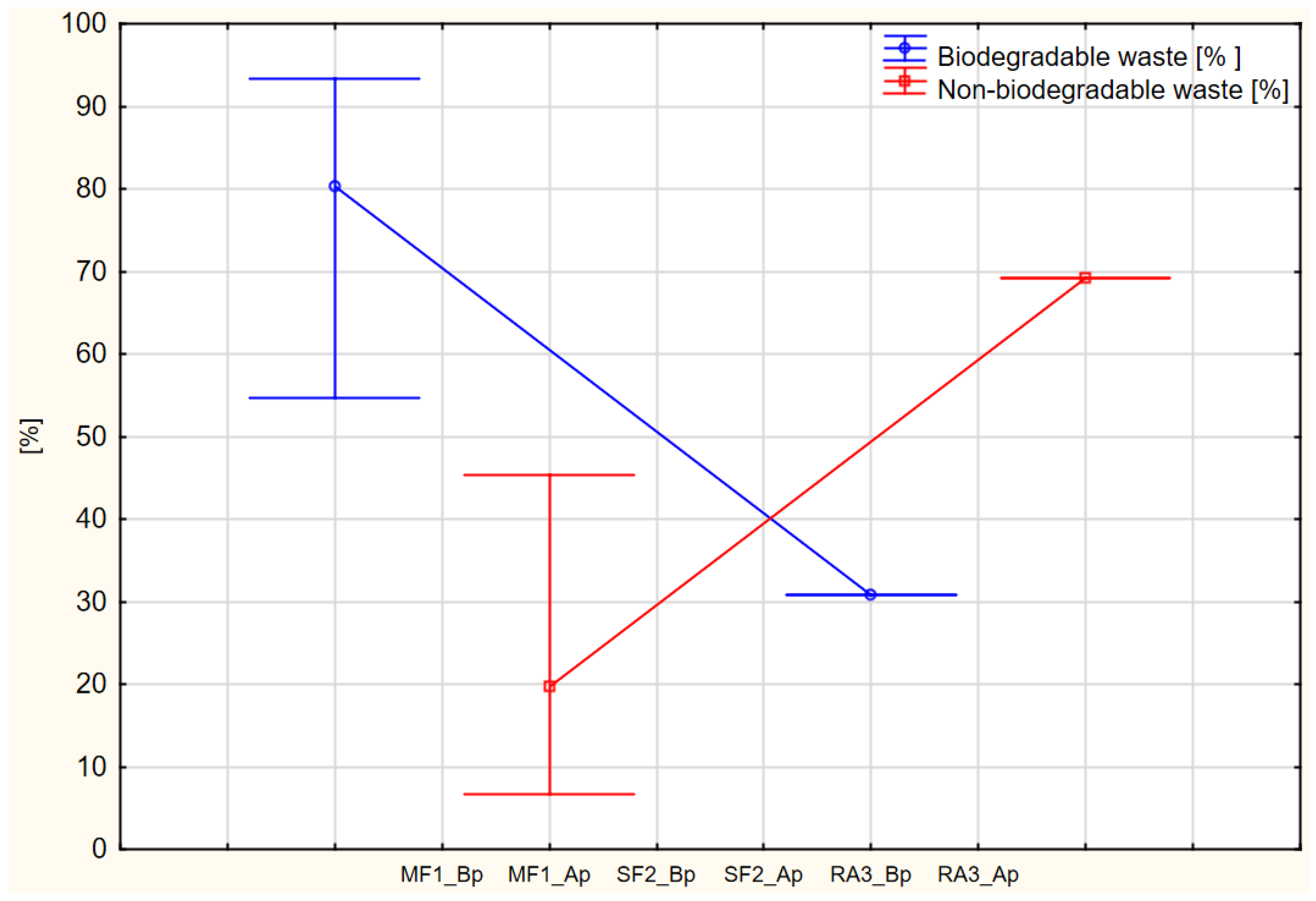

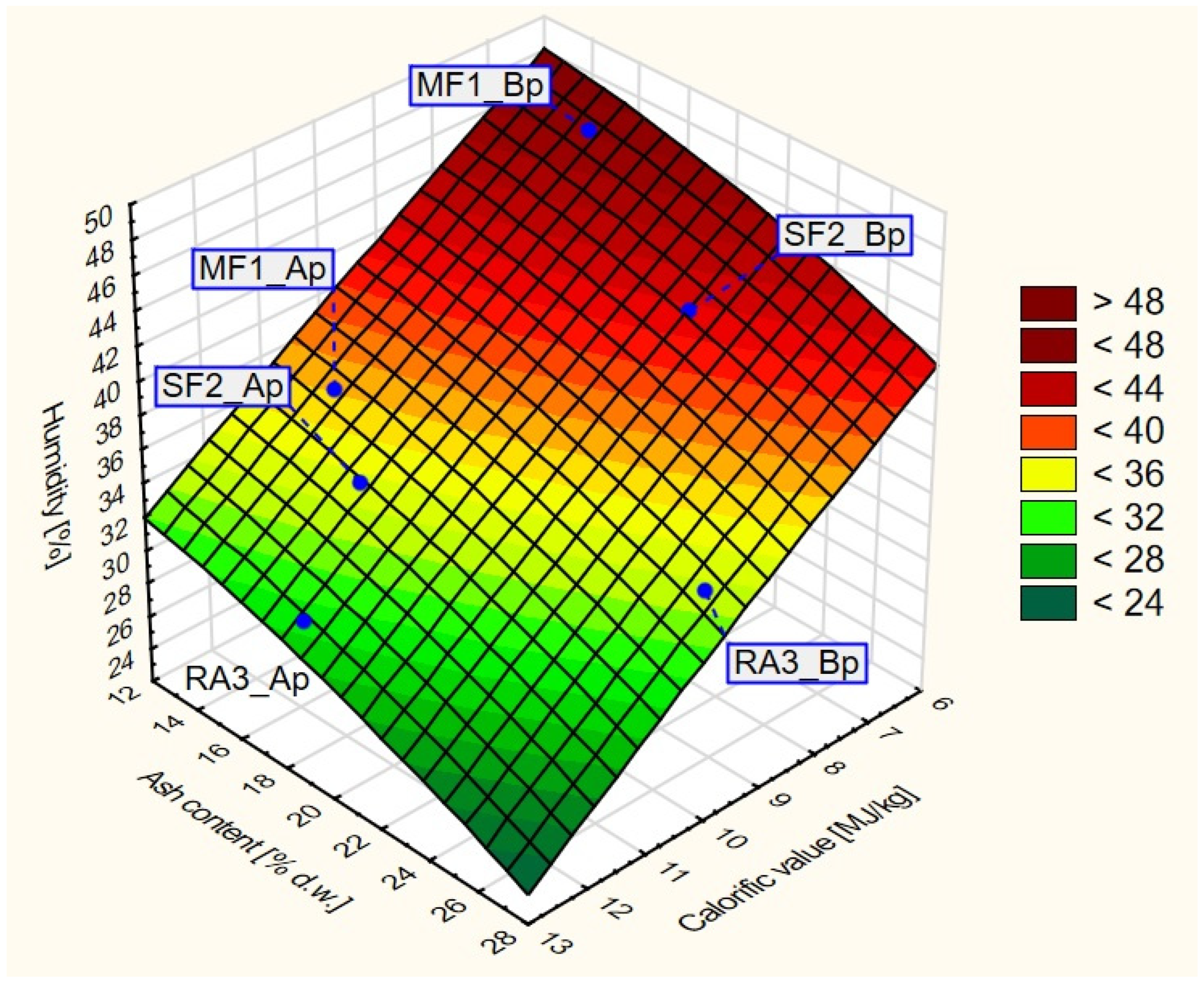

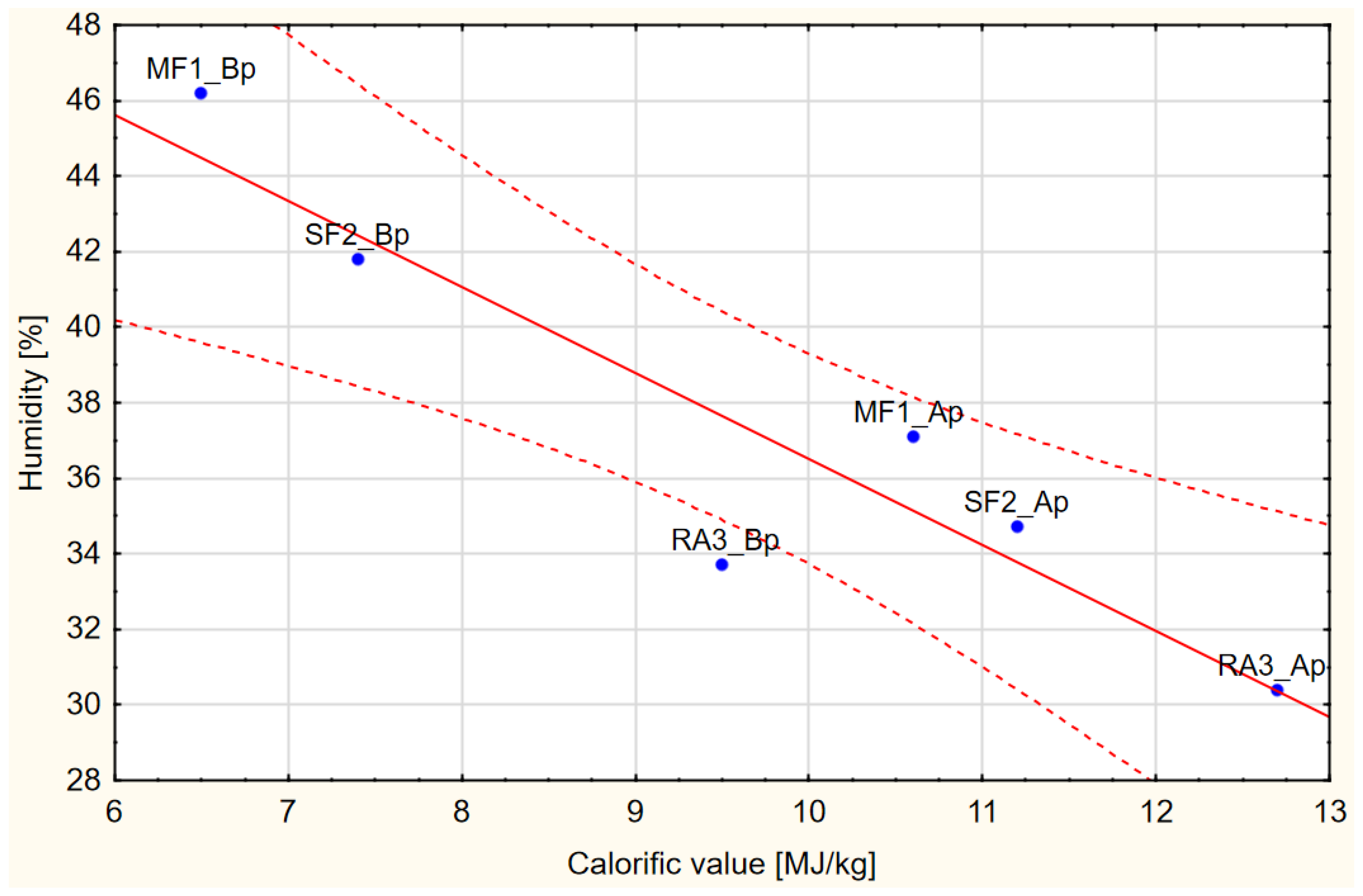

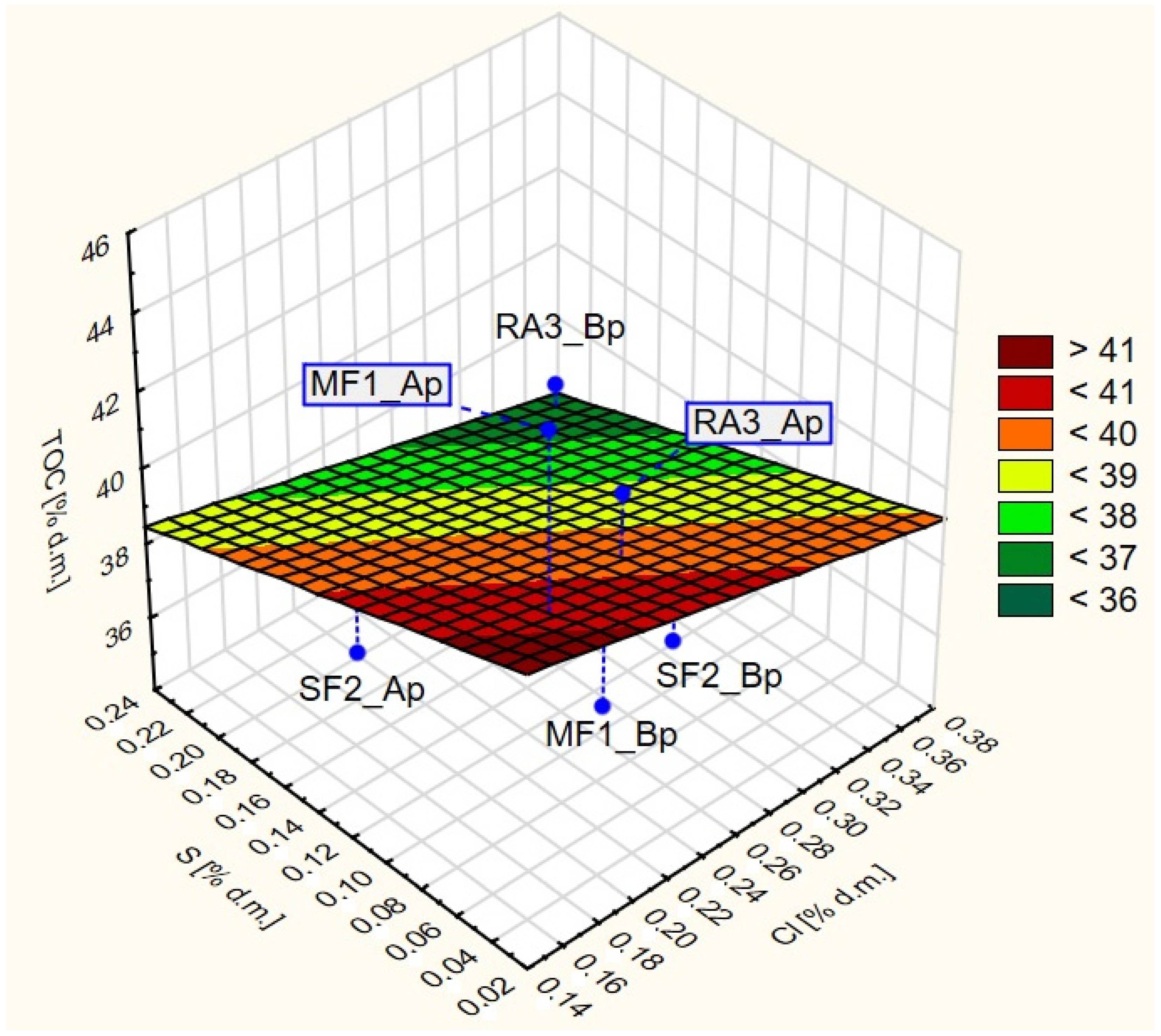

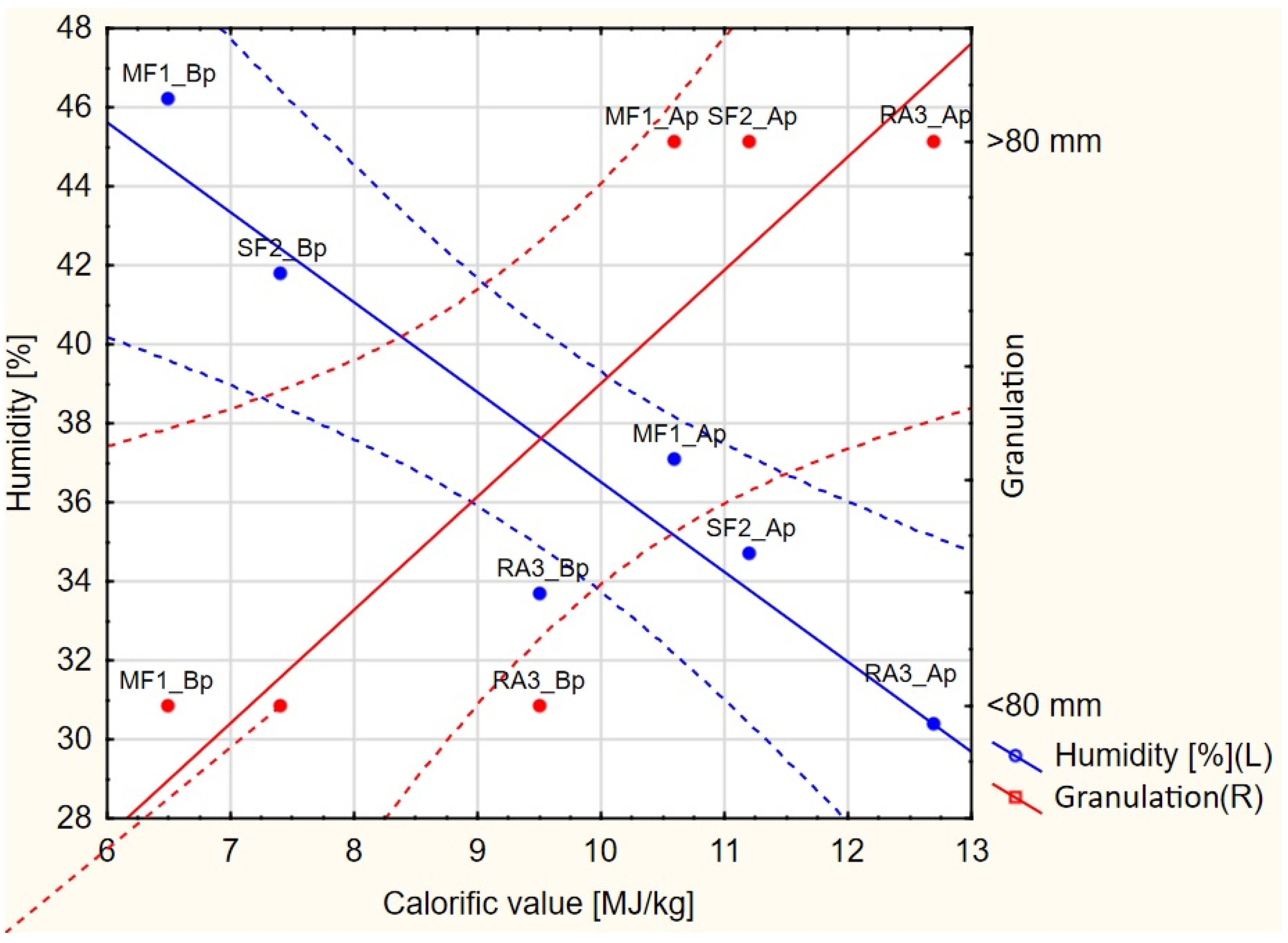

- MF1_Bp—raw (mixed) waste before processing on the sorting line, generated in a town, in multi-family housing;

- MF1_Ap—waste after mechanical treatment on the rotary sieve of the sorting line, generated in a town, in multi-family housing;

- SF2_Bp—raw waste before processing on the sorting line generated in single-family urban and suburban housing in a town;

- SF2_Ap—waste after mechanical treatment on the rotary sieve of the sorting line, generated in single-family urban and suburban housing in a town;

- RA3_Bp—raw (mixed) waste before processing on the sorting line, generated in single-family housing in rural areas of the municipality;

- RA3_Ap—waste after mechanical treatment on the rotary sieve of the sorting line, generated in single-family housing in rural areas of the municipality.

4. Results and Discussion

4.1. Granulometric Analysis

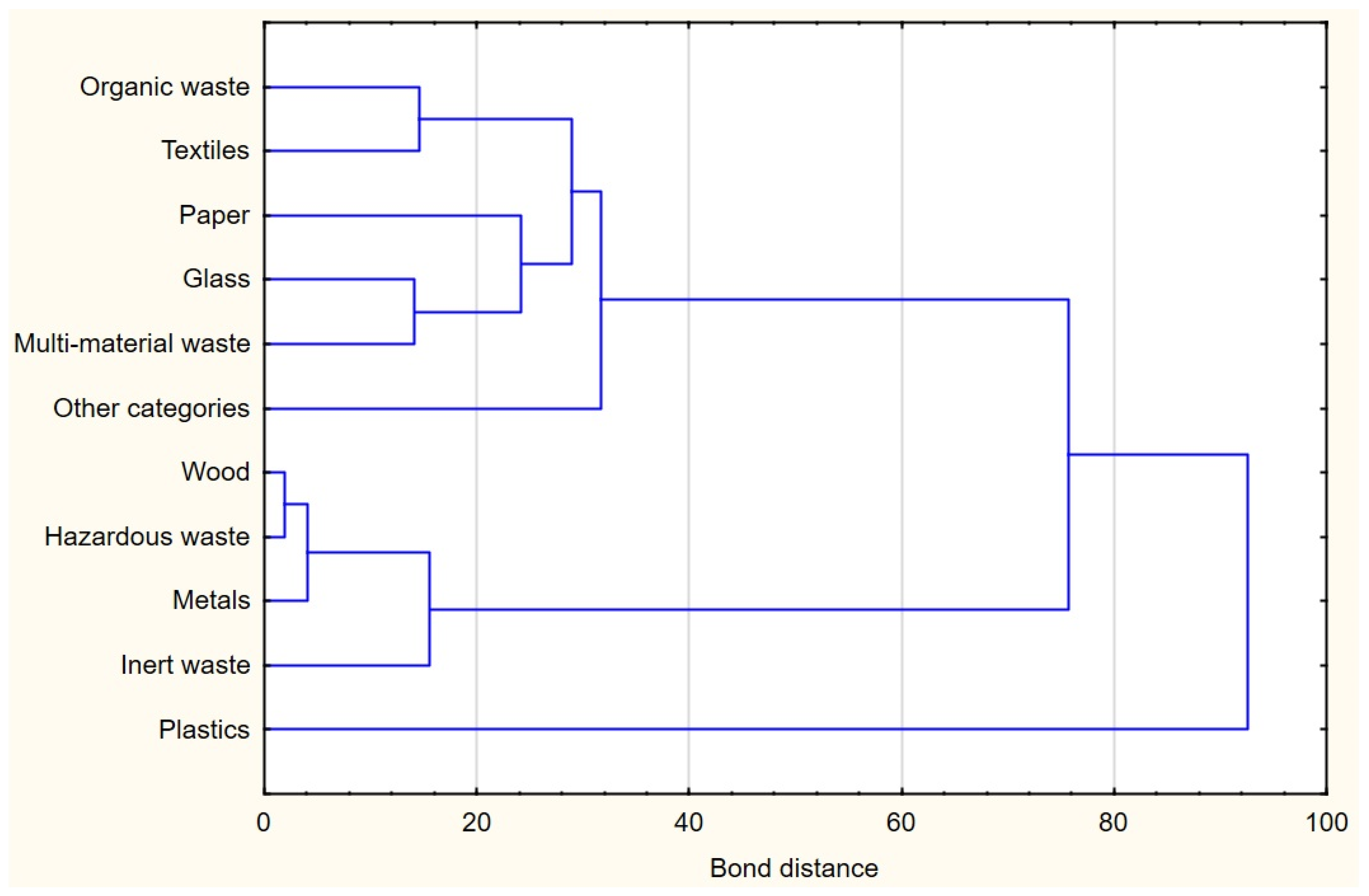

4.2. Morphological Analysis

4.3. Physicochemical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Delgado, M.; López, A.; Esteban-García, A.L.; Lobo, A. The importance of particularising the model to estimate landfill GHG emissions. J. Environ. Manag. 2023, 325, 116600. [Google Scholar] [CrossRef]

- Przydatek, G.; Basta, E. Systemic Efficiency Assessment of Municipal Solid Waste Management in the Suburban Municipality. E3S Web Conf. 2019, 154, 03001. [Google Scholar] [CrossRef]

- Wysowska, E.; Wiewiórska, I.; Kicińska, A. Minerals in tap water and bottled waters and their impact on human health. Desalination Water Treat. 2022, 259, 133–151. [Google Scholar] [CrossRef]

- Zwolińska, N.; Basta, E. Emissions of Gases and Dust into the Air as a Result of the Conversion of Landfill Gas into Electricity and Heat in a Cogeneration Plant. Rocz. Ochr. Sr. 2024, 26, 94–105. [Google Scholar] [CrossRef]

- Graz, K.; Gronba-Chyla, A.; Chyla, K. Microplastics found in compost as a barrier to the circular economy (CE). Przemysł Chem. 2023, 102, 381–383. [Google Scholar] [CrossRef]

- EU Commission. COM(96) 399 Final—Communication from the Commission on the Review of the Community Strategy for Waste Management; European Communities: Brussel, Belgium, 1996. [Google Scholar]

- Act of 14 December 2012 on Waste. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20130000021/U/D20130021Lj.pdf (accessed on 20 March 2024). (In Polish)

- Ciuła, J.; Kowalski, S.; Generowicz, A.; Barbusiński, K.; Matuszak, Z.; Gaska, K. Analysis of Energy Generation Efficiency and Reliability of a Cogeneration Unit Powered by Biogas. Energies 2023, 16, 2180. [Google Scholar] [CrossRef]

- Przydatek, G.; Generowicz, A.; Kanownik, W. Evaluation of the Activity of a Municipal Waste Landfill Site in the Operational and Non-Operational Sectors Based on Landfill Gas Productivity. Energies 2024, 17, 2421. [Google Scholar] [CrossRef]

- Oleksy-Gębczyk, A.; Rydwańska, P.; Witowska, W. Local enteprises during the COVID-19 pandemic on the example of enterprises from the Sądecki subregion. Economic Studies. Econ. Soc. Environ. 2020, 2, 171–186. [Google Scholar]

- Kang, Y.O.; Yabar, H.; Mizunoya, T.; Higano, Y. Environmental and economic performances of municipal solid waste management strategies based on LCA method: A case study of kinshasa. Heliyon 2023, 9, e14372. [Google Scholar] [CrossRef] [PubMed]

- Ghoze, M.K.; Dikshit, A.K.; Sharma, S.K. A GIS based transportation model for solid waste disposal—A case study on Asansol municipality. Waste Manag. 2006, 26, 1287–1293. [Google Scholar] [CrossRef] [PubMed]

- Kochanek, A.J.; Kobylarczyk, S. The Analysis of the Main Geospatial Factors Using Geoinformation Programs Required for the Planning, Design and Construction of a Photovoltaic Power Plant. J. Ecol. Eng. 2024, 25, 49–65. [Google Scholar] [CrossRef] [PubMed]

- Maizel, A.C.; Remucal, C.K. The effect of advanced secondary municipal wastewater treatment on the molecular composition of dissolved organic matter. Water Res. 2017, 122, 42–52. [Google Scholar] [CrossRef] [PubMed]

- Oleksy-Gebczyk, A. Preferences and Consumer Choices: A Case of Polish Markets for Goods and Services. Asian J. Appl. Econ./Appl. Econ. J. 2023, 30, 80–99. Available online: https://ideas.repec.org/s/ris/apecjn.html (accessed on 25 July 2024).

- Ciuła, J.; Wiewiórska, I.; Banaś, M.; Pająk, T.; Szewczyk, P. Balance and Energy Use of Biogas in Poland: Prospects and Directions of Development for the Circular Economy. Energies 2023, 16, 3910. [Google Scholar] [CrossRef]

- Naveenkumar, R.; Iyyappan, J.; Pravin, R.; Kadry, S.; Han, J.; Sindhu, R.; Awasthi, M.K.; Rokhum, S.L.; Baskar, G. A strategic review on sustainable approaches in municipal solid waste management andenergy recovery: Role of artificial intelligence, economic stability andlife cycle assessment. Bioresour. Technol. 2023, 379, 129044. [Google Scholar] [CrossRef]

- Mihaliková, M.; Čulková, E.; Stehlíková, K.; Tauš, B.; Kudelas, P.; Štrba, D.; Domaracká, L. Analysis of Municipal Waste Development and Management in Self-Governing Regions of Slovakia. Sustainability 2020, 12, 5818. [Google Scholar] [CrossRef]

- Hansen, W.; Christopher, M.; Verbuecheln, M. EU Waste Policy and Challenges for Regional and Local Authorities; Ecologic, Institute for International and European Environmental Policy: Berlin, Germany, 2002. [Google Scholar]

- Pamukçu, H.; Yapıcıoğlu, P.S.; Yeşilnacar, M.I. Investigating the mitigation of greenhouse gas emissions from municipal solid waste management using ant colony algorithm, Monte Carlo simulation and LCA approach in terms of EU Green Deal. Waste Manag. Bull. 2023, 1, 6–14. [Google Scholar] [CrossRef]

- Cohen, E. The Waste Landfill Policy in Israel: Economic and Political Perspectives. Sustainability 2024, 16, 2791. [Google Scholar] [CrossRef]

- Lombardi, L.; Castaldi, M.J. Energy Recovery from Residual Municipal Solid Waste: State of the Art and Perspectives within the Challenge to Climate Change. Energies 2024, 17, 395. [Google Scholar] [CrossRef]

- Kwon, Y.; Lee, S.; Bae, J.; Park, S.; Moon, H.; Lee, T.; Kim, K.; Kang, J.; Jeon, T. Evaluation of Incinerator Performance and Policy Framework for Effective Waste Management and Energy Recovery: A Case Study of South Korea. Sustainability 2024, 16, 448. [Google Scholar] [CrossRef]

- Edo, M. Waste-to-Energy and Social Acceptance: Copenhill Waste-to-Energy Plant in Copenhagen. IEA Bioenergy. 2021. Available online: https://www.ieabioenergy.com/wp-content/uploads/2021/03/T36_WtE-and-Social-Acceptance_Copnehhill-WtE-plant-in-Copenhagen.pdf (accessed on 25 May 2024).

- Housing Economy and Municipal Infrastructure in 2022. Central Statistical Office. Statistical Office in Lublin: Warszawa, Lublin, 2023. Available online: https://stat.gov.pl/obszary-tematyczne/infrastruktura-komunalna-nieruchomosci/nieruchomosci-budynki-infrastruktura-komunalna/gospodarka-mieszkaniowa-i-infrastruktura-komunalna-w-2022-roku,13,17.html (accessed on 14 July 2024). (In Polish)

- Nomoto, H. 12—Development in materials for ultra-supercritical (USC) and advanced ultra-supercritical (A-USC) steam turbines. In Advances in Steam Turbines for Modern Power Plants; Tanuma, T., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 263–278. [Google Scholar] [CrossRef]

- Kerbstadt, M.; White, E.M.H.; Galetz, M.C. Novel Cr/Si-Slurry Diffusion Coatings for High Temperatures. Materials 2023, 16, 7480. [Google Scholar] [CrossRef] [PubMed]

- Sun, F.; Gu, Y.F.; Yan, J.B.; Zhong, Z.H.; Yuyama, M. Phenomenological and microstructural analysis of intermediate temperatures creep in a Ni-Fe-based alloy for advanced ultra-supercritical fossil power plants. Acta Mater. 2016, 102, 70–78. [Google Scholar] [CrossRef]

- Niu, L.-B.; Okano, K.; Izumi, S.; Shiokawa, K.; Yamashita, M.; Sakai, Y. Effect of chloride and sulfate ions on crevice corrosion behavior of low-pressure steam turbine materials. Corros. Sci. 2018, 132, 284–292. [Google Scholar] [CrossRef]

- Yoo, J.; Thuy Chung, N.; Lee, Y.; Kim, Y.; Kim, J. Effect of Sulfide and Chloride Ions on Pitting Corrosion of Type 316 Austenitic Stainless Steel in Groundwater Conditions Using Response Surface Methodology. Materials 2023, 17, 178. [Google Scholar] [CrossRef] [PubMed]

- Kong, Z.; Yang, B.; Shi, C.; Huang, X.; Vasdravellis, G.; Vu, Q.; Kim, S. Mechanical behavior of 316L austenitic stainless steel bolts after fire. Steel Compos. Struct. 2024, 50, 281–298. [Google Scholar] [CrossRef]

- Htut, T.; Tanaka, S.; Ma, D.; Okada, J.; Honnami, M.; Shinoda, K.; Abe, M.; Katayama, T. Study of fatigue fracture characteristics for duplex stainless steel STHE welded joint specimen. Eng. Fail. Anal. 2024, 155, 107763. [Google Scholar] [CrossRef]

- Karpe, B.; Prijatelj, K.; Bizjak, M.; Kosec, T. Corrosion properties of aluminized 16Mo3 steel. J. Min. Metall. Sect. B Metallurgy 2023, 59, 91–100. [Google Scholar] [CrossRef]

- Koclęga, D.; Radziszewska, A.; Dymek, S.; Morgiel, J.; Maj, Ł.; Kranzmann, A. Improvement of Corrosion Resistance of 13CrMo4-5 Steel by Ni-Based Laser Cladding Coatings. J. Mater. Eng. Perform. 2020, 29, 3702–3713. [Google Scholar] [CrossRef]

- Kopec, M.; Brodecki, A.; Kowalewski, Z. Fatigue damage development in 10CrMo9-10 steel for power plant pipes in as-received state and after 280,000 h of exploitation. Arch. Civ. Mech. Eng. 2023, 23, 98. [Google Scholar] [CrossRef]

- Michler, T.; Ebling, F.; Fischer, C.; Oeser, S.; Wackermann, K. Tensile testing in high pressure gaseous hydrogen using conventional and tubular specimens: Ferritic steels. Int. J. Hydrogen Energy 2024, 70, 262–275. [Google Scholar] [CrossRef]

- Zaharia, M.G.; Stanciu, S.; Cimpoesu, R.; Ionita, I.; Cimpoesu, N. Preliminary results on effect of H2S on P265GH commercial material for natural gases and petroleum transportation. Appl. Surf. Sci. 2018, 438, 20–32. [Google Scholar] [CrossRef]

- Eurostat. 920230. Municipal Waste Statistic. Available online: https://ec.europa.eu/eurostat (accessed on 12 June 2024).

- Kotlińska, J.; Żukowska, H. Task of Municipalities in the Field of Municipal Waste Management in Poland and Source of Their Financing. Przegląd Prawno-Ekon. 2023, 4, 43–73. [Google Scholar] [CrossRef]

- Almazora, B.R.; De, V.; Barros, R.T. Review of municipal waste management charging methods in different countries. Waste Manag. 2020, 115, 47–55. [Google Scholar] [CrossRef]

- Act of 13 September 1996 on Maintaining Cleanliness and Order in Municipalities, Unified Text Dz. U. of 2023, Item 1469. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU19961320622/U/D19960622Lj.pdf (accessed on 12 May 2024). (In Polish)

- Di Foggia, G.; Beccarello, M. Designing circular economy-compliant municipal solid waste management charging schemes. Util. Policy 2023, 8, 10150. [Google Scholar] [CrossRef]

- Chu, Z.; Wang, W.; Zhou, A.; Huang, W.-C. Charging for municipal solid waste disposal in Beijing. Waste Manag. 2019, 94, 85–94. [Google Scholar] [CrossRef] [PubMed]

- Morlok, J.; Schoenberger, H.; Styles, D.; Galvez-Martos, J.-L.L.; Zeschmar-Lahl, B. The impact of pay-as-you-throw schemes on municipal solid waste management: The exemplar case of the county of Aschaffenburg, Germany. Resources 2017, 6, 8. [Google Scholar] [CrossRef]

- Chamizo-Golonzalez, J.; Cano-Montero, E.I.; Muñoz-Colomina, C.I. Municipal Solid Waste Management services and its funding in Spain. Resour. Conserv. Recycl. 2016, 107, 65–72. [Google Scholar] [CrossRef]

- Debnath, S.; Bose, S.K. Exploring full cost accounting approach to evaluate cost of MSW services in India. Resour. Conserv. Recycl. 2014, 83, 87–95. [Google Scholar] [CrossRef]

- Di Foggia, G.; Beccarello, M. Designing waste management systems to meet circular economy goals: The Italian case. Sustain. Prod. Consum. 2012, 26, 1074–1083. [Google Scholar] [CrossRef]

- Nelles, M.; Grünes, J.; Morscheck, G. Waste management in Germany—Development to a sustainable circular economy? Procedia Environ. Sci. 2016, 35, 6–14. [Google Scholar] [CrossRef]

- Dahlén, L.; Lagerkvist, A. Pay as you throw: Strengths and weaknesses of weight-based billing in household waste collection systems in Sweden. Waste Manag. 2010, 30, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Batllevell, H. The fairness of PAYT systems: Some guidelines for decisions-makers. Waste Manag. 2008, 28, 2793–2800. [Google Scholar] [CrossRef] [PubMed]

- Jędrczak, A.; den Boer, E.; Kamińska-Borak, J.; Szpadt, R.; Krzyśków, A.; Wielgosiński, G. Municipal Waste Management in Poland. Cost Analysis of Municipal Waste Management. IOŚ-PIB, Warszawa 2022. Available online: https://ios.edu.pl/wp-content/uploads/2021/11/55848_gospodarka_odpadami_3.pdf (accessed on 15 July 2024). (In Polish).

- Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. 2023. Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/?uri=CELEX:32018L0851 (accessed on 18 May 2024).

- Ciuła, J.; Generowicz, A.; Oleksy-Gębczyk, A.; Gronba-Chyła, A.; Wiewiórska, I.; Kwaśnicki, P.; Herbut, P.; Koval, V. Technical and Economic Aspects of Environmentally Sustainable Investment in Terms of the EU Taxonomy. Energies 2024, 17, 2239. [Google Scholar] [CrossRef]

- Jomit, C.P.; Sajith, C. Development of Management Systems for Sustainable Municipal Waste Management Systems. Trends Financ. Econ. 2023, 1, 28–34. [Google Scholar] [CrossRef]

- Fadhullah, W.; Imran, N.I.N.; Ismail, S.N.S.; Jaafar, M.H.; Abdullah, H. Household solid waste management practices and perceptions among residents in the East Coast of Malaysia. BMC Public Health 2022, 1, 22. [Google Scholar] [CrossRef] [PubMed]

- Funari, V.; Dalconi, M.C.; Farnaud, S.; Nawab, J.; Gupta, N.; Yadav, K.K.; Kremser, K.; Toller, S. Modern management options for solid waste and by-products: Sustainable treatment and environmental benefits. Front. Environ. Sci. 2024, 12, 138566. [Google Scholar] [CrossRef]

- Czekała, W.; Drozdowski, J.; Łabiak, P. Modern Technologies for Waste Management: A Review. Appl. Sci. 2023, 13, 8847. [Google Scholar] [CrossRef]

- Krūmiņš, J.; Kļaviņš, M. Integrated Circulating Fluidized Bed Gasification System for Sustainable Municipal Solid Waste Management: Energy Production and Heat Recovery. Energies 2023, 16, 5203. [Google Scholar] [CrossRef]

- Buenrostro, O.; Bocco, G. Solid waste management in municipalities in Mexico: Goals and perspectives, Resources. Conserv. Recycl. 2003, 39, 251–263. [Google Scholar] [CrossRef]

- Kowalski, Z.; Kulczycka, J.; Makara, A.; Verhé, R.; De Clercq, G. Assessment of Energy Recovery from Municipal Waste Management Systems Using Circular Economy Quality Indicators. Energies 2022, 15, 8625. [Google Scholar] [CrossRef]

- Ginevičius, R. The efficiency of municipal waste management systems in the environmental context in the countries of the European Union. J. Int. Stud. 2022, 15, 63–79. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj (accessed on 9 May 2024).

- Doaemo, W.; Dhiman, S.; Borovskis, A.; Zhang, W.; Bhat, S.; Jaipuria, S.; Betasolo, M. Assessment of municipal solid waste management system in Lae City, Papua New Guinea in the context of sustainable development. Environ. Dev. Sustain. 2021, 23, 18509–18539. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi Ahangar, S.; Sadati, A.; Rabbani, M. Sustainable design of a municipal solid waste management system in an integrated closed-loop supply chain network using a fuzzy approach: A case study. J. Ind. Prod. Eng. 2021, 38, 323–340. [Google Scholar] [CrossRef]

- Luz, F.G.F.; Rozenský, L.; Vrba, Z.; Hansen, J.M.; Lípa, J.; Dolista, J.; Vítek, M.; Alves de Castro, M.C.A. Assessment of municipal waste management systems using performance indicators to analyze recycling capacity The case study of Corumbataí basin, São Paulo state, Brazil. Waste Forum 2021, 2, 61–77. Available online: https://www.wasteforum.cz/cisla/WF_2_2021_p61.pdf (accessed on 10 June 2024).

- Przydatek, G.A. Comparative Analysis of Municipal Waste Management Systems. Pol. J. Environ. Stud. 2016, 25, 2107–2112. [Google Scholar] [CrossRef] [PubMed]

- Jakubus, M.; Stejskal, B. Municipal solid waste management systems in Poland and the Czech Republic. A comparative study. Environ. Prot. Eng. 2020, 46, 61–78. [Google Scholar] [CrossRef]

- Domaracka, L.; Matuskova, S.; Tausova, M.; Kowal, B.; Culkova, K. A Comparison and Development of Municipal Waste Management in Three Countries, Slovakia, the Czech Republic and Poland, with an Emphasis on the Slovak Republic. Eng. Proc. 2023, 57, 40. [Google Scholar] [CrossRef]

- Iwase, D.; Dilokwanich, S. The Management of Capital Allocation for Sustainable Municipal Solid Waste Management System: A Case Study of Bang Saen, Thailand. Environ. Asia 2013, 6, 51–59. Available online: https://www.thaiscience.info/Journals/Article/ENVA/10895340.pdf (accessed on 10 June 2024).

- Yu, H.; Solvang, W.D.; Li, S. Optimization of long-term performance of municipal solid waste management system: A bi-objective mathematical model. Int. J. Energy Environ. 2015, 6, 153–164. Available online: https://hdl.handle.net/10037/10456 (accessed on 11 June 2024).

- Huebner, C.; Flessa, S. Strategic Management in Healthcare: A Call for Long-Term and Systems-Thinking in an Uncertain System. Int. J. Environ. Res. Public Health 2022, 19, 8617. [Google Scholar] [CrossRef] [PubMed]

- Ayoubi, M.; Mehrabanfar, E.; Banaitis, A. Guidelines on Designing Conceptual Framework for Strategic Management with Application to the Energy Industry. Adm. Sci. 2018, 8, 27. [Google Scholar] [CrossRef]

- Dimić, S.; Pamučar, D.; Ljubojević, S.; Đorović, B. Strategic Transport Management Models—The Case Study of an Oil Industry. Sustainability 2016, 8, 954. [Google Scholar] [CrossRef]

- Bubenik, P.; Capek, J.; Rakyta, M.; Binasova, V.; Staffenova, K. Impact of Strategy Change on Business Process Management. Sustainability 2022, 14, 11112. [Google Scholar] [CrossRef]

- Martín-Gómez, A.M.; Pineda-Ganfornina, M.; Ávila-Gutiérrez, M.J.; Agote-Garrido, A.; Lama-Ruiz, J.R. Balanced Scorecard for Circular Economy: A Methodology for Sustainable Organizational Transformation. Sustainability 2024, 16, 1464. [Google Scholar] [CrossRef]

- Antonova, N.; Ruiz-Rosa, I.; Mendoza-Jimenez, J. Water Resource Management in Hotels Using a Sustainable Balanced Scorecard. Sustainability 2022, 14, 8171. [Google Scholar] [CrossRef]

- Thyberg, K.L.; Tonjes, D.J. A Management Framework for Municipal Solid Waste Systems and Its Application to Food Waste Prevention. Systems 2015, 3, 133–151. [Google Scholar] [CrossRef]

- EC—European Commission. Communication from the Commission to the European Parliament, The European Council, The Council, The European Economic and Social Committee and the Committee of the Regions. 11 December 2019. COM (2019) 640 Final. In The European Green Deal; EC: Brussels, Belgium, 2019. [Google Scholar]

- Shaban, A.; Zaki, F.-E.; Afefy, I.H.; Di Gravio, G.; Falegnami, A.; Patriarca, R. An Optimization Model for the Design of a Sustainable Municipal Solid Waste Management System. Sustainability 2022, 14, 6345. [Google Scholar] [CrossRef]

- Mierzwiński, A.; Mierzwiński, M.; Tomaszewski, K.; Obłąkowska, K.; Moskwik, K. Cement Industry in Waste Management; Instytut Jagielloński: Warszawa, Poland, 2021. (In Polish) [Google Scholar]

- Un, C. A Sustainable Approach to the Conversion of Waste into Energy: Landfill Gas-to-Fuel Technology. Sustainability 2023, 15, 14782. [Google Scholar] [CrossRef]

- PN-ISO 11465:1993; Soil quality—Determination of Soil Dry Matter and Soil Water Content Expressed on Dry Soil Mass—Gravimetric Method. International Organization for Standardization: Geneva, Switzerland, 1993.

- PN-EN 15035:2022-01; Characterization of waste—Determination of loss on ignition of waste, sludge and sludge. International Organization for Standardization: Geneva, Switzerland, 2022.

- PN-EN 14582:2011; Characterization of waste—Halogen and sulfur content—Oxygen combustion in closed systems and methods of determination. International Organization for Standardization: Geneva, Switzerland, 2011.

- Decree of the Minister of Climate and Environment of 28 December 2022 on Mechanical-Biological Processing of Non-SEGREGATED (Mixed) Municipal Waste. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20230000056/O/D20230056.pdf (accessed on 14 July 2024). (In Polish)

- Statistica, version 14.1.0.4; TIBCOI Software Inc.: Palo Alto, CA, USA, 2023.

- Banaś, M.; Pająk, T.; Bator, J.; Wróbel, W.; Ciuła, J. Energy Efficiency Analysis of Waste-to-Energy Plants in Poland. Energies 2024, 17, 2390. [Google Scholar] [CrossRef]

- Ríos, A.M.; Picazo-Tadeo, A.J. Measuring environmental performance in the treatment of municipal solid waste: The case of the European Union-28. Ecol. Indic. 2021, 123, 107328. [Google Scholar] [CrossRef]

- Bányai, T.; Tamás, P.; Illés, B.; Stankevičiūtė, Ž.; Bányai, Á. Optimization of Municipal Waste Collection Routing: Impact of Industry 4.0 Technologies on Environmental Awareness and Sustainability. Int. J. Environ. Res. Public Health 2019, 16, 634. [Google Scholar] [CrossRef] [PubMed]

- Navajas, A.; Uriarte, L.; Gandía, L.M. Application of Eco-Design and Life Cycle Assessment Standards for Environmental Impact Reduction of an Industrial Product. Sustainability 2017, 9, 1724. [Google Scholar] [CrossRef]

- Xu, S.; Liu, H.; Xu, G. Selection of Recycling Channels and Product Eco-Design with Take-Back Regulation. Sustainability 2021, 13, 8961. [Google Scholar] [CrossRef]

- Andrae, A.S.G.; Xia, M.; Zhang, J.; Tang, X. Practical Eco-Design and Eco-Innovation of Consumer Electronics—The Case of Mobile Phones. Challenges 2016, 7, 3. [Google Scholar] [CrossRef]

- Satyro, W.C.; Contador, J.C.; Monken, S.F.d.P.; Lima, A.F.d.; Soares Junior, G.G.; Gomes, J.A.; Neves, J.V.S.; do Nascimento, J.R.; de Araújo, J.L.; Correa, E.d.S. Industry 4.0 Implementation Projects: The Cleaner Production Strategy—A Literature Review. Sustainability 2023, 15, 2161. [Google Scholar] [CrossRef]

- Wandosell, G.; Parra-Meroño, M.C.; Alcayde, A.; Baños, R. Green Packaging from Consumer and Business Perspectives. Sustainability 2021, 13, 1356. [Google Scholar] [CrossRef]

- Sastre, R.M.; de Paula, I.C.; Echeveste, M.E.S. A Systematic Literature Review on Packaging Sustainability: Contents, Opportunities, and Guidelines. Sustainability 2022, 14, 6727. [Google Scholar] [CrossRef]

- Babaremu, K.; Adediji, A.; Olumba, N.; Okoya, S.; Akinlabi, E.; Oyinlola, M. Technological Advances in Mechanical Recycling Innovations and Corresponding Impacts on the Circular Economy of Plastics. Environments 2024, 11, 38. [Google Scholar] [CrossRef]

- Capuzzi, S.; Timelli, G. Preparation and Melting of Scrap in Aluminum Recycling: A Review. Metals 2018, 8, 249. [Google Scholar] [CrossRef]

- Podara, C.; Termine, S.; Modestou, M.; Semitekolos, D.; Tsirogiannis, C.; Karamitrou, M.; Trompeta, A.-F.; Milickovic, T.K.; Charitidis, C. Recent Trends of Recycling and Upcycling of Polymers and Composites: A Comprehensive Review. Recycling 2024, 9, 37. [Google Scholar] [CrossRef]

- Tun, M.M.; Palacky, P.; Juchelkova, D.; Síťař, V. Renewable Waste-to-Energy in Southeast Asia: Status, Challenges, Opportunities, and Selection of Waste-to-Energy Technologies. Appl. Sci. 2020, 10, 7312. [Google Scholar] [CrossRef]

- Algethami, H.; Alhothali, G.T. Waste Collection Optimisation: A Path to a Green and Sustainable City of Makkah. Logistics 2023, 7, 54. [Google Scholar] [CrossRef]

- Alkahtani, M.; Ziout, A.; Salah, B.; Alatefi, M.; Abd Elgawad, A.E.E.; Badwelan, A.; Syarif, U. An Insight into Reverse Logistics with a Focus on Collection Systems. Sustainability 2021, 13, 548. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, Y.; Hu, W.; Dong, J.; Sun, B.; Cheng, H. Underground Logistics Network Design for Large-Scale Municipal Solid Waste Collection: A Case Study of Nanjing, China. Sustainability 2023, 15, 16392. [Google Scholar] [CrossRef]

- Lingaitienė, O.; Burinskienė, A.; Davidavičienė, V. Case Study of Municipal Waste and Its Reliance on Reverse Logistics in European Countries. Sustainability 2022, 14, 1809. [Google Scholar] [CrossRef]

- Ardolino, F.; Parrillo, F.; Di Domenico, C.; Costarella, F.; Arena, U. Combined Use of an Information System and LCA Approach to Assess the Performances of a Solid Waste Management System. Appl. Sci. 2023, 13, 707. [Google Scholar] [CrossRef]

- Medina-Mijangos, R.; Seguí-Amórtegui, L. Research Trends in the Economic Analysis of Municipal Solid Waste Management Systems: A Bibliometric Analysis from 1980 to 2019. Sustainability 2020, 12, 8509. [Google Scholar] [CrossRef]

- Vaverková, M.D. Landfill Impacts on the Environment—Review. Geosciences 2019, 9, 431. [Google Scholar] [CrossRef]

- Zhang, O.; Takaffoli, M.; Ertz, M.; Addar, W. Environmental Impact Assessment of Plastic Waste Management Scenarios in the Canadian Context. Environments 2023, 10, 213. [Google Scholar] [CrossRef]

- Sobiecka, E. The Biological Processes of Chloride Ions Removal from the Environment. Appl. Sci. 2022, 12, 8818. [Google Scholar] [CrossRef]

- ISO 14001:2004; Environmental Management Systems–Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO 14040:2006; Environmental Management–Life Cycle Assessment–Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Sobiecka, E.; Mroczkowska, M.; Olejnik, T.P.; Nowak, A. The Use of Macrophytes for the Removal of Chlorpyrifos from the Aquatic Environment. Water 2024, 16, 1071. [Google Scholar] [CrossRef]

- Wereda, W.S.; Zacłona, T.; Wołowiec, T. Role of public—Private partnerships in investment project management in local government units. In Proceedings of the 4th International Conference on Changes in Social and Business Environment, CISABE ‘11, Panevezys, Lithuania, 3–4 November 2011; p. 269. [Google Scholar]

| Waste Fraction Size | Multi-Family Housing, Town MF | Single-Family Housing, Urban and Suburban, Town SF | Single-Family Housing, Rural Area of the Municipality RA |

|---|---|---|---|

| MF1_Bp | SF2_Bp | RA3_Bp | |

| % of Waste Mass | |||

| >80 mm | 35.84 | 33.61 | 43.83 |

| 20–80 mm | 49.15 | 52.42 | 33.85 |

| 10–20 mm | 7.58 | 5.84 | 6.77 |

| <10 mm | 7.43 | 8.13 | 15.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciuła, J.; Sobiecka, E.; Zacłona, T.; Rydwańska, P.; Oleksy-Gębczyk, A.; Olejnik, T.P.; Jurkowski, S. Management of the Municipal Waste Stream: Waste into Energy in the Context of a Circular Economy—Economic and Technological Aspects for a Selected Region in Poland. Sustainability 2024, 16, 6493. https://doi.org/10.3390/su16156493

Ciuła J, Sobiecka E, Zacłona T, Rydwańska P, Oleksy-Gębczyk A, Olejnik TP, Jurkowski S. Management of the Municipal Waste Stream: Waste into Energy in the Context of a Circular Economy—Economic and Technological Aspects for a Selected Region in Poland. Sustainability. 2024; 16(15):6493. https://doi.org/10.3390/su16156493

Chicago/Turabian StyleCiuła, Józef, Elżbieta Sobiecka, Tomasz Zacłona, Paulina Rydwańska, Aneta Oleksy-Gębczyk, Tomasz P. Olejnik, and Sławomir Jurkowski. 2024. "Management of the Municipal Waste Stream: Waste into Energy in the Context of a Circular Economy—Economic and Technological Aspects for a Selected Region in Poland" Sustainability 16, no. 15: 6493. https://doi.org/10.3390/su16156493