Abstract

Buildings play a significant role in the rise of energy consumption and carbon emissions. Building operations are responsible for 28% of the world’s carbon emissions. It is crucial, therefore, to evaluate the environmental impact of various buildings’ operational phase in order to implement sustainable strategies for the mitigation of their energy usage and associated carbon footprint. While numerous studies have been conducted to determine the carbon footprint of conventional building operation phases, there are still a lack of actual data on the operational carbon (OC) emissions of mass timber buildings. There is also a lack of research pertaining to the operational carbon of buildings within larger campuses and their inherent energy usage. This study, therefore, aims to quantify empirical data on the carbon footprint of a mass timber building, using, as a case study, the recent Adohi Hall building, situated at the University of Arkansas, Fayetteville. The study also aims to examine and identify the best energy use scenarios for the campus building under consideration. The research team obtained data on Adohi Hall’s energy consumption, fuel input usage, and other utilities (such as water, electricity, chilled water, and natural gas) accounting for the operation of the building from 2021 to 2023, a span of three years. The University of Arkansas Facilities Management (FAMA) provided the data. The study relies on the life cycle assessment (LCA) as its primary approach, with SimaPro 9, Ecoinvent v3.7 database, DataSmart, version 2023.1 and the U.S. Life Cycle Inventory (USLCI) database utilized to model the energy and water consumption of Adohi Hall during the operational phase (B6 & B7). The results indicate 4496 kg CO2 eq emissions associated with the operation per square meter of Adohi Hall over its 50-year lifespan. The study also examines various scenarios of fuel sources leading to carbon emissions and provides insights into reduction strategies during the operational phase of buildings. Among them, the electricity based on a cleaner fuel source diversification, according to realistic expectations and technological advancements projections, results in a 17% reduction in Adohi Hall’s OC. Due to the usage of the combined heat and power (CHP) plant on the campus of the University of Arkansas as a complementary source of electricity and heating for Adohi Hall, the resulting carbon emission is approximately 21% (20.73%) less when compared to similar buildings in the same city but outside the campus. The study, therefore, reveals that CHP plant development is a highly effective strategy for building OC reduction.

1. Introduction

1.1. Overall Influence of Mass Timber Operation on Carbon Emission

The issue of climate change and sustainable environment has gained increased global attention [1,2,3,4], and the building sector stands as a prominent agent of environmental degradation, refs. [5,6] accounting for approximately 40% of greenhouse gas (GHG) emissions related to energy use [7,8,9,10,11]. As a result, emphasis is put on quantifying and mitigating the building sector environmental burdens in response to climate change and other deleterious effects [12,13]. Emissions emanating from buildings can be systematically classified into two distinct categories, namely, operational carbon (OC) and embodied carbon (EC), as elucidated in the scholarly literature [14,15,16]. The OC component consists of emissions linked to the occupancy of a building, encompassing activities such as heating, lighting, and air conditioning [17]. Conversely, EC encapsulates emissions originating from the quarry, production, and transportation of building materials to the work site, the construction process itself, and demolition, as well as recycling or reuse activities undertaken at the termination of the building’s lifecycle [14,15]. The most significant environmental effects linked to the building sector are predominantly manifested during the operational phase of buildings, as described in numerous studies [18,19,20,21,22,23]. A study by Hafner [24] reveals OC constitutes 45% to 80% of any given building’s total GHG emissions. A whole building life cycle assessment (LCA) has been done by Vidal et al. [25] for a mass timber structure of a residential building in Granada-Spain. The result of the study shows that about 65% of the global warming potential (GWP) is associated with the operation of the building. Quintana-Gallardo and colleagues [26] conducted a study that revealed the significant contribution of the use phase to the overall carbon emissions of a building life cycle, ranging from 65% to 76%.

1.2. Past Research LCA Metric on Mass Timber Buildings Operation

Mass timber products, like glulam and cross-laminated timber (CLT), have excellent opportunities to emerge as potential competitors to conventional multi-story buildings due to reduced environmental impacts [10,23,27,28]. While there is a considerable increase in the use of mass timber as an emergent material, the construction industry faces limited knowledge regarding the OC specificities associated with this material’s application in a building structure or a district of buildings, for instance, a campus. For example, in the whole building LCA undertaken by Chen et al. [29], a comparative analysis is presented between a mass timber building and a reinforced concrete (RC) building in Portland, Oregon. The investigation posits the assumption of operational energy parity between the two material alternatives. In another study conducted by Greene et al. [30], available utility data were employed in conjunction with building energy consumption simulation tools to appraise the operational emissions spanning the entire lifespan of a designed four-story, 10,033 m2, office building in the city of Fort Collins, Colorado, United States. Here again, the study compares a mass timber-designed building to an equivalent steel alternative, with the investigation considering a presumption of equality in operational energy between the two alternatives [30].

Very few studies, however, provide OC data associated with mass timber structures [10,31,32], and more so for campus buildings. The study outcomes of a whole building LCA conducted by Chen et al. [29] indicate a quantity of 2799 kg CO2 eq per square meter over a 60-year operational period (module B6) of the studied building in Portland, Oregon. Takano et al. [33] conducted an LCA study on a four-story apartment located in Mietraching, Germany. The result shows 1119 kg CO2 eq per square meter of the building over a 50-year operational period. The findings of another study [30] convey 2859 kg CO2 eq per square meter over a 50-year operational period of a building in Fort Collins, Colorado.

Furthermore, a study conducted by Dong et al. [34] examines the carbon performance during the operational phase of mass timber stadiums in China. The simulation results indicate that the carbon footprint during the operational phase of mass timber buildings in various regions ranges from 3230 to 7545 kg CO2 equivalent per square meter over a 50-year period. This considerable variation is, mainly, attributed to differences in climate zones and the electricity emission factor, which varies from 0.67 t-CO2/MWh to 1.14 t-CO2/MWh across different regions in China. The findings of this study underscore the role of the climate zone and energy fuel source in influencing the OC of these buildings. Likewise, a study conducted by Quintana-Gallardo et al. [26], using Design Builder 6.1 tool to run the energy simulations, reveals the influential impact of fuel sources and the composition of the electricity generation mix as determinants in the environmental consequences associated with buildings [26].

A comprehensive study [10] comparing the simulation results of the life-cycle carbon footprint of mass timber buildings versus RC buildings in midrise residential structures across three Australian cities reveals significant reductions in carbon emissions associated with mass timber construction. Notably, the study consistently favors mass timber buildings over their RC counterparts throughout the entire building life cycle, with the results showing 34%, 30%, and 29% carbon footprint reductions compared to RC structures in Sydney, Melbourne, and Brisbane, respectively [10]. In contrast, the operational phase of the mass timber structures over a 50-year period tends to produce higher carbon footprint values compared to those of concrete structures [10], which aligns with studies done by [35,36]. While wood production emits less CO2 initially, studies suggest that concrete buildings may be more energy efficient overall. This efficiency is due to concrete’s greater thermal mass, which allows it to store and release heat more effectively. Consequently, concrete buildings often achieve energy savings in heating and cooling throughout the year. These savings can potentially offset the lower initial CO2 emissions from wood production over the building’s entire life cycle. Although mass timber reduces emissions during construction, the long-term operational efficiency of concrete buildings can balance out the carbon footprint, making the overall environmental impact of both materials comparable [10].

1.3. Efforts at Reducing OC at University Campuses

Due to the critical role that large building portfolios, such as university campuses, play in achieving sustainable development goals [6,13,37,38,39,40,41], the initiative of campus greening has become a focal point for many universities. Despite the fact that transitioning to a low-carbon campus is a long-term strategy, many universities are now emphasizing high energy efficiency, least emissions, and sustainable environmental awareness [42,43,44]. For example, the University of Arkansas committed to the College and University Presidents Climate Commitment, aiming to achieve carbon neutrality by 2040 [45].

An LCA study [42] conducted on the University of Utah campus explores strategies aimed at assessing the potential of reducing the overall carbon footprint of campus buildings. The study involves the simulation of the operation and energy consumption of buildings equipped with various types of HVAC systems from a campus-level perspective. The study shows that the implementation of a combination of systems, rather than relying on a single type of HVAC system, can reduce carbon emissions by 15% [42]. Another study [44] shows that by converting the campus heating infrastructure from steam to hot water in the University of British Academic District, carbon emissions can be reduced by 22% [44].

Del Borghi et al. [41] conducted a comparative analysis of carbon emissions related to the operational activities of the campus districts at the University of Genoa (UNIGE), Italy, and Florida International University (FIU) in Miami, USA. The findings revealed a significant disparity, with FIU exhibiting a notably higher total impact of nearly 145 kg of CO2-eq per square meter compared to UNIGE’s 76 kg CO2-eq per square meter. This disparity was primarily attributed to factors such as the energy mix employed by each campus [41].

These studies underscore the importance of tailored approaches to reducing carbon emissions, considering the unique energy infrastructure and operational practices of each campus. By implementing diverse and innovative strategies, universities can make substantial progress toward their sustainability goals, ultimately contributing to the global effort of mitigating climate change.

1.4. Procedural Approaches to Data Use in Building Operations

The calculation of OC for buildings is addressed through three main procedures [17]. The first approach considers real energy consumption data extracted from utility bills [46]. The second one applies published average energy consumption levels based on energy use databases [17]. For example, in the research investigation by Takano et al. [33], a comprehensive LCA of the entire building was undertaken, but due to the unavailability of actual energy consumption data, the energy consumed through the building operation was established using calculated values based on the German standard DIN V 4108-6 [47]. The third and final approach estimates OC through energy simulation models. As seen in the literature review mentioned above, very few LCA studies are related to a real case study and most of them rely on simulated rather than actual data for their analyses [10,12,25,26,29,30,34,42,48,49,50]. This last approach is largely due to the challenges and the considerable time investment required to acquire actual energy consumption data from existing buildings. Many studies indicate a remarkable gap between the actual measured data and simulated energy use from building energy models [51,52,53,54,55,56,57,58]. For example, a study conducted by Balaras et al. [53] compared buildings’ heating energy consumption data from simulated results, using energy performance certificates, with the real energy usage in more than 8500 buildings, discovering that the actual energy measurements were 44% less than the simulation values. Wang and colleagues [54] examined, in five green buildings in China, the discrepancy between the anticipated and the actual energy consumption. The result of the study revealed a variation ranging from 3.0% to 53.5%. There is, therefore, a serious need of investigations that examine real case studies based on actual consumption and empirical data, and according to various climatic zones which profoundly influence the resulting carbon emissions.

1.5. Data Need for OC in Campus Mass Timber Buildings

While numerous studies have been conducted to determine the carbon footprint of conventional building operation phases [37,59,60], there remains a significant lack of empirical data on the OC emissions of mass timber buildings, especially within the unique energy infrastructure context of university campuses. The operational carbon footprint of such campuses remains largely unexplored in the current literature [41,61]. Adohi Hall, a five-story mass timber residential building on the University of Arkansas campus, presents a distinctive case study opportunity in this regard.

The University of Arkansas campus’s energy infrastructure and sustainability goals provide a unique backdrop for examining the GWP associated with the operation of mass timber buildings. This investigation encompasses an assessment of the various energy use scenarios aimed at carbon reduction. Analyzing the operational carbon footprint and GWP of Adohi Hall provides valuable insights into the performance and sustainability benefits of mass timber in a university setting. This study expands the existing body of research [41,42,43,44] through the inclusion of operational carbon emissions.

The subsequent organization of this manuscript unfolds in the following sequence: Initially, the materials and methods employed in the study are shared, followed by the presentation of the results and the related discussion. Ultimately, the study’s conclusions are issued, accompanied by recommendations of relevance to OC in buildings.

2. Materials and Methods

2.1. Quantitative Method

The chosen methodology for this case study is primarily quantitative, stemming from the employed LCA tool. LCA as a quantitative tool examines the environmental impact of a building throughout the building lifespan [62,63,64,65,66].

2.2. LCA, Tools, and Databases

Regarding the LCA approach, various tools and databases are accessible for environmental assessment. Among all LCA tools, SimaPro [67] has achieved considerable acclaim as a leading program within academic circles, owing to internationally recognized methodologies and its use of scientifically validated databases [68]. Considering this, SimaPro version 9.5.0.0 [67] has been applied for this study to provide information on the environmental relevance of the resources used and the emissions associated with the structure. By definition, DATASMART (US-EI), discussed below, is an LCI package provided by Long Trail Sustainability (LTS). This dataset is developed by combining Ecoinvent and US LCI database, customized to be representative of U.S. context [69]). Also, utilizing data from Ecoinvent [70], U.S. Life Cycle Inventory (USLCI) database [71], and DATASMART facilitate the calculation of the life cycle impact assessment, providing essential information for constructing the life cycle inventory (LCI) matrix. These matrices can differ according to users, applications, data sources, geographic location, and the scope of study. Data related to building energy usage were tailored to a real case study scenario, located in the United States. Typically, emissions undergo categorization and are then multiplied by characterization factors (CF), (quantities × inventories × CF) [72]. CF consists of specialized coefficients designed to standardize the assessment by converting diverse emissions into a uniform metric, such as GWP. This formula enables a standardized evaluation and comparison of the environmental footprint associated with different emissions [72]. The impact assessment method employed in the SimaPro LCA modeling framework is TRACI (Tool for Reduction and Assessment of Chemicals and other environmental Impacts) [73]. TRACI is opted for as the modeling engine due to its utilization of a methodology developed by the Environmental Protection Agency (EPA), tailored specifically to the North American context [74]. The final environmental indicator combines the aggregated total of impacts identified in the flows during the operational phase of the building [72].

2.3. The Case Study, Adohi Hall

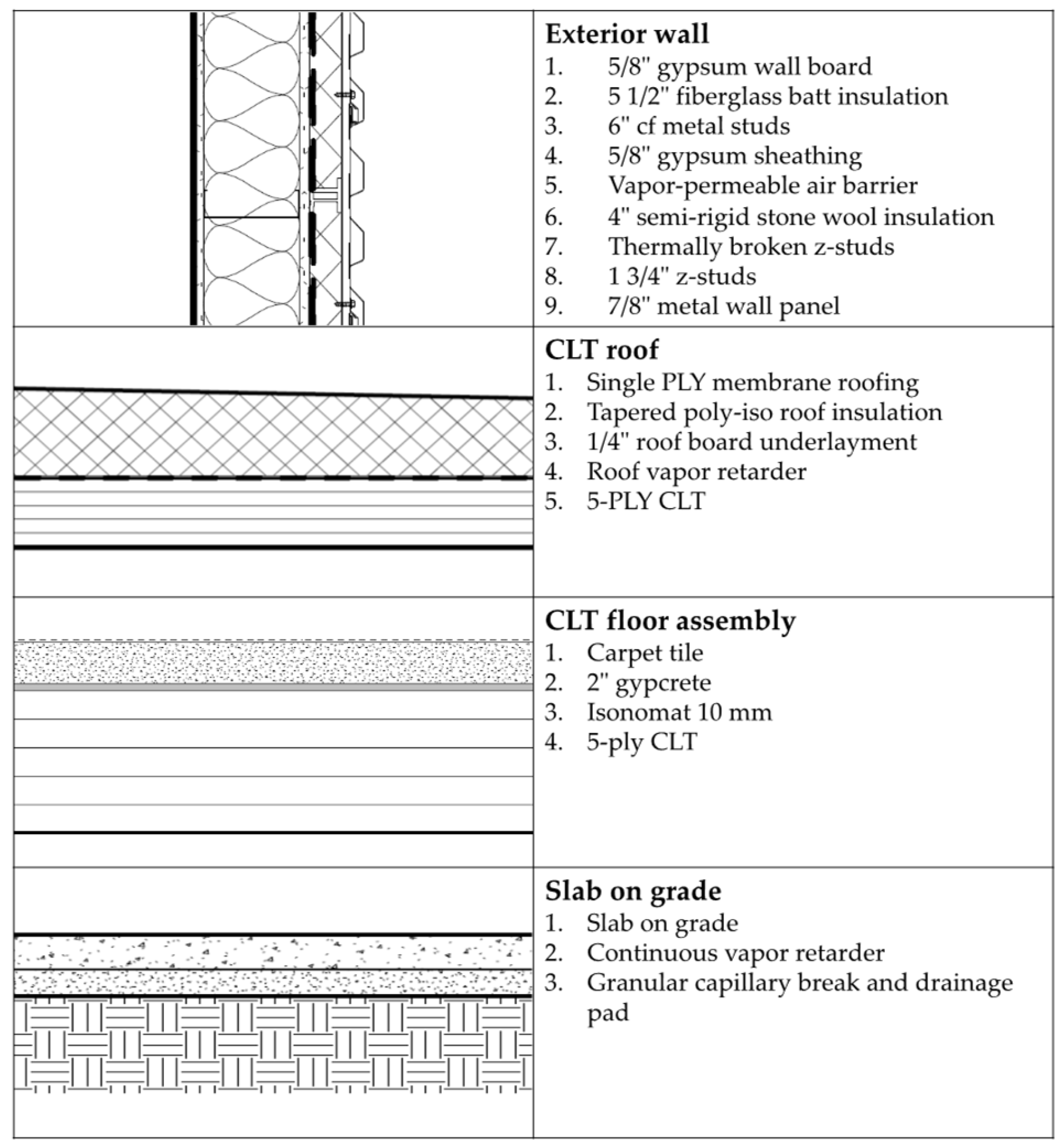

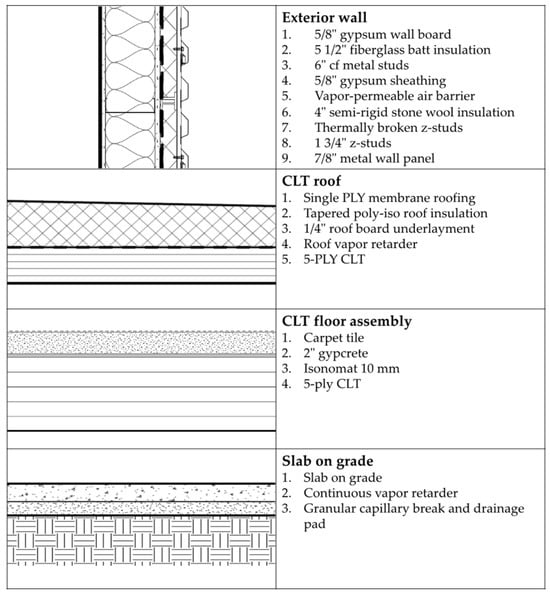

A recently erected edifice, Adohi Hall is a residential facility spanning 200,000 square feet and accommodating 708 beds and is selected for analyses in this investigation (Figure 1). Located within the precincts of the University of Arkansas campus, Adohi Hall is situated in a mixed-humid climate, defined by hot and humid summers and mild to cool winters [75]. Adohi Hall contains a range of activities. While predominantly dedicated to being a student residential hall, Adohi Hall is complemented by select auxiliary spaces like compact studios, business spaces, and storage areas [16]. The architectural composition of Adohi Hall is articulated through six wings and five floors, where CLT slabs are the predominant structural elements, supported by glulam columns and beams. A notable exception consists of the subterranean and ground floor sections, which are built of concrete slabs alongside a composite framework of steel and concrete columns and beams [16]. Adohi Hall walls are constructed with studs and gypsum boards, as documented by MODUS Studio and Nabholz Construction Corp. Details of external walls, roofs, and floors of Adohi Hall are presented in Figure 2.

Figure 1.

Adohi Hall, University of Arkansas campus, Fayetteville, AR (MODUS Studio).

Figure 2.

The details of external walls, roof, and floors of Adohi Hall.

In parallel with other structures on the University of Arkansas campus, Adohi Hall is reliant on a centralized facility, known as the central plant, to furnish necessary services, which encompass a spectrum of utilities, including heating, cooling, electrical power, air conditioning, and water. The central plant efficiently manages heat generation, power generation, and chilled water production to meet the diverse needs of Adohi Hall. Notably, these essential services are aligned with the broader campus infrastructure. Adohi Hall does not have its own means for generating heating and cooling. For instance, the building has no chiller or boiler, as usually found in autonomous buildings. The centrally located University of Arkansas plant heats and cools a conglomerate of campus buildings that include Adohi Hall, which is conditioned by means of circulated hot and chilled water. Further, Adohi Hall heating, ventilation, and air conditioning (HVAC) is quite different than the autonomous systems typically found in non-campus buildings. The hot or chilled water supply and return pipes originate from the power plant, travel in underground tunnels under the paved sidewalks leading to the building, and run in a continuous loop from the power plant to the building and back. All HVAC equipment, including air handling units (AHUs) and fan coil units (FCUs), is connected to both the hot and cold water supply and return pipes. The water pipe enters each unit at one end, coils inside the AHU and FCU in a serpentine pattern, and then exits back to the return pipe, carrying the water to either be re-heated or re-chilled in the plant depending on the load demands.

Additionally, the edifice employs a distinctive method to generate hot water for domestic usage, such as showers and baths, by harnessing heat derived from steam originating at the central plant.

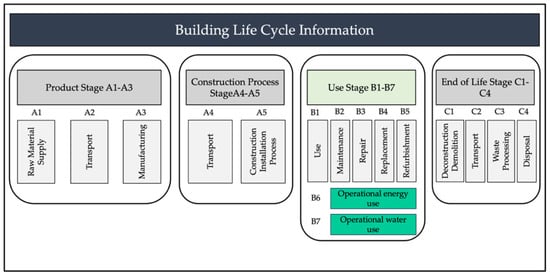

2.4. Goals, Scope, and System Boundaries

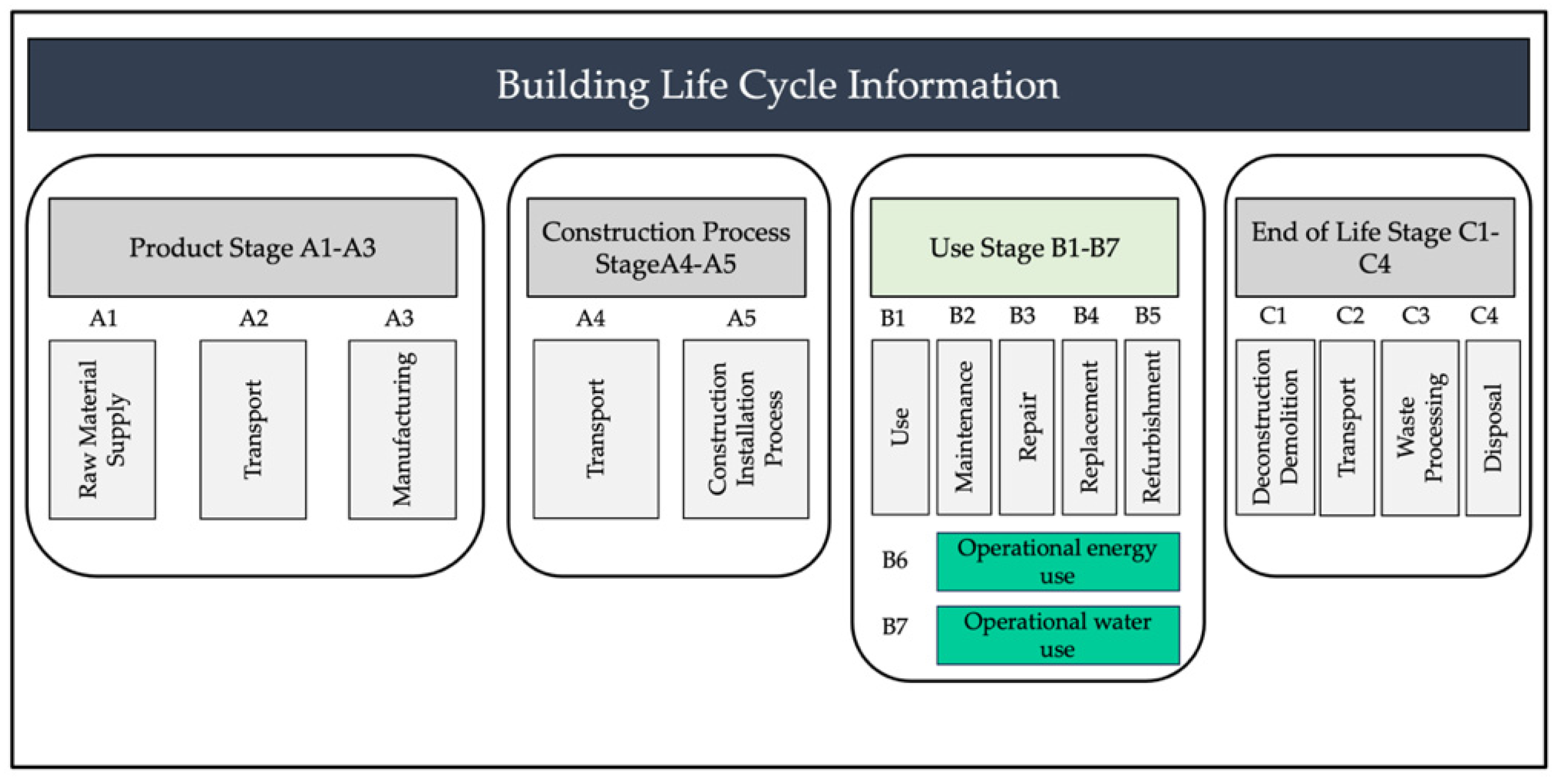

The life cycle stages of a building, outlined by the EN 15978 standard [76], are clarified for LCA analysis. Building LCA encompasses various stages, as shown in Figure 3. LCA studies can, however, be streamlined by omitting certain stages. The main objective of this study is to examine the carbon footprint associated with Adohi Hall during the operation phase (module B6–B7) as highlighted in Figure 3, applying the combination of various energy sources utilization (including renewable and conventional fuels). The employed analytical framework adheres to the principles delineated in [76,77,78]. The functional unit chosen for the LCA of this building is operation per one square meter of gross floor area of the building over 50 years lifespan, a basis for comparison.

Figure 3.

Building life cycle stages (adapted from [74]).

Given the considerable impact of the construction industry on global climate change, this study is specifically focused on evaluating GWP impacts. To assess the environmental profile, GWP is presented in kilograms of CO2 equivalents (kg CO2 eq).

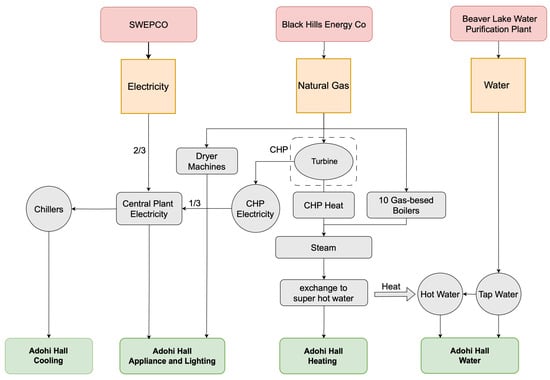

3. Adohi Hall Operational Energy Flows and Energy Generation

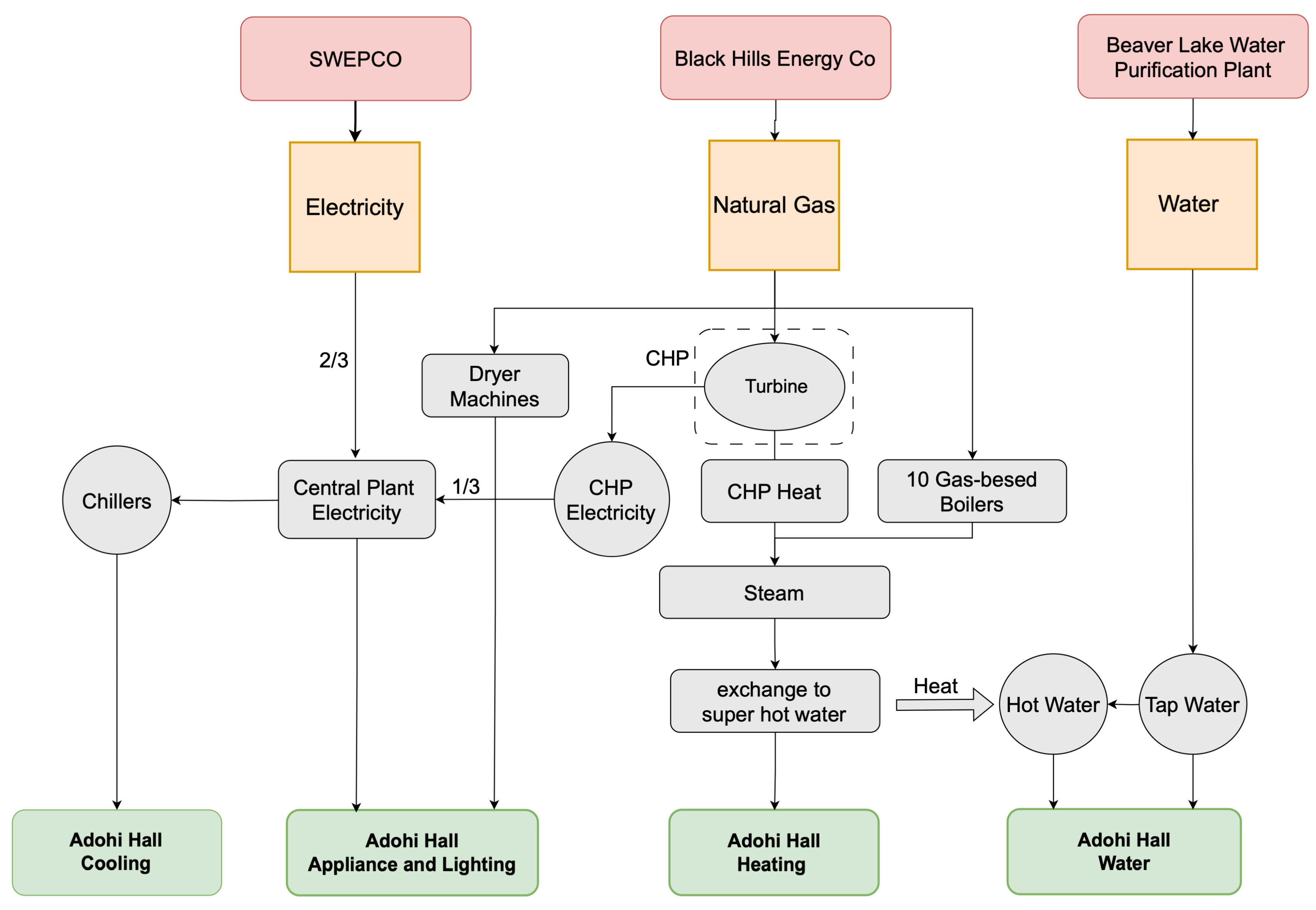

The utilities servicing Adohi Hall fall into four distinct categories: appliance and lighting, heating, cooling, and water. Figure 4 depicts the flows of the various fuel sources and other utilities in Adohi Hall.

Figure 4.

Diagram depicting the flows of the various fuel sources and other utilities.

3.1. Appliance and Lighting

Adohi Hall mainly uses electricity to power most of its appliances. This encompasses various kitchen equipment such as refrigerators, stoves, ovens, microwaves, and dishwashers, as well as washing machines, and an array of electronic devices including televisions and computers. A noteworthy exception is discerned with the dryers, which rely on natural gas for the purpose of clothes drying.

3.1.1. Electricity

The electricity fed to Adohi Hall originates from the University of Arkansas central plant, which draws its energy from two providers: Southwestern Electric Power Company (SWEPCO) and the on-campus combined heat and power (CHP) plant. According to data collected from surveys and interviews with the University of Arkansas Facilities Management (FAMA) representatives, roughly two thirds of the electricity of the University of Arkansas campus including Adohi Hall comes from SWEPCO, while the remaining third is supplied by the on-campus CHP plant. The Adohi Hall annual electricity consumption for appliances and lighting for the years 2021, 2022, and 2023 is presented in Table 1.

Table 1.

Adohi Hall annual electricity consumption for appliances and lighting.

3.1.2. Natural Gas

The Adohi Hall laundry room contains 16 dryer units powered by natural gas for the mechanisms of heating and drying clothes. The annual natural gas consumption attributed to the dryer machines is presented in Table 2 for the years 2021, 2022, and 2023. The annual data of Adohi Hall’s natural gas consumption, as supplied by FAMA, is delineated in centum cubic feet (CCF) units, a prevalent metric employed for quantifying natural gas usage. This unit of measurement corresponds to one hundred cubic feet in volume. One CCF is approximately equal to 100,000 British Thermal Units (BTU).

Table 2.

Adohi Hall annual natural gas consumption for dryer machines.

3.2. Heating

As mentioned above, the on-campus CHP plant simultaneously produces electricity power and steam. The by-product heat generated in the turbine is transferred to a boiler to produce steam. The required heating for almost all on-campus buildings is supplied by steam that is produced through the CHP system in the central plant. Table 3 presents the annual steam consumption for heating Adohi Hall. According to data provided by FAMA, the temperature of steam is 353 degrees Fahrenheit, and its pressure is 100 Psi. According to published conversion data, the energy carried per pound of steam is equal to 1189 BTU [79].

Table 3.

Adohi Hall annual steam consumption for heating.

As a contingency plan for steam production, the central plant has incorporated 10 gas-based boilers. These boilers serve as a backup system in case the CHP system’s steam production output fails to meet the heating requirements of the buildings. Given their infrequent utilization, the backup boilers have been omitted from consideration within the scope of this study.

3.3. Cooling

The campus-established infrastructure delivers chilled water to AHUs and FCUs to cool the spaces in the building. As stated above, an electrically powered chiller to produce chilled water is located in the central plant of the campus. A chilled water system, in contrast to conventional air-based cooling systems, represents a more efficient option of transporting the coolth. This system intricately regulates the ambient temperature within the respective indoor spaces. Table 4 displays the annual recorded data by FAMA regarding ton-hour of chilled water consumption in Adohi Hall.

Table 4.

Adohi Hall annual energy consumption for cooling.

3.4. Water

3.4.1. Water Supply

Adohi Hall’s water supply is sourced from the municipality of Fayetteville, Arkansas. Fayetteville, in turn, procures its water on a wholesale basis from Beaver Water District, the primary supplier of drinking water in Northwest Arkansas. The water treatment plant at Beaver Lake in Springdale, AR, serves as the point of service where the water undergoes treatment to meet established drinking water standards [80]. Subsequently, the treated water is conveyed to the municipal system via two parallel water transmission mains spanning a distance of 10 miles, with diameters of 36 inches and 42 inches [80]. Table 5 presents Adohi Hall’s annual water consumption.

Table 5.

Adohi Hall annual water consumption.

3.4.2. Hot Water Supply

Rather than directly producing hot water from steam, Adohi Hall employs a heat exchanger wherein water is heated by passing through the steam pipes. This indirect process efficiently transfers the heat energy from the steam to the water, providing the necessary temperature for domestic applications in Adohi Hall.

4. Results

4.1. Appliance and Lighting GWP Impact

4.1.1. Emissions from Electricity

SWEPCO

SWEPCO is the primary electricity supplier in Fayetteville, Arkansas. The main sources used for generating electricity in SWEPCO are gas (47%), coal/lignite (36%), and wind (17%), respectively [81].

The DataSmart (US-EI) database [69] is selected to simulate an electricity model showcasing the SWEPCO source mix. As illustrated in Table 6, this database utilizes a proportional representation that amalgamates three distinct databases corresponding to the three primary SWEPCO electricity sources: gas, coal, and wind.

Table 6.

LCI choices to develop a database for SWEPCO electricity mix.

The developed database of the mix of sources for SWEPCO’s electricity generation is directly obtained from the DataSmart database, showing 0.842 Kg CO2 eq emissions per KWh of SWEPCO consumed electricity.

CHP

Interviews with the executive team at the university’s central plant reveal that the power distributed by SWEPCO is insufficient to meet the campus building annual electrical energy requirements and the annual peak power demand. To make up for the shortfall, the central plant of the University of Arkansas activates the CHP system to supply the complementary power needed. A CHP plant, also known as cogeneration, constitutes an establishment designed for the concurrent generation of electricity and valuable thermal energy (by-product heat) derived from a singular energy source [82].

On average, the campus CHP turbine provides approximately one third of the total electricity required by all campus buildings, as indicated in the data provided by the executives. The campus turbine generates electricity with a capacity of around 12 MWh. This turbine’s fuel source is natural gas supplied by Black Hills Energy Company. Table 7 presents the LCI chosen for the electricity produced by the CHP plant from the DataSmart database.

Table 7.

LCI choice for the electricity produced by the CHP plant.

The chosen data from the DataSmart database for electricity produced by the CHP plant represent 0.334 Kg CO2 eq emissions per KWh of electricity.

Adohi Hall Electricity Mix

Considering two thirds of Adohi Hall electric power is sourced from SWEPCO, with the remaining one third provided by the on-campus CHP plant, the Adohi Hall electricity mix represents 0.672 Kg CO2 eq emissions per KWh electricity consumption.

In addition, the 2021, 2022, and 2023 yearly electricity consumption attributed to appliances and lighting in Adohi Hall, as delineated in Table 1, stands, respectively, at 872, 936, and 966 tonnes CO2 eq.

4.1.2. Emissions from Natural Gas

As mentioned in Section 3.1.2, Adohi Hall’s laundry includes 16 natural gas-powered dryer units. Table 8 presents the LCI chosen for the heat produced by natural gas from DataSmart database. The chosen database from the DataSmart database for the heat produced by natural gas in the dryer machines is 9.44 Kg CO2 eq emissions per CCF natural gas consumption.

Table 8.

LCI choice for the heat produced in dryers by natural gas.

The yearly natural gas consumption attributed to the dryer machines in Adohi Hall, as is shown in Table 2, and the associated GWP for the years 2021, 2022, and 2023, respectively, amount to 21, 30, and 32 tonnes CO2 eq.

4.2. Heating GWP Impact

As mentioned above, the on-campus CHP facility concurrently generates both electricity and steam. Waste heat from the turbine is utilized to generate steam in a boiler, which serves as the primary source of heating for nearly all on-campus structures. Table 9 shows the LCI chosen for the heat produced by the CHP plant for Adohi Hall’s heating. The unit for the chosen LCI is BTU.

Table 9.

LCI choice for the heat produced by the CHP plant for Adohi Hall heating.

4.3. Cooling GWP Impact

As mentioned in Section 3.3, the cooling system implemented for Adohi Hall relies on an on-campus network of chilled water produced in electric chillers and pumps for transportation. These central chillers show an average consumption of 0.67 KWh electricity per ton-hour production of chilled water. Accordingly, the electricity consumption attributed to the production of chilled water can be calculated using the following equation:

where:

E = CW × 0.67

E is the electricity used to produce chilled water (KWh)

CW is the chilled water consumption (ton-hour)

The annual electricity consumed by the chilled water plant, and associated carbon footprint, is presented in Table 10.

Table 10.

Adohi Hall annual electricity consumption for cooling.

4.4. Water GWP Impact

As indicated in Section 3.4.1, Adohi Hall’s water provision originates from the municipal network of Fayetteville, Arkansas. The LCI chosen for Adohi Hall water consumption is presented in Table 11. The chosen data consist of 0.00334 Kg CO2 eq emissions per gallon of water consumption. Considering Adohi Hall’s annual water consumption, presented in Table 5, the GWP associated with Adohi Hall’s water consumption for the years 2021, 2022, and 2023, respectively, stands at 14, 21, and 27 tonnes CO2 eq.

Table 11.

LCI choice for water consumption.

Regarding the hot water supply to Adohi Hall, mentioned in Section 3.4.2, water is warmed by circulating it through steam heat exchangers. As the energy consumption and emissions related to steam production have already been accounted for in Section 4.2, there is no need to double count the heat content.

4.5. Total GWP Impact

Table 12 shows that the total GWP associated with Adohi Hall for the respective years of building occupancy, 2021, 2022, and 2023, amounts to 1528, 1638, and 1670 tonnes CO2 eq.

Table 12.

GWP (tonne CO2 eq) associated with Adohi Hall annual operation.

The analysis of the results over the past three years indicates that the carbon footprint has remained relatively constant. Only a slight upward trend is observed between the years 2021 and 2023. The lower footprint in the earlier years may be attributed to the impact of COVID-19, which led to underutilization of the building’s maximum residential capacity [43]. Considering this factor, the 2023 results can be deemed more reliable than those of the preceding year. From this point forward, the 2023 results will, therefore, serve as the basis for the analyses in this study.

Table 13 presents the GWP (kg CO2 eq) associated with the operation per square meter of Adohi Hall over its 50-year lifespan. The research findings indicate that appliances and lighting usage exert the most pronounced influence, while water consumption exhibits the least significant impact. Moreover, the GWP attributed to cooling and heating activities demonstrates a notable degree of proximity; roughly equal emissions are observed during the heating and cooling seasons.

Table 13.

GWP (kg CO2 eq) associated with operation per square meter of Adohi Hall over 50-year lifespan.

5. Discussion

5.1. Sensitivity Analysis

In the quest to mitigate OC emissions in buildings, various strategies can be identified. Sensitivity analyses are conducted to evaluate the results derived from the different strategies. In this section, variations in key assumptions and input parameters are considered in the way they affect the GWP outcomes for Adohi Hall’s operational phase. The five scenarios examined for this sensitivity analysis include different energy mixes combined with configurations of the CHP system, reflecting plausible future changes in energy sourcing and technology improvements. Since these research findings clearly highlight the significant impact of appliances and lighting usage on the overall GWP, the next step is to examine the inherent primary energy sources. Since electricity powers these utilities, it becomes important to scrutinize other power sources to gauge their environmental implications. In response, the following scenarios were identified and analyzed to assess their potential influence on carbon emissions and environmental sustainability. The scenarios are explained in detail in Section 5.1.1. The scenarios are analyzed and compared with each other, and with the baseline values associated with Adohi Hall in Section 5.1.2.

5.1.1. Scenarios

Scenario 1—Adohi Hall’s Electricity Power Sourced Entirely from SWEPCO

This scenario has been chosen to assess the carbon emissions of a building whose power consumption mirrors that of a norm building in Fayetteville, Arkansas. The electricity typically powering buildings in the area is supplied by the city’s electric power company, SWEPCO, to run appliances, electric lighting, cooling, and other related equipment. In addition, the gas-fired boilers, which produce heating and hot water, are selected as the popular heating systems for buildings in the area outside the campus. The overarching objective is to conduct a comparison of the carbon emissions stemming from Adohi Hall if the building was powered comparably to the buildings outside the campus, versus its current operational configuration, which integrates a composite energy provision system from the SWEPCO and CHP technologies.

Scenario 2—SWEPCO Future, Improving SWEPCO’s Efficiency by Incorporating Wind and Solar Resources

Adohi Hall predominantly utilizes electricity from SWEPCO, which is largely generated by burning coal and gas. Currently, only 17% of the SWEPCO electricity mix comes from wind. Based on SWEPCO’s long-term strategy, it is projected that one third of SWEPCO’s energy will be sourced from renewable energies [81,83]. This scenario draws inspiration from SWEPCO’s long-term vision. The scenario evaluates the future trajectory of energy production as envisioned by SWEPCO.

The implications of Adohi Hall being powered exclusively by the future energy mix predicted by SWEPCO are investigated. The objective is to determine the GWP under such a scenario and whether, given SWEPCO’s future development plans, the utilization of CHP for GHG emissions reduction would remain necessary.

Like scenario 1, gas-fired boilers are being evaluated as the alternative source for heating and hot water in the building. Comparing this scenario with other scenarios will help to assess how shifts in the electricity supply impact carbon emissions.

Table 14 presents the projected future SWEPCO electricity mix, offering insights into the anticipated composition of energy sources. In this scenario, the primary sources utilized for electricity generation by SWEPCO include 47% gas, 20% coal/lignite, 27% wind, and 6% solar. Notably, the contribution of gas remains consistent with the current SWEPCO electricity mix (the current SWEPCO electricity mix is presented in Table 6). However, there are notable adjustments, including a 16% reduction in coal/lignite utilization and a 10% increase in wind energy allocation. Additionally, the scenario predicts a 6% contribution from solar energy within the future SWEPCO electricity mix.

Table 14.

Assumed future SWEPCO electricity mix.

Scenario 3—Adohi Hall’s Electric Power Sourced Entirely from the On-Campus CHP Plant

As previously pointed out, the distinguishing feature of Adohi Hall, and all buildings on the UARK campus from other structures in the city of Fayetteville, Arkansas, lies in the utilization of CHP systems to cater to a portion of its electricity and heating requisites. This scenario examines the GWP impact if the entire electricity and heating requirements of the campus are strictly met only with CHP.

Scenario 4—SWEPCO Future with CHP Plant Contribution

In this scenario, two thirds of Adohi Hall’s electric power is sourced from the SWEPCO future electricity mix, which has been explained in scenario 2, and the rest is supplied by the on-campus CHP plant. As indicated above, the CHP plant also provides the heating and hot water for the building. This scenario is the most realistic scenario as it considers the provision of one third of Adohi Hall’s electricity from CHP, which is already there, as well as considering the increase in renewable energy sources in the electricity future mix by considering the likely implementation of SWEPCO’s vision.

Scenario 5—SWEPCO Future with No Coal Contribution

Coal is a notable source of carbon emissions in the SWEPCO electricity mix. Considering this highly polluting source of fuel, this scenario suggests examining an idealized case in which coal contribution is reduced to 0% in the SWEPCO electricity mix by replacing it with wind and solar sources.

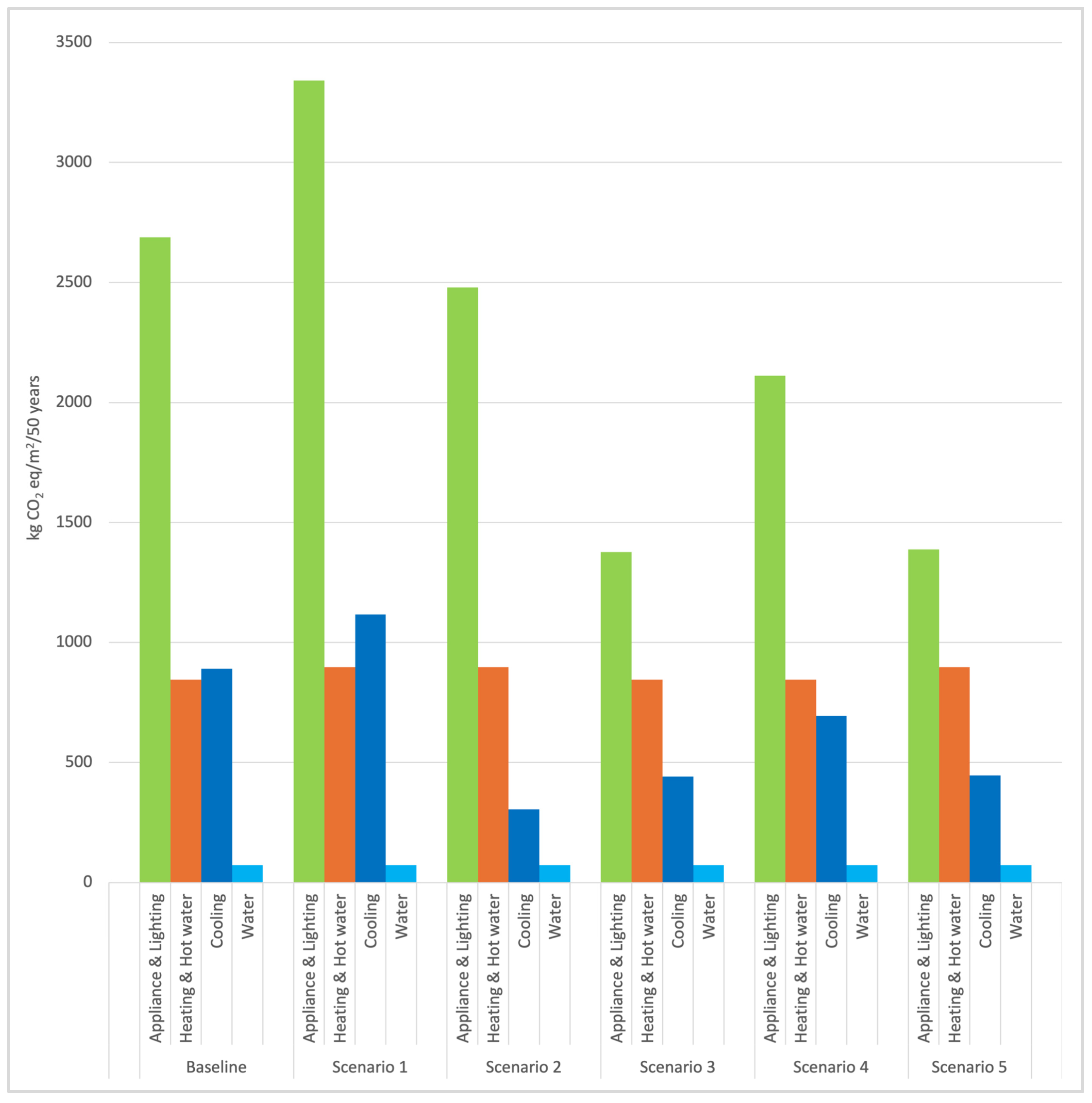

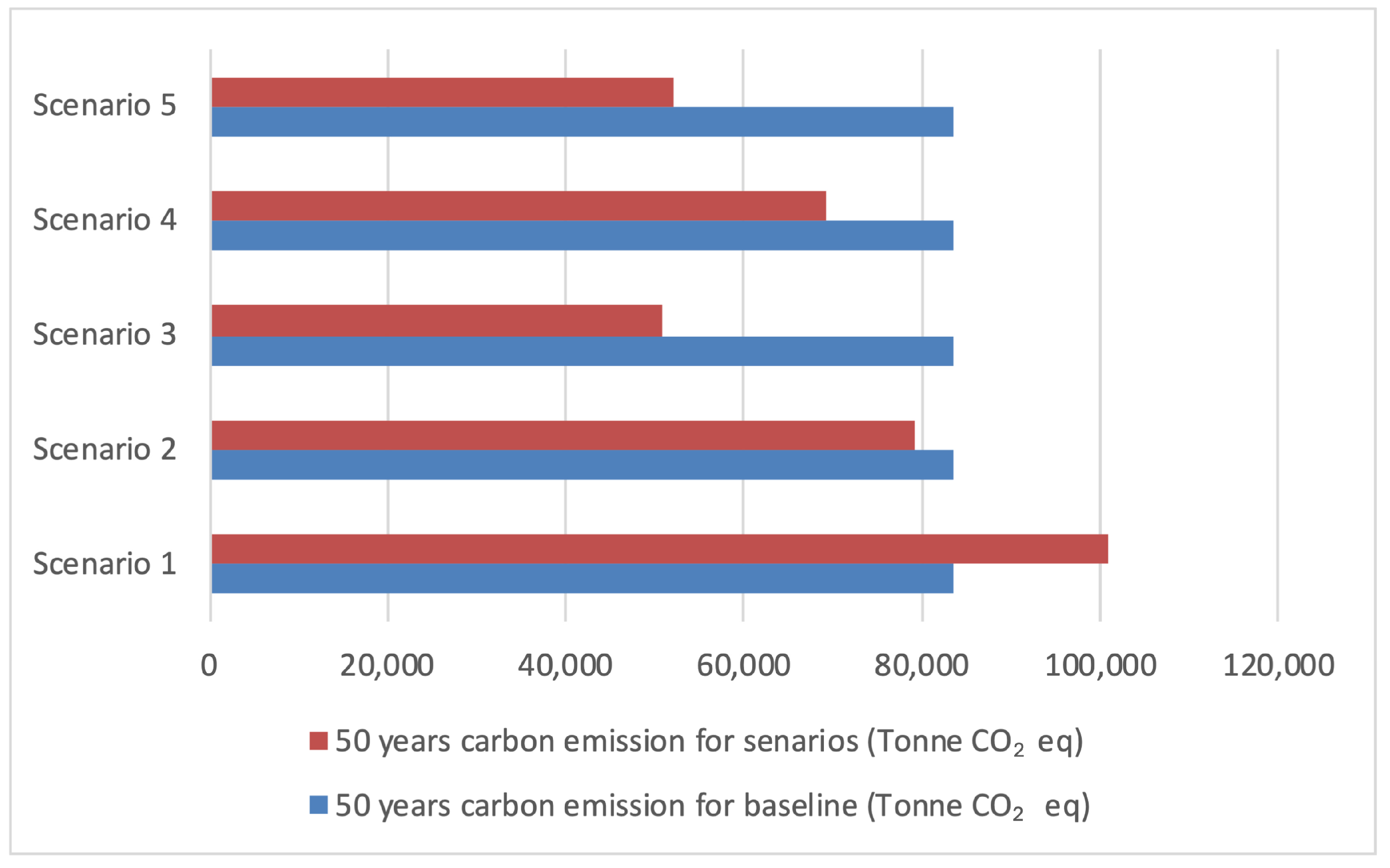

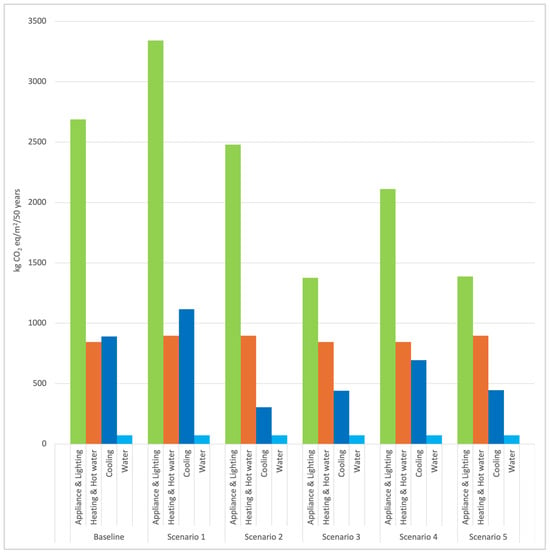

Table 15 presents comparative discrepancies in descriptions between the baseline and each scenario. Figure 5 shows the GWP (kg CO2 eq) associated with the operation per square meter of Adohi Hall over its 50-year lifespan for each scenario.

Table 15.

Comparative discrepancies in descriptions between the baseline and each scenario.

Figure 5.

GWP (kg CO2 eq) associated with operation per square meter of Adohi Hall for each scenario over 50-year lifespan.

5.1.2. Analytical Results

The sensitivity analysis results are displayed in Table 16 and reveal a notable trend. Scenario 3 conveys the highest GWP reduction, with the potential to achieve nearly a 40% decrease. It must be noted, however, that supplying 100% of electricity needs through CHP plants may not be feasible for many buildings due to the required infrastructure. Consequently, its implementation may be impractical. Also, the exact emissions reduction would depend on the specific fuel mix and efficiency of each CHP plant. Since CHP is, however, the most efficient option available, its adoption would be the most effective strategy for GWP reduction. Conversely, scenario 1, which excludes the CHP plant and relies solely on SWEPCO’s current electricity mix, exhibited the most pronounced augmentation, with an approximately 21% increase in total GWP from 4496 to 5428 kg CO2 eq per square meter of Adohi Hall’s operation over 50 years. These results underscore, first, the polluted mix for SWEPCO that must be addressed in the long term, and second, the important role played by the CHP plant in significantly mitigating the GWP associated with on-campus buildings, among them, Adohi Hall. Considering that one third of the electricity of all campus buildings is supplied by the CHP plant, it makes a remarkable reduction in the campus carbon footprint.

Table 16.

Sensitivity analysis. Scenarios are referenced respect baseline. Values expressed by kg CO2 eq associated with operation of per square meter of Adohi Hall over 50 years.

Scenario 2 shows that solely implementing the SWEPCO vision could reduce GWP by 5% compared to the current situation. Scenario 4, in which the SWEPCO energy source is diversified and supplemented by CHP, stands out as the most logical and realistic scenario among the options. This scenario results in a 17% reduction in carbon emissions, making it a more balanced approach that combines improvements in energy sourcing with the advantages of CHP. The integration of improved SWEPCO performance and CHP utilization offers a pragmatic path forward, aligning with realistic expectations and technological advancements.

The analysis of scenario 5 highlights the critical importance of eliminating coal from SWEPCO’s energy mix, given that this fuel source is a major contributor to increased GWP. This scenario indicates that the removal of coal, along with its high conversion coefficient, could potentially achieve similar GWP reductions as those projected in scenario 3, the scenario focused solely on CHP. Regardless, the scenario may not be realistic in the near future; however, prioritizing the replacement of coal with renewable energy sources, such as wind and solar power, is essential to achieving significant reductions in GWP and enhancing sustainability.

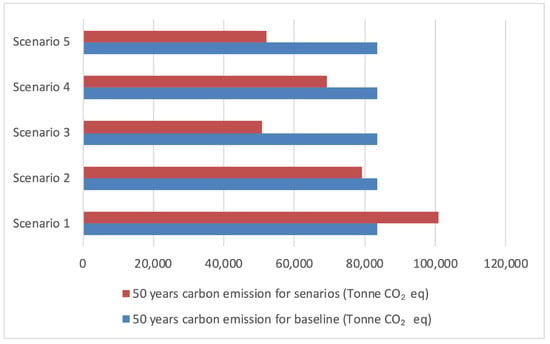

Figure 6 shows the CO2 equivalent emissions associated with the operation of Adohi Hall over a 50-year period, considering each scenario in comparison with the baseline.

Figure 6.

The CO2 equivalent emissions associated with the operation of Adohi Hall over a 50-year period, considering each scenario in comparison with the baseline.

6. Conclusions and Future Research

The results from these comparisons indicate that Adohi Hall outperforms typical buildings in Fayetteville, AR, by approximately 21% through leveraging a unique energy configuration and utilizing a CHP plant as an electricity and heating source. Clearly, the complementary operation of the CHP plant to meet the entire campus’ needs is one of the most effective strategies for reducing OC emissions in the buildings.

Other scenarios of mitigating carbon emissions provide insights about emission reduction strategies during building operation. First, increasing the share of renewable energy in the electricity mix can significantly reduce the GWP associated with building operations. Thus, the improvements towards cleaner electricity generation, aligned with realistic expectations and technological advancements, can achieve a 17% reduction in Adohi Hall’s OC emissions.

Second, coal-based generation of electricity is the primary factor influencing carbon emissions. The removal of coal from the Adohi Hall electricity mix can potentially achieve an almost 38% carbon reduction. Prioritizing, therefore, the replacement of pollutant energy sources with clean and green energy, such as wind power, is a highly effective strategy to pursue.

Since the highest carbon footprint of Adohi Hall is associated with the energy used for appliances and lighting, immediate actions call for the use of Energy Star-rated appliances and highly efficient lighting systems with high efficacy for the operational life of buildings. Future research in further abating carbon emissions includes the role of the building envelope in combination with the contribution of the heat capacity inherent to the materials. The proper detailing and sealing of exterior envelope connections and window apertures, combined with efficient heating and cooling systems, can substantially reduce carbon emissions. All these strategies integrated into a whole building approach not only address the direct energy sources, but also consider the structural and operational modifications necessary for a substantial, long-term reduction of carbon emissions. Through these multi-level interventions, the potential for a significant decrease in the carbon footprint through building operations can be further realized.

Author Contributions

Conceptualization, M.H. (Moein Hemmati) and T.M.; methodology, M.H. (Moein Hemmati), T.M. and H.G.; software, M.H. (Moein Hemmati) and M.H. (Mahboobeh Hemmati); validation, M.H. (Moein Hemmati), M.H. (Mahboobeh Hemmati), T.M. and H.G.; formal analysis, M.H. (Moein Hemmati) and M.H. (Mahboobeh Hemmati); investigation, M.H. (Moein Hemmati); resources, M.H. (Moein Hemmati); data curation, M.H. (Moein Hemmati) and M.H. (Mahboobeh Hemmati); writing—original draft preparation, M.H. (Moein Hemmati); writing—review and editing, M.H. (Moein Hemmati), M.H. (Mahboobeh Hemmati), T.M. and H.G.; visualization, M.H. (Moein Hemmati); supervision, T.M. and H.G.; project administration, T.M.; funding acquisition, T.M. and H.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the U.S. Forest Service Forest Products Laboratory through a Joint Venture Agreement (20-JV-11111137-046) with the University of Arkansas.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to express their gratitude to Scott Turley, Jeffrey E. Siebler, Gordon Harriman, James A. Hamilton, Randy Green and Brian A. Gray, and James Milner along with the University of Arkansas Facilities Management (FAMA) team, for their invaluable assistance and support. Their provision of critical information regarding Adohi Hall’s energy consumption, fuel input usage, and other utilities (such as water, electricity, chilled water, and natural gas) was very helpful for this study. Additionally, we appreciate their efforts at graciously explaining the process involved with Adohi Hall’s complex flow network of the various fuel sources and other utilities, which greatly enhanced the comprehensiveness of our research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Averchenkova, A.; Fankhauser, S.; Finnegan, J.J. The impact of strategic climate legislation: Evidence from expert interviews on the UK Climate Change Act. Clim. Policy 2021, 21, 251–263. [Google Scholar] [CrossRef]

- Scannell, L.; Grouzet, F.M.E. The metacognitions of climate change. New Ideas Psychol. 2010, 28, 94–103. [Google Scholar] [CrossRef]

- Rostami, E.; Vahid, R.; Zarei, A.; Amani, M. Dynamic Analysis of Water Surface Extent and Climate Change Parameters in Zarivar Lake, Iran. Environ. Sci. Proc. 2024, 29, 71. [Google Scholar] [CrossRef]

- Mansourihanis, O.; Zaroujtaghi, A.; Hemmati, M.; Maghsoodi Tilaki, M.J.; Alipour, M. Unraveling the Tourism–Environment–Equity Nexus: A Neighborhood-Scale Analysis of Texas Urban Centers. Urban Sci. 2024, 8, 82. [Google Scholar] [CrossRef]

- Sandanayake, M.; Lokuge, W.; Zhang, G.M.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef]

- Nagpal, S.; Reinhart, C.F. A comparison of two modeling approaches for establishing and implementing energy use reduction targets for a university campus. Energy Build. 2018, 173, 103–116. [Google Scholar] [CrossRef]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Yan, H.; Shen, Q.P.; Fan, L.C.H.; Wang, Y.W.; Zhang, L. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef]

- Ingrao, C.; Scrucca, F.; Tricase, C.; Asdrubali, F. A comparative Life Cycle Assessment of external wall-compositions for cleaner construction solutions in buildings. J. Clean. Prod. 2016, 124, 283–298. [Google Scholar] [CrossRef]

- Jayalath, A.; Navaratnam, S.; Ngo, T.; Mendis, P.; Hewson, N.; Aye, L. Life cycle performance of Cross Laminated Timber mid-rise residential buildings in Australia. Energy Build. 2020, 223, 110091. [Google Scholar] [CrossRef]

- Zhu, H.; Liou, S.R.; Chen, P.C.; He, X.Y.; Sui, M.L. Carbon Emissions Reduction of a Circular Architectural Practice: A Study on a Reversible Design Pavilion Using Recycled Materials. Sustainability 2024, 16, 1729. [Google Scholar] [CrossRef]

- Rinne, R.; Ilgin, H.E.; Karjalainen, M. Comparative Study on Life-Cycle Assessment and Carbon Footprint of Hybrid, Concrete and Timber Apartment Buildings in Finland. Int. J. Environ. Res. Public Health 2022, 19, 774. [Google Scholar] [CrossRef] [PubMed]

- Guan, J.; Nord, N.; Chen, S.Q. Energy planning of university campus building complex: Energy usage and coincidental analysis of individual buildings with a case study. Energy Build. 2016, 124, 99–111. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Xiao, J. Estimation and minimization of embodied carbon of buildings: A review. Buildings 2017, 7, 5. [Google Scholar] [CrossRef]

- Upton, B.; Miner, R.; Spinney, M.; Heath, L.S. The greenhouse gas and energy impacts of using wood instead of alternatives in residential construction in the United States. Biomass Bioenergy 2008, 32, 1–10. [Google Scholar] [CrossRef]

- Hemmati, M.; Messadi, T.; Gu, H.M. Life Cycle Assessment of Cross-Laminated Timber Transportation from Three Origin Points. Sustainability 2022, 14, 336. [Google Scholar] [CrossRef]

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Blengini, G.A.; Di Carlo, T. The changing role of life cycle phases, subsystems and materials in the LCA of low energy buildings. Energy Build. 2010, 42, 869–880. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S.H. Environmental life cycle assessment of a commercial office building in Thailand. Int. J. Life Cycle Assess. 2008, 13, 498–511. [Google Scholar] [CrossRef]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA based comparative case study in the U.S. Pacific Northwest. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Marjaba, G.E.; Chidiac, S.E. Sustainability and resiliency metrics for buildings—Critical review. Build. Environ. 2016, 101, 116–125. [Google Scholar] [CrossRef]

- Hemmati, M.; Messadi, T.; Gu, H.; Seddelmeyer, J.; Hemmati, M. Comparison of Embodied Carbon Footprint of a Mass Timber Building Structure with a Steel Equivalent. Buildings 2024, 14, 1276. [Google Scholar] [CrossRef]

- Hafner, A. Contribution of timber buildings on sustainability issues. World Sustain. Build. 2014, 4. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C4&q=.+Contribution+of+timber+buildings+on+sustainability+issues&btnG= (accessed on 5 March 2024).

- Vidal, R.; Sánchez-Pantoja, N.; Martínez, G. Life cycle assessment of a residential building with cross-laminated timber structure in Granada-Spain. Inf. Constr. 2019, 71, 289. [Google Scholar] [CrossRef]

- Quintana-Gallardo, A.; Schau, E.M.; Niemelä, E.P.; Burnard, M.D. Comparing the environmental impacts of wooden buildings in Spain, Slovenia, and Germany. J. Clean. Prod. 2021, 329, 129587, Erratum in J. Clean. Prod. 2022, 331, 129984. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.; Lee, S. Optimal Design of Truss Structures for Sustainable Carbon Emission Reduction in Korean Construction. Sustainability 2024, 16, 5830. [Google Scholar] [CrossRef]

- Felmer, G.; Morales-Vera, R.; Astroza, R.; González, I.; Puettmann, M.; Wishnie, M. A Lifecycle Assessment of a Low-Energy Mass-Timber Building and Mainstream Concrete Alternative in Central Chile. Sustainability 2022, 14, 1249. [Google Scholar] [CrossRef]

- Chen, Z.J.; Gu, H.M.; Bergman, R.D.; Liang, S.B. Comparative Life-Cycle Assessment of a High-Rise Mass Timber Building with an Equivalent Reinforced Concrete Alternative Using the Athena Impact Estimator for Buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Greene, J.M.; Hosanna, H.R.; Willson, B.; Quinn, J.C. Whole life embodied emissions and net-zero emissions potential for a mid-rise office building constructed with mass timber. Sustain. Mater. Technol. 2023, 35, e00528. [Google Scholar] [CrossRef]

- Hacker, J.N.; De Saulles, T.P.; Minson, A.J.; Holmes, M.J. Embodied and operational carbon dioxide emissions from housing: A case study on the effects of thermal mass and climate change. Energy Build. 2008, 40, 375–384. [Google Scholar] [CrossRef]

- Bejo, L. Operational vs. Embodied Energy: A Case for Wood Construction. Drv. Ind. 2017, 68, 163–172. [Google Scholar] [CrossRef]

- Takano, A.; Hafner, A.; Linkosalmi, L.; Ott, S.; Hughes, M.; Winter, S. Life cycle assessment of wood construction according to the normative standards. Eur. J. Wood Wood Prod. 2015, 73, 299–312. [Google Scholar] [CrossRef]

- Dong, Y.; Qin, T.; Zhou, S.; Huang, L.; Bo, R.; Guo, H.; Yin, X. Comparative Whole Building Life Cycle Assessment of Energy Saving and Carbon Reduction Performance of Reinforced Concrete and Timber Stadiums-A Case Study in China. Sustainability 2020, 12, 1566. [Google Scholar] [CrossRef]

- Duan, Z.C. Impact of climate change on the life cycle greenhouse gas emissions of cross-laminated timber and reinforced concrete buildings in China. J. Clean. Prod. 2023, 395, 136446. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Effect of thermal mass on life cycle primary energy balances of a concrete-and a wood-frame building. Appl. Energy 2012, 92, 462–472. [Google Scholar] [CrossRef]

- Xue, Z.Y.; Liu, H.B.; Zhang, Q.X.; Wang, J.X.; Fan, J.L.; Zhou, X. The Impact Assessment of Campus Buildings Based on a Life Cycle Assessment-Life Cycle Cost Integrated Model. Sustainability 2020, 12, 294. [Google Scholar] [CrossRef]

- Chung, M.H.; Rhee, E.K. Potential opportunities for energy conservation in existing buildings on university campus: A field survey in Korea. Energy Build. 2014, 78, 176–182. [Google Scholar] [CrossRef]

- Anand, C.K.; Bisaillon, V.; Webster, A.; Amor, B. Integration of sustainable development in higher education—A regional initiative in Quebec (Canada). J. Clean. Prod. 2015, 108, 916–923. [Google Scholar] [CrossRef]

- Findler, F.; Schönherr, N.; Lozano, R.; Stacherl, B. Assessing the Impacts of Higher Education Institutions on Sustainable Development-An Analysis of Tools and Indicators. Sustainability 2019, 11, 59. [Google Scholar] [CrossRef]

- Del Borghi, A.; Spiegelhalter, T.; Moreschi, L.; Gallo, M. Carbon-Neutral-Campus Building: Design Versus Retrofitting of Two University Zero Energy Buildings in Europe and in the United States. Sustainability 2021, 13, 9023. [Google Scholar] [CrossRef]

- Legorburu, G.; Smith, A.D. Incorporating observed data into early design energy models for life cycle cost and carbon emissions analysis of campus buildings. Energy Build. 2020, 224, 110279. [Google Scholar] [CrossRef]

- Busaeri, N.; Hiron, N.; Giriantari, I.A.D.; Ariastina, W.G.; Swamardika, I.B.A. Green Campus Establishment Through Carbon Emission and Energy Efficiency Control. In Proceedings of the 2021 International Conference on Smart-Green Technology in Electrical and Information Systems (ICSGTEIS), Sanur, Bali, Indonesia, 28–30 October 2021; pp. 106–111. [Google Scholar]

- Save, P.; Cavka, B.T.; Froese, T. Evaluation and Lessons Learned from a Campus as a Living Lab Program to Promote Sustainable Practices. Sustainability 2021, 13, 1739. [Google Scholar] [CrossRef]

- Sustainability. Available online: https://sustainability.uark.edu/ (accessed on 2 March 2024).

- Ascione, F.; Bianco, N.; De Masi, R.F.; Vanoli, G.P. Rehabilitation of the building envelope of hospitals: Achievable energy savings and microclimatic control on varying the HVAC systems in Mediterranean climates. Energy Build. 2013, 60, 125–138. [Google Scholar] [CrossRef]

- DIN V 4108; Wärmeschutz und Energie-Einsparung in Gebäuden–Berechnung des Jahresheizwärme-und des Jahresheizenergiebedarfs. Beuth: Berlin, Germany, 2003.

- Ramon, D.; Allacker, K.; Trigaux, D.; Wouters, H.; van Lipzig, N.P.M. Dynamic modelling of operational energy use in a building LCA: A case study of a Belgian office building. Energy Build. 2023, 278, 112634. [Google Scholar] [CrossRef]

- Mansourihanis, O.; Tilaki, M.J.M.; Yousefian, S.; Zaroujtaghi, A. A Computational Geospatial Approach to Assessing Land-Use Compatibility in Urban Planning. Land 2023, 12, 2083. [Google Scholar] [CrossRef]

- Wang, S.; Huang, X.; Liu, P.; Zhang, M.; Biljecki, F.; Hu, T.; Fu, X.; Liu, L.; Liu, X.; Wang, R.; et al. Mapping the landscape and roadmap of geospatial artificial intelligence (GeoAI) in quantitative human geography: An extensive systematic review. Int. J. Appl. Earth Obs. Geoinf. 2024, 128, 103734. [Google Scholar] [CrossRef]

- Cuerda, E.; Guerra-Santin, O.; Sendra, J.; Neila, F. Understanding the performance gap in energy retrofitting: Measured input data for adjusting building simulation models. Energy Build. 2020, 209, 109688. [Google Scholar] [CrossRef]

- La Fleur, L.; Moshfegh, B.; Rohdin, P. Measured and predicted energy use and indoor climate before and after a major renovation of an apartment building in Sweden. Energy Build. 2017, 146, 98–110. [Google Scholar] [CrossRef]

- Balaras, C.; Dascalaki, E.; Droutsa, K.; Kontoyiannidis, S. Empirical assessment of calculated and actual heating energy use in Hellenic residential buildings. Appl. Energy 2016, 164, 115–132. [Google Scholar] [CrossRef]

- Wang, D.; Pang, X.; Wang, W.; Qi, Z.; Ji, Y.; Yin, R. Evaluation of the dynamic energy performance gap of green buildings: Case studies in China. Build. Simul. 2020, 13, 1191–1204. [Google Scholar] [CrossRef]

- Sun, K.; Hong, T.; Kim, J.; Hooper, B. Application and evaluation of a pattern-based building energy model calibration method using public building datasets. Build. Simul. 2022, 15, 1385–1400. [Google Scholar] [CrossRef]

- Hong, T.; Langevin, J.; Sun, K. Building simulation: Ten challenges. Build. Simul. 2018, 11, 871–898. [Google Scholar] [CrossRef]

- Yoshino, H.; Hong, T.; Nord, N. IEA EBC annex 53: Total energy use in buildings Analysis and evaluation methods. Energy Build. 2017, 152, 124–136. [Google Scholar] [CrossRef]

- Yin, L.; Shaw, S.-L.; Yu, H. Potential effects of ICT on face-to-face meeting opportunities: A GIS-based time-geographic approach. J. Transp. Geogr. 2011, 19, 422–433. [Google Scholar] [CrossRef]

- Zabalza, I.; Scarpellini, S.; Aranda, A.; Llera, E.; Jáñez, A. Use of LCA as a Tool for Building Ecodesign. A Case Study of a Low Energy Building in Spain. Energies 2013, 6, 3901–3921. [Google Scholar] [CrossRef]

- Kurian, R.; Kulkarni, K.; Ramani, P.; Meena, C.; Kumar, A.; Cozzolino, R. Estimation of Carbon Footprint of Residential Building in Warm Humid Climate of India through BIM. Energies 2021, 14, 4237. [Google Scholar] [CrossRef]

- Leal, W.; Vidal, D.; Dinis, M.; Lambrechts, W.; Vasconcelos, C.; Molthan-Hill, P.; Abubakar, I.; Dunk, R.; Salvia, A. Low carbon futures: Assessing the status of decarbonisation efforts at universities within a 2050 perspective. Energy Sustain. Soc. 2023, 13, 5. [Google Scholar] [CrossRef]

- Dibazar, A.S.; Aliasghar, A.; Behzadnezhad, A.; Shakiba, A.; Pazoki, M. Energy cycle assessment of bioethanol production from sugarcane bagasse by life cycle approach using the fermentation conversion process. Biomass Convers. Biorefin. 2023, 20, 1–20. [Google Scholar] [CrossRef]

- Sadeghi, M.; Naghedi, R.; Behzadian, K.; Shamshirgaran, A.; Tabrizi, M.R.; Maknoon, R. Customisation of green buildings assessment tools based on climatic zoning and experts judgement using K-means clustering and fuzzy AHP. Build. Environ. 2022, 223, 109473. [Google Scholar] [CrossRef]

- Cornago, S.; Tan, Y.S.; Ramakrishna, S.; Low, J.S.C. Temporal hotspot identification using dynamic life cycle inventory: Which are the critical time-spans within the product life cycle? Procedia CIRP 2022, 105, 249–254. [Google Scholar] [CrossRef]

- Delehan, S.; Vilceková, S.; Melehanych, H.; Burdová, E.; Khorolskyi, A. A comparative assessment of the capabilities and success of the wood construction industry in Slovakia and Ukraine based on life cycle assessment certification standards. Front. Environ. Sci. 2024, 12, 1319823. [Google Scholar] [CrossRef]

- Schenk, D.; Amiri, A. Life cycle energy analysis of residential wooden buildings versus concrete and steel buildings: A review. Front. Built Environ. 2022, 8, 975071. [Google Scholar] [CrossRef]

- PRé. Sustainability That Makes a Difference. 2024. Available online: https://www.pre-sustainability.com/ (accessed on 5 March 2024).

- Ciroth, A. Software for life cycle assessment. In Life Cycle Assessment Handbook; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 143–157. [Google Scholar]

- LTS. DATASMART LCI Package. Available online: https://longtrailsustainability.com/software/datasmart-life-cycle-inventory/ (accessed on 2 February 2024).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- U.S. Life Cycle Inventory Database. Available online: https://www.lcacommons.gov/nrel/search (accessed on 2 February 2024).

- Ortiz, O.; Castells, F.; Sonnemann, G. Operational energy in the life cycle of residential dwellings: The experience of Spain and Colombia. Appl. Energy 2010, 87, 673–680. [Google Scholar] [CrossRef]

- Bare, J.; Young, D.; Qam, S.; Hopton, M.; Chief, S. Tool for the Reduction and Assessment of Chemical and other Environmental Impacts (TRACI); US Environmental Protection Agency: Washington, DC, USA, 2012.

- Hemmati, M.; Messadi, T.; Gu, H. Life Cycle Assessment of the Construction Process in a Mass Timber Structure. Sustainability 2024, 16, 262. [Google Scholar] [CrossRef]

- Climate Zones Buildings. Available online: https://www.energy.gov/eere/buildings/climate-zones (accessed on 22 May 2024).

- BS ISO EN 15978: 2011; Sustainability of Construction Works-Assessment of Environmental Performance of Buildings-Calculation Method. British Standards Institution: London, UK, 2011.

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Management. ISO: Geneva, Switzerland, 2006.

- Saturated Steam—Properties—Imperial Units. Available online: https://www.engineeringtoolbox.com/saturated-steam-properties-d_273.html (accessed on 10 February 2024).

- Water and Sewer Operations. Available online: https://www.fayetteville-ar.gov/426/Water-and-Sewer-Operations (accessed on 2 February 2024).

- About SWEPCO. Available online: www.swepco.com/lib/docs/company/about/SWEPCO_Fact%20Sheet_2024_03112024.pdf (accessed on 22 May 2024).

- Wang, Y.; Bermukhambetova, A.; Wang, J.-H.; Donner, M.; Lv, J.-F.; Gao, Q.-R. Modelling of the whole process of a university campus CHP power plant and dynamic performance study. Int. J. Autom. Comput. 2016, 13, 53–63. [Google Scholar] [CrossRef]

- Louisiana Public Service Commission Approves SWEPCO Renewable Projects. Available online: https://www.swepco.com/company/news/view?releaseID=9011 (accessed on 22 May 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).