Performance and Sustainability of Organic and Conventional Cotton Farming Systems in Egypt: An Environmental and Energy Assessment

Abstract

:1. Introduction

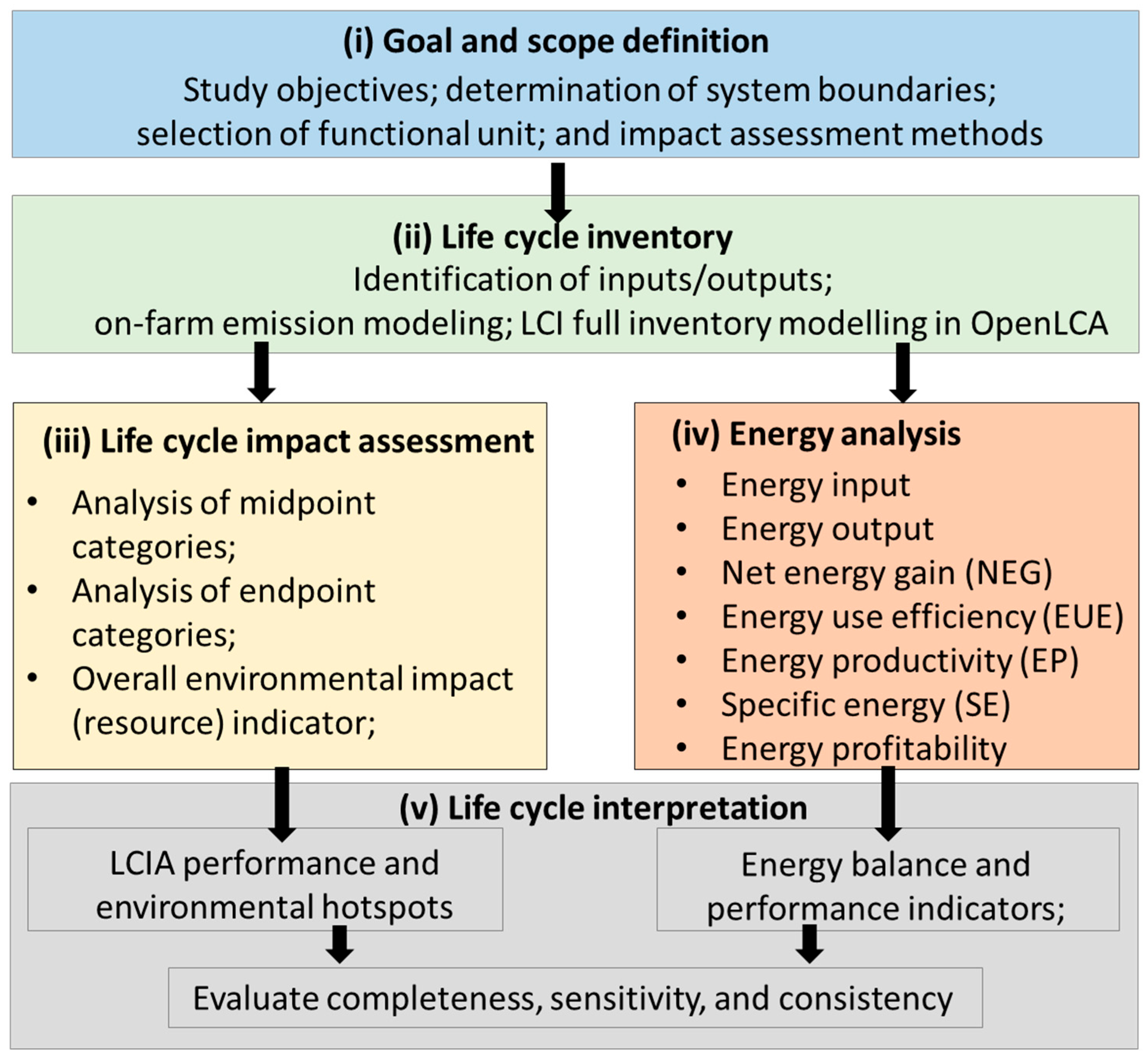

2. Materials and Methods

2.1. Goal and Scope

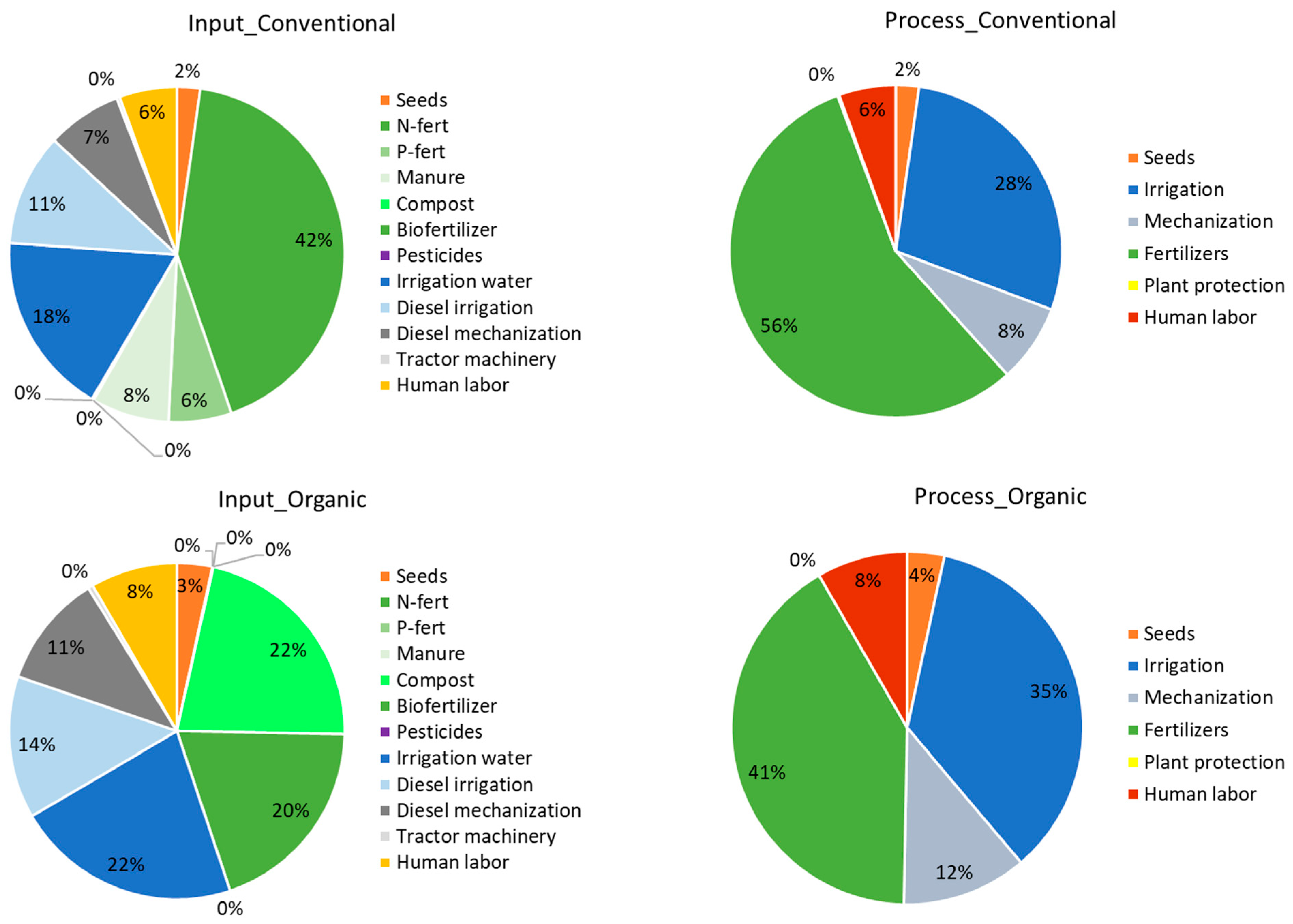

2.2. Life Cycle Inventory

2.2.1. On-Farm (Foreground) Emissions

2.2.2. Off-Farm (Background) Emissions

2.3. Life Cycle Impact Assessment (LCIA)

2.4. Energy Analysis and Performance Indices

3. Results

3.1. Energy Balance Performance Indicators

| Author | Year | Country | Energy Input (MJ ha−1) | EUE | EP (kg MJ−1) | SE (MJ kg−1) | Direct/Indirect | Renewable/Non-Renewable | Primary Hotspot * | Secondary Hotspot * |

|---|---|---|---|---|---|---|---|---|---|---|

| Tsatsarelis [12] | 1991 | Greece | 82,600 | 0.19 | 0.012 | 80.64 | - | - | EFI (44%) | F (23.5%) |

| Yilmaz et al. [13] | 2005 | Türkiye | 49,736.9 | 0.74 | 0.06 | 15.97 | 42.5%/57.5%) | 12.6%/87.4% | DF (31.1%) | F (28.8%) |

| Dagistan et al. [43] | 2009 | Türkiye | 19,558 | 2.36 | 0.2 | 4.99 | 28.87%/71.13% | 12.3%/87.7% | CF (45.31%) | IW (22.37%) |

| Khan et al. [46] | 2009 | China | 34,322.40 | 1.51 | 0.21 | 4.78 | 11%/89% | 12.3%/87.7% | CF (75.6%) | HL (11%) |

| Zahedi et al. [44] | 2014 | Iran | 52,507.8 | 0.7 | 0.1 | 19.2 | 68.3%/31.7% | 22.3%/77.7% | DF (47.4%) | F (19.8%) |

| Sami and Reyhani [16] | 2018 | Iran | 34,424 | 1.21 | 0.1 | 9.8 | 29.8%/70.2% | 10.8%/89.2% | CF (44.7%) | DF (18.4%) |

| Kazemi et al. [17] | 2018 | Iran | 31,860.6–36,189.03 | 0.942–1.106 | 0.079–0.0937 | 10.67–12.53 | 68.08%/31.92% | 6.89%/93.11% | DF (39%) | IW (20.41%) |

| Imran et al. [19] | 2020 | Pakistan | 58,374.07 | 0.70 | 0.04 | 20.28 | 61.23%/38.77% | 34.7%/65.3% | CF (22.43%) | IW (20.85%) |

| Baran et al. [14] | 2021 | Türkiye | 54, 617.62 | 1.21 | 0.21 | 9.77 | 67.43%/32.57% | 7.62%/92.38% | EFI (34.06%) | CF (27.93%) |

| Singh et al. [18] | 2022 | India | 23,960 | 3.1 | 0.083 | 13.0 | 49.6%/50.4% | 25%/75% | CF (44.3%) | IW (17.8%) |

| Abbas [20] | 2022 | Pakistan | 30,744.99 | 1.53 | 0.13 | 7.69 | 55.66%/44.34% | 21.05%/78.95% | CF (37%) | DF (36%) |

| Aytop [15] | 2023 | Türkiye | 83,869.49 | 0.87 | 0.07 | 17.31 | 48.01%/51.99% | 89.96%/10.04% | MCH (28.69%) | EFI (22.79%) |

| Ranguwal et al. [45] | 2023 | India | 23,022.71 | 7.79 | n.a. | 10.23 | 68%/32% | 4%/96% | DF (>60%) | CF (<25%) |

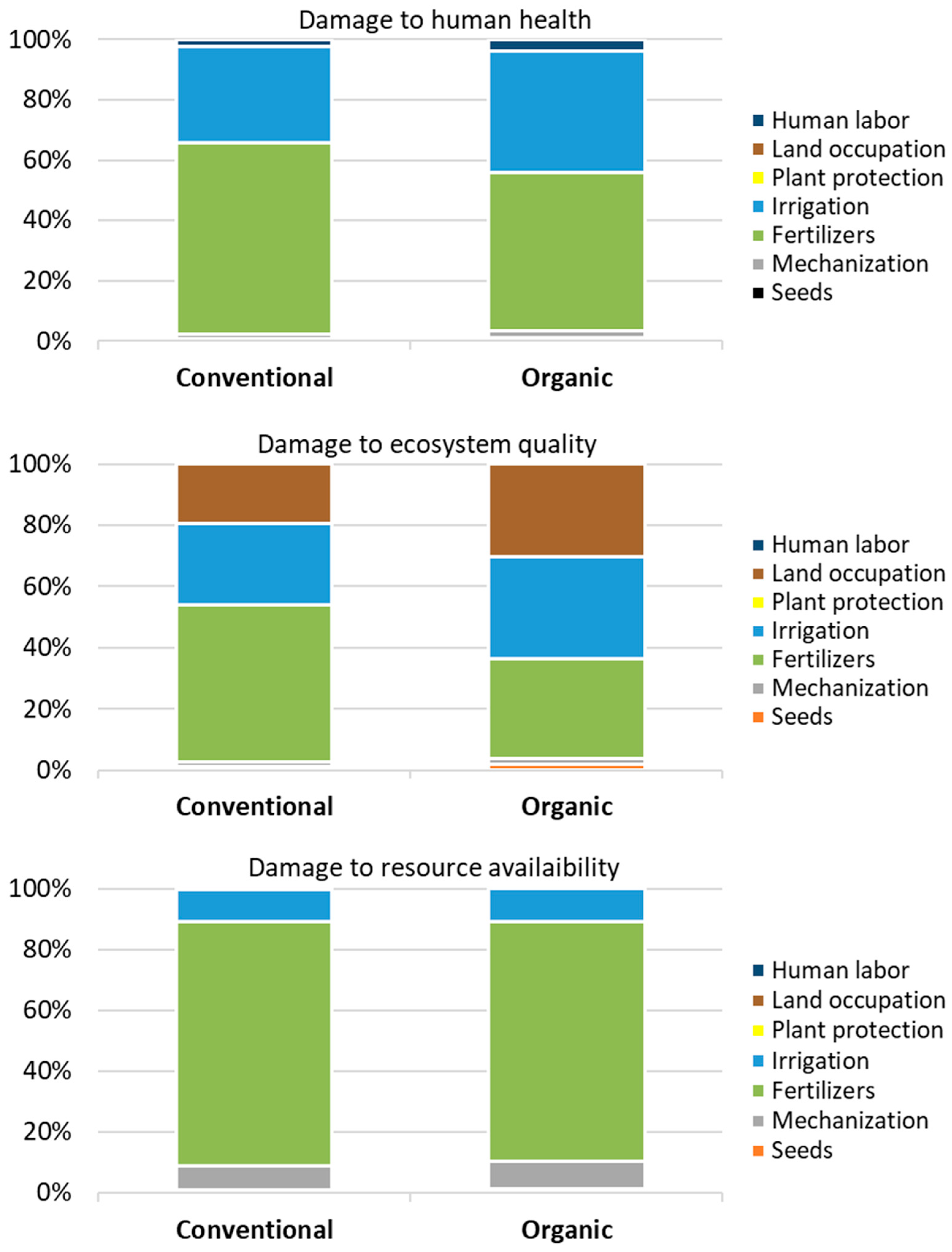

3.2. Midpoint and Endpoint Environmental Impacts

3.3. Total Environmental Impact—Single Score Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DALY | Disability-Adjusted Life Year |

| EOFP | Ecosystem ozone formation |

| EUE | Energy use efficiency |

| EP | Energy productivity |

| FEP | Freshwater eutrophication |

| FFP | Fossil fuel scarcity |

| GWP | Global Warming |

| HOFP | Human health ozone formation |

| HTPc | Human carcinogenic toxicity |

| HTPnc | Human non-carcinogenic toxicity |

| IRP | Ionizing radiation |

| ISO | International Organization for Standardization |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Costing |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| LU | Land use |

| MEP | Marine eutrophication |

| METP | Marine ecotoxicity |

| ODP | Stratospheric ozone depletion |

| PMPF | Particulate matter formation |

| SE | Specific energy |

| SOP | Mineral resource scarcity |

| TAP | Terrestrial acidification |

| TETP | Terrestrial ecotoxicity |

| WCP | Water consumption |

| 1.4-DB Eq. | 14 Dichlorobenzene equivalent |

References

- Long, L.; Zhao, X.-T.; Feng, Y.-M.; Fan, Z.-H.; Zhao, J.-R.; Wu, J.-F.; Xu, F.-C.; Yuan, M.; Gao, W. Profile of Cotton Flavonoids: Their Composition and Important Roles in Development and Adaptation to Adverse Environments. Plant Physiol. Biochem. 2023, 201, 107866. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Wahid, A.; Ahmad, M.; Tahir, M.T.; Ahmed, M.; Ahmad, S.; Hasanuzzaman, M. World Cotton Production and Consumption: An Overview. In Cotton Production and Uses; Springer: Singapore, 2020; pp. 1–7. [Google Scholar]

- OECD/FAO. OECD-FAO Agricultural Outlook 2023–2032; OECD-FAO Agricultural Outlook; OECD: Paris, France, 2023; ISBN 9789264619333. [Google Scholar]

- Naderi Mahdei, K.; Esfahani, S.M.J.; Lebailly, P.; Dogot, T.; Van Passel, S.; Azadi, H. Environmental Impact Assessment and Efficiency of Cotton: The Case of Northeast Iran. Environ. Dev. Sustain. 2022, 25, 10301–10321. [Google Scholar] [CrossRef]

- Delate, K.; Heller, B.; Shade, J. Organic Cotton Production May Alleviate the Environmental Impacts of Intensive Conventional Cotton Production. Renew. Agric. Food Syst. 2021, 36, 405–412. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, J.; Yao, Y.; Peters, G.; Macdonald, B.; La Rosa, A.D.; Wang, Z.; Scherer, L. Environmental Impacts of Cotton and Opportunities for Improvement. Nat. Rev. Earth Environ. 2023, 4, 703–715. [Google Scholar] [CrossRef]

- Tuomisto, H.L.; Hodge, I.D.; Riordan, P.; Macdonald, D.W. Does Organic Farming Reduce Environmental Impacts?—A Meta-Analysis of European Research. J. Environ. Manag. 2012, 112, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Eyhorn, F.; Muller, A.; Reganold, J.P.; Frison, E.; Herren, H.R.; Luttikholt, L.; Mueller, A.; Sanders, J.; Scialabba, N.E.-H.; Seufert, V.; et al. Sustainability in Global Agriculture Driven by Organic Farming. Nat. Sustain. 2019, 2, 253–255. [Google Scholar] [CrossRef]

- Muneret, L.; Mitchell, M.; Seufert, V.; Aviron, S.; Djoudi, E.A.; Pétillon, J.; Plantegenest, M.; Thiéry, D.; Rusch, A. Evidence That Organic Farming Promotes Pest Control. Nat. Sustain. 2018, 1, 361–368. [Google Scholar] [CrossRef]

- van der Werf, H.M.G.; Knudsen, M.T.; Cederberg, C. Towards Better Representation of Organic Agriculture in Life Cycle Assessment. Nat. Sustain. 2020, 3, 419–425. [Google Scholar] [CrossRef]

- Hercher-Pasteur, J.; Loiseau, E.; Sinfort, C.; Hélias, A. Energetic Assessment of the Agricultural Production System. A Review. Agron. Sustain. Dev. 2020, 40, 29. [Google Scholar] [CrossRef]

- Tsatsarelis, C.A. Energy Requirements for Cotton Production in Central Greece. J. Agric. Eng. Res. 1991, 50, 239–246. [Google Scholar] [CrossRef]

- Yilmaz, I.; Akcaoz, H.; Ozkan, B. An Analysis of Energy Use and Input Costs for Cotton Production in Turkey. Renew. Energy 2005, 30, 145–155. [Google Scholar] [CrossRef]

- Baran, M.F.; Gökdoğan, O.; Bayhan, Y. Determination of Energy Balance and Greenhouse Gas Emissions (GHG) of Cotton Cultivation in Turkey: A Case Study from Bismil District of Diyarbakır Province. J. Tekirdag Agric. Fac. 2021, 18, 322–332. [Google Scholar] [CrossRef]

- Aytop, Y. Determination of Energy Consumption and Technical Efficiency of Cotton Farms in Türkiye. Sustainability 2023, 15, 11194. [Google Scholar] [CrossRef]

- Sami, M.; Reyhani, H. Energy and Greenhouse Gases Balances of Cotton Farming in Iran: A Case Study. Acta Univ. Agric. Silvic. Mendel. Brun. 2018, 66, 101–109. [Google Scholar] [CrossRef]

- Kazemi, H.; Shokrgozar, M.; Kamkar, B.; Soltani, A. Analysis of Cotton Production by Energy Indicators in Two Different Climatic Regions. J. Clean. Prod. 2018, 190, 729–736. [Google Scholar] [CrossRef]

- Singh, P.; Singh, G.; Sodhi, G.P.S. Data Envelopment Analysis Based Optimization for Improving Net Ecosystem Carbon and Energy Budget in Cotton (Gossypium hirsutum L.) Cultivation: Methods and a Case Study of North-Western India. Environ. Dev. Sustain. 2022, 24, 2079–2119. [Google Scholar] [CrossRef]

- Imran, M.; Özçatalbaş, O.; Bashir, M.K. Estimation of Energy Efficiency and Greenhouse Gas Emission of Cotton Crop in South Punjab, Pakistan. J. Saudi Soc. Agric. Sci. 2020, 19, 216–224. [Google Scholar] [CrossRef]

- Abbas, A.; Zhao, C.; Waseem, M.; Ahmed khan, K.; Ahmad, R. Analysis of Energy Input–Output of Farms and Assessment of Greenhouse Gas Emissions: A Case Study of Cotton Growers. Front. Environ. Sci. 2022, 9, 826838. [Google Scholar] [CrossRef]

- Huang, W.; Wu, F.; Han, W.; Li, Q.; Han, Y.; Wang, G.; Feng, L.; Li, X.; Yang, B.; Lei, Y.; et al. Carbon Footprint of Cotton Production in China: Composition, Spatiotemporal Changes and Driving Factors. Sci. Total Environ. 2022, 821, 153407. [Google Scholar] [CrossRef]

- Boschiero, M.; De Laurentiis, V.; Caldeira, C.; Sala, S. Comparison of Organic and Conventional Cropping Systems: A Systematic Review of Life Cycle Assessment Studies. Environ. Impact Assess. Rev. 2023, 102, 107187. [Google Scholar] [CrossRef]

- Sala, S.; Amadei, A.M.; Beylot, A.; Ardente, F. The Evolution of Life Cycle Assessment in European Policies over Three Decades. Int. J. Life Cycle Assess. 2021, 26, 2295–2314. [Google Scholar] [CrossRef]

- Ullah, A.; Perret, S.R.; Gheewala, S.H.; Soni, P. Eco-Efficiency of Cotton-Cropping Systems in Pakistan: An Integrated Approach of Life Cycle Assessment and Data Envelopment Analysis. J. Clean. Prod. 2016, 134, 623–632. [Google Scholar] [CrossRef]

- Zhang, T.; Zhai, Y.; Ma, X.; Shen, X.; Bai, Y.; Zhang, R.; Ji, C.; Hong, J. Towards Environmental Sustainability: Life Cycle Assessment-Based Water Footprint Analysis on China’s Cotton Production. J. Clean. Prod. 2021, 313, 127925. [Google Scholar] [CrossRef]

- Avadí, A.; Marcin, M.; Biard, Y.; Renou, A.; Gourlot, J.-P.; Basset-Mens, C. Life Cycle Assessment of Organic and Conventional Non-Bt Cotton Products from Mali. Int. J. Life Cycle Assess. 2020, 25, 678–697. [Google Scholar] [CrossRef]

- Shah, P.; Bansal, A.; Singh, R.K. Life Cycle Assessment of Organic, BCI and Conventional Cotton: A Comparative Study of Cotton Cultivation Practices in India. In Designing Sustainable Technologies, Products and Policies; Springer International Publishing: Cham, Switzerland, 2018; pp. 67–77. [Google Scholar]

- Chen, F.; Ji, X.; Chu, J.; Xu, P.; Wang, L. A Review: Life Cycle Assessment of Cotton Textiles. Ind. Textila 2021, 72, 19–29. [Google Scholar] [CrossRef]

- Gonzalez, V.; Lou, X.; Chi, T. Evaluating Environmental Impact of Natural and Synthetic Fibers: A Life Cycle Assessment Approach. Sustainability 2023, 15, 7670. [Google Scholar] [CrossRef]

- Fidan, F.Ş.; Aydoğan, E.K.; Uzal, N. Recent Progress on Life Cycle Sustainability Assessment in Textile Industry: Applications for Environmental, Economic, and Social Impacts of Cotton and Its Derivatives. In Progress on Life Cycle Assessment in Textiles and Clothing; Springer: Singapore, 2023. [Google Scholar]

- Karkour, S.; Rachid, S.; Maaoui, M.; Lin, C.-C.; Itsubo, N. Status of Life Cycle Assessment (LCA) in Africa. Environments 2021, 8, 10. [Google Scholar] [CrossRef]

- Denora, M.; Candido, V.; D’Antonio, P.; Perniola, M.; Mehmeti, A. Precision Nitrogen Management in Rainfed Durum Wheat Cultivation: Exploring Synergies and Trade-Offs via Energy Analysis, Life Cycle Assessment, and Monetization. Precis. Agric. 2023, 24, 2566–2591. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Eyhorn, F.; Ratter, S.G.; Ramakrishnan, M. Organic Cotton Crop Guide Organic Cotton Crop Guide—A Manual for Practitioners in the Tropics; Research Institute of Organic Agriculture (FibL): Frick, Switzerland, 2005. [Google Scholar]

- Nemecek, T.; Kägi, T.; Dübendorf, Z. Life Cycle Inventories of Agricultural Production Systems Data v2.0 (2007); Ecoinvent Report No. 15; Agroscope: Reckenholz-Tänikon, Switzerland, 2007. [Google Scholar]

- CarbonCloud Calculating GHG Emissions at Farm-Gate. Available online: https://carboncloud.com/agricultural-model/ (accessed on 15 September 2023).

- Ecoinvent Database 3.1; Ecoinvent Centre: Zurich, Switzerland, 2014.

- Canaj, K.; Mehmeti, A.; Cantore, V.; Todorović, M. LCA of Tomato Greenhouse Production Using Spatially Differentiated Life Cycle Impact Assessment Indicators: An Albanian Case Study. Environ. Sci. Pollut. Res. 2020, 27, 6960–6970. [Google Scholar] [CrossRef]

- GreenDelta OpenLCA 1.11. Available online: https://www.openlca.org/download/ (accessed on 18 March 2024).

- Canaj, K.; Mehmeti, A. Analyzing the Water-Energy-Environment Nexus of Irrigated Wheat and Maize Production in Albania. Energy Nexus 2022, 7, 100100. [Google Scholar] [CrossRef]

- Alam, M.J.; Al Mahmud, A.; Gaber, A.; Hossain, A. Energy Efficiency and Water Use Indices for Sweet Potato (Ipomoea Batatas L.) Production under Subtropical Climatic Conditions of Bangladesh. J. Water Clim. Change 2023, 14, 576–589. [Google Scholar] [CrossRef]

- Amiryousefi, M.; Tadayon, M.R.; Ebrahimi, R. Energy and Exergy Efficiencies Assessment for Two Quinoa Cultivars Productions. Energy Rep. 2021, 7, 2324–2331. [Google Scholar] [CrossRef]

- Dagistan, E.; Akcaoz, H.; Demirtas, B.; Yilmaz, Y. Energy Usage and Benefit-Cost Analysis of Cotton Production in Turkey. Afr. J. Agric. Res. 2009, 4, 599–604. [Google Scholar]

- Zahedi, M.; Eshghizadeh, H.R.; Mondani, F. Energy Use Efficiency and Economical Analysis in Cotton Production System in an Arid Region: A Case Study for Isfahan Province, Iran. Int. J. Energy Econ. Policy 2014, 4, 43–52. [Google Scholar]

- Ranguwal, S.; Sidana, B.K.; Singh, J.; Sachdeva, J.; Kumar, S.; Sharma, R.K.; Dhillon, J. Quantifying the Energy Use Efficiency and Greenhouse Gas Emissions in Punjab (India) Agriculture. Energy Nexus 2023, 11, 100238. [Google Scholar] [CrossRef]

- Khan, M.; Khan, S.; Mushtag, S. Energy and Economic Efficiency Analysis of Rice and Cotton Production in China. Sahad J. Agric. 2009, 25, 291–300. [Google Scholar]

- Singh, R.; Agarwal, R.; Bos, U.; Kanekar, H. Life Cycle Assessment of Cotton Cultivation Systems—Better Cotton, Conventioal Cotton and Organic Cotton; Thinkstep Sustainability Solutions Pvt. Ltd., Study commissioned by C&A Foundation. 2018. Available online: https://www.laudesfoundation.org/media/43anrffi/4332-environmentall-care-port-june19.pdf (accessed on 18 March 2024).

- De la Cruz, V.Y.V.; Tantriani; Cheng, W.; Tawaraya, K. Yield Gap between Organic and Conventional Farming Systems across Climate Types and Sub-Types: A Meta-Analysis. Agric. Syst. 2023, 211, 103732. [Google Scholar] [CrossRef]

- Meier, M.S.; Stoessel, F.; Jungbluth, N.; Juraske, R.; Schader, C.; Stolze, M. Environmental Impacts of Organic and Conventional Agricultural Products—Are the Differences Captured by Life Cycle Assessment? J. Environ. Manag. 2015, 149, 193–208. [Google Scholar] [CrossRef]

- PE International. The Life Cycle Assessment of Organic Cotton Fiber Summary of Findings—A Global Average. 2014. Available online: https://www.ajsosteniblebcn.cat/the-life-cycle-assessment-of-organic-cotton-fiber_38172.pdf (accessed on 18 March 2024).

- Fidan, F.Ş. A Comparative Life Cycle Assessment of Conventional and Organic Cotton in Denim Fabric. Pharmacoecon. Theory Pract. 2017, 5, 1–8. [Google Scholar]

- Meemken, E.M.; Qaim, M. Organic Agriculture, Food Security, and the Environment. Annu. Rev. Resour. Econ. 2018, 10, 39–63. [Google Scholar] [CrossRef]

- Bilalis, D.; Patsiali, S.; Karkanis, A.; Konstantas, A.; Makris, M.; Efthimiadou, A. Effects of Cultural System (Organic and Conventional) on Growth and Fiber Quality of Two Cotton (Gossypium hirsutum L.) Varieties. Renew. Agric. Food Syst. 2010, 25, 228–235. [Google Scholar] [CrossRef]

- Bachmann, F. Potential and Limitations of Organic and Fair Trade Cotton for Improving Livelihoods of Smallholders: Evidence from Central Asia. Renew. Agric. Food Syst. 2012, 27, 138–147. [Google Scholar] [CrossRef]

- Riar, A.; Mandloi, L.S.; Sendhil, R.; Poswal, R.S.; Messmer, M.M.; Bhullar, G.S. Technical Efficiencies and Yield Variability Are Comparable across Organic and Conventional Farms. Sustainability 2020, 12, 4271. [Google Scholar] [CrossRef]

- Barahmand, Z.; Eikeland, M.S. Life Cycle Assessment under Uncertainty: A Scoping Review. World 2022, 3, 39. [Google Scholar] [CrossRef]

- da Silva Cardoso, A.; Junqueira, J.B.; Reis, R.A.; Ruggieri, A.C. How Do Greenhouse Gas Emissions Vary with Biofertilizer Type and Soil Temperature and Moisture in a Tropical Grassland? Pedosphere 2020, 30, 607–617. [Google Scholar] [CrossRef]

- Pajura, R.; Masłoń, A.; Czarnota, J. The Use of Waste to Produce Liquid Fertilizers in Terms of Sustainable Development and Energy Consumption in the Fertilizer Industry—A Case Study from Poland. Energies 2023, 16, 1747. [Google Scholar] [CrossRef]

- Kumar, S.; Diksha; Sindhu, S.S.; Kumar, R. Biofertilizers: An Ecofriendly Technology for Nutrient Recycling and Environmental Sustainability. Curr. Res. Microb. Sci. 2022, 3, 100094. [Google Scholar] [CrossRef]

- Alengebawy, A.; Mohamed, B.A.; Jin, K.; Liu, T.; Ghimire, N.; Samer, M.; Ai, P. A Comparative Life Cycle Assessment of Biofertilizer Production towards Sustainable Utilization of Anaerobic Digestate. Sustain. Prod. Consum. 2022, 33, 875–889. [Google Scholar] [CrossRef]

| Parameters | Process Modeled/ Compartment | Unit | Conventional Cotton | Organic Cotton |

|---|---|---|---|---|

| Resource and yield data 1 | ||||

| Crop yield | Cotton, EG | kg ha−1 | 3400 | 3364 |

| Seeds, for sowing | Market for cotton seed, for sowing | kg t−1 | 21 | 21.2 |

| Diesel Fuel | Diesel, burned in building machine | l t−1 | 14.1 | 14.2 |

| Lubricating oil | Market for lubricating oil | kg t−1 | 0.22 | 0.225 |

| Tractor work | market for tractor, 4-wheel, agricultural | hour t−1 | 1.11 | 1.112 |

| Ammonium nitrate, as N | Market for ammonium nitrate, as N | kg N t−1 | 70.7 | - |

| Superphosphate, as P2O5 | Single superphosphate production | kg P2O5 t−1 | 53.6 | - |

| Farmyard manure | Average digestate | kg t−1 | 2753 | - |

| Plant/Animal compost | Average compost, from green waste, biowaste, sludge, manure, slurry | kg t−1 | - | 4815.3 |

| Biofertilizers | kg t−1 | - | 71.3 | |

| Pesticides | Market for pesticide, unspecified | kg t−1 | 0.097 | - |

| Irrigation water | Water, river, EG | m3 t−1 | 1906 | 1565 |

| Diesel fuel for irrigation | Diesel, burned in building machine | MJ t−1 | 819 | 687.8 |

| Human labor | Carbon dioxide, to air | h t−1 | 310.5 | 314 |

| Emission to Environment 2 | ||||

| Ammonia | Emission to air, low population density | kg t−g | 18.13 | 17.39 |

| Benzo(a)pyrene | Emission to air, low population density | kg t−g | 3.52 × 10−7 | 3.87 × 10−7 |

| Cadmium | Emission to air, low population density | kg t−g | 1.17 × 10−7 | 1.29 × 10−7 |

| Carbon dioxide, fossil | Emission to air, low population density | kg t−g | 36.6190 | 40.2809 |

| Carbon monoxide, fossil | Emission to air, low population density | kg t−g | 0.134 | 0.146 |

| Chromium | Emission to air, low population density | kg t−g | 5.9 × 10−7 | 6.5 × 10−7 |

| Copper | Emission to air, low population density | kg t−g | 2 × 10−5 | 2.2 × 10−5 |

| Dinitrogen monoxide | Emission to air, low population density | kg t−g | 2.86 | 2.85 |

| Tetrachlorodibenzo-p-dioxin | Emission to air, low population density | kg t−g | 1.18 | 1.23 |

| Methane, fossil | Emission to air, low population density | kg t−g | 125.37 | 120.19 |

| Nickel | Emission to air, low population density | kg t−g | 125.11 | 119.97 |

| Nitrogen oxides | Emission to air, low population density | kg t−g | 5.61 | 6.11 |

| NMVOC | Emission to air, low population density | kg t−g | 124.98 | 119.82 |

| Polycyclic aromatic hydrocarbons | Emission to air, low population density | kg t−g | 0.19 | 0.21 |

| Particulates, <2.5 μm | Emission to air, low population density | kg t−g | 0.13 | 0.15 |

| Particulates, >10 μm | Emission to air, low population density | kg t−g | 0.29 | 0.17 |

| Particulates, >2.5 μm, and <10 μm | Emission to air, low population density | kg t−g | 0.0021 | 0.0023 |

| Selenium | Emission to air, low population density | kg t−g | 1.17 × 10−5 | 1.29 × 10−5 |

| Sulfur dioxide | Emission to air, low population density | kg t−g | 0.01 | 0.01 |

| Zinc | Emission to air, low population density | kg t−g | 1.17 × 10−5 | 1.29 × 10−5 |

| Nitrates | Emission to water, groundwater | kg t−g | 137.4 | 54.1 |

| Phosphate | Emission to water, groundwater | kg t−g | 0.095 | 0.095 |

| Phosphorus | Emission to water, surface water | kg t−g | 0.53 | 0.38 |

| Parameter | Energy Equivalents (MJ Unit−1) | Unit | References |

|---|---|---|---|

| Human labor | 1.96 | h | [40] |

| Seeds cotton | 11.8 | kg | [14,15] |

| Pesticide, unspecified | 193 | kg | [40] |

| Diesel fuel | 56.31 | Liter | [41] |

| Nitrogen (N) | 66.14 | MJ/kg | [41] |

| Phosphorus (P) | 12.44 | MJ/kg | [41] |

| Bio-fertilizers | 19.64 | MJ/kg | [42] |

| Farm manure/Compost | 0.3 | MJ/kg | [40] |

| Tractor machinery | 62.7 | kg | [40] |

| Water, irrigation | 1.03 | m3 | [40] |

| Cotton, yield | 11.8 | kg | [14,15,16,17,18,20,43,44] |

| Item | Unit | Conventional Cotton | Organic Cotton |

|---|---|---|---|

| Energy input | MJ ha−1 | 37,472 | 24,763 |

| Energy output | MJ ha−1 | 40,120 | 39,699 |

| Net energy gain (NEG) | MJ ha−1 | 2648 | 14,936 |

| Energy use efficiency (EUE) | - | 1.07 | 1.60 |

| Energy productivity (EP) | kg MJ−1 | 0.091 | 0.136 |

| Specific energy (SE) | MJ kg−1 | 11.02 | 7.36 |

| Energy profitability | - | 0.071 | 0.603 |

| Indicator | Unit | Conventional | Organic | ||

|---|---|---|---|---|---|

| 1 ton | 1 ha | 1 ton | 1 ha | ||

| Midpoint | |||||

| Fine particulate matter formation | kg PM2.5-eq | 5.56 | 18.89 | 4.41 | 14.82 |

| Fossil resource scarcity | kg oil-eq | 275.83 | 937.81 | 230.70 | 776.15 |

| Freshwater ecotoxicity | kg 1,4-DCB-eq | 45.44 | 154.49 | 30.41 | 102.31 |

| Freshwater eutrophication | kg P-eq | 0.59 | 1.99 | 0.45 | 1.50 |

| Global warming | kg CO2-eq | 2622.6 | 8916.8 | 2273.94 | 7650.22 |

| Human carcinogenic toxicity | kg 1,4-DCB-eq | 33.00 | 112.20 | 22.74 | 76.50 |

| Human non-carcinogenic toxicity | kg 1,4-DCB-eq | 1132.85 | 3851.69 | 722.24 | 2429.82 |

| Ionizing radiation | kBq Co-60-eq | 84.93 | 288.75 | 40.06 | 134.78 |

| Land use | m2a crop-eq | 1570.34 | 5339.16 | 1585.48 | 5334.02 |

| Marine ecotoxicity | kg 1,4-DCB-eq | 63.01 | 214.23 | 41.63 | 140.06 |

| Marine eutrophication | kg N-eq | 21.09 | 71.71 | 17.97 | 60.46 |

| Mineral resource scarcity | kg Cu-eq | 13.37 | 45.44 | 6.44 | 21.66 |

| Ozone formation, Human health | kg NOx-eq | 5.98 | 20.35 | 4.95 | 16.65 |

| Ozone formation, Terrestrial ecosystems | kg NOx-eq | 15.24 | 51.81 | 12.70 | 42.71 |

| Stratospheric ozone depletion | kg CFC11-eq | 0.06 | 0.21 | 0.06 | 0.19 |

| Terrestrial acidification | kg SO2-eq | 30.28 | 102.96 | 25.25 | 84.95 |

| Terrestrial ecotoxicity | kg 1,4-DCB-eq | 5339.10 | 18,152.93 | 4038.56 | 13,586.94 |

| Water consumption | m3 consumed | 2171.83 | 7384.21 | 1786.41 | 6010.01 |

| Indicator | Unit | Conventional | Organic | ||

|---|---|---|---|---|---|

| 1 ton | 1 ha | 1 ton | 1 ha | ||

| Endpoint | |||||

| Damage to human health | DALY | 0.0122 | 0.04144 | 0.0088 | 0.02957 |

| Damage to ecosystem quality | species.yr | 4.98 × 10−5 | 0.00017 | 3.66 × 10−5 | 0.00012 |

| Damage to resource availability | USD2013 | 104.64 | 355.76 | 88.33 | 297.16 |

| Strategy | Energy Use Efficiency (EUE) | Energy Productivity (EP) | Specific Energy (SE) | Total Environmental Impact (TEI) |

|---|---|---|---|---|

| Organic baseline | 1.60 | 0.136 | 7.36 | 150.7 |

| Conventional +10% yield | 1.17 | 0.099 | 10.13 | 214.3 |

| Conventional +20% yield | 1.27 | 0.108 | 9.28 | 196.5 |

| Conventional +30% yield | 1.38 | 0.117 | 8.57 | 181.4 |

| Conventional +40% yield | 1.48 | 0.126 | 7.96 | 168.4 |

| Conventional +50% yield | 1.59 | 0.135 | 7.43 | 157.2 |

| Conventional −20% fertilizer use | 1.19 | 0.101 | 9.92 | 206.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehmeti, A.; Abdelhafez, A.A.M.; Ellssel, P.; Todorovic, M.; Calabrese, G. Performance and Sustainability of Organic and Conventional Cotton Farming Systems in Egypt: An Environmental and Energy Assessment. Sustainability 2024, 16, 6637. https://doi.org/10.3390/su16156637

Mehmeti A, Abdelhafez AAM, Ellssel P, Todorovic M, Calabrese G. Performance and Sustainability of Organic and Conventional Cotton Farming Systems in Egypt: An Environmental and Energy Assessment. Sustainability. 2024; 16(15):6637. https://doi.org/10.3390/su16156637

Chicago/Turabian StyleMehmeti, Andi, Ahmed Abdelwahab M. Abdelhafez, Pierre Ellssel, Mladen Todorovic, and Generosa Calabrese. 2024. "Performance and Sustainability of Organic and Conventional Cotton Farming Systems in Egypt: An Environmental and Energy Assessment" Sustainability 16, no. 15: 6637. https://doi.org/10.3390/su16156637