AI-Driven Prediction of Compressive Strength in Self-Compacting Concrete: Enhancing Sustainability through Ultrasonic Measurements

Abstract

:1. Introduction

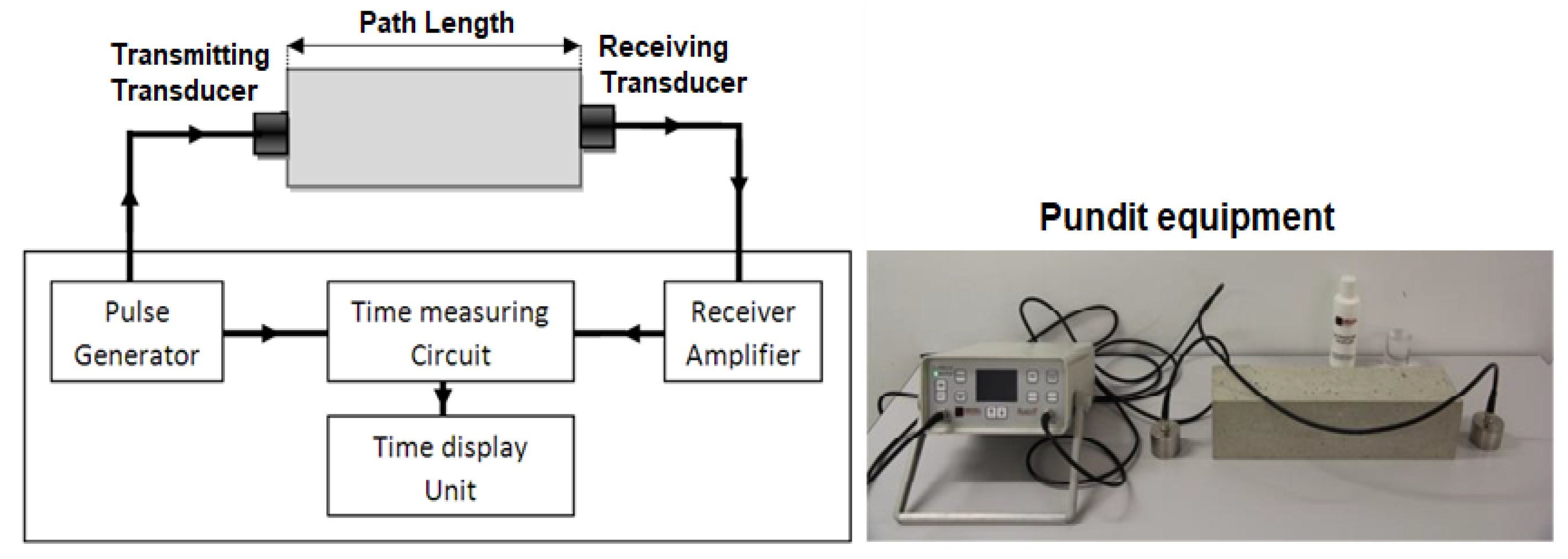

2. Application of Ultrasonic Testing

3. Analysis of ANNs Modeling

4. Results and Discussion

4.1. Materials and Mix Design

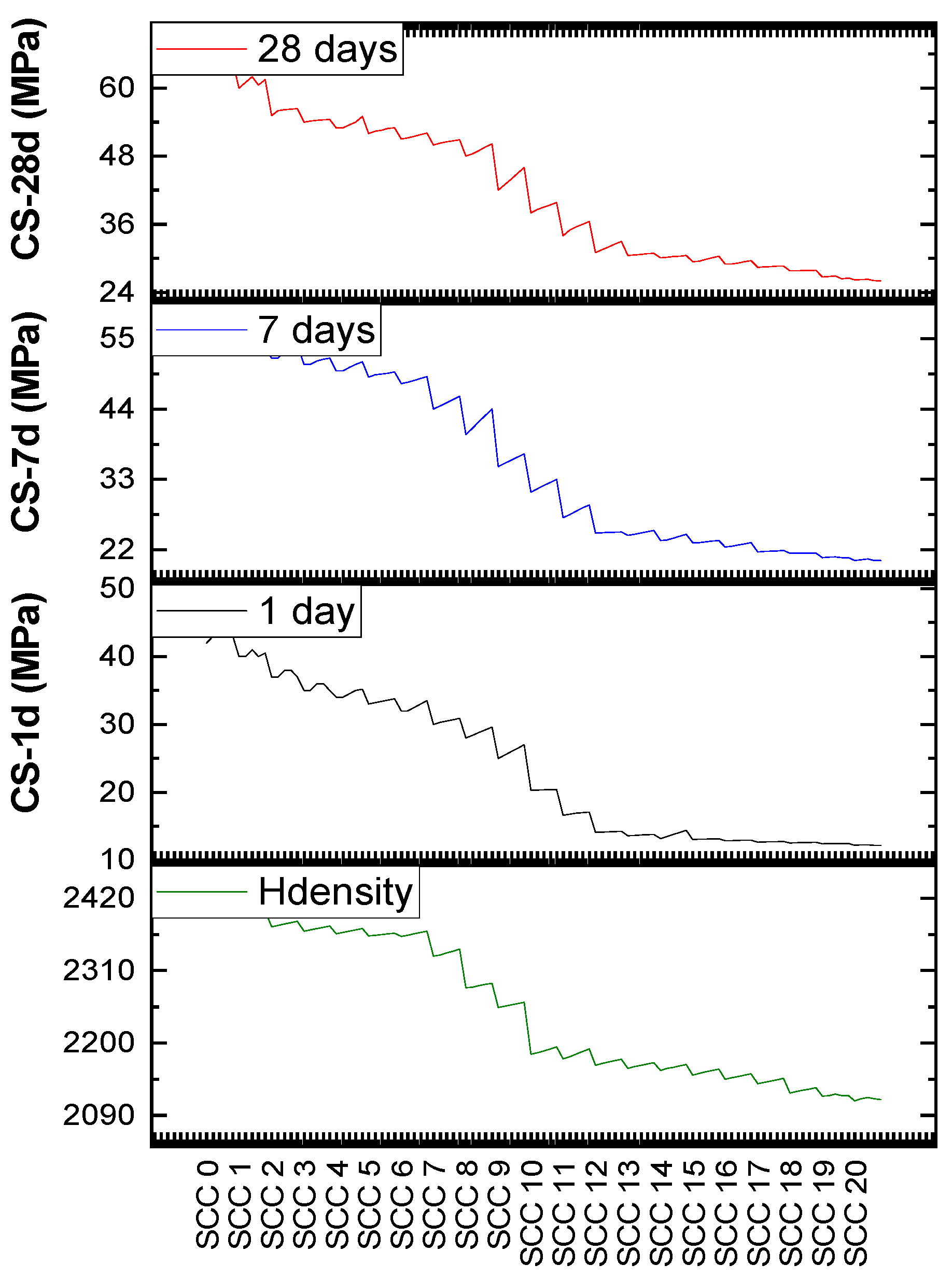

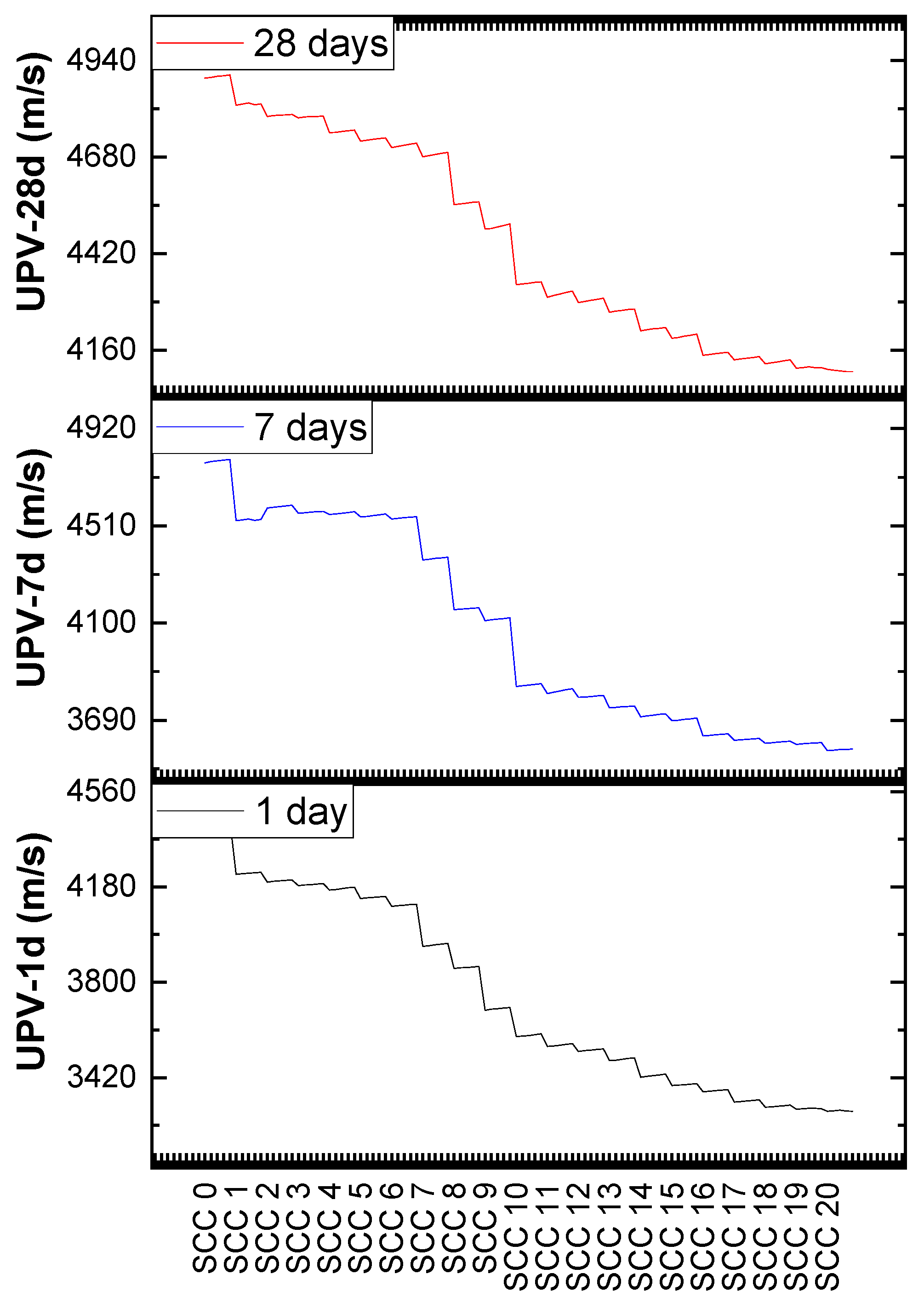

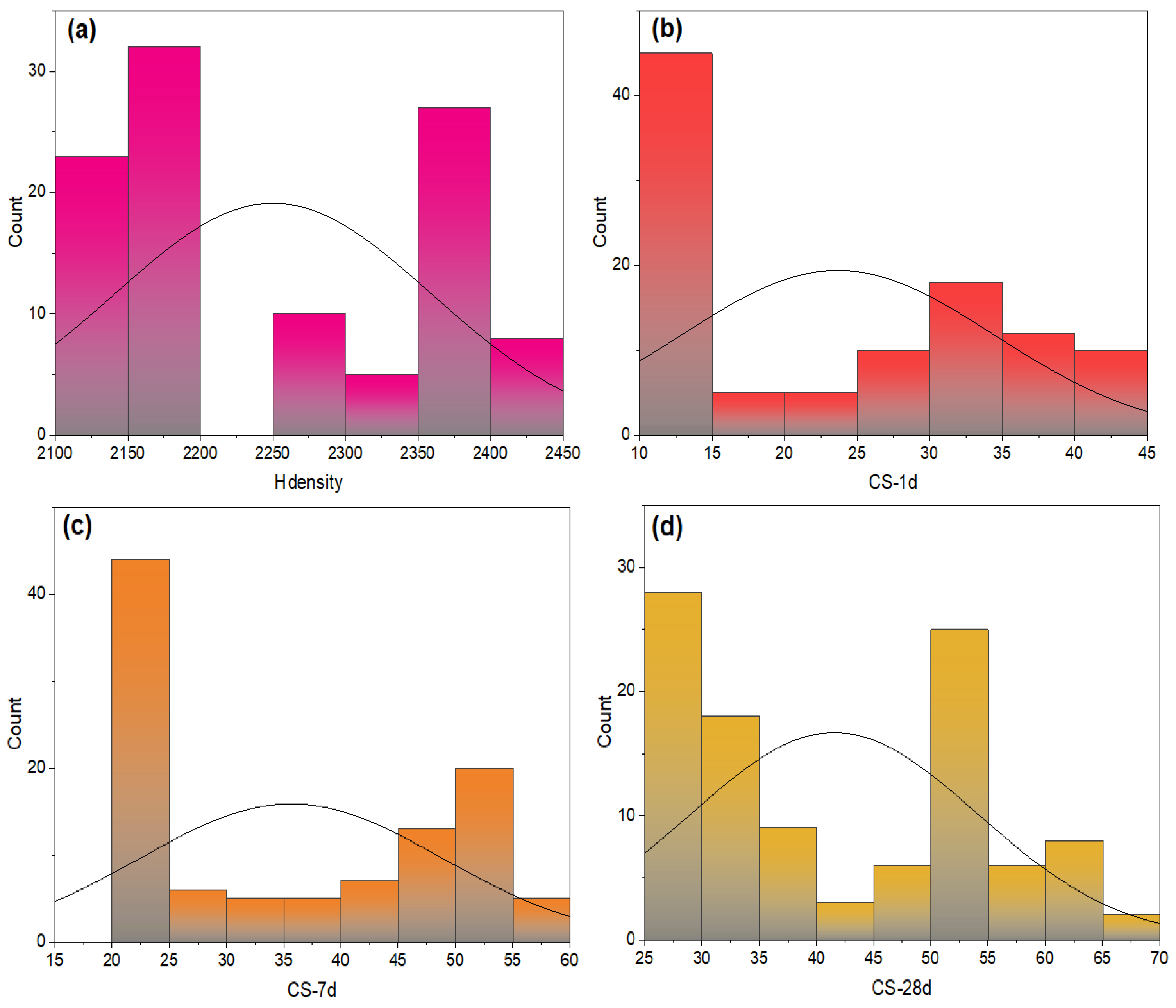

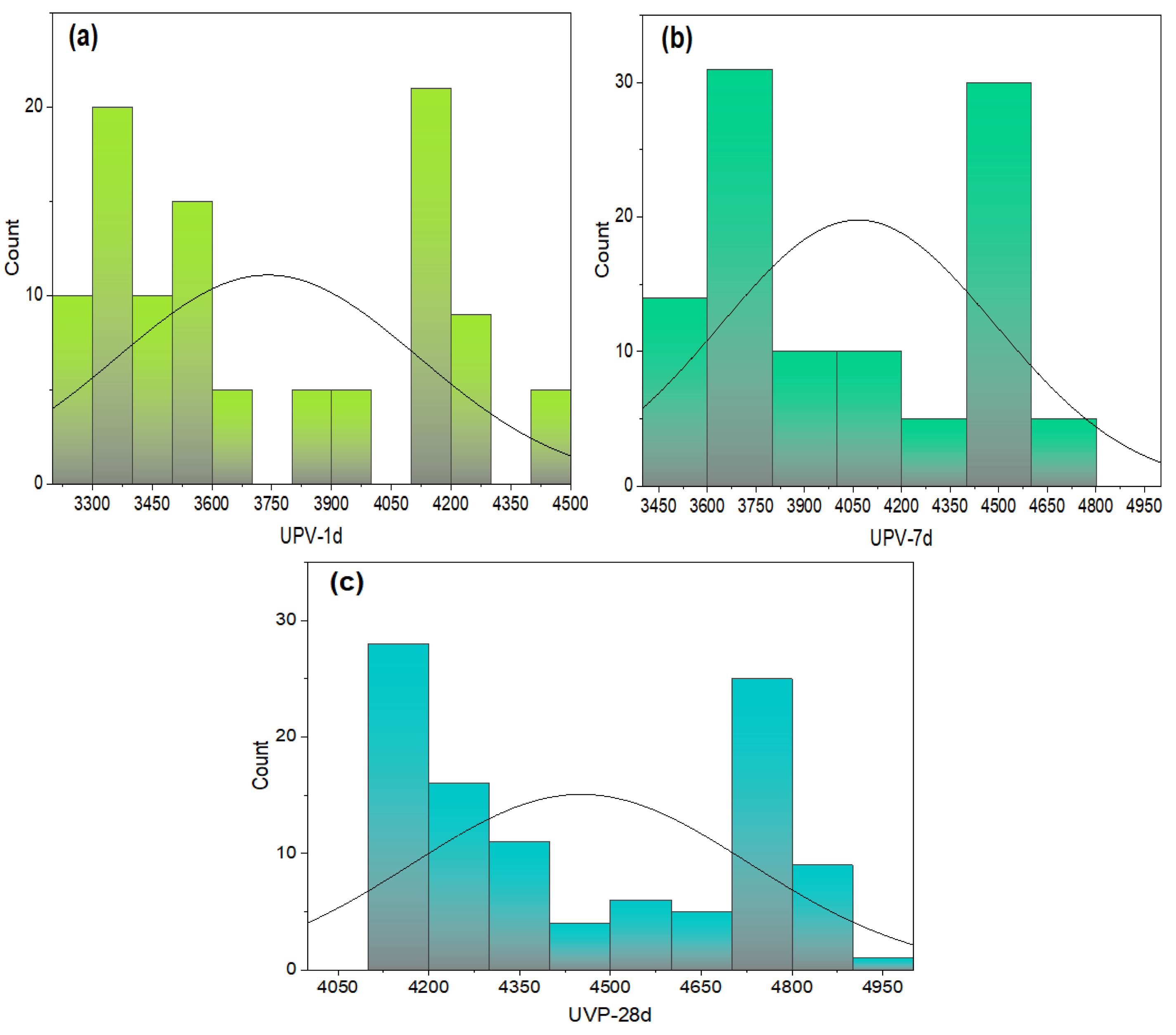

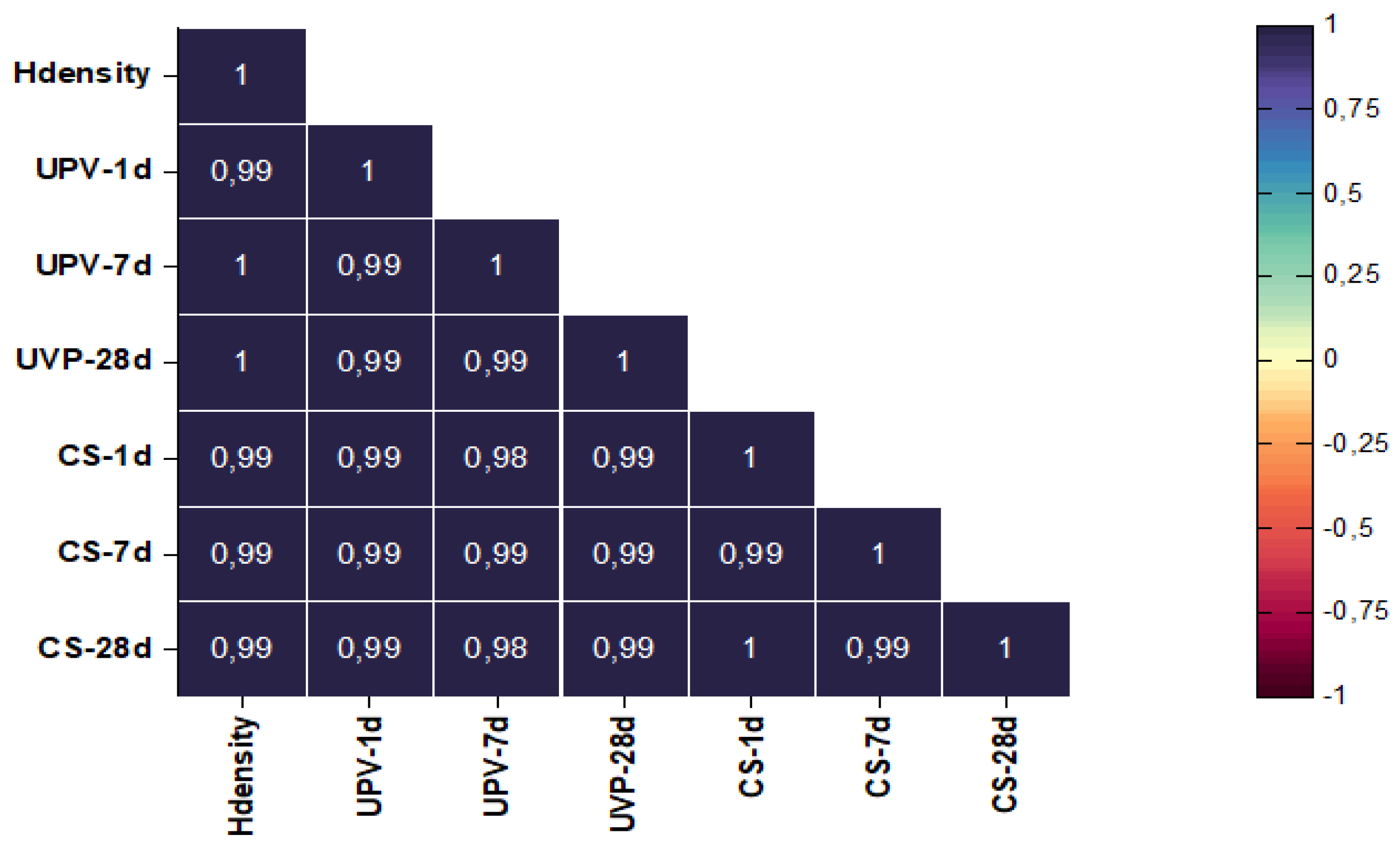

4.2. Experimental Data

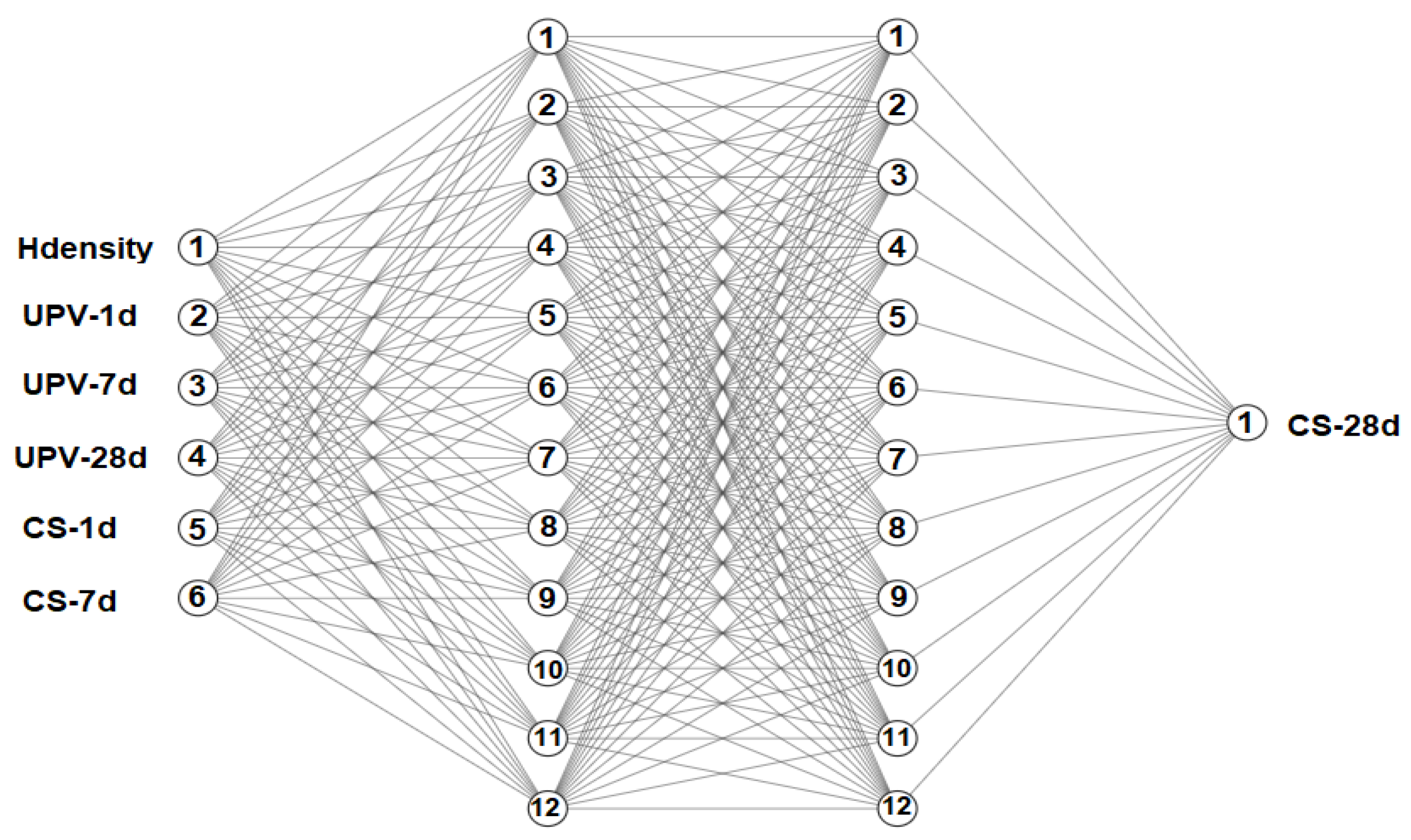

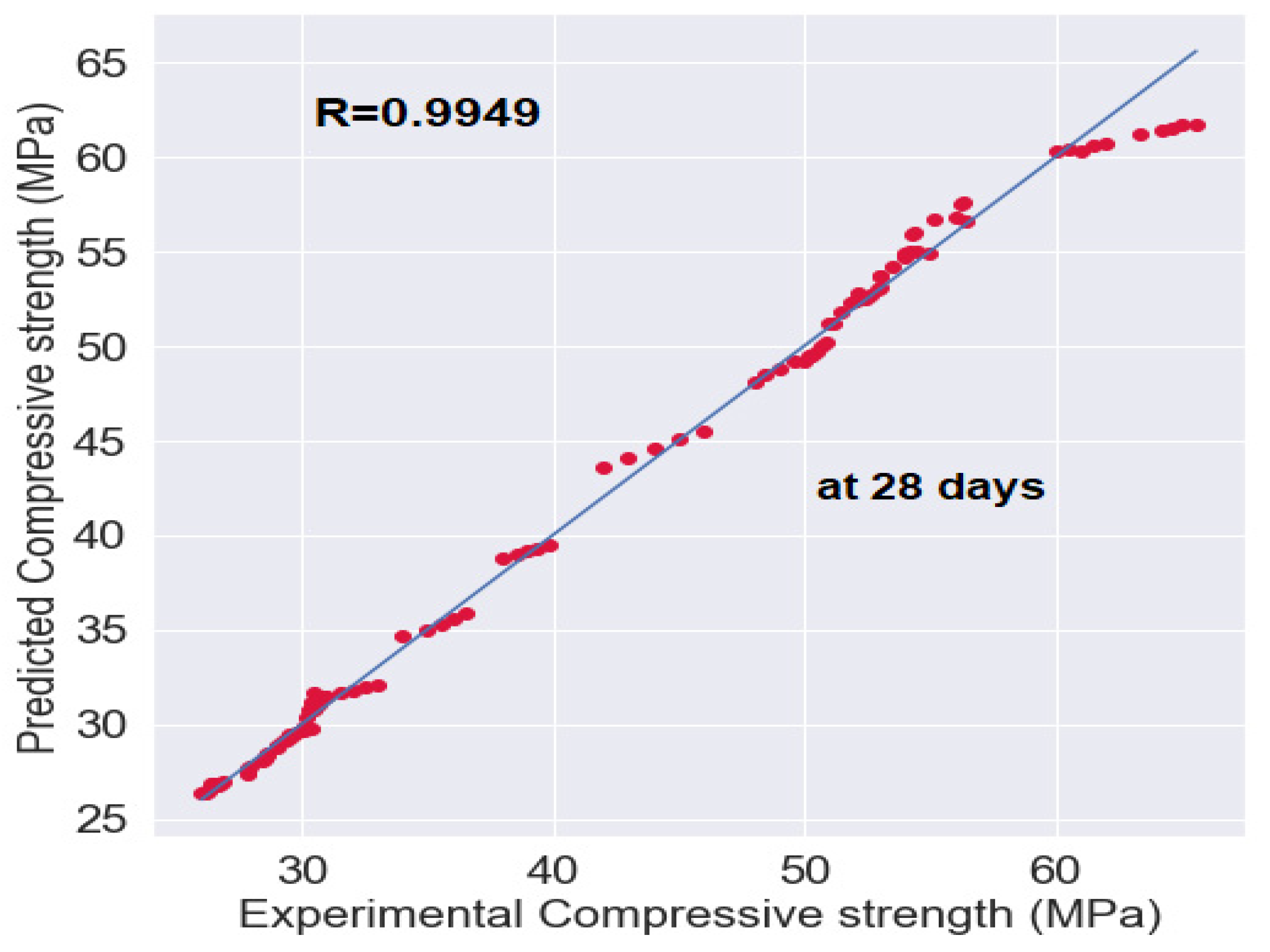

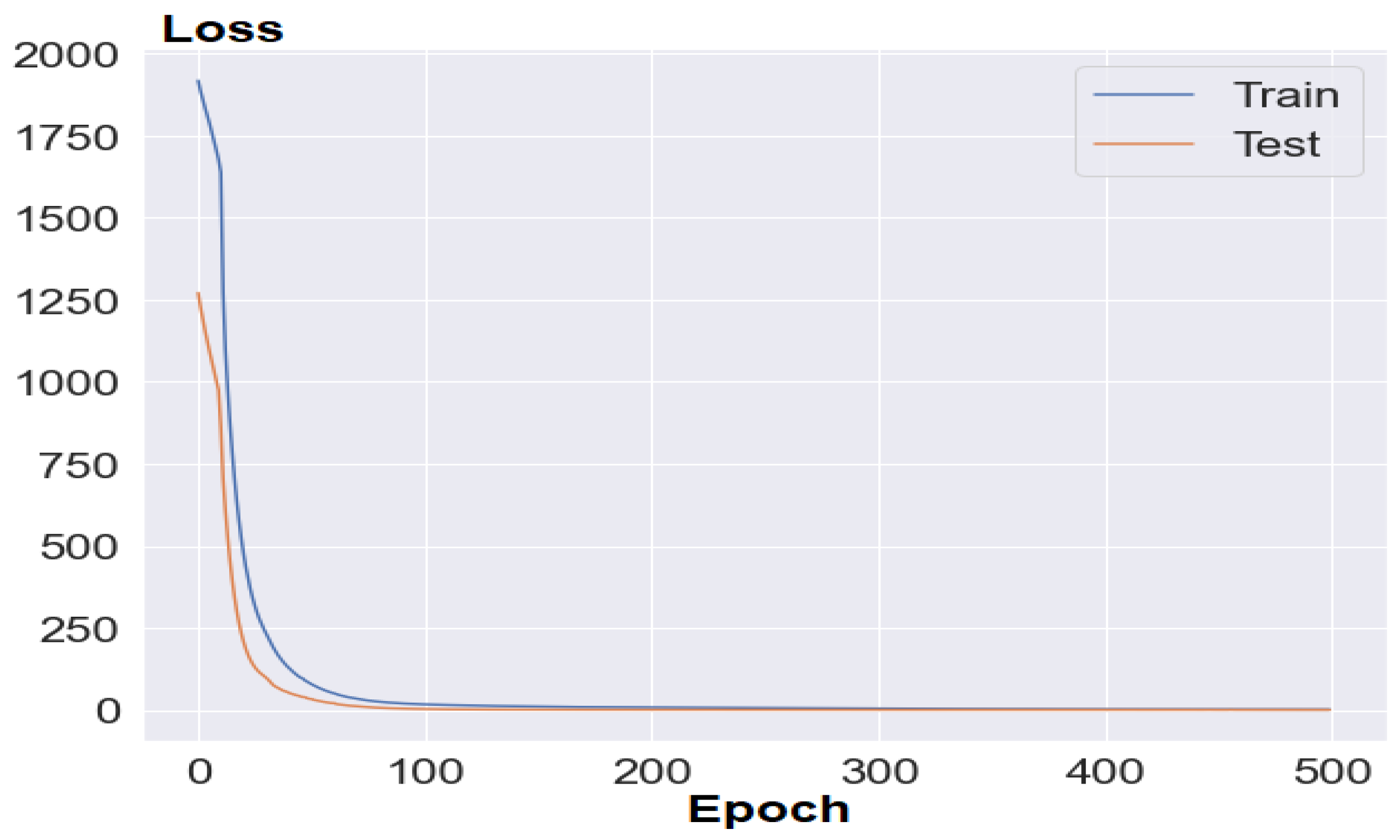

4.3. BPNN Model Analysis

4.4. Analysis and Prediction of Ultrasonic Velocity and Compressive Strength

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rasekh, H.; Joshaghani, A.; Jahandari, S.; Aslani, F.; Ghodrat, M. Rheology and Workability of SCC. In Self-Compacting Concrete: Materials, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 31–63. [Google Scholar]

- Ramkumar, K.B.; Kannan Rajkumar, P.R.; Noor Ahmmad, S.; Jegan, M. A Review on Performance of Self-Compacting Concrete—Use of Mineral Admixtures and Steel Fibres with Artificial Neural Network Application. Constr. Build. Mater. 2020, 261, 120215. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K. An Overview on Mixture Design of Self-compacting Concrete. Struct. Concr. 2019, 20, 371–395. [Google Scholar] [CrossRef]

- Benaicha, M.; Jalbaud, O.; Hafidi Alaoui, A.; Burtschell, Y. Porosity Effects on Rheological and Mechanical Behavior of Self-Compacting Concrete. J. Build. Eng. 2022, 48, 103964. [Google Scholar] [CrossRef]

- Mandal, R.; Panda, S.K.; Nayak, S. Rheology of Concrete: Critical Review, Recent Advancements, and Future Prospectives. Constr. Build. Mater. 2023, 392, 132007. [Google Scholar] [CrossRef]

- Wang, Y.; Iqtidar, A.; Amin, M.N.; Nazar, S.; Hassan, A.M.; Ali, M. Predictive Modelling of Compressive Strength of Fly Ash and Ground Granulated Blast Furnace Slag Based Geopolymer Concrete Using Machine Learning Techniques. Case Stud. Constr. Mater. 2024, 20, e03130. [Google Scholar] [CrossRef]

- Aslam, F.; Shahab, M.Z. Supplementary Cementitious Materials in Blended Cement Concrete: Advancements in Predicting Compressive Strength through Machine Learning. Mater. Today Commun. 2024, 38, 107725. [Google Scholar] [CrossRef]

- Boccacci, G.; Frasca, F.; Bertolin, C.; Siani, A.M. Diagnosis of Historic Reinforced Concrete Buildings: A Literature Review of Non-Destructive Testing (NDT) Techniques. Procedia Struct. Integr. 2024, 55, 160–167. [Google Scholar] [CrossRef]

- Sathiparan, N.; Jeyananthan, P.; Subramaniam, D.N. Surface Response Regression and Machine Learning Techniques to Predict the Characteristics of Pervious Concrete Using Non-Destructive Measurement: Ultrasonic Pulse Velocity and Electrical Resistivity. Measurement 2024, 225, 114006. [Google Scholar] [CrossRef]

- Kouddane, B.; Sbartaï, Z.M.; Elachachi, S.M.; Lamdouar, N. New Multi-Objective Optimization to Evaluate the Compressive Strength and Variability of Concrete by Combining Non-Destructive Techniques. J. Build. Eng. 2023, 77, 107526. [Google Scholar] [CrossRef]

- Abbass, W.; Aslam, F.; Ahmed, M.; Ahmed, A.; Alyousef, R.; Mohamed, A. Predicting the Performance of Existing Pre-Cast Concrete Pipes Using Destructive and Non-Destructive Testing Techniques. Heliyon 2023, 9, e15471. [Google Scholar] [CrossRef]

- Wang, Y.; Mukherjee, A.; Castel, A. Non-Destructive Monitoring of Incipient Corrosion in Reinforced Concrete with Top-Bar Defect Using a Combination of Electrochemical and Ultrasonic Techniques. Constr. Build. Mater. 2022, 360, 129346. [Google Scholar] [CrossRef]

- Asteris, P.G.; Skentou, A.D.; Bardhan, A.; Samui, P.; Lourenço, P.B. Soft Computing Techniques for the Prediction of Concrete Compressive Strength Using Non-Destructive Tests. Constr. Build. Mater. 2021, 303, 124450. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Q.; Yi, J.; Zhang, J. Effects of Coral Aggregate Properties on the Ultrasonic Pulse Velocity of Concrete. J. Build. Eng. 2023, 80, 107935. [Google Scholar] [CrossRef]

- Moura, M.A.d.N.; Moreno, A.L.; Ferreira, G.C.d.S. Ultrasonic Testing on Evaluation of Concrete Residual Compressive Strength: A Review. Constr. Build. Mater. 2023, 373, 130887. [Google Scholar] [CrossRef]

- Trtnik, G.; Kavčič, F.; Turk, G. Prediction of Concrete Strength Using Ultrasonic Pulse Velocity and Artificial Neural Networks. Ultrasonics 2009, 49, 53–60. [Google Scholar] [CrossRef]

- Ansari, M.A.; Ansari, S.S.; Ghazi, M.S.; Saqib, M.; Ibrahim, S.M.; Saquib, M. Incorporating Non-Destructive UPV into Machine Learning Models for Predicting Compressive Strength in SCM Concrete. Mater. Today Proc. 2024, 4, 59–67. [Google Scholar] [CrossRef]

- Pazouki, G.; Tao, Z.; Saeed, N.; Kang, W.-H. Using Artificial Intelligence Methods to Predict the Compressive Strength of Concrete Containing Sugarcane Bagasse Ash. Constr. Build. Mater. 2023, 409, 134047. [Google Scholar] [CrossRef]

- Pal, A.; Ahmed, K.S.; Hossain, F.Z.; Alam, M.S. Machine Learning Models for Predicting Compressive Strength of Fiber-Reinforced Concrete Containing Waste Rubber and Recycled Aggregate. J. Clean. Prod. 2023, 423, 138673. [Google Scholar] [CrossRef]

- Mehta, V. Machine Learning Approach for Predicting Concrete Compressive, Splitting Tensile, and Flexural Strength with Waste Foundry Sand. J. Build. Eng. 2023, 70, 106363. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Azmi, N.J.; Abdullahi, M. Evaluation of Rubbercrete Based on Ultrasonic Pulse Velocity and Rebound Hammer Tests. Constr. Build. Mater. 2011, 25, 1388–1397. [Google Scholar] [CrossRef]

- Marie, I. Zones of Weakness of Rubberized Concrete Behavior Using the UPV. J. Clean. Prod. 2016, 116, 217–222. [Google Scholar] [CrossRef]

- Shi, M.; Jeong, D.H.; Lee, S.W.; Choi, Y. Relationship between UPV and Strength of Rubber-Concrete. Defect Diffus. Forum; Trans Tech Publications Ltd: Zurich, Switzerland, 2018; pp. 225–229. [Google Scholar] [CrossRef]

- Ramlan, M.R.; Shahidan, S.; Zuki, S.S.M.; Abdullah, S.R.; Ibrahim, M.H.W.; Rahim, M.A. Strength and Quality Assessment of Recycled Aggregate and Crumb Rubber Concrete Using the Ultra Pulse Velocity Method. In Proceedings of AICCE’19; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 799–806. [Google Scholar]

- Boudjedra, F.; Benouis, A.; Boudaoud, Z. Estimation of Rubber Waste Concrete Properties by Ultrasonic Velocities: Effect of Transducers’ Diameters and Frequencies. Civ. Environ. Eng. Rep. 2020, 30, 200–220. [Google Scholar] [CrossRef]

- Girskas, G.; Nagrockienė, D. Crushed Rubber Waste Impact of Concrete Basic Properties. Constr. Build. Mater. 2017, 140, 36–42. [Google Scholar] [CrossRef]

- Meddah, M.S.; Zitouni, S.; Belâabes, S. Effect of Content and Particle Size Distribution of Coarse Aggregate on the Compressive Strength of Concrete. Constr. Build. Mater. 2010, 24, 505–512. [Google Scholar] [CrossRef]

- Hunag, L.-J.; Wang, H.-Y.; Wu, Y.-W. Properties of the Mechanical in Controlled Low-Strength Rubber Lightweight Aggregate Concrete (CLSRLC). Constr. Build. Mater. 2016, 112, 1054–1058. [Google Scholar] [CrossRef]

- Benaicha, M.; Jalbaud, O.; Roguiez, X.; Hafidi Alaoui, A.; Burtschell, Y. Prediction of Self-Compacting Concrete Homogeneity by Ultrasonic Velocity. Alex. Eng. J. 2015, 54, 1181–1191. [Google Scholar] [CrossRef]

- Ben aicha, M.; Burtschell, Y.; Alaoui, A.H.; El Harrouni, K.; Jalbaud, O. Correlation between Bleeding and Rheological Characteristics of Self-Compacting Concrete. J. Mater. Civ. Eng. 2017, 29, 05017001. [Google Scholar] [CrossRef]

- Benaicha, M.; Jalbaud, O.; Hafidi Alaoui, A.; Burtschell, Y. Correlation between the Mechanical Behavior and the Ultrasonic Velocity of Fiber-Reinforced Concrete. Constr. Build. Mater. 2015, 101, 702–709. [Google Scholar] [CrossRef]

- Asri, Y.; Benaicha, M.; Zaher, M.; Hafidi Alaoui, A. Prediction of the Compressive Strength of Self-compacting Concrete Using Artificial Neural Networks Based on Rheological Parameters. Struct. Concr. 2022, 23, 3864–3876. [Google Scholar] [CrossRef]

| Material | Type | Dosage (kg/m3) | Standard Compliance |

|---|---|---|---|

| Cement | CEM I 52.5 R | 350 | EN 197-1 |

| Water | 175 | ||

| Superplasticizer | Krono 20 HE | 0.4% of cement | EN 480-8 |

| Sand | 0/2 mm | 890 | EN 13139 |

| Gravel | 0/10 mm | 900 | EN 13139 |

| Limestone filler | Carmeuse | 170 | EN 206-1 |

| Air-entraining admixture | SIKA AER 5 | 0.05–1% of cement | NF EN 934-2 |

| SCC Code | Hardened Density (Kg/m3) | Ultrasonic Velocity (m/s) | Compressive Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|

| 1 Day | 7 Days | 28 Days | 1 Day | 7 Days | 28 Days | ||

| SCC 0 | 2432 | 4432 | 4776 | 4893 | 42 | 55 | 63.4 |

| 2434 | 4438 | 4781 | 4895 | 43 | 56 | 64.2 | |

| 2438 | 4440 | 4784 | 4898 | 44 | 57 | 65.6 | |

| 2438 | 4442 | 4787 | 4899 | 44 | 57 | 65 | |

| 2436 | 4444 | 4790 | 4902 | 43 | 56 | 64.6 | |

| SCC 1 | 2398 | 4230 | 4532 | 4820 | 40 | 53 | 60 |

| 2400 | 4232 | 4535 | 4823 | 40 | 53 | 61 | |

| 2403 | 4234 | 4538 | 4826 | 41 | 54 | 62 | |

| 2399 | 4236 | 4533 | 4821 | 40 | 53 | 60.5 | |

| 2401 | 4238 | 4536 | 4824 | 40.5 | 53.5 | 61.5 | |

| SCC 2 | 2377 | 4199 | 4585 | 4790 | 37 | 52 | 55.2 |

| 2379 | 4202 | 4588 | 4792 | 37 | 52 | 56 | |

| 2381 | 4204 | 4591 | 4793 | 38 | 53 | 56.2 | |

| 2383 | 4206 | 4594 | 4794 | 38 | 53 | 56.3 | |

| 2385 | 4208 | 4597 | 4795 | 37 | 54 | 56.4 | |

| SCC 3 | 2370 | 4185 | 4563 | 4786 | 35 | 51 | 54 |

| 2372 | 4187 | 4565 | 4788 | 35 | 51 | 54.2 | |

| 2374 | 4189 | 4567 | 4789 | 36 | 51.5 | 54.3 | |

| 2376 | 4191 | 4569 | 4790 | 36 | 51.8 | 54.4 | |

| 2378 | 4193 | 4571 | 4791 | 35 | 52 | 54.5 | |

| SCC 4 | 2366 | 4167 | 4558 | 4746 | 34 | 50 | 53 |

| 2368 | 4170 | 4560 | 4747 | 34 | 50 | 53 | |

| 2370 | 4173 | 4563 | 4749 | 34.5 | 50.5 | 53.5 | |

| 2372 | 4176 | 4566 | 4751 | 35 | 51 | 54 | |

| 2374 | 4179 | 4569 | 4753 | 35.2 | 51.4 | 55 | |

| SCC 5 | 2363 | 4134 | 4548 | 4723 | 33 | 49 | 52 |

| 2364 | 4136 | 4550 | 4726 | 33.2 | 49.4 | 52.4 | |

| 2365 | 4138 | 4553 | 4728 | 33.4 | 49.5 | 52.6 | |

| 2366 | 4140 | 4556 | 4730 | 33.6 | 49.6 | 52.9 | |

| 2367 | 4142 | 4559 | 4732 | 33.8 | 49.8 | 53 | |

| SCC 6 | 2362 | 4103 | 4539 | 4706 | 32 | 48 | 51 |

| 2364 | 4105 | 4542 | 4709 | 32 | 48.2 | 51.2 | |

| 2366 | 4107 | 4544 | 4712 | 32.5 | 48.5 | 51.5 | |

| 2368 | 4109 | 4546 | 4715 | 33 | 48.8 | 51.8 | |

| 2370 | 4111 | 4548 | 4718 | 33.5 | 49.1 | 52.1 | |

| SCC 7 | 2332 | 3943 | 4366 | 4681 | 30 | 44 | 50 |

| 2334 | 3946 | 4369 | 4684 | 30.3 | 44.5 | 50.3 | |

| 2337 | 3949 | 4372 | 4687 | 30.5 | 45 | 50.5 | |

| 2340 | 3952 | 4375 | 4690 | 30.7 | 45.5 | 50.7 | |

| 2343 | 3955 | 4378 | 4693 | 30.9 | 46 | 50.9 | |

| SCC 8 | 2284 | 3855 | 4156 | 4552 | 28 | 40 | 48 |

| 2285 | 3857 | 4158 | 4554 | 28.4 | 41 | 48.4 | |

| 2287 | 3859 | 4160 | 4556 | 28.8 | 42 | 49 | |

| 2289 | 3861 | 4162 | 4558 | 29.2 | 43 | 49.6 | |

| 2291 | 3863 | 4164 | 4560 | 29.6 | 44 | 50.2 | |

| SCC 9 | 2254 | 3688 | 4110 | 4486 | 25 | 35 | 42 |

| 2256 | 3693 | 4113 | 4488 | 25.5 | 35.5 | 43 | |

| 2258 | 3695 | 4116 | 4492 | 26 | 36 | 44 | |

| 2260 | 3697 | 4119 | 4496 | 26.5 | 36.5 | 45 | |

| 2262 | 3699 | 4122 | 4500 | 27 | 37 | 46 | |

| SCC 10 | 2183 | 3583 | 3832 | 4336 | 20.3 | 31 | 38 |

| 2185 | 3585 | 3835 | 4338 | 20.33 | 31.5 | 38.6 | |

| 2188 | 3588 | 3838 | 4340 | 20.36 | 32 | 39 | |

| 2191 | 3591 | 3841 | 4342 | 20.39 | 32.5 | 39.4 | |

| 2194 | 3594 | 3844 | 4344 | 20.42 | 33 | 39.8 | |

| SCC 11 | 2176 | 3544 | 3802 | 4302 | 16.6 | 27 | 34 |

| 2179 | 3546 | 3808 | 4307 | 16.8 | 27.5 | 35 | |

| 2183 | 3549 | 3813 | 4311 | 16.9 | 28 | 35.5 | |

| 2187 | 3552 | 3818 | 4315 | 17 | 28.5 | 36 | |

| 2191 | 3555 | 3823 | 4319 | 17.1 | 29 | 36.5 | |

| SCC 12 | 2166 | 3524 | 3786 | 4288 | 14.1 | 24.6 | 31 |

| 2169 | 3528 | 3788 | 4291 | 14.14 | 24.64 | 31.5 | |

| 2171 | 3530 | 3790 | 4294 | 14.18 | 24.68 | 32 | |

| 2173 | 3532 | 3792 | 4297 | 14.22 | 24.72 | 32.5 | |

| 2175 | 3534 | 3794 | 4300 | 14.26 | 24.76 | 33 | |

| SCC 13 | 2161 | 3488 | 3742 | 4262 | 13.6 | 24.2 | 30.5 |

| 2164 | 3490 | 3744 | 4265 | 13.65 | 24.4 | 30.6 | |

| 2166 | 3493 | 3746 | 4267 | 13.7 | 24.6 | 30.7 | |

| 2168 | 3496 | 3748 | 4269 | 13.75 | 24.8 | 30.8 | |

| 2170 | 3499 | 3750 | 4271 | 13.8 | 25 | 30.9 | |

| SCC 14 | 2158 | 3422 | 3704 | 4212 | 13.2 | 23.4 | 30.1 |

| 2161 | 3425 | 3708 | 4215 | 13.5 | 23.5 | 30.2 | |

| 2163 | 3428 | 3711 | 4217 | 13.8 | 23.8 | 30.3 | |

| 2165 | 3431 | 3714 | 4219 | 14.1 | 24.1 | 30.4 | |

| 2167 | 3434 | 3717 | 4221 | 14.4 | 24.4 | 30.5 | |

| SCC 15 | 2151 | 3388 | 3688 | 4192 | 13 | 23.1 | 29.4 |

| 2154 | 3390 | 3690 | 4194 | 13.1 | 23.1 | 29.5 | |

| 2156 | 3392 | 3693 | 4197 | 13.1 | 23.2 | 29.8 | |

| 2158 | 3394 | 3696 | 4200 | 13.12 | 23.3 | 30.1 | |

| 2160 | 3396 | 3699 | 4203 | 13.14 | 23.4 | 30.4 | |

| SCC 16 | 2145 | 3364 | 3624 | 4146 | 12.88 | 22.4 | 29 |

| 2147 | 3366 | 3626 | 4148 | 12.9 | 22.5 | 29 | |

| 2149 | 3368 | 3628 | 4150 | 12.92 | 22.7 | 29.2 | |

| 2151 | 3370 | 3630 | 4152 | 12.94 | 22.9 | 29.4 | |

| 2153 | 3372 | 3632 | 4154 | 12.96 | 23.1 | 29.6 | |

| SCC 17 | 2138 | 3323 | 3605 | 4134 | 12.65 | 21.6 | 28.4 |

| 2140 | 3325 | 3607 | 4136 | 12.68 | 21.7 | 28.5 | |

| 2142 | 3327 | 3609 | 4138 | 12.7 | 21.75 | 28.55 | |

| 2144 | 3329 | 3611 | 4140 | 12.72 | 21.8 | 28.6 | |

| 2146 | 3331 | 3613 | 4142 | 12.74 | 21.85 | 28.65 | |

| SCC 18 | 2124 | 3302 | 3592 | 4123 | 12.53 | 21.4 | 27.8 |

| 2126 | 3304 | 3595 | 4125 | 12.55 | 21.43 | 27.83 | |

| 2128 | 3306 | 3597 | 4128 | 12.58 | 21.45 | 27.85 | |

| 2130 | 3308 | 3599 | 4131 | 12.61 | 21.47 | 27.87 | |

| 2132 | 3310 | 3601 | 4134 | 12.64 | 21.49 | 27.89 | |

| SCC 19 | 2119 | 3294 | 3588 | 4111 | 12.4 | 20.7 | 26.7 |

| 2120 | 3296 | 3590 | 4113 | 12.42 | 20.8 | 26.8 | |

| 2122 | 3298 | 3593 | 4115 | 12.45 | 20.85 | 26.9 | |

| 2120 | 3298 | 3594 | 4112 | 12.44 | 20.75 | 26.4 | |

| 2120 | 3296 | 3596 | 4112 | 12.44 | 20.7 | 26.5 | |

| SCC 20 | 2112 | 3286 | 3562 | 4108 | 12.2 | 20.3 | 26.2 |

| 2115 | 3288 | 3564 | 4106 | 12.24 | 20.4 | 26.25 | |

| 2117 | 3290 | 3566 | 4104 | 12.26 | 20.5 | 26.3 | |

| 2115 | 3287 | 3566 | 4102 | 12.2 | 20.3 | 26.1 | |

| 2114 | 3286 | 3568 | 4102 | 12.2 | 20.3 | 26 | |

| Parameter | Count | Mean | std | Sum | Min | Max |

|---|---|---|---|---|---|---|

| Hdensity | 105 | 2250.21905 | 109.61287 | 236,273 | 2112 | 2438 |

| UPV-1d | 105 | 3740.54286 | 378.02414 | 392,757 | 3286 | 4444 |

| UPV-7d | 105 | 4065.07619 | 423.7774 | 426,833 | 3562 | 4790 |

| UPV-28d | 105 | 4451.66667 | 278.04353 | 467,425 | 4102 | 4902 |

| CS-1d | 105 | 23.66581 | 10.80855 | 2484.91 | 12.2 | 44 |

| CS-7d | 105 | 35.65181 | 13.18774 | 3743.44 | 20.3 | 57 |

| CS-28d | 105 | 41.56324 | 12.55785 | 4364.14 | 26 | 65.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benaicha, M. AI-Driven Prediction of Compressive Strength in Self-Compacting Concrete: Enhancing Sustainability through Ultrasonic Measurements. Sustainability 2024, 16, 6644. https://doi.org/10.3390/su16156644

Benaicha M. AI-Driven Prediction of Compressive Strength in Self-Compacting Concrete: Enhancing Sustainability through Ultrasonic Measurements. Sustainability. 2024; 16(15):6644. https://doi.org/10.3390/su16156644

Chicago/Turabian StyleBenaicha, Mouhcine. 2024. "AI-Driven Prediction of Compressive Strength in Self-Compacting Concrete: Enhancing Sustainability through Ultrasonic Measurements" Sustainability 16, no. 15: 6644. https://doi.org/10.3390/su16156644

APA StyleBenaicha, M. (2024). AI-Driven Prediction of Compressive Strength in Self-Compacting Concrete: Enhancing Sustainability through Ultrasonic Measurements. Sustainability, 16(15), 6644. https://doi.org/10.3390/su16156644