Change in the Properties of Expanded Polystyrene Exposed to Solar Radiation in Real Aging Conditions

Abstract

1. Introduction

2. Methodology

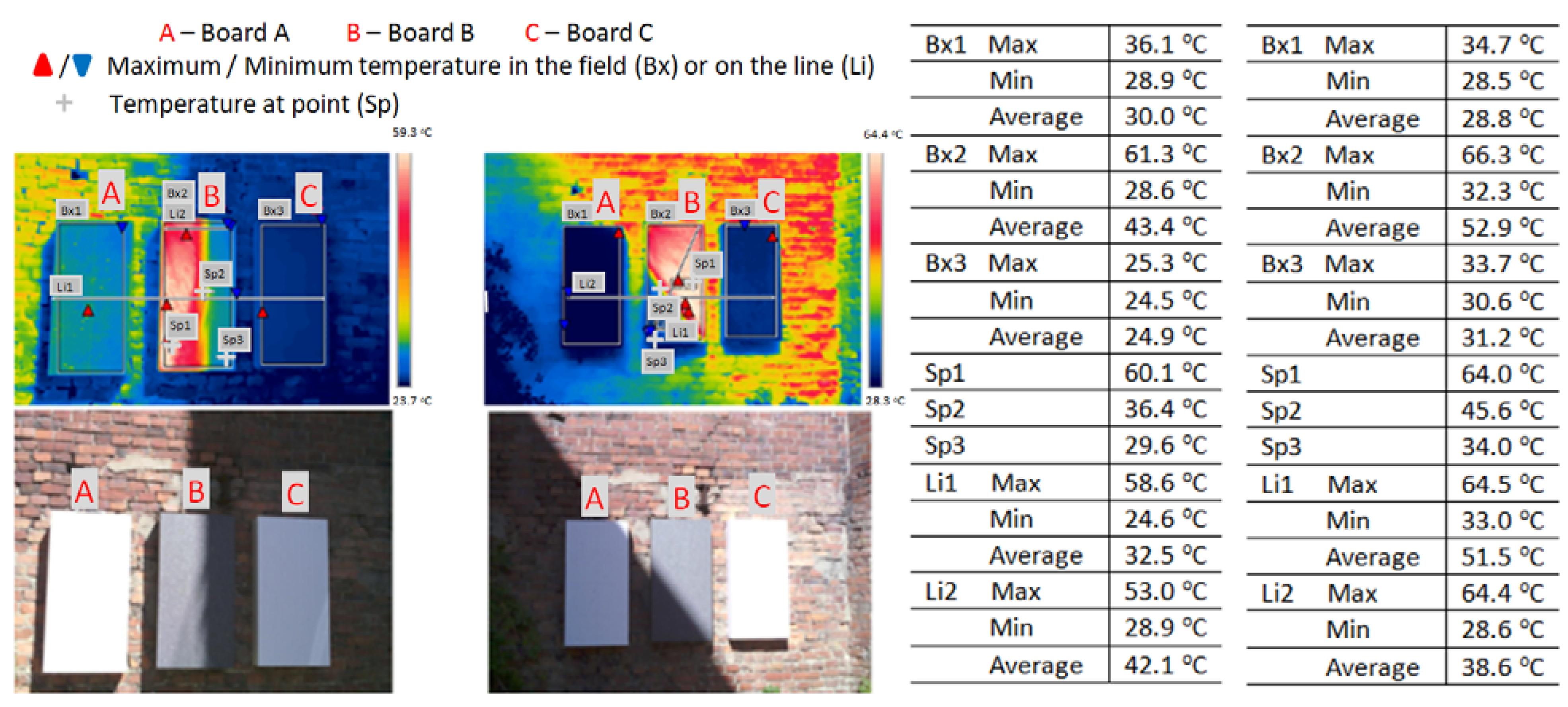

2.1. Emissivity of the Boards

- A thermal imaging camera (Teledyne FLIR LLC 27700 SW Parkway Ave, Wilsonville, OR, USA) with a temperature measurement range of −20 °C ± 1500 °C, resolution of 161,472 pixels, thermal sensitivity for the lens of 42° × 32° < 30 mK, IFOV spatial resolution of 2.41 mrad/pixel for the lens 42° × 32°, and segmental spectral sensitivity of 7.5–14 μm;

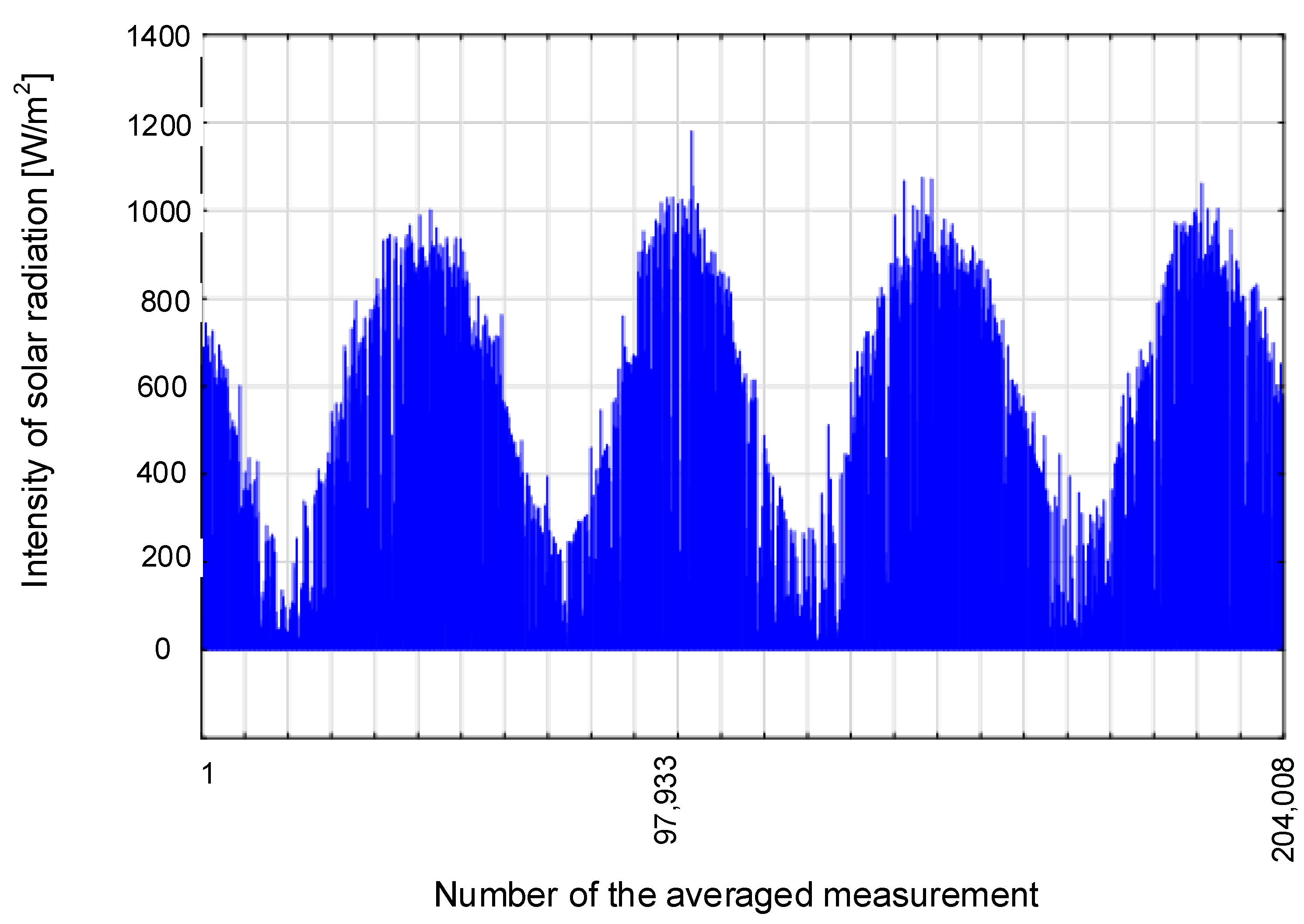

- The VantagePro2 meteorological station (Davis Instruments, Hayward, CA, USA) with the temperature measurement range of −40 °C ÷ 65 °C ± 0.5 °C, humidity of 1% ÷ 100% ± 3%, and solar radiation intensity of 0–1999 W/m2 ± 1 W/m2.

2.2. Thermal Conductivity Measurements

2.3. Measurements of Compressive Stress

2.4. Tensile Strength Measurements

2.5. Water Absorption Measurements

3. Results and Discussion

4. Conclusions

- Despite the 4-year impact of external environmental conditions on the unprotected surfaces of the thermal insulation materials tested, there was no significant change in the thickness of the tested EPS boards. The damage that occurred (holes or polystyrene melting) was merely local and uneven (random?). As a consequence, they did not cause significant deterioration of the thermal resistance related to the reduction in their thickness as a result of ongoing aging processes. It can be assumed that the dynamics of changes related to the reduction inof the polystyrene thickness were not constant and changed over time. This has been demonstrated by examples of unprotected polystyrene exposed to weather conditions for a dozen or so years.

- In addition, under the influence of degradation, expanded polystyrene with an admixture of graphite (samples A and B) improved its compressive and tensile strength properties. This may be due to the degradation manner of this material, where the polystyrene balls stuck together, creating a homogeneous structure (without air). Of course, the increase in strength did not fully compensate for the effects of such deformations.

- Definitely, the negative effect of direct exposure of expanded polystyrene with the addition of graphite (samples A and B) was attributed to an increase in water absorption of up to 50% (Table 4). This effect was not found for white polystyrene (sample C). Despite the increase in the strength of samples A and B resulting from exposure to direct solar radiation, such measures were not recommended.

- Gray polystyrene (sample B) after direct exposure to solar radiation deformed so much that the increase in its compressive or tensile strength did not compensate for the losses resulting from the boards falling off the building facade.

- It should be noted that the composite panel (sample A) improved its strength properties, but its protection with a white coating on the side exposed to radiation may indicate that there was no significant stress. Such studies are planned in the future and may yield positive results for such panels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benchouia, H.E.; Boussehel, H.; Guerira, B.; Sedira, L.; Tedeschi, C.; Becha, H.E.; Cucchi, M. An experimental evaluation of a hybrid biocomposite based on date palm petiole fibers, expanded polystyrene waste, and gypsum plaster as a sustainable insulating building material. Constr. Build. Mater. 2024, 422, 135735. [Google Scholar] [CrossRef]

- Mahmoodzadeh, M.; Gretka, V.; Blue, A.; Adams, D.; Dallimore, B.; Mukhopadhyaya, P. Evaluating thermal performance of verical building envalopes: Case studies in a Canadian university campus. J. Build. Eng. 2021, 40, 102712. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An overviev of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Patil, S.B.N.; Jaiswal, T.P.; Selvakumar, K.K.; Jyothi, M.S.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar]

- Berardi, U.; Sprengard, C. An overview of and introduction to current researches on super insulating materials for high-performance buildings. Energy Build. 2020, 214, 109890. [Google Scholar] [CrossRef]

- Krause, P.; Nowoświat, A.; Pawłowski, K. The impact of international insulation on heat transport through the wall: Case Study. Appl. Sci. 2020, 10, 7484. [Google Scholar] [CrossRef]

- ASHRAE HVAC 2001 Fundamentals Handbook 2001 (SI). In American Society of Heating Refrigerating & Air Conditioning Engineers Incoporated; Elsevier: Amsterdam, The Netherlands, 2001.

- Al-Homoud, M.S. Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Walker, R.; Pavia, S. Thermal performance of a selection of insulation materials suitable for historic buildings. Build. Environ. 2015, 94, 155–165. [Google Scholar] [CrossRef]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A review and evaluation of thermal insulation materials and methods for thermal energy storage systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- Khoukhi, M.; Abdelbagi, S.; Hassan, A.; Darsaleh, A. Impact of dynamic thermal conductivity change of EPS insulation on temperature variation through a wall assembly. Case Stud. Therm. Eng. 2021, 25, 100917. [Google Scholar] [CrossRef]

- Berardi, U. The impact of aging and environmental conditions on the effective thermal conductivity of several foam materials. Energy 2019, 182, 777–794. [Google Scholar] [CrossRef]

- Winkler-Skalna, A.; Łoboda, B. Determination of the thermal insulation properties of cylindrical PUR foam products throughout the entire life cycle using accelerated aging procedures. J. Build. Eng. 2020, 31, 101348. [Google Scholar] [CrossRef]

- Orlik-Kożdoń, B.; Nowoświat, A. Modelling and testing of a granular insulating material. J. Build. Phys. 2018, 42, 6–15. [Google Scholar] [CrossRef]

- Kaya, A.; Kar, F. Properties of concrete containing waste expanded polystyrene and natural resin. Constr. Build. Mater. 2016, 105, 572–578. [Google Scholar]

- Lu, J.; Wang, D.; Jiang, P.; Zhang, S.; Chen, Z.; Bourbigot, S.; Fontaine, G.; Wei, M. Design of fire resistant, sound-absorbing and thermal-insulated expandable polystyrene based lightweight particleboard composites. Constr. Build. Mater. 2021, 305, 124773. [Google Scholar] [CrossRef]

- Sulong, N.H.R.; Mustpa, S.; Rashid, M. Application of expanded polystyrene (EPS) in buildings and constructions: A review. J. Appl. Polym. Sci. 2019, 136, 47529. [Google Scholar] [CrossRef]

- Li, L.; Chen, S.; Wang, S.; Tao, X.; Zhu, X.; Cheng, G.; Gui, D. Influence of pickling on the surface composition and flotability of Daliuta long-flame coal. Powder Technol. 2019, 352, 413–421. [Google Scholar] [CrossRef]

- Tang, L.; Chen, S.; Wang, S.; Tao, X.; He, H.; Zheng, L.; Ma, C.; Zhao, Y. Heterocyclic sulfur removal of coal based on potassium tert-butoxide and hydrosilane system. Fuel Process. Technol. 2018, 177, 194–199. [Google Scholar] [CrossRef]

- Nowoświat, A.; Krause, P.; Miros, A. Properties of expanded graphite polystyrene damaged by the impact of solar radiation. J. Build. Eng. 2021, 34, 101920. [Google Scholar] [CrossRef]

- Lakatos, Á.; Kalmár, F. Investigation of thickness and density dependence of thermal conductivity of expanded polystyrene insulation materials. Mater. Struct. 2013, 46, 1101–1105. [Google Scholar] [CrossRef]

- Ricciardi, P.; Belloni, E.; Cotana, F. Innovative panels with recycled materials: Thermal and acoustic performance and life cycle assessment. Appl. Energy 2014, 134, 150–162. [Google Scholar] [CrossRef]

- Biolek, V.; Hanák, T. LCC Estimation Model: A construction material perspective. Buildings 2019, 9, 182. [Google Scholar] [CrossRef]

- Gomes, R.; Silvestre, J.D.; de Brito, J. Environmental life cycle assessment of thermal insulation tiles for flat roofs. Materials 2019, 12, 2595. [Google Scholar] [CrossRef]

- Krause, P.; Nowoświat, A. Experimental studies involving the impact of solar radiation on the properties of expanded graphite polystyrene. Energies 2020, 13, 75. [Google Scholar] [CrossRef]

- EN 12667:2001; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. European Committee for Standardization: Brussels, Belgium, 2001.

- EN 826; Thermal Insulating Products for Building Applications—Determination of Compression Behavior. European Committee for Standardization: Brussels, Belgium, 2013.

- EN 1607; Thermal Insulating Products for Building Applications—Determination of Tensile Strength Perpendicular to Faces. European Committee for Standardization: Brussels, Belgium, 2013.

| Sample Type | Sample Thickness, mm | Thermal Conductivity Coefficient, W/mK |

|---|---|---|

| Sample A | 149.40 | 0.03061 |

| Sample B | 149.64 | 0.03060 |

| Sample C | 149.41 | 0.03930 |

| Sample Type | Sample Number | Compressive Stress at 10% Strain, kPa | Standard Uncertainty |

|---|---|---|---|

| Sample A | 2 | 60.9 | 4.59 |

| 5 | 71.3 | 3.13 | |

| Sample B | 3 | 67.9 | 3.42 |

| 6 | 68.2 | 0.854 | |

| Sample C | 1 | 90.6 | 3.10 |

| 4 | 77.2 | 0.874 |

| Sample Type | Sample Number | σmt, kPa | Standard Uncertainty |

|---|---|---|---|

| Sample A | 2 | 82 | 15 |

| 5 | 89 | 4.2 | |

| Sample B | 3 | 70 | 14 |

| 6 | 96 | 10 | |

| Sample C | 1 | 96 | 23 |

| 4 | 84 | 9.8 |

| Sample Type | Sample Number | Water Absorption, kg/m2 | Standard Uncertainty |

|---|---|---|---|

| Sample A | 2 | 0.10 | 0.033 |

| 5 | 0.16 | 0.034 | |

| Sample B | 3 | 0.09 | 0.048 |

| 6 | 0.13 | 0.084 | |

| Sample C | 1 | 0.23 | 0.094 |

| 4 | 0.19 | 0.047 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowoświat, A.; Miros, A.; Krause, P. Change in the Properties of Expanded Polystyrene Exposed to Solar Radiation in Real Aging Conditions. Sustainability 2024, 16, 7320. https://doi.org/10.3390/su16177320

Nowoświat A, Miros A, Krause P. Change in the Properties of Expanded Polystyrene Exposed to Solar Radiation in Real Aging Conditions. Sustainability. 2024; 16(17):7320. https://doi.org/10.3390/su16177320

Chicago/Turabian StyleNowoświat, Artur, Artur Miros, and Paweł Krause. 2024. "Change in the Properties of Expanded Polystyrene Exposed to Solar Radiation in Real Aging Conditions" Sustainability 16, no. 17: 7320. https://doi.org/10.3390/su16177320

APA StyleNowoświat, A., Miros, A., & Krause, P. (2024). Change in the Properties of Expanded Polystyrene Exposed to Solar Radiation in Real Aging Conditions. Sustainability, 16(17), 7320. https://doi.org/10.3390/su16177320