Abstract

This study presents the development of a comprehensive model for evaluating the level of readiness of buildings for digital transformation during the pre-construction phase. The proposed model utilizes structural equation modeling (SEM) and includes a full list of key factors for achieving success. This tool is designed to support industry stakeholders in assessing operational efficiency in terms of digital transformation readiness in the pre-construction phase (DTRPC) and analyze the effectiveness and limitations of DTRPC across various management levels. Key success factors were identified through interviews with experts and a review of the relevant literature. These variables were then validated through two rounds of the 8 Delphi technique, which included the input of 13 highly qualified experts. Finally, an online questionnaire was disseminated to industry professionals, who assessed the factors’ relative levels of significance. Questionnaire responses were collected from a sample of 300 individuals from different professional fields. SEM was then used to quantitatively analyze the relationships between the various components of the DTRPC success factors. The goal was to determine the impact of each construct on the overall level of readiness. The model underwent a thorough evaluation to determine its strength and stability across several parameters, including accuracy, conformity to multivariate normalcy, and reliability and validity. A hypothesis analysis was also conducted. The collected data were used to develop the proposed DTRPC model, consisting of 30 essential performance indicators grouped into four categories. The use of SEM uncovered a significant correlation between the operational indicators of these critical factors and the construct groups, as well as the influence of effective DTRPC constructs on overall project performance. This research expands the current knowledge by identifying important indications for evaluating the success of the DTRPC model and using them to create a comprehensive global SEM that can be used as a tool for measuring readiness at the pre-construction stage. This has the potential to provide essential assistance to organizations, project managers, and policymakers in making informed decisions.

Keywords:

digital transformation; digitalized construction industry; digital sustainable construction; sustainability; digitalization; digital transformation; pre-construction; industry 4.0 technologies; Construction 4.0; emerging technologies; critical success factors; smart buildings; infrastructure; policies; structural equation model (SEM); confirmatory factor analysis; digital transformation readiness level 1. Introduction

The construction business has profited greatly from the global digital transformation trend, in which new digital technologies have replaced conventional methods. A plethora of technologies have been implemented across the various stages of the building life cycle, including building information modeling (BIM), virtual reality (VR), augmented reality (AR), mixed reality, 3D printing, cloud computing, artificial intelligence (AI), big data, the Internet of Things (IoT), robotics, drones (unmanned aerial vehicles), mobile and wearable devices, and smart data [1]. Nevertheless, the construction sector has been slower to adopt digital technologies than other industries. Because of the fragmented structure of the construction business, various technologies function independently, highlighting a need for greater integration. The implementation of a digital transformation roadmap is essential in order to mitigate this fragmentation and guarantee optimal performance and productivity within this sector. The construction sector is reaping substantial advantages from the adoption of innovative technologies, which have enhanced productivity and efficiency in multiple facets of construction projects. Digital transformation has had significant effects throughout the construction project lifecycle, across the pre-construction, construction, and facility management phases. Digital transformation enhances the detection of possible design and construction problems, promotes cooperation among stakeholders, and improves the engagement of individuals, procedures, and surroundings in a constructed setting [2,3,4]. Furthermore, according to [5], the Cyber–Physical System (CPS) framework, which is built upon five main development environments, has demonstrated notable improvements in both completion times and quality within building projects. Nevertheless, as mentioned by [6], the implementation of new technologies in the construction sector encounters obstacles such as the lack of appropriate legislation and regulations, the intricate nature of projects, and the fragmented structure of the industry. Utilizing these technologies like AI and smart bulding has been greatly balue added to the industry [7]. In addition, there is a need for senior management in the construction industry to prioritize digital transformation projects and include them in the vision and purpose statements of both public and private sector organizations. This paper examines the implementation of digital transformation in three specific stages of the vertical aspect of the building construction sector.

Communication and coordination issues commonly arise in construction projects due to the participation of multiple stakeholders representing different organizations during the project’s lifespan. This can disrupt decision-making and information exchange [8,9] argues that the fragmented nature of construction projects has led to ongoing issues in their performance. Participants in a project tend to make independent decisions without consulting other key members, which not only hampers decision-making but can result in the fragmentation of tasks, leading to uncertainty and suboptimal planning, as well as multiple modifications during the construction process. Activities that have higher levels of uncertainty require increased coordination efforts to overcome these challenges and achieve a desirable level of performance. The level of coordination necessary for a project is determined by the project’s limitations [10,11].

The impact of many factors on the duration, cost, and quality of construction projects has been thoroughly studied in the context of construction projects in Malaysia and Indea [10,12]. However, understanding the impact of coordinating factors on digital transformation readiness levels is challenging due to the scarcity of research in this domain. Furthermore, previous studies have not adequately addressed the need to prevent the ineffective utilization of technology in construction projects. Specifically, there is a lack of comprehensive analysis on how to establish a coordinated environment, by accurately measuring and effectively taking into account the organization’s level of preparedness. Therefore, it is evident that a framework for understanding the connections between success variables and the level of preparation in pre-construction projects is a crucial subject for enabling digital transformation [13]. Digital transformation in pre-construction may be defined as the reorganization of pre-construction activities and tasks, as well as the coordination of the pre-requisites of the construction stage. Hence, the pre-construction process typically encompasses a diverse array of project responsibilities related to resource management and coordination of stakeholders. The current study encompasses two primary aims: (1) to investigate the significance of critical success factors that impact digital transformation readiness during the preconstruction phase, which enhances overall sustainability in organizations, and (2) to construct a structural equation model (SEM) that can serve as a tool to measure the weight of importance of each factor to evaluate the overall digital transformation readiness in the preconstruction phase. This tool will provide recommendations and assessments to help senior leadership and project managers make informed decisions about digital transformation initiatives.

2. Literature Review

2.1. The Principle of Digital Transformation in the Construction Industry in the Pre-Construction Phase

Pre-construction involves a variety of workflow processes, such as model coordination, quantification, estimating, bidding, initial meetings and follow-ups, schematic design, budget estimate, material and equipment selection, value engineering, review of design documents, and establishment of a final budget [14]. This project phase may also include passing information to the main contractor, preparing pre-construction information, determining delegation of responsibilities, ensuring compliance with regulations and project requirements, controlling or eliminating risks through design work, and developing coordination and cooperation processes [15]. While some planners and designers of construction projects are enthusiastically embracing the possibilities that a shift to a digital environment might bring, in some areas, progress is still regrettably slow. Ref. [16] reports that in 2016, 93% of German players in the construction industry concurred that digitization would impact every procedure in the pre-construction phase, and 100% of schedulers of building materials were convinced they had not yet completely reached their target output. However, fewer than 6% of construction firms were fully utilizing digital planning tools.

The recent literature suggests that there is an increasing connection between the use of digital technologies in the design phase and improvements in sustainability. Notable examples are six-dimensional BIM, AR/VR, and AI. Six-dimensional BIM surpasses conventional 3D modeling by incorporating additional dimensions of time (4D), cost (5D), and sustainability (6D). The latter includes factors such as energy performance [17], resource efficiency [18], carbon emissions reduction [19], and retrofit processes [20]. As part of a lifecycle approach [21], BIM can be utilized to guide decisions throughout the design phase, with the goal of minimizing the environmental impact and encouraging the adoption of sustainable building practices. Moreover, Building Information Modeling (BIM) offers significant advantages during the initial stages of a building project’s design [22].

The utilization of BIM by project managers allows them to generate exhaustive, accurate architectural models, which facilitates the early identification of potential risks and issues. By proactively addressing these detected concerns early in the design process, project managers can prevent costly redesigns and minimize the risk of construction delays. This early intervention not only enhances the efficiency and accuracy of the design process but also ensures the resolution of potential issues before they escalate, thereby contributing to the overall success of the project. Meanwhile, AR/VR technologies have advanced to greatly enhance design visualization and stakeholder involvement [23]. These technologies have also expanded into the metaverse, providing immersive environments for interactive experiences. The metaverse can enhance sustainability by enabling widespread participation in decision-making and resource allocation [24]. AI, and specifically generative design [25], is utilized to generate multiple sustainable design options that adhere to defined limitations and objectives, with a particular emphasis on reducing material usage [8] and optimizing energy efficiency [26].

In a typical project, the pre-construction phase might include steps such as business justification, feasibility study, concept design, detailed design, tendering, mobilization, production information, and bidding [27]. Maximizing the effectiveness of digital transformation in the preconstruction stage requires optimizing both internal and customer-facing processes to meet requirements such as fast access to data for analysis using innovative tools such as AI and cloud storage of vast amounts of information. Moreover, Ref. [28] highlights the importance of advanced technologies such as AI and IoT, which improve various functions like quantity surveys and accurate estimation. This clearly demonstrates how data is transforming the construction industry from its inception to its completion, This means that both construction firms and end users will benefit from the digital transformation of the initial stages of the construction process because the preliminary activities will be planned for and organized faster and more accurately [29]. This enables builders to be more proactive in their everyday operations, adjust to changing markets, and react swiftly to consumer requests. This not only makes businesses run more effectively but also increases the likelihood that projects will be completed on schedule and within budget, improving the overall experience for clients.

For the majority of construction companies, digital transformation involves more than just the implementation of new software. Once certain fundamental tools are in place, more sophisticated digital processes can be introduced. This can entail, for example, gathering information for analytics and enhancing workflows through the incorporation of current software into an agility layer. Ref. [28] mentioned that the construction sector will require digital transformation in order to effectively address the escalating difficulties of increasing design complexity, cost overruns, and schedule delays. Construction organizations can optimize their operations by using digital technologies, resulting in improved productivity and a decrease in error risk. Enhanced cooperation is an additional advantage since digital tools enable more effective communication and coordination among all parties involved, including architects, engineers, contractors, and clients. Furthermore, digital transformation allows construction organizations to make data-driven decisions by utilizing sophisticated analytics and up-to-date information, resulting in more precise forecasting and resource allocation. This not only improves project outcomes but also boosts client satisfaction by ensuring timely completion of projects, adhering to budgetary constraints, and meeting the highest quality standards.

According to the literature, the main challenge in pre-construction projects is the delay in planning, design, and organizing requirements. For example, Ref. [30] identified a variety of factors that influence construction projects, with one of the most common causes of delays being that design changes frequently occur due to unforeseen site conditions, evolving client requirements, or blunders in initial planning, necessitating revisions that can impede progress. Furthermore, the lack of comprehensive documentation for design documents can lead to miscommunications and errors during construction. Digital tools can assist project managers in avoiding delays at this stage. However, although many construction firms have tried to adopt disruptive technologies in recent years, the sector still lags behind other industries. The main contributing factor is often that construction firms are not fully aware of the most effective and current digital tools and practices available for managing preconstruction projects.

There remains a gap in the literature regarding how construction companies can use digital tools to prevent delays in take-offs during pre-construction design. The design and schedule of projects during the preconstruction stage must provide an effective foundation from which contractors and site managers can work in order for construction to be completed on time.

To address this gap, current research explores how construction firms can identify and apply the right digital tools to use in the pre-construction phase. The main motivating factor for this study is that allocating the correct digital tools and adopting effective policies and procedures in the pre-construction phase of a project will help construction firms achieve competitive performance in the industry.

The authors have not been able to identify any existing studies exploring the digital transformation suitability of buildings in the pre-construction phase. As a result, there is an additional gap in the knowledge regarding the extent to which asset-owning businesses are prepared to embrace digital technology. Likewise, there are no tools currently available for measuring or evaluating the digitalization readiness of a construction project. Therefore, additional study is needed to understand to which extent the construction firms are equipped for digital transformation. There is also insufficient research on the government’s readiness for digital transformation, particularly in relation to the internet. To the best of the authors’ knowledge, no specific study has been undertaken to determine the factors that influence the digital transformation readiness of the pre-construction phase of a building project. Existing techniques for assessing digital transformation readiness also do not account for the specific needs of the construction industry.

2.2. Selection of Success Factors Affecting Buildings at the Pre-Construction Stage

2.2.1. Technology

A wide variety of technologies can potentially be employed during the pre-construction phase, along with examples showcasing their application. For instance, utilizing drones in the pre-construction stage facilitates improved communication among stakeholders throughout design, site survey, and planning [31]. In addition, drones can improve safety by supporting the assessment of project risks and simulation of dangerous situations. BIM is a significant technology, as stated in [32], and can enhance the spatial arrangement and optimize the process of selecting contractors. AI has the capacity to greatly influence pre-construction activities through data analysis; for example, it is capable of identifying suitable contractors by evaluating multiple criteria such as previous achievements, knowledge, background, and expenses [33]. Blockchain technology can now be employed to supervise construction contracts and project expenses [34]. These technologies streamline operations and guarantee the availability of data during the pre-construction stage. According to [35], geographic information systems (GIS) can be used to analyze land development opportunities based on spatial data. VR can be utilized to identify flaws in 3D models, and the incorporation of VR technology can improve communication, stakeholder involvement, and design visualization in the pre-construction stage [36]. Agent-based modeling and cybersecurity technology can be utilized to detect and assess risks, threats, and vulnerabilities in relation to processes, entities, and stakeholders [37]. The incorporation of these technologies during the pre-construction stage has a significant impact, enhancing efficiency, collaboration, and the precision of decision-making. As new technologies continue to be incorporated into the construction industry, they will continue to drive improvements in the pre-construction phase, leading to construction projects that are more sustainable, cost-effective, and efficiently implemented.

2.2.2. Policy

The implementation of digital technologies in the construction industry is greatly facilitated by policy and regulation. Thus, the notion of Construction 4.0 has been examined in prior studies. As stated in [38], Construction 4.0 aims to achieve its objectives through a multifaceted strategic plan that involves adopting an ecosystem-compliant approach, developing a pilot project, defining capabilities, generating data, and initiating digital enterprise transformation. As an illustration, Ref. [39] showcases the utilization of BIM in Malaysia to enhance stakeholder involvement in Industry 4.0. This example underscores the value of instantaneous collaboration for efficient allocation of resources, strategic planning, and decision-making. In addition, the authors suggest implementing technological training programs to enhance understanding of Construction 4.0 and advise associations and organizations to actively seek out highly skilled personnel, promote productivity, and facilitate intergenerational transfer of knowledge. The importance of training sessions for upskilling and reskilling to improve the performance of a company’s employees is also highlighted in [40]. These sessions offer a basis for ongoing education, a fundamental understanding of Industry 4.0-related competencies, and a workforce prepared for the future. Ref. [41], meanwhile, provides solid evidence that the absence of relevant laws and standards in South Africa significantly impedes the adoption of Construction 4.0 technology, and emphasizes the need for rules and standards to achieve effective digital transformation.

2.2.3. Design

The design phase of a construction project strongly depends on the application of technology and the adoption of novel design tools, leading to a significant enhancement in productivity [42]. The utilization of BIM technology throughout the design process has been successful in promoting sustainable development in China’s building industry. As stated by [43], integrating technology throughout the design phase can be a vital means to enhance stakeholder engagement and reduce risks. Employing VR technologies can provide a visual depiction of a structure, offering insight into its aesthetic characteristics.

2.2.4. Management

At the management level, the implementation of AR technology can enhance decision-making processes and facilitate further digital transformation. As indicated by [44], this technology enhances the pre-construction planning process by offering up-to-date information on subterranean utilities, enhancing decision-making for project teams. In addition, according to [45], blockchain technology is being used in the tendering process in some projects, along with smart contracts. This implementation has successfully ensured the accuracy and reliability of information provided by all parties participating in the procurement process, while also improving project governance.

The fundamental purpose of applying multivariate approaches is to improve the statistical efficiency and explanatory power of researchers. Most first-generation analytical techniques have the same drawback of being limited to examining one relationship at a time. The method that is now most frequently used in the construction industry, SEM, is an extension of various multivariate techniques and can look at several interdependent relationships at once.

Complex statistical data analysis methods and techniques, including causal analysis and SEM-based methods, are needed due to the complexity of social reality, i.e., the latent nature of many social phenomena. These methods and techniques, in the statistical sense, refer to a collection of equations and supporting presumptions for the system under study, the parameters of which are established through statistical observation. Thus, according to [46], structural equations are equations that use parameters to analyze observable or latent variables.

Multivariate approaches like SEM are increasingly used in research to examine and assess multivariate causal linkages. The key difference between SEMs and other modeling methodologies is that SEMs assess the direct and indirect impacts on hypothesized causal linkages [47]. Researchers using SEMs can, with enough participants, readily set up and dependably test hypothetical links between theoretical constructs as well as those between the constructs and their observed indicators.

3. Digital Transformation Readiness SEM Model in the Pre-Construction of Buildings

This paper describes the development and application of an all-encompassing, cross-disciplinary assessment framework for determining digital transformation readiness in building project preconstruction. The proposed DTRPC framework was developed through the use of SEM. It represents a methodical approach to managing pre-construction, which also makes it possible to gain knowledge of the digitization readiness that is necessary to deliver great management and execution. Critical indicators that are specific to each construct are connected with the framework so that the efficacy of each construct can be evaluated. The model consists of thirty indicators, which include individuals’ responsibilities, the accountability of the project team of the organization, and enhanced project management in design and other activities.

This technique is applicable in the current research because it examines the structural link between latent constructs and measured variables by combining component analysis and multiple regression analysis. The benefit of SEM is that it allows one to pinpoint the directionality of the impact of activity spreading from one location to another. In addition to accommodating modeling of interactions, correlated independents, nonlinearities, and correlated error terms, SEM performs similar functions to linear regression. In this sense, multiple regressions are a part of general linear models, which include SEM. Researchers have stressed the effectiveness of this technique in resolving some of the core issues in organizational and consumer behavioral studies [48]. The ability to control measurement error, improved ability to assess the impacts of experimental manipulations, and capacity to test intricate theoretical structures are only a few benefits of SEM.

4. Research Methodology

This study incorporates both quantitative and qualitative methods. Figure 1 shows the components of the model.

Figure 1.

Pre-construction success factor constructs in digital transformation.

4.1. Data Collection

In order to determine the crucial success elements for the digital transformation of the pre-construction phase, the authors of this study consulted a variety of pertinent literature sources. The choice of indicators was made by considering a wide variety of global publications, without any limitations based on location or specific journals. This wide selection of references allows for the extraction of highly generalizable findings [49]. Following the data retrieval, a systematic qualitative content analysis was conducted to identify and categorize the key factors that contribute to the digitalization readiness of the pre-construction phase of building projects. Content analysis is a widely used methodology for collecting and organizing data, and is effective in identifying important trends and patterns in written materials [50]. The classification of data into discrete categories is an essential part of the process of qualitative content analysis [51]. Based on a review of the literature, the authors compiled a list of 30 factors as shown in Appendix A. These factors are grouped into four categories: management, policy, technology, and design.

4.2. Checking the Identified Variables for Validity

According to [52], establishing content and construct validity is an important component of ensuring acceptable results. To enhance the accuracy and comprehensiveness of the identified variables, four experts with extensive knowledge in the technical and managerial aspects of the construction industry were consulted. The participants were interviewed individually using a semi-structured format. They were given a thorough summary of the study’s goals, after which they were asked to give consent for participation. They were then told about the identified critical factors and factor categories. The experts were asked to critically evaluate the factors and their categorization and suggest any necessary modifications. The four experts consulted represent various roles in building projects, namely client, consultant, contractor, and supplier. They possessed extensive experience in a wide range of building sectors. The selection requirements for participants included a minimum of fifteen years of expertise in pre-construction management, working with organizations of a medium to large scale.

4.3. The Questionnaire for the Latent Variable Expert Survey

Following the interviews, a survey was used to gather feedback from a larger sample of experts on the relative importance of each of the digital transformation model’s factors. SurveyMonkey, a web-based survey creation and distribution tool, was used to develop and distribute the survey. Pre-construction management specialists were invited to participate via the SurveyMonkey tool, social media, or email. The survey had three parts. The introduction explained the study and survey goals and provided clear directions for answering questions. Each section presented detailed descriptions of the question categories and scales. The second section included questions regarding the participant’s job title, industry, organization sector, and professional experience. In the third section, the 30 essential factors and four categories that determine digital transformation readiness were presented as shown in Appendix B. Based on their practical experience, survey participants were asked to evaluate the importance of these essential factors and constructs. These questions were answered on a five-point Likert scale with responses ranging from ‘1—not important at all’ to ‘5—extremely crucial’. Table 1 shows the scale used to quantify indicators and construct influence.

Table 1.

Selected experts’ background.

4.4. The Distribution Mechanism

A purposive sampling approach was used to disseminate the survey. The choice of this approach was based on the need for experienced and well-informed participants in order to produce valuable and accurate results [53]. Purposive sampling is a frequently employed semi-random sampling technique in which the researcher randomly selects participants from a deliberately chosen subset of the overall population. This approach enables an accurate representation of the specific population that is important to the researcher [54]. The multi-step, sequential purposive sampling process consists of five steps [55]: (1) identifying the research problem and the precise data required; (2) establishing selection criteria for participants or participant groups; (3) locating appropriate participants or participant groups in accordance with the criteria; (4) employing suitable techniques for data collection; and (5) recognizing potential biases in the data evaluation and result interpretation.

Inclusion criteria for survey participants in this study were currently professional engagement in the pre-construction management field. The sample represents a heterogeneous panel of specialists from different geographical areas in order to mitigate any potential location-based bias.

4.5. The Sample Size Calculation and Determination

Conducting a comprehensive study is crucial to ensure that the collected data accurately reflects a wide variety of samples, thereby providing a solid basis for further investigation. The ideal sample size for SEM models remains a topic of debate. Ref. [48] implies that a sample size below a specific threshold may be considered appropriate in specific situations with a small number of variables and favorable statistical features. However, they also propose that a sample size greater than 200 is ideal. Ref. [56] performed a comprehensive examination of 84 academic papers in the domains of construction and management, focusing on the application of SEM, and found that 77% of the studies analyzed had a sample size of under 200. The sample in our study included 201 professionals.

4.6. Examine the Multivariate and Normality Distributions

One crucial aspect to consider in SEM is evaluating whether the sample demonstrates a normal multivariate distribution. Applying estimation methods based on normal distribution theory to the collected data shows that a multivariate non-normal distribution might result in inaccurate estimations. Mardia’s multivariate kurtosis, introduced by [46], is employed in IBM AMOS to evaluate the multivariate normality. Outliers are identified by computing their Mahalanobis distance-squared, which quantifies the standardized squared distance between the factor in question and the sample mean factor of all variables [57]. As the distance grows, the impact of the observation on Mardia’s multivariate kurtosis becomes stronger, resulting in a larger departure from the multivariate normal distribution [58]. Therefore, removing an outlier will result in a reduction in Mardia’s multivariate kurtosis, based on the studies conducted by [56,59].

We identified outliers by evaluating whether an individual participant’s contribution was inconsistent with the other inputs with the use of IBM AMOS software V.26 [46]. The survey was distributed to a total of 533 potential participants, and 244 responses were obtained. In total, 31 incomplete responses and 12 outliers were excluded, resulting in a final sample of 201 legitimate responses. The survey response rate is thus roughly 37%. All constructs and indicators were found to be within the acceptable range for normal distribution.

5. The Structural Equation Model

This study employed a two-stage methodology to build a robust framework for investigating the correlation between various components and indicators in the DTRPC. The validity and reliability of the model were evaluated using confirmatory factor analysis along with the structural model. The approach of bootstrapping maximum likelihood was employed to estimate the structural routes and factor loadings [59].

5.1. Model Specification, Classification, and Estimation

The model specification defines the assumed relationships and accompanying equations that make up a thorough conceptual model. Model identification ensures the presence of a unique mathematical solution for the specified model, while model estimation involves the meticulous choice of an appropriate estimation approach to determine the model parameters. The proposed model was subjected to confirmatory factor analysis (CFA) to evaluate the association between the factors (indicators) and the core components. The framework comprises 30 latent variables that are grouped into four constructs, as shown in Figure 2.

Figure 2.

DTRPC measurement model.

The development of a structural model enables the prediction of the relationships between the first and second iterative structures. The structural framework consists of four main latent constructs (referred to as management, policy, technology, and design in Figure 2). These four constructs combine to determine overall digital transformation readiness in the pre-construction phase (DTRPC). The DTRPC model demonstrates a link between the four first-order components and the DTRPC, indicating a positive relationship. Two primary hypotheses were created based on these assumptions, with the original hypothesis further broken down into sub-hypotheses. The inquiry was conducted based on the following hypotheses:

H1:

Each of the four constructs considered has a beneficial effect on DTRPC.

H2:

Overall readiness is shaped by the combination of the four components in the model integrates.

5.2. Assessment of Goodness of Fit Indices (GOF)

In order to refine models and demonstrate how well each item fits within its underlying component, goodness of fit (GOF) evaluations are crucial. Ref. [58] offers detailed explanations of several tests employed to assess the adequacy of a model. However, there is still no agreement on the best suitable indexes. Using the metrics listed in [60] and [61], an assessment of the model’s fit with the study’s goals was conducted using the root mean squared residual (RMR), root mean square error of approximation (RMSEA), and relative chi-square (χ2/df).

Chi-square (χ2) measures the degree to which the observed covariance matrices differ from the expected values [62]. There is a significant discrepancy between the data and the model if the χ2 test result is high. According to [58] the relative chi-square (χ2/df), which should be between 1 and 3, is used to determine the appropriate value. The RMSEA quantifies the differences in covariance compared to the saturated model, and thus the extent of disagreement between the observed and predicted covariance. The RMSEA quantifies how well a model fits the data. According to [56], the optimal range for the RMSEA is between 0.05 and 0.1. Nevertheless, as highlighted by [59], it is widely acknowledged that a score below 0.08 indicates a respectable degree of fit.

As per [56], indicators with factor loadings below 0.40 should be eliminated from the revised model. The tenuous correlation between these variables and their corresponding constructs has the potential to undermine the model’s integrity. In addition, Ref. [59] established a threshold of 0.5 for the loading factor of the latent construct. The model included factor loadings that were less than 0.5, specifically G01-02. Consequently, the DTRPC model underwent modifications by removing these loadings and making adjustments to the indices, as shown in Figure 3.

Figure 3.

DTRPC modified measurement model.

The GOF indices confirm the modified measurement model’s exact appropriateness, as shown in Table 2. For example, according to [56], the suggested cutoff value of 3.00 is higher than the computed χ2/df 2.201 value. The RMR and RMSEA values are 0.061 and 0.078, respectively, which are below the threshold levels set by [60]. By these measurements, the model meets the GOF criteria.

Table 2.

The scale for the significance degree.

5.3. Reliability and Validity of the Measurement Model

The proposed model must also be evaluated for validity and reliability. According to [58], verifying the construct is a crucial component of assessing the model’s reliability and strengthening its basis. The process of evaluating dependability includes evaluating the constructs’ consistency using Cronbach’s alpha test and determining their one-dimensionality. A comprehensive evaluation of discriminant and convergent validity is required for validity assessment. In order to determine the reliability of the survey results, we used the Cronbach’s alpha (α) test in SPSS v29. This test evaluates the reliability of the measurement by employing a minimum threshold of 0.7 [56]. The findings of this examination are displayed in Table 3.

Table 3.

GOF assessment for the modified DTRPC model.

All constructs exhibited alpha values greater than 0.7. Therefore, the inputs given by the respondents were considered to be logical and reliable enough for additional examination, and the variety of indicators showed a unified structure. The unidimensionality assessment was carried out using the SFL approach. All of the indicators’ SFLs (Standardized Factor Loadings) had positive values and were over the 0.5 threshold value suggested by [56]. Consequently, the readiness measuring model successfully satisfied the unidimensionality requirement.

5.4. Testing Convergent Validity

The degree to which various measurements of a certain concept—which theoretical models suggest should be correlated—actually exhibit a relationship with one another is known as convergent validity, or CV [63]. According to [59], a composite reliability (CR) higher than 0.7 and SFLs higher than 0.5 for all factors within a construct indicate a strong CV.

Equation (1), as defined by [52], is used to calculate CR:

Equation (1) defines the variable “Li” as the SFL (Specific Feature Level). The variable “i” represents each individual item in a set, and “n” represents the total number of items. The term “ei” denotes the variability of error in construct “i”. According to [64], it is possible for the researcher to establish satisfactory convergent validity solely based on construct reliability. As shown in Table 3, the results indicate that all constructs showed a critical ratio value higher than 0.70. Furthermore, the results shown in the final model demonstrate that all the SFLs surpassed the 0.5 threshold, thus confirming satisfactory convergent validity as per [58,64]. As per [65], these findings indicate a high level of reliability for the model and a strong internal consistency for the construct. In addition, the convergent validity criteria have been satisfied based on the values of SFL and CR.

5.5. DTRPC Model

Using an SEM, a conceptual framework was created to show how each component affects the DTRPC. This was achieved by establishing direct connections between the DTRPC as a whole and each individual construct. The structural model, depicted in Figure 4, illustrates the extent to which the primary construct influences each construct in the model.

Figure 4.

DTRPC final measurement model.

Table 4 displays a concise overview of the outcomes derived from the application of the preceding structural model. The data demonstrate that all GOF indices were achieved, indicating that the structural model adequately fulfills the criteria for a satisfactory fit.

Table 4.

Calculated reliability coefficients for composites using the latent variables’ Cronbach’s alpha.

The model’s GOF exceeds the threshold value of 0.50 proposed by [58] and [56]. All SFL values were higher than the cutoff of 0.5, as shown in Table 4. As a consequence, DTRPC and the modified constructs were shown to be strongly correlated.

6. Analysis and Discussion of the Results

The proposed model provides a coherent approach that decision-makers in organizations may use to evaluate readiness for digital transformation in building projects. The framework considers many different elements linked to multi-operationalism. The methodology used an SEM to evaluate the importance of numerous components that determine the degree of readiness. Additionally, it assesses the constructs by considering their SFLs. The results emphasize that the degree of readiness is greatly affected by the pre-construction factors.

6.1. The Data Survey Validation

To assess the influence of each latent variable that influences readiness levels in the pre-construction management phase, a survey was electronically disseminated to a diverse group of industry experts worldwide, in accordance with the sampling method detailed previously. Feedback was obtained from 201 individuals in executive, facility, project, and department management positions from a wide variety of backgrounds. The present study thus encompasses a diverse group of individuals who possess substantial abilities and competence in the domain of pre-construction. The survey was disseminated to potential respondents by email and social media channels, as indicated in the Methodology section. A survey was sent to 533 prospective participants, resulting in the collection of 244 responses. Among the received responses, 201 were deemed complete and legitimate, while 31 had to be removed since they were either outliers or incomplete. This represents a response rate of 37%, which is in accordance with the average response rate for online surveys reported in the meta-analysis by [66], which was 34%. It is also higher than the average response rates seen in [67], 22.9% in [68] and 14.8% in [69]. The findings suggest that the survey is representative of a wide range of people working in the construction industry, which is consistent with the study’s assumptions.

6.2. Respondents Demographics

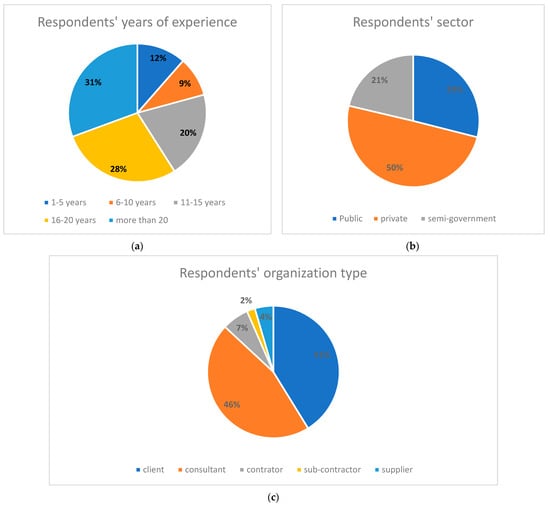

Figure 5 shows a breakdown of the survey participants’ years of experience, industry, job position, type of organization, and type of work. Approximately 31% of the survey participants were in managerial roles within their respective companies, which included duties such as project manager, executive manager, and department manager. The remaining 68.6% of the participants worked in technical fields like senior engineering or supervision. A breakdown of participants based on key organizational types reveals that a sizable majority of respondents were employed by either client organizations (41% of the sample) or consulting companies (45%). Of the remaining participants, 6.5% were employed by contractors, 4.5% by suppliers, and 3% by sub-contractors. Figure 5a illustrates the mean level of professional experience demonstrated by the respondents of the survey. The participants had an average of 21 years of professional experience. In order to ascertain the breadth of knowledge in the industry, the authors compared the levels of expertise of the participants in this study with those of previous studies conducted in the pre-construction management domain. According to research by [70], while some respondents had ten to thirty years of experience in construction, 52.7% of participants had less than ten years of experience. Forty percent of respondents to the poll by [71] said they had been in their current position for more than 10 years. The gathered data properly reflect the opinions of persons with extensive expertise in this study, as may be seen from the distributions presented above.

Figure 5.

(a): Respondents’ years of experience; (b) respondents’ sector; (c) respondents’ type of organization.

Figure 5a–c respondent profile and demography.

6.3. Comparisons Amongst Respondents’ Construct Rankings

In order to assess and rank the significance of each construct according to the responses of participants representing different sectors and organization types, the data from the survey were evaluated using the relative importance index (RII). In order to examine how each set of respondents saw pre-construction management structures in the context of building project management, we also compared the factor rankings. RII is determined by the following Equation (2):

W represents the respondents’ weighting, ranging from 1 to 5, for each construct. The frequency of responses given for each value of W is indicated by X. The maximum weight, denoted by A, is 5. N represents the total number of survey respondents, i.e., 201. A higher number on the RII value scale, which ranges from 0 to 1, indicates that a given construct is more important than the others.

The ranking of each construct was based on the average of the individual ranks, as shown in Table 5. For this measure, the lower the number, the greater the importance to the sector. Additionally, the client placed a greater emphasis on management due to its significance and the need to ensure a project is being executed as per the client’s requirements, and the importance of demonstrating the contractors’ performance capability. A particularly important element of the management construct for clients is cyber-security. On the other hand, the contractors, sub-contractors and consultants were making significant investments in technology and understood its significance for construction projects. This was because they possessed knowledge of these technologies and experience in using them, and understood their value for the construction process. Lastly, suppliers primarily highlighted the importance of design because of the significance it holds for both their companies and the items they provide.

Table 5.

GOF assessment for the final DTRPC model.

To assess the relative important of individual factor ranking table is shown as Table 6 is necessary for leaders to focus to enhance the adoption process.

Table 6.

Ranking of the latent variables and their corresponding constructs.

7. Analysis of the SEM Results

According to the results of the construct-level analysis, it can be inferred that the technology construct is the most important in the DTRPC model as shown in Table 7, with a significance level of 0.98 (SFL 0.98). Previous research findings similarly highlight the importance of technology [72]. It is widely acknowledged that digital transformation cannot be achieved without the use of technology.

Table 7.

Ranking of the constructs among the different types of organizations.

The policy construct is the second-most significant (SFL 0.97) due to its critical role in facilitating the adoption of digital transformation in infrastructure. This is supported by the high response rate from the client sector, making it a key reference point for policy formulation.

With a standard factor loading of 0.82, the final DTRPC model reveals that G04-04, which refers to the use of 5D for project design, is the most significant critical factor. This demonstrates the significance of 5D throughout the pre-construction phase, as well as its capacity to increase the chance of a project being successful by enabling more efficient planning and enhanced project control [73]. It provides thorough insight not only during the pre-construction phase but also throughout construction by monitoring progress. This is accomplished by factoring time and cost factors into the design of the project. In addition, it helps facility management keep track of the expense of the original design for the sake of maintenance.

G4-07, “Integration of virtual reality with design,” was the second-most significant crucial factor, with an SFL of 0.80. This underscores the significance of VR in the design process, which is becoming increasingly important as Construction 4.0 continues to become more prominent worldwide. Increasing stakeholder engagement [36] and making it easier to generate optimization ideas for project design are both benefits of VR technology. Furthermore, the utilization of VR during the preliminary stages of a project helps to streamline the logistics of the project site and enhance the training of the staff involved in the project [40].

The third-most significant factors have standard factor loadings of 0.79. These factors are G02.03 (upskilling the preconstruction team for digitalization processes), G03.03 (using blockchain technology with the organization’s cloud system), and G03.05 (the availability of robotics during site preparation). Effective digital transformation in building project organizations requires upskilling current personnel to effectively utilize cutting-edge technology. As a result, onboarding onto the digitalization process is essential, as the industry’s most significant obstacle to digital transformation is the need to enhance the skills of existing staff [38]. Disrupting current approaches and achieving leadership in the industry requires a significant endeavor to revamp processes and evaluate pre-construction procedures. The implementation of blockchain technology during the pre-construction phase of building projects ensures decentralization and transparency [74]. Blockchain allows for the transformation of supply chain management, automation of contract execution, verification of document validity, and facilitation of stakeholder involvement. The utilization of robotics in site preparation, as represented by G03.05, has been shown to be highly crucial in reducing the duration of hazardous tasks performed by workers, enabling remote operation, and improving safety training [75]. These technologies not only enhance worker safety but also raise the efficiency of project management at construction sites.

Tendering plays a crucial role in the pre-construction phase due to the large number of tendering packages, and the selection of construction contractors; implementing AI technology, represented by G01.01, can improve the automation of laborious tender management activities. This may involve identifying pertinent opportunities, evaluating bid documents, submitting information requests, and generating proposals. This has the potential to save providers a substantial amount of time and resources, enabling bid teams to concentrate on refining their solutions and achieving higher evaluation scores. Every bidding submission must incorporate a comprehensive range of company information, including classified and delicate intelligence, such as pricing, financial information, competitive distinctiveness, and so forth.

If tender submissions are quickly created without careful verification and approval of the content, there is a high probability that they will include incorrect or obsolete information. This leaves the business vulnerable to potential hazards to its brand reputation and financial health. AI can utilize previous data to determine the types of tenders that have the highest probability of success, identify the most active rivals in the market, and ascertain the most effective pricing methods. This can assist providers in making well-informed choices regarding which tenders to pursue and how to organize their offers.

G02.02 refers to the availability of life cycle assessment (LCA) tools integrated with BIM, which supports the achievement of sustainable development goals. LCA is a valuable tool for evaluating the ecological consequences of products, and integrating LCA with BIM is pushing construction companies towards sustainability [71]. LCA holds great potential for the development of environmentally friendly designs. However, significant knowledge and skills are required in order to harness its advantages. International standards on LCA, such as ISO 14040/44 [76], offer a general framework but do not specify precise methods for calculating environmental impacts. LCAs can thus be developed with a range of boundary conditions, making it challenging to provide a meaningful comparison between different LCAs and the suitability of their associated building projects. Therefore, it is important to carefully conduct comparisons, considering all relevant information about the LCAs being studied. Transparent communication of this background information enables accurate interpretation of LCAs [77].

Although there may be variation in the importance levels of the latent variables and constructs, this study demonstrates that all identified elements significantly contribute to the overall readiness of the DTRPC model. Neglecting any of these items may result in errors when carrying out crucial responsibilities; therefore, no item should be ignored or exempted from implementation. DTRPC can be effectively utilized in the creation of a resilient pre-construction management decision-making framework and can support the evaluation of compliance with international project management standards. In addition, DTRPC can be used as a tool to measure performance, compare design indicators to benchmarks, and analyze the monitoring of pre-construction teams responsible for specific activities. This is carried out through an appraisal approach that rates performance outcomes as an index representing readiness for transformation, using the relative weight methodology suggested by [78]. Hence, the adoption of DTRPC has the potential to offer a reliable solution that improves the effectiveness of transformation plans, reduces problems, enhances design management, and facilitates the evaluation of pre-construction personnel’s performance in digitization throughout the entire project duration. This can be accomplished by enhancing compliance with regulations, optimizing management processes, providing comprehensive training, and implementing effective monitoring and control measures throughout the pre-construction phase. If there is a specific constraint that is more important within a given project, significant critical factors may be assigned higher weights to highlight their importance in relation to other critical factors. Moreover, when the scope of particular indicators is restricted, their impact might be spread out among other indicators within the same construct. If any of the constructs do not match the DTRPC criteria, their contribution may be divided among the other structures.

8. Conclusions

To the best of the authors’ knowledge, no empirical research has previously been carried out to examine digital transformation readiness within the pre-construction period. Therefore, this study represents the first of its kind in this field. The purpose of this study is to enhance the current understanding of performance measures in construction projects related to digital technology implementation and their impact on project companies through a systematic research investigation. This study presents a comprehensive model that uses four constructs and 30 latent variables to evaluate the success elements of pre-construction models. The 30 indicators represent optimal methodologies and elements that contribute to achieving success. A sample of 201 industry professionals from around the world assessed the importance of the indicators and constructs through an online survey. Statistical analysis was conducted using SEM via SPSS AMOS V26. SEM successfully demonstrated adherence to validity benchmarks regarding the model’s assessment of fitness and data reliability.

The successful implementation of digital transformation in building projects depends on the policy and regulation department to establish the necessary foundation. This necessitates the implementation of a training program aimed at enhancing the skills of the personnel and establishing benchmarks to enhance collaboration and cooperation. A well-defined organizational plan is necessary to effectively carry out the process of digital transformation and demonstrate a strong commitment from the leadership. In order to achieve success, building project executives should establish an incentive program to encourage internal and external support. Both research studies have determined that digital transformation policies and laws play a vital role in building projects. Asserts that the deployment of digital twin technology is crucial for the digital transformation of construction projects.

Early adoption of technology and effective project management are crucial. This entails the utilization of artificial intelligence (AI) for the purpose of cost estimation and project scheduling, as well as the implementation of 4D Building Information Modeling (BIM) for enhanced scheduling and design. Utilizing digital key performance indicators (KPIs) and platforms effectively engages sponsors and sustains their interest in the project. Big data is crucial for estimating and procuring digitalization projects.

Technological innovation is essential for the process of digital transformation. Once criteria and prerequisites have been established, technology becomes essential in the pre-construction phase. Unmanned aerial vehicles can be used for conducting site surveys, while artificial intelligence can be applied in the initial stages of project design to enhance the likelihood of success. Technology is being utilized in pre-construction activities. The utilization of robotics in construction projects and the integration of IoT (Internet of Things) technology in excavators are employed to enhance the efficiency and effectiveness of the construction industry. The implementation of 5G technology, 3D modeling, and BIM updates has proven to be highly effective. Utilizing 3D printing for constructing modular structures can significantly reduce both construction expenses and the time required. Technology plays a crucial role in facility management, particularly in areas like building security and monitoring where Internet of Things (IoT) systems are utilized. Unmanned aerial vehicles have the capability to explore distant or hard-to-reach areas, hence reducing the potential danger to human beings. Artificial intelligence, such as facial recognition technology, plays a crucial role in facility management. Utilizing technology across all stages is crucial for digitizing any construction project.

Effective implementation of digital technology in construction projects necessitates the presence of well-crafted design. The objective of this group is to streamline the design phase by implementing 5D design optimization. In order to prevent conflicts and enhance stakeholder involvement, virtual reality technology is utilized, incorporating accurate renderings. BIM facilitates the process of determining the appropriate distances and arrangements for a given space. Implementing digital transformation in this process enhances design precision and minimizes the risk of non-conformity.

The results of this research suggest that important elements of the pre-construction phase are greatly influenced by the identified indicators, which in turn are positively affected by the latent variables of these important elements. The results indicate that the Technology construct (SFL 0.98) has the greatest influence on DTRPC. We strongly advise industry leaders to prioritize critical factors that have a substantial impact on overall performance in this phase. These factors include the implementation of 5D for project design (G04-04), the integration of virtual reality with design (G04-07), the upskilling of the preconstruction team in relation to digitalization processes (G02-03), the utilization of blockchain technology with the organization’s cloud system (G03-03), and the availability of robotics for site preparation (G03.05).

The purpose of the proposed DTRPC is to provide a quantitative measuring tool that can aid decision-making teams in various aspects of the pre-construction process, including planning, monitoring, regulating, assessing, and benchmarking. Furthermore, the model’s conceptual model can offer top-level decision-makers a deeper understanding of the most significant issues affecting this phase which should be prioritized. Assessing the performance of each process group allows for the identification of strengths and weaknesses in the execution of this model. This assessment serves as the basis for developing improvement plans in areas that are doing poorly. In addition, the deployment of the DTRPC model will provide a greater level of understanding, visibility, oversight, and management of initial tasks to address and mitigate any possible issues and resulting conflicts arising from insufficient execution of the activities.

This study addresses the gaps in the existing literature on the subject of pre-construction management. As a result, it contributes to the present body of knowledge in this area. In future research, alternative analysis methodologies or a combination of methods, such as analytical hierarchy process (AHP), weighted synergy network (WSN), Ref. [79] and partial least squares structural equation modeling (PLS-SEM) [80,81], might be utilized in order to further investigate the factors and constructions that have been identified in this research.

Author Contributions

Conceptualization, K.K.N., M.G. and F.A.-H.; Methodology, K.K.N., M.G. and F.A.-H.; Software, F.A.-H.; Validation, K.K.N. and F.A.-H.; Formal analysis, F.A.-H.; Investigation, K.K.N., M.G. and F.A.-H.; Resources, K.K.N., M.G. and F.A.-H.; Data curation, F.A.-H.; Writing—original draft, F.A.-H.; Writing—review & editing, K.K.N. and M.G.; Visualization, M.G. and F.A.-H.; Supervision, K.K.N. and M.G.; Project administration, K.K.N., M.G. and F.A.-H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Pre-Construction Digital Transformation Critical Success Factors

Figure A1.

Pre-Construction Digital Transformation Critical Success Factors [3,15,22,27,29,32,33,35,36,39,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131].

Appendix B. Survey Questionnaire Used to Collect the Data

Part one: General information (This part consists of some background information and career related to field expertise)

- 1-

- Which organization do you represent _____?

- Client

- Consultant

- Contractor

- Supplier

- 2-

- How many years of experience do you have in the construction industry?

- 0–5 years

- 6–10 years

- 11–15 years

- 16–20 years

- 20> years

- 3-

- Which sector do you represent?

- Public sector

- Private sector

- Semi-government

- Others (please specify)

- 4-

- How many years of digitalization (digital technologies) experience do you have in the construction industry?

- None

- 1–5 years

- 6–10 years

- 11–15 years

- 16–20 years

- 20> years

- 5-

- Which is your area of expertise? (you can choose more than one item below)

- Civil Engineering

- Mechanical Engineering

- Electrical Engineering

- Project/Construction Management

- Program Engineer

- Environmental Engineer

- Quality and Safety Engineer

- Research & Development

- IT Engineer

- Design/Contract Engineer

- Facility Management

- Other (please specify)

- 6-

- In which phase(s) does your organization implement Digital transformation?

- Initiation phase

- Planning phase

- Implementation phase

- Hand-over phase

- Others (please specify)

- 7-

- What is your position at your company?

- Executive manager

- Department manager

- Project manager

- Senior engineer

- Quantity surveyor

- Engineer or supervisor

- Others (please specify)

- 8-

- Have you had special training on digital transformation?

- Yes

- No

In this part 30 factors were identified and categorized into 4 groups (Management, Policy, Technology, design). The aim is to measure to level of readiness for Digital transformation in building at pre-construction phase in Likert scale based on the importance of factors that will impact on project performance in buildings during Pre-construction.

The selected factors are categorized under the following 4 groups.

- Group 1—Management

- Group 2—Policy

- Group 3—Technology

- Group 4—Design

Group 3—Management factors are defined as the required management tools and skills that support the digital transformation to support decision making and systems at the early stage of projects. These factors might be helpful tools for engineering and project managers, clients, and the engineering contractors of building projects).

In this question, you will be asked to assess the importance of implementing various technologies to improve the Facility Management performance. A 5-point Likert scale will be used to measure the impact. Each point on the scale corresponds to a different level of importance. Please choose the option that best reflects your judgment:

|

| 1: Not important at all |

| 2: Slightly important |

| 3: Moderately important |

| 4: Very important |

| 5: Extremely important |

G1-01. What is the importance of a Implementation of AI on selection of contractors

Example: utilizing AI on bidders selection during tendering stage

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-02. What is the importance of Availability of cloud computing to store previous projects data?

Example (e.g., referencing on past projects data for cost, schedule and other issues)

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-03. What is the importance of cost control by using AI technology (e.g., using AI in design cost, cost, schedule cost, etc.)

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-04. What is the importance of Utilization of a digital platform for key performance indicators during pre-construction for project sponsors?

Example: (e.g., using data analytics for dashboard for project sponsors).

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-05. Availability of digitalized estimation process for major project items?

Example: (e.g., using BIM on project estimation of the existing assets.)

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-06. What is the importance of The availability of 4D BIM modelling for scheduling accuracy?

Example: (e.g using BIM on developing accurate schedule based on previous database)

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-07. What is the importance of Implementation of big data and analytics for labour productivity?

Example: Safety Data, task completion per hr and integration of labor and technology per time for utilization of tools.

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-08. What is the importance of the Utilizating of BIM modelling for stakeholder management?

Example: using of BIM to enhance stakeholder engagement and control their influence to the project

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-09. What is the importance of Availability of big data for procurement process? Example: having a large amount of data from previous project or data banks for procuring major items and usage for inhouse estimation

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-10. What is the importance of Utilization of real time 3D modelling for customers review? Example: (e.g., utilizaing 3D Modeling for early stage of concept design.)

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G1-11. What is the importance of the Availability of cloud computing for tracking transmittals on pre-construction stage?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G01-12. What is the importance of Utilization of cyber-security for information management at pre-construction stage? Example: (securing Data in the initial phases to prevent leaking or scavenging of financial data like estimations and schedules to outside bidders)

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

Group 2: Policy factors defined as the Policy and regulation to support the digital transformation of Pre-construction phase.

G2-01. What is the importance of the availability of Regulatory incentive to use digitalized technologies in pre-construction stage?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G2-02. What is the importance of the availability of LCA tools integrated with BIM model for achievement of sustainable development goals (e.g., almost its is a mandatory for any organization to setup a sustainability goals and objectives to be competitive due to the global development goals, how this is important to have it).?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G2-03 What is the importance of Upskilling the preconstruction team for digitalization processes?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G2-04. What is the importance of the availability of digitalization standards for pre-construction management?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

Group 3: Technology factors are defined as the required technologies that support the digital transformation to enhance the activities at the early stage of projects. These factors might be helpful tools for engineering and project managers, clients, and the engineering contractors of building projects)

G3-01. Using of machine learning during pre-construction? (e.g., cost, schedule, visible light transmittance calculation, solar heat gain coefficient calculation, etc.)?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G3-02. What is the importance of Implementation for 3D Mapping for BIM Modelling (e.g., site selection, onsite material layout, etc.)?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G3-03. What is the importance of Using of blockchain technology with the organization’s cloud system?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G3-04. What is the importance of Utilizing of drones for site surveying?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G3-05. What is the importance of The availability of robotics on site preparation.?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G3-06. What is the importance of Utilization of GIS for site selection?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

Group 4: Design factors are defined as the technology utilized to support engineering and design phase and to digitally ehance the quality of the design produced to clients.

G4-01. What is the importance of Using of BIM modelling for the spacing layout?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G4-02. What is the importance of Using of drones for site localization?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G4-03. What is the importance of Using of big data and analytics for design optimization?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G4-04. What is the importance of Implementation of 5D for detailed engineering optimization?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G4-05. What is the importance of Utilizing of digital twins on project design?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G4-06. What is the importance of Implementation of AI to capture and assess the impact of design documentations updates?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G4-07. What is the importance of Integration of virtual reality with design?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

G4-08. What is the importance of Utilization of laser scanning during design stage?

- Not important at all

- Slightly important

- Moderately important

- Very important

- Extremely important

- I don’t know, I prefer not to answer this question.

References

- Sawhney, A.; Riley, M.; Irizarry, J.; Pérez, C.T. A proposed framework for construction 4.0 based on a review of literature. EPiC Ser. Built Environ. 2020, 1, 301–309. [Google Scholar] [CrossRef]

- Musarat, M.A.; Hameed, N.; Altaf, M.; Alaloul, W.S.; Al Salaheen, M.; Alawag, A.M. Digital Transformation of the Construction Industry: A Review. In Proceedings of the 2021 International Conference on Decision Aid Sciences and Application (DASA), Sakheer, Bahrain, 7–8 December 2021; pp. 897–902. [Google Scholar] [CrossRef]

- Nisa Lau, S.E.; Zakaria, R.; Aminudin, E.; Saar, C.C.; Yusof, A.; Wahid, C.M.F.H.C. A review of Application Building Information Modeling (BIM) during pre-construction stage: Retrospective and Future Directions. IOP Conf. Ser. Earth Environ. Sci. 2018, 143, 012050. [Google Scholar] [CrossRef]

- Xu, J.; Lu, W.; Xue, F.; Chen, K. ‘Cognitive facility management’: Definition, system architecture, and example scenario. Autom. Constr. 2019, 107, 102922. [Google Scholar] [CrossRef]