Exploring Industrial Engineering Knowledge and Environmental Sustainability

Abstract

:1. Introduction

“Industrial Engineering is concerned with the design, improvement and installation of integrated systems of people, material, information, equipment and energy. It draws upon specialised knowledge and skill in the mathematical, physical and social sciences together with the principles and methods of engineering analysis and design to specify, predict and evaluate the results to be obtained from such systems”.

2. Research Question, Aim, and Objectives

- Identify which are the most prominent forms of industrial engineering knowledge that promote environmental sustainability.

- Determine the most prominent forms of industrial engineering and environmental sustainability strategies, theories, methods, and practices.

- Identify overlapping knowledge components associated with industrial engineering and environmental sustainability.

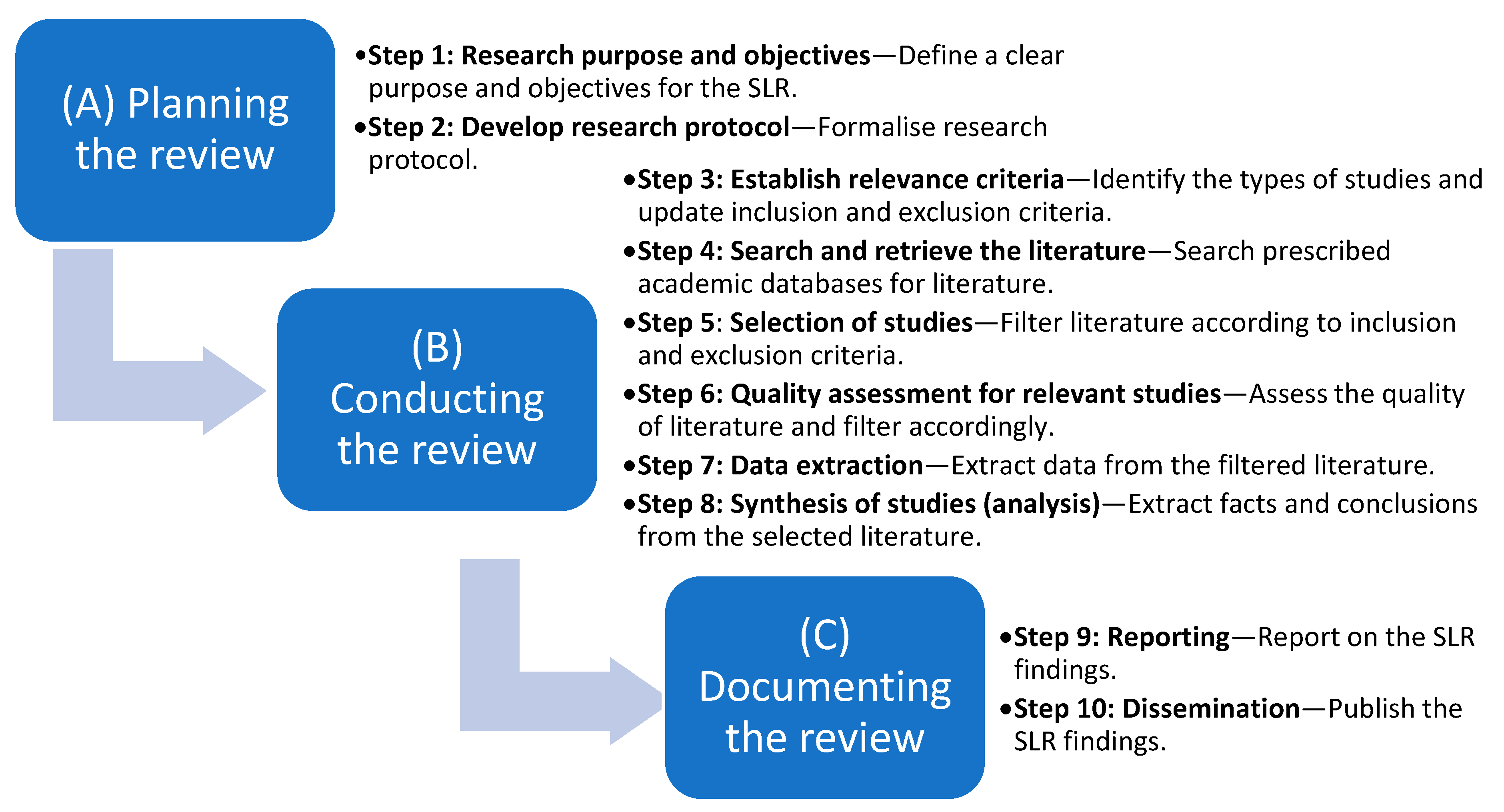

3. Research Method

4. Results and Findings

4.1. Step 1: Research Purpose and Objective

4.2. Step 2: Develop Research Protocol

4.3. Step 3: Establish Relevance Criteria

4.4. Steps 4 to 6: Search, Selection, and Quality Assessment of the Literature

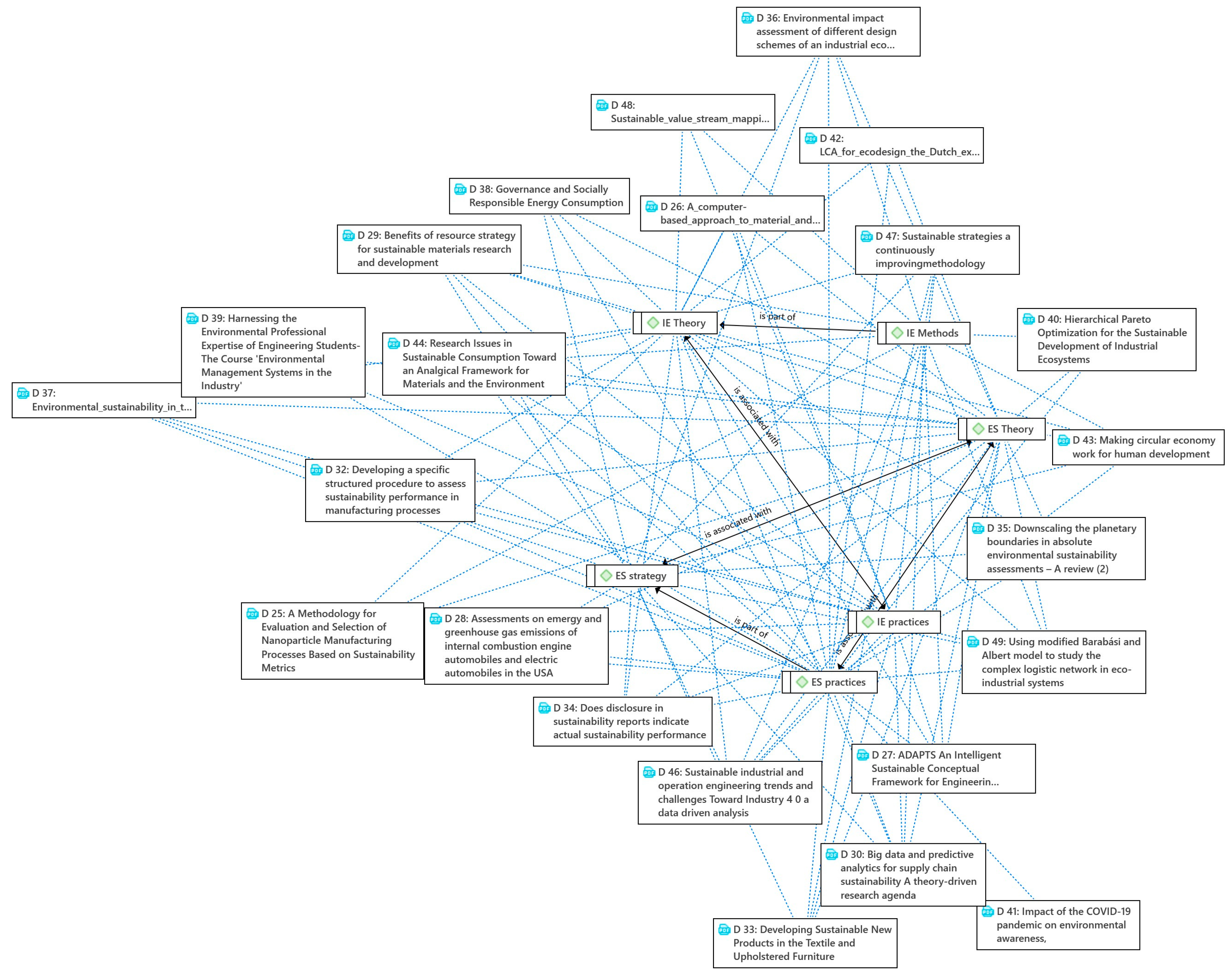

4.5. Steps 7 to 8: Data Extraction and Synthesis of Core Findings

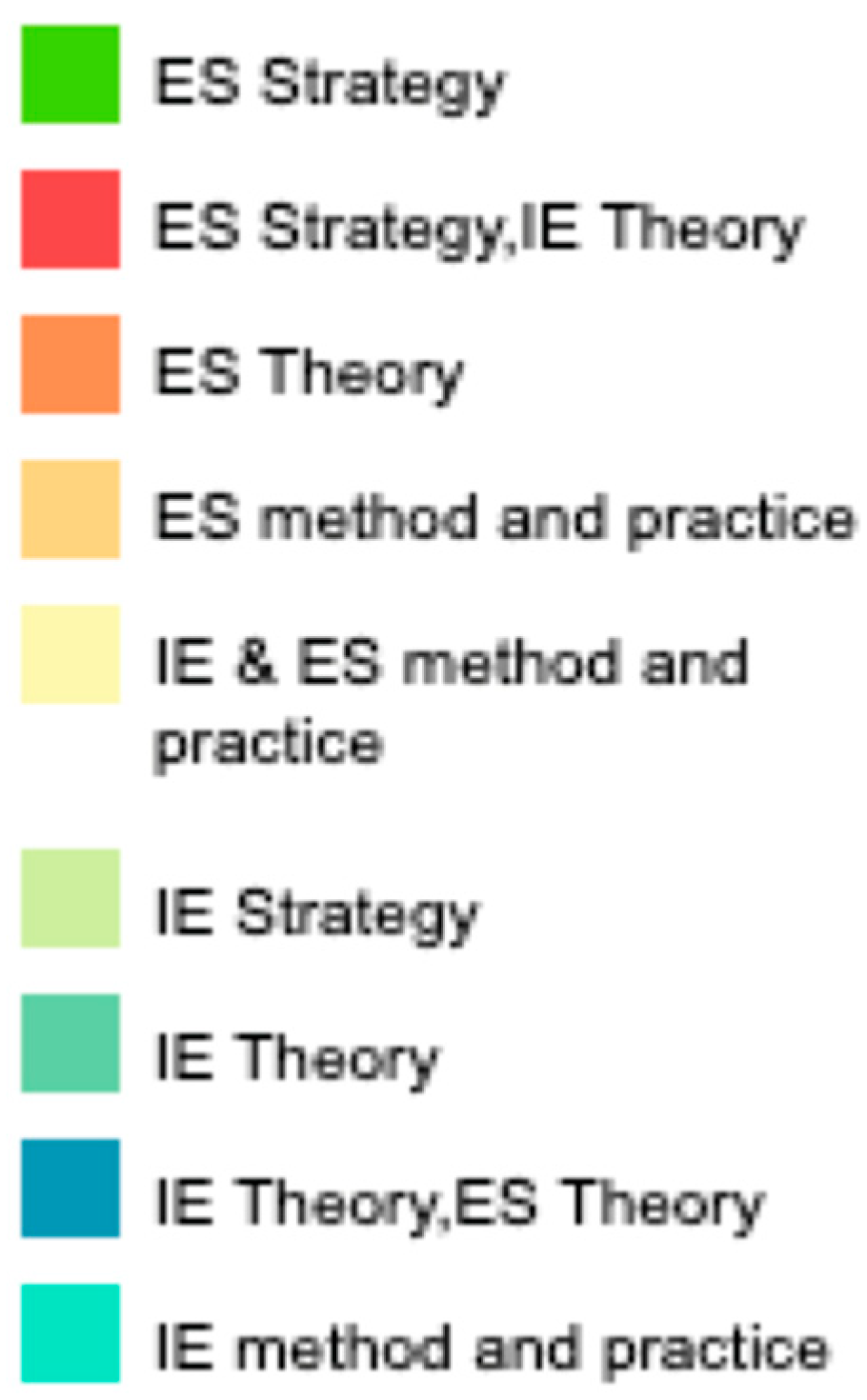

4.5.1. Strategy

4.5.2. Theory

4.5.3. Methods and Practices

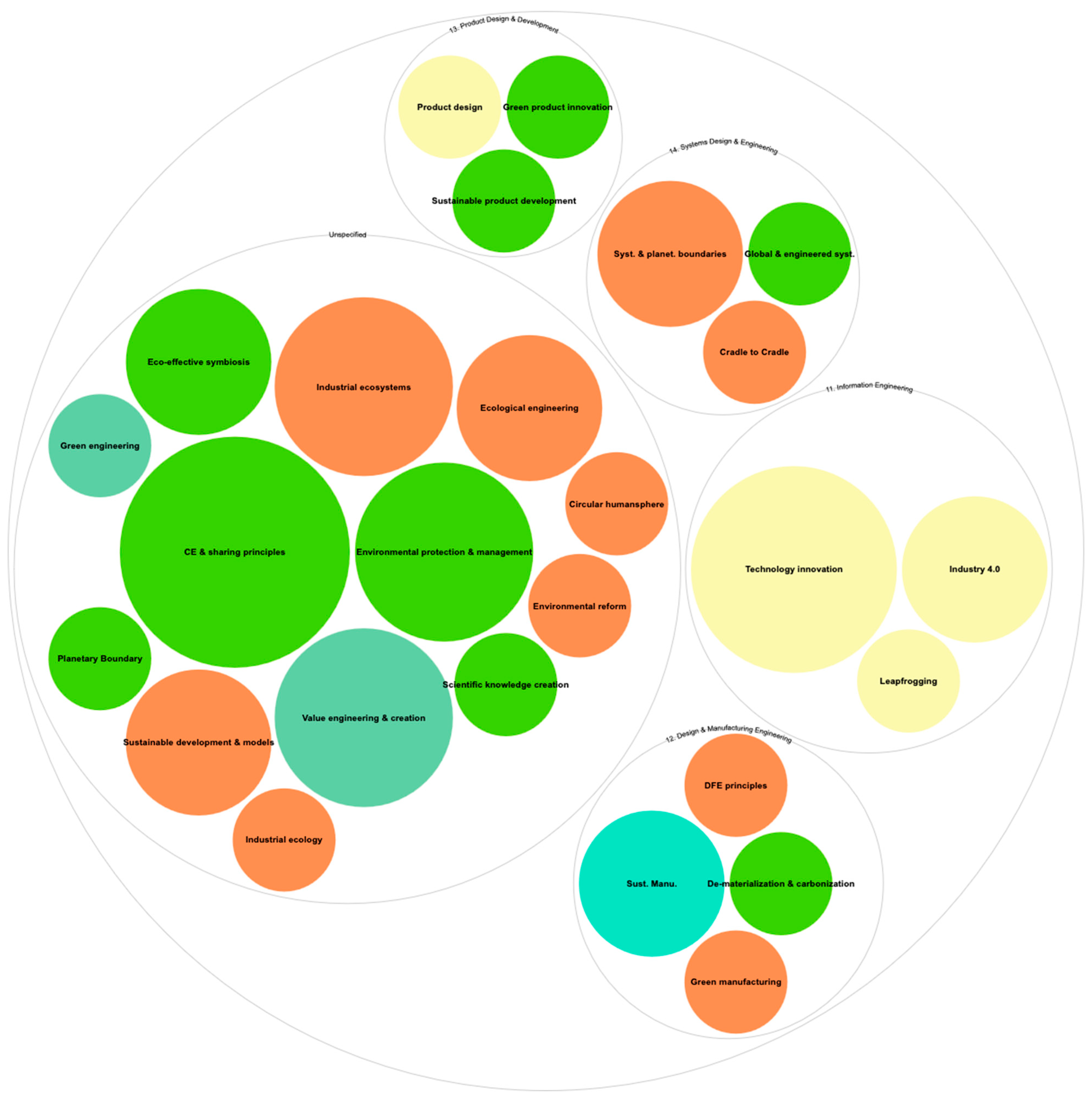

4.5.4. Circle Packing Knowledge Components

5. Discussion of Results

6. Conclusions, Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Das, T.K. Industrial Environmental Management: Engineering, Science, and Policy; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Xiong, J.; Xu, D. Relationship between energy consumption, economic growth and environmental pollution in China. Environ. Res. 2021, 194, 110718. [Google Scholar] [CrossRef] [PubMed]

- Stearns, P.N. The Industrial Revolution in World History; Taylor & Francis: Abingdon, UK, 2020. [Google Scholar]

- Ramalingam, B.; Clarke, P.K. Meeting the urban challenge: Adapting humanitarian efforts to an urban world. In Proceedings of the Meeting the Urban Challenge: Adapting Humanitarian Efforts to an Urban World, Washington, DC, USA, 17–19 January 2012; p. 31. [Google Scholar]

- Ameen, R.F.M.; Mourshed, M.J. Urban environmental challenges in developing countries—A stakeholder perspective. Habitat Int. 2017, 64, 1–10. [Google Scholar] [CrossRef]

- Indriawati, R.M.; Gravitiani, E.; Soesilo, A.M.; Cahyadin, M. Long-term investigation of emissions and economic growth in developed and developing countries: A bibliometric analysis. Int. J. Energy Econ. Policy 2023, 13, 219–234. [Google Scholar] [CrossRef]

- Mangaroo-Pillay, M.; Roopa, M.; Maisiri, W. Could digital Ubuntu be the South African version of industry 4.0? S. Afr. J. Ind. Eng. 2023, 34, 1–12. [Google Scholar] [CrossRef]

- Darwish, H. Expanding Industrial Thinking by Formalizing the Industrial Engineering Identity for the Knowledge Era; North-West University: Potchefstroom, South Africa, 2018. [Google Scholar]

- Goodland, R. The concept of environmental sustainability. Annu. Rev. Ecol. Syst. 1995, 26, 1–24. [Google Scholar] [CrossRef]

- Kuhlman, T.; Farrington, J. What is Sustainability? Sustainability 2010, 2, 3436–3448. [Google Scholar] [CrossRef]

- Morelli, J. Environmental sustainability: A definition for environmental professionals. J. Environ. Sustain. 2011, 1, 2. [Google Scholar]

- Dittmer, L.D.; Reimer-Watts, K.; Dobai, J.; Riemer, M. Contributions, missed opportunities, and future directions: A critical reflection on global climate change and environmental sustainability in AJCP over five decades. Am. J. Community Psychol. 2023, 72, 288–301. [Google Scholar] [CrossRef]

- Dörner, D.; Funke, J. Complex problem solving: What it is and what it is not. Front. Psychol. 2017, 8, 1153. [Google Scholar] [CrossRef]

- Li, X.; Liu, D.; Sun, J.; Zhu, Z. Challenges of Industrial Engineering in Big Data Environment and Its new Directions on Extension Intelligence. Procedia Comput. Sci. 2022, 214, 1561–1567. [Google Scholar] [CrossRef]

- IISE. What Is Industrial and Systems Engineering? (IISE Official Definition). Available online: https://www.iise.org/Details.aspx?id=282 (accessed on 30 June 2024).

- Darwish, H.; van Dyk, L. The industrial engineering identity: From historic skills to modern values, duties, and roles. J. S. Afr. J. Ind. Eng. 2016, 27, 50–63. [Google Scholar] [CrossRef]

- Bowman, C.; Ambrosini, V. Value creation versus value capture: Towards a coherent definition of value in strategy. BJM 2000, 11, 1–15. [Google Scholar] [CrossRef]

- Ozturk, O. Bibliometric review of resource dependence theory literature: An overview. Manag. Rev. Q. 2021, 71, 525–552. [Google Scholar] [CrossRef]

- Sperotto, F. In the Footsteps of Homo Industrialis: A Chronology of Industry and Industrial Engineering; Production and Inventory Control, Systems and Industrial Engineering (PICSIE) Press: Buckingham, UK, 1994. [Google Scholar]

- Bruner, R.F.; Miller, S.C. The great industrial revolution in Europe: 1760–1860. SSRN Electron. J. 2020. [Google Scholar] [CrossRef]

- Mangaroo-Pillay, M.; Roopa, M. Beyond the industrial engineering frontier: A few steps in history and a giant leap into the future. S. Afr. J. Ind. Eng. 2021, 32, 1–9. [Google Scholar] [CrossRef]

- Salvendy, G. Handbook of Industrial Engineering: Technology and Operations Management; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- IISE. Institute of Industrial & Systems Engineering Body of Knowledge. Available online: https://www.iise.org/details.aspx?id=43631 (accessed on 30 June 2024).

- Seifi, S. Governance and Socially Responsible Energy Consumption. In The Governance of Risk; Emerald Group Publishing Limited: Bingley, UK, 2013; Volume 5, pp. 95–110. [Google Scholar]

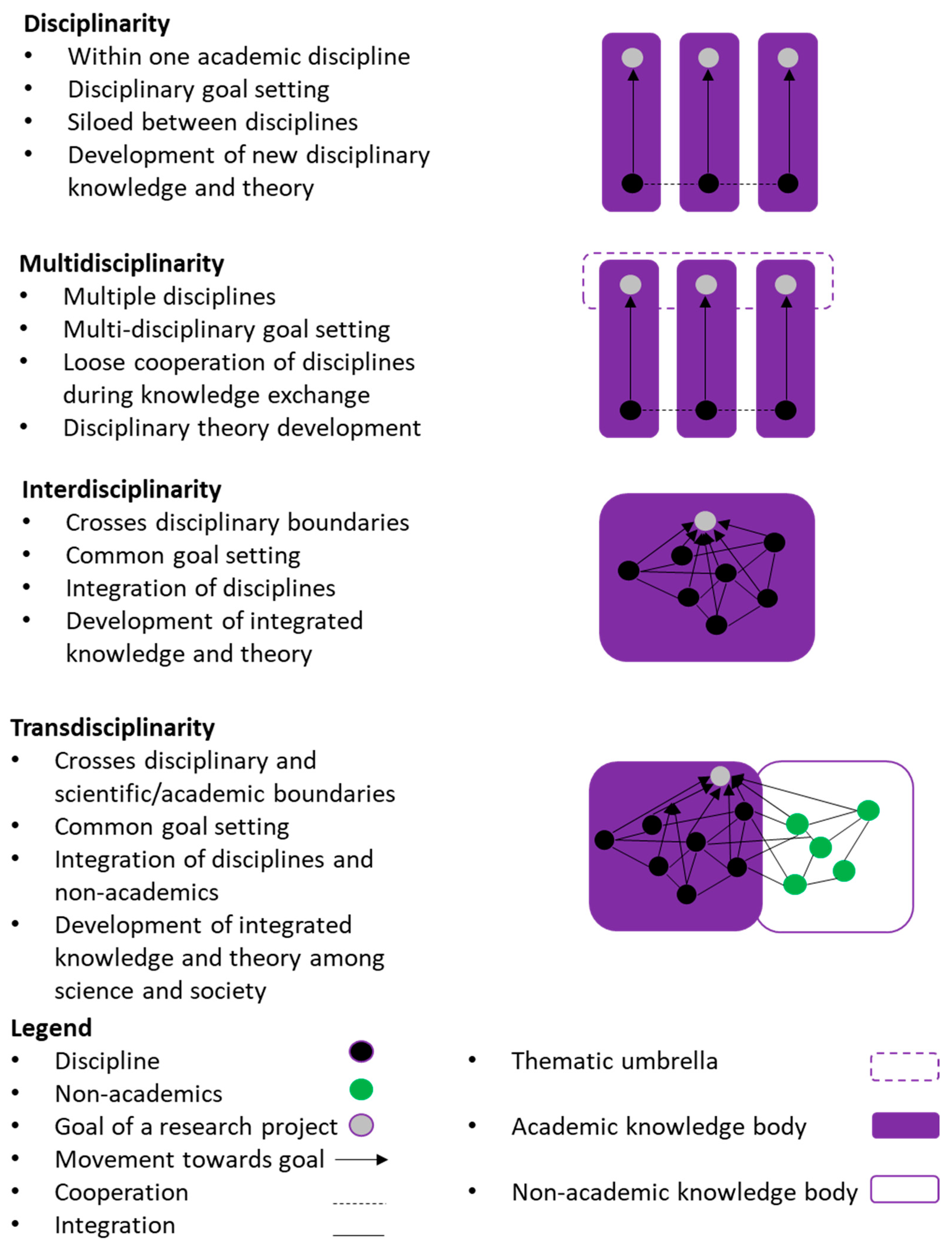

- Lang, D.J.; Wiek, A.; Bergmann, M.; Stauffacher, M.; Martens, P.; Moll, P.; Swilling, M.; Thomas, C.J. Transdisciplinary research in sustainability science: Practice, principles, and challenges. Sustain. Sci. 2012, 7, 25–43. [Google Scholar] [CrossRef]

- Tress, G.; Tress, B.; Fry, G. Clarifying integrative research concepts in landscape ecology. Landsc. Ecol. 2005, 20, 479–493. [Google Scholar] [CrossRef]

- Lawrence, M.G.; Williams, S.; Nanz, P.; Renn, O. Characteristics, potentials, and challenges of transdisciplinary research. One Earth 2022, 5, 44–61. [Google Scholar] [CrossRef]

- Stuart, J.A. Integration of industrial ecology concepts into industrial engineering curriculum. In Proceedings of the 2000 Annual Conference, St. Louis, MO, USA, 18–21 June 2000; pp. 5.379.1–5.379.8. [Google Scholar]

- Fet, A.M.; Deshpande, P.C. Closing the loop: Industrial ecology, circular economy and material flow analysis. In Business Transitions: A Path to Sustainability: The CapSEM Model; Springer International Publishing: Cham, Switzerland, 2023; pp. 113–125. [Google Scholar]

- Erkman, S. Industrial ecology: An historical view. J. Clean. Prod. 1997, 5, 1–10. [Google Scholar] [CrossRef]

- Aarikka-Stenroos, L.; Ritala, P.; Thomas, L.D. Circular economy ecosystems: A typology, definitions, and implications. In Research Handbook of Sustainability Agency; Edward Elgar: Cheltenham, UK, 2021; pp. 260–276. [Google Scholar]

- Ben-Zvi-Assaraf, O.; Ayal, N. Harnessing the environmental professional expertise of engineering students—The course: “Environmental Management Systems in the Industry”. J. Sci. Educ. Technol. 2010, 19, 532–545. [Google Scholar] [CrossRef]

- Marco-Ferreira, A.; Stefanelli, N.O.; Seles, B.M.R.P.; Fidelis, R. Lean and Green: Practices, paradigms and future prospects. Benchmarking Int. J. 2019, 27, 2077–2107. [Google Scholar] [CrossRef]

- Zokaei, K.; Lovins, H.; Wood, A.; Hines, P. Creating a Lean and Green Business System: Techniques for Improving Profits and Sustainability; Productivity Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper; SAGE Publications: Thousand Oaks, CA, USA, 2019. [Google Scholar]

- Mangaroo-Pillay, M.; Coetzee, R. Lean frameworks: A systematic literature review (SLR) investigating methods and design elements. Maig 2022, 15, 202–214. [Google Scholar] [CrossRef]

- Albliwi, S.; Antony, J.; Lim, S.A.; van der Wiele, T. Critical failure factors of Lean Six Sigma: A systematic literature review. Int. J. Qual. Reliab. Manag. 2014, 31, 1012–1030. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- Rethlefsen, M.L.; Kirtley, S.; Waffenschmidt, S.; Ayala, A.P.; Moher, D.; Page, M.J.; Koffel, J.B. PRISMA-S: An extension to the PRISMA statement for reporting literature searches in systematic reviews. Syst. Rev. 2021, 10, 39. [Google Scholar] [CrossRef]

- Djassemi, M. A computer-based approach to material and process selection using sustainability and ecological criteria. In Proceedings of the PICMET’09-2009 Portland International Conference on Management of Engineering & Technology, Portland, OR, USA, 2–6 August 2009; pp. 2316–2321. [Google Scholar]

- Naidu, S.; Sawhney, R.; Li, X. A methodology for evaluation and selection of nanoparticle manufacturing processes based on sustainability metrics. Environ. Sci. Technol. 2008, 42, 6697–6702. [Google Scholar] [CrossRef]

- Luque, A.; Heras, A.D.L.; Ávila-Gutiérrez, M.J.; Zamora-Polo, F. ADAPTS: An Intelligent Sustainable Conceptual Framework for Engineering Projects. Sensors 2020, 20, 1553. [Google Scholar] [CrossRef]

- Jing, R.; Yuan, C.; Rezaei, H.; Qian, J.; Zhang, Z. Assessments on emergy and greenhouse gas emissions of internal combustion engine automobiles and electric automobiles in the USA. J. Environ. Sci. 2020, 90, 297–309. [Google Scholar] [CrossRef]

- Helbig, C.; Kolotzek, C.; Thorenz, A.; Reller, A.; Tuma, A.; Schafnitzel, M.; Krohns, S. Benefits of resource strategy for sustainable materials research and development. Sustain. Mater. Technol. 2017, 12, 1–8. [Google Scholar] [CrossRef]

- Hazen, B.T.; Skipper, J.B.; Ezell, J.D.; Boone, C.A. Big data and predictive analytics for supply chain sustainability: A theory-driven research agenda. Comput. Ind. Eng. 2016, 101, 592–598. [Google Scholar] [CrossRef]

- Tagliari, L.D.; Pandolfo, A.; Zeilmann, R.P. Developing a specific structured procedure to assess sustainability performance in manufacturing processes. J. Clean. Prod. 2020, 269, 122404. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pontrandolfo, P.; Pujari, D. Developing sustainable new products in the textile and upholstered furniture industries: Role of external integrative capabilities. J. Prod. Innov. Manag. 2013, 30, 642–658. [Google Scholar] [CrossRef]

- Papoutsi, A.; Sodhi, M.S. Does disclosure in sustainability reports indicate actual sustainability performance? J. Clean. Prod. 2020, 260, 121049. [Google Scholar] [CrossRef]

- Ryberg, M.W.; Andersen, M.M.; Owsianiak, M.; Hauschild, M.Z. Downscaling the planetary boundaries in absolute environmental sustainability assessments—A review. J. Clean. Prod. 2020, 276, 123287. [Google Scholar] [CrossRef]

- Singh, A.; Lou, H.H.; Yaws, C.L.; Hopper, J.R.; Pike, R.W. Environmental impact assessment of different design schemes of an industrial ecosystem. Resour. Conserv. Recycl. 2006, 51, 294–313. [Google Scholar] [CrossRef]

- Harland, J.; Reichelt, T.; Yao, M. Environmental sustainability in the semiconductor industry. In Proceedings of the 2008 IEEE International Symposium on Electronics and the Environment, San Francisco, CA, USA, 19–22 May 2008; pp. 1–6. [Google Scholar]

- Singh, A.; Lou, H.H. Hierarchical pareto optimization for the sustainable development of industrial ecosystems. Ind. Eng. Chem. Res. 2006, 45, 3265–3279. [Google Scholar] [CrossRef]

- Severo, E.A.; De Guimarães, J.C.F.; Dellarmelin, M.L. Impact of the COVID-19 pandemic on environmental awareness, sustainable consumption and social responsibility: Evidence from generations in Brazil and Portugal. J. Clean. Prod. 2021, 286, 124947. [Google Scholar] [CrossRef]

- Brezet, H.; Stevels, A.; Rombouts, J. LCA for ecodesign: The Dutch experience. In Proceedings of the First International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 1–3 February 1999; pp. 36–40. [Google Scholar]

- Schröder, P.; Lemille, A.; Desmond, P. Making the circular economy work for human development. Resour. Conserv. Recycl. 2020, 156, 104686. [Google Scholar] [CrossRef]

- Thomas, V.M.; Graedel, T.E. Research issues in sustainable consumption: Toward an analytical framework for materials and the environment. Environ. Sci. Technol. 2003, 37, 5383–5388. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Tran, T.P.T.; Ha, H.M.; Bui, T.-D.; Lim, M.K. Sustainable industrial and operation engineering trends and challenges Toward Industry 4.0: A data driven analysis. J. Ind. Prod. Eng. 2021, 38, 581–598. [Google Scholar] [CrossRef]

- Raffaeli, R.; Rossi, M.; Cappelletti, F. Sustainable strategies: A continuously improving methodology. Int. J. Interact. Des. Manuf. (IJIDeM) 2021, 15, 151–154. [Google Scholar] [CrossRef]

- Phuong, N.A.; Guidat, T. Sustainable value stream mapping and technologies of Industry 4.0 in manufacturing process reconfiguration: A case study in an apparel company. In Proceedings of the 2018 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Singapore, 31 July–2 August 2018; pp. 85–90. [Google Scholar]

- Xiao, Z.; Zhou, G.; Wang, B. Using modified Barabási and Albert model to study the complex logistic network in eco-industrial systems. Int. J. Prod. Econ. 2012, 140, 295–304. [Google Scholar] [CrossRef]

- Schmidt, G.; Wilhelm, W.E. Strategic, tactical and operational decisions in multi-national logistics networks: A review and discussion of modelling issues. Int. J. Prod. Res. 2000, 38, 1501–1523. [Google Scholar] [CrossRef]

- Fong, M.W. Technology leapfrogging for developing countries. In Encyclopedia of Information Science and Technology, Second Edition; IGI Global: Hershey, PA, USA, 2009; pp. 3707–3713. [Google Scholar]

- Revell, A. The ecological modernisation of SMEs in the UK’s construction industry. Geoforum 2007, 38, 114–126. [Google Scholar] [CrossRef]

- Galán-Martín, Á.; Guillén-Gosálbez, G.; Stamford, L.; Azapagic, A. Enhanced data envelopment analysis for sustainability assessment: A novel methodology and application to electricity technologies. Comput. Chem. Eng. 2016, 90, 188–200. [Google Scholar] [CrossRef]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; De Vries, W.; De Wit, C.A. Planetary boundaries: Guiding human development on a changing planet. Sciences 2015, 347, 1259855. [Google Scholar]

- Sen, S.K. Symbiotic linkage of sustainability, development and differentiation. Compet. Rev. Int. Bus. J. 2014, 24, 95–106. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World; Simon & Schuster: London, UK, 2008. [Google Scholar]

- Munholfen, J.; Myers, A.; Ng, K.; Nierenberg, L.; Nosal, C.; Nowak, M. Industrial Ecology. 1995. Available online: http://www2.dnr.cornell.edu/saw44/NTRES331/Products/Spring%202004/Powerpoints/IndustrialEcologyPresentation.pdf (accessed on 19 August 2024).

- Rombouts, J.P. LEADS-II. A knowledge-based system for ranking dfe-options. In Proceedings of the 1998 IEEE International Symposium on Electronics and the Environment ISEE-1998 (Cat. No. 98CH36145), Danvers, MA, USA, 13 May 1998; pp. 287–291. [Google Scholar]

- MacIntosh, R.; MacLean, D. Conditioned emergence: Researching change and changing research. Int. J. Oper. Prod. Manag. 2001, 21, 1343–1357. [Google Scholar] [CrossRef]

- Kinder, T. Go with the flow—A conceptual framework for supply relations in the era of the extended enterprise. Res. Policy 2003, 32, 503–523. [Google Scholar] [CrossRef]

- Ulrich, D.; Barney, J.B. Perspectives in organizations: Resource dependence, efficiency, and population. Acad. Manag. Rev. 1984, 9, 471–481. [Google Scholar] [CrossRef]

- Bekius, F.; Gomes, S.L. A framework to design game theory-based interventions for strategic analysis of real-world problems with stakeholders. Eur. J. Oper. Res. 2023, 309, 925–938. [Google Scholar] [CrossRef]

- Muralikrishna, I.V.; Manickam, V. Chapter Ten—ISO 9000, 14000 Series, and OHSAS 18001. In Environmental Management; Muralikrishna, I.V., Manickam, V., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 177–208. [Google Scholar] [CrossRef]

- Muralikrishna, I.V.; Manickam, V. Chapter Seven—Environmental Accounting. In Environmental Management; Muralikrishna, I.V., Manickam, V., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 113–134. [Google Scholar] [CrossRef]

- Amaral, L.P.; Martins, N.; Gouveia, J.B. A review of emergy theory, its application and latest developments. Renew. Sustain. Energy Rev. 2016, 54, 882–888. [Google Scholar] [CrossRef]

- Gallastegui, I.G. The use of eco-labels: A review of the literature. Eur. Environ. 2002, 12, 316–331. [Google Scholar] [CrossRef]

- Farias, L.M.S.; Santos, L.C.; Gohr, C.F.; Oliveira, L.C.d.; Amorim, M.H.d.S. Criteria and practices for lean and green performance assessment: Systematic review and conceptual framework. J. Clean. Prod. 2019, 218, 746–762. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Campbell, D.F.J. ‘Mode 3’ and ‘Quadruple Helix’: Toward a 21st century fractal innovation ecosystem. Int. J. Technol. Manag. 2009, 46, 201–234. [Google Scholar] [CrossRef]

| Search Component | Specifications | Rationale |

|---|---|---|

| Keywords | Industrial Engineering, Environmental Sustainability. | Key terms relevant to the purposes of this study. |

| Platforms | Science Direct, Scopus, IEEE Explore, Web of Science, EBSCO host, Emerald Insight. | Reputable academic databases accessible to the researcher. |

| Search strategy | “Industrial Engineering” AND “Environmental Sustainability”. | Boolean operator for the union of the content. Wildcards are not considered. |

| Time frame | No lower bound, until October 2023. | Structured so as to unveil all available literature. |

| Inclusion criteria | Publications discussing theory, concepts, methods, strategies, and techniques that achieve or promote environmental sustainability. | Screen publications to conform with the scope of the study. |

| Exclusion criteria | Publications that are not in English, undergoing review. Curriculum design papers. | Protect the academic integrity and ability to analyse the research publications according to the aim of this study. |

| Quality assessment criteria | Remove all duplicates and filter according to papers relevant to the research aim. | Filter literature according to aspects beyond those in the inclusion and exclusion criteria. |

| Search Database | Search String | Results |

|---|---|---|

| Science Direct | “Industrial Engineering” AND “Environmental sustainability” | 1 |

| Scopus | (TITLE-ABS-KEY (“Industrial Engineering”) AND TITLE-ABS-KEY (“Environmental sustainability”)) | 37 |

| IEEE Explore | (“Abstract”:Industrial Engineering) AND (“Abstract”:Environmental sustainability) | 20 |

| Web of Science | “Industrial Engineering” (Abstract) and “Environmental sustainability” (Abstract) | 3 |

| EbscoHost | AB Industrial Engineering AND AB environmental sustainability | 30 |

| Emerald Insight | abstract:”Industrial Engineering” AND (abstract:”Environmental sustainability”) | 4 |

| # | Author(s) and Year | Title | Year | Novelty |

|---|---|---|---|---|

| 1 | Djassemi [40] | A computer-based approach to material and process selection using sustainability and ecological criteria | 2009 | In a holistic computer-based approach, material and process selection is performed in accordance with sustainability and ecological criteria. |

| 2 | Naidu, et al. [41] | A methodology for evaluation and selection of nanoparticle manufacturing processes based on sustainability metrics | 2008 | An evaluation method that focuses on sustainability metrics ranging from economic, environmental, and sociological dimensions. Three nanoparticle manufacturing processes are evaluated. |

| 3 | Luque, et al. [42] | ADAPTS: An Intelligent Sustainable Conceptual Framework for Engineering Projects | 2020 | A description of the ADAPTS framework that includes the application, data, approach, tool, and sensing dimensions used to improve environmental sustainability of an olive oil manufacturing plant. |

| 4 | Jing, et al. [43] | Assessments on emergy and greenhouse gas emissions of internal combustion engine automobiles and electric automobiles in the USA | 2020 | Integrated analysis of GHG emissions and emergy in the industrial area of automobile engineering in the USA. |

| 5 | Helbig, et al. [44] | Benefits of resource strategy for sustainable materials research and development | 2017 | A framework proposed to reduce supply risk and enhance environmental sustainability taking into account basic research, technical development, application, and re-phase across a product life cycle |

| 6 | Hazen, et al. [45] | Big data and predictive analytics for supply chain sustainability: A theory-driven research agenda | 2016 | The paper proposes a research agenda for using big data and predictive analytics to improve supply chain sustainability by reviewing eight theories. |

| 7 | Tagliari, et al. [46] | Developing a specific structured procedure to assess sustainability performance in manufacturing processes | 2020 | A structured procedure to assess sustainability performance in manufacturing processes by taking into account the environmental, social, and economic dimensions of sustainability. |

| 8 | Dangelico, et al. [47] | Developing sustainable new products in the textile and upholstered furniture industries: Role of external integrative capabilities | 2013 | Proposes a new framework for understanding the role of external integrative capabilities in sustainable green product development. |

| 9 | Papoutsi and Sodhi [48] | Does disclosure in sustainability reports indicate actual sustainability performance? | 2020 | The research suggests that disclosure in sustainability reports can be a useful indicator of actual (realised) sustainability performance. |

| 10 | Ryberg, et al. [49] | Downscaling the planetary boundaries in absolute environmental sustainability assessments—A review | 2020 | The paper provides a comprehensive review of methods for downscaling planetary boundaries in absolute environmental sustainability assessments (AESA). |

| 11 | Singh, et al. [50] | Environmental impact assessment of different design schemes of an industrial ecosystem | 2007 | An LCA environmental assessment impact of industrial ecosystems. |

| 12 | Harland, et al. [51] | Environmental sustainability in the semiconductor industry | 2008 | A framework to address environmental sustainability challenges of the semiconductor industry is presented. |

| 13 | Seifi [24] | Governance and Socially Responsible Energy Consumption | 2013 | A discussion on the links between industrial engineering and environmental sustainability while using Bayes Theorem as a method of analysis to compare energy consumption. |

| 14 | Ben-Zvi-Assaraf, et al. [32] | Harnessing the Environmental Professional Expertise of Engineering Students-The Course: ‘Environmental Management Systems in the Industry’ | 2010 | The study explores their perception of industrial–environmental issues. |

| 15 | Singh and Lou [52] | Hierarchical pareto optimisation for the sustainable development of industrial ecosystems | 2006 | The paper proposes a novel methodology for improving the sustainable development of industrial ecosystems (IEs) by using hierarchical Pareto optimisation. |

| 16 | Severo, et al. [53] | Impact of the COVID-19 pandemic on environmental awareness, sustainable consumption and social responsibility: Evidence from generations in Brazil and Portugal | 2021 | An analysis of the impact of COVID-19 on environmental awareness in relation to various generations. |

| 17 | Brezet, et al. [54] | LCA for ecodesign: the Dutch experience | 1999 | Evaluation of various LCA industrial eco-design case studies to extract limitations and opportunities. |

| 18 | Schröder, et al. [55] | Making the circular economy work for human development | 2020 | A novel hybrid framework for human development focused circular economy. |

| 19 | Thomas, et al. [56] | Research Issues in Sustainable Consumption: Toward an Analytical Framework for Materials and the Environment | 2003 | Central research questions are addressed within the context of industrial ecology. |

| 20 | Tseng, et al. [57] | Sustainable industrial and operation engineering trends and challenges Toward Industry 4.0: a data driven analysis | 2021 | Bibliometric analysis of sustainable industrial and operations engineering in relation to Industry 4.0. |

| 21 | Raffaeli, et al. [58] | Sustainable strategies: a continuously improving methodology | 2021 | An 11-step continuous improvement methodology for environmental and economic performance. |

| 22 | Phuong and Guidat [59] | Sustainable value stream mapping and technologies of Industry 4.0 in manufacturing process reconfiguration: A case study in an apparel company | 2018 | Sustainable value stream mapping (SVSM) is applied in an apparel company to identify sustainability issues. |

| 23 | Xiao, et al. [60] | Using modified Barabási and Albert model to study the complex logistic network in eco-industrial systems | 2012 | An eco-industrial system is improved upon. |

| Environmental Sustainability (ES) Codes | |||||

|---|---|---|---|---|---|

| ES Method Gr = 24 | ES Practices Gr = 94 | ES Strategy Gr = 61 | ES Theory Gr = 55 | ||

| Industrial Engineering (IE) codes | IE Methods Gr = 24 | 2 | 0 | 1 | 0 |

| IE Practices Gr = 44 | 2 | 7 | 1 | 1 | |

| IE Strategies Gr = 19 | 0 | 1 | 1 | 0 | |

| IE Theory Gr = 41 | 0 | 3 | 2 | 5 | |

| IE Strategies | Paper References |

|---|---|

| Industry 4.0 | [3,20] |

| Leapfrogging | [6] |

| Decision support systems and data analytics | [1,6] |

| Supply chain management (SCM) | [8] |

| Technology innovation | [6,8,18,19] |

| Risk mitigation | [5] |

| Product design | [8] |

| Resource consumption | [20] |

| Business strategy and profitability | [8,11,12] |

| ES Strategy | Paper Reference |

|---|---|

| Circular economy and sharing principles | [3,5,10,18,20] |

| Resource strategy, resource conservation (reduce, reuse, recycle) | [5,9,11] |

| Reducing carbon footprint, emissions, and emergy (Reduce carbon) | [4,5,9,11] |

| Triple bottom line | [6] |

| Scientific knowledge creation | [6] |

| Environmental protection, management | [6,9,19] |

| The resource-based view | [6,8] |

| Low carbon impact, dematerialisation, decarbonisation and substitution (De-materialisation and carbonisation) | [8] |

| Green product and environmental innovation | [8] |

| Sustainable product development | [8] |

| Supplier evaluation | [9] |

| Reduce water consumption | [9] |

| Reduce energy consumption | [9,12] |

| Supply chain | [9,18,23] |

| Planetary Boundary | [10] |

| Eutrophication | [11] |

| Eco-effective symbiosis and an eco-industrial park | [11,19] |

| Clean production | [12] |

| LEED (Leadership in Energy and Environmental Design) | [12,18] |

| Sustainable resource management (SRM) and lifecycle thinking (LT) | [12] |

| Risk management | [13] |

| Energy labelling | [13] |

| Sustainable lifestyles | [18] |

| Global systems and engineered systems | [19] |

| IE Theory | Paper Reference |

|---|---|

| Lean | [9,17,20,21,22] |

| Analytical models, algorithms, and machine learning | [1,3,6,7,11,18,20,23] |

| Multicriteria decision analysis | [1] |

| Facility planning | [2] |

| Value engineering and value creation | [3,5,6] |

| Simulations | [3,11,20] |

| Supply chain sustainability, reversed logistics, and closed-loop supply chains | [6,8,12,18,23] |

| Risk management | [13] |

| Game theory | [13] |

| Green engineering | [19] |

| ES Theory | Paper Reference |

|---|---|

| Sustainable development and sustainability models | [1,7] |

| Environmental Management Systems | [1] |

| Building Information Modelling (BIM) | [3] |

| Life cycle analysis (LCA) | [3,8,9,10,19] |

| Cradle to cradle (C2C) | [3] |

| System boundary and planetary boundaries framework | [4,10] |

| Ecological engineering and modernization theory | [4,6] |

| Agency Theory (AT) | [6] |

| Environmental reform | [6] |

| Green manufacturing | [8] |

| Greenwashing | [9] |

| Institutional and distributive justice theory | [9,10] |

| Design for Environment (DFE) principles | [12] |

| Moore’s Law | [12] |

| Product and human ecology | [12,13] |

| Game theory | [13] |

| Cleaner and safer production | [14] |

| Industrial ecosystems and eco-industrial systems | [11,15,23] |

| LEADS (Lifecycle Expert Analysis of Design Strategies) | [17] |

| STRETCH | [17] |

| Circular humansphere | [18] |

| Industrial ecology | [19] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roopa, M.; Siriram, R.; Coetzee, R. Exploring Industrial Engineering Knowledge and Environmental Sustainability. Sustainability 2024, 16, 7392. https://doi.org/10.3390/su16177392

Roopa M, Siriram R, Coetzee R. Exploring Industrial Engineering Knowledge and Environmental Sustainability. Sustainability. 2024; 16(17):7392. https://doi.org/10.3390/su16177392

Chicago/Turabian StyleRoopa, Meelan, Rajenlall Siriram, and Rojanette Coetzee. 2024. "Exploring Industrial Engineering Knowledge and Environmental Sustainability" Sustainability 16, no. 17: 7392. https://doi.org/10.3390/su16177392