Abstract

Starch has overtaken the bioplastic market in developing thermoplastic starch-based blends and composite systems owing to its biodegradability and sustainability. Thermoplastic starch (TPS) development is mostly a two-stage process involving plasticizing starch and blending plasticized starch with a polymer. Most of the research focuses on improving the properties of the blend system through different methodologies, including various plasticizers and co-plasticizers. However, limited studies have analyzed the environmental effects of plasticizers or co-plasticizers and their processing. Thus, in this research, the environmental impact of starch plasticization processes performed by co-plasticization (glycerol–urea, glycerol–citric acid, and glycerol–succinic anhydride) and by conventional glycerol-based plasticization is compared through life cycle assessment (LCA). The results showed that glycerol–citric acid- and glycerol–succinic anhydride-based co-plasticization had a comparable environmental impact to traditional glycerol-based plasticization. In contrast, the glycerol–urea-based co-plasticization process exhibited the highest effect on the environment. Furthermore, to reduce the environmental impact, a sensitivity analysis of the plasticization processes was conducted by changing the energy aspect of the processes through quantitative and qualitative approaches. The qualitative approach significantly reduced major impact categories such as global warming, carcinogens, ecotoxicity, and fossil fuel depletion.

1. Introduction

The usage and production of long-lasting polymers for transient uses (such as packaging, catering, surgery, and cleanliness) are increasing rapidly daily. The increase in production is unacceptable, considering the growing concern about conserving ecological practices. Most synthetic polymers used today are not environmentally sustainable because they are made from petroleum products. When these persistent polymeric materials are spread across the ecosystem, they endanger species and constitute a substantial source of pollution [1]. A potential alternative to this issue is using biodegradable polymers, such as polysaccharides. Starch is widely used to develop biodegradable polymeric materials owing to its abundance, inexpensive, renewability, and biodegradability [2]. However, the melting temperature of starch is higher than its degradation temperature, which makes it unable to process with polymers. Thus, plasticizers, low molecular weight molecules, are incorporated into starch to improve its processability. Plasticizers enhance the mobility, elasticity, and processability of macromolecules [3]. Adding a plasticizer to starch breaks hydrogen bonds, partially depolymerizes the starch, and lowers its melting temperature below the degradation point [4]. Low molecular weight plasticizers for starch include sorbitol, glycerol, urea, formamide, citric acid, and water [5,6,7,8].

The effectiveness of plasticizing processes depends on the type and quantity of plasticizers used. A hydrophilic polar molecule with a boiling point above the temperature of polymer processing and a material compatible with starch would make an effective plasticizer. Plasticization efficiency varies with the starch source due to differences in amylose and amylopectin. Glycerol is an effective plasticizer of starch but cannot prevent starch retrogradation. Amide-based plasticizers, such as urea and formamide, are more effective in suppressing starch retrogradation [4]; however, urea-plasticized starch tends to be rigid and brittle. To rectify this issue, co-plasticization, or the use of multiple plasticizers, was introduced for the starch plasticization process. A study conducted by Ma et al. showed that the thermal and mechanical properties of plasticized starch improved with the use of urea and ethanolamine as co-plasticizing agents [9]. Furthermore, this combination reduced the retrogradation of starch. Shi et al. studied the effect of using citric acid and glycerol as co-plasticizers for cornstarch plasticization [10]. The results showed that co-plasticization could reduce retrogradation and improve processability, biodegradation, and polyester compatibility.

Numerous studies explored thermoplastic starch (TPS) manufacturing. However, very few of them could quantify the environmental impact of the production process. Broeren et al. analyzed the life cycle assessment (LCA) of six types of starch plastic formulations from virgin and wastewater-reclaimed starch material [11]. The study revealed significant variation among starch grades in environmental impact, with reclaimed starch notably showing less damage across all indicators. Increasing biobased material usage in plastic composition heightens eutrophication by 30–250%. Extending the extrusion process by 66% increased impacts in all indicators by more than 6% due to heightened energy requirements. Rojas-Bringas et al. conducted an LCA assessment to compare starch sources and plasticizers like glycerol or sorbitol in 1 kg bio-composite output [12]. Corn starch, which is widely available and mass-produced, was chosen. The results favored starch-based bio-composites over polylactic acid (PLA)-Brazil nut fiber and polypropylene (PP) glass fiber composites in the life cycle environmental impact.

Benetto et al. assessed the cradle-to-gate LCA analysis of multilayer PLA-based TPS blend development through thermoforming and plasma treatment methodologies [13]. The plasma treatment has depicted a higher environmental impact even though the process improved the compatibility between the PLA and plasticized starch. The study showed that a reduction of 20% in treatment time could reduce the environmental impact. Furthermore, the study concluded that the type of starch, plasticizer, processing methodology, and degradability/recyclability greatly influence environmental impacts. Ruini et al. also conducted an LCA study that focused on the effects of five LA-derived ketal-diester derivatives on biopolymer processability and environmental sustainability [14]. With 1 g per bio-plasticizer, the study found the lowest environmental impact in processes contributing most to the category. The global warming impact was primarily due to 18.5 kg CO2 from base plasticizer LCA, while the human health impact reached 45% across all plasticizers. Sensitivity analysis adjusted the energy mix, as electricity use in synthesis significantly impacts plasticizer LCA. Rice and corn starches are ideal sustainable plasticizers due to their local availability [15].

In this study, three types of co-plasticizer combinations, glycerol–urea, glycerol–citric acid, and glycerol–succinic anhydride, and commercial plasticizer glycerol were chosen to analyze their environmental effects during the production of plasticized corn starch through melt extrusion methodology. The study will assess the impacts of sole laboratory plasticizer production before bioplastic processing. Completing this LCA study will benefit industries by enabling them to choose an efficient plasticizer for starch other than glycerol, thereby achieving efficient plasticization of starch with less environmental impact. Furthermore, previous studies have not adequately addressed the environmental effects of using alternative co-plasticizers in plasticized starch development for TPS. Additionally, there are limited data on the end-of-life impacts of these materials.

2. Materials and Methods

The method used in this LCA study follows the ISO 14040 and 14044 standards for quantifying environmental impacts that exclude economic or societal implications [16,17]. Data for the impact assessment were obtained from the Ecoinvent 3 database in the SimaPro 8.0.4.26 software [18,19].

2.1. Goal and Scope

This LCA study aims to evaluate the environmental effect of producing plasticized starches through co-plasticization and compare them with commercial plasticizer glycerol. In this LCA analysis, corn starch was considered a starch source and glycerol as a common plasticizer. The corn starch was chosen because it is a mass-produced and commercially available product in North America [20]. The different co-plasticizer combinations were glycerol–urea, glycerol–citric acid, and glycerol–succinic anhydride, which were compared with glycerol.

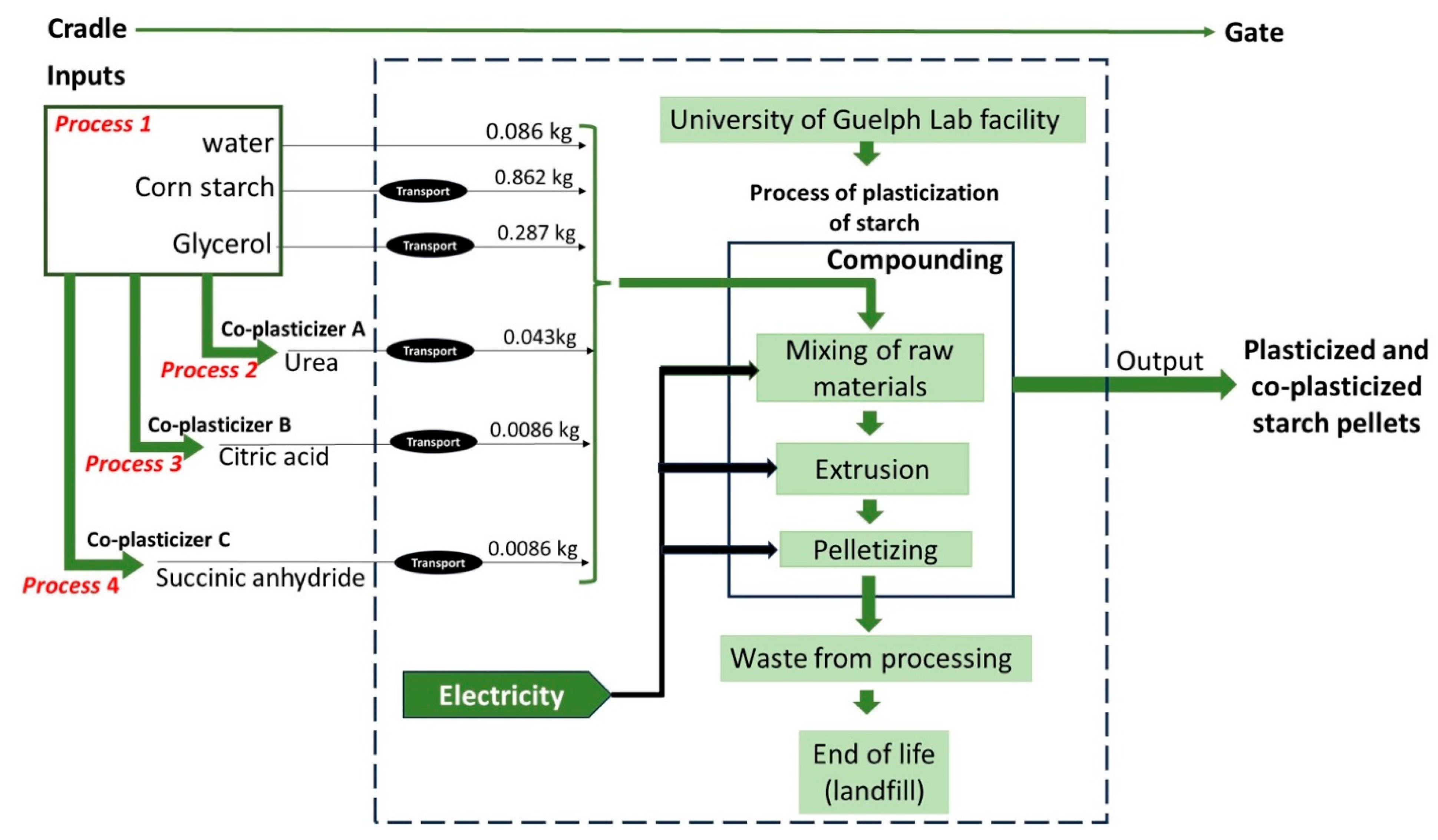

Starch plasticization and co-plasticization utilized melt extrusion. Raw materials were mixed using a kitchen mixer and then melt-blended using a twin-screw extruder (Micro-27, Leistritz Advanced Technologies Corporation, Allendale, NJ, USA) and pelletized (Model: Reduction Engineering (RE) dry strands cut pelletizer, bullet 62, Kent, OH, USA). The waste collected during processing and its end of life is further included in this study. The transportation of raw materials to the lab and energy consumption during the compounding procedure were included in the LCA study. This LCA study analyzed the process from cradle to gate to quantify the environmental impact of the plasticizing agent before the development of the final product material. The materials entering the lab (cradle) to the material produced (gate) are shown in Figure 1.

Figure 1.

The system boundary of the LCA analysis (assumption: water directly obtained from the university; succinic anhydride was substituted with maleic anhydride in SimaPro). Process 1, 2, 3, and 4 represent different plasticization processes of corn starch. Process 1 used glycerol, water as plasticizers, Process 2 used glycerol, water and urea (co-plasticizer A) as plasticizers, Process 3 used glycerol, water, and citric acid (co-plasticizer B) as plasticizers and Process 4 used glycerol, water, and succinic anhydride (co-plasticizer C) as plasticizers.

For ease of comparison, all process inputs and output flows inside the system boundary were normalized using a functional unit (FU), which includes all the system functions. In this instance, the use phase and end-of-life are outside the system’s constraints. The FU of this study is 1 kg of output (mass basis) from the plasticization of starch through extrusion melt-blending processes.

2.2. Life Cycle Inventory (LCI)

The unit process to produce each raw material, such as corn starch, water, glycerol, urea, citric acid, and succinic anhydride, was added to each plasticization process. The inventory data consist of secondary sources of Ecoinvent 3 and primary data from laboratory experimentation. Ecoinvent 3 was used for all material origins. The plasticizer combinations are as follows: GPCS-glycerol plasticized corn starch, UPCS-urea added glycerol plasticized corn starch, CPCS-citric acid added glycerol plasticized corn starch, and SAPCS-succinic anhydride added glycerol plasticized corn starch. The mass of each component required to produce plasticized or co-plasticized starch is shown in Table 1. Table 2 shows the calculated mass used in LCA analysis, which includes an additional mass for expected material loss of 15% per kg of final output during processing. The transportation of raw materials from local merchants to the lab is shown in Table 3.

Table 1.

The ratio of materials required in the production process of plasticized wheat starch.

Table 2.

Complete LCI of GPCS, UPWS, CPCS, and SAPCS for the system boundary for the cradle-to-gate/FU analysis.

Table 3.

Estimated transportation distances are included in the LCA study.

The electricity used for melt extrusion, including mixing in the kitchen mixture, extrusion, and pelletizer, was specific to Ontario and comprised 59% nuclear, 24% hydro, 9% wind, 7% natural gas, and 1% biomass [21]. An output weight loss of 15 wt. % during melt blending resulted in waste material being diverted to the solid waste transfer station 2 km from the University of Guelph. Under landfill conditions, the starch materials would decompose to sugars, potentially converting to CO2 and water for plasticizing agents, excluding UPCS, which also generates NO2. The complete LCI of this study showing the plasticization components and the complete LCI for Figure 1 are within Table 1 and Table 2, respectively. Table 1, Table 2 and Table 3 were sourced from the SimaPro software that used the Ecoinvent database [18,19].

2.3. Life Cycle Impact Assessment (LCIA)

SimaPro 8.0.4.26 software and TRACI 2.1 (a Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts) methods were used in the study. TRACI is a midpoint LCIA method developed by the United States Environmental Protection Agency (US EPA). Environmental indicators of ozone depletion, global warming, smog, acidification, eutrophication, carcinogenics, non-carcinogenics, respiratory effects, ecotoxicity, and fossil fuel depletion are assessed in this study. These impact categories, normalization factors, and associated units are included in Table 4.

Table 4.

TRACI 2.1 impact categories with normalization factors and specific units. [22].

3. Results and Discussion

The LCIA analysis analyzed the environmental effects of the life cycle processes of plasticization and/or co-plasticization of starch. The study further examined whether the co-plasticization of starch is environmentally sustainable compared to conventional glycerol-plasticized starch.

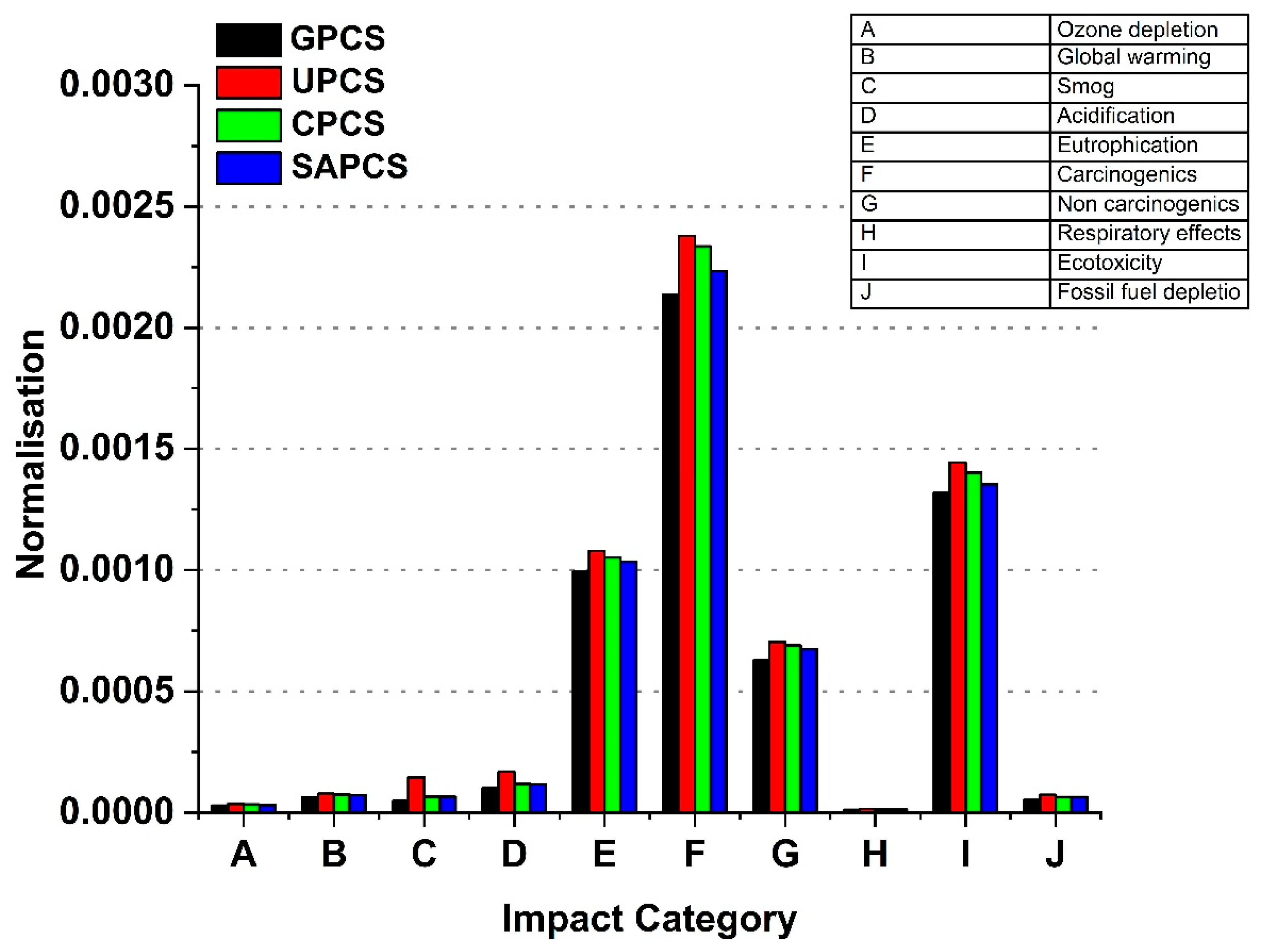

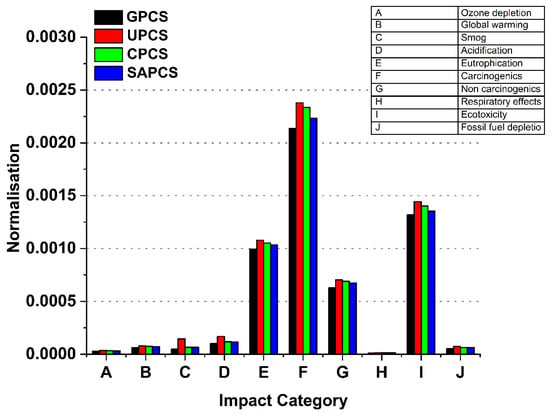

Figure 2 and Table 5 illustrate normalized LCA results for GPCS-glycerol plasticized corn starch. The data compare 10 environmental impacts using TRACI 2.1 Canada 2005. Figure 2 highlights eutrophication, ecotoxicity, and human toxicity (cancer and non-cancer) as the most significant impact categories for GPCS, UPCS, CPCS, and SAPCS production. Rojas-Bringas et al. found that switching from glycerol to sorbitol for plasticized corn starch in TPS development increased total human toxicity (human toxicity (cancer) (HTC) and human toxicity (non-cancer) (HTN)) by 58.28% [12]. Global warming and ozone depletion have the least environmental effects compared to other impact categories. Fossil fuel depletion showed an equivalent effect with plasticizers and co-plasticizers such as citric acid and succinic anhydride. However, urea has a slightly higher impact on the fossil fuel depletion category than the other co-plasticizers and glycerol. This is because of the use of coal as a primary energy production material during the synthesis of urea [23]. Smog and acidification categories in Figure 2 depict GPCS as having the most negligible impact. CPCS and SAPCS pose equivalent environmental burdens but are lower than the extent of the burden of UPCS. The ozone depletion and respiratory effect categories are inconsequential compared to the other categories for all four products. Notably, the UPCS is the most environmentally unfriendly option compared to the other co-plasticizers, having the most impact to least in the order of CPCS and SAPCS, respectively. Urea production’s high energy demand from petroleum results in higher CO2 emissions and ozone depletion [23]. Furthermore, urea-based processing releases more toxic components into the air during processing [24]. Glycerol’s environmental sustainability as a plasticizer in GPCS is evident in contrast to the co-plasticizers, as it poses a substantially lower impact on the 10 categories within its cradle-to-gate life cycle. In contrast, the study conducted by Volpe et al. showed that sunflower seed fried oil as a plasticizer for starch in developing PLA-based TPS showed less environmental impact than glycerol as a plasticizer [25]. Ultimately, incorporating co-plasticizers results in higher environmental effects, which could be mitigated by selecting environmentally sustainable plasticizers such as glycerol, sunflower seed oil, or a combination of both.

Figure 2.

Normalization of impact within 10 impact categories from cradle-to-gate for plasticizers of GPCS/Functional unit (FU) and co-plasticizers of UPCS/FU, CPCS/FU, and SAPCS/FU using TRACI 2.1. (GPCS-glycerol plasticized corn starch, UPCS-urea added glycerol plasticized corn starch, CPCS-citric acid added glycerol plasticized corn starch, and SAPCS-succinic anhydride added glycerol plasticized corn starch.).

Table 5.

Percentage increase in the impacts of UPCS, CPCS, and SAPCS relative to GPCS. (GPCS-glycerol plasticized corn starch, UPCS-urea added glycerol plasticized corn starch, CPCS-citric acid added glycerol plasticized corn starch, and SAPCS-succinic anhydride added glycerol plasticized corn starch.)

Specific comparisons between the co-plasticizers and plasticizers have been calculated in Table 5. Assuming the equivalent weight of all impact categories, each co-plasticizer’s total impact increase was calculated and compared to GPCS, representing a cumulative deviation. Cumulative deviation for UPCS, CPCS, and SAPCS are 427.4%, 158.8%, and 123.1%, respectively. Accordingly, the most sustainable co-plasticizer based on its cumulative score is SAPCS, which is a better environmental choice than the CPCS and a significantly greater environmental choice than UPCS.

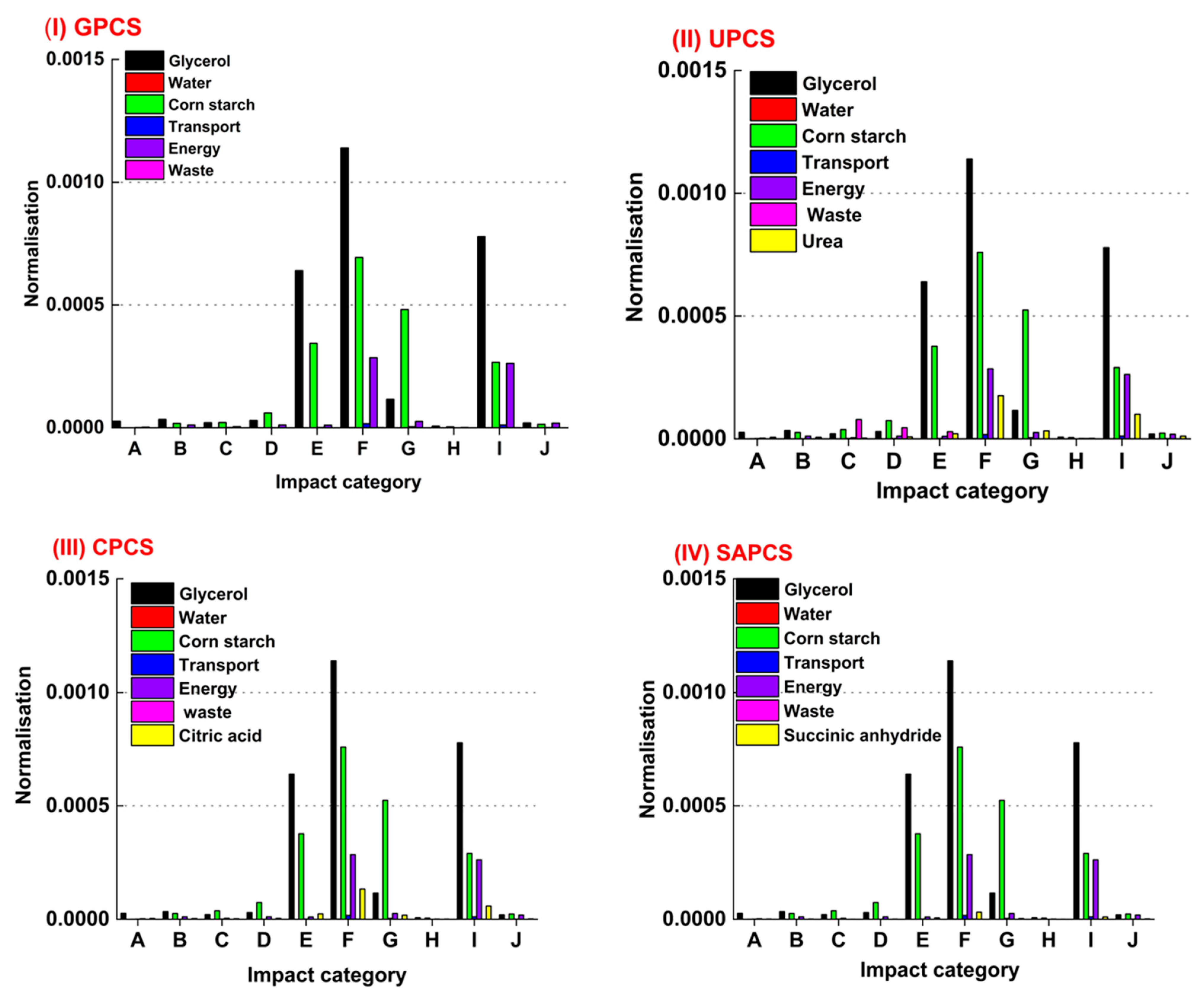

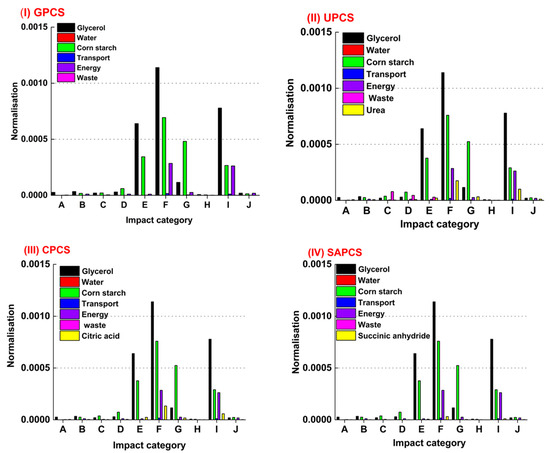

Figure 3 shows the normalized impact of materials, transportation, energy, and waste for GPCS (I), UPCS (II), CPCS (III), and SAPCS (IV). The inventory flows with heightened impact are materials, energy, and waste. Figure 3 (II) conveys urea significantly impacting carcinogenicity and ecotoxicity (yellow bars) relative to succinic anhydride. Meanwhile, citric acid additives pose a lower and insignificant environmental impact on carcinogenic and ecotoxicity relative to urea additives. Moreover, relative to the materials and energy, the end-of-life contributed impact is negligible and inconsistent with showing this impact across co-plasticizers other than UPCS. UPCS, specifically grouped with urea, has an increasingly negative end-of-life environmental impact than other co-plasticizers and GPCS. Furthermore, specific categories where the deleterious impact from materials and energy exists are eutrophication, carcinogenics, non-carcinogenics, and ecotoxicity. However, the output materials have a significantly lower impact on the other categories within this method, indicating that the hotspots of this study are associated with the form of energy and utilization of these energy forms. Energy use in mixing and melt extrusion affects regional impacts like human toxicity and ecotoxicity. Glycerol’s impact remains a significant hotspot but other plasticization factors can be adjusted to reduce environmental effects.

Figure 3.

The distribution of impact by raw materials, transport of raw materials, the total energy consumption during processing and the waste from processing that ends up in landfills during each plasticized starch development process. (A) Ozone depletion, (B) global warming, (C) smog, (D) acidification, (E) eutrophication, (F) carcinogenics, (G) non-carcinogenic, (H) respiratory effects, (I) ecotoxicity, (J) fossil fuel depletion. (GPCS-glycerol plasticized corn starch, UPCS-urea added glycerol plasticized corn starch, CPCS-citric acid added glycerol plasticized corn starch, and SAPCS-succinic anhydride added glycerol plasticized corn starch.)

4. Sensitivity Analysis

Even though the material was a leading hotspot, modifying it would alter the classification of the research outputs and hinder the purpose of assessing glycerol plasticizers compared with the co-plasticizers.

Eutrophication, carcinogenic, non-carcinogenic, and ecotoxicity were major hotspots in the normalized results, prompting efforts to minimize these hotspots by finding the underlying impact contributor. The energy input (Ontario energy mix in the LCI) had the most notable impact in these four categories (Figure 3). The studies conducted by Violeta et al. and Edwin et al. described that impact categories could be modified by implementing changes in energy management [26,27]. Thus, in this study, sensitivity analysis will focus on energy both quantitatively (reduced energy consumption (REC)) (scenario 1) and qualitatively (energy form (EF)) (scenario 2).

4.1. Scenario 1

The energy consumption reduction of 30% during the mixing stage utilizing the kitchen mixer can be applied to all plasticizer productions without hindering the final product. The adjustment of energy during the extrusion process results in a satisfactory impact on the physical and mechanical properties of the output materials of this study and thus remains unchanged. This input is adjusted and the characterized results of the plasticizers with and without this adjustment are shown in Table 6, showing the percentage of environmental impact reduction from GPCS, UPCS, CPCS, and SAPCS related to the base case. Maximum results were seen in global warming, carcinigenics, ecotoxicity, and fossil fuel depletion. While this is a step in the right direction, this is not the most effective option compared to qualitatively changing the energy requirements.

Table 6.

Sensitivity analysis of altering the energy requirements during the mixing process by 30% for all output materials.

4.2. Scenario 2

Natural gas accounts for 7% of the energy mix and poses the highest environmental impact from the LCA network relative to the other energy conversion systems. In this sensitivity analysis, this will be substituted with hydro energy. Furthermore, biomass, accounting for 1%, and wind, which accounts for 9%, were assigned to hydropower since Canada has a higher hydro capacity [28]. In many situations, the GHGs from wind are more significant than from hydro, while remaining the more prominent energy source than hydro and solar energy [29]. Since more than 59% of Ontario’s energy relies on nuclear, this parameter remained unchanged, while biomass was excluded since hydropower is more flexible and consistent. Thus, for this sensitivity analysis, the energy mix was taken as a mix of hydro (41%) and nuclear (59%).

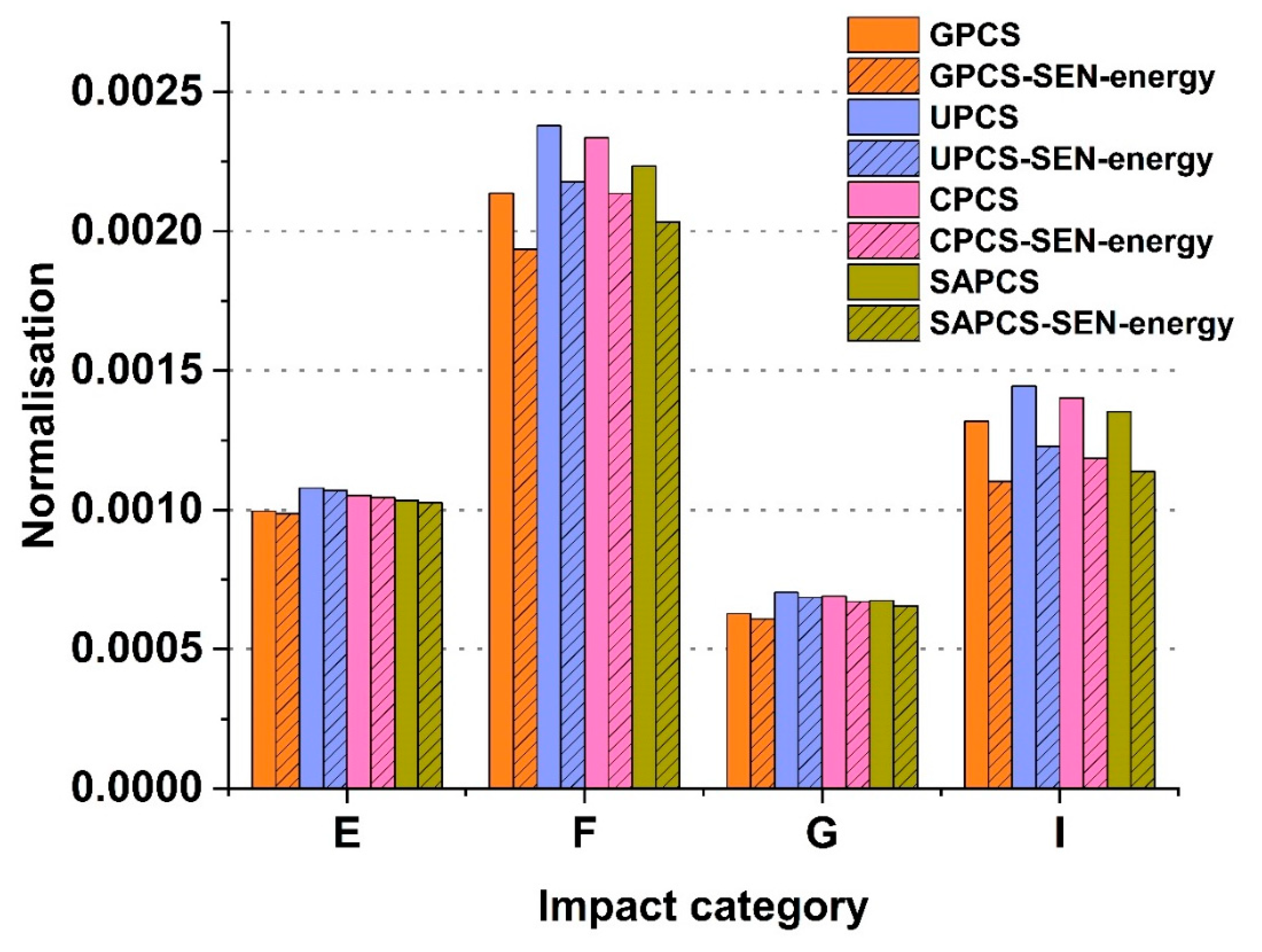

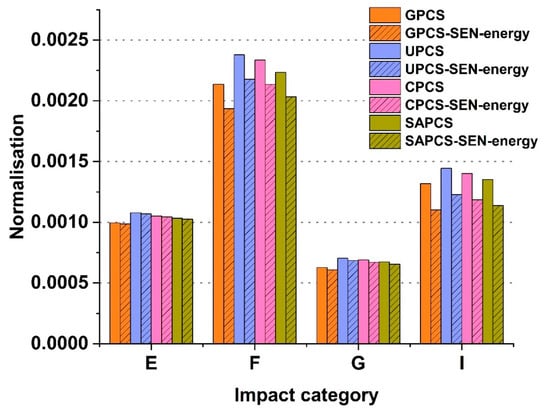

As shown in Figure 4, the GPCS, UPCS, CPCS, and SAPCS, with EF sensitivity analysis applied, had reduced impacts that were visually applicable to the impact categories of carcinogens and ecotoxicity. Slight reductions are observed in the categories of eutrophication and non-carcinogens. Table 7 shows the percentage reduction in impact categories observed with change in energy form (EF) for the different outputs. Table 7 shows that the decrease in impact was more effective in impact categories such as global warming, carcinogens, ecotoxicity, and fossil fuel depletion.

Figure 4.

Sensitivity analysis of electricity qualitatively changed to show the mitigation of GPCS, UPCS, CPCS, and SAPCS plasticizer’s environmental impacts for impact categories of eutrophication (E), carcinogenics (F), non-carcinogenic (G), and ecotoxicity (I). GPCS-glycerol plasticized corn starch, UPCS-urea added glycerol plasticized corn starch, CPCS-citric acid added glycerol plasticized corn starch, and SAPCS-succinic anhydride added glycerol plasticized corn starch.

Table 7.

TRACI 2.1 sensitivity analysis of altering the energy forms (EF) within the Life Cycle/FU. A color gradient with extreme (red), to less extreme (orange) and decreasing in quantity from dark green to yellow is applied for qualitative observation purposes. GPCS-glycerol plasticized corn starch, UPCS-urea added glycerol plasticized corn starch, CPCS-citric acid added glycerol plasticized corn starch, and SAPCS-succinic anhydride added glycerol plasticized corn starch.

Considering the results from the attempt to minimize the environmental impact by altering the energy qualitatively and quantitatively, the most beneficial effects are seen when substituting most non-dominant non-renewable energy forms with renewable energy. Specifically, the maximum results with 59% nuclear and 41% hydro energy combination were for the impact category of fossil fuel depletion, having a reduction of 33, 24, 27, and 27% for GPCS, UPCS, CPCS, and SAPCS, respectively. The inventory flow of energy is one of many avenues to mitigate the environmental impact of plasticizers and co-plasticizers within their LC from cradle to gate.

5. Conclusions

This study showed the environmental impacts of co-plasticizing starch over glycerol-plasticized starch in developing starch-based biodegradable plastic. It was evident that succinic anhydride and citric acid, as co-plasticizers, showed a comparable environmental impact to glycerol as a plasticizer for the plasticization processes in LCA analysis. However, a comparatively higher environmental impact has been observed for the plasticization process with urea as a co-plasticizing agent. Thus, the plasticization of starch glycerol–urea as a co-plasticizer is not recommended from an environmental perspective. Energy was a major factor influencing environmental impacts among all input categories. A sensitivity analysis on energy was conducted to reduce environmental impact by changing energy quantitatively through reduced energy consumption and qualitatively through EF. A significant reduction in impact categories was observed for the qualitative change through energy form. From the sensitivity analysis, it was evident that reducing energy consumption was not more effective in reducing environmental impacts; however, changing energy form to a combination of nuclear and hydro depicted a significant reduction in all impact categories, especially for global warming, carcinogens, ecotoxicity, and fossil fuel depletion. Using an energy combination of nuclear and hydro, fossil fuel depletion was reduced by 33%, 24%, 27%, and 27%, respectively, for GPCS, UPCS, CPCS, and SAPCS. In conclusion, the LCA study showed that the co-plasticization of starch with citric acid and succinic anhydride is more environmentally sustainable than urea as a co-plasticizer. From an environmental impact perspective, citric acid and succinic anhydride could be the best alternative for glycerol-plasticized starch. In addition, by changing the energy form, a significant change in environmental impact could be achieved during the co-plasticization process, primarily when produced in large quantities in an industry.

Author Contributions

A.S.: Software, Methodology, Investigation, Visualization, Formal analysis, Data curation, and Writing—original draft. Y.H.: Software, Methodology, Investigation, Visualization, Formal analysis, and Writing—original draft. B.A.: Conceptualization, Validation, and Writing—review and editing. A.K.M.: Conceptualization, Investigation, Resources, Funding acquisition, and Writing—review and editing. M.M.: Conceptualization, Investigation, Resources, Funding acquisition, Project administration, Supervision, and Writing—review and editing. All authors contributed to the manuscript’s discussion, reviews, and approval for publication. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by: (i) the Ontario Research Fund, Research Excellence Program; Round 11 (ORF-RE11) Ontario Ministry of Colleges and Universities (MCU), Canada (grant No. 056106); (ii) The Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), Canada/University of Guelph—HQP program; (iii) OMAFRA—Bioeconomy for Industrial Uses Research Program (grant Nos. 030578 and 030671); (iv) OMAFRA—Ontario Agri-Food Research Initiative (grant No. 055217); (v) The Natural Sciences and Engineering Research Council of Canada (NSERC), Canada Research Chair (CRC) program (grant No. 460788).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors will make the raw data supporting this article’s conclusions available upon request.

Acknowledgments

The authors would like to acknowledge Bioproducts discovery and development center (BDDC) and School of Engineering of University of Guelph to provide the facilities to complete this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Avérous, L. Biodegradable Multiphase Systems Based on Plasticized Starch: A Review. J. Macromol. Sci.-Polym. Rev. 2004, 44, 231–274. [Google Scholar] [CrossRef]

- Wan, Z.; Li, G.; Wang, Y.; Zhu, H.; Lan, X.; Xie, L. Mechanochemical Effect of Starch during the Plasticization. J. Food Eng. 2024, 369, 111941. [Google Scholar] [CrossRef]

- Han, Y.; Weng, Y.; Zhang, C. Development of Biobased Plasticizers with Synergistic Effects of Plasticization, Thermal Stabilization, and Migration Resistance: A Review. J. Vinyl Addit. Technol. 2024, 30, 26–43. [Google Scholar] [CrossRef]

- Surendren, A.; Mohanty, A.K.; Liu, Q.; Misra, M. A Review of Biodegradable Thermoplastic Starches, Their Blends and Composites: Recent Developments and Opportunities for Single-Use Plastic Packaging Alternatives. Green Chem. 2022, 24, 8606–8636. [Google Scholar] [CrossRef]

- Wang, J.L.; Cheng, F.; Zhu, P.X. Structure and Properties of Urea-Plasticized Starch Films with Different Urea Contents. Carbohydr. Polym. 2014, 101, 1109–1115. [Google Scholar] [CrossRef] [PubMed]

- Paluch, M.; Ostrowska, J.; Tyński, P.; Sadurski, W.; Konkol, M. Structural and Thermal Properties of Starch Plasticized with Glycerol/Urea Mixture. J. Polym. Environ. 2022, 30, 728–740. [Google Scholar] [CrossRef]

- Salomão Garcia, P.; Victória Eiras Grossmann, M.; Yamashita, F.; Mali, S.; Henrique Dall, L.; Wagner José Barreto, A. Citric Acid as Multifunctional Agent in Blowing Films of Starch/PBAT. Quim. Nova 2011, 34, 1507–1510. [Google Scholar] [CrossRef]

- Ma, X.; Yu, J. Formamide as the Plasticizer for Thermoplastic Starch. J. Appl. Polym. Sci. 2004, 93, 1769–1773. [Google Scholar] [CrossRef]

- Ma, X.F.; Yu, J.G.; Wan, J.J. Urea and Ethanolamine as a Mixed Plasticizer for Thermoplastic Starch. Carbohydr. Polym. 2006, 64, 267–273. [Google Scholar] [CrossRef]

- Shi, R.; Zhang, Z.; Liu, Q.; Han, Y.; Zhang, L.; Chen, D.; Tian, W. Characterization of Citric Acid/Glycerol Co-Plasticized Thermoplastic Starch Prepared by Melt Blending. Carbohydr. Polym. 2007, 69, 748–755. [Google Scholar] [CrossRef]

- Broeren, M.L.M.; Kuling, L.; Worrell, E.; Shen, L. Environmental Impact Assessment of Six Starch Plastics Focusing on Wastewater-Derived Starch and Additives. Resour. Conserv. Recycl. 2017, 127, 246–255. [Google Scholar] [CrossRef]

- Rojas-Bringas, P.M.; De-la-Torre, G.E.; Torres, F.G. Influence of the Source of Starch and Plasticizers on the Environmental Burden of Starch-Brazil Nut Fiber Biocomposite Production: A Life Cycle Assessment Approach. Sci. Total Environ. 2021, 769, 144869. [Google Scholar] [CrossRef] [PubMed]

- Benetto, E.; Jury, C.; Igos, E.; Carton, J.; Hild, P.; Vergne, C.; Di Martino, J. Using Atmospheric Plasma to Design Multilayer Film from Polylactic Acid and Thermoplastic Starch: A Screening Life Cycle Assessment. J. Clean. Prod. 2015, 87, 953–960. [Google Scholar] [CrossRef]

- Ruini, C.; Neri, P.; Cavalaglio, G.; Coccia, V.; Cotana, F.; Raspolli Galletti, A.M.; Morselli, D.; Fabbri, P.; Ferrari, A.M.; Rosa, R. Innovative Bioplasticizers from Residual Cynara Cardunculus L. Biomass-Derived Levulinic Acid and Their Environmental Impact Assessment by LCA Methodology. ACS Sustain. Chem. Eng. 2023, 11, 12014–12026. [Google Scholar] [CrossRef]

- Shafqat, A.; Tahir, A.; Ullah Khan, W.; Mahmood, A.; Abbasi, G.H.; Khan, W.U. Production and Characterization of Rice Starch and Corn Starch Based Biodegradable Bioplastic Using Various Plasticizers and Natural Reinforcing Fillers. Cellul. Chem. Technol. 2021, 55, 867. [Google Scholar] [CrossRef]

- ISO. ISO 14044:2006; International Organisation for Standardisation Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006; pp. 1–46.

- ISO. ISO 14040:2006; International Organisation for Standardisation Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006; pp. 1–20.

- PRé Sustainability SimaPro 8.4.0. Available online: https://support.simapro.com/s/ (accessed on 5 August 2024).

- Ecoinvent Association Ecoinvent v3.10. Available online: https://ecoinvent.org/ecoinvent-v3-10/ (accessed on 5 June 2024).

- Tanklevska, N.; Petrenko, V.; Karnaushenko, A.; Melnykova, K. World Corn Market: Analysis, Trends, and Prospects of Its Deep Processing. Agric. & Resour. Econ. Int. Sci. E-J. 2020, 6, 96–111. [Google Scholar]

- Canada Energy Regulator. Provincial and Territorial Energy Profiles-Ontario; Canada Energy Regulator: Calgary, AB, Canada, 2024.

- Matthews, H.S.; Hendrickson, C.T.; Matthews, D.H. Life Cycle Assessment: Quantitative Approaches for Decisions That Matter; Self Published, 2014.

- Shi, L.; Liu, L.; Yang, B.; Sheng, G.; Xu, T. Evaluation of Industrial Urea Energy Consumption (EC) Based on Life Cycle Assessment (LCA). Sustainability 2020, 12, 3793. [Google Scholar] [CrossRef]

- Yang, M.; Rosentrater, K.A. Life Cycle Assessment of Urea-Formaldehyde Adhesive and Phenol-Formaldehyde Adhesives. Environ. Process. 2020, 7, 553–561. [Google Scholar] [CrossRef]

- Volpe, V.; De Feo, G.; De Marco, I.; Pantani, R. Use of Sunflower Seed Fried Oil as an Ecofriendly Plasticizer for Starch and Application of This Thermoplastic Starch as a Filler for PLA. Ind. Crops Prod. 2018, 122, 545–552. [Google Scholar] [CrossRef]

- Blanco, E.E.; Ochoa, G.V.; Forero, J.D. Cycle Assessment Indicators to Promote Sustainability in a Paper Production Plant. Resources 2020, 9, 75. [Google Scholar] [CrossRef]

- Motuzienė, V.; Čiuprinskas, K.; Rogoža, A.; Lapinskienė, V. A Review of the Life Cycle Analysis Results for Different Energy Conversion Technologies. Energies 2022, 15, 8488. [Google Scholar] [CrossRef]

- Qudrat-Ullah, H. Green Power in Ontario: A Dynamic Model-Based Analysis. Energy 2014, 77, 859–870. [Google Scholar] [CrossRef]

- Varun; Bhat, I.K.; Prakash, R. LCA of Renewable Energy for Electricity Generation Systems-A Review. Renew. Sustain. Energy Rev. 2009, 13, 1067–1073. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).