Innovative Cross-Sectional Configurations for Low-Cost Bamboo Composite (LCBC) Structural Columns

Abstract

1. Introduction

2. Materials and Methods

2.1. Bamboo Species

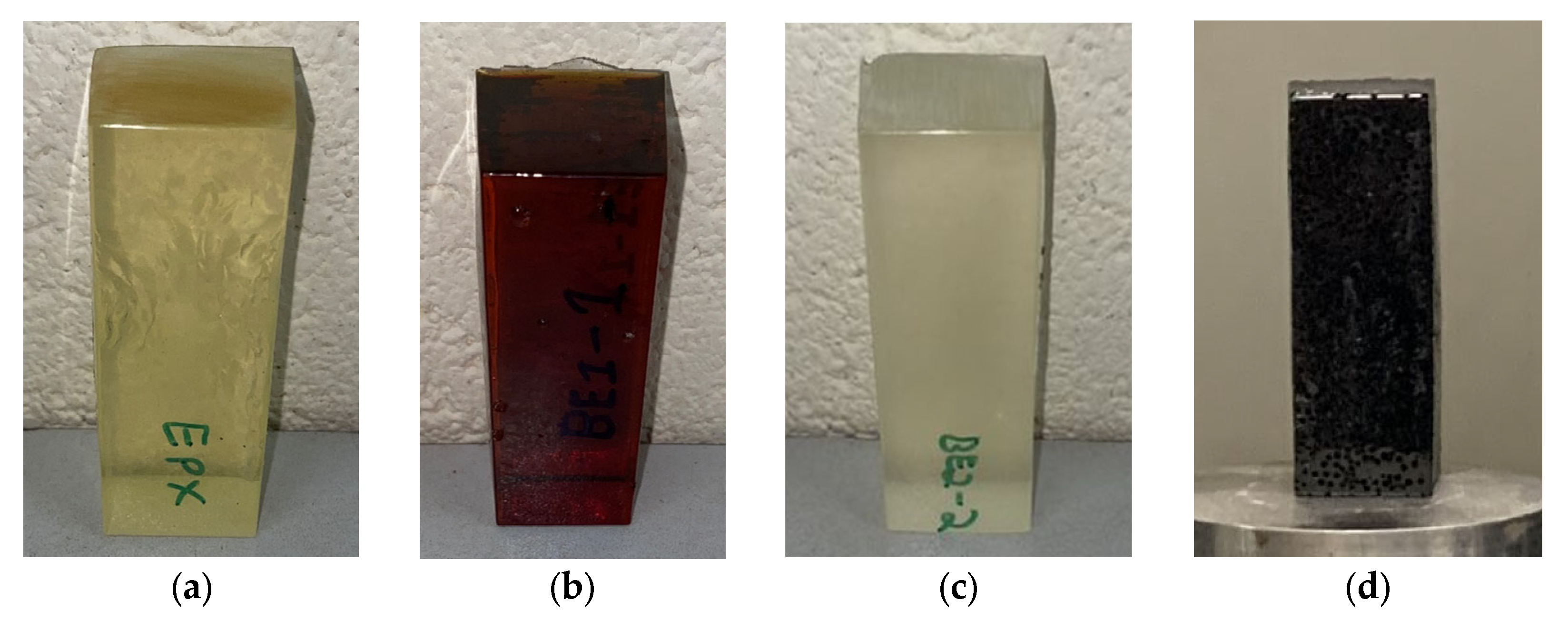

2.2. Resin Matrices

2.3. Cross-Sectional Configurations

2.4. Labelling Conventions

2.5. Experimental Testing Method

3. Experimental Testing Results

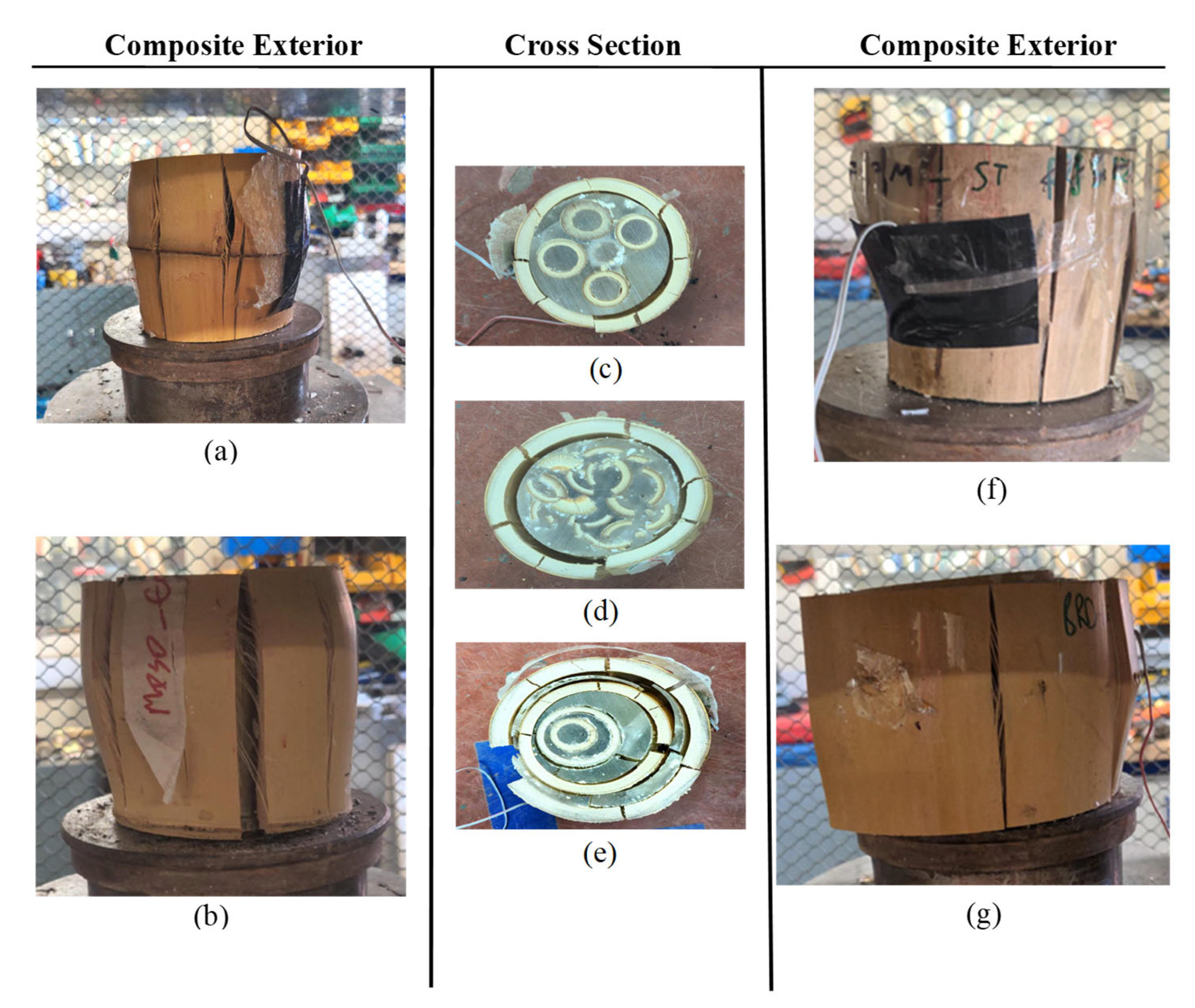

3.1. Cross-Sectional Configuration Choice

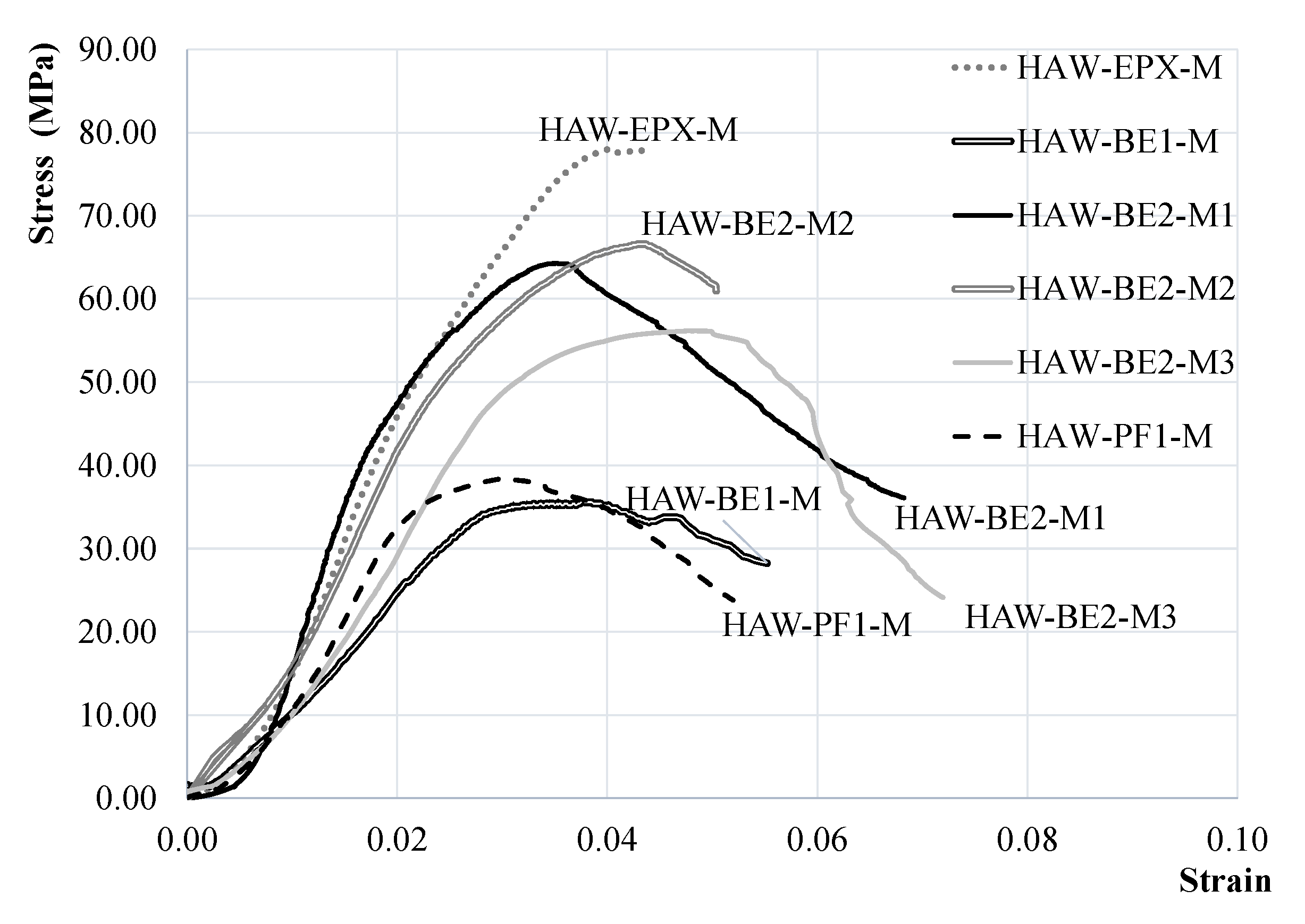

3.1.1. Compressive Properties

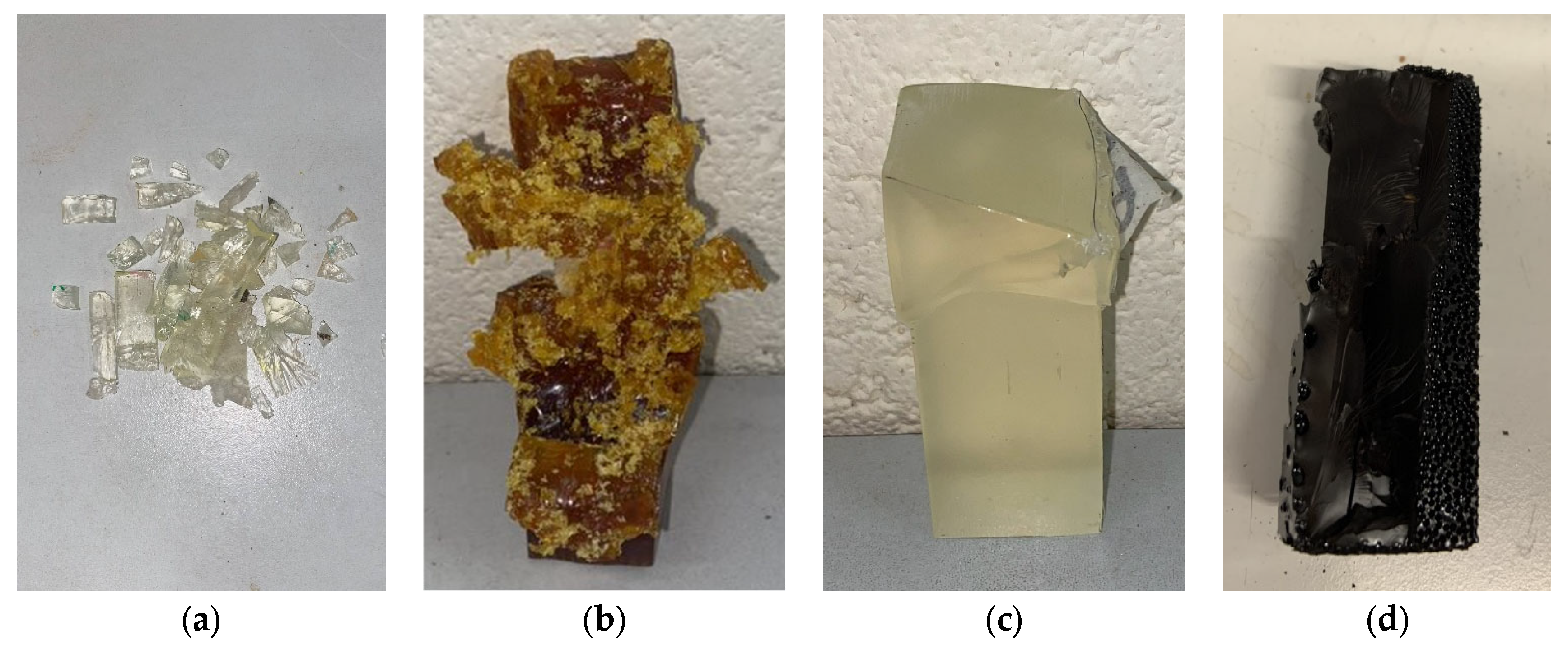

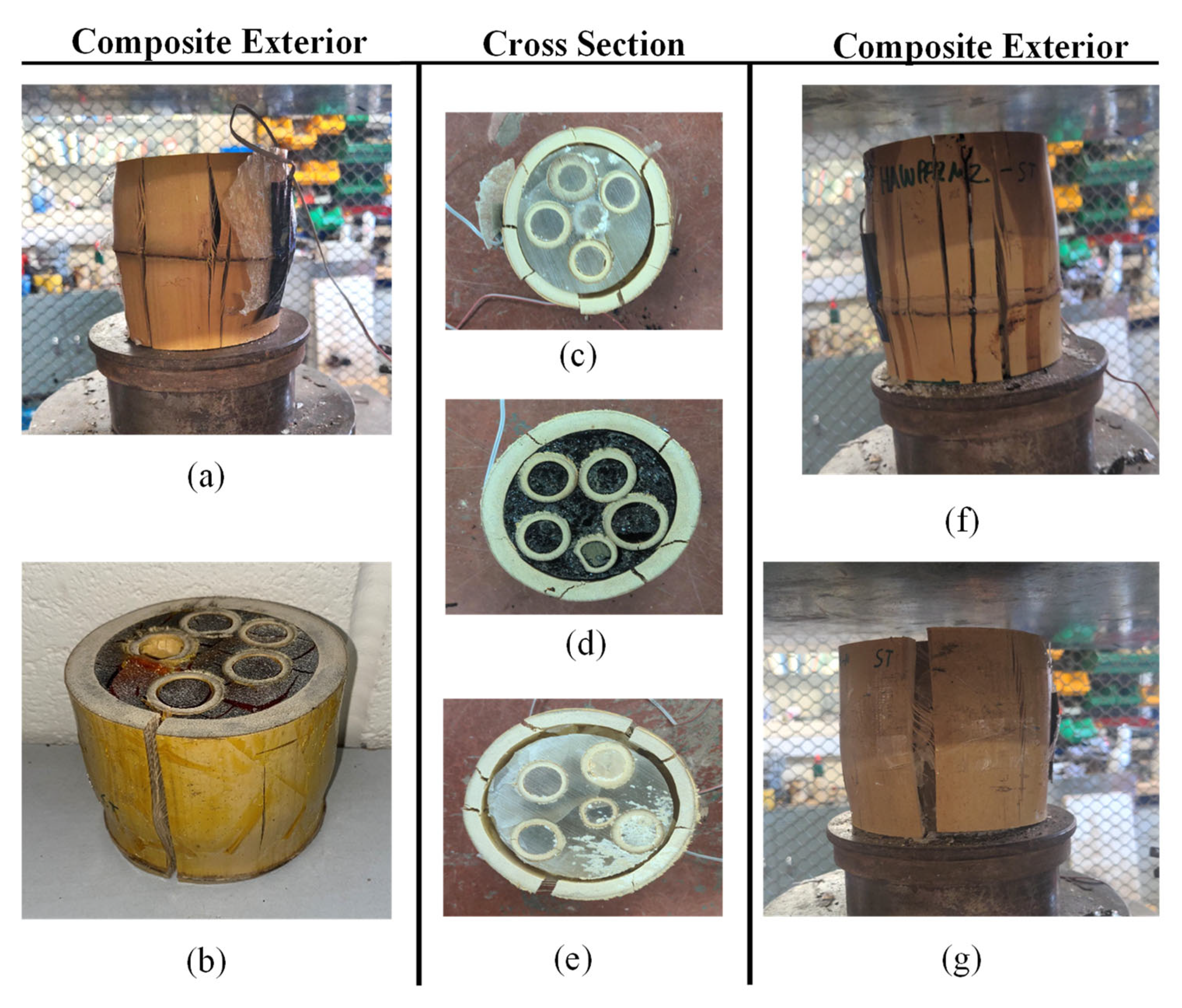

3.1.2. Failure Modes

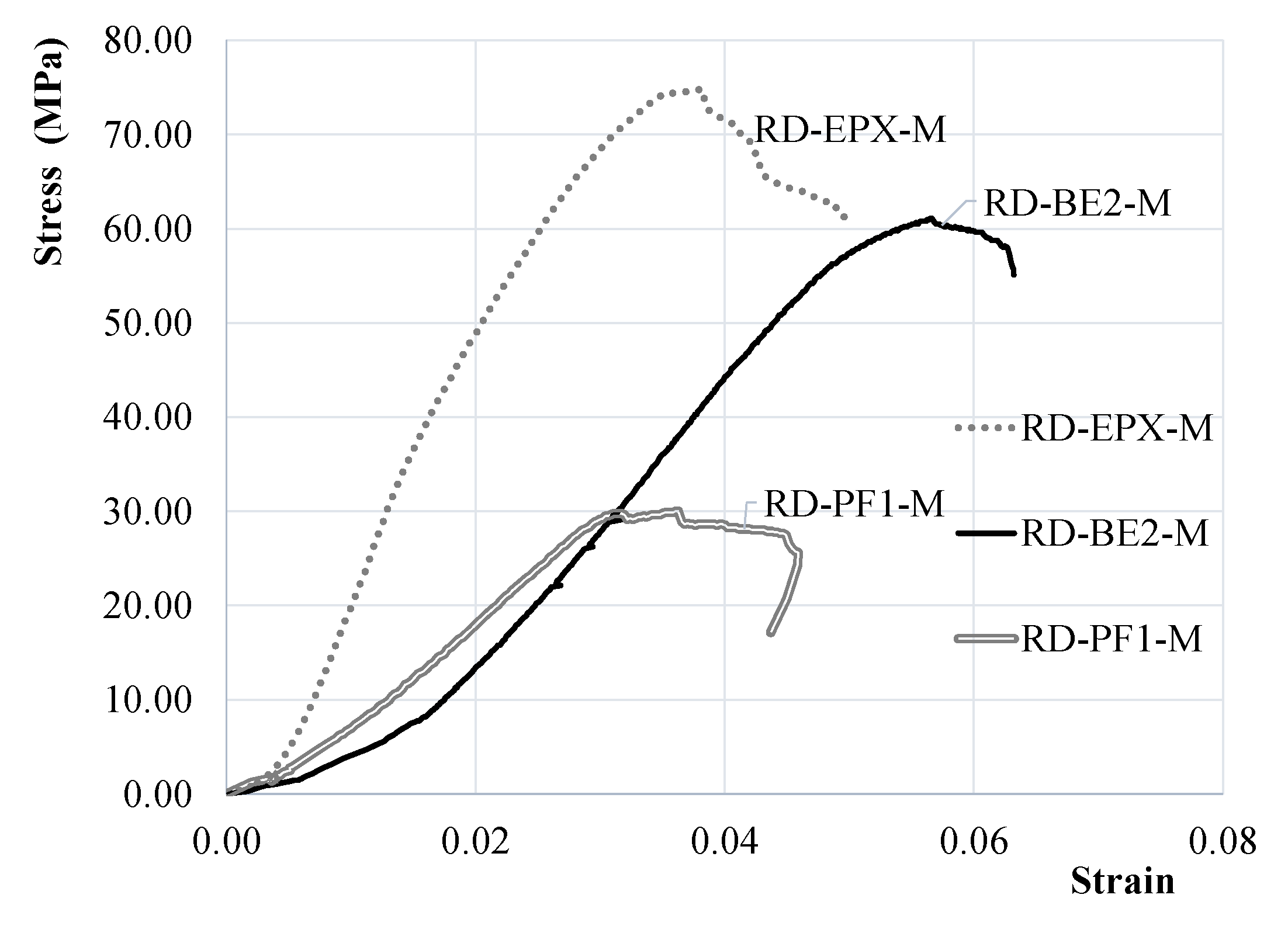

3.2. Bamboo Species Choice

Compressive Properties

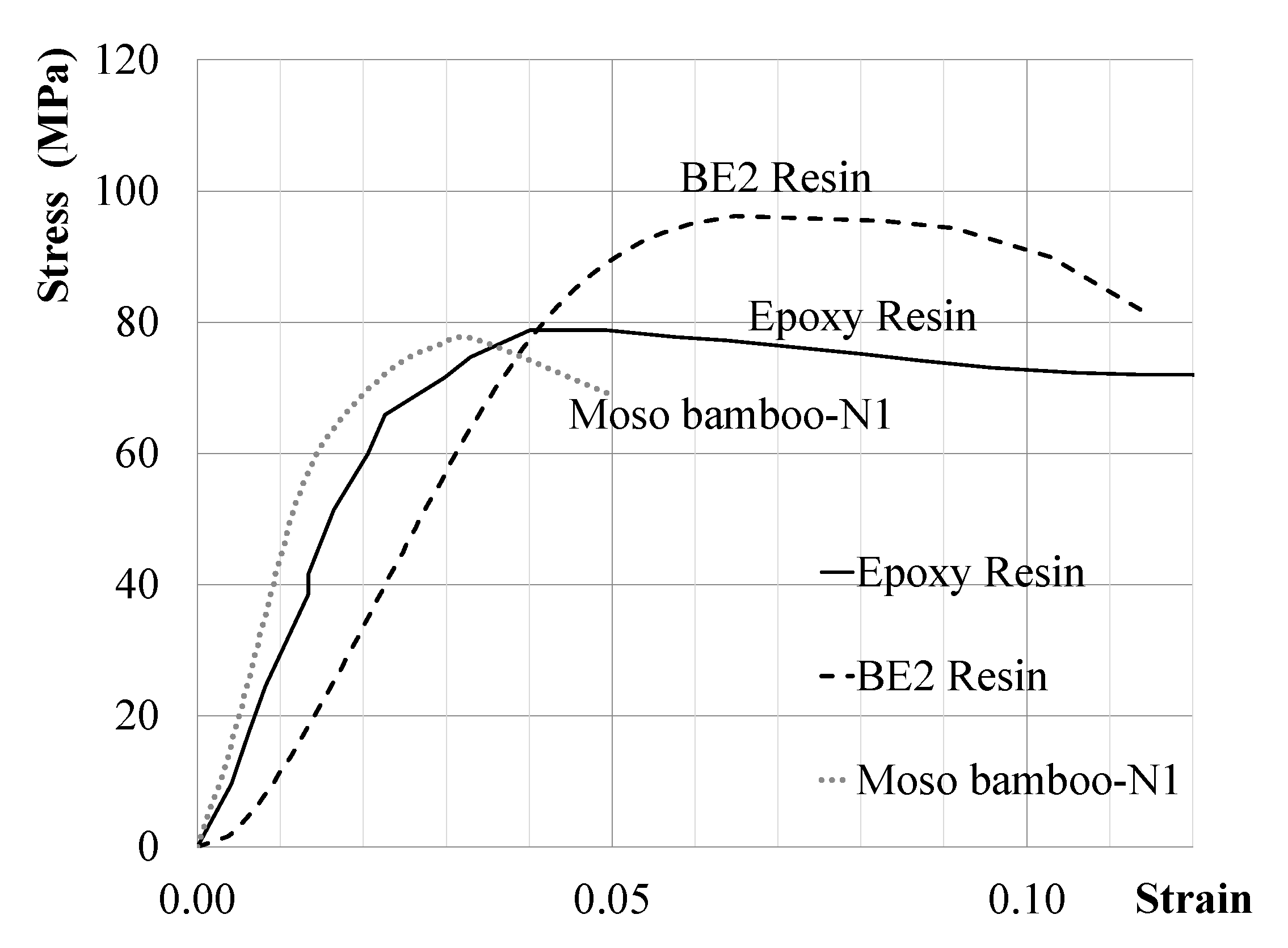

3.3. Resin Matrix Choice

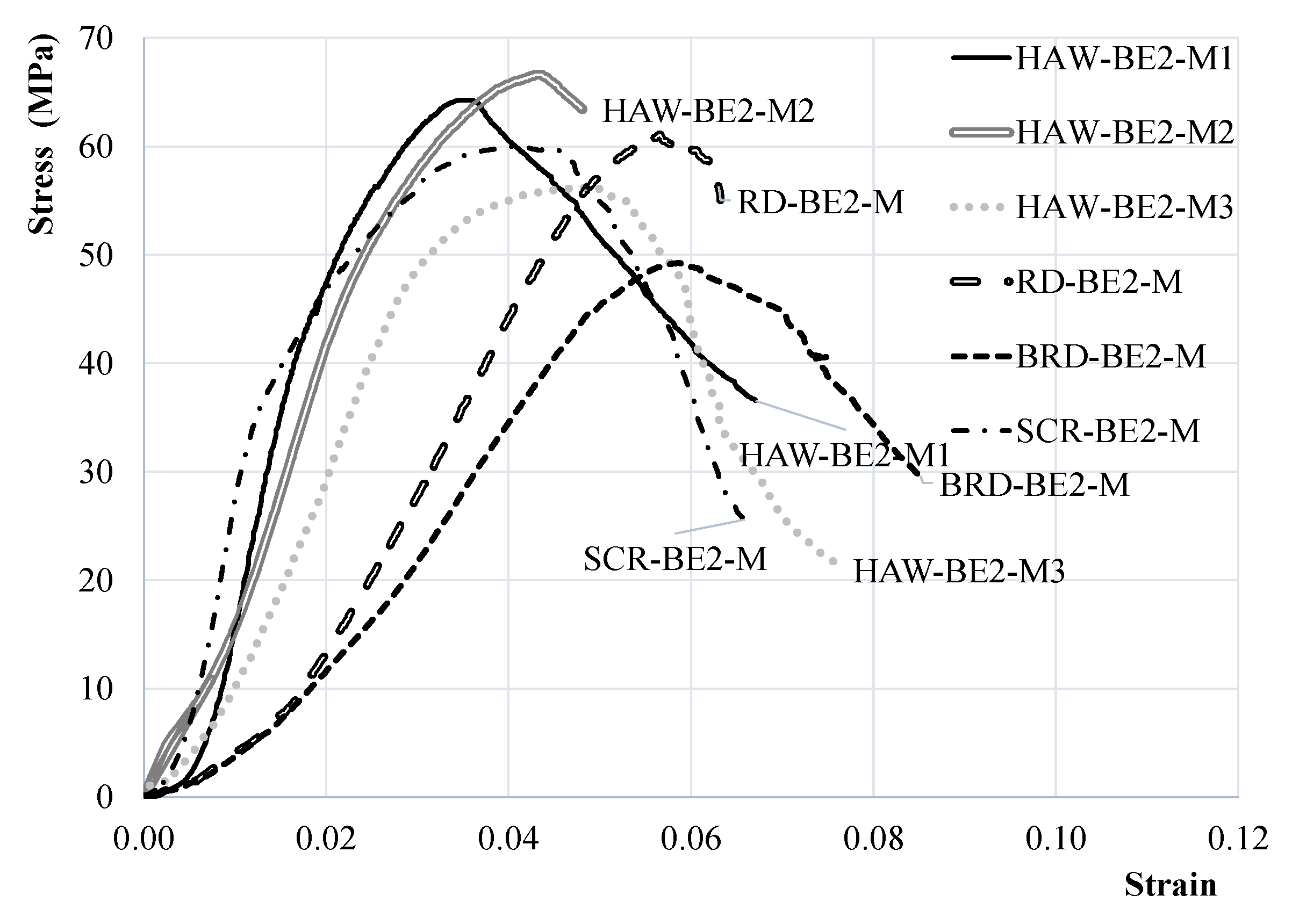

Compressive Properties

4. Theoretical Analysis

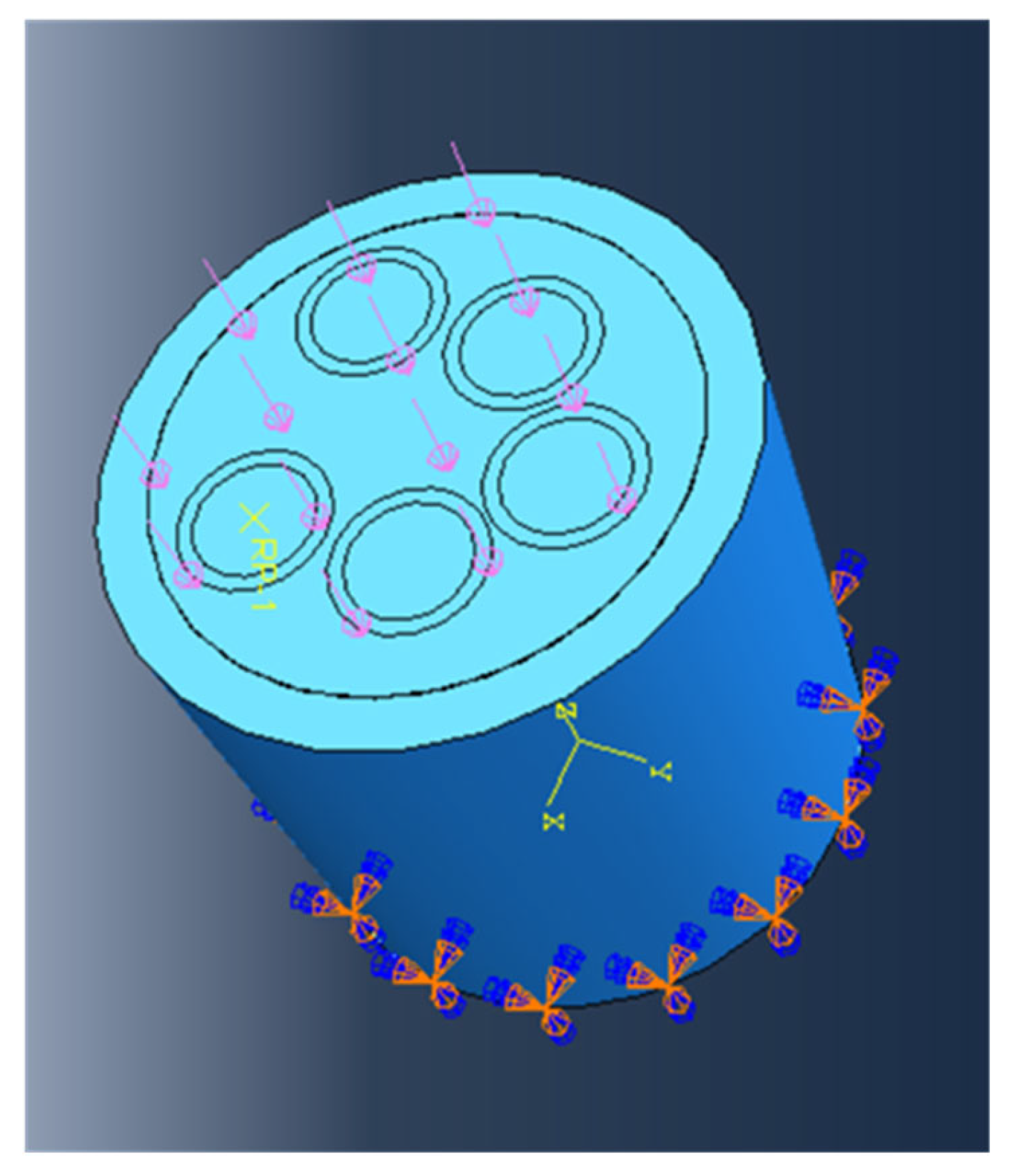

5. Finite Element Analysis

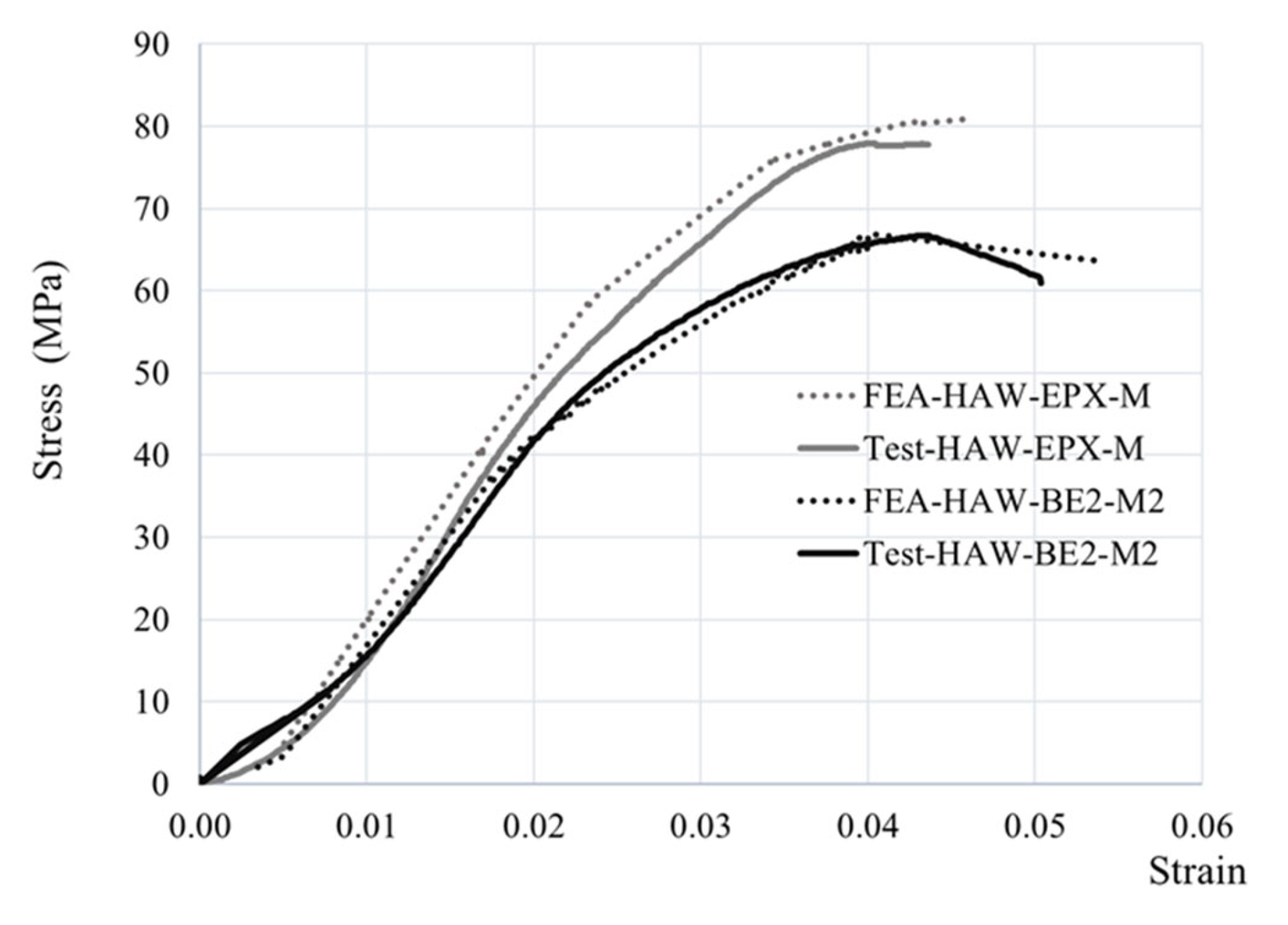

5.1. Compressive Behaviour

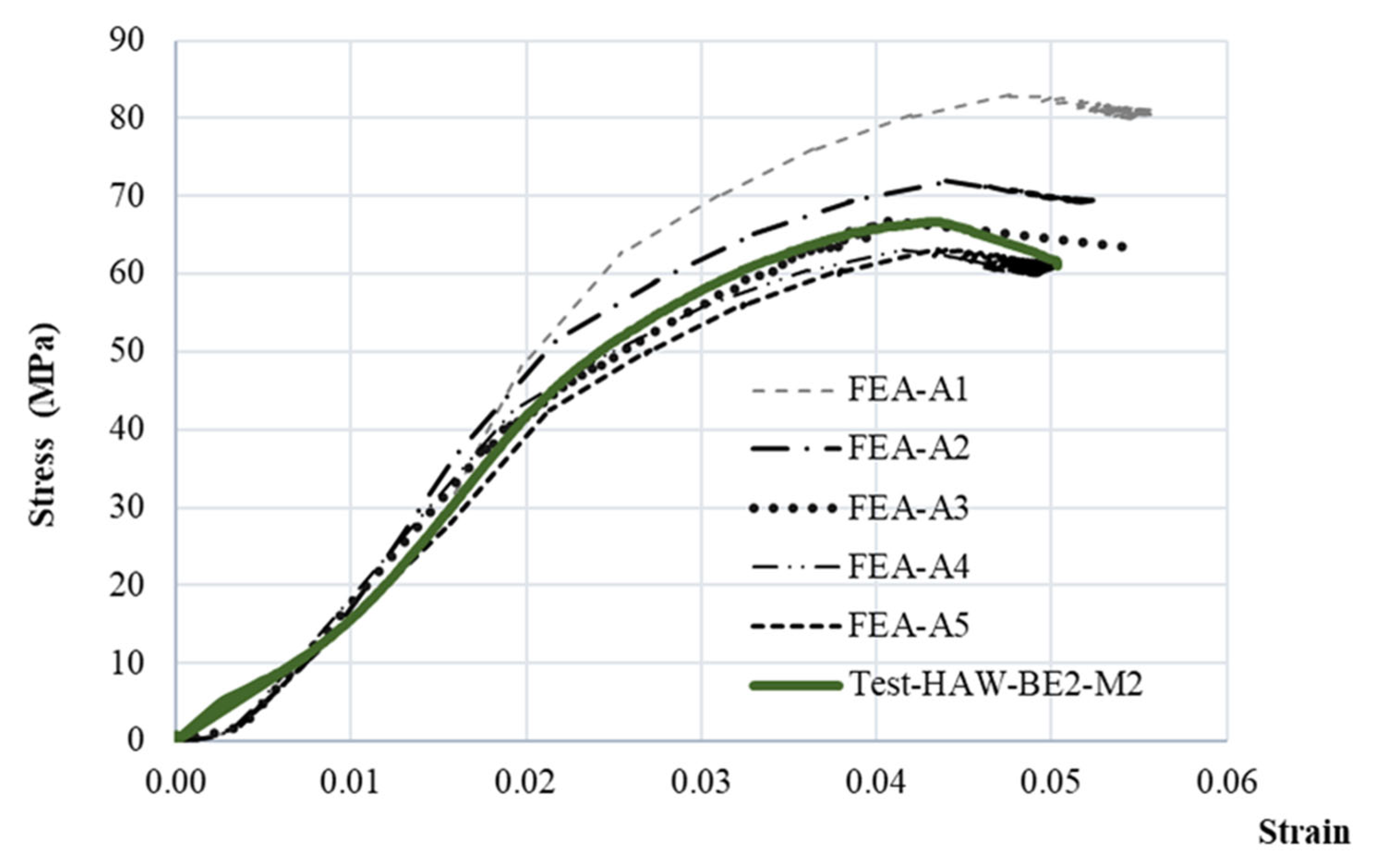

5.2. Resin Content Rate Effect

- The reduction in stiffness observed in columns employing BE2 is less pronounced compared to those utilizing an EPX matrix, attributable to the inherently greater stiffness of EPX.

- The degree of stress softening, defined as the difference between the maximum stress and the failure stress, exhibits negligible variation across the five cases examined.

- The difference in peak stress levels between sections A1 and A2 is more pronounced in columns using BE2 materials than those using EPX.

6. Conclusions

- Unprecedented LCBC compressive members with bio-based resins were able to reach a massive compressive capacity of 567 kN for a member with 104.1 mm diameter, which corresponds to 67 MPa (HAW-BE2-M).

- The maximum compressive strengths (MPa) were achieved by two specimens with synthetic epoxy, closely followed by a specimen with bio-epoxy, namely HAW-EPX-M, RD-EPX-M, and RD-BE2-G specimens, with 78 MPa, 75 MPa, and 72 MPa, respectively.

- In terms of the modulus of elasticity of LCBC with different resin matrices, the stiffest specimens are HAW-BE2-M1, HAW-EPX-M, and HAW-BE2-M2, with 3.89 GPa, 3.08 GPa, and 2.54 GPa, respectively.

- The theoretical predictions of the specimens in the HAW series reached a reasonable accuracy with a Mean value equal to 0.88 and CoV equal to 16% for the Pmeasured/Ptheory ratio.

- FEA conducted with ABAQUS effectively simulates the response of the LCBC columns with HAW configuration to axial compression. The numerical model integrates constitutive models for Moso bamboo and epoxy resins. Mesh refinement strategies, with elements of 5 mm, ensure convergence and accuracy.

- The numerical analysis output closely matches experimental results, with only minor differences observed, such as a 2 MPa difference for axial stress at failure in HAW-EPX-M specimens and a 3 MPa difference in HAW-BE2-M2 specimens.

- Resin content profoundly affects composite properties like strength and stiffness, emphasizing the need for precise control during manufacturing. Parametric studies show that adjusting outer column dimensions while keeping wall thickness consistent alters resin content, peak stress, and stiffness. A discernible trend is observed wherein the SP reduces gradually with increasing resin content. Additionally, the initial stiffness of the column decreases with decreasing the resin content, particularly up to a 50% reduction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BADGE | Bisphenol A diglycidyl ether |

| BE1 | Bio-based Experimental soft filler; |

| BE2 | Bio-Epoxy resin matrix; |

| BRD | Big Russian doll cross-sectional configuration; |

| EPX | Synthetic epoxy resin matrix; |

| FEA | Finite Element Analysis |

| HAW | Hawser cross-sectional configuration; |

| LCBC | Low-Cost Bamboo Composites; |

| RC | Reinforced Concrete; |

| RD | Russian Doll cross-sectional configuration; |

| SCR | Scrimber cross-sectional configuration; |

| SP | Stress at Peak |

| SR | Stress at Failure |

| PFA | Polyfurfuryl alcohol; |

| PF1 | Furan-based resin matrix. |

References

- Javadian, A.; Wielopolski, M.; Smith, I.F.C.; Hebel, D.E. Bond-behavior study of newly developed bamboo-composite reinforcement in concrete. Constr. Build. Mater. J. 2016, 122, 110–117. [Google Scholar] [CrossRef]

- Arioğlu Akan, M.Ö.; Dhavale, D.G.; Sarkis, J. Greenhouse gas emissions in the construction industry: An analysis and evaluation of a concrete supply chain. J. Clean. Prod. 2017, 167, 1195–1207. [Google Scholar] [CrossRef]

- Zayed, A.M.; Masoud, M.A.; Shahien, M.G.; Gökçe, H.S.; Sakr, K.; Kansouh, W.A.; El-Khayatt, A.M. Physical, mechanical, and radiation attenuation properties of serpentine concrete containing boric acid. Constr. Build. Mater. 2021, 272, 121641. [Google Scholar] [CrossRef]

- Zayed, A.M.; Masoud, M.A.; Rashad, A.M.; El-Khayatt, A.M.; Sakr, K.; Kansouh, W.A.; Shahien, M.G. Influence of heavyweight aggregates on the physico-mechanical and radiation attenuation properties of serpentine-based concrete. Constr. Build. Mater. 2020, 260, 120473. [Google Scholar] [CrossRef]

- Birol, F.; Solheim, E. Global Status Report 2017: Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector; United Nations Environment: Nairobi, Kenya, 2017; 48p. [Google Scholar]

- Khatib, J.M. Sustainability of Construction Materials, 2nd ed.; Woodhead Publishing: Sawston, UK, 2016; 742p. [Google Scholar]

- Richardson, C.; Mofidi, A. Non-Linear Numerical Modelling of Sustainable Advanced Composite Columns Made from Bamboo Culms. Constr. Mater. 2021, 1, 169–187. [Google Scholar] [CrossRef]

- van der Lugt, P. Design Interventions for Stimulating Bamboo Commercialization: Dutch Design Meets Bamboo as a Replicable Model. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2008. [Google Scholar]

- Shu, B.; Xiao, Z.; Hong, L.; Zhang, S.; Li, C.; Fu, N.; Lu, X. Review on the application of bamboo-based materials in construction engineering. J. Renew. Mater. 2020, 8, 1215–1242. [Google Scholar] [CrossRef]

- Trujillo, D.J.A.; Malkowska, D. Empirically derived connection design properties for Guadua bamboo. Constr. Build. Mater. 2018, 163, 9–20. [Google Scholar] [CrossRef]

- Koenigsberger, O.H. World consultation on the use of wood in housing: Wood in housing in developing countries (Section 6) Unasylva. J. Food Agric. Organ. United Nations 1971, 25, 101–103. [Google Scholar]

- Harries, K.A.; Sharma, B.; Richard, M. Structural Use of Full Culm Bamboo: The Path to Standardization. International Journal of Architecture. Eng. Constr. 2012, 1, 66–75. [Google Scholar]

- Bhagat, D.; Maheshwari, A.; Bhalla, S. Composite bamboo beam elements for structural applications. In Proceedings of the UK-India Education and Research Initiative (UKIERI) Congress on Innovations in Concrete Construction, Jalandhar, India, 5 August 2013. [Google Scholar]

- Nunes, N. Nonwood bio-based materials. In Performance of Bio-Based Building Materials; Woodhead Publishing: Sawston, UK, 2017; pp. 97–186. [Google Scholar]

- Kaminski, S.; Lawrence, A.; Trujillo, D. Structural use of bamboo. Part 1: Introduction to bamboo. Struct. Eng. 2016, 98, 40–43. [Google Scholar] [CrossRef]

- Trujillo, D.; López, L.F. Bamboo material characterisation. In Nonconventional and Vernacular Construction Materials, 2nd ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 365–392. [Google Scholar]

- Harries, K.A.; Mofidi, A.; Naylor, J.; Trujillo, D.J.A.; Gutierrez, M.; Sharma, B. Knowledge Gaps and Research Needs for Bamboo in Construction. In Proceedings of the 18th International Conference on Non-Conventional Materials and Technologies, Online, 7 July 2022. [Google Scholar]

- Nurdiah, E.A. The Potential of Bamboo as Building Material in Organic Shaped Buildings. Procedia Soc. Behav. Sci. 2016, 216, 30–38. [Google Scholar] [CrossRef]

- Lin, M.Y.; Hsieh, I.F.; Lin, P.H.; Laplace, S.; Ohashi, M.; Chen, T.H.; Kume, T. Moso bamboo (Phyllostachys pubescens) forests as a significant carbon sink? A case study based on 4-year measurements in central Taiwan. Ecol. Res. 2017, 32, 845–857. [Google Scholar] [CrossRef]

- Mofidi, A.; Abila, J.; Ng, J.T.M. Novel Advanced Composite Bamboo Structural Members with Bio-Based and Synthetic Matrices for Sustainable Construction. Sustainability 2020, 12, 2485. [Google Scholar] [CrossRef]

- Han, H.; Lou, Z.; Wang, Q.; Xu, L.; Li, Y. Introducing rich heterojunction surfaces to enhance the high-frequency electromagnetic attenuation response of flexible fiber-based wearable absorbers. Adv. Fiber Mater. 2024, 6, 739–757. [Google Scholar] [CrossRef]

- Lou, Z.; Zheng, Z.; Yan, N.; Jiang, X.; Zhang, X.; Chen, S.; Xu, R.; Liu, C.; Xu, L. Modification and application of bamboo-based materials: A review—Part II: Application of bamboo-based materials. Forests 2023, 14, 2266. [Google Scholar] [CrossRef]

- Lou, Z.; Han, X.; Liu, J.; Ma, Q.; Yan, H.; Yuan, C.; Yang, L.; Han, H.; Weng, F.; Li, Y. Nano-Fe3O4/bamboo bundles/phenolic resin oriented recombination ternary composite with enhanced multiple functions. Compos. Part B Eng. 2021, 226, 109335. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fibre-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Correal, J.F. Bamboo Design and Construction In Nonconventional and Vernacular Construction Materials, 2nd ed.; Woodhead Publishing: Sawston, UK, 2020; pp. 393–429. [Google Scholar]

- Drury, B.; Padfield, C.; Russo, M.; Swygart, L.; Spalton, O.; Froggatt, S.; Mofidi, A. Assessment of the Compression Properties of Different Giant Bamboo Species for Sustainable Construction. Sustainability 2023, 15, 6472. [Google Scholar] [CrossRef]

- Kenneth, O.I.; Uzodimma, U.O. Evaluation of the Compressive Strength of Bamboo Culms under Node and Internode Conditions. Saudi J. Civ. Eng. 2021, 5, 251–258. [Google Scholar]

- Klose, L.; Meyer-Heydecke, N.; Wongwattanarat, S.; Chow, J.; Pérez García, P.; Carré, C.; Streit, W.; Antranikian, G.; Romero, A.M.; Liese, A. Towards Sustainable Recycling of Epoxy-Based Polymers: Approaches and Challenges of Epoxy Biodegradation. Polymers 2023, 15, 2653. [Google Scholar] [CrossRef]

- Terry, J.S.; Taylor, A.C. The properties and suitability of commercial bio-based epoxies for use in fiberfibre-reinforced composites. J. Appl. Polym. Sci. 2021, 138, 50417. [Google Scholar] [CrossRef]

- Ferdosian, F.; Zhang, Y.; Yuan, Z.; Anderson, M.; Xu, C.C. Curing kinetics and mechanical properties of bio-based epoxy composites comprising lignin-based epoxy resins. Eur. Polym. J. 2016, 82, 153–165. [Google Scholar] [CrossRef]

- Hoydonckx, H.E.; Van Rhijn, W. Application of novel furan resins in composites. JEC Compos. Mag. 2008, 45, 34–35. [Google Scholar]

- ASTM D695; Standard Test Method for Compressive Properties of Rigid Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ISO 22157:2019; Bamboo Structures—Determination of Physical and Mechanical Properties of Bamboo Culms—Test Methods. International Standards Organization: Geneva, Switzerland, 2019; 25p.

- Nie, Y.; Wei, Y.; Huang, L.; Liu, Y.; Dong, F. Influence of slenderness ratio and sectional geometry on the axial compression behaviour of original bamboo columns. J. Wood Sci. 2021, 67, 36. [Google Scholar] [CrossRef]

- ABAQUS. Abaqus Unified FEA-3DEXPERIENCE R2018; Dassault Systèmes, Ed.; 3DS-SIMULIA: Vélizy-Villacoublay, France, 2018. [Google Scholar]

- Torres, L.A.; Ghavami, K.; Garcia, J.J. A transversely isotropic law for the determination of the circumferential Young’s modulus of bamboo with diametric compression tests. Lat. Am. Appl. Res. 2007, 37, 255–260. [Google Scholar]

- Zhang, X.; Li, J.; Yu, Z.; Yu, Y.; Wang, H. Compressive failure mechanism and buckling analysis of the graded hierarchical bamboo structure. J. Mater. Sci. 2017, 52, 6999–7007. [Google Scholar] [CrossRef]

- Lopez, J. Optimizing the Mechanical Characteristics of Bamboo to Improve the Flexural Behavior for Biocomposite Structural Application. MSc Thesis, California Polytechnic State University, San Luis Obispo, CA, USA, 2012. [Google Scholar]

- Fard, M.Y. Nonlinear Inelastic Mechanical Behavior of Epoxy Resin Polymeric Materials. Doctoral Dissertation, Arizona State University, Tempe, AZ, USA, 2011. [Google Scholar]

- Cease, H.; Derwent, P.F.; Diehl, H.T.; Fast, J.; Finley, D. Measurement of Mechanical Properties of Three Epoxy Adhesives at Cryogenic Temperatures for CCD Construction; Fermi Lab Report Fermilab TM-2366-A; Fermi National Accelerator Laboratory: Batavia, IL, USA, 2006. [Google Scholar]

- Morelle, X.P.; Chevalier, J.; Bailly, C.; Pardoen, T.; Lani, F. Mechanical characterization and modeling of the deformation and failure of the highly crosslinked RTM6 epoxy resin. Mech. Time-Depend. Mater. 2017, 21, 419–454. [Google Scholar] [CrossRef]

- Cetisli, F.; Naito, C.J. State of the Art of Analytical Prediction for Confined Concrete; ATLSS Engineering Research Center, Lehigh University: Bethlehem, PA, USA, 2003. [Google Scholar]

- Rabearison, N.; Jochum, C.; Grandidier, J.C. A FEM coupling model for properties prediction during the curing of an epoxy matrix. Comput. Mater. Sci. 2009, 45, 715–724. [Google Scholar] [CrossRef]

- Yagimli, B.; Lion, A. Modelling and simulation of curing processes of epoxy resin. In PAMM: Proceedings in Applied Mathematics and Mechanics; WILEY-VCH: Berlin, Germany, 2009; Volume 9, pp. 325–326. [Google Scholar]

- Bai, X.; Lee, A.W.; Thompson, L.L.; Rosowsky, D.V. Finite element analysis of Moso bamboo-reinforced southern pine OSB composite beams. Wood Fiber Sci. 2007, 31, 403–415. [Google Scholar]

- Zhao, M. On Nonlinear Buckling and Collapse Analysis using Riks Method. In Proceedings of the Abaqus Users’ Conference (1–9), Newport, RI, USA, 19–22 May 2008; Simulia: Johnston, RI, USA, 2008. [Google Scholar]

- Henriques, J.; da Silva, L.S.; Valente, I.B. Numerical modeling of composite beam to reinforced concrete wall joints: Part I: Calibration of joint components. Eng. Struct. 2013, 52, 747–761. [Google Scholar] [CrossRef]

| Configuration | Specimen | DOuter (mm) | Length (mm) | Mass (g) | Bamboo Content (%) | Resin Content (%) |

|---|---|---|---|---|---|---|

| Hawser (HAW) | HAW-EPX-M | 96.3 | 96.9 | 649 | 41 | 59 |

| HAW-BE1-M | 98.5 | 93.6 | 586 | 55 | 45 | |

| HAW-BE2-M1 | 88.8 | 94.2 | 521 | 53 | 47 | |

| HAW-BE2-M2 | 104.1 | 93.8 | 682 | 50 | 50 | |

| HAW-BE2-M3 | 90.7 | 92.5 | 480 | 48 | 52 | |

| HAW-PF1-M | 88.5 | 99.7 | 347 | 52 | 48 | |

| Russian Doll (RD) | RD-EPX-M | 98.7 | 97.6 | 679 | 43 | 57 |

| RD-BE1-G | 82.9 | 87.0 | 422 | 47 | 53 | |

| RD-BE2-M | 93.2 | 92.8 | 545 | 49 | 51 | |

| RD-BE2-T | 84.7 | 98.3 | 406 | 54 | 42 | |

| RD-BE2-G | 80.6 | 95.2 | 424 | 49 | 44 | |

| RD-PF1-M | 100.9 | 128.5 | 792 | 56 | 41 | |

| RD-PF1-T | 82.7 | 99.6 | 330 | 48 | 52 | |

| Big Russian Doll (BRD) | BRD-BE2-M | 119.8 | 93.5 | 819 | 59 | 41 |

| BRD-PF1-M | 125.9 | 99.2 | 850 | 63 | 37 | |

| Scrimber (SCR) | SCR-BE2-M | 91.3 | 100.0 | 513 | 56 | 44 |

| SCR-PF1-M | 90.8 | 146.9 | 695 | 54 | 46 |

| Configuration | Specimen | ΔLc,0 (mm) | εc,0 | Fult (kN) | fc,0 (MPa) | Ec,0 (GPa) |

|---|---|---|---|---|---|---|

| Hawser (HAW) | HAW-EPX-M | 4.30 | 0.044 | 568 | 78 | 3.08 |

| HAW-BE1-M | 3.76 | 0.038 | 220 | 36 | 1.32 | |

| HAW-BE2-M1 | 3.37 | 0.035 | 398 | 64 | 3.89 | |

| HAW-BE2-M2 | 4.23 | 0.043 | 567 | 67 | 2.54 | |

| HAW-BE2-M3 | 4.48 | 0.049 | 363 | 56 | 2.01 | |

| HAW-PF1-M | 3.01 | 0.031 | 236 | 38 | 2.06 | |

| Russian Doll (RD) | RD-EPX-M | 3.73 | 0.038 | 571 | 75 | 3.07 |

| RD-BE1-G | 2.18 | 0.025 | 166 | 31 | 1.74 | |

| RD-BE2-M | 5.26 | 0.059 | 417 | 61 | 1.50 | |

| RD-BE2-T | 1.54 | 0.016 | 204 | 36 | 4.47 | |

| RD-BE2-G | 3.98 | 0.043 | 366 | 72 | 3.85 | |

| RD-PF1-M | 3.70 | 0.072 | 234 | 30 | 1.08 | |

| RD-PF1-T | 2.69 | 0.027 | 166 | 31 | 1.29 | |

| Big Russian Doll (BRD) | BRD-BE2-M | 5.49 | 0.059 | 555 | 49 | 1.10 |

| BRD-PF1-M | 4.28 | 0.043 | 500 | 40 | 1.18 | |

| Scrimber (SCR) | SCR-BE2-M | 4.43 | 0.041 | 391 | 60 | 3.87 |

| SCR-PF1-M | 5.54 | 0.038 | 225 | 35 | 1.39 |

| Specimen | Strain of the First Failed Component | Predicted Bamboo Share (kN) | Predicted Resin Share (kN) | Ptheory (kN) | Pmeasured (kN) | Pmeasured/ Ptheory |

|---|---|---|---|---|---|---|

| HAW-EPX-M | 0.037 (b) * | 208.5 | 313.0 | 522 | 568 | 1.09 |

| HAW-BE1-M | 0.037 (b) | 292.7 | 0.1 | 293 | 220 | 0.75 |

| HAW-BE2-M1 | 0.037 (b) | 229.3 | 188.3 | 418 | 398 | 0.95 |

| HAW-BE2-M2 | 0.037 (b) | 297.2 | 275.4 | 573 | 567 | 0.99 |

| HAW-BE2-M3 | 0.037 (b) | 216.6 | 217.4 | 434 | 363 | 0.84 |

| HAW-PF1-M | 0.019 (r) | 222.1 | 123.9 | 346 | 236 | 0.68 |

| Property/Specimen Name | FEA-A1 | FEA-A2 | FEA-A3 | FEA-A4 | FEA-A5 |

|---|---|---|---|---|---|

| Radius of section (RS) | 1.2r | 1.1r | r | 0.9r | 0.8r |

| Peak stress (SP), MPa | 83.7 | 82.1 | 80.6 | 78 | 74.96 |

| Stress at failure (SF), MPa | 79.3 | 80.0 | 79.5 | 77.2 | 73.69 |

| Degree of Stress softening (SP − SF), MPa | 4.40 | 2.11 | 1.10 | 0.80 | 0.65 |

| Strain at peak (εP) | 0.040 | 0.050 | 0.043 | 0.033 | 0.043 |

| Strain at failure (εF) | 0.050 | 0.052 | 0.046 | 0.045 | 0.05 |

| Strain gradient at softening (εF − εP) | 0.010 | 0.002 | 0.003 | 0.012 | 0.007 |

| Stiffness (E0), GPa | 3.70 | 2.94 | 2.55 | 2.49 | 2.30 |

| Property/Specimen Name | FEA-A1 | FEA-A2 | FEA-A3 | FEA-A4 | FEA-A5 |

|---|---|---|---|---|---|

| Radius of section (RS) | 1.2r | 1.1r | r | 0.9r | 0.8r |

| Peak stress (SP), MPa | 82.95 | 71.93 | 66.90 | 63.05 | 63.15 |

| Stress at failure (SF), MPa | 80.45 | 69.28 | 63.50 | 60.41 | 61.50 |

| Degree of Stress softening (SP − SF), MPa | 2.50 | 2.65 | 3.40 | 2.64 | 1.65 |

| Strain at peak (εP) | 0.048 | 0.044 | 0.04 | 0.042 | 0.044 |

| Strain at failure (εF) | 0.056 | 0.053 | 0.054 | 0.047 | 0.050 |

| Strain gradient at softening (εF − εP) | 0.008 | 0.009 | 0.014 | 0.005 | 0.006 |

| Stiffness (E0), GPa | 2.70 | 2.20 | 1.94 | 1.65 | 1.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Padfield, C.; Drury, B.; Soltanieh, G.; Rajabifard, M.; Mofidi, A. Innovative Cross-Sectional Configurations for Low-Cost Bamboo Composite (LCBC) Structural Columns. Sustainability 2024, 16, 7451. https://doi.org/10.3390/su16177451

Padfield C, Drury B, Soltanieh G, Rajabifard M, Mofidi A. Innovative Cross-Sectional Configurations for Low-Cost Bamboo Composite (LCBC) Structural Columns. Sustainability. 2024; 16(17):7451. https://doi.org/10.3390/su16177451

Chicago/Turabian StylePadfield, Cameron, Ben Drury, Ghazaleh Soltanieh, Mona Rajabifard, and Amir Mofidi. 2024. "Innovative Cross-Sectional Configurations for Low-Cost Bamboo Composite (LCBC) Structural Columns" Sustainability 16, no. 17: 7451. https://doi.org/10.3390/su16177451

APA StylePadfield, C., Drury, B., Soltanieh, G., Rajabifard, M., & Mofidi, A. (2024). Innovative Cross-Sectional Configurations for Low-Cost Bamboo Composite (LCBC) Structural Columns. Sustainability, 16(17), 7451. https://doi.org/10.3390/su16177451