The Nexus between Green Supply Chain Management and Sustainability Performance in the Past Decade

Abstract

1. Introduction

1.1. Emergence and Relevance of GSCM

1.2. GSCM and the Firm’s Performance

1.3. Research Gap and Scope

- To analyze the reporting and collaboration trends in GSCM and FP among authors, countries, and sources;

- To identify the trending topics and emerging themes in GSCM and FP, along with figuring out their impact, centrality, and density;

- To find out the different methodologies, affiliating concepts, influencers, drivers, and impacts of GSCM and performance through content analysis of themes identified through thematic analysis.

2. Literature Review

2.1. GSCM and Indirect Performance Affecting Concept Analysis

2.2. Digital Supply Chain Management and Blockchain Intervention for SSCs

2.3. GSCM and Performance Analysis

2.4. Miscellaneous Analysis Related to Sustainable Supply Chains

- RQ1.

- What are the research trends in reporting the relationship between sustainability in the SC and performance by authors, countries, and sources?

- RQ2.

- What are the trending topics and different themes, and what are their impact, centrality, and density in the relationship between SSCs and performance?

- RQ3.

- What are the different methodologies used to develop and assess sustainability along the supply chain, based on the different themes identified through clustering?

- RQ4.

- What are the affiliating concepts for green and sustainable supply chains?

- RQ5.

- What are the drivers and influencers of green and sustainable supply chains?

- RQ6.

- What is the impact of green and sustainable SCs on performance?

- RQ7.

- What has been the trend in collaboration between authors and countries in SSCs and performance?

- RO1.

- To identify the reporting trend by authors, countries, and sources in SSCs and performance.

- RO2.

- To identify the trending topics and different themes, and their impact, centrality and density with regard to the relationship between SSCs and performance.

- RO3.

- To identify the methodologies used to develop and assess sustainability along the supply chain, based on the different themes identified through clustering.

- RO4.

- To identify the affiliating concepts for green and sustainable supply chains.

- RO5.

- To identify the drivers and influencers of green and sustainable supply chains.

- RO6.

- To assess the probable impact of green and sustainable SCs on performance.

- RO7.

- To identify the trend in collaboration of authors and countries in the realm of SSCs and performance, taken together.

3. Methodology

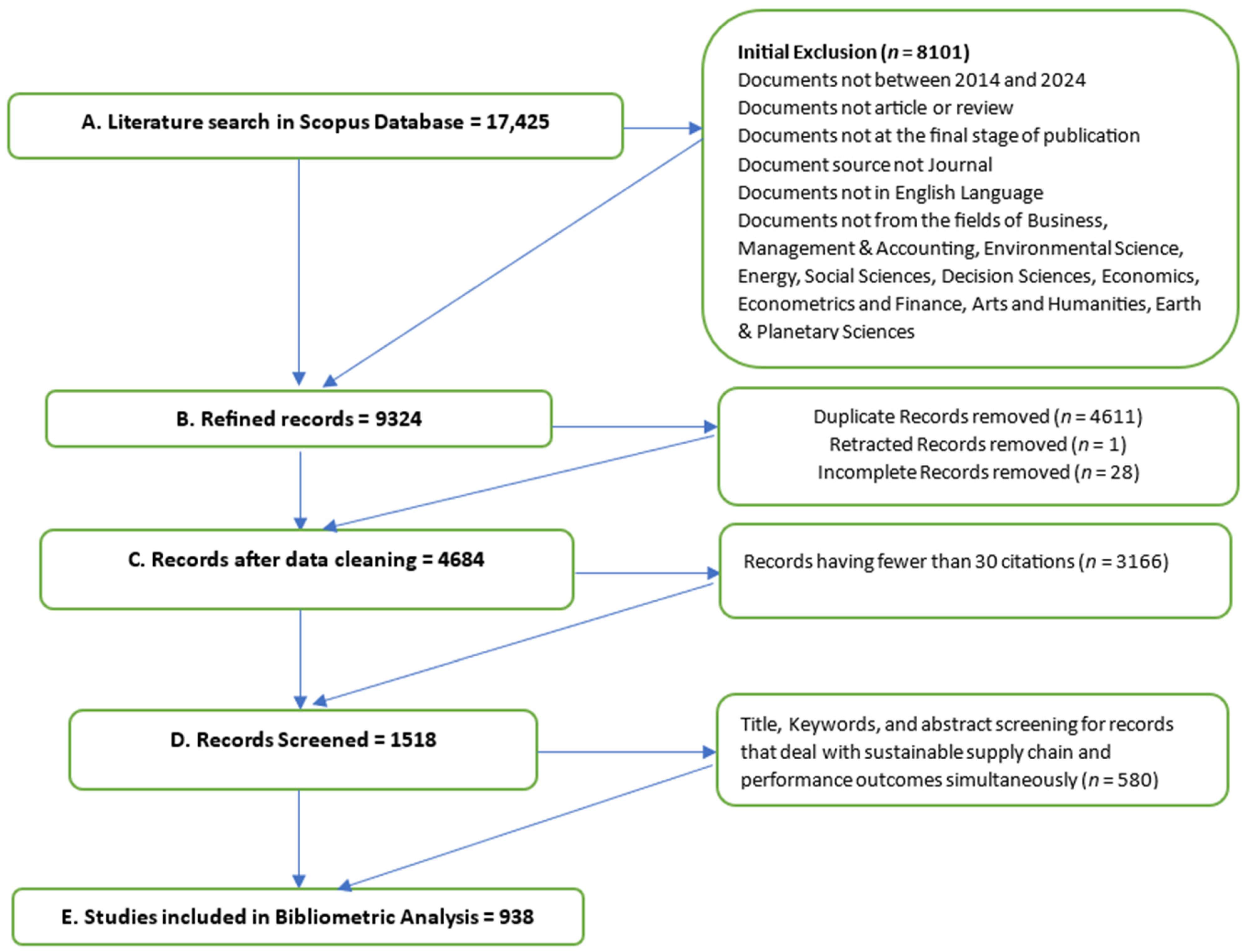

3.1. Data Collection and Screening

3.2. Data Analysis

4. Results and Discussion

4.1. Descriptive Statistics

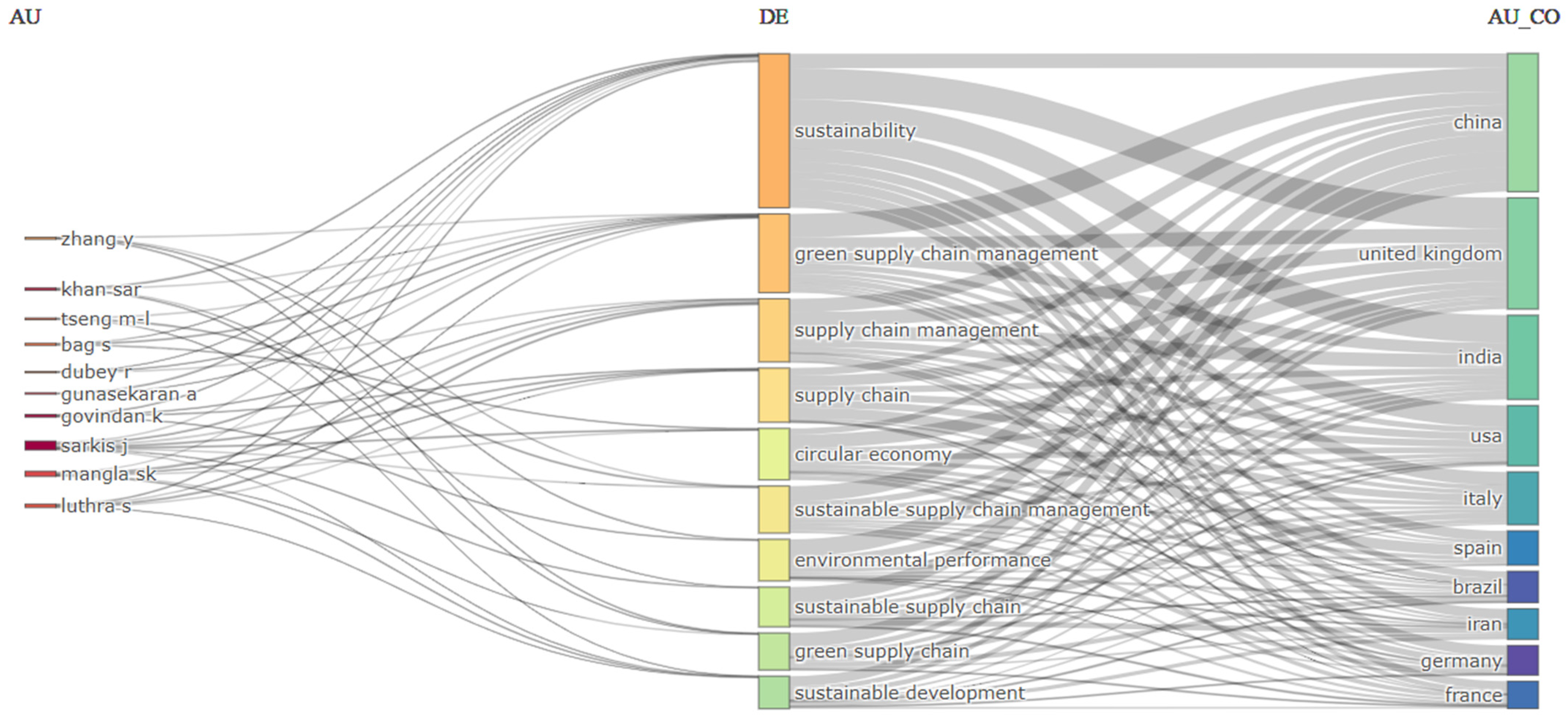

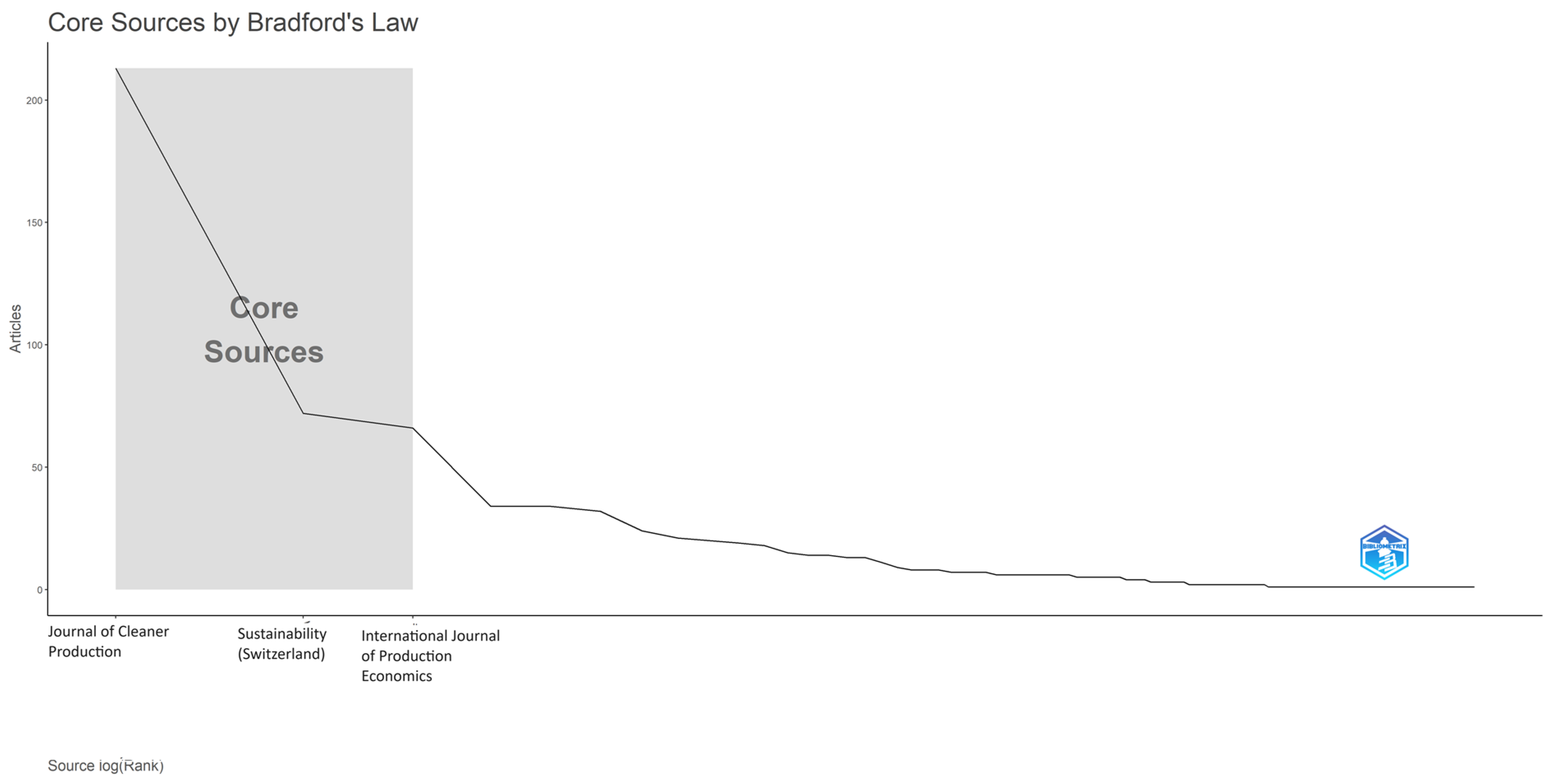

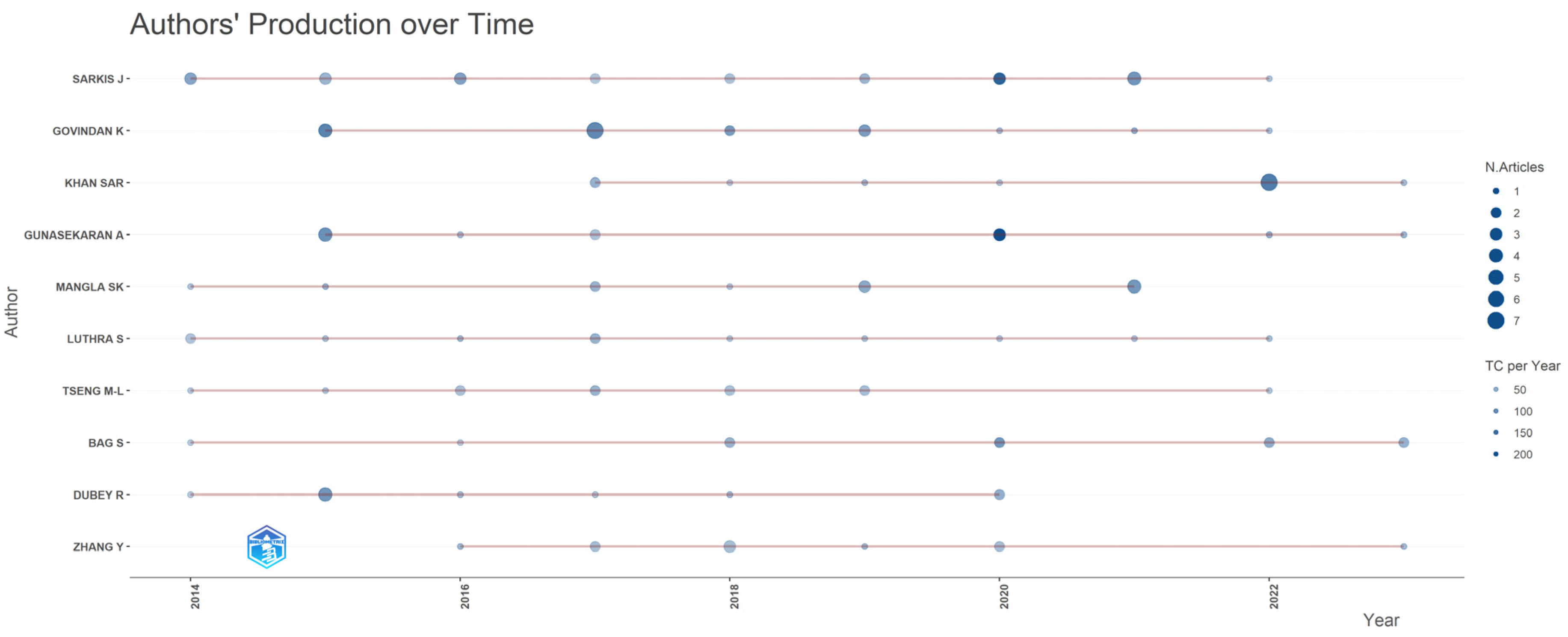

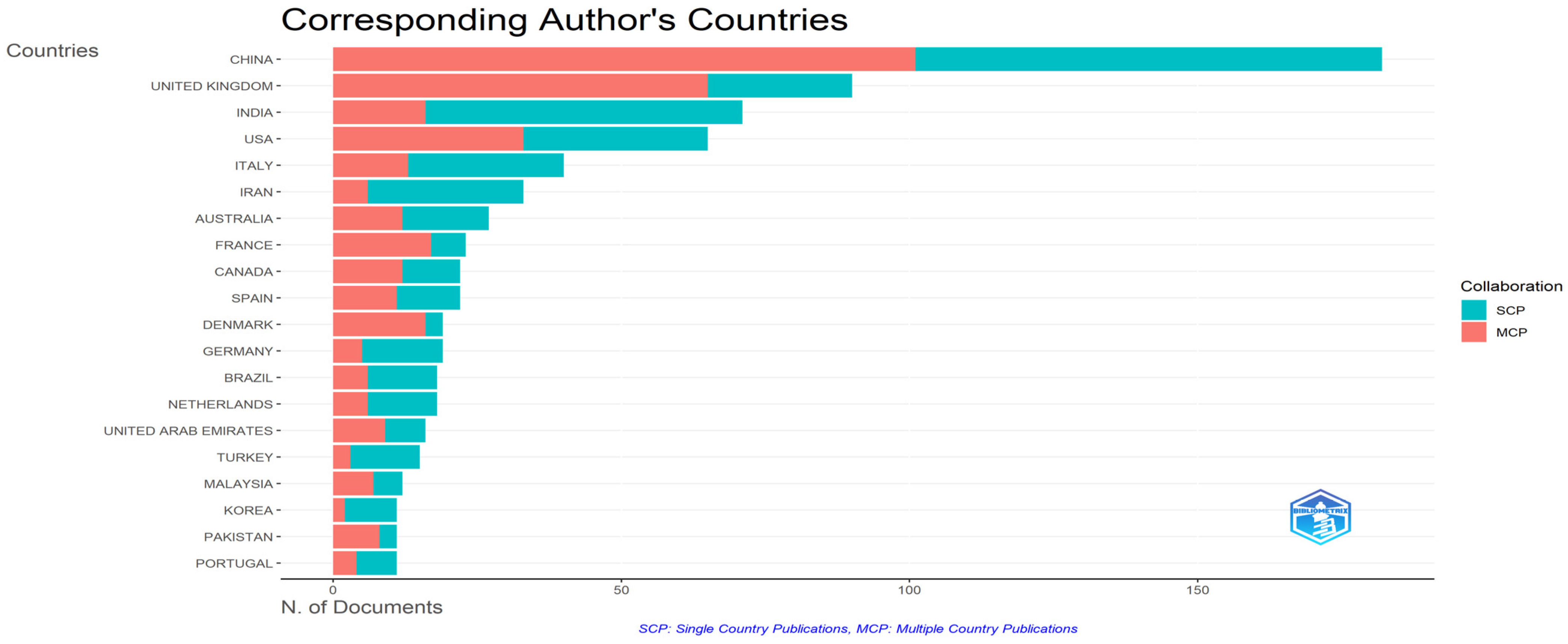

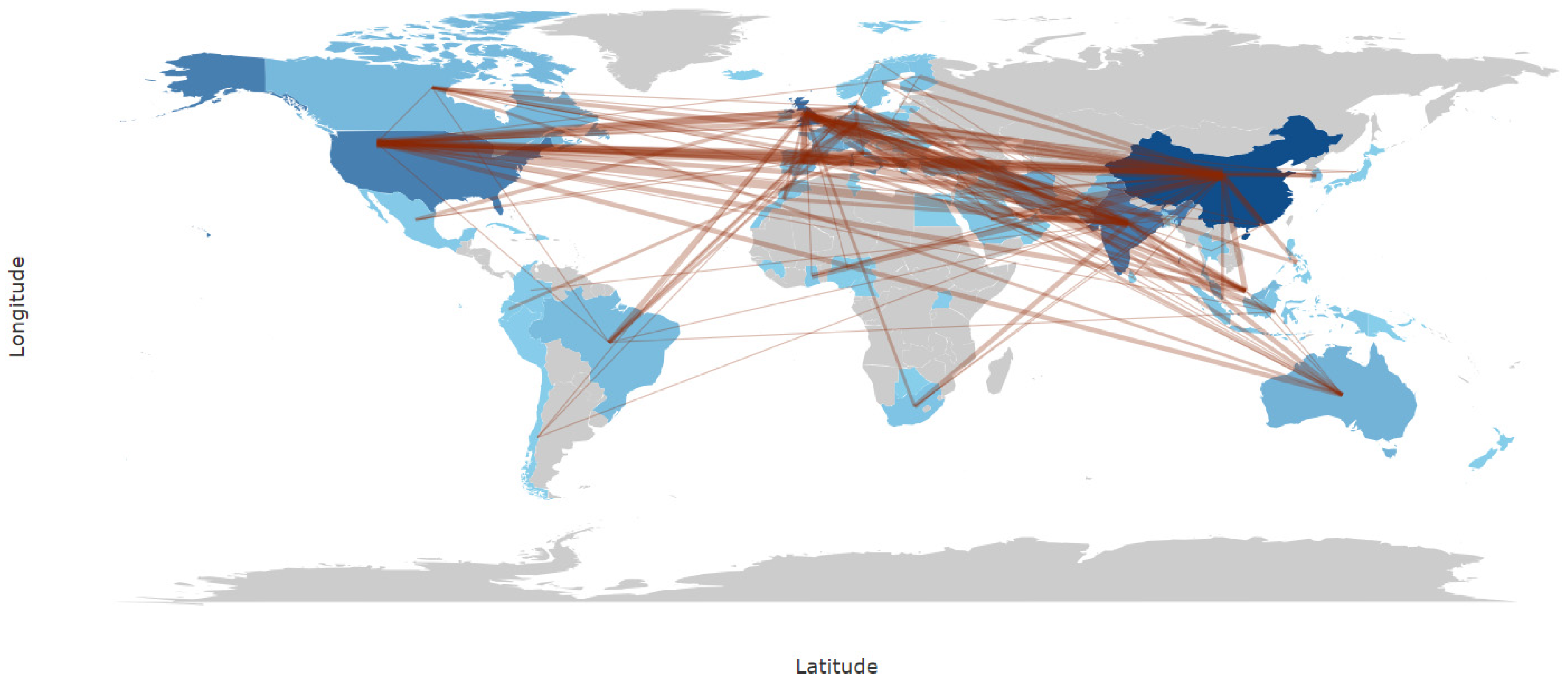

4.2. Trends in Reporting by Sources, Authors, and Countries

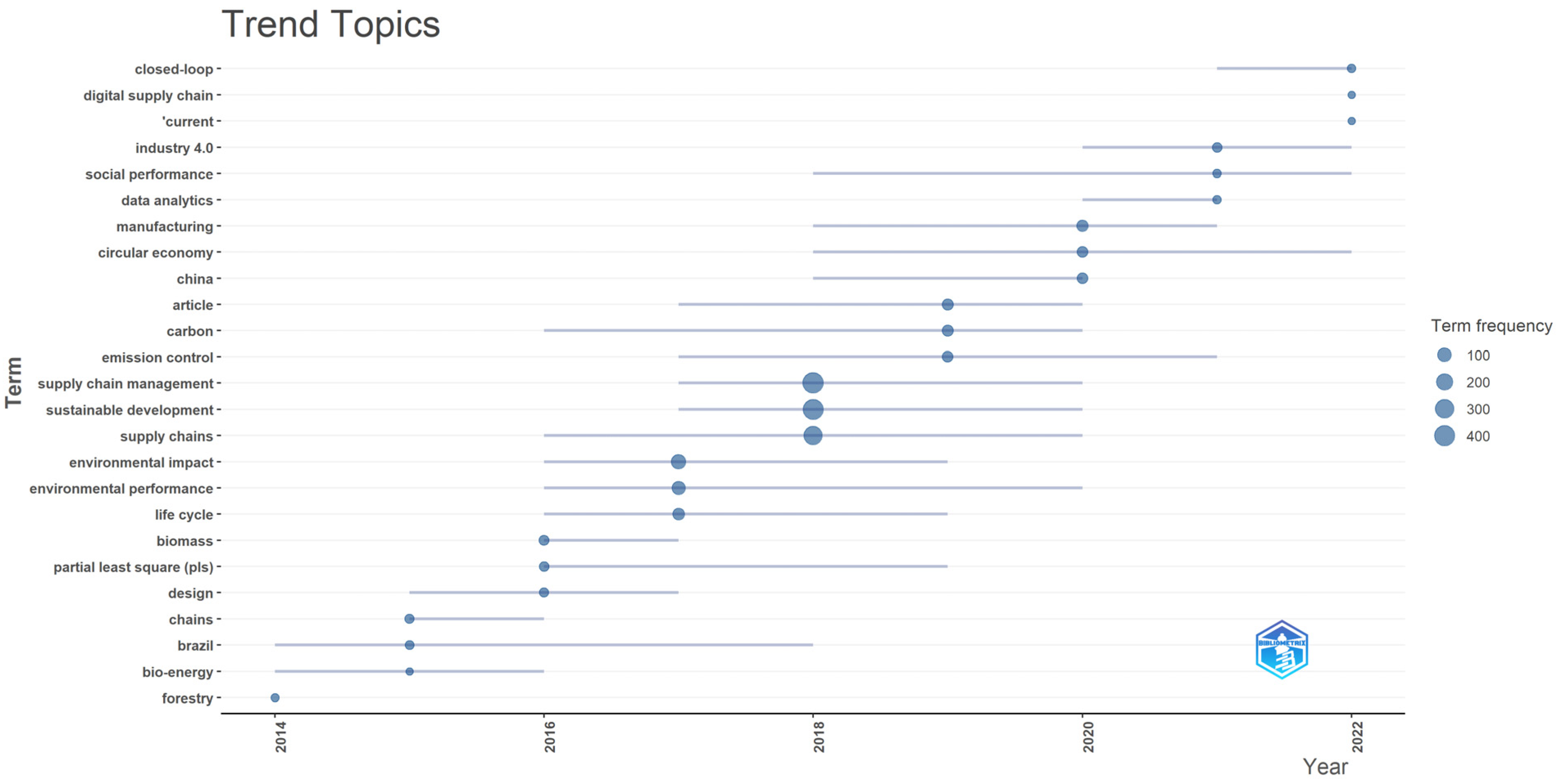

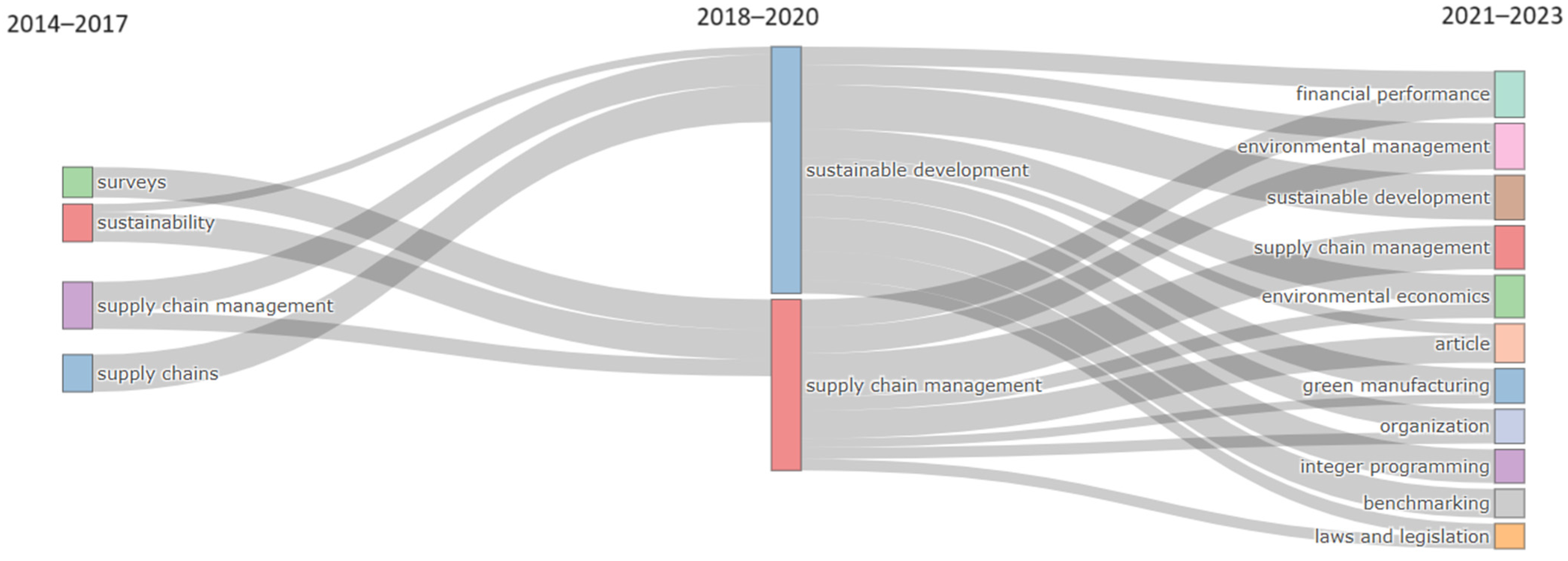

4.3. Analysis of Trending Topics through Keyword Analysis

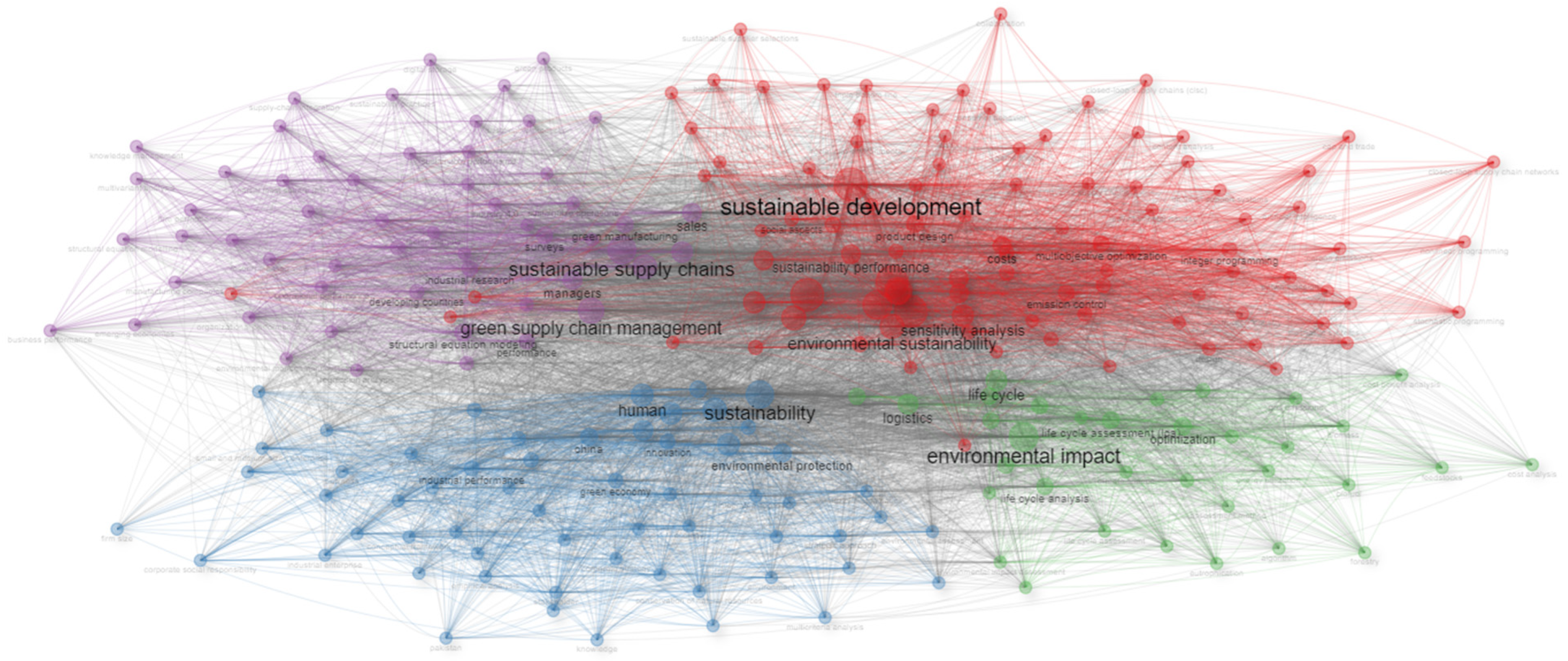

4.4. Analysing Impact, Centrality, and Network of Clusters by Coupling of Authors’ Keywords

4.5. Analyzing Different Clusters through Co-Occurrence of Keywords

4.6. Identifying Different Themes through Thematic Analysis

4.7. Analysis of Collaborations among Authors and Countries

4.8. Content Analysis of Identified Themes

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations. UNFCCC. 2017. Available online: https://unfccc.int/ (accessed on 26 April 2024).

- Habib, A.; Bao, Y. Impact of knowledge management capability and green supply chain management practices on firm performance. Int. J. Res. Bus. Soc. Sci. (2147-4478) 2019, 8, 240–255. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Islam, M.S.; Karia, N.; Fauzi, F.A.; Afrin, S. A literature review on green supply chain management: Trends and future challenges. Resour. Conserv. Recycl. 2019, 141, 145–162. [Google Scholar] [CrossRef]

- Lèbre, É.; Stringer, M.; Svobodova, K.; Owen, J.R.; Kemp, D.; Côte, C.; Arratia-Solar, A.; Valenta, R.K. The social and environmental complexities of extracting energy transition metals. Nat. Commun. 2020, 11, 4823. [Google Scholar] [CrossRef] [PubMed]

- Aminzadegan, S.; Shahriari, M.; Mehranfar, F.; Abramović, B. Factors affecting the emission of pollutants in different types of transportation: A literature review. Energy Rep. 2022, 8, 2508–2529. [Google Scholar] [CrossRef]

- Pamenter, S.; Myers, R.J. Decarbonizing the cementitious materials cycle: A whole-systems review of measures to decarbonize the cement supply chain in the UK and European contexts. J. Ind. Ecol. 2021, 25, 359–376. [Google Scholar] [CrossRef]

- Suer, J.; Traverso, M.; Jäger, N. Review of Life Cycle Assessments for Steel and Environmental Analysis of Future Steel Production Scenarios. Sustainability 2022, 14, 14131. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- Laguir, I.; Stekelorum, R.; El Baz, J. Going green? Investigating the relationships between proactive environmental strategy, GSCM practices and performances of third-party logistics providers (TPLs). Prod. Plan. Control 2020, 32, 1049–1062. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Green, K.W., Jr.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Beamon, B.M. Designing the green supply chain. Logist. Inf. Manag. 1999, 12, 332–342. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Qianli, D. Impact of green supply chain management practices on firms’ performance: An empirical study from the perspective of Pakistan. Environ. Sci. Pollut. Res. 2017, 24, 16829–16844. [Google Scholar] [CrossRef]

- Handfield, R.B.; Walton, S.V.; Seegers, L.K.; Melnyk, S.A. ‘Green’ value chain practices in the furniture industry. J. Oper. Manag. 1997, 15, 293–315. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Lakhal, S.Y.; H’Mida, S.; Islam, M.R. Green supply chain parameters for a Canadian petroleum refinery company. Int. J. Environ. Technol. Manag. 2007, 7, 56. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Klassen, R.D. Drivers and Enablers That Foster Environmental Management Capabilities in Small- and Medium-Sized Suppliers in Supply Chains. Prod. Oper. Manag. 2008, 17, 573–586. [Google Scholar] [CrossRef]

- Tran, H.L.; Hoang, N.T.; Do, V.V.; Nguyen, T.D.; Nguyen, V.H.; Phan, T.T.H.; Doan, T.D.U. Impact of green supply chain management on competitive advantage and firm performance in Vietnam. Uncertain Supply Chain Manag. 2022, 10, 1175–1190. [Google Scholar] [CrossRef]

- Elkington, J. Towards the Sustainable Corporation: Win-Win-Win Business Strategies for Sustainable Development. Calif. Manag. Rev. 1994, 36, 90–100. [Google Scholar] [CrossRef]

- Le, T.T. The effect of green supply chain management practices on sustainability performance in Vietnamese construction materials manufacturing enterprises. Uncertain Supply Chain Manag. 2020, 8, 43–54. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Ikram, M. A Relationship between Supply Chain Practices, Environmental Sustainability and Financial Performance: Evidence from Manufacturing Companies in Jordan. Sustainability 2021, 13, 2152. [Google Scholar] [CrossRef]

- Resat, H.G.; Unsal, B. A novel multi-objective optimization approach for sustainable supply chain: A case study in packaging industry. Sustain. Prod. Consum. 2019, 20, 29–39. [Google Scholar] [CrossRef]

- Boukherroub, T.; Ruiz, A.; Guinet, A.; Fondrevelle, J. An integrated approach for sustainable supply chain planning. Comput. Oper. Res. 2015, 54, 180–194. [Google Scholar] [CrossRef]

- Banasik, A.; Kanellopoulos, A.; Claassen, G.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.G. Closing loops in agricultural supply chains using multi-objective optimization: A case study of an industrial mushroom supply chain. Int. J. Prod. Econ. 2017, 183, 409–420. [Google Scholar] [CrossRef]

- Das, K. Integrating lean systems in the design of a sustainable supply chain model. Int. J. Prod. Econ. 2018, 198, 177–190. [Google Scholar] [CrossRef]

- Carvalho, H.; Govindan, K.; Azevedo, S.G.; Cruz-Machado, V. Modelling green and lean supply chains: An eco-efficiency perspective. Resour. Conserv. Recycl. 2017, 120, 75–87. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J.; Dou, Y. Constructing a process model for low-carbon supply chain cooperation practices based on the DEMATEL and the NK model. Supply Chain Manag. Int. J. 2017, 22, 237–257. [Google Scholar] [CrossRef]

- Ramirez-Peña, M.; Sotano, A.J.S.; Pérez-Fernandez, V.; Abad, F.J.; Batista, M. Achieving a sustainable shipbuilding supply chain under I4.0 perspective. J. Clean. Prod. 2019, 244, 118789. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Liu, Y.; Hartley, J.L. Circular supply chain management: Performance outcomes and the role of eco-industrial parks in China. Transp. Res. Part E Logist. Transp. Rev. 2022, 157, 102596. [Google Scholar] [CrossRef]

- Bag, S.; Dhamija, P.; Bryde, D.J.; Singh, R.K. Effect of eco-innovation on green supply chain management, circular economy capability, and performance of small and medium enterprises. J. Bus. Res. 2022, 141, 60–72. [Google Scholar] [CrossRef]

- Niero, M.; Olsen, S.I. Circular economy: To be or not to be in a closed product loop? A Life Cycle Assessment of aluminium cans with inclusion of alloying elements. Resour. Conserv. Recycl. 2016, 114, 18–31. [Google Scholar] [CrossRef]

- Pan, S.-Y.; Shah, K.J.; Chen, Y.-H.; Wang, M.-H.; Chiang, P.-C. Deployment of Accelerated Carbonation Using Alkaline Solid Wastes for Carbon Mineralization and Utilization Toward a Circular Economy. ACS Sustain. Chem. Eng. 2017, 5, 6429–6437. [Google Scholar] [CrossRef]

- Hsu, C.W.; Kuo, R.J.; Chiou, C.Y. A multi-criteria decision-making approach for evaluating carbon performance of suppliers in the electronics industry. Int. J. Environ. Sci. Technol. 2013, 11, 775–784. [Google Scholar] [CrossRef]

- Azadi, M.; Jafarian, M.; Saen, R.F.; Mirhedayatian, S.M. A new fuzzy DEA model for evaluation of efficiency and effectiveness of suppliers in sustainable supply chain management context. Comput. Oper. Res. 2015, 54, 274–285. [Google Scholar] [CrossRef]

- Zhan, Y.; Tan, K.H.; Ji, G.; Chung, L.; Chiu, A.S. Green and lean sustainable development path in China: Guanxi, practices and performance. Resour. Conserv. Recycl. 2018, 128, 240–249. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; Chowdhury, S.; Saha, K.; Budhwar, P.; De, D. Adoption of circular economy practices in small and medium-sized enterprises: Evidence from Europe. Int. J. Prod. Econ. 2022, 248, 108496. [Google Scholar] [CrossRef]

- Inman, R.A.; Green, K.W. Lean and green combine to impact environmental and operational performance. Int. J. Prod. Res. 2018, 56, 4802–4818. [Google Scholar] [CrossRef]

- Govindan, K.; Jha, P.; Agarwal, V.; Darbari, J.D. Environmental management partner selection for reverse supply chain collaboration: A sustainable approach. J. Environ. Manag. 2019, 236, 784–797. [Google Scholar] [CrossRef]

- Validi, S.; Bhattacharya, A.; Byrne, P.J. A case analysis of a sustainable food supply chain distribution system—A multi-objective approach. Int. J. Prod. Econ. 2014, 152, 71–87. [Google Scholar] [CrossRef]

- Zarbakhshnia, N.; Kannan, D.; Mavi, R.K.; Soleimani, H. A novel sustainable multi-objective optimization model for forward and reverse logistics system under demand uncertainty. Ann. Oper. Res. 2020, 295, 843–880. [Google Scholar] [CrossRef]

- Badiezadeh, T.; Saen, R.F.; Samavati, T. Assessing sustainability of supply chains by double frontier network DEA: A big data approach. Comput. Oper. Res. 2018, 98, 284–290. [Google Scholar] [CrossRef]

- Yu, Z.; Khan, S.A.R.; Umar, M. Circular economy practices and industry 4.0 technologies: A strategic move of automobile industry. Bus. Strat. Environ. 2021, 31, 796–809. [Google Scholar] [CrossRef]

- Nayal, K.; Raut, R.D.; Narkhede, B.E.; Priyadarshinee, P.; Panchal, G.B.; Gedam, V.V. Antecedents for blockchain technology-enabled sustainable agriculture supply chain. Ann. Oper. Res. 2021, 327, 293–337. [Google Scholar] [CrossRef] [PubMed]

- Sharabati, A.-A.A. Green Supply Chain Management and Competitive Advantage of Jordanian Pharmaceutical Industry. Sustainability 2021, 13, 13315. [Google Scholar] [CrossRef]

- Khan, M.T.; Idrees, M.D.; Rauf, M.; Sami, A.; Ansari, A.; Jamil, A. Green Supply Chain Management Practices’ Impact on Operational Performance with the Mediation of Technological Innovation. Sustainability 2022, 14, 3362. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Piprani, A.Z.; Yu, Z. Digital technology and circular economy practices: Future of supply chains. Oper. Manag. Res. 2022, 15, 676–688. [Google Scholar] [CrossRef]

- Tuni, A.; Rentizelas, A.; Duffy, A. Environmental performance measurement for green supply chains. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 765–793. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Critical success factors of green supply chain management for achieving sustainability in Indian automobile industry. Prod. Plan. Control 2014, 26, 339–362. [Google Scholar]

- Gardas, B.B.; Raut, R.D.; Narkhede, B. Modelling the challenges to sustainability in the textile and apparel (T&A) sector: A Delphi-DEMATEL approach. Sustain. Prod. Consum. 2018, 15, 96–108. [Google Scholar] [CrossRef]

- Majumdar, A.; Sinha, S. Modeling the barriers of green supply chain management in small and medium enterprises A case of Indian clothing industry. Manag. Environ. Qual. Int. J. 2018, 29, 1110–1122. [Google Scholar] [CrossRef]

- Nobanee, H.; Al Hamadi, F.Y.; Abdulaziz, F.A.; Abukarsh, L.S.; Alqahtani, A.F.; AlSubaey, S.K.; Alqahtani, S.M.; Almansoori, H.A. A Bibliometric Analysis of Sustainability and Risk Management. Sustainability 2021, 13, 3277. [Google Scholar] [CrossRef]

- Bhatt, Y.; Ghuman, K.; Dhir, A. Sustainable manufacturing. Bibliometrics and content analysis. J. Clean. Prod. 2020, 260, 120988. [Google Scholar] [CrossRef]

- Ren, R.; Hu, W.; Dong, J.; Sun, B.; Chen, Y.; Chen, Z. A Systematic Literature Review of Green and Sustainable Logistics: Bibliometric Analysis, Research Trend and Knowledge Taxonomy. Int. J. Environ. Res. Public Health 2019, 17, 261. [Google Scholar] [CrossRef] [PubMed]

- El Baz, J.; Iddik, S. Green supply chain management and organizational culture: A bibliometric analysis based on Scopus data (2001–2020). Int. J. Organ. Anal. 2021, 30, 156–179. [Google Scholar] [CrossRef]

- Shaharudin, M.S.; Fernando, Y.; Jabbour, C.J.C.; Sroufe, R.; Jasmi, M.F.A. Past, present, and future low carbon supply chain management: A content review using social network analysis. J. Clean. Prod. 2019, 218, 629–643. [Google Scholar] [CrossRef]

- Ferasso, M.; Beliaeva, T.; Kraus, S.; Clauss, T.; Ribeiro-Soriano, D. Circular economy business models: The state of research and avenues ahead. Bus. Strategy Environ. 2020, 29, 3006–3024. [Google Scholar] [CrossRef]

- Zekhnini, K.; Cherrafi, A.; Bouhaddou, I.; Benabdellah, A.C.; Bag, S. A model integrating lean and green practices for viable, sustainable, and digital supply chain performance. Int. J. Prod. Res. 2021, 60, 6529–6555. [Google Scholar] [CrossRef]

- Andaloussi, M.B. A Bibliometric Literature Review of Digital Supply Chain: Trends, Insights, and Future Directions. SAGE Open 2024, 14, 21582440241240340. [Google Scholar] [CrossRef]

- Chakraborty, K.; Ghosh, A.; Pratap, S. Adoption of blockchain technology in supply chain operations: A comprehensive literature study analysis. Oper. Manag. Res. 2023, 16, 1989–2007. [Google Scholar] [CrossRef]

- Cruz, L.; De Arruda Ignacio, P.S. Application of Blockchain Disruptive Technology in Agri-Food Chains for Sustainable Development, a Systematic Review. Int. J. Supply Oper. Manag. 2023, 10, 523–544. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, X.; Tang, O.; Price, L.; Zhang, S.; Zhu, W. Supply chain collaboration for sustainability: A literature review and future research agenda. Int. J. Prod. Econ. 2017, 194, 73–87. [Google Scholar] [CrossRef]

- Beske-Janssen, P.; Johnson, M.P.; Schaltegger, S. 20 years of performance measurement in sustainable supply chain management—What has been achieved? Supply Chain Manag. Int. J. 2015, 20, 664–680. [Google Scholar] [CrossRef]

- Maditati, D.R.; Munim, Z.H.; Schramm, H.-J.; Kummer, S. A review of green supply chain management: From bibliometric analysis to a conceptual framework and future research directions. Resour. Conserv. Recycl. 2018, 139, 150–162. [Google Scholar] [CrossRef]

- Balon, V. Green supply chain management: Pressures, practices, and performance—An integrative literature review. Bus. Strat. Dev. 2019, 3, 226–244. [Google Scholar] [CrossRef]

- Yang, R.; Wong, C.W.; Miao, X. Analysis of the trend in the knowledge of environmental responsibility research. J. Clean. Prod. 2021, 278, 123402. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C.; Jaber, M.Y. Energy-related performance measures employed in sustainable supply chains: A bibliometric analysis. Sustain. Prod. Consum. 2016, 7, 1–15. [Google Scholar] [CrossRef]

- Taticchi, P.; Garengo, P.; Nudurupati, S.S.; Tonelli, F.; Pasqualino, R. A review of decision-support tools and performance measurement and sustainable supply chain management. Int. J. Prod. Res. 2014, 53, 6473–6494. [Google Scholar] [CrossRef]

- Chopra, M.; Saini, N.; Kumar, S.; Varma, A.; Mangla, S.K.; Lim, W.M. Past, present, and future of knowledge management for business sustainability. J. Clean. Prod. 2021, 328, 129592. [Google Scholar] [CrossRef]

- Braz, A.C.; De Mello, A.M.; Gomes, L.A.d.V.; Nascimento, P.T.d.S. The bullwhip effect in closed-loop supply chains: A systematic literature review. J. Clean. Prod. 2018, 202, 376–389. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Appolloni, A.; Treiblmaier, H.; Iranmanesh, M. Circular Economy Research in the COVID-19 Era: A Review and the Road Ahead. Circ. Econ. Sustain. 2023, 3, 2127–2157. [Google Scholar] [CrossRef]

- Elsevier. Elsevier|An Information Analytics Business|Empowering Knowledge. 2019. Available online: https://www.elsevier.com/ (accessed on 26 April 2024).

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- PRISMA. 2020. Available online: http://www.prisma-statement.org/prisma-2020 (accessed on 20 April 2024).

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Yu, Z.; Golpîra, H.; Sharif, A.; Mardani, A. A State-of-The-Art Review and Meta-Analysis on Sustainable Supply Chain Management: Future Research Directions. J. Clean. Prod. 2021, 278, 123357. [Google Scholar] [CrossRef]

- He, M.; Lin, T.; Wu, X.; Luo, J.; Peng, Y. A Systematic Literature Review of Reverse Logistics of End-of-Life Vehicles: Bibliometric Analysis and Research Trend. Energies 2020, 13, 5586. [Google Scholar] [CrossRef]

- Du, H.S.; Xu, J.; Li, Z.; Liu, Y.; Chu, S.K.W. Bibliometric mapping on sustainable development at the base-of-the-pyramid. J. Clean. Prod. 2021, 281, 125290. [Google Scholar] [CrossRef]

- Ranjbari, M.; Saidani, M.; Esfandabadi, Z.S.; Peng, W.; Lam, S.S.; Aghbashlo, M.; Quatraro, F.; Tabatabaei, M. Two decades of research on waste management in the circular economy: Insights from bibliometric, text mining, and content analyses. J. Clean. Prod. 2021, 314, 128009. [Google Scholar] [CrossRef]

- Gheyle, N.; Jacobs, T. Content Analysis: A Short Overview. In Internal Research Notes; Ghent University: Ghent, Belgium, 2017. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- El-Kassar, A.N.; Singh, S.K. Green innovation and organizational performance: The influence of big data and the moderating role of management commitment and HR practices. Technol. Forecast. Soc. Chang. 2019, 144, 483–498. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Ali, S.S. Exploring the relationship between leadership, operational practices, institutional pressures and environmental performance: A framework for green supply chain. Int. J. Prod. Econ. 2015, 160, 120–132. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposa. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Qin, J.; Liu, X.; Pedrycz, W. An extended TODIM multi-criteria group decision making method for green supplier selection in interval type-2 fuzzy environment. Eur. J. Oper. Res. 2017, 258, 626–638. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Achieving sustainable performance in a data-driven agriculture supply chain: A review for research and applications. Int. J. Prod. Econ. 2020, 219, 179–194. [Google Scholar] [CrossRef]

- Hong, Z.; Guo, X. Green product supply chain contracts considering environmental responsibilities. Omega 2019, 83, 155–166. [Google Scholar] [CrossRef]

- Rezaei, J.; Nispeling, T.; Sarkis, J.; Tavasszy, L. A supplier selection life cycle approach integrating traditional and environmental criteria using the best worst method. J. Clean. Prod. 2016, 135, 577–588. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Tavana, M. An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. Int. J. Prod. Econ. 2015, 159, 178–191. [Google Scholar] [CrossRef]

- Mitra, S.; Datta, P.P. Adoption of green supply chain management practices and their impact on performance: An exploratory study of Indian manufacturing firms. Int. J. Prod. Res. 2013, 52, 2085–2107. [Google Scholar] [CrossRef]

- Vanalle, R.M.; Ganga, G.M.D.; Filho, M.G.; Lucato, W.C. Green supply chain management: An investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J. Clean. Prod. 2017, 151, 250–259. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Upadhyay, A.; Mukhuty, S.; Kumar, V.; Kazancoglu, Y. Blockchain technology and the circular economy: Implications for sustainability and social responsibility. J. Clean. Prod. 2021, 293, 126130. [Google Scholar] [CrossRef]

- Schrettle, S.; Hinz, A.; -Rathje, M.S.; Friedli, T. Turning sustainability into action: Explaining firms’ sustainability efforts and their impact on firm performance. Int. J. Prod. Econ. 2014, 147, 73–84. [Google Scholar] [CrossRef]

- Kazancoglu, I.; Sagnak, M.; Mangla, S.K.; Kazancoglu, Y. Circular economy and the policy: A framework for improving the corporate environmental management in supply chains. Bus. Strat. Environ. 2020, 30, 590–608. [Google Scholar] [CrossRef]

- Schmidt, C.G.; Foerstl, K.; Schaltenbrand, B. The Supply Chain Position Paradox: Green Practices and Firm Performance. J. Supply Chain Manag. 2016, 53, 3–25. [Google Scholar] [CrossRef]

- Perrin, A.; Wohlfahrt, J.; Morandi, F.; Østergård, H.; Flatberg, T.; De La Rua, C.; Bjørkvoll, T.; Gabrielle, B. Integrated design and sustainable assessment of innovative biomass supply chains: A case-study on miscanthus in France. Appl. Energy 2017, 204, 66–77. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Fazlollahtabar, H.; Khalilzadeh, M. A robust fuzzy stochastic programming for sustainable procurement and logistics under hybrid uncertainty using big data. J. Clean. Prod. 2020, 258, 120640. [Google Scholar] [CrossRef]

- Vafaei, A.; Yaghoubi, S.; Tajik, J.; Barzinpour, F. Designing a sustainable multi-channel supply chain distribution network: A case study. J. Clean. Prod. 2020, 251, 119628. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Nand, A.; Castka, P. Lean-green integration and its impact on sustainability performance: A critical review. J. Clean. Prod. 2019, 236, 117697. [Google Scholar] [CrossRef]

- Chen, Q.; Gu, Y.; Tang, Z.; Wang, D.; Wu, Q. Optimal design and techno-economic assessment of low-carbon hydrogen supply pathways for a refueling station located in Shanghai. Energy 2021, 237, 121584. [Google Scholar] [CrossRef]

- Zhang, Q.; Dhir, A.; Kaur, P. Circular economy and the food sector: A systematic literature review. Sustain. Prod. Consum. 2022, 32, 655–668. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A.; Yu, M.; Kumar, V.; Upadhyay, A. Total quality environmental management: Adoption status in the Chinese manufacturing sector. TQM J. 2018, 30, 2–19. [Google Scholar] [CrossRef]

- Feng, M.; Yu, W.; Wang, X.; Wong, C.Y.; Xu, M.; Xiao, Z. Green supply chain management and financial performance: The mediating roles of operational and environmental performance. Bus. Strat. Environ. 2018, 27, 811–824. [Google Scholar] [CrossRef]

- Chavez, R.; Yu, W.; Feng, M.; Wiengarten, F. The Effect of Customer-Centric Green Supply Chain Management on Operational Performance and Customer Satisfaction. Bus. Strat. Environ. 2016, 25, 205–220. [Google Scholar] [CrossRef]

- Kumar, D.; Rahman, Z. Buyer supplier relationship and supply chain sustainability: Empirical study of Indian automobile industry. J. Clean. Prod. 2016, 131, 836–848. [Google Scholar] [CrossRef]

- Stindt, D. A generic planning approach for sustainable supply chain management—How to integrate concepts and methods to address the issues of sustainability? J. Clean. Prod. 2017, 153, 146–163. [Google Scholar] [CrossRef]

- Yue, D.; Gong, J.; You, F. Synergies between Geological Sequestration and Microalgae Biofixation for Greenhouse Gas Abatement: Life Cycle Design of Carbon Capture, Utilization, and Storage Supply Chains. ACS Sustain. Chem. Eng. 2015, 3, 841–861. [Google Scholar] [CrossRef]

- Allaoui, H.; Guo, Y.; Sarkis, J. Decision support for collaboration planning in sustainable supply chains. J. Clean. Prod. 2019, 229, 761–774. [Google Scholar] [CrossRef]

- Arampantzi, C.; Minis, I. A new model for designing sustainable supply chain networks and its application to a global manufacturer. J. Clean. Prod. 2017, 156, 276–292. [Google Scholar] [CrossRef]

- Yu, H.; Solvang, W.D. A fuzzy-stochastic multi-objective model for sustainable planning of a closed-loop supply chain considering mixed uncertainty and network flexibility. J. Clean. Prod. 2020, 266, 121702. [Google Scholar] [CrossRef]

- Feitó-Cespón, M.; Sarache, W.; Piedra-Jimenez, F.; Cespón-Castro, R. Redesign of a sustainable reverse supply chain under uncertainty: A case study. J. Clean. Prod. 2017, 151, 206–217. [Google Scholar] [CrossRef]

- dos Santos, B.M.; Godoy, L.P.; Campos, L.M.S. Performance evaluation of green suppliers using entropy-TOPSIS-F. J. Clean. Prod. 2019, 207, 498–509. [Google Scholar] [CrossRef]

- Govindan, K.; Darbari, J.D.; Agarwal, V.; Jha, P. Fuzzy multi-objective approach for optimal selection of suppliers and transportation decisions in an eco-efficient closed loop supply chain network. J. Clean. Prod. 2017, 165, 1598–1619. [Google Scholar] [CrossRef]

- Miah, J.; Griffiths, A.; McNeill, R.; Halvorson, S.; Schenker, U.; Espinoza-Orias, N.; Morse, S.; Yang, A.; Sadhukhan, J. Environmental management of confectionery products: Life cycle impacts and improvement strategies. J. Clean. Prod. 2018, 177, 732–751. [Google Scholar] [CrossRef]

- Paksoy, T.; Özceylan, E. Environmentally conscious optimization of supply chain networks. J. Oper. Res. Soc. 2014, 65, 855–872. [Google Scholar] [CrossRef]

- Yang, L.; Cai, Y.; Wei, Y.; Huang, S. Choice of technology for emission control in port areas: A supply chain perspective. J. Clean. Prod. 2019, 240, 118105. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Goli, A.; Faridnia, A.; Soltani, M.; Weber, G.-W. Multi-objective optimization for the reliable pollution-routing problem with cross-dock selection using Pareto-based algorithms. J. Clean. Prod. 2020, 276, 122927. [Google Scholar] [CrossRef]

- Miao, Z.; Fu, K.; Xia, Z.; Wang, Y. Models for closed-loop supply chain with trade-ins. Omega 2017, 66, 308–326. [Google Scholar] [CrossRef]

- Reyes, J.; Mula, J.; Díaz-Madroñero, M. Development of a conceptual model for lean supply chain planning in industry 4.0: Multidimensional analysis for operations management. Prod. Plan. Control 2021, 34, 1209–1224. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental Sustainability and Energy-Efficient Supply Chain Management: A Review of Research Trends and Proposed Guidelines. Energies 2018, 11, 275. [Google Scholar] [CrossRef]

- Sudusinghe, J.I.; Seuring, S. Supply chain collaboration and sustainability performance in circular economy: A systematic literature review. Int. J. Prod. Econ. 2021, 245, 108402. [Google Scholar] [CrossRef]

- Woo, C.; Kim, M.G.; Chung, Y.; Rho, J.J. Suppliers’ communication capability and external green integration for green and financial performance in Korean construction industry. J. Clean. Prod. 2016, 112, 483–493. [Google Scholar] [CrossRef]

- Hervani, A.A.; Nandi, S.; Helms, M.M.; Sarkis, J. A performance measurement framework for socially sustainable and resilient supply chains using environmental goods valuation methods. Sustain. Prod. Consum. 2021, 30, 31–52. [Google Scholar] [CrossRef]

- Ghaderi, H.; Moini, A.; Pishvaee, M.S. A multi-objective robust possibilistic programming approach to sustainable switchgrass-based bioethanol supply chain network design. J. Clean. Prod. 2018, 179, 368–406. [Google Scholar] [CrossRef]

- Shuang, Y.; Diabat, A.; Liao, Y. A stochastic reverse logistics production routing model with emissions control policy selection. Int. J. Prod. Econ. 2019, 213, 201–216. [Google Scholar] [CrossRef]

- Yazdani, M.; Pamucar, D.; Chatterjee, P.; Chakraborty, S. Development of a decision support framework for sustainable freight transport system evaluation using rough numbers. Int. J. Prod. Res. 2019, 58, 4325–4351. [Google Scholar] [CrossRef]

- Aktin, T.; Gergin, Z. Mathematical modelling of sustainable procurement strategies: Three case studies. J. Clean. Prod. 2016, 113, 767–780. [Google Scholar] [CrossRef]

- Hatami-Marbini, A.; Agrell, P.J.; Tavana, M.; Khoshnevis, P. A flexible cross-efficiency fuzzy data envelopment analysis model for sustainable sourcing. J. Clean. Prod. 2017, 142, 2761–2779. [Google Scholar] [CrossRef]

- Van Engeland, J.; Beliën, J.; De Boeck, L.; De Jaeger, S. Literature review: Strategic network optimization models in waste reverse supply chains. Omega 2020, 91, 102012. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Varbanov, P.S.; Ocłoń, P.; Chin, H.H. Towards Efficient and Clean Process Integration: Utilisation of Renewable Resources and Energy-Saving Technologies. Energies 2019, 12, 4092. [Google Scholar] [CrossRef]

- Wu, C.; Barnes, D. An integrated model for green partner selection and supply chain construction. J. Clean. Prod. 2016, 112, 2114–2132. [Google Scholar] [CrossRef]

- Mohammed, A.; Setchi, R.; Filip, M.; Harris, I.; Li, X. An integrated methodology for a sustainable two-stage supplier selection and order allocation problem. J. Clean. Prod. 2018, 192, 99–114. [Google Scholar] [CrossRef]

- Giannakis, M.; Dubey, R.; Vlachos, I.; Ju, Y. Supplier sustainability performance evaluation using the analytic network process. J. Clean. Prod. 2020, 247, 119439. [Google Scholar] [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.; Chiu, K.K.-S. Multi-attribute approach to sustainable supply chain management under uncertainty. Ind. Manag. Data Syst. 2016, 116, 777–800. [Google Scholar] [CrossRef]

- Genovese, A.; Morris, J.; Piccolo, C.; Koh, S.L. Assessing redundancies in environmental performance measures for supply chains. J. Clean. Prod. 2017, 167, 1290–1302. [Google Scholar] [CrossRef]

- Alizadeh-Basban, N.; Taleizadeh, A.A. A hybrid circular economy—Game theoretical approach in a dual-channel green supply chain considering sale’s effort, delivery time, and hybrid remanufacturing. J. Clean. Prod. 2020, 250, 119521. [Google Scholar] [CrossRef]

- Qian, X.; Chan, F.T.; Zhang, J.; Yin, M.; Zhang, Q. Channel coordination of a two-echelon sustainable supply chain with a fair-minded retailer under cap-and-trade regulation. J. Clean. Prod. 2019, 244, 118715. [Google Scholar] [CrossRef]

- Asghari, T.; Taleizadeh, A.A.; Jolai, F.; Moshtagh, M.S. Cooperative game for coordination of a green closed-loop supply chain. J. Clean. Prod. 2022, 363, 132371. [Google Scholar] [CrossRef]

- Han, X.; Wu, H.; Yang, Q.; Shang, J. Reverse channel selection under remanufacturing risks: Balancing profitability and robustness. Int. J. Prod. Econ. 2016, 182, 63–72. [Google Scholar] [CrossRef]

- Hosseini-Motlagh, S.-M.; Nami, N.; Farshadfar, Z. Collection disruption management and channel coordination in a socially concerned closed-loop supply chain: A game theory approach. J. Clean. Prod. 2020, 276, 124173. [Google Scholar] [CrossRef] [PubMed]

- Kang, K.; Zhao, Y.; Zhang, J.; Qiang, C. Evolutionary game theoretic analysis on low-carbon strategy for supply chain enterprises. J. Clean. Prod. 2019, 230, 981–994. [Google Scholar] [CrossRef]

- Zhang, X.; Yousaf, H.A.U. Green supply chain coordination considering government intervention, green investment, and customer green preferences in the petroleum industry. J. Clean. Prod. 2019, 246, 118984. [Google Scholar] [CrossRef]

- Yu, H.; Solvang, W.D. Incorporating flexible capacity in the planning of a multi-product multi-echelon sustainable reverse logistics network under uncertainty. J. Clean. Prod. 2018, 198, 285–303. [Google Scholar] [CrossRef]

- Hong, Z.; Wang, H.; Gong, Y. Green product design considering functional-product reference. Int. J. Prod. Econ. 2019, 210, 155–168. [Google Scholar] [CrossRef]

- Sarkar, B.; Ahmed, W.; Kim, N. Joint effects of variable carbon emission cost and multi-delay-in-payments under single-setup-multiple-delivery policy in a global sustainable supply chain. J. Clean. Prod. 2018, 185, 421–445. [Google Scholar] [CrossRef]

- Pushpamali, N.; Agdas, D.; Rose, T.M.; Yigitcanlar, T. Stakeholder perception of reverse logistics practices on supply chain performance. Bus. Strat. Environ. 2020, 30, 60–70. [Google Scholar] [CrossRef]

- Xu, J.; Chen, Y.; Bai, Q. A two-echelon sustainable supply chain coordination under cap-and-trade regulation. J. Clean. Prod. 2016, 135, 42–56. [Google Scholar] [CrossRef]

- Wong, C.Y.; Wong, C.W.Y.; Boon-itt, S. Effects of green supply chain integration and green innovation on environmental and cost performance. Int. J. Prod. Res. 2020, 58, 4589–4609. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Zhou, M. Firms’ green R&D cooperation behaviour in a supply chain: Technological spillover, power and coordination. Int. J. Prod. Econ. 2019, 218, 118–134. [Google Scholar] [CrossRef]

- Hrouga, M.; Sbihi, A.; Chavallard, M. The potentials of combining Blockchain technology and Internet of Things for digital reverse supply chain: A case study. J. Clean. Prod. 2022, 337, 130609. [Google Scholar] [CrossRef]

- Mumtaz, U.; Ali, Y.; Petrillo, A. A linear regression approach to evaluate the green supply chain management impact on industrial organizational performance. Sci. Total Environ. 2018, 624, 162–169. [Google Scholar] [CrossRef]

- Bu, X.; Dang, W.V.; Wang, J.; Liu, Q. Environmental Orientation, Green Supply Chain Management, and Firm Performance: Empirical Evidence from Chinese Small and Medium-Sized Enterprises. Int. J. Environ. Res. Public Health 2020, 17, 1199. [Google Scholar] [CrossRef]

- Sharma, M.; Kumar, A.; Luthra, S.; Joshi, S.; Upadhyay, A. The impact of environmental dynamism on low-carbon practices and digital supply chain networks to enhance sustainable performance: An empirical analysis. Bus. Strat. Environ. 2022, 31, 1776–1788. [Google Scholar] [CrossRef]

- Hung, S.-W.; Chen, P.-C.; Chung, C.-F. Gaining or losing? The social capital perspective on supply chain members’ knowledge sharing of green practices. Technol. Anal. Strat. Manag. 2013, 26, 189–206. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R. A hybrid Pythagorean fuzzy AHP—CoCoSo framework to rank the performance outcomes of circular supply chain due to adoption of its enablers. Waste Manag. 2021, 130, 48–60. [Google Scholar] [CrossRef] [PubMed]

- Jabbour, A.B.L.d.S.; Frascareli, F.C.d.O.; Jabbour, C.J.C. Green supply chain management and firms’ performance: Understanding potential relationships and the role of green sourcing and some other green practices. Resour. Conserv. Recycl. 2015, 104, 366–374. [Google Scholar] [CrossRef]

- Valdez-Juárez, L.E.; Gallardo-Vázquez, D.; Ramos-Escobar, E.A. CSR and the Supply Chain: Effects on the Results of SMEs. Sustainability 2018, 10, 2356. [Google Scholar] [CrossRef]

- Nguyen, H.M.; Onofrei, G.; Truong, D.; Lockrey, S. Customer green orientation and process innovation alignment: A configuration approach in the global manufacturing industry. Bus. Strat. Environ. 2020, 29, 2498–2513. [Google Scholar] [CrossRef]

- Kim, M.; Chai, S. Implementing Environmental Practices for Accomplishing Sustainable Green Supply Chain Management. Sustainability 2017, 9, 1192. [Google Scholar] [CrossRef]

- Zhou, C.; Xia, W.; Feng, T.; Jiang, J.; He, Q. How environmental orientation influences firm performance: The missing link of green supply chain integration. Sustain. Dev. 2019, 28, 685–696. [Google Scholar] [CrossRef]

- Namagembe, S.; Ryan, S.; Sridharan, R. Green supply chain practice adoption and firm performance: Manufacturing SMEs in Uganda. Manag. Environ. Qual. Int. J. 2019, 30, 5–35. [Google Scholar] [CrossRef]

- Jawaad, M.; Zafar, S. Improving sustainable development and firm performance in emerging economies by implementing green supply chain activities. Sustain. Dev. 2019, 28, 25–38. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Goh, M. Moderating the Role of Firm Size in Sustainable Performance Improvement through Sustainable Supply Chain Management. Sustainability 2018, 10, 1654. [Google Scholar] [CrossRef]

- García-Arca, J.; Garrido, A.T.G.-P.; Prado-Prado, J.C. “Sustainable Packaging Logistics”. The link between Sustainability and Competitiveness in Supply Chains. Sustainability 2017, 9, 1098. [Google Scholar] [CrossRef]

- Nayal, K.; Raut, R.D.; Yadav, V.S.; Priyadarshinee, P.; Narkhede, B.E. The impact of sustainable development strategy on sustainable supply chain firm performance in the digital transformation era. Bus. Strat. Environ. 2021, 31, 845–859. [Google Scholar] [CrossRef]

- Silva, G.M.; Gomes, P.J.; Sarkis, J. The role of innovation in the implementation of green supply chain management practices. Bus. Strat. Environ. 2019, 28, 819–832. [Google Scholar] [CrossRef]

- Bai, C.; Satir, A. Barriers for green supplier development programs in manufacturing industry. Resour. Conserv. Recycl. 2020, 158, 104756. [Google Scholar] [CrossRef]

- Li, X.; Du, J.; Long, H. Understanding the Green Development Behavior and Performance of Industrial Enterprises (GDBP-IE): Scale Development and Validation. Int. J. Environ. Res. Public Health 2020, 17, 1716. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Mangla, S.K. Structural model for sustainable consumption and production adoption—A grey-DEMATEL based approach. Resour. Conserv. Recycl. 2017, 125, 198–207. [Google Scholar] [CrossRef]

- Sudusinghe, J.I.; Seuring, S. Social Sustainability Empowering the Economic Sustainability in the Global Apparel Supply Chain. Sustainability 2020, 12, 2595. [Google Scholar] [CrossRef]

- Nureen, N.; Liu, D.; Ahmad, B.; Irfan, M. Exploring the technical and behavioral dimensions of green supply chain management: A roadmap toward environmental sustainability. Environ. Sci. Pollut. Res. 2022, 29, 63444–63457. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, M.; Hendry, L.C.; Bu, M.; Wang, S. Supplier Development Practices for Sustainability: A Multi-Stakeholder Perspective. Bus. Strat. Environ. 2017, 27, 100–116. [Google Scholar] [CrossRef]

- Rentizelas, A.A.; Li, J. Techno-economic and carbon emissions analysis of biomass torrefaction downstream in international bioenergy supply chains for co-firing. Energy 2016, 114, 129–142. [Google Scholar] [CrossRef]

- Kulak, M.; Nemecek, T.; Frossard, E.; Gaillard, G. Eco-efficiency improvement by using integrative design and life cycle assessment. The case study of alternative bread supply chains in France. J. Clean. Prod. 2016, 112, 2452–2461. [Google Scholar] [CrossRef]

- Kesharwani, R.; Sun, Z.; Dagli, C.; Xiong, H. Moving second generation biofuel manufacturing forward: Investigating economic viability and environmental sustainability considering two strategies for supply chain restructuring. Appl. Energy 2019, 242, 1467–1496. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, S.; Yan, X.; Gao, S.; Cui, X.; Cui, Z. Life cycle assessment of petroleum refining process: A case study in China. J. Clean. Prod. 2020, 256, 120422. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. LCA for assessing environmental benefit of eco-design strategies and forest wood short supply chain: A furniture case study. Int. J. Life Cycle Assess. 2014, 19, 1536–1550. [Google Scholar] [CrossRef]

- Pierobon, F.; Zanetti, M.; Grigolato, S.; Sgarbossa, A.; Anfodillo, T.; Cavalli, R. Life cycle environmental impact of firewood production—A case study in Italy. Appl. Energy 2015, 150, 185–195. [Google Scholar] [CrossRef]

- Dorr, E.; Koegler, M.; Gabrielle, B.; Aubry, C. Life cycle assessment of a circular, urban mushroom farm. J. Clean. Prod. 2021, 288, 125668. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Schaafsma, M.; Egoh, B.N. Towards sustainable palm oil production: The positive and negative impacts on ecosystem services and human wellbeing. J. Clean. Prod. 2021, 278, 123914. [Google Scholar] [CrossRef]

- La Scalia, G.; Saeli, M.; Miglietta, P.P.; Micale, R. Coffee biowaste valorization within circular economy: An evaluation method of spent coffee grounds potentials for mortar production. Int. J. Life Cycle Assess. 2021, 26, 1805–1815. [Google Scholar] [CrossRef]

- Schaubroeck, T.; De Clippeleir, H.; Weissenbacher, N.; Dewulf, J.; Boeckx, P.; Vlaeminck, S.E.; Wett, B. Environmental sustainability of an energy self-sufficient sewage treatment plant: Improvements through DEMON and co-digestion. Water Res. 2015, 74, 166–179. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Ziegler-Rodriguez, K.; Laso, J.; Quispe, I.; Aldaco, R.; Kahhat, R. Production of cement in Peru: Understanding carbon-related environmental impacts and their policy implications. Resour. Conserv. Recycl. 2019, 142, 283–292. [Google Scholar] [CrossRef]

- Dolman, M.; Sonneveld, M.; Mollenhorst, H.; de Boer, I. Benchmarking the economic, environmental and societal performance of Dutch dairy farms aiming at internal recycling of nutrients. J. Clean. Prod. 2014, 73, 245–252. [Google Scholar] [CrossRef]

- Corcelli, F.; Fiorentino, G.; Vehmas, J.; Ulgiati, S. Energy efficiency and environmental assessment of papermaking from chemical pulp—A Finland case study. J. Clean. Prod. 2018, 198, 96–111. [Google Scholar] [CrossRef]

- Osmani, A.; Zhang, J. Multi-period stochastic optimization of a sustainable multi-feedstock second generation bioethanol supply chain—A logistic case study in Midwestern United States. Land Use Policy 2017, 61, 420–450. [Google Scholar] [CrossRef]

- Mirkouei, A.; Haapala, K.R.; Sessions, J.; Murthy, G.S. A mixed biomass-based energy supply chain for enhancing economic and environmental sustainability benefits: A multi-criteria decision making framework. Appl. Energy 2017, 206, 1088–1101. [Google Scholar] [CrossRef]

- Susanty, A.; Tjahjono, B.; Sulistyani, R.E. An investigation into circular economy practices in the traditional wooden furniture industry. Prod. Plan. Control 2020, 31, 1336–1348. [Google Scholar] [CrossRef]

- Ghadimi, P.; O’Neill, S.; Wang, C.; Sutherland, J.W. Analysis of enablers on the successful implementation of green manufacturing for Irish SMEs. J. Manuf. Technol. Manag. 2020, 32, 85–109. [Google Scholar] [CrossRef]

- Ghosh, M. Determinants of Green Procurement Implementation and Its Impact on Firm Performance. J. Manuf. Technol. Manag. 2019, 30, 462–482. [Google Scholar] [CrossRef]

- Kuei, C.; Madu, C.N.; Chow, W.S.; Chen, Y. Determinants and Associated Performance Improvement of Green Supply Chain Management in China. J. Clean. Prod. 2015, 95, 163–173. [Google Scholar] [CrossRef]

- Junaid, M.; Zhang, Q.; Syed, M.W. Effects of Sustainable Supply Chain Integration on Green Innovation and Firm Performance. Sustain. Prod. Consum. 2021, 30, 145–157. [Google Scholar] [CrossRef]

- Kumar, N.; Brint, A.; Shi, E.; Upadhyay, A.; Ruan, X. Integrating Sustainable Supply Chain Practices with Operational Performance: An Exploratory Study of Chinese SMEs. Prod. Plan. Control 2019, 30, 464–478. [Google Scholar] [CrossRef]

- Fritz, M.M.C.; Schöggl, J.-P.; Baumgartner, R.J. Selected Sustainability Aspects for Supply Chain Data Exchange: Towards a Supply Chain-Wide Sustainability Assessment. J. Clean. Prod. 2017, 141, 587–607. [Google Scholar] [CrossRef]

- Sahoo, S.; Vijayvargy, L. Green Supply Chain Management Practices and Its Impact on Organizational Performance: Evidence from Indian Manufacturers. J. Manuf. Technol. Manag. 2020, 32, 862–886. [Google Scholar] [CrossRef]

- Lim, M.K.; Tseng, M.-L.; Tan, K.H.; Bui, T.D. Knowledge management in sustainable supply chain management: Improving performance through an interpretive structural modelling approach. J. Clean. Prod. 2017, 162, 806–816. [Google Scholar] [CrossRef]

- Singh, S.K.; El-Kassar, A.-N. Role of big data analytics in developing sustainable capabilities. J. Clean. Prod. 2019, 213, 1264–1273. [Google Scholar] [CrossRef]

- Umar, M.; Khan, S.A.R.; Zia-Ul-Haq, H.M.; Yusliza, M.Y.; Farooq, K. The role of emerging technologies in implementing green practices to achieve sustainable operations. TQM J. 2021, 34, 232–249. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, J.; Zhu, J. When to increase firms’ sustainable operations for efficiency? A data envelopment analysis in the retailing industry. Eur. J. Oper. Res. 2019, 277, 1010–1026. [Google Scholar] [CrossRef]

- Edwin Cheng, T.C.; Kamble, S.S.; Belhadi, A.; Ndubisi, N.O.; Lai, K.; Kharat, M.G. Linkages between Big Data Analytics, Circular Economy, Sustainable Supply Chain Flexibility, and Sustainable Performance in Manufacturing Firms. Int. J. Prod. Res. 2021, 60, 6908–6922. [Google Scholar] [CrossRef]

- Agyabeng-Mensah, Y.; Tang, L. The relationship among green human capital, green logistics practices, green competitiveness, social performance and financial performance. J. Manuf. Technol. Manag. 2021, 32, 1377–1398. [Google Scholar] [CrossRef]

- Burki, U.; Ersoy, P.; Dahlstrom, R. Achieving triple bottom line performance in manufacturer-customer supply chains: Evidence from an emerging economy. J. Clean. Prod. 2018, 197, 1307–1316. [Google Scholar] [CrossRef]

- Lu, J.; Ren, L.; Zhang, C.; Rong, D.; Ahmed, R.R.; Streimikis, J. Modified Carroll’s pyramid of corporate social responsibility to enhance organizational performance of SMEs industry. J. Clean. Prod. 2020, 271, 122456. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, M.; Al-Aomar, R. A framework for supply chain sustainability in service industry with Confirmatory Factor Analysis. Renew. Sustain. Energy Rev. 2016, 55, 1301–1312. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Srivastava, R.K. Antecedents of implementation success in closed-loop supply chain: An empirical investigation. Int. J. Prod. Res. 2019, 57, 7344–7360. [Google Scholar] [CrossRef]

- Pakdeechoho, N.; Sukhotu, V. Sustainable supply chain collaboration: Incentives in emerging economies. J. Manuf. Technol. Manag. 2018, 29, 273–294. [Google Scholar] [CrossRef]

- Gupta, H.; Kumar, A.; Wasan, P. Industry 4.0, cleaner production and circular economy: An integrative framework for evaluating ethical and sustainable business performance of manufacturing organizations. J. Clean. Prod. 2021, 295, 126253. [Google Scholar] [CrossRef]

- Fang, C.; Zhang, J. Performance of green supply chain management: A systematic review and meta analysis. J. Clean. Prod. 2018, 183, 1064–1081. [Google Scholar] [CrossRef]

- Jiang, S.; Han, Z.; Huo, B. Patterns of IT use: The impact on green supply chain management and firm performance. Ind. Manag. Data Syst. 2020, 120, 825–843. [Google Scholar] [CrossRef]

- Birou, L.M.; Green, K.W.; Inman, R.A. Sustainability knowledge and training: Outcomes and firm performance. J. Manuf. Technol. Manag. 2019, 30, 294–311. [Google Scholar] [CrossRef]

- Gopal, P.; Thakkar, J. Sustainable supply chain practices: An empirical investigation on Indian automobile industry. Prod. Plan. Control 2016, 27, 49–64. [Google Scholar] [CrossRef]

- Ni, W.; Sun, H. The effect of sustainable supply chain management on business performance: Implications for integrating the entire supply chain in the Chinese manufacturing sector. J. Clean. Prod. 2019, 232, 1176–1186. [Google Scholar] [CrossRef]

- Zaid, A.A.; Jaaron, A.A.M.; Bon, A.T. The impact of green human resource management and green supply chain management practices on sustainable performance: An empirical study. J. Clean. Prod. 2018, 204, 965–979. [Google Scholar] [CrossRef]

- Ghadimi, P.; Ghassemi Toosi, F.; Heavey, C. A Multi-Agent Systems Approach for Sustainable Supplier Selection and Order Allocation in a Partnership Supply Chain. Eur. J. Oper. Res. 2018, 269, 286–301. [Google Scholar] [CrossRef]

- Al-Ghwayeen, W.S.; Abdallah, A.B. Green Supply Chain Management and Export Performance. J. Manuf. Technol. Manag. 2018, 29, 1233–1252. [Google Scholar] [CrossRef]

- Das, D. Sustainable supply chain management in Indian organisations: An empirical investigation. Int. J. Prod. Res. 2018, 56, 5776–5794. [Google Scholar] [CrossRef]

- Geng, R.; Mansouri, S.A.; Aktas, E. The relationship between green supply chain management and performance: A meta-analysis of empirical evidences in Asian emerging economies. Int. J. Prod. Econ. 2017, 183, 245–258. [Google Scholar] [CrossRef]

- Abu Seman, N.A.; Govindan, K.; Mardani, A.; Ozkul, S.; Zakuan, N.; Saman, M.Z.M.; Hooker, R.E. The mediating effect of green innovation on the relationship between green supply chain management and environmental performance. J. Clean. Prod. 2019, 229, 115–127. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104559. [Google Scholar] [CrossRef]

- Luthra, S.; Qadri, M.A.; Garg, D.; Haleem, A. Identification of critical success factors to achieve high green supply chain management performances in Indian automobile industry. Int. J. Logist. Syst. Manag. 2014, 18, 170. [Google Scholar] [CrossRef]

- Esfahbodi, A.; Zhang, Y.; Watson, G. Sustainable supply chain management in emerging economies: Trade-offs between environmental and cost performance. Int. J. Prod. Econ. 2016, 181, 350–366. [Google Scholar] [CrossRef]

| Themes | Author | No. of Articles Examined | Time Span of Review | Objectives | Method | Findings |

|---|---|---|---|---|---|---|

| GSCM and Indirect Performance Affecting Concept Analysis | Nobanee et al. (2021) [52] | 1233 | 1990–2020 | To collectively analyze sustainability practices and risk management | Bibliometric analysis through VOSviewer | Six major themes related to 1. Moral responsibilities and sustainability developments. 2. Blockchain technology and risk reduction. 3. Social sustainability and SC. 4. Environmental Impacts. 5. Safety engineering and risk identification. 6. Optimization and Sustainability practices were identified. |

| Bhatt et al. (2020) [53] | 343 | 1990–2019 | To examine lean and green manufacturing principles | Bibliometric and content analysis | Most of the research focuses on the relationship of lean and Green Manufacturing with Organizational and environmental performance, with less concern given to sustainability. | |

| Ren et al. (2020) [54] | 306 | 1999–2019 | To undertake a collective quantitative and qualitative analysis of Green and Sustainable Logistics | Bibliometric analysis, science mapping, Literature Review | Five major research alignments related to 1. TBL research, 2. Policy, Planning and Management, 3. Practice and implementation, 4. Technology, and 5. Operation Research were identified. | |

| El Baz and Iddik (2021) [55] | 46 | 2001–2020 | To study the relationship b/w GSCM and Organizational Culture | Bibliometric and Content analysis | Increasing research in the time frame of 2012–2020. Research relates to studying organizational culture both as a driver and barrier to GSCM. | |

| Shaharudin et al. (2019) [56] | 1136 | 2001–2021 | To study the past, present, and future of Low-carbon SCM. | Content Analysis and Social Network Analysis | Six main realms under Low-carbon SCM have been explored, viz., sustainability, GSCM, SCM, innovation, environmental management, sustainable development, and climate change. | |

| Ferasso et al. (2020) [57] | 253 | 2013–2019 | To study the relationship between Circular Economy and Business Models | Bibliometric analysis through VOSviewer and qualitative review | Emerging topics related to the fields of CE, SCs, waste and reuse were identified in the domain of supply-side aspects, demand-side aspects, managerial implications, networking, performance and contextual considerations. | |

| Digital Supply Chain Management and Blockchain Intervention for SSC | Zekhnini et al. (2021) [58] | 86 | NA | To study the relationship between digital technologies, lean, green, sustainable SC, and SC performance. | Bibliometric Analysis and Literature Review | Industry 4.0 has an impact on SC performance. There exists a relationship between lean, green, and sustainable practices and digital SCs. |

| Manal Benatiya Andaloussi (2024) [59] | 114 | 2000–2023 | To study the literature related to Digital Supply Chains | Bibliometric LR and content analysis through VOSviewer | Digital Technology has a significant impact on SCM. The main research trends in this field include intelligent SCM, disruptive technology to stimulate SC performance, Circular SC, information reliability in SC, and SSC. | |

| Chakraborty et al. (2023) [60] | 477 | 2017–2022 | To study the literature related to the application of blockchain technology in SSCs | Bibliometric Analysis and SLR | Six key themes are identified related to SC visibility, traceability, collaboration, adaptability, resilience, sustainability, performance, finance, agility, challenges to blockchain, and carbon auditing. | |

| Cruz and De Arruda Ignacio (2023) [61] | NA | NA | To study the literature related to the implementation of Blockchain Technology in agri-food supply chain for sustainability | Bibliometric analysis and SLR | Blockchain technology helps in improving SC performance. Environmental concerns are addressed less in this field. | |

| GSCM and Performance Analysis | Chen et al. (2017) [62] | 174 | 1987–2015 | To analyze the link b/w SC collaboration and TBL metrics | Bibliometric Analysis and SLR | There is a growing interest in SC collaboration for sustainability, with the dominance of economic and environmental concerns over social concerns. |

| Beske-Janssen et al. (2015) [63] | 140 | 1995–2014 | To measure sustainability performance for SSCM | Bibliometric Analysis and SLR | The research interest in this field grew between 2010 and 2014, whereby environmental and economic aspects dominate the field over social aspects of sustainability. | |

| Maditati et al. (2018) [64] | 1523 | 1997–2016 | To study structural relationships among different GSCM factors | Bibliometric citation meta-analysis and Content analysis through HistCite software | Six major research streams related to 1. Conceptual development, 2. Impact of GSCM on performance, 3. Green and Sustainable SC operations, 4. Green Supplier Development 5. Drivers to GSCM implementation, and 6. Future Scope were identified. | |

| Balon (2019) [65] | 150 | 1999–2014 | To review the literature related to pressures, practices and performance related to green supply chain management | Bibliometric analysis and Literature Review | Government rules and regulations, CSR, IR, and green market are identified as the key pressures. ED, IEM, waste management, GP aspect, quality, and IR have been identified as the key practices. FP, operational performance, and EVP have been identified as the key performances. | |

| Miscellaneous analysis related to Sustainable Supply Chains | Yang et al. (2021) [66] | 3656 | 1992–2019 | To conduct a review on knowledge progress of Environmental Responsibility (ER) | Bibliometric analysis through CiteSpace software | Five research paradigms related to 1. Stakeholder participations,, 2. ER theories, 3. Management and performance 4. Sustainable SC development, and 5. Drivers to ER are identified. |

| Ahi et al. (2016) [67] | 445 | 1996–2012 | To identify the metrics used for energy-related issues in GSCM and SSCM | Bibliometric Analysis | “Energy use, consumption, and efficiency” have been identified as the top three metrics used frequently. There is a lack of consensus on the measurement of energy-related performance measurement in GSCM and SSCM. | |

| Taticchi et al. (2014) [68] | 384 | 2000–2013 | To study the literature related to Decision Support tools and Performance measurement in SSCM | Bibliometric analysis and SLR | There is an urgent need to integrate performance models with decision-support tools inculcating TBL. Moreover, there is a need to develop industry-specific TBL metrics. | |

| Chopra et al. (2021) [69] | 1136 | 2001–2021 | To study the literature related to knowledge management for sustainability | Bibliometric analysis and LR | Nine foundational clusters are identified, viz., informed sustainability practices, social network, FP, knowledge-sharing culture, green innovation, sustainability models, global warming, knowledge management and innovation performance. | |

| Braz et al. (2018) [70] | 56 | 2004–2018 | To study the causes and mitigation factors of bullwhip effect in forward SC and CLSC. | Bibliometric and content analysis | It was found that causes are similar for both the SCs, whereas increasing product return rate can be accounted as a mitigating factor through which CLSC could reduce the bullwhip effect and thus improve performance. | |

| Rejeb et al. (2023) [71] | 160 | 2020–2022 | To study the literature related to CE in the COVID-19 era | Bibliometric analysis and SLR | Five key themes were identified, viz., 1. Waste management, 2. DSCM and SSCM 3. COVID-19 impacting the food system, 4. SDGs, smart cities, and bio-economy, and 5. CLSCs. |

| S.No. | Search Strings | Initial Results | Refined Results |

|---|---|---|---|

| 1 | (TITLE-ABS-KEY (“green” OR “environmental” OR “ecological” OR “sustainable”) AND TITLE-ABS-KEY ({supply chain} OR {supply-chain} OR {scm}) AND TITLE-ABS-KEY (“sustainability” OR “sustainable” OR {triple bottom line} AND “performance” OR “outcome” OR “achievement”)) | 6852 | 3563 |

| 2 | (TITLE-ABS-KEY (gscm) AND TITLE-ABS-KEY (“environment” OR “economic” OR “financial” OR “social” OR “Operational” AND “performance” OR “outcomes” OR “achievement”)) | 452 | 284 |

| 3 | (TITLE-ABS-KEY (gscm) AND TITLE-ABS-KEY (“firm” OR “organizational” OR “corporate” AND “performance” OR “outcome” OR “achievement”)) | 395 | 262 |

| 4 | TITLE-ABS-KEY (gscm) AND TITLE-ABS-KEY (“sustainability” OR “sustainable” OR {triple bottom line} AND “performance” OR “outcome” OR “achievement”)) | 348 | 206 |

| 5 | TITLE-ABS-KEY (“green” OR “environmental” OR “sustainable” OR “ecological”) AND TITLE-ABS-KEY ({supply chain} OR {supply-chain} OR {scm}) AND TITLE-ABS-KEY (“environment” OR “economic” OR “financial” OR “social” OR “operational” AND “performance” OR “outcomes” OR “achievement”)) | 6349 | 3150 |

| 6 | (TITLE-ABS-KEY (“green” OR “environmental” OR “sustainable” OR “ecological”) AND TITLE-ABS-KEY ({supply chain} OR {supply-chain} OR {scm}) AND TITLE-ABS-KEY (“firm” OR “organizational” OR “corporate” AND “performance” OR “outcome” OR “achievement”)) | 3029 | 1859 |

| TOTAL | 17,425 | 9324 |

| Country | Articles | Articles % | SCP | MCP | MCP % |

|---|---|---|---|---|---|

| China | 181 | 19.3 | 81 | 100 | 55.2 |

| U.K | 90 | 9.6 | 25 | 65 | 72.2 |

| India | 71 | 7.6 | 55 | 16 | 22.5 |

| USA | 65 | 6.9 | 32 | 33 | 50.8 |

| Italy | 40 | 4.3 | 27 | 13 | 32.5 |

| Iran | 33 | 3.5 | 27 | 6 | 18.2 |

| Australia | 27 | 2.9 | 15 | 12 | 44.4 |

| France | 23 | 2.4 | 6 | 17 | 73.9 |

| Canada | 22 | 2.3 | 10 | 12 | 54.5 |

| Spain | 22 | 2.3 | 11 | 11 | 50 |

| Words | Occurrences |

|---|---|

| Supply Chain Management sustainable development | 419 386 |

| supply chains | 294 |

| environmental management | 204 |

| decision making | 152 |

| environmental impact | 125 |

| sustainability | 123 |

| sustainable supply chains | 123 |

| environmental performance | 89 |

| green supply chain management | 87 |

| Label | Group | Freq | Centrality | Impact |

|---|---|---|---|---|

| supply chain management-conf 24.8% green supply chain management-conf 70.4% environmental management-conf 45% | 1 | 36 | 0.244 | 2.192 |

| sustainable development-conf 84.7% supply chain management-conf 65.5% supply chains-conf 96.8% | 2 | 187 | 0.43 | 1.872 |

| supply chain management-conf 9.7% sustainable development-conf 5.6% performance assessment-conf 26.3% | 3 | 20 | 0.457 | 1.771 |

| Cluster | Callon Centrality | Callon Density | Rank Centrality | Rank Density | Cluster Frequency |

|---|---|---|---|---|---|

| supply chain management | 8.185 | 18.935 | 4 | 3 | 2913 |

| sustainability | 5.244 | 22.854 | 2 | 4 | 1022 |

| environmental impact | 4.809 | 18.395 | 1 | 2 | 670 |

| Green supply chain management | 5.915 | 17.208 | 3 | 1 | 1114 |

| Clusters No. | Cluster Name | Keywords Used |

|---|---|---|

| 1 | supply chain management | supply chain management, decision making, environmental performance, commerce, economic and social effects, sensitivity analysis, environmental sustainability, sustainability performance, green supply chain, costs, environmental management, carbon, integer programming, circular economy, emission control, closed-loop supply chain, environmental technology, multiobjective optimization, profitability, product design, economic and environmental performance, benchmarking, data envelopment analysis, planning, efficiency, game theory, sustainable development, investments, social aspects, uncertainty analysis, supply chains, waste management, literature reviews, systematic literature review, carbon emissions, chains, design, stochastic systems, cost effectiveness, energy efficiency, fuzzy sets, performance measurements, stochastic models, supplier selection, cost reduction, ecodesign, network design, remanufacturing, reverse logistics, marketing, social sustainability, sustainable manufacturing, triple bottom line, blockchain, decision support systems, decision theory, environmental and economic performance, supply chain network design, sustainable supplier selections, behavioral research, closed-loop, conceptual frameworks, environmental issues, linear programming, multi criteria decision making, reverse supply chains, social and environmental, transportation, analytic network process, artificial intelligence, closed-loop supply chains (CLSC), construction industry, content analysis, customer satisfaction, environmental concerns, food industries, freight transportation, green, lean, mixed integer linear programming model, laws and legislation, environmental regulations, nonlinear programming, outsourcing, performance measure, stochastic programming, supply chain collaboration, supply chain operation, sustainability issues, agri-food supply chains, cap and trade, closed-loop supply chain networks, collaboration, consumer, consumer behavior, fuzzy logic, low carbon |

| 2 | sustainability | Sustainability, environmental economics, performance assessment, manufacturing, article, china, human, industrial performance, environmental protection, innovation, literature review, numerical model, stakeholder, management practice, strategic approach, green economy, industry, integrated approach, fuzzy mathematics, competitiveness, conceptual framework, empirical analysis, india, Pakistan, analytical hierarchy process, environmental assessment, small and medium-sized enterprise, environment, brazil, ecology, economic aspect, economic development, environmental policy, risk assessment, commercial phenomena, investment, least squares method, multicriteria analysis, corporate social responsibility, organization, business, conservation of natural resources, environmental issue, hierarchical systems, implementation process, knowledge, corporate strategy, government, industrial enterprise, manager, modeling, qualitative analysis, research work, supply chain management practices, DEMATEL, developing world, firm size, future prospect, humans, industrial development |

| 3 | environmental impact | environmental impact, life cycle, logistics, life cycle assessment (lca), optimization, food supply, carbon footprint, greenhouse gases, biomass, recycling, carbon dioxide, economics, life cycle analysis, climate change, economic analysis, global warming, carbon emission, agriculture, life cycle assessment, environmental impact assessment, gas emissions, cost benefit analysis, eutrophication, energy utilization, food industry, pollution, assessment method, biofuel, cost analysis, feedstocks, fossil fuels, priority journal, algorithm, forestry |

| 4 | Green supply chain management | green supply chain management, sustainable supply chains, manufacture, sales, competition, managers, design/methodology/approach, surveys, industrial research, structural equation modeling, least squares approximations, sustainable performance, developing countries, performance, Industry 4.0, economic performance, factor analysis, finance, integration, partial least squares (pls), financial performance, information management, regression analysis, big data, supply chain performance, sustainable operations, human resource management, green manufacturing, industrial economics, operational performance, resource-based view, sustainability practices, electronics industry, managerial implications, manufacturing firms, organizational performance, pollution control, manufacturing companies, automotive industry, emerging economies, environmental management systems, firm performance, green innovations, sustainable production, corporate social responsibilities (csr), data analytics, small and medium enterprise, social performance, competitive advantage, digital storage, green products, multivariant analysis, structural equation modeling, supply-chain integration, business performance, knowledge management |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamra, J.; Mani, A.P.; Sharma, M.; Joshi, S. The Nexus between Green Supply Chain Management and Sustainability Performance in the Past Decade. Sustainability 2024, 16, 7474. https://doi.org/10.3390/su16177474

Kamra J, Mani AP, Sharma M, Joshi S. The Nexus between Green Supply Chain Management and Sustainability Performance in the Past Decade. Sustainability. 2024; 16(17):7474. https://doi.org/10.3390/su16177474

Chicago/Turabian StyleKamra, Juhi, Ambica Prakash Mani, Manu Sharma, and Sudhanshu Joshi. 2024. "The Nexus between Green Supply Chain Management and Sustainability Performance in the Past Decade" Sustainability 16, no. 17: 7474. https://doi.org/10.3390/su16177474

APA StyleKamra, J., Mani, A. P., Sharma, M., & Joshi, S. (2024). The Nexus between Green Supply Chain Management and Sustainability Performance in the Past Decade. Sustainability, 16(17), 7474. https://doi.org/10.3390/su16177474