Characteristics of Overburden Damage and Rainfall-Induced Disaster Mechanisms in Shallowly Buried Coal Seam Mining: A Case Study in a Gully Region

Abstract

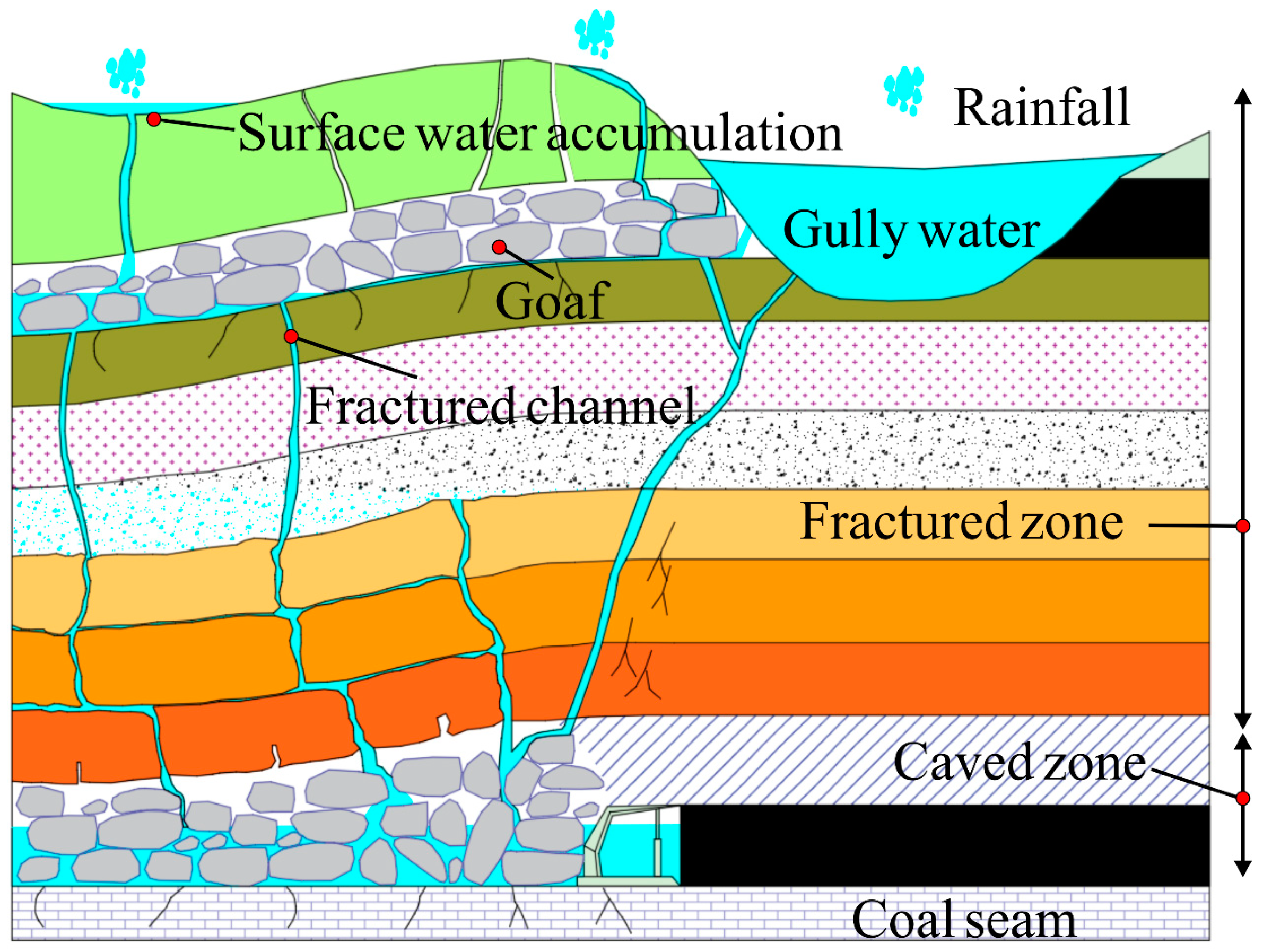

:1. Introduction

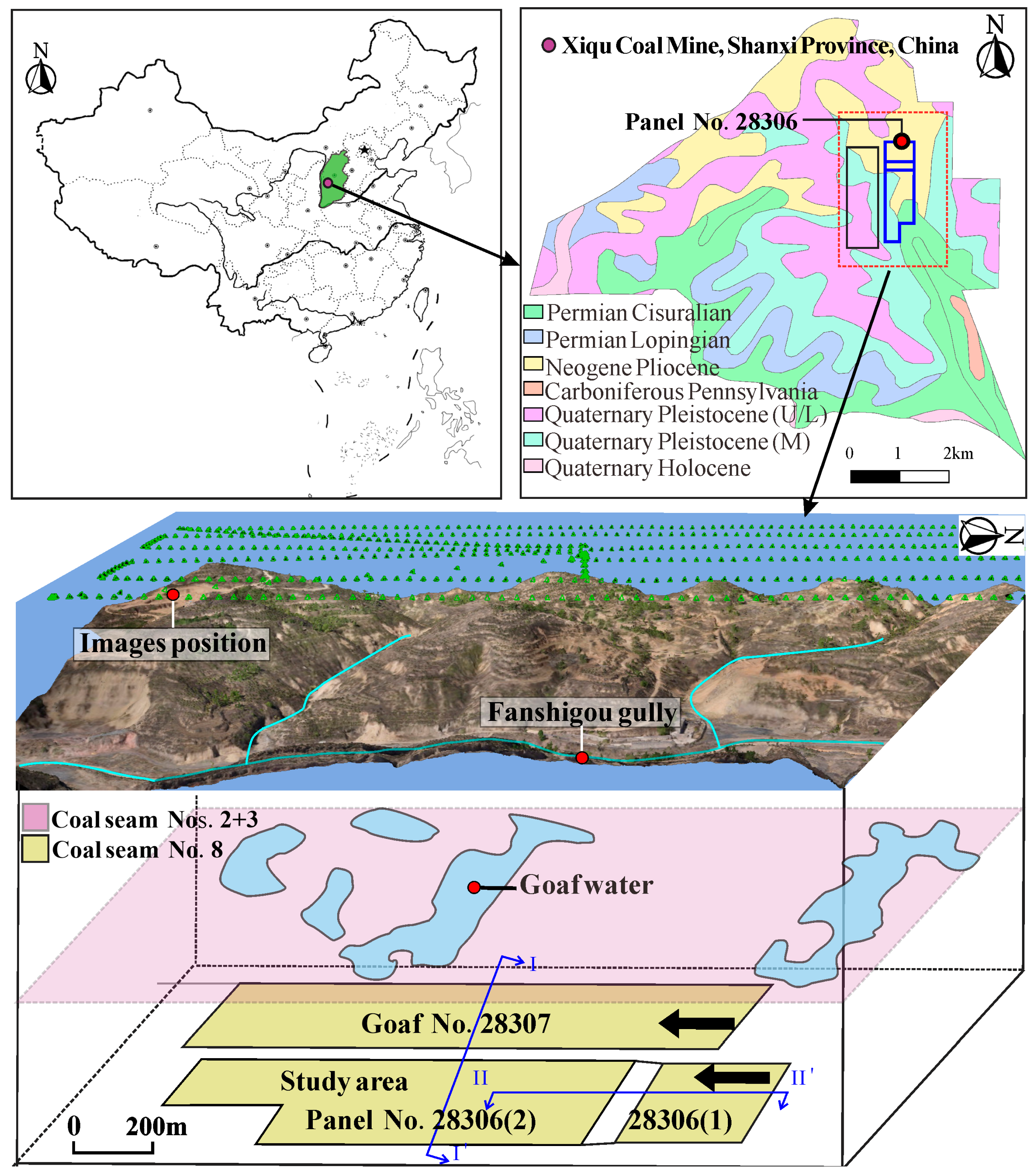

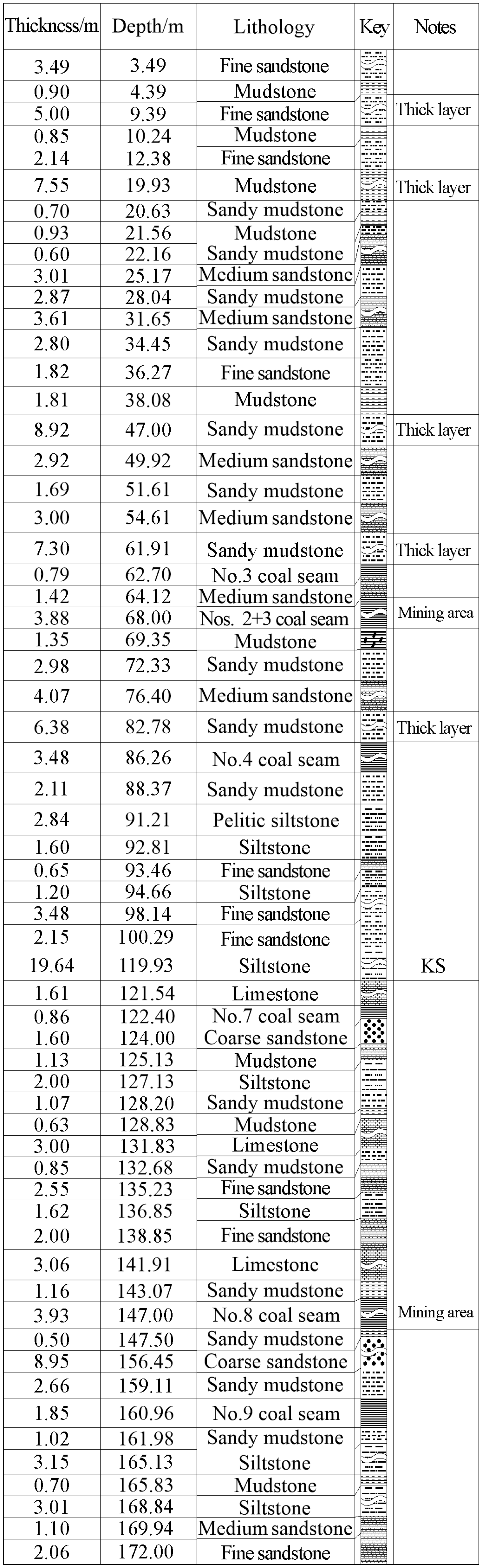

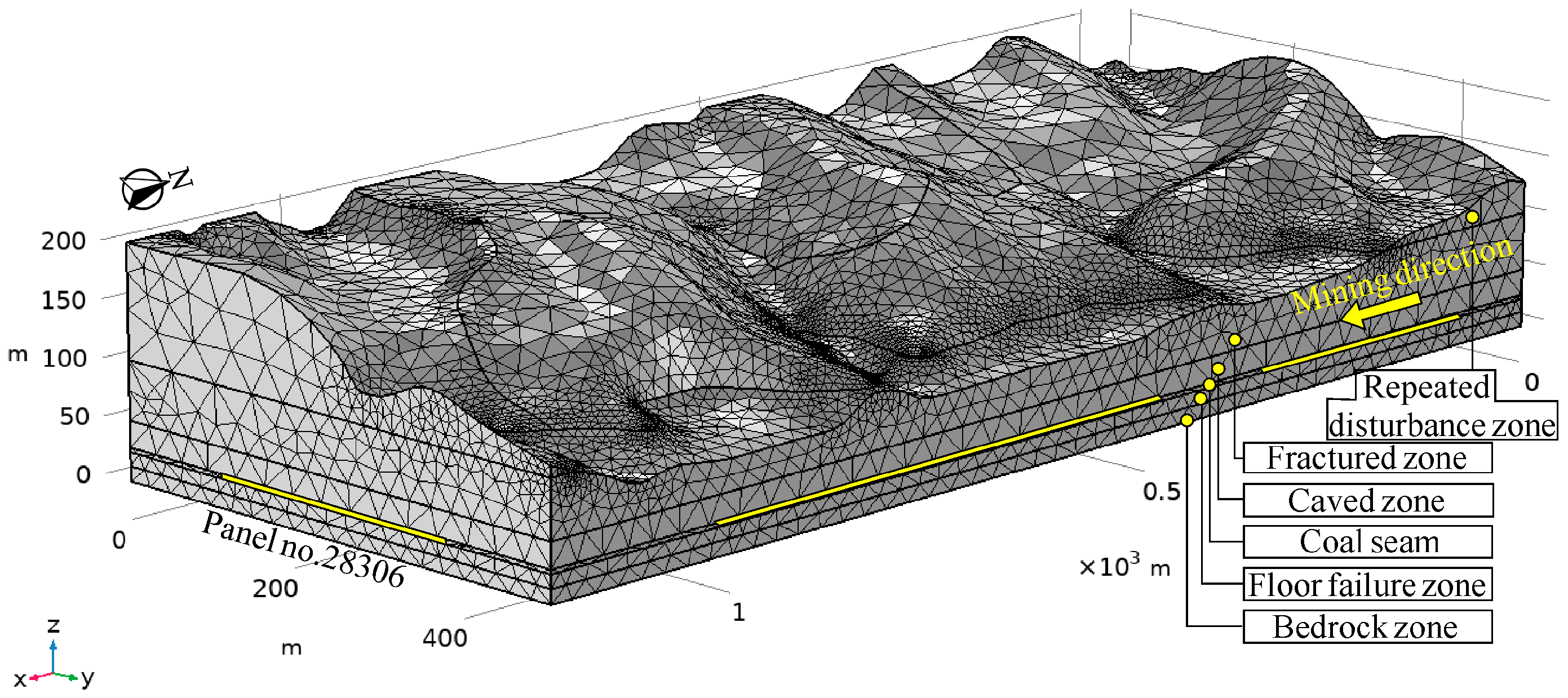

2. Engineering Background

3. Materials and Methods

3.1. Site Investigation and Distinct Element Method

3.2. Similar Simulation Experiment

3.3. Rainfall Runoff and Infiltration Simulation Method

4. Results

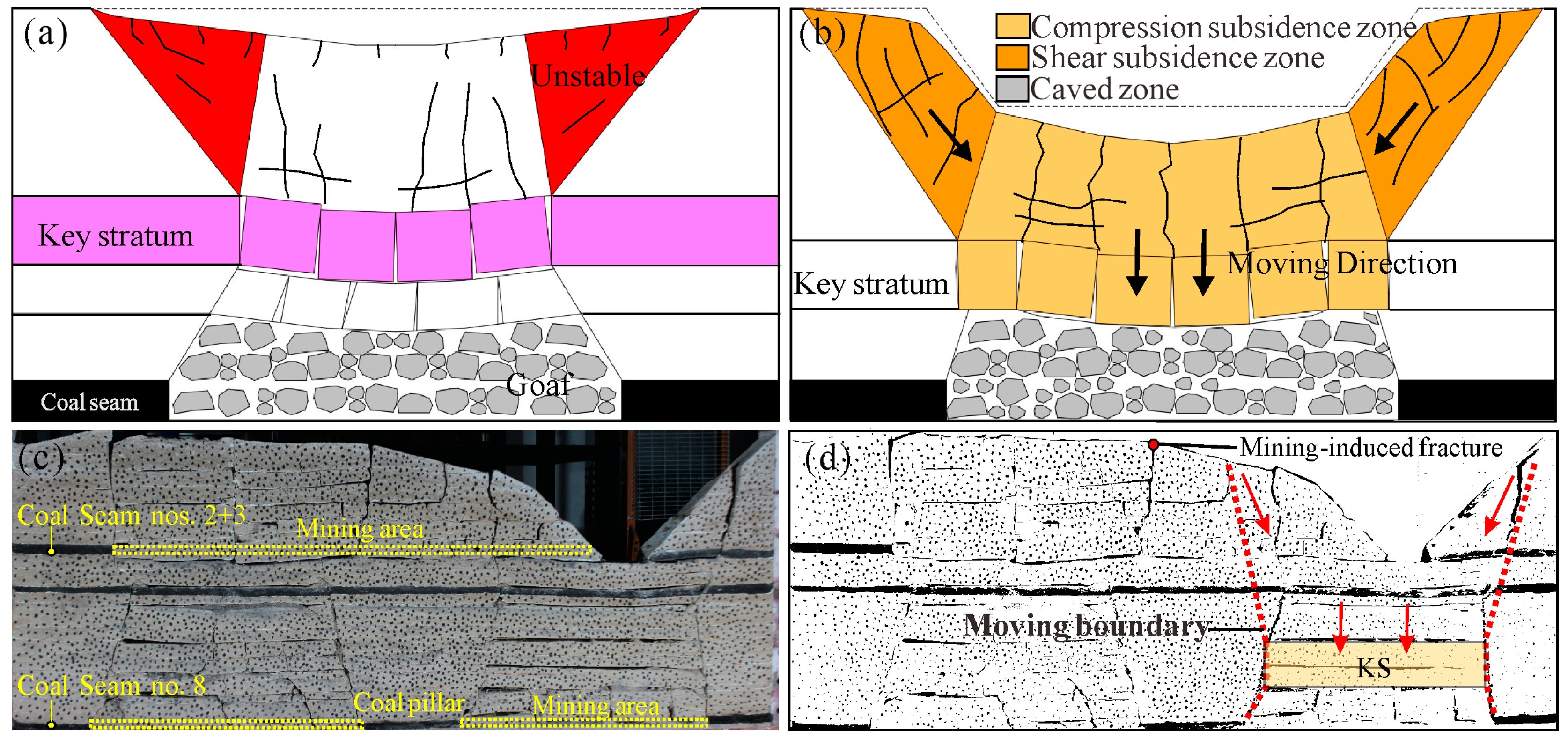

4.1. Characteristics of Surface Subsidence and Crack Development

4.2. Rainfall-Runoff Inundation of Study Area

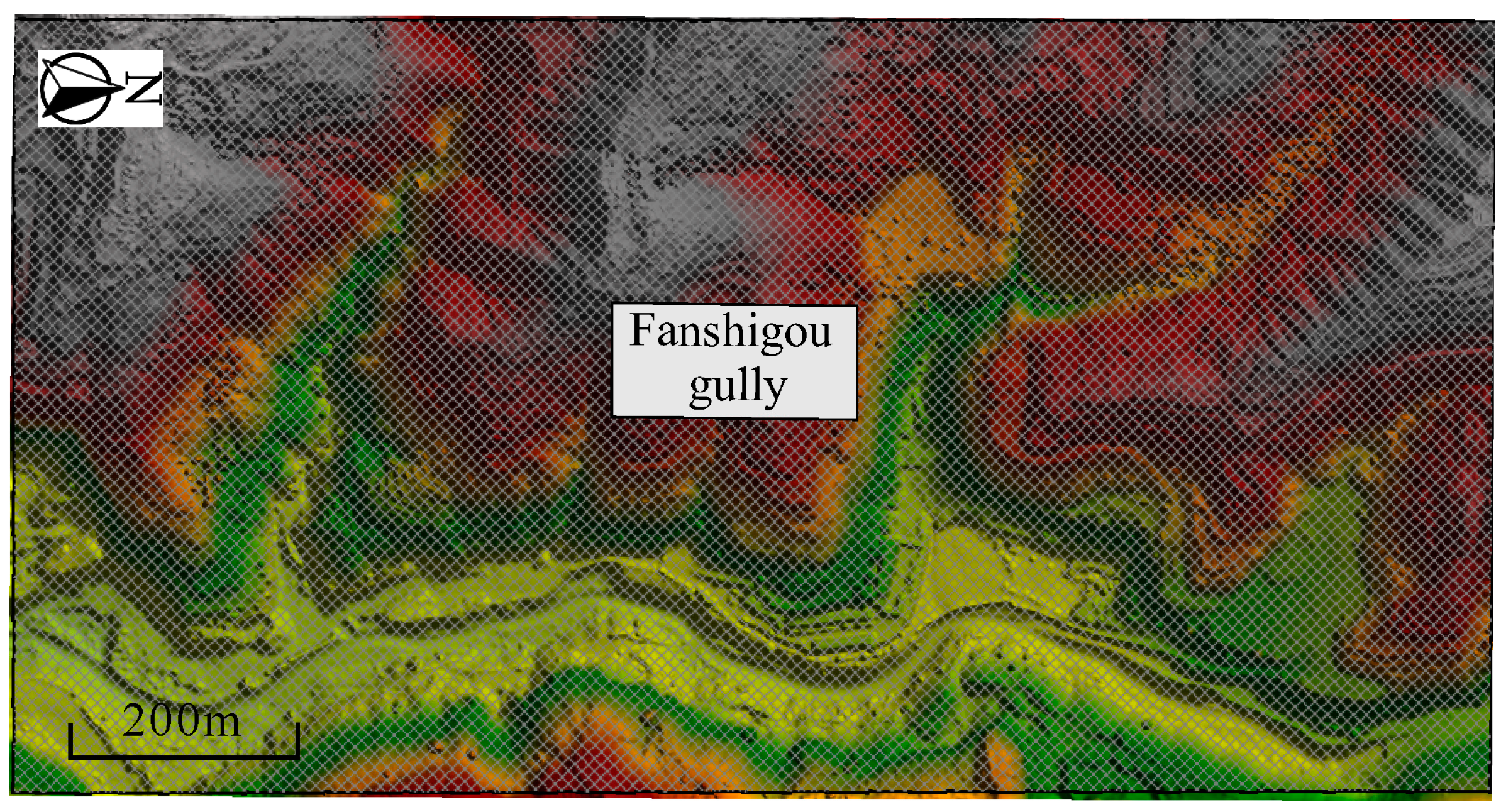

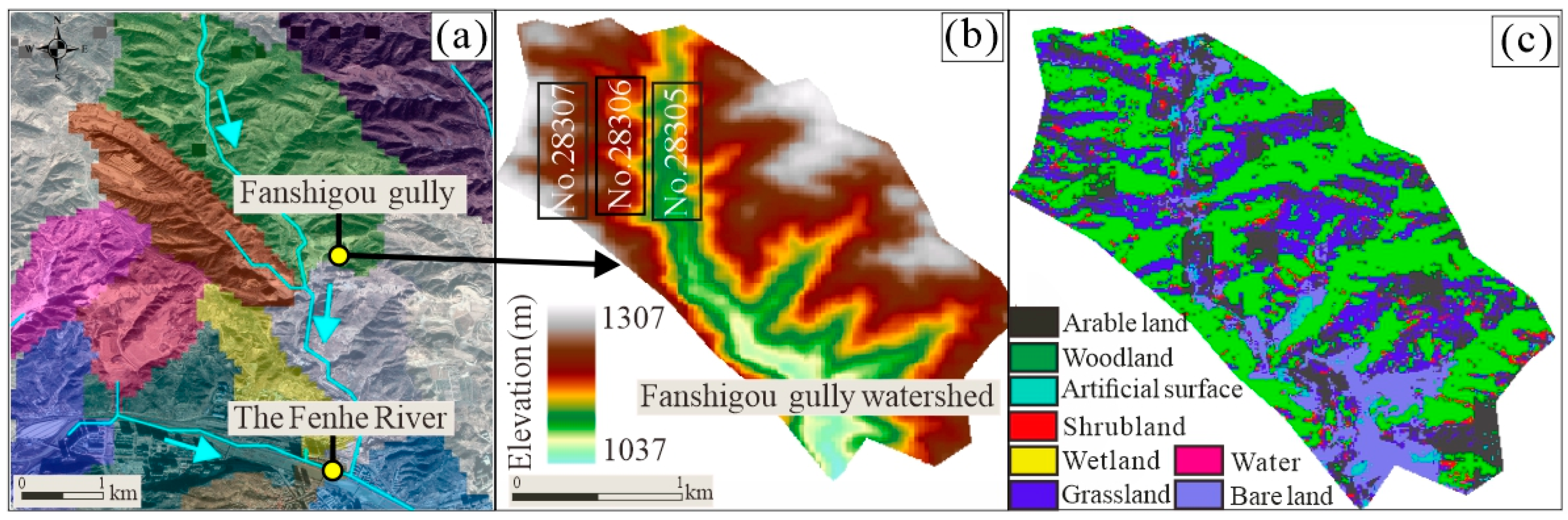

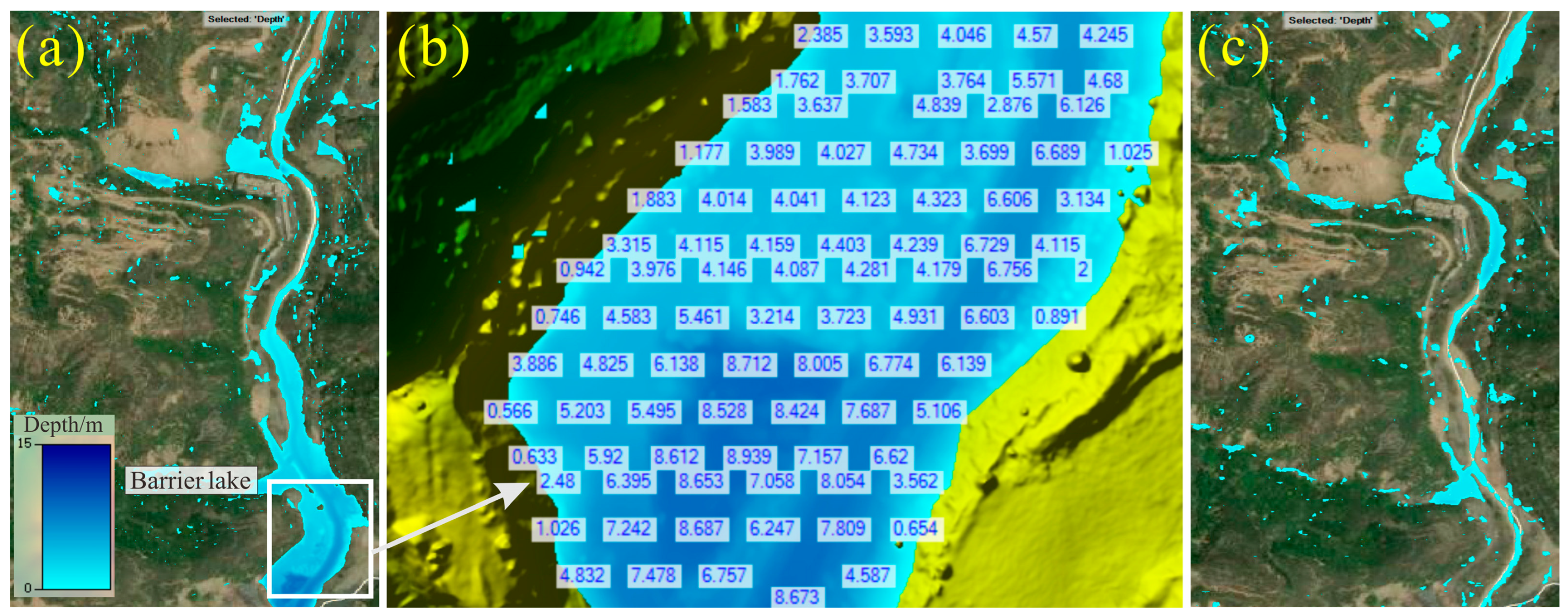

4.2.1. Characteristics of the Fanshigou Basin

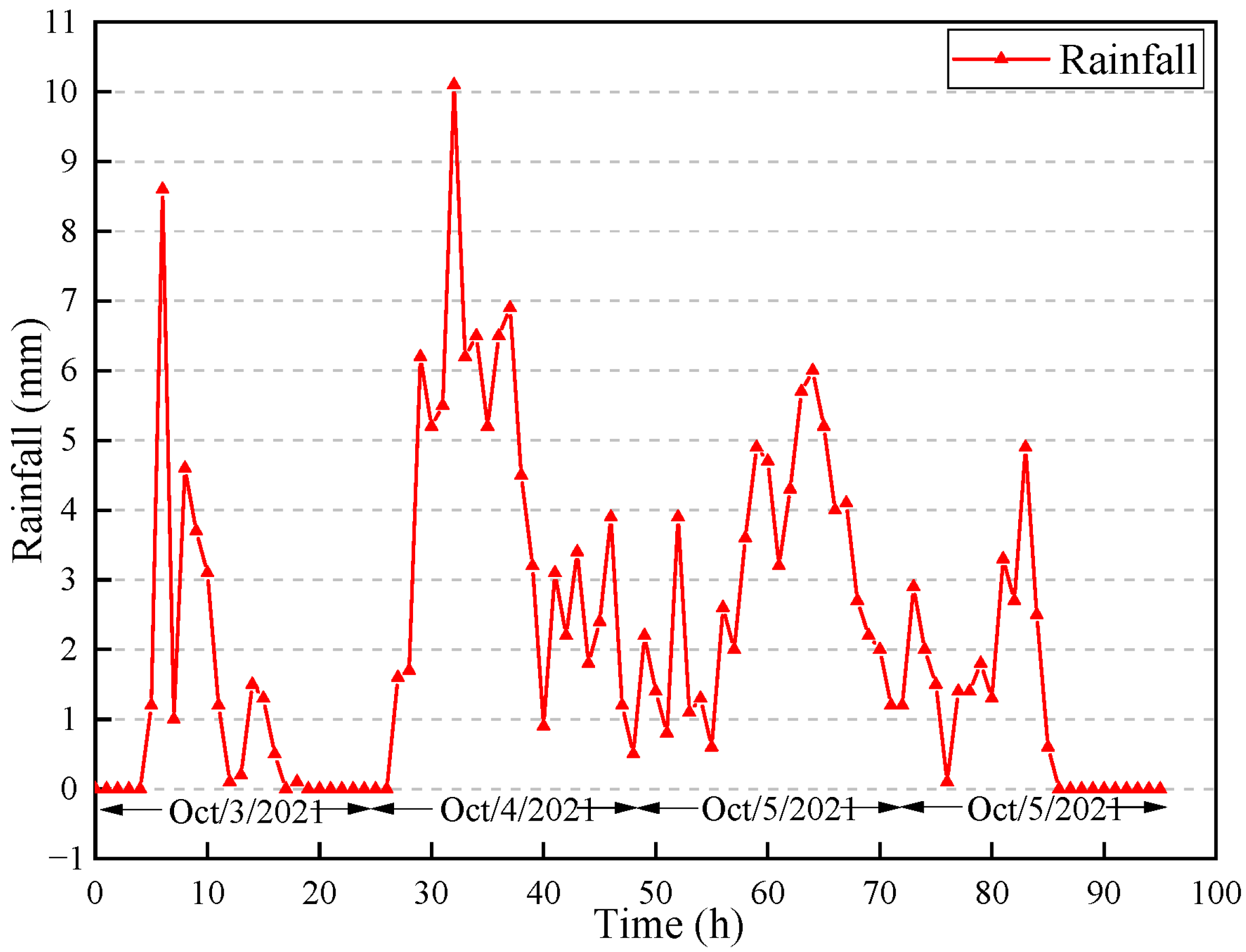

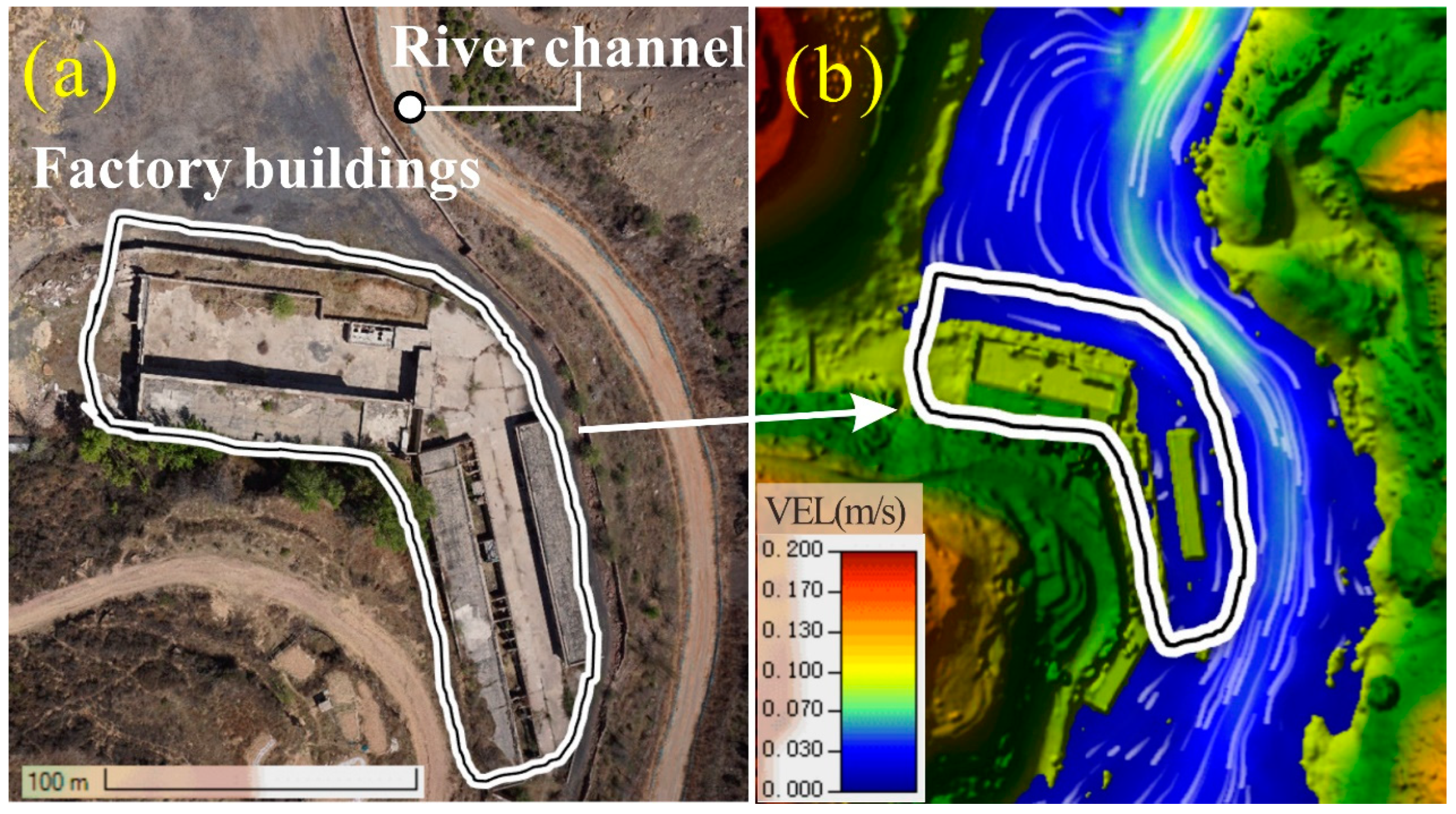

4.2.2. Rainfall-Runoff Simulation Based on HEC-RAS

4.2.3. Analysis of Rainfall Flooding Results

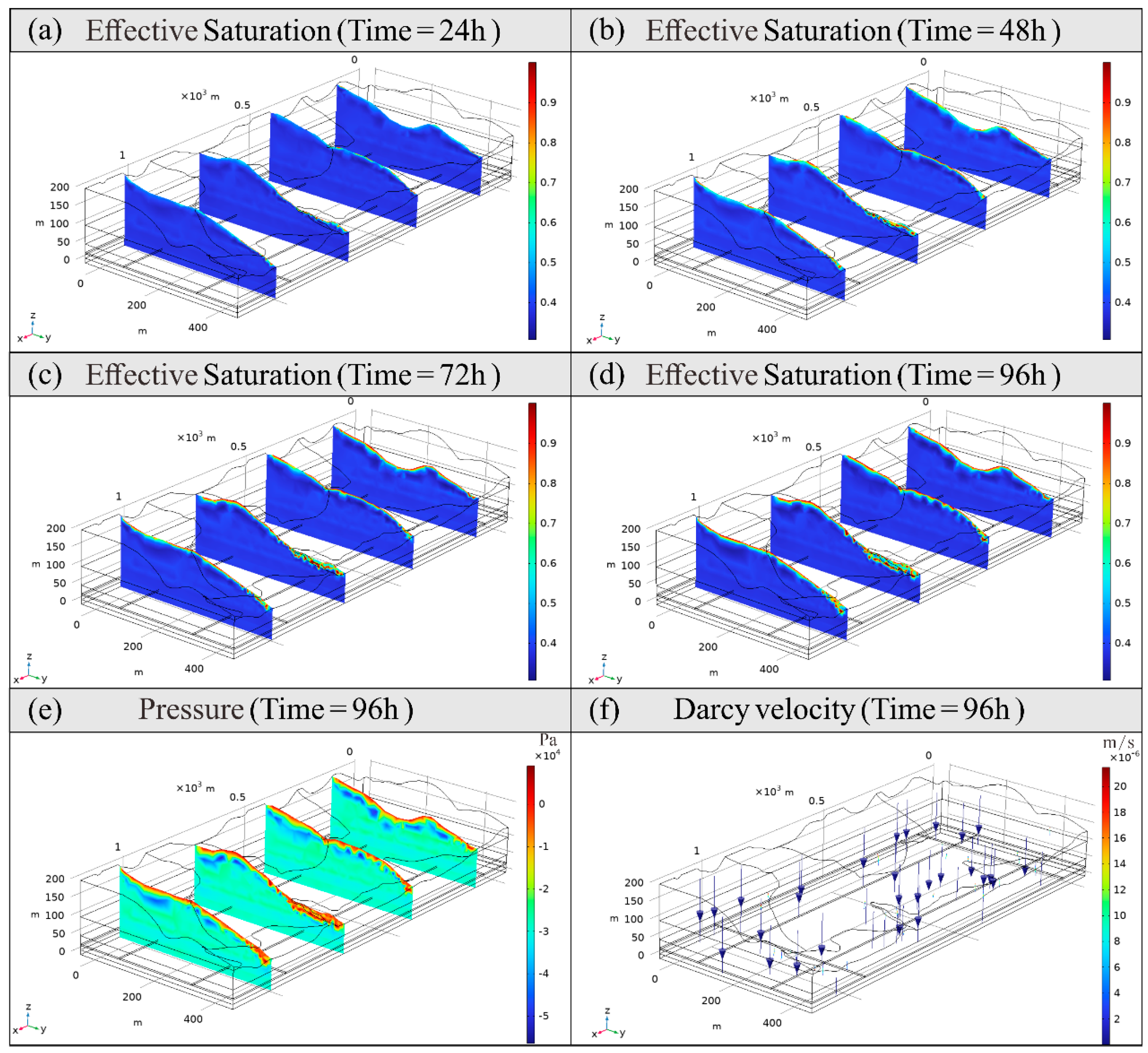

4.3. Rainfall Infiltration Characteristics of Mining Areas

4.3.1. Control Equation for Unsaturated Seepage in Porous Media

4.3.2. Geometric Models and Parameters

4.3.3. Simulation Results of Rainfall Infiltration

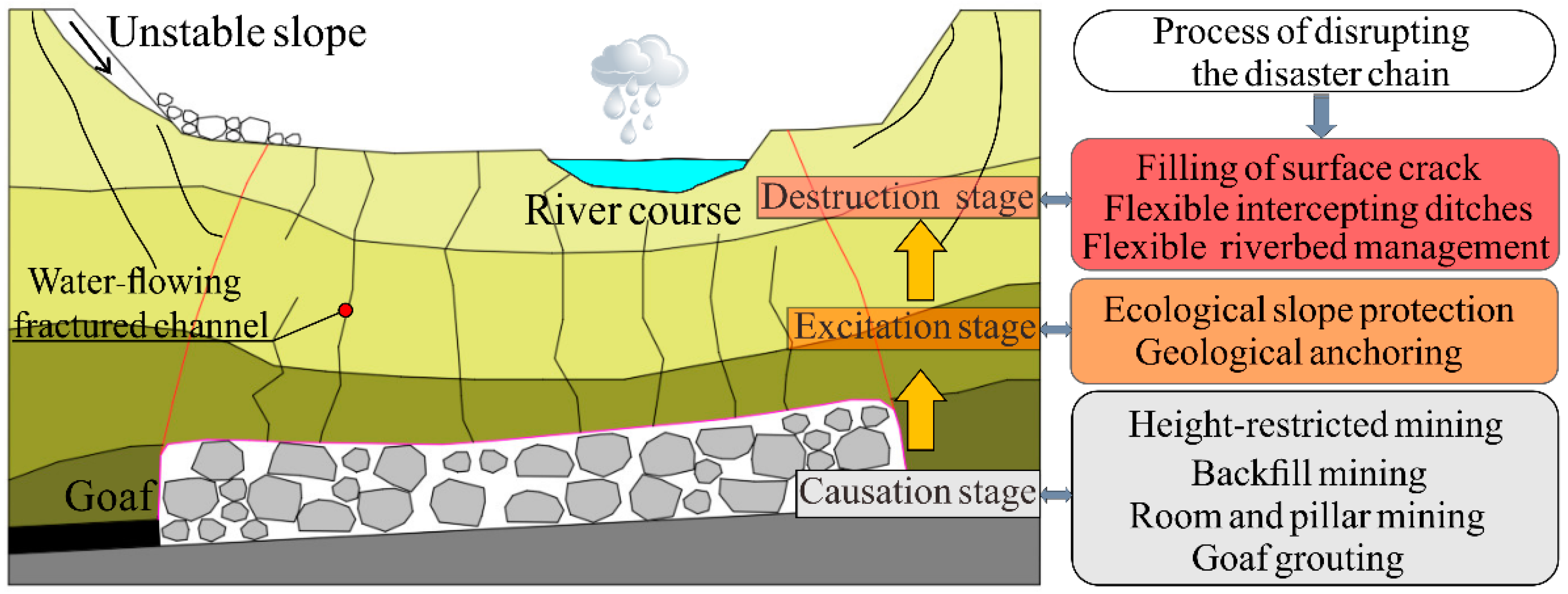

5. Discussion

6. Conclusions

- (1)

- After shallow coal seam mining, the overlying strata are divided vertically into two zones: caved and fractured zones. The fractured zone is further divided horizontally into compression and shear subsidence zones. These zones are influenced by factors such as the thickness and strength of the key strata (KS) and the gully slope. The shear subsidence zone, which generates both compression and shear deformation, intercepts rainfall runoff and is a critical area for crack landfill treatment.

- (2)

- The HEC-RAS program efficiently calculates hydrological and hydrodynamic features, such as the water level of the barrier lake (ranging from 4.0 to 8.6 m after rainfall), the maximum flow velocity of the river channel (0.17 m/s), and the inundation range in the study area. By integrating annual maximum daily rainfall data under different frequencies, this program can develop a dynamic risk assessment method for mining-induced geohazards, such as landslides and barrier lakes in gully regions. The combination of LSM and rainfall-runoff simulation shows promise for assessing surface water-related geohazards in mining areas.

- (3)

- Infiltration and seepage analysis in the gully area shows that under a rainfall intensity of 3.67 mm/h, saturation increases more in low-lying areas, with the infiltration line descending. Seepage prevention measures should be implemented in riverbeds affected by mining-induced subsidence to ensure the sustainability of coal extraction and surface water resources. Matric suction is a critical factor in large-scale numerical modeling. Rainfall infiltration reduces matric suction in unsaturated zones, decreasing the effective stress of rock strata, which in turn reduces their shear strength—a key factor in rainfall-induced landslides.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gui, H.R.; Lin, M.L. Types of water hazards in China coalmines and regional characteristics. Nat. Hazard. 2016, 84, 1501–1512. [Google Scholar] [CrossRef]

- Fan, G.; Zhang, D.; Zhang, S.; Zhang, C. Assessment and prevention of water and sand inrush associated with coal mining under a water-filled buried gully: A case study. Mine Water Environ. 2018, 37, 565–576. [Google Scholar] [CrossRef]

- Wu, Q.; Cui, F.; Zhao, S.; Liu, S.; Zeng, Y.; Gu, Y. Type classification and main characteristics of mine water disasters. J. China Coal Soc. 2013, 38, 561–565. [Google Scholar]

- Huang, M.; Zhang, L.; Zhang, C.; Chen, S. Characteristics of permeability changes in bituminous coal under conditions of stress variation due to repeated mining activities. Nat. Resour. Res. 2020, 29, 1687–1704. [Google Scholar] [CrossRef]

- Cui, G.; Wei, J.; Feng, X.-T.; Liu, J.; Elsworth, D.; Chen, T.; Xiong, W. Preliminary study on the feasibility of co-exploitation of coal and uranium. Int. J. Rock Mech. Min. Sci. 2019, 123, 104098. [Google Scholar] [CrossRef]

- Altun, A.O.; Yilmaz, I.; Yildirim, M. A short review on the surficial impacts of underground mining. Sci. Res. Essays 2010, 5, 3206–3212. [Google Scholar] [CrossRef]

- Bell, F.G.; Stacey, T.R.; Genske, D.D. Mining subsidence and its effect on the environment: Some differing examples. Environ. Geol. 2000, 40, 135–152. [Google Scholar] [CrossRef]

- Prakash, A.; Kumar, N.; Kumbhakar, D.; Singh, A.K.; Paul, A. A safe depillaring design for shallow depth of cover with influence of surface ground movements: A study in Jharia Coalfield. Arab. J. Geosci. 2018, 11, 164. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Y.; Zhang, J.; Yang, T.; Jia, P.; Guo, R. Modelling surface subsidence of coal mines using a bonded block numerical method. Geomat. Nat. Hazards Risk 2024, 15, 2336017. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.; Zhao, X.; Liao, L.; Zhang, S. Dynamic structural evolution of overlying strata during shallow coal seam longwall mining. Int. J. Rock Mech. Min. Sci. 2018, 103, 20–32. [Google Scholar] [CrossRef]

- Zuo, J.; Yu, M.; Li, C.; Sun, Y.; Hu, S.; Li, Z. Analysis of Surface Cracking and Fracture Behavior of a Single Thick Main Roof Based on Similar Model Experiments in Western Coal Mine, China. Nat. Resour. Res. 2021, 30, 657–680. [Google Scholar] [CrossRef]

- Guo, W.; Zhao, G.; Lou, G.; Wang, S. A new method of predicting the height of the fractured water-conducting zone due to high-intensity longwall coal mining in China. Rock Mech. Rock Eng. 2019, 52, 2789–2802. [Google Scholar] [CrossRef]

- Qu, Q.; Xu, J.; Wu, R.; Qin, W.; Hu, G. Three-zone characterisation of coupled strata and gas behaviour in multi-seam mining. Int. J. Rock Mech. Min. Sci. 2015, 78, 91–98. [Google Scholar] [CrossRef]

- Du, W.; Chai, J.; Zhang, D.; Lei, W. Application of optical fiber sensing technology in similar model test of Shallow-buried and thick coal seam mining. Measurement 2021, 181, 109559. [Google Scholar] [CrossRef]

- Troncone, A.; Pugliese, L.; Conte, E. Analysis of an excavation-induced landslide in stiff clay using the material point method. Eng. Geol. 2022, 296, 106479. [Google Scholar] [CrossRef]

- Chai, J.; Ma, Z.; Zhang, D.; Yang, J.; Huang, Z.; Qiu, F. Multi-method joint monitoring study on strata behavior in shallow seam mining under bedrock gully. Sci. Rep. 2023, 13, 15350. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Wang, S.; Song, S.; Sun, Q.; Yang, T. Experiment and numerical simulation of overburden and surface damage law in shallow coal seam mining under the gully. Bull. Eng. Geol. Environ. 2022, 81, 207. [Google Scholar] [CrossRef]

- Yang, Z.; Zhao, Q.; Liu, X.; Yin, Z.; Zhao, Y.; Li, X. Experimental study on the movement and failure characteristics of karst mountain with deep and large fissures induced by coal seam mining. Rock Mech. Rock Eng. 2022, 55, 4839–4867. [Google Scholar] [CrossRef]

- Lu, M.; Sun, X.; Xiao, Y.; Zhang, C. The development mining-induced surface cracks in shallow coal seam through double-gully terrain: A case study in a coal mine. Bull. Eng. Geol. Environ. 2022, 81, 383. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, D.; Zhang, J.; Liang, B. Research on the dynamic evolution law of fissures in shallow-buried and short-distance coal seam mining in Lijiahao Coal Mine. Sci. Rep. 2023, 13, 5625. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Dai, Z.; Wang, Y.; Zhang, L. Fracture failure of consequent bedding rock slopes after underground mining in mountainous area. Rock Mech. Rock Eng. 2019, 52, 2853–2870. [Google Scholar] [CrossRef]

- Li, Z.; Yu, S.; Zhu, W.; Feng, G.; Xu, J.; Guo, Y.; Qi, T. Dynamic loading induced by the instability of voussoir beam structure during mining below the slope. Int. J. Rock Mech. Min. Sci. 2020, 132, 104343. [Google Scholar] [CrossRef]

- Zhang, D.; Fan, G.; Wang, X. Characteristics and stability of slope movement response to underground mining of shallow coal seams away from gullies. Int. J. Min. Sci. Technol. 2012, 22, 47–50. [Google Scholar] [CrossRef]

- Yu, X.Y.; Mao, X.W. A preliminary discrimination model of a deep mining landslide and its application in the Guanwen coal mine. Bull. Eng. Geol. Environ. 2020, 79, 485–493. [Google Scholar] [CrossRef]

- Marschalko, M.; Yilmaz, I.; Bednarik, M.; Kubecka, K. Influence of underground mining activities on the slope deformation genesis: Doubrava Vrchovec, Doubrava Ujala and Staric case studies from Czech Republic. Eng. Geol. 2012, 147, 37–51. [Google Scholar] [CrossRef]

- Yang, D.; Qiu, H.; Ma, S.; Liu, Z.; Du, C.; Zhu, Y.; Cao, M. Slow surface subsidence and its impact on shallow loess landslides in a coal mining area. CATENA 2022, 209, 105830. [Google Scholar] [CrossRef]

- Waddington, A.; Kay, D.; Raper, W.; Wold, M.; Choi, X.; Hebblewhite, B.; Wybrow, P. Research into the Impacts of Mine Subsidence on the Strata and Hydrology of River Valleys and Development of Management Guidelines for Undermining Cliffs, Gorges and River Systems. Final Report on ACARP Research Project C8005, March 2001. Available online: https://www.acarp.com.au/abstracts.aspx?repId=C9067 (accessed on 5 August 2024).

- Zhang, C.; Mitra, R.; Oh, J.; Hebblewhite, B. Analysis of mining-induced valley closure movements. Rock Mech. Rock Eng. 2016, 49, 1923–1941. [Google Scholar] [CrossRef]

- Tokgöz, N. Case study of the Agacli landslide–gully complex during post-coal-mining reclamation and afforestation. Environ. Earth Sci. 2010, 59, 1559–1567. [Google Scholar] [CrossRef]

- Fathi Salmi, E.; Nazem, M.; Karakus, M. Numerical analysis of a large landslide induced by coal mining subsidence. Eng. Geol. 2017, 217, 141–152. [Google Scholar] [CrossRef]

- Kumar, V.S.; Chandrasekaran, S.S. Analysis of failure of high slope subjected to rainfall infiltration at Peringavu in Kerala, India. Eng. Fail. Anal. 2022, 138, 106423. [Google Scholar] [CrossRef]

- Wang, S.-H.; Yang, T.-J.; Zhang, Z.; Sun, Z.-H. Unsaturated seepage–stress–damage coupling and dynamic analysis of stability on discrete fractured rock slope. Environ. Earth Sci. 2021, 80, 660. [Google Scholar] [CrossRef]

- Yu, D.; Huang, Q.; Kang, X.; Liu, Y.; Chen, X.; Xie, Q.; Guo, Z. The unsaturated seepage process and mechanism of internal interfaces in loess-filled slopes during intermittent rainfall. J. Hydrol. 2023, 619, 129317. [Google Scholar] [CrossRef]

- Xu, J.; Du, X.; Zhao, X.; Li, L. Analytical stability analysis of rainfall-infiltrated slopes based on the Green-Ampt model. Int. J. Geomech. 2023, 23, 04022277. [Google Scholar] [CrossRef]

- Wu, L.Z.; Selvadurai, A.P.S. Rainfall infiltration-induced groundwater table rise in an unsaturated porous medium. Environ. Earth Sci. 2016, 75, 135. [Google Scholar] [CrossRef]

- Kim, Y.; Jeong, S. Modeling of shallow landslides in an unsaturated soil slope using a coupled model. Geomech. Eng. 2017, 13, 353–370. [Google Scholar] [CrossRef]

- Shreedharan, S.; Kulatilake, P.H.S.W. Discontinuum-equivalent continuum analysis of the stability of tunnels in a deep coal mine using the Distinct Element Method. Rock Mech. Rock Eng. 2016, 49, 1903–1922. [Google Scholar] [CrossRef]

- Zhang, K.; Yang, T.; Bai, H.; Gamage, R.P. Longwall mining-induced damage and fractures: Field measurements and simulation using FDM and DEM coupled method. Int. J. Geomech. 2018, 18, 04017127. [Google Scholar] [CrossRef]

- Li, J.; Gao, Y.; Yang, T.; Zhang, P.; Zhao, Y.; Deng, W.; Liu, H.; Liu, F. Integrated simulation and monitoring to analyze failure mechanism of the anti-dip layered slope with soft and hard rock interbedding. Int. J. Min. Sci. Technol. 2023, 33, 1147–1164. [Google Scholar] [CrossRef]

- Choi, Y.; Park, H.-D.; Sunwoo, C. Flood and gully erosion problems at the Pasir open pit coal mine, Indonesia: A case study of the hydrology using GIS. Bull. Eng. Geol. Environ. 2008, 67, 251–258. [Google Scholar] [CrossRef]

- Stupar, D.I.; Roser, J.; Vulic, M. Investigation of Unmanned Aerial Vehicles-based photogrammetry for large mine subsidence monitoring. Minerals 2020, 10, 196. [Google Scholar] [CrossRef]

- Costabile, P.; Costanzo, C.; Ferraro, D.; Macchione, F.; Petaccia, G. Performances of the new HEC-RAS version 5 for 2-D hydrodynamic-based rainfall-runoff simulations at basin scale: Comparison with a state-of-the art model. Water 2020, 12, 2326. [Google Scholar] [CrossRef]

- Dasallas, L.; Kim, Y.; An, H. Case study of HEC-RAS 1D-2D coupling simulation: 2002 Baeksan flood event in Korea. Water 2019, 11, 2048. [Google Scholar] [CrossRef]

- Shiferaw, H.; Zenebe, A.; Yazew, E.; Yisak, B.; Girma, A.; Araya, M.; Zenebe, G.; Giannini, A. Characterization of flood and drought hazards on the Gereb-Geba water supply dam in the semi-arid northern Ethiopian highlands. Geomat. Nat. Hazards Risk 2024, 15, 2290846. [Google Scholar] [CrossRef]

- Gao, Y.; Li, J.; Yang, T.; Meng, L.; Deng, W.; Zhang, P. Formation of pit lake and slope stability following mine closure: A case study of Fushun West Open-pit Mine. Geomat. Nat. Hazards Risk 2024, 15, 2340612. [Google Scholar] [CrossRef]

- Nian, G.; Chen, Z.; Zhang, L.; Bao, M.; Zhou, Z. Three-dimensional stability analysis of unsaturated slopes under variable rainfall conditions using a numerical method. Bull. Eng. Geol. Environ. 2023, 82, 59. [Google Scholar] [CrossRef]

- Ju, J.; Xu, J. Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 7.0m height chocks. Int. J. Rock Mech. Min. Sci. 2013, 58, 46–54. [Google Scholar] [CrossRef]

- Cheng, G.; Yang, T.; Liu, H.; Wei, L.; Zhao, Y.; Liu, Y.; Qian, J. Characteristics of stratum movement induced by downward longwall mining activities in middle-distance multi-seam. Int. J. Rock Mech. Min. Sci. 2020, 136, 104517. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, X.; Tan, Y.; Elsworth, D.; Shang, J.; Song, D.; Liu, X.; Yan, F. Numerical study of mechanical properties and microcrack evolution of double-layer composite rock specimens with fissures under uniaxial compression. Eng. Fract. Mech. 2023, 289, 109403. [Google Scholar] [CrossRef]

- Yang, H.; Cao, S.; Li, Y.; Fan, Y.; Wang, S.; Chen, X. Assessment of excavation broken zone around gateways under various geological conditions: A case study in Sichuan Province, China. Minerals 2016, 6, 72. [Google Scholar] [CrossRef]

- Patel, D.P.; Ramirez, J.A.; Srivastava, P.K.; Bray, M.; Han, D. Assessment of flood inundation mapping of Surat city by coupled 1D/2D hydrodynamic modeling: A case application of the new HEC-RAS 5. Nat. Hazard. 2017, 89, 93–130. [Google Scholar] [CrossRef]

- Rahmati, O.; Zeinivand, H.; Besharat, M. Flood hazard zoning in Yasooj region, Iran, using GIS and multi-criteria decision analysis. Geomat. Nat. Hazards Risk 2016, 7, 1000–1017. [Google Scholar] [CrossRef]

- Sun, Y.; Zuo, J.; Karakus, M.; Wang, J. Investigation of movement and damage of integral overburden during shallow coal seam mining. Int. J. Rock Mech. Min. Sci. 2019, 117, 63–75. [Google Scholar] [CrossRef]

- Rossman, L.A. Storm Water Management Model User’s Manual, Version 5.0; National Risk Management Research Laboratory, Office of Research and Development, US Environmental Protection Agency: Cincinnati, OH, USA, 2010. [Google Scholar]

- Liang, Z.; Wang, D.; Li, G.; Sun, G.; Yu, M.; Xia, D.; Ding, C. Three-dimensional stability calculation method for high and large composite slopes formed by mining stope and inner dump in adjacent open pits. Int. J. Min. Sci. Technol. 2024, 34, 507–520. [Google Scholar] [CrossRef]

- He, X.; Zhao, Y.; Yang, K.; Zhang, C.; Han, P. Development and formation of ground fissures induced by an ultra large mining height longwall panel in Shendong mining area. Bull. Eng. Geol. Environ. 2021, 80, 7879–7898. [Google Scholar] [CrossRef]

- Sui, W.; Hang, Y.; Ma, L.; Wu, Z.; Zhou, Y.; Long, G.; Wei, L. Interactions of overburden failure zones due to multiple-seam mining using longwall caving. Bull. Eng. Geol. Environ. 2015, 74, 1019–1035. [Google Scholar] [CrossRef]

- Li, X.; Li, D. A numerical procedure for unsaturated seepage analysis in rock mass containing fracture networks and drainage holes. J. Hydrol. 2019, 574, 23–34. [Google Scholar] [CrossRef]

- Xu, Y.; Ma, L.; Yu, Y. Water preservation and conservation above coal mines using an innovative approach: A case study. Energies 2020, 13, 2818. [Google Scholar] [CrossRef]

- Zhu, X.; Zha, F.; Guo, G.; Zhang, P.; Cheng, H.; Liu, H.; Yang, X. Subsidence control design method and application to backfill-strip mining technology. Adv. Civ. Eng. 2021, 2021, 5177174. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, S.-E.; Deng, K.-Z.; Wang, P.; Fan, H.-D. Subsidence mechanism and stability assessment methods for partial extraction mines for sustainable development of mining cities-a review. Sustainability 2018, 10, 113. [Google Scholar] [CrossRef]

- Shi, H.; Zhang, Y.; Tang, L. Physical test of fracture development in the overburden strata above the goaf and diffusion process of permeable grout slurry. Bull. Eng. Geol. Environ. 2021, 80, 4791–4802. [Google Scholar] [CrossRef]

- Du, Y.; Li, H.; Chicas, S.D.; Huo, L. Progress and perspectives of geotechnical anchor bolts on slope engineering in China. Front. Environ. Sci. 2022, 10, 928064. [Google Scholar] [CrossRef]

- Faiz, H.; Ng, S.; Rahman, M. A state-of-the-art review on the advancement of sustainable vegetation concrete in slope stability. Constr. Build. Mater. 2022, 326, 126502. [Google Scholar] [CrossRef]

- Yilmaz, I. Landslide susceptibility mapping using frequency ratio, logistic regression, artificial neural networks and their comparison: A case study from Kat landslides (Tokat-Turkey). Comput. Geosci. 2009, 35, 1125–1138. [Google Scholar] [CrossRef]

- Nandi, A.; Shakoor, A. A GIS-based landslide susceptibility evaluation using bivariate and multivariate statistical analyses. Eng. Geol. 2010, 110, 11–20. [Google Scholar] [CrossRef]

| Lithology | Bulk Modulus (GPa) | Shear Modulus (GPa) | Density (kg·m−3) | Cohesion (MPa) | Tensile Strength (MPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|---|

| Sandstone | 16.7 | 7.7 | 2700 | 5.6 | 3.5 | 29 |

| Sand-mudstone interbed | 13.4 | 6.62 | 2600 | 4.95 | 3.25 | 31 |

| Sandy mudstone | 14.2 | 6.5 | 2520 | 4.36 | 3.2 | 34 |

| Coal | 5.2 | 2.78 | 1460 | 2.4 | 1.28 | 25 |

| Limestone | 16.57 | 4.53 | 2750 | 5.9 | 3.9 | 38 |

| Joint Material | Joint Normal Stiffness (GPa) | Joint Shear Stiffness (GPa) | Joint Cohesion (MPa) | Joint Friction Angle (°) | Joint Tensile Strength (MPa) | Joint Type |

|---|---|---|---|---|---|---|

| 1 | 140 | 14 | 2 | 28 | 1 | Bedding joint |

| 2 | 100 | 10 | 4 | 35 | 2 | Vertical joint |

| Thickness (m) | Lithology | Strata Classification after Coal Mining | Hydraulic Conductivity (m/s) | Porosity |

|---|---|---|---|---|

| 70 | Sand-mudstone interbed | Repeated disturbance zone | 1.704 × 10−5 | 0.24 |

| 9 | Sandy mudstone | |||

| 17 | Sand-mudstone interbed | |||

| 4 | Nos. 2 + 3 coal seam | |||

| 15 | Sand-mudstone interbed | Fractured zone | 2.336 × 10−5 | 0.22 |

| 3 | No.4 coal seam | |||

| 5 | Sandy mudstone | |||

| 9 | Sand-mudstone interbed | |||

| 20 | Sandstone | |||

| 2 | Limestone | Caved zone | 5.247 × 10−5 | 0.32 |

| 7 | Sandstone | |||

| 3 | Limestone | |||

| 7 | Sandstone | |||

| 4 | Limestone | |||

| 4 | No. 8 coal seam | No. 8 coal seam | 7.018 × 10−7 | 0.15 |

| 12 | Sand-mudstone interbed | Floor failure zone | 2.036 × 10−5 | 0.20 |

| 2 | No. 9 coal seam | Bedrock zone | 4.522 × 10−7 | 0.12 |

| 11 | Sand-mudstone interbed |

| Coal Mine | Overview of Mining Panels | Height of Caved Zone/m | ||||||

|---|---|---|---|---|---|---|---|---|

| Mining Panel | Length/m | Mining Thickness/m | Burial Depth/m | Coal Seam Inclination Angle/° | Coal Seam | The Roof of the Coal Seam | ||

| Dongqu | No. 28806 | 226 | 4.83 | 333 | 4 | No. 8 | Limestone | 20.98 |

| No. 28206 | 170 | 4.79 | 255 | 4 | No. 8 | Limestone | 18.32 | |

| No. 18311 | 179 | 3.77 | 231 | 4 | No. 8 | Mudstone | 19.28 | |

| Malan | No. 10702 | 216 | 2.08 | 402 | 4 | Nos. 2 + 3 | Sandy mudstone | 21.00 |

| No. 12511 | 196 | 2.47 | 359 | 3 | Nos. 2 + 3 | Sandy mudstone | 22.00 | |

| No. 18301 | 225 | 4.03 | 470 | 4 | No. 8 | Limestone | 19.00 | |

| Tunlan | No. 28120 | 235 | 3.33 | 431 | 4 | No. 8 | Limestone | 27.58 |

| Guandi | No. 22611 | 220 | 2.99 | 679 | 6 | Nos. 2 + 3 | Sandy mudstone | 20.70 |

| Xiqu * | No. 28306 | 220 | 4.00 | 147 | 4 | No. 8 | Sandy mudstone, limestone | 23.00 |

| Type | Area (m2) | Proportion (%) | Manning’s Roughness Coefficient |

|---|---|---|---|

| Arable land | 1,034,953.85 | 19.02 | 0.03 |

| Woodland | 2,365,485.31 | 43.47 | 0.15 |

| Grassland | 1,209,895.56 | 22.23 | 0.04 |

| Shrubland | 208,735.47 | 3.84 | 0.07 |

| Wetland | 785.90 | 0.01 | 0.05 |

| Water | 550.13 | 0.01 | 0.025 |

| Artificial surface | 78,432.98 | 1.44 | 0.035 |

| Bare land | 543,293.80 | 9.98 | 0.025 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Yang, T.; Deng, W.; Liu, H.; Gao, Y.; Ma, K.; Zhao, Y.; Sun, D. Characteristics of Overburden Damage and Rainfall-Induced Disaster Mechanisms in Shallowly Buried Coal Seam Mining: A Case Study in a Gully Region. Sustainability 2024, 16, 7538. https://doi.org/10.3390/su16177538

Liu Y, Yang T, Deng W, Liu H, Gao Y, Ma K, Zhao Y, Sun D. Characteristics of Overburden Damage and Rainfall-Induced Disaster Mechanisms in Shallowly Buried Coal Seam Mining: A Case Study in a Gully Region. Sustainability. 2024; 16(17):7538. https://doi.org/10.3390/su16177538

Chicago/Turabian StyleLiu, Yilong, Tianhong Yang, Wenxue Deng, Honglei Liu, Yuan Gao, Kai Ma, Yong Zhao, and Dongdong Sun. 2024. "Characteristics of Overburden Damage and Rainfall-Induced Disaster Mechanisms in Shallowly Buried Coal Seam Mining: A Case Study in a Gully Region" Sustainability 16, no. 17: 7538. https://doi.org/10.3390/su16177538