A Comparative Life Cycle Assessment (LCA) of a Composite Bamboo Shear Wall System Developed for El Salvador

Abstract

:1. Introduction

1.1. Background

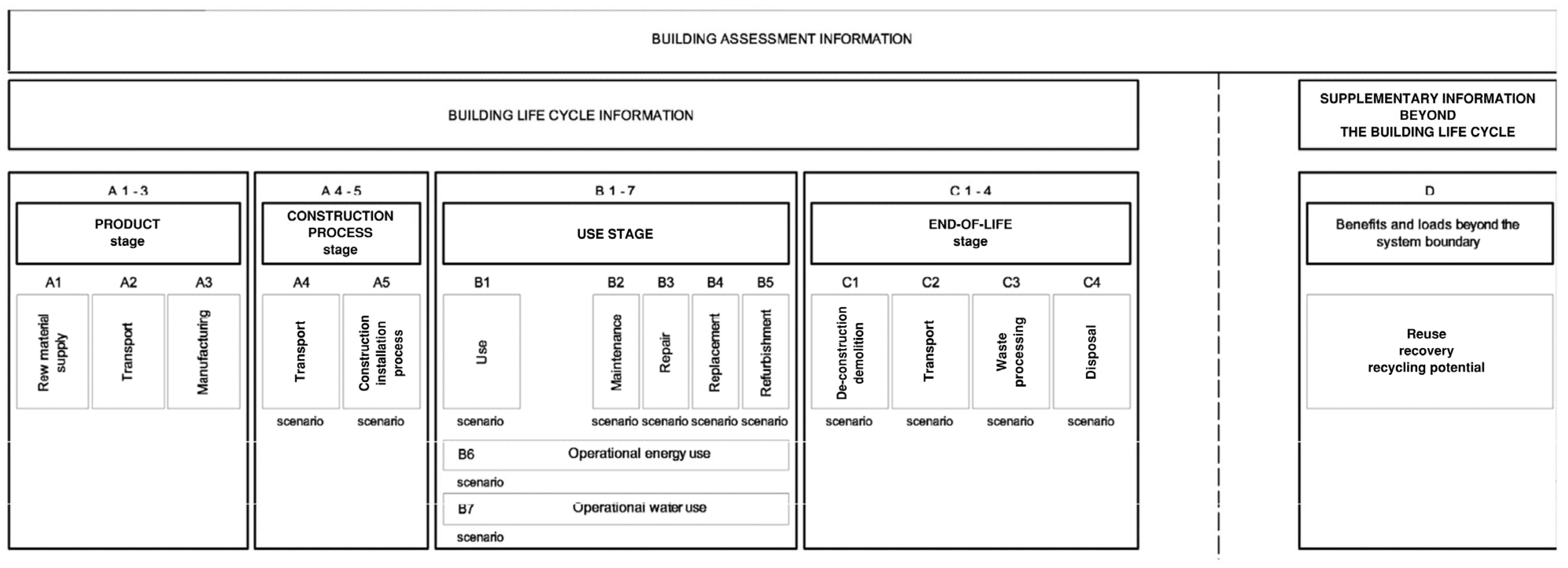

1.2. Life Cycle Assessment (LCA)

- A1 to A5—upfront carbon modules, which include the following:

- a.

- A1 to A3—product modules (raw material supply, transport, and manufacturing).

- b.

- A4 and A5—construction of the building (transport of materials to site and construction/installation process).

- B1 to B7—in-use modules, which include the following:

- a.

- B1 to B5, use, maintenance, repair, replacement, and refurbishment.

- b.

- B6 and B7, operational modules (energy and water use).

- C—end-of-life modules.

- D—beyond-life benefits and loads beyond the system boundaries.

- Section 2—Materials and Methods—includes step (i) definition of goal and scope, step (ii) material inventory analysis, and step (iii) impact assessment methodology and assumptions.

- Section 3—Results—includes the outputs of the impact assessment and sensitivity analyses.

- Section 4—Discussion—includes step (iv): interpretation of results.

1.3. Literature Review

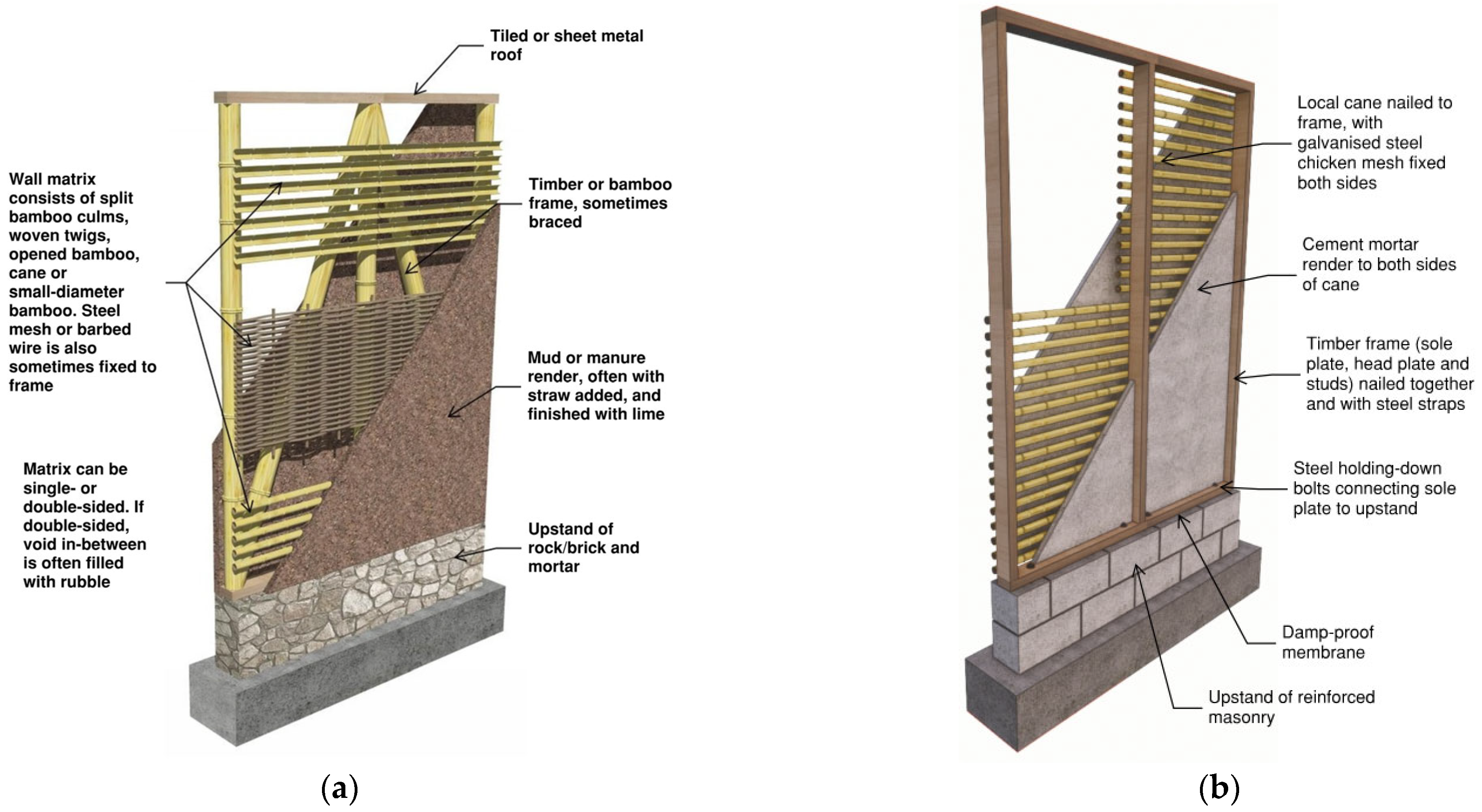

1.3.1. Bamboo Shear Wall Technology in Colombia

1.3.2. Bamboo Shear Wall Technology in the Philippines

1.3.3. Bio-Based Materials in LCAs

2. Materials and Methods

2.1. Setting Out the Goal and Scope

2.1.1. Goal and Scope

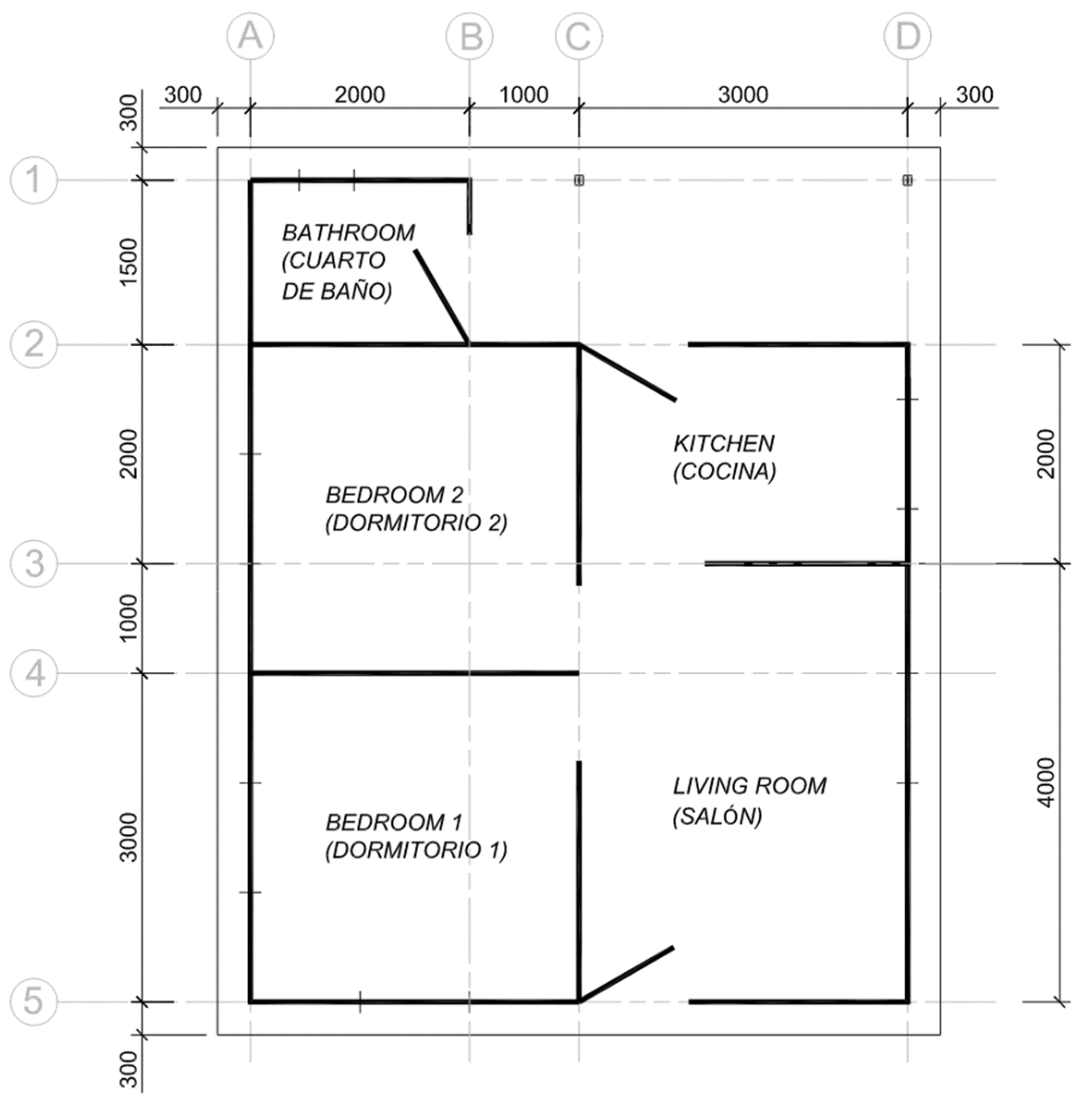

2.1.2. Functional Unit Requirements

- Adequacy: must provide all that is necessary for a decent quality of life; the house must be well designed to house residents comfortably.

- Structural safety: must meet national building codes for wind and earthquakes; does not put residents at risk to health issues caused by the building materials/design.

- Affordability: must be affordable for people living in rural communities in El Salvador.

- Durability: must have a minimum 50-year design life, during which the building is expected to perform its intended purposes and be serviceable with minimum maintenance and repair.

- Sustainability: must have a minimal environmental impact over the building’s lifespan, without compromising any of the other four criteria.

- A CBSW design developed for the El Salvadoran context;

- A reinforced masonry house.

2.1.3. CBSW Functional Unit

2.1.4. Reinforced Masonry Functional Unit

2.1.5. Design/Service Life

2.2. Reasoning for Scope Limitations

2.2.1. Including Upfront Carbon (A1 to A5)

- Connection elements have been rounded up to the nearest kg of material.

- Cane quantities have been increased by 20% to account for damaged cane in the delivery.

- Boron quantities have been increased by 50% boron to account for liquid lost during the treatment method.

- Chicken mesh quantities have been increased by 15% to account for offcuts.

- Offcuts of reinforcement have not been included as wastage, as it is assumed that they can be used for small elements such as shear links of beams.

- Offcuts of timber have not been included as wastage, as it is assumed that they can be used for infill pieces, stubs, and noggins in the design.

- Raw materials for the mixes of concrete (cement, sand, and aggregate) have been included in exact amounts, as informed by procurement information from previous project experience. It is likely leftover material from bags of product can be used on other projects, so it is realistic to compare the embodied carbon of the exact amounts used in each building assuming minimal wastage.

2.2.2. Including the Replacement (B4) Module

2.2.3. Exclusion of Remaining Use Modules (B1 to B3 and B5)

2.2.4. Exclusion of Operational Carbon (B6 and B7)

2.2.5. Exclusion of End-of-Life Modules (C)

2.2.6. Exclusion of Beyond-Life Modules (D)

- (a)

- Report biogenic carbon separately, if only considering modules A1 to A5;

- (b)

- If considering modules A to C, biogenic carbon should be included within the total value reported.

2.3. Life Cycle Inventory

2.3.1. Process and Material Quantities

2.3.2. (A1 and A3) Raw Material Extraction and Component Manufacturing Assumptions

2.3.3. (A2 and A4) Transport Assumptions

2.3.4. (A5) Construction Assumptions

2.3.5. (B4) Replacement Assumptions

2.4. Life Cycle Impact Assessment

- It grows in the wild, not from managed plantations. No fertiliser, irrigation, or management of plantations is conducted.

- Harvesting is conducted manually via machete.

- The rotation period (time to maturity) is 9 months.

- Wastage is around 20% (including rotten culms and offcuts).

- Drying is completely natural, to around 14–16% moisture content.

- It is treated with disodium octoborate tetrahydrate to achieve a boric acid equivalent retention of 4 kg/m3.

- Treatment and processing are conducted on site where the houses are built.

2.5. Biogenic Carbon Calculation

- The carbon content of the timber and cane was assumed to be 0.5 kg carbon per kg dry mass.

- The biogenic carbon is assumed to be stored for 50 years, the buildings’ service life.

- The “Cool Temperate/Pine all (Pinus)” option was selected for the timber.

- The “Tropical moist/wet/Bamboo (Phyllostachy pubescens)” option was chosen for the cane, since this was considered the best option to represent the cane. Cane and bamboo do not have root decay once the biomass is chopped down for use, compared to trees, so it is more appropriate to use a biogenic carbon value for a bamboo. The rotation cycle of this species of cane is only 1 year compared to bamboo which has a rotation cycle of 5 years (as defined in the WWF Tool Database [49]), so using a value for bamboo with a longer rotation cycle is likely to give a conservative estimate for the cane.

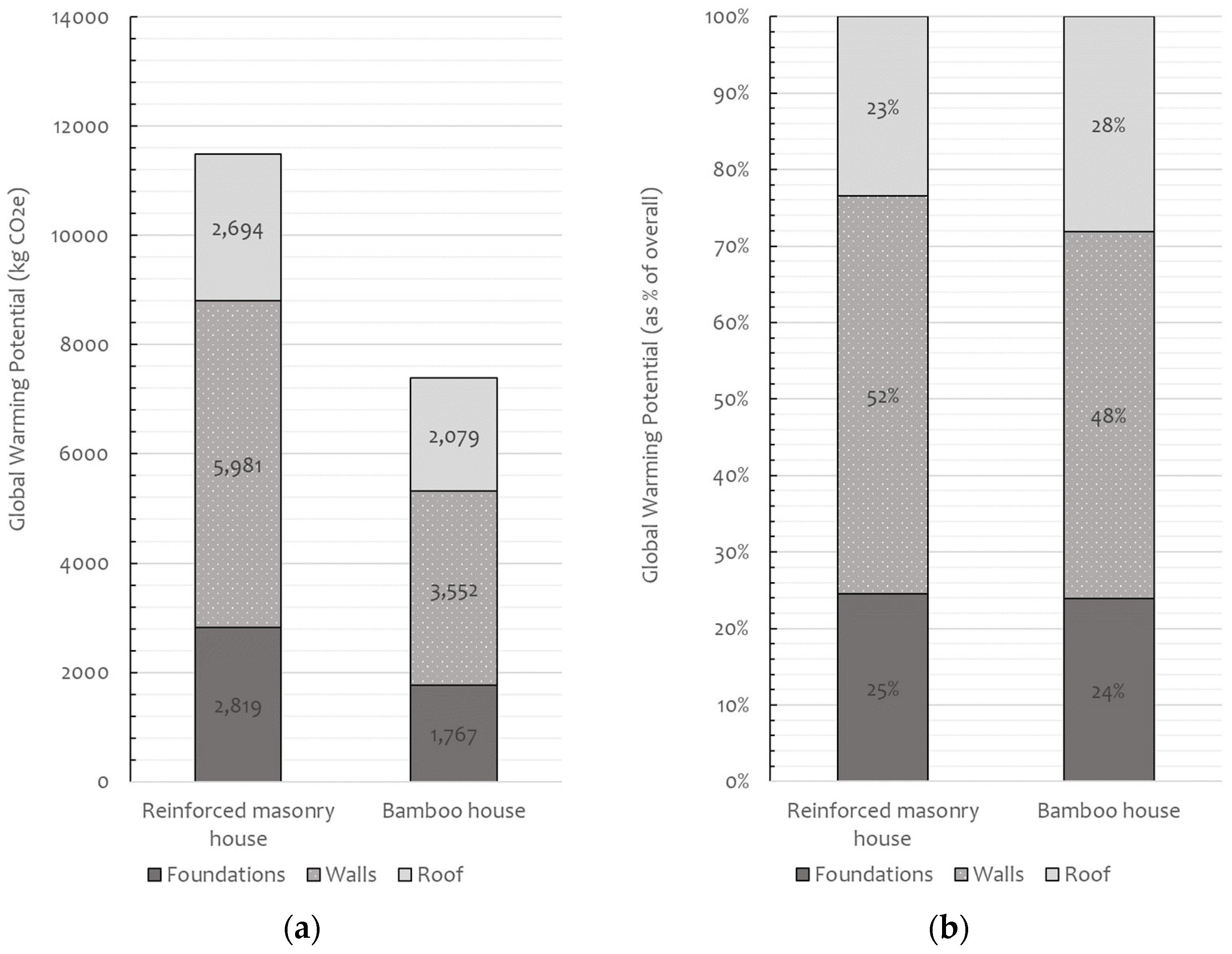

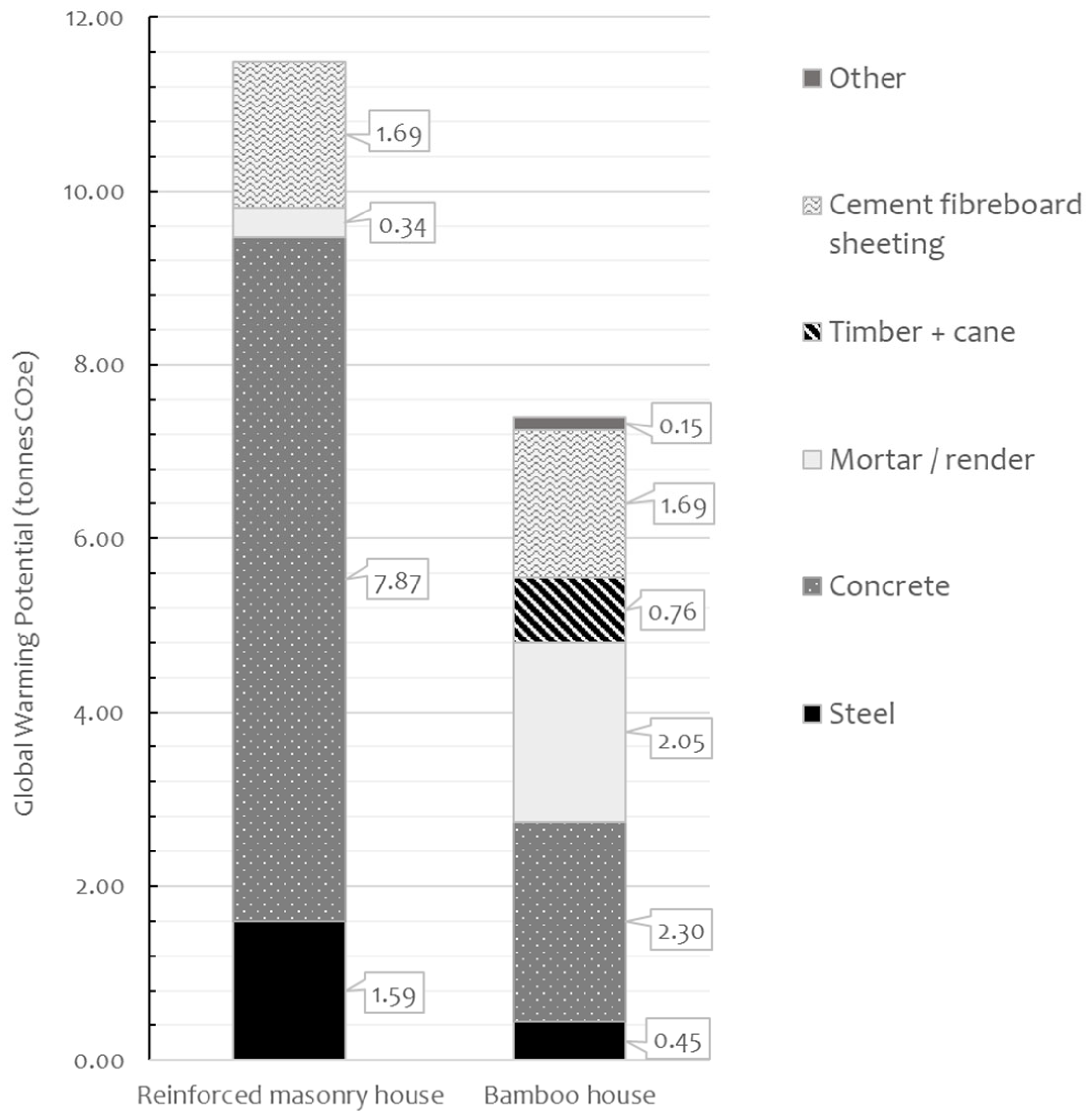

3. Results

3.1. Biogenic Carbon

3.2. Sensitivity on Transport Distances

4. Discussion

4.1. Limiting Scope of LCA

4.2. Biogenic Carbon

4.2.1. End-of-Life Considerations and Delayed Re-Emission of CO2

- Long-Term Fixation (LTF).

- In total, 50% of the material being burnt as biofuel, and the remaining being reused or sent to landfill, of which 10% is released as CO2 and 1% is released as CH4.

4.2.2. Forest Type

4.3. Environmental Impact Factors

4.4. Data Inputs

4.5. An Efficient Reference House Design

4.6. Comparison with Other Assessments of CBSW Systems

4.6.1. Colombian CBSW House

4.6.2. Filipino CBSW House

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UN-Habitat. Priorities 2022–2023: Adequate Housing, Cities and Climate Change and Localising the Sustainable Development Goals; UN-Habitat: Nairobi, Kenya, 2022. [Google Scholar]

- United Nations SDG 11. Available online: https://sdgs.un.org/goals/goal11 (accessed on 1 June 2024).

- Arce, R.; Guevara, P. Estado de la Vivienda en Centroamérica; Habitat for Humanity: San José, Costa Rica, 2016. [Google Scholar]

- Solera, E. Characterization of the Dry Corridor in Central America’s Northern Triangle—Executive Summary; Habitat for Humanity: San José, Costa Rica, 2021. [Google Scholar]

- WFP El Salvador Country Brief April 2022—Situation Report. Available online: https://reliefweb.int/report/el-salvador/wfp-el-salvador-country-brief-april-2022 (accessed on 1 June 2024).

- Asif, M. 2—Sustainability of timber, wood and bamboo in construction. In Sustainability of Construction Materials a Volume in Woodhead Publishing Series in Civil and Structural Engineering; Khatib, J.M., Ed.; Woodhead Publishing: Cambridge, UK, 2009; pp. 31–54. [Google Scholar]

- Escamilla, E.Z.; Habert, G.; Daza, J.F.C.; Archilla, H.F.; Fernández, J.S.E.; Trujillo, D. Industrial or Traditional Bamboo Construction? Comparative Life Cycle Assessment (LCA) of Bamboo-Based Buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef]

- Kaminski, S.; Lawrence, A.; Coates, K.; Foulkes, L. A low-cost vernacular improved housing design. Special Issue on Humanitarian Engineering. In Proceedings of the Institution of Civil Engineers; Thomas Telford Ltd.: London, UK, 2016; Volume 169, pp. 25–31. [Google Scholar]

- Kaminski, S.; Lawrence, A.; Trujillo, D. Design Guide for Engineered Bahareque Housing; International Network for Bamboo and Rattan (INBAR): Beijing, China, 2016. [Google Scholar]

- López, M.; Bommer, J.; Méndez, P. The Seismic Performance of Bahareque Dwellings in El Salvador. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Kaminski, S.; Grant, D.; Harries, K.; Trujillo, D.; Lopez, L. Seismic performance of whole culm bamboo structures and recommendations for design using ISO 22156. In Proceedings of the 18th World Conference on Earthquake Engineering 2024 (18WCEE 2024), Milan, Italy, 30 June–5 July 2024. [Google Scholar]

- Kaminski, S.; Lopez, L.; Trujillo, D.; Escamilla, E. Composite bamboo shear walls—A shear wall system for affordable and sustainable housing in tropical developing countries. In Proceedings of the Society for Earthquake and Civil Engineering Dynamics (SECED 2023) Conference, Cambridge, UK, 14–15 September 2023. [Google Scholar]

- International Organization for Standardization (ISO). ISO 22156:2021 (en)—Bamboo Structures—Bamboo Culms—Structural Design, 2nd ed.; ISO: Geneva, Switzerland, 2021. [Google Scholar]

- El Salvador Project. Low-Cost Earthquake-Resistant Housing Project Report; Imperial College London: London, UK, 2012. [Google Scholar]

- Rashid, A.F.A.; Yusoff, S. A review of life cycle assessment method for building industry. Renew. Sustain. Energy Rev. 2015, 45, 244–248. [Google Scholar] [CrossRef]

- Fava, J.; Baer, S.; Cooper, J. Increasing Demands for Life Cycle Assessments in North America. J. Ind. Ecol. 2009, 13, 491–494. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO14040:2006 Environmental Management—Life Cycle Assessment—Principles and Framework, 2nd ed.; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- BS EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. BSI: London, UK, 2011.

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Roberts, M.; Allen, S.; Coley, D. Life cycle assessment in the building design process—A systematic literature review. Build. Environ. 2020, 185, 107274. [Google Scholar] [CrossRef]

- Mattinzioli, T.; Lo Presti, D.; Jiménez del Barco Carrión, A. A critical review of life cycle assessment benchmarking methodologies for construction materials. Sustain. Mater. Technol. 2022, 33, e00496. [Google Scholar] [CrossRef]

- Bahramian, M.; Yetilmezsoy, K. Life cycle assessment of the building industry: An overview of two decades of research (1995–2018). Energy Build. 2020, 219, 109917. [Google Scholar] [CrossRef]

- BS EN 15804:2012+A2:2019; Sustainability of Construction Works—Environmental Product Declarations Product Category of Construction Products. BSI: London, UK, 2012.

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Murphy, R.J.; Trujillo, D.; Londono, X. Life Cycle Assessment (LCA) of a Guadua House. In Proceedings of the Simposio Internacional Guadua 2004, Pereira, Colombia, 27 September–2 October 2004. [Google Scholar]

- Salzer, C.; Wallbaum, H.; Ostermeyer, Y.; Kono, J. Environmental performance of social housing in emerging economies: Life cycle assessment of conventional and alternative construction methods in the Philippines. Int. J. Life Cycle Assess. 2017, 22, 1785–1801. [Google Scholar] [CrossRef]

- Ministry of Housing, Spatial Planning and the Environment. Eco-Indicator 99 Manual for Designers|A Damage Oriented Method for Life Cycle Impact Assessment; PRé Sustainability (Ministry of Housing, Spatial Planning and the Environment Communications Directorate): The Hague, The Netherlands, 2000. [Google Scholar]

- Hoxha, E.; Passer, A.; Saade, M.R.M.; Trigaux, D.; Shuttleworth, A.; Pittau, F.; Allacker, K.; Habert, G. Biogenic carbon in buildings: A critical overview of LCA methods. Build. Cities 2020, 1, 504–524. [Google Scholar] [CrossRef]

- Fouquet, M.; Levasseur, A.; Margni, M.; Lebert, A.; Lasvaux, S.; Souyri, B.; Buhé, C.; Woloszyn, M. Methodological challenges and developments in LCA of low energy buildings: Application to biogenic carbon and global warming assessment. Build. Environ. 2015, 90, 51–59. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M.; Svanström, M. Life cycle assessment of construction materials: The influence of assumptions in end-of-life modelling. Int. J. Life Cycle Assess. 2014, 19, 723–731. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Samson, R. Biogenic Carbon and Temporary Storage Addressed with Dynamic Life Cycle Assessment. J. Ind. Ecol. 2013, 17, 117–128. [Google Scholar] [CrossRef]

- The Masonry Society. TMS 402/602-22: Building Code Requirements and Specification for Masonry Structures; The Masonry Society: Longmont, CO, USA, 2022. [Google Scholar]

- American Society of Civil Engineers (ASCE). Seismic Evaluation and Retrofit of Existing Buildings, ASCE41-22; ASCE: Reston, VA, USA, 2022. [Google Scholar]

- Kaminski, S. Engineered Bamboo houses for low-income communities in Latin America. Struct. Eng. 2013, 91, 14–23. [Google Scholar]

- Kaminski, S.; Harries, K.; Lopez, L.; Trujillo, D. Durability of Whole Culm Bamboo: Facts, misconceptions and the new ISO 22156 Framework. In Proceedings of the International conference on non-conventional materials and technologies (NOCMAT) 2022, Virtual, 7–23 June 2022. [Google Scholar]

- BS 8500-1: 2015+A2:2019; Concrete—Complementary British Standard to BS EN 206: Part 1: Method of Specifying and Guidance for the Specifier. BSI: London, UK, 2020.

- Gibbons, O.P.; Orr, J.J.; Archer-Jones, C.; Arnold, W.; Green, D. How to Calculate Embodied Carbon, 2nd ed.; IStructE Ltd.: London, UK, 2022. [Google Scholar]

- Greater London Authority. London Plan Guidance—Whole Life-Cycle Carbon Assessments; Greater London Authority: London, UK, 2022. [Google Scholar]

- RICS. Whole Life Carbon Assessment for the Built Environment, 2nd ed.; The Royal Institution of Chartered Surveyors (RICS): London, UK, 2017. [Google Scholar]

- One Click LCA. Available online: https://www.oneclicklca.com (accessed on 1 June 2024).

- Life Cycle Carbon—Global. Available online: https://oneclicklca.zendesk.com/hc/en-us/articles/360016978800-Life-Cycle-Carbon-Global (accessed on 1 June 2024).

- Databases Available in One Click LCA. Available online: https://oneclicklca.zendesk.com/hc/en-us/articles/360015064399-Databases-available-in-One-Click-LCA (accessed on 1 June 2024).

- Escamilla, E.Z.; Habert, G. Global or local construction materials for post-disaster reconstruction? Sustainability assessment of twenty post-disaster shelter designs. Build. Environ. 2015, 92, 692–702. [Google Scholar] [CrossRef]

- El Salvador Summary. Available online: https://www.britannica.com/summary/El-Salvador (accessed on 1 June 2024).

- Sea Route & Distance. Available online: http://ports.com/sea-route/port-of-guangzhou-canton,china/port-of-acajutla,el-salvador (accessed on 1 June 2024).

- CML-IA Characterisation Factors. Available online: https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors (accessed on 1 June 2024).

- Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI). Available online: https://www.epa.gov/chemical-research/tool-reduction-and-assessment-chemicals-and-other-environmental-impacts-traci (accessed on 1 June 2024).

- Biogenic Carbon Footprint Calculator for Harvested Wood Products. Available online: https://www.worldwildlife.org/projects/biogenic-carbon-footprint-calculator-for-harvested-wood-products (accessed on 1 June 2024).

- Chan, C. The Mechanical Properties of the Local Cane In El Salvador and Its Utilisation in Wall Matrix Structure of Bespoke Housing. Master’s Thesis, Coventry University, Coventry, UK, 2014. [Google Scholar]

- Forest Products Laboratory. Wood Handbook: Wood as an Engineering Material, General Technical Report FPL-GTR-190, Centennial Edition; United States Department of Agriculture (USDA): Madison, WI, USA, 2010; Chapter 16; p. 5.

- Ding, G.K. Life Cycle Assessment in Buildings: An Overview of Methodological Approach. Encycl. Renew. Sustain. Mater. 2020, 4, 462–475. [Google Scholar]

| Goal | To evaluate and compare the environmental performance—solely in terms of global warming potential (GWP)—of adequate, safe, and affordable single-storey houses in El Salvador |

| Service life | 50 years |

| Functional unit | Single-storey house with 39 m2 internal floor area, which meets functional unit requirements outlined in Section 2.1.2 |

| Phases of LCA included in scope | Upfront carbon (A1 to A5) |

| Replacement (B4) | |

| Phases of LCA excluded from scope 1 | Use (B1), maintenance (B2), repair (B3), and refurbishment (B5) |

| Operational carbon (B6 and B7) | |

| End-of-life carbon (C) | |

| Beyond-life carbon (D) | |

| Impact categories | Global warming potential (kg CO2e) |

| Sensitivities | Transport assumptions |

| End-of-life scenarios | |

| Biogenic carbon |

| Building Element | Component | Quantity | Units | Specification | Source |

|---|---|---|---|---|---|

| Foundations | Blinding concrete | 0.25 | m3 | 1:3:9 mix * | National |

| Structural concrete | 3.68 | m3 | 1:2:4 mix * | National | |

| Reinforcement | 0.028 | m3 | Deformed Grade 70 | National | |

| Blockwork | 0.57 | m3 | 1:3:5 mix * | National | |

| Pointing mortar | 0.048 | m3 | 1:4 mix * | National | |

| Walls | Blockwork | 0.98 | m3 | 1:3:5 mix * | National |

| Structural concrete (infill) | 1.04 | m3 | 1:2:4 mix * | National | |

| Reinforcement | 0.005 | m3 | Deformed Grade 70 | National | |

| Pointing mortar | 0.082 | m3 | 1:4 mix * | National | |

| Timber | 1.84 | m3 | Grade 2 Southern Yellow Pine, 0.05 CA-C-treated | Imported (US) | |

| Cane | 0.66 | m3 | Gynerium Saggitatum | National local | |

| Boron | 3.95 | kg | Disodium octaborate tetrahydrate | National | |

| Chicken mesh | 122 | m2 | 13 × 13 × 0.7 galvanised steel | National | |

| Cement render | 5.07 | m3 | 1:5 mix * | National | |

| Steel plates | 0.0012 | m3 | Grade A36 | Imported (global) | |

| Nails | 3021 | No. | 2.7 × 50 mm ** | Imported (global) | |

| Nails | 2037 | No. | 3.75 × 75 mm ** | Imported (global) | |

| Nails | 180 | No. | 3.75 × 37.5 mm ** | Imported (global) | |

| Paint | 27 | m2 | White masonry paint | Imported (global) | |

| Damp-proof membrane | 8.75 | m2 | Heavy-duty plastic | Imported (global) | |

| Roof | Timber | 1.46 | m3 | Grade 2 Southern Yellow Pine, 0.05 CA-C-treated | Imported (US) |

| Steel plates | 0.0014 | m3 | Grade A36 | Imported (global) | |

| Nails | 860 | No. | 3.75 × 75 mm ** | Imported (global) | |

| Purlin screws | 220 | No. | 6 × 60 mm ** | Imported (global) | |

| Roof screws | 383 | No. | 6 × 150 mm ** | Imported (global) | |

| Cement fibreboard roof sheeting | 0.77 | m3 | 6 mm | National |

| Building Element | Component | Quantity | Units | Specification | Source |

|---|---|---|---|---|---|

| Foundations | Blinding concrete | 0.29 | m3 | 1:3:9 mix * | National |

| Structural concrete | 5.28 | m3 | 1:2:4 mix * | National | |

| Reinforcement | 0.053 | m3 | Deformed Grade 70 | National | |

| Blockwork | 1.50 | m3 | 1:3:5 mix * | National | |

| Pointing mortar | 0.13 | m3 | 1:4 mix * | National | |

| Walls | Blockwork | 7.52 | m3 | 1:3:5 mix * | National |

| Structural concrete (infill) | 8.17 | m3 | 1:2:4 mix * | National | |

| Reinforcement | 0.065 | m3 | Deformed Grade 70 | National | |

| Pointing mortar | 0.63 | m3 | 1:4 mix * | National | |

| Roof | Steel | 0.041 | m3 | 275 N/mm2 | Imported (global) |

| Roof screws | 383 | No. | 6 × 150 mm ** | Imported (global) | |

| Cement fibreboard roof sheeting | 0.77 | m3 | 6 mm | National |

| Component | Total Mass in Building (kg) | Biogenic Carbon Storage (kg CO2e/kg) | Carbon Sequestered (kg CO2e) |

|---|---|---|---|

| Cane | 540 | −0.68 | −367 |

| Timber | 1683 | −0.46 | −772 |

| Scenario | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Service life (years) | 50 | 50 | 45 | 25 | 10 | 1 |

| Carbon sequestered (t CO2e) | −1.14 | −1.14 | −0.96 | −0.27 | +0.22 | +0.50 |

| Carbon released into atmosphere (t CO2e) | 0.00 | +0.94 | +0.94 | +0.94 | +0.94 | +0.94 |

| Net biogenic carbon (t CO2e) | −1.14 | −0.19 | −0.01 | +0.68 | +1.16 | +1.44 |

| Total GWP of CBSW house (t CO2e) | 6.26 | 7.20 | 7.39 | 8.07 | 8.56 | 8.84 |

| % reduction in GWP of reinforced masonry house compared to CBSW house | 46% | 37% | 36% | 30% | 26% | 23% |

| Route (i) | Route (ii) | Average | ||||

|---|---|---|---|---|---|---|

| Max | Min | Max | Min | |||

| Distance by land (km) | Plantation to port 1, US | 1610 | 480 | 2300 | 870 | 1315 |

| Port 2 to vendor | 80 | 80 | 380 | 380 | 230 | |

| Vendor to community | 60 | 60 | 60 | 60 | 60 | |

| Total | 1750 | 620 | 2740 | 1310 | 1605 | |

| Distance by sea (km) | 5430 | 5430 | 1800 | 1800 | 3615 | |

| Total GWP of CBSW house (t CO2e) | 7.45 | 7.18 | 7.65 | 7.31 | 7.40 | |

| % difference | +1% | −3% | +3% | −1% | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Young, L.; Kaminski, S.; Kovacs, M.; Zea Escamilla, E. A Comparative Life Cycle Assessment (LCA) of a Composite Bamboo Shear Wall System Developed for El Salvador. Sustainability 2024, 16, 7602. https://doi.org/10.3390/su16177602

Young L, Kaminski S, Kovacs M, Zea Escamilla E. A Comparative Life Cycle Assessment (LCA) of a Composite Bamboo Shear Wall System Developed for El Salvador. Sustainability. 2024; 16(17):7602. https://doi.org/10.3390/su16177602

Chicago/Turabian StyleYoung, Louisa, Sebastian Kaminski, Mike Kovacs, and Edwin Zea Escamilla. 2024. "A Comparative Life Cycle Assessment (LCA) of a Composite Bamboo Shear Wall System Developed for El Salvador" Sustainability 16, no. 17: 7602. https://doi.org/10.3390/su16177602