Abstract

Smart manufacturing encompasses a category of manufacturing that employs computer-integrated capabilities and technologies to enhance supply chain optimization, production efficiency, and recyclability. Yet, limited studies have been conducted to optimize these prospects from the perspective of low-resource countries where such innovative studies have not been adequately explored. This paper aims to examine the implications of smart manufacturing practices (Smart Procurement, Smart Supply Chain, Smart Production Planning and Control, Automation and Industrial Robot, and Supply Chain Configuration) on pro-environmental behaviour and develop a baseline moderated mediation model to explain the relationship between smart manufacturing and pro-environmental behaviour as well as the indirect effects of environmental awareness and green dynamic capability. This study employs a quantitative research approach, utilizing inductive reasoning and an explanatory design. Data from 382 manufacturing enterprises in Ghana were collected through a cross-sectional survey. We tested our hypotheses using SMART-PLS software version 3.8.9 and SEM technique. The study found a strong and positive relationship between smart manufacturing practices and pro-environmental behaviour. Additionally, the relationship between smart manufacturing and pro-environmental behaviour is influenced by green dynamic capacity and environmental orientation. The study’s implications involve the creation of a fundamental model that can assist policy makers, practitioners, and academics in understanding the connection between smart manufacturing and sustainable production in developing nations. Again, the social implication of the study includes the realisation of decent job and economic growth, responsible consumption, and production as well as actions taken to combat climate change.

1. Introduction

According to the latest findings from UN Climate Change News, a staggering 30 million individuals were compelled to vacate their residences in the year 2020 as a direct consequence of climate-induced disturbances. The exacerbation of climate issues in recent times has posed a grave threat to the existence and well-being of the human species. In the year 2021, the occurrence of severe climatic conditions in isolation has led to substantial financial ramifications, with insurance claims amounting to a staggering sum exceeding USD 120 billion. The escalating prevalence of a myriad of environmental concerns has engendered a considerable amount of interest in the pursuit of remedies to effectively tackle these issues and bolster the prospects of environmental sustainability [1,2,3,4]. Environmental issues arise primarily as a consequence of human behaviour. In order to ameliorate the current state of the environment, it is imperative that a shift in behavioural patterns is undertaken. Engaging in environmentally conscious behaviour serves as a potent instrument in tackling environmental challenges and upholding the integrity of our natural surroundings. This practice effectively curtails the squandering of precious natural resources, mitigates the release of harmful pollutants, and mitigates the detrimental impact on our environment [5,6]. As per the scholarly works of [7,8,9], it is posited that pro-environmental behaviour encompasses a repertoire of deliberate actions or conduct that seeks to mitigate the adverse ramifications of one’s actions on the ecological and constructed realms. It may encompass endeavours such as engaging in recycling practices, actively participating in environmental advocacy initiatives, or conscientiously employing eco-conscious products, thereby encompassing both communal and personal spheres. The adoption of pro-environmental behaviours has been shown to have a significant impact on enhancing environmental sustainability and performance, resulting in a reduction in emissions, pollution, and environmental degradation [10,11,12,13,14]. Pro-environmental behaviour, when viewed through the prism of sustainability, can be delineated as the conscious and deliberate engagement in activities that foster and enhance the overall ecological equilibrium, thereby promoting long-term environmental sustainability. In essence, this study posits that endeavours undertaken with the deliberate intention of safeguarding the environment and enhancing its capacity for long-term viability are deemed to be pro-environmental in nature [15].

Smart manufacturing, a distinguished domain within the realm of manufacturing, harnesses the power of computer-integrated technologies and capabilities to enhance the efficacy of production processes, bolster the potential for recyclability, and optimize the intricate web of supply chain operations. The methodologies encompassed within this framework encompass the strategic arrangement of supply chains, the implementation of automation and industrial robotics, the application of intelligent production planning and control techniques, the utilization of intelligent procurement strategies, and the establishment of intelligent supply chains. Utilizing internet-enabled apparatus for the purpose of overseeing the production process, smart manufacturing represents a technologically advanced approach [16,17]. The underlying concept of intelligent manufacturing revolves around the optimization of supply and demand requirements, both in the present and future, through the harmonization of physical and digital operations within factory settings and throughout various supply chain endeavours. As per the scholarly works of [5,6,18,19,20], it has been established that the concept of smart production is precisely employed to denote the realm of digital production networks. A smart manufacturing system represents a concerted endeavour to optimize its capacities through the utilization of state-of-the-art technologies that enable expeditious and extensive dissemination of digital information across diverse industrial systems. In order to optimize energy and labour utilisation and enhance manufacturing efficiency, “smart manufacturing” [21,22,23] incorporates and utilizes advanced robotics, big data processing, and artificial intelligence.

In the nation of Ghana, numerous governing bodies have endeavoured to implement policies and initiatives aimed at fostering sustainable industrialization, as outlined in Sustainable Development Goal 9. Additionally, their efforts have been directed towards promoting decent employment opportunities and fostering economic development, aligning with the objectives of Sustainable Development Goal 8. Furthermore, Ghana’s commitment to sustainable consumption and production, as emphasized in Sustainable Development Goal 12, has been a focal point of their endeavours. Lastly, the pursuit of climate action has also been a prominent aspect of their agenda, recognizing the urgent need to address environmental concerns. An illustrative instance would be the manifestation of Ghana’s enduring strategic vision aimed at cementing its middle-income status and fostering an economy propelled by industry, capable of generating commendable employment opportunities that are both suitable and enduring for the purpose of development. This vision finds expression in the National Entrepreneurship and Innovation Programme (NEIP). Furthermore, it is imperative to acknowledge that the fundamental objectives of NEIP encompass the provision of unwavering assistance to nascent enterprises, with the ultimate aim of fostering their transformation into prosperous ventures. Moreover, NEIP is resolute in its commitment to furnish financial resources and establish incubation centres, as substantiated by the scholarly works of [24,25]. Furthermore, in July 2021, a transitory collaboration between Results for Development and the United Nations Department of Economic and Social Affairs was inaugurated, aiming to delve into the intricacies of Ghana’s innovation ecosystem. In the interim, it has come to our attention that several challenges persistently recur in previous assessments of Ghana’s innovation ecosystem. Ghana harbours a substantial and burgeoning reservoir of innovations that possess the capacity to profoundly enhance developmental outcomes. Nevertheless, there exist several impediments that hinder the triumphant alignment of this abundant supply with the corresponding demand, encompassing both the individual inventors and the broader ecosystem. The UNDESA-R4D Demand-Led Innovator Support Program serves as a prime illustration of an endeavour aimed at formulating a comprehensive strategy that effectively harmonizes and equalizes the requisites of the ecosystem (demand) with the necessities of innovators (supply) [25,26].

This paper examines the implications of smart manufacturing practices on pro-environmental behaviour using the Natural Resources-Based View (NRBV) and the Dynamic Capability Theory (DCT). It also develops a baseline moderated mediation model to explain the relationship between smart manufacturing and pro-environmental behaviour and green dynamic capability and green innovation. In order to promote responsible consumption and production, sustainable industrialization, climate action, respectable work, and economic growth, as well as the achievement of Agenda 2030, this study offers substantial and intriguing insights for policymakers, practitioners, academics, and theorists. Furthermore, an additional significant contribution pertains to the implementation of smart manufacturing practices within the manufacturing industry, which serves to promote environmentally conscious behaviour, attain environmental sustainability, and enhance environmental performance. Again, the social implication of the study includes the realisation of SDGs including no poverty, zero hungry, decent job and economic growth, responsible consumption and production, as well as actions taken to combat climate change. Finally, this paper has re-examined the relationship between smart manufacturing practices and pro-environmental behaviour with a focus on a developing country where such innovative studies have not been adequately explored.

The study has been guided by the following research questions: RQ1—What are the relationships between smart manufacturing practices and pro-environment behaviour. RQ2—What is the mediating role of smart manufacturing adoption on the relationship between sustainable production intention and pro-environmental behaviour? RQ3—What is the moderating role of green dynamic capability and environmental orientation on the relationship between sustainable production intention and pro-environmental behaviour? This paper is divided into six parts. The introduction is covered in part one, the literature review and creation of hypotheses are covered in Section 2, the research methodology is covered in Section 3, the findings are covered in Section 4, the discussions are covered in Section 5, and the conclusions and implications are included in Section 6.

2. Literature Review

2.1. Theoretical Review

The main propositions of the paper are based on NRBV and DCT. These theories have been used in the current study to enhance the relationship between smart manufacturing and pro-environmental behaviour. According to Hart (1995), companies that embrace sustainability principles demonstrate superior performance in comparison to those who do not implement such programs. The integration of NRBV smart manufacturing practices, including Smart Procurement, Smart Supply Chain Management, Smart Production Planning and Control, Automation and Industrial Robotics, and Supply Chain Configuration, along with pro-environmental behaviour, has the potential to contribute to various positive outcomes such as pollution reduction, biodiversity preservation, the promotion of product stewardship, and advancement of sustainable development [4,8,9,15]. The concept of dynamic capabilities has been previously discussed. Dynamic capabilities refer to the aptitude and assets that can be effectively aligned and realigned to accommodate changes in the business landscape. According to [27,28], dynamic capabilities refer to the competencies and assets possessed by a firm, enabling it to proficiently integrate, expand, and adapt its internal and external resources. These qualities are crucial for organisations to successfully navigate and exert influence in the face of swiftly changing business environments. The valuation of dynamic talents in markets does not align with their true worth to a buyer who has complementary assets, particularly those that are co-specialized. This implies that an organisation with a multitude of these competencies may potentially achieve atypical profits. This has the potential to significantly enhance the company’s profitability.

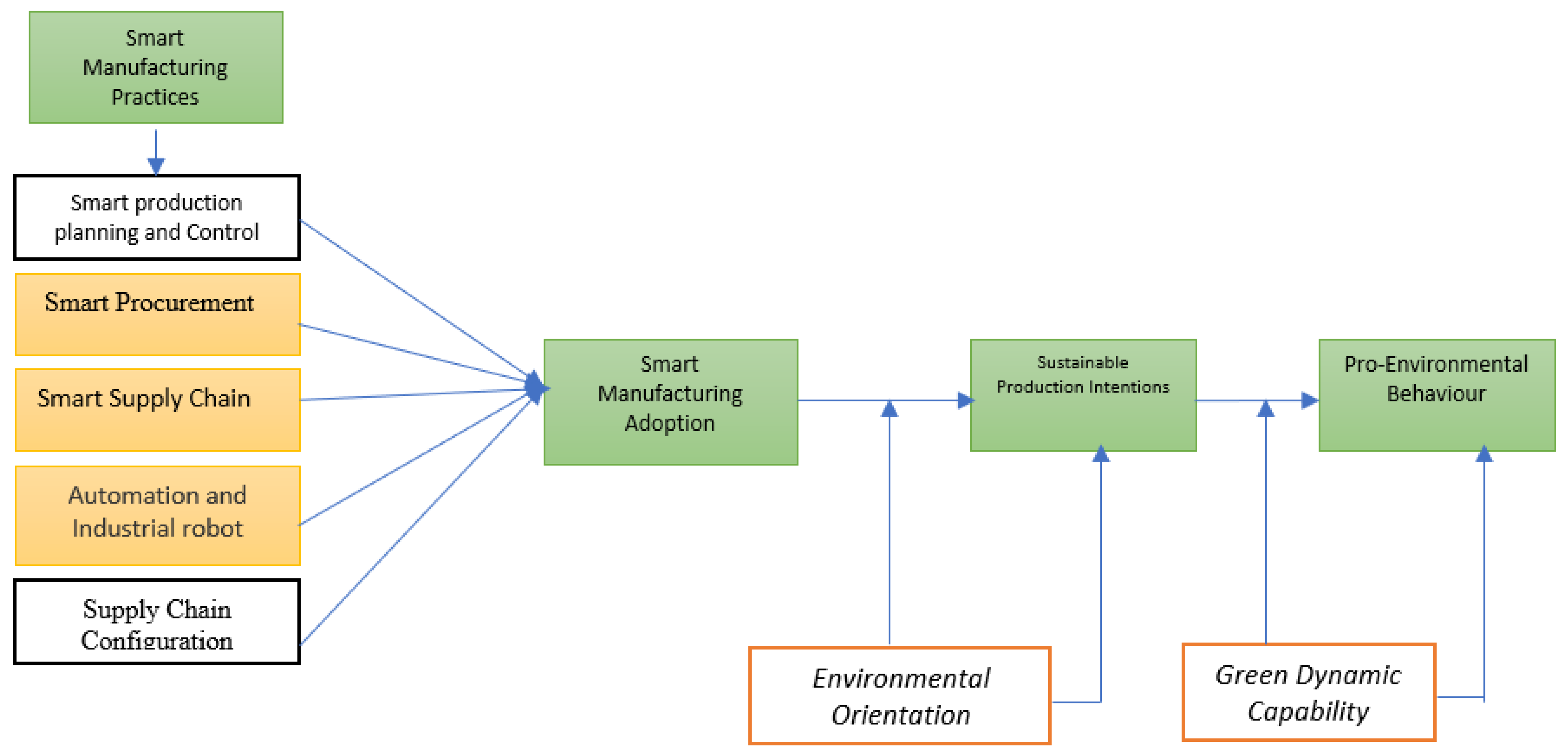

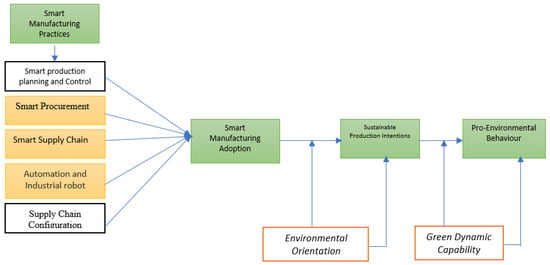

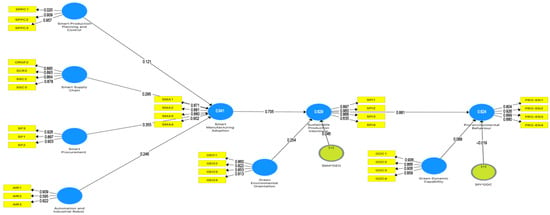

Sensing, seizing, and transforming are distinct characteristics shown by organizations that facilitate their ability to adapt and mutually develop in response to changes in the economic environment. The possession of such competencies is of utmost importance for ensuring sustained profitability in the long run [29]. This publication is one of the few scholarly works that has contributed to the development of a smart manufacturing model by incorporating the theories of NRBV and DCT. These two ideas are mutually complementary when used in conjunction. Consequently, the present research has integrated the aspects of both theories in order to establish a novel paradigm that has been used for the purpose of elucidating pro-environmental behaviour. The newly built baseline model is shown in Figure 1:

Figure 1.

Research Framework.

2.2. Hypotheses Development

2.2.1. Smart Production Planning and Control and Smart Manufacturing Adoption

The scholarly literature has elucidated the relationship between Smart Production Planning and Control (PPC) and sustainable performance through the works of [6,16,22,30,31]. The focal point of Production Planning and Control (PPC) revolves around the effective administration of manufacturing operations, aiming to strategically coordinate and supervise the utilization of current industrial assets and materials, while also contemplating the integration of forthcoming production systems that possess enhanced flexibility and adaptability. Significantly, prior research conducted by [6,16] has delved into the utilization and advantages of Smart PPC within this particular domain. A highly refined PPC system harnesses state-of-the-art technology, encompassing the IoTs, big-data, and cloud or edge-based machine learning, to enhance the efficiency and efficacy of PPC processes. The facilitation of PPC activities is effectively achieved through the utilization of enterprise resource planning tools and spreadsheet solutions, as highlighted by [32]. Based on the extant body of evidence, it becomes apparent that PPC assumes a pivotal role in cultivating sustainable performance. The current study puts forth the following hypotheses:

H1:

Smart Production Planning and Control is a significant of determinants of smart manufacturing adoption.

2.2.2. Smart Procurement and Smart Manufacturing Adoption

The existing literature, exemplified by [5,20,33], has elucidated the correlation between Smart Procurement (SP) and its influence on sustainable performance. The acronym “SP” denotes the utilization of technological advancements to optimize and streamline traditionally arduous and labour-intensive procurement procedures. Intelligent procurement tools leverage cutting-edge technologies such as machine learning, artificial intelligence, the Internet of Things, and advanced data analytics to enhance the efficiency, precision, and seamless nature of the procurement process. The utilization of cutting-edge technologies, notably artificial intelligence, serves to alleviate procurers from burdensome and repetitive tasks, thereby facilitating enhanced efficacy [34]. Moreover, SP entails the utilization of advanced technological solutions to streamline and mechanize mundane procurement activities. Intelligent procurement has the potential to harness automation in various aspects such as contract management, vendor management, and request management, among others [35,36]. SP represents a pioneering procurement methodology that holds the potential to enhance operational efficiency and optimize the efficacy of the purchasing process. Once more, the utilization of SP facilitates enhanced coordination and communication among purchasers, suppliers, and additional stakeholders, thereby yielding the potential for cost reduction and the attainment of superior product quality. Furthermore, the essence lies in the fulfilment of customer requirements; in the advancement and refinement of our assortment of contemporary acquisition methodologies; and in the collaboration with the industrial sector [17,37]. Based on the current circumstances, it is evident that intelligent procurement plays a pivotal role in fostering enduring performance. The present study posits the following hypothesis:

H2:

Smart Procurement is a significant determinant of smart manufacturing adoption.

2.2.3. Smart Supply Chain and Smart Manufacturing Adoption

In the extant literature [23,38,39], it is evident that SSC has been studied enormously. The SSC is a sophisticated framework that harnesses cutting-edge technology and employs automated data analysis techniques to streamline the intricate process of goods and services distribution, ensuring optimal efficiency from suppliers to end consumers. The SCC is further expounded upon through the interconnectedness of three fundamental attributes, namely connection, collaboration, and customization. The interconnectedness of SCC is a result of the intricate network that binds together various entities, assets, IT systems, and products. This interconnectedness is further accentuated by the remarkable extent of engagement with customers, suppliers, and IT systems, as noted by [40]. The phenomenon known as SSC, or Smart Supply Chain, is distinguished by the utilization of diverse and sophisticated Information and Communication Technologies within the manufacturing domain. The primary objective is to enhance the seamless exchange of information among disparate entities, encompassing objects, IT systems, and enterprises [41,42]. The prominence of SSC ought to be underscored not solely by the elevated degree of confidence exhibited among the constituents of the supply chain, but also by the establishment of a robust rapport between the information systems and information technologies involved [43]. Based on the current circumstances, it is evident that the implementation of an intelligent supply chain system significantly influences the attainment of sustainable performance. This study proposes the following hypothesis:

H3:

Smart Supply Chain is a significant determinant of smart manufacturing adoption.

2.2.4. Automation and Industrial Robots and Smart Manufacturing Adoption

Several studies have been conducted on the subject of automation and robotics [44,45,46,47,48]. Industrial automation refers to the use of computer software, machinery, or other technological means to execute activities that would otherwise be performed by human beings. Industrial robots are widely recognized as a fundamental element of competitive production strategies, as they strive to integrate optimal productivity, superior quality, and versatile flexibility while minimizing costs. Automation refers to the process of transforming a labour process, technique, or equipment from manual operation or control to automated operation or control [49]. The field of robotics is primarily concerned with the development and study of systems that consist of sensors and actuators. These systems are designed to function independently or with little human intervention, and they often collaborate with people in their operations [50,51]. Automation refers to the use of control systems and information technologies with the aim of diminishing the reliance on human labour in the manufacturing and provision of products and services. Robots have a comparable degree of flexibility to that of humans, using advanced methods of feedback vision and reasoning capabilities [52,53]. The potential outcomes and impacts of automation might vary significantly based on the socioeconomic and organizational decisions made during the process. Robotic systems present themselves as appealing options for reducing costs in labour-intensive tasks, extending beyond the automotive sector to include a wide range of industrial applications. Based on the current evidence, it is evident that the use of automation and robotics significantly contributes to the achievement of sustainable performance. This study proposes the following hypothesis:

H4:

Automation and robotics are significant determinants of smart manufacturing adoption.

2.2.5. Smart Manufacturing Adaption and Sustainable Production Intention

Prior empirical investigations [54,55,56] have discovered that smart manufacturing (SM) is an emerging technology-driven methodology that monitors and controls the manufacturing process via internet-connected devices. By means of data analytics, the principal objective of SM is to streamline mechanized business processes and boost industrial output. Smart manufacturing aims to optimize current and future demand and supply dynamics throughout the supply chain and manufacturing facilities through the seamless integration of physical and digital operations. Ref. [57] asserted that the term “smart manufacturing” is frequently employed to refer to a network of digitalized production. Ref. [18] proposes that “smart manufacturing” is a collection of production methods that employ ICTs and interconnected data to manage processes precisely. The primary objective of a highly smart manufacturing system is to optimise output by leveraging state-of-the-art technologies that enable smooth and uninterrupted data exchange across all phases of the production process. In order to optimize the allocation of resources, materials, and labour in an efficient manner, smart manufacturing systems prioritise the integration of Information and Communication Technologies (ICT). It is also noteworthy to mention that these systems have been deliberately designed to adapt effectively to fluctuations in the market and changes in customer demand [19,58]. Smart manufacturing is distinguished by numerous attributes, including interoperability, real-time monitoring and control, adaptable production, rapid response to market fluctuations, advanced sensor technology, and sizable data analytics. This approach aims to optimize productivity in the manufacturing sector, as outlined in [44,59]. Given the prevailing conditions, it is clear that the integration of smart manufacturing methods is essential to promote sustainable performance. This study raises the following hypotheses:

H5:

Smart manufacturing adoption significantly relates to sustainable production intention.

H6:

Smart manufacturing practices significantly mediate the relationship between smart manufacturing adoption and sustainable production intention.

2.3. Sustainable Production Intention and Pro-Environmental Behaviour

Among others, refs. [4,60,61,62,63] have established that environmentally responsible manufacturing and behaviour are correlated. The concept of “sustainable production” pertains to the manufacturing procedure wherein limited resources are utilized in an efficient manner while ensuring environmental hygiene. Sustainable production involves the process of creating goods and services in a manner that minimizes the adverse effects on the environment while optimizing the utilization of scarce resources such as energy and materials. Furthermore, the economic viability of the manufacturing processes is considered, which is an essential component of sustainability. Furthermore, we shall diligently strive to maintain a corporate environment that places the well-being and security of consumers, employees, and the general public first. Furthermore, it is crucial to note that an inherent aim of sustainable production is to improve the social and spiritual welfare of every employee [64]. Sustainable production entails the extent to which industry can support society’s desire to produce wealth in a way that promotes sustainable economic growth [65]. Ensuring that manufactured goods meet the current needs and preferences of society constitutes the essence of sustainable manufacturing, an expansive and intricate domain within industrial production. Concurrently, provisions must be made for the desires and requirements of future generations. According to [66], evaluating the product’s advancement at every stage of its life cycle is crucial. Environmental, social, and economic factors all have an impact on sustainable production, which is a crucial component of sustainable development [67].

According to the research work of [68], the concept of sustainable manufacturing includes the production of goods using production process methods that prioritize mitigating adverse environmental impacts; conserving energy and natural resources; ensuring the well-being of workers, communities, and consumers; and promoting economic sustainability. Given the current circumstances, it is clear that the trend towards sustainable production is having a significant impact on environmentally friendly behaviour. This study proposes the following hypotheses:

H7:

Sustainable production intention significantly relates to pro-environmental behaviour.

H8:

Sustainable production intention significantly mediates the relationship between smart manufacturing adoption and pro-environment behaviour.

2.4. Environmental Orientation

The research in academia [3,69,70] has demonstrated a correlation between environmental orientation and endeavours to develop products and services that are favourable to the environment (sustainable production). To what extent do corporations incorporate environmental considerations into the process of formulating strategic decisions? The aforementioned involves “environmental orientation,” as established by [71] in their study. The concept of environmental orientation means that a company recognizes its harmful impact on the environment and works ceaselessly to eliminate that impact. Like the concept of corporate social responsibility, it serves as a concrete embodiment of an organization’s core principles. In addition, it is important that employees demonstrate characteristics of organizational citizenship, such as respect, sincere concern for the environment, and adherence to responsibilities to external stakeholders [2]. It includes ethical standards. This is achieved through the development of environmentally conscious individuals and a strong commitment to environmental protection [1,2]. The adoption of an environmental orientation has the potential to have beneficial effects on both cost and productivity across a firm’s whole value chain. This is achieved by implementing innovative practices that target the reduction of pollution and waste. The concept of environmental orientation may be seen as a corporate value that has resemblance to the notion of corporate social responsibility. It encompasses the principles of showing reverence and concern for the environment, as well as addressing the demands of external stakeholders [72,73]. Based on the current evidence, it is evident that an environmental focus significantly influences the achievement of sustainable outcomes. This study proposes the following hypothesis:

H9:

Environmental orientation significantly moderates the relationship between smart manufacturing adoption and sustainable production intention.

2.5. Green Dynamic Capabilities and Sustainable Production Intention

The available research [8,9,15,74,75] provides evidence supporting the association between green dynamic capabilities (GDCs) and sustainable performance. GDC refer to the capacity of firms to effectively use their current resources and expertise in order to develop and enhance environmentally sustainable organizational capabilities. GDC is responsible for converting sustainable organizational skills into environmental performance indicators, namely via the implementation of eco-designing and eco-efficiency efforts throughout the process of developing new products. According to [76], dynamic capabilities refer to a distinct and recognizable business process. GDCs refer to predictable patterns of communication that organizations use to effectively allocate resources in order to accomplish their goals [77]. The GDC places significant emphasis on the integration, creation, and reallocation of both internal and external resources pertaining to the field of environmental protection. According to [78], GDCs are responsible for generating novel goods and processes that have the potential to transform the business landscape and uncover lucrative commercial prospects. The use of existing knowledge and resources by enterprises facilitates the development and cultivation of green organizational skills [75,79]. GDCs play a pivotal role in enhancing the endeavours of corporations to innovate in the realm of sustainability, particularly when accompanied by a robust knowledge base. GDCs refer to the overarching capacity of companies to effectively attain sustainable and environmentally friendly growth within the dynamic market landscape. According to [80], the implementation of GDCs has been shown to positively impact enterprises’ endeavours in green innovation. This is achieved via the enhancement of green management practices, the pursuit of green strategic goals, and the facilitation of green research and development. Based on the current evidence, it is evident that GDCs have a significant impact on promoting environmentally friendly behaviour. This study proposes the following hypothesis:

H10:

GDC significantly moderates the relationship between sustainable production intention and pro-environmental behaviour.

3. Research Methodology

The primary focus of this study pertains to the private sector within the nation of Ghana. The study, with this specific focus, delves into the realm of private business investors within the confines of two prominent urban centres in Ghana. Specifically, the two cities in question are Accra and Kumasi. As per the findings of the Ghana Enterprise Agency (GEA), it has been determined that a total of 2825 business entities have been duly formalized and registered under the agency. Furthermore, it is noteworthy that the GEA has established a network of 190 operational district offices to effectively administer its functions and provide support to these registered enterprises. The research primarily concentrated on enterprises situated within the metropolitan regions of Kumasi and Accra. The rationale behind this decision is predicated upon the findings of the GEA report, which posit that the metropolitan regions of Kumasi and Accra persist in their pre-eminence within the small and medium enterprises sector, both in terms of sheer quantity and the breadth of commercial pursuits. Moreover, owing to Accra’s status as the esteemed administrative capital of Ghana, a multitude of enterprises are inclined towards establishing a formidable presence within the city’s boundaries, primarily driven by the desire to harness the abundant opportunities presented by the readily accessible market. The participants selected for this study comprise a cohort of SMEs owners and managers, chosen through a random sampling method. Of the designated sample size of 450, a total of 422 questionnaires were successfully collected. After conducting a more thorough examination, it was discovered that a total of 18 questionnaires had to be excluded from the analysis due to inconsistencies and the presence of multiple responses. Additionally, an additional 22 questionnaires were deemed unfit for inclusion as they were completed by individuals who were neither owners nor managers of the organization under study. Consequently, the final number of questionnaires deemed suitable for analysis amounted to 382, which represents an impressive response rate of 84.89%. The latest research endeavours [81,82] conducted in a congruous setting have yielded comparable and valuable insights. Furthermore, it is imperative to note that the present study has employed a confirmatory research design alongside a quantitative research approach. The utilization of a quantitative research approach in this study is justified by its reliance on statistical models and adherence to the notion of objectivity in comprehending social reality. The present study employed a survey methodology, utilizing items that were quantitatively assessed using numerical ratings.

The study centres its attention on SMEs that are engaged in various sectors such as transportation, oil and gas, hospitality, construction, recreation, and tourism, among other industries. The criteria for inclusion were as follows: (i) SMEs that are owned by individuals of Ghanaian nationality; (ii) SMEs that are duly registered in accordance with the legal framework; and (iii) SMEs that have demonstrated a commendable longevity of over three years. The measurement instruments underwent adaptation based on prior studies that were closely aligned with the underlying theoretical assumptions. Table 1 provides additional information regarding the measurement of constructs, including the quantity of measurement items utilized and the underlying theoretical foundations. The process of data collection was carried out through the utilization of structured questionnaires and the implementation of a 5-point Likert scale of measurement. In this particular context, we assign the numerical values of 5, 4, 3, 2, and 1 to represent the levels of agreement or disagreement. More specifically, a rating of 5 signifies a strong inclination towards agreement, while a rating of 4 indicates agreement, a rating of 3 denotes neutrality, a rating of 2 signifies disagreement, and a rating of 1 represents a strong inclination towards disagreement.

Table 1.

Measurement instruments, sources, number of items, and underlying theory.

Ethical Considerations

This paper involves human participants and, as a result, all due ethical considerations have been observed, including respecting human rights, anonymity, confidentiality, protection from harm, and informed consent. Ethical approval of the ethical review committee of the Kumasi Technical University in Kumasi, Ghana was obtained to conduct this study.

In order to enhance comprehension and discern intricate connections and patterns among latent variables, scholars employ the structural equation modelling framework offered by partial least squares (PLS-SEM). By adhering to the structural plan illustrated in Figure 1, this enquiry employed a reflective framework and concentrated on a solitary variable (an indicator). In the context of PLS-SEM, the external model and the internal model are two distinct categories of model fit requirements that must be identified and carefully considered. The external model evaluates the reliability and validity of the connection between variables. In order to assess the fit of the external model, measurement models were employed, while regression analyses served as the foundation for evaluating the structural model of the internal model [83,84]. A thorough examination was conducted on path coefficients and T-values to derive an approximation of the structural model. The statistical measures mentioned above were employed to assess the validity of the hypothesis. The measurement model was evaluated for construct validity, specifically focusing on the assessment of convergence and variability of the measures. To establish the construct validity of a test, it is crucial to demonstrate both strong convergent and discriminant validity. Strong correlation between the test results and results of other assessments measuring the same premise is crucial, indicating significant convergent validity. The test results should demonstrate a lack of correlation with assessments designed to measure different constructs, indicating a high level of discriminant validity [85]. This study employed composite reliability (CR), Cronbach’s alpha, and factor loading as analysis techniques to evaluate the adequacy of convergent validity. Furthermore, discriminant validity was evaluated using Average Variance Extracted and Cross Loading techniques.

4. Results and Analysis

4.1. Descriptive Statistics and Variance Inflation Factor (VIF)

The results of the summary data and VIF can be seen in Table 2. The study gives the distribution measures, skewness, and kurtosis scores, as well as the means and standard deviations. The average scores were found to be between 3.620 and 3.904. The subjects had standard deviations that ranged from 0.926 to 1.204, which shows that there was a lot of variation (SD > 1). To check for multicollinearity, variance inflation factor (VIF) values were used. The study’s results show that the VIF values were between 1.183 and 0.425, which is less than the accepted level of 5 set by [86]. As shown by the variance inflation factor (VIF) being less than 5, the results show that multilinearity is not a significant problem. To check if the distribution was regular, the skewness and kurtosis numbers were evaluated. The values for skewness were between −1.041 and −0.350, and the values for kurtosis were between −0.569 and 0.846. In this case, the numbers were between −1.041 and −0.350 and between −0.569 and 0.846. Based on these results, it seems that the distribution fits the normality assumption.

Table 2.

Descriptive statistics and variance inflation factor (VIF).

4.2. Measurement Model—Construct Validity

Table 3 displays the outcomes of the model measurement, which is also referred to as structure validation. This evaluation comprises two components: convergent and discriminant validity. Convergent validity of the model was assessed using CR, CA, and factor loadings. According to the findings, the CR values ranged from 0.859 to 0.952, which is higher than the minimal criterion of 0.7 that is considered acceptable. Table 4 displays the HTMT ratios, which were analysed to assess the robustness of the Heterotrait-Monotrait. The values fell within the range of 0.043 to 0.789, all of which were below the minimum recommended threshold of 0.85 [85]. The results of Table 5 indicate that the factor loadings are higher than the minimum allowable level of 0.7. The results indicate that the model exhibits strong convergent validity. The AVE values range from 0.677 to 0.868, all of which exceed the minimum threshold of 0.5. Table 3 displays the quadratic AVE values along the diagonal. The correlation coefficients of the structures were smaller than the quadratic values, indicating acceptable discriminant validity [85]. The results have provided sufficient justification for accepting the validity of the construct (measurement model).

Table 3.

Discriminant validity and convergent validity—Fornell–Larcker criterion.

Table 4.

Heterotrait–Monotrait Ratio (HTMT).

Table 5.

Construct cross-validated redundancy.

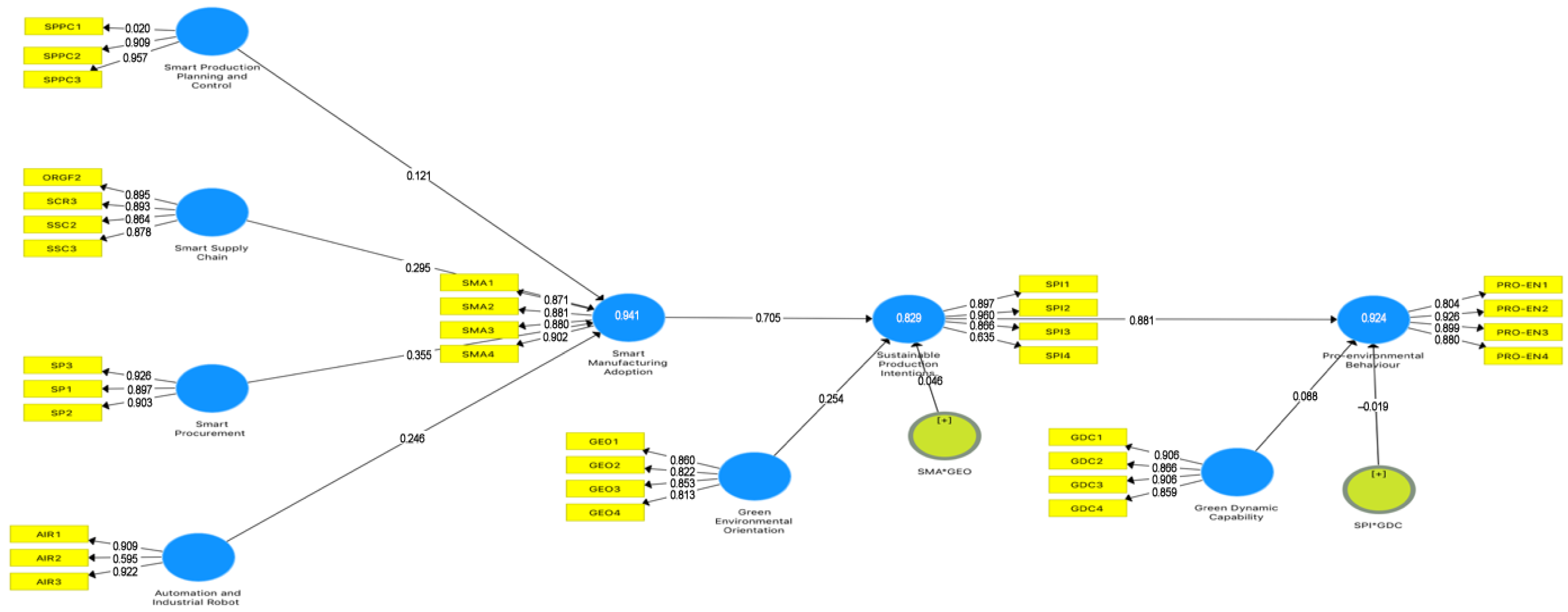

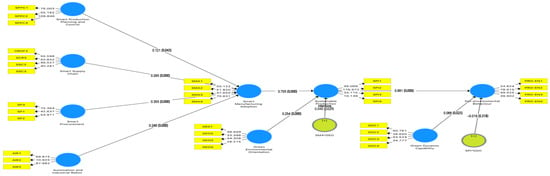

4.3. Structural Model

The purpose of the structural model is to assess the model’s predictive capacity, analyse the path coefficients, and conduct hypothesis testing using T-values. The model’s predictive power, as indicated by Table 5 and Figure 2, ranges from 0.829 to 0.941. This suggests that intelligent production planning and control, intelligent supply chain, intelligent purchasing, and automation collectively account for 94.1% of the variance in the adoption of smart manufacturing. Smart manufacturing adoption accounts for 82.9% of the variability in sustainable production intentions. The intention to engage in sustainable production accounts for 92.4% of the variability observed in pro-environmental behaviour. To evaluate the predictive validity of the model in Table 5, a design redundancy analysis was performed using cross-validation. The Q2 values, ranging from 0.581 to 0.728, indicate that the model possesses significant predictive relevance as they are greater than zero. Figure 3 displays the path coefficients and corresponding hypotheses.

Figure 2.

Factor loadings.

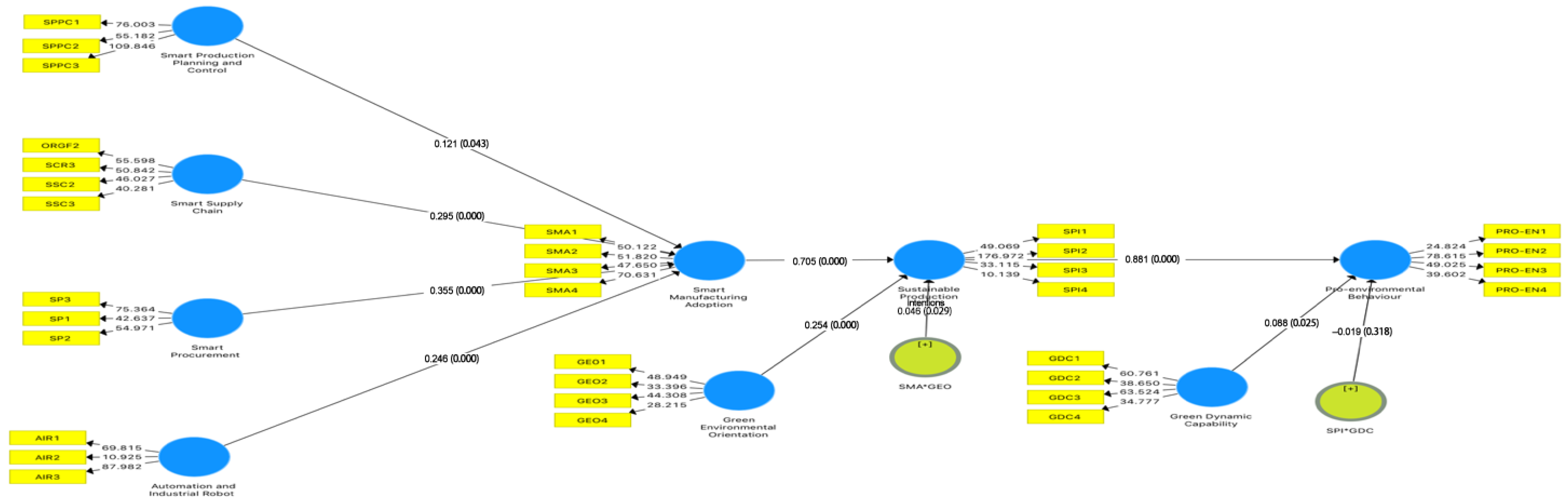

Figure 3.

Path coefficients and p-values.

4.4. Path Coefficients and Hypothesis Testing

As showed in Table 6, AIR (B = 0.246, T-value = 7.2.460) significantly affects SMA, GDC (B = 0.088, T-value = 2.246) significantly affects Pro-EB, GEO (B = 0.254, T-value = 3.891) significantly affects SPI, SMA and GEO (B = 0.046, T-value = 2.196) significantly affect SPI, SPI and GDC (B = −0.019, T-value = 0.999) insignificantly affect Pro-EB, SMA (B = 0.705, T-value = 11.085) significantly affects SPI, SP (B = 0.355, T-value = 2.027) significantly affects SMA, SPPC (B = 0.121, T-value = 2.027) significantly affects SMA, SSC (B = 0.295, T-value = 4.840) significantly affects SMA, SPI (B = 0.881, T-value = 24.493) significantly affects Pro-EB, SPI (B = 0.041, T-value = 2.149) significantly mediates SMA*GEO and Pro-EB, SMA and SPI (B = 0.221, T-value = 4.569) significantly mediate SPM and Pro-EB, SMA and SPI (B = 0.153, T-values = 6.217) significantly mediate AIR and Pro-EB, SMA (B = 0.173, T-value = 6.500) significantly affects AIR and SPI. SPI (B = 0.621, T-value = 10.244) significantly mediates SMA and Pro-EB, SMA and SPI (B = 0.075, T-value = 1.838) significantly mediate SPPC and Pro-EB, SMA (B = 0.250, T-value = 4.569) significantly mediate SP and SPI, SMA and SPI (B = 0.183, T-value = 4.389) significantly mediate SSC and Pro-EB, SPI (B = 0.224, T-value = 4.814) significantly affects GEO and Pro-EB, and SMA (B = 0.208, T-value = 4.377) significantly affects SPI.

Table 6.

Path coefficients and hypothesis testing.

5. Discussions

A broad subdivision of the manufacturing sector, smart manufacturing entails the application of technology and computer-integrated functionalities to enhance product recycling, supply chain effectiveness, and production efficiency. It is imperative to reassess the correlation between environmentally conscious behaviour and “smart” manufacturing practices (including Smart Procurement, Smart Supply Chain, Smart Production Planning And Control, Automation and Industrial Robots, and Supply Chain Configuration), particularly in the context of a developing nation, due to the insufficient number of innovative studies in this area. More specifically, the subsequent goals have been accomplished.

In answer to RO1—to ascertain the implication of SMP on PEB among manufacturing companies—this study has found that smart manufacturing practices, specifically Smart Procurement, Smart Supply Chain, Smart Production Planning and Control, Automation and Industrial Robot, and Supply Chain Configuration, significantly affect pro-environmental behaviour. This is consistent with prior related studies. Smart manufacturing, a distinguished domain within the realm of manufacturing, harnesses the power of computer-integrated technologies and capabilities to enhance the efficacy of production processes, bolster the potential for recyclability, and optimize the intricate web of supply chain operations. The methodologies encompassed within this framework encompass the strategic arrangement of supply chains, the implementation of automation and industrial robotics, the application of intelligent production planning and control techniques, the utilization of intelligent procurement strategies, and the establishment of intelligent supply chains. Utilizing internet-enabled apparatus for the purpose of overseeing the production process, smart manufacturing represents a technologically advanced approach [17]. The underlying concept of intelligent manufacturing revolves around the optimization of supply and demand requirements, both in the present and future, through the harmonization of physical and digital operations within factory settings and throughout various supply chain endeavours. As per the scholarly works of [5,6,18,19,20], it has been established that the concept of “smart production” is precisely employed to denote the realm of digital production networks [84,85].

RO2—to determine the mediating role of smart manufacturing adoption and sustainable production intention between SMP and PED. This study has found that smart manufacturing adoption and sustainable production intention significantly mediates the relation between smart manufacturing practices and pro-environmental behaviour. Engaging in environmentally conscious behaviours serves as a potent instrument in tackling environmental challenges and upholding the integrity of our natural surroundings. This practice effectively curtails the squandering of precious natural resources, mitigates the release of harmful pollutants, and mitigates the detrimental impact on our environment [5,6]. As per the scholarly works of [7,8,9], it is posited that pro-environmental behaviour encompasses a repertoire of deliberate actions or conduct that seeks to mitigate the adverse ramifications of one’s actions on the ecological and constructed realms. It may encompass endeavours such as engaging in recycling practices, actively participating in environmental advocacy initiatives, or conscientiously employing eco-conscious products, thereby encompassing both communal and personal spheres [85,86].

RO3—to determine the moderating role of environmental orientation and green dynamic capability on the relationship between SMP and environmental orientation. This study has found that the relationship between smart manufacturing and pro-environmental behaviour is influenced by green dynamic capacity and environmental orientation. The adoption of pro-environmental behaviours has been shown to have a significant impact on enhancing environmental sustainability and performance, resulting in a reduction in emissions, pollution, and environmental degradation [10,11,12,13,14]. Pro-environmental behaviour, when viewed through the prism of sustainability, can be delineated as the conscious and deliberate engagement in activities that foster and enhance the overall ecological equilibrium, thereby promoting long-term environmental sustainability [85,86]. In essence, this study posits that endeavours undertaken with the deliberate intention of safeguarding the environment and enhancing its capacity for long-term viability are deemed to be pro-environmental in nature [15].

6. Conclusions and Implications

This paper has examined the implications of smart manufacturing practices (Smart Procurement, Smart Supply Chain, Smart Production Planning and Control, Automation and Industrial Robot, and Supply Chain Configuration) on pro-environmental behaviour and developed a baseline-moderated mediation model to explain the relationship between smart manufacturing and pro-environmental behaviour as well as the indirect effects of environmental awareness and green dynamic capability. It was demonstrated that smart manufacturing practices correlate significantly and positively with pro-environmental behaviour [5,6]. In addition, green dynamic capability and environmental attitude establish the connection between smart manufacturing and pro-environmental conduct. This study concludes that a baseline model has been built to guide policymakers, practitioners, and academicians to explain the relationship between smart manufacturing and pro-environmental emerging countries including Ghana, Gambia, Nigeria, and Kenya. Again, the findings from this study could be used to prospect the realisation of decent job and economic growth, responsible consumption and production, as well as actions taken to combat climate change [7,8,9]. The practical and policy implications of these results are elaborated upon in the next section.

The theoretical implication of the study includes the creation of a fundamental model that can assist policy makers, practitioners, and academics in understanding the connection between smart manufacturing and pro-environmental behaviour in low-developed economic context [4,8,9,15]. Again, the social implication of the study includes the realisation of decent job and economic growth, responsible consumption and production, as well as actions taken to combat climate change. Moreover, the study has established that smart manufacturing practices significantly and positively relate to pro-environmental behaviour. Moreover, green dynamic capability and environmental orientation moderate the relationship between smart manufacturing and pro-environmental behaviour. Moreover, another important contribution is to achieve environmental sustainability and improve environmental performance, there is the need to adopt smart manufacturing practices in manufacturing industries to promote pro-environmental behaviour [10,11,12,13,14].

Again, the social policy implication of the study includes the realisation of SDGs including no poverty, zero hungry, decent job and economic growth, responsible consumption and production, as well as actions taken to combat climate change. The Government of Ghana is required to intensive and re-enforce environmental laws, policies, and frameworks in order to sustain the environment [85,86]. Other stakeholders and environmental actors should continuously encourage best environmental practices. Finally, this paper has re-examined the relationship between smart manufacturing practices and pro-environmental behaviour with a focus on a developing country where such innovative studies have not been adequately explored. The paper has its own limitations, which predominantly include the scope and time horizon. This paper focused on manufacturing companies using a cross-sectional survey design. It is suggested that future studies should consider multiple industries and longitudinal studies.

Author Contributions

Conceptualization, E.O.A.-D. and M.K.A.; methodology, E.O.A.-D., M.K.A. and J.C.D.; software, E.O.A.-D., M.K.A. and J.C.D.; validation, E.O.A.-D., M.K.A. and J.C.D.; formal analysis, M.K.A. and E.O.A.-D.; investigation E.O.A.-D., M.K.A. and J.C.D.; resources, data curation, E.O.A.-D., M.K.A. and J.C.D.; writing—original draft preparation, M.K.A. and J.C.D.; writing—review and editing, E.O.A.-D. and M.K.A.; supervision E.O.A.-D. and M.K.A.; project administration E.O.A.-D., M.K.A. and J.C.D.; funding acquisition, E.O.A.-D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data would be made available upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Medrano, N.; Cornejo-Cañamares, M.; Olarte-Pascual, C. The impact of marketing innovation on companies’ environmental orientation. J. Bus. Ind. Mark. 2020, 35, 1–12. [Google Scholar] [CrossRef]

- Yasir, M.; Majid, A.; Yasir, M.; Qudratullah, H. Promoting environmental performance in manufacturing industry of developing countries through environmental orientation and green business strategies. J. Clean. Prod. 2020, 275, 123003. [Google Scholar] [CrossRef]

- Chavez, R.; Malik, M.; Ghaderi, H.; Yu, W. Environmental orientation, external environmental information exchange and environmental performance: Examining mediation and moderation effects. Int. J. Prod. Econ. 2021, 240, 108222. [Google Scholar] [CrossRef]

- Begum, H.; Abbas, K.; Alam, A.S.A.F.; Song, H.; Chowdhury, M.T.; Abdul Ghani, A.B. Impact of the COVID-19 pandemic on the environment and socioeconomic viability: A sustainable production chain alternative. Foresight 2022, 24, 456–475. [Google Scholar] [CrossRef]

- Weingärtner, T.; Batista, D.; Köchli, S.; Voutat, G. Prototyping a Smart Contract Based Public Procurement to Fight Corruption. Computers 2021, 10, 85. [Google Scholar] [CrossRef]

- Rahmani, M.; Romsdal, A.; Sgarbossa, F.; Strandhagen, J.O.; Holm, M. Towards smart production planning and control; a conceptual framework linking planning environment characteristics with the need for smart production planning and control. Annu. Rev. Control 2022, 53, 370–381. [Google Scholar] [CrossRef]

- Lee, P.S.; Sung, Y.H.; Wu, C.C.; Ho, L.C.; Chiou, W.B. Using episodic future thinking to pre-experience climate change increases pro-environmental behavior. Environ. Behav. 2020, 52, 60–81. [Google Scholar] [CrossRef]

- Yu, D.; Tao, S.; Hanan, A.; Ong, T.S.; Latif, B.; Ali, M. Fostering Green Innovation Adoption through Green Dynamic Capability: The Moderating Role of Environmental Dynamism and Big Data Analytic Capability. Int. J. Environ. Res. Public Health 2022, 19, 10336. [Google Scholar] [CrossRef]

- Bresciani, S.; Rehman, S.U.; Alam, G.M.; Ashfaq, K.; Usman, M. Environmental MCS package, perceived environmental uncertainty and green performance: In green dynamic capabilities and investment in environmental management perspectives. Rev. Int. Bus. Strategy 2023, 33, 105–126. [Google Scholar] [CrossRef]

- Lange, F.; Steinke, A.; Dewitte, S. The Pro-Environmental Behavior Task: A laboratory measure of actual pro-environmental behavior. J. Environ. Psychol. 2018, 56, 46–54. [Google Scholar] [CrossRef]

- Li, J.J.; Zhang, J.; Zhang, D.Y.; Ji, Q. Does gender inequality affect household green consumption behaviour in China? Energy Policy 2019, 135, 111071. [Google Scholar] [CrossRef]

- Schmitt, M.T.; Aknin, L.B.; Axsen, J.; Shwom, R.L. Unpacking the Relationships Between Pro-Environmental Behavior, Life Satisfaction, and Perceived Ecological Threat. Ecol. Econ. 2018, 143, 130–140. [Google Scholar] [CrossRef]

- Truelove, H.B.; Gillis, A.J. Perception of pro-environmental behavior. Glob. Environ. Chang. 2018, 49, 175–185. [Google Scholar] [CrossRef]

- Lange, F.; Dewitte, S. Measuring pro-environmental behavior: Review and recommendations. J. Environ. Psychol. 2019, 63, 92–100. [Google Scholar] [CrossRef]

- Yuan, B.; Cao, X. Do corporate social responsibility practices contribute to green innovation? The mediating role of green dynamic capability. Technol. Soc. 2022, 68, 101868. [Google Scholar] [CrossRef]

- Oluyisola, O.E.; Sgarbossa, F.; Strandhagen, J.O. Smart Production Planning and Control: Concept, Use-Cases and Sustainability Implications. Sustainability 2020, 12, 3791. [Google Scholar] [CrossRef]

- Özkan, E.; Azizi, N.; Haass, O. Leveraging Smart Contract in Project Procurement through DLT to Gain Sustainable Competitive Advantages. Sustainability 2021, 13, 13380. [Google Scholar] [CrossRef]

- Davis, J.; Edgar, T.; Graybill, R. Smart manufacturing. Annu. Rev. Chem. Biomol. Eng. 2015, 6, 141–160. [Google Scholar] [CrossRef]

- Phuyal, S.; Bista, D.; Bista, R. Challenges, Opportunities and Future Directions of Smart Manufacturing: A State of Art Review. Sustain. Futures 2020, 2, 100023. [Google Scholar] [CrossRef]

- Musonda, I.; Gambo, N. Mediation effect of partnership on procurement strategy factors influencing sustainable smart housing development, Nigeria. Built Environ. Proj. Asset Manag. 2021, 11, 454–467. [Google Scholar] [CrossRef]

- Lu, Y.; Morris, K.C.; Frechette, S. Current Standards Landscape for Smart Manufacturing Systems; NISTIR 8107; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016; 39p.

- Cañas, H.; Mula, J.; Campuzano-Bolarín, F.; Poler, R. A conceptual framework for smart production planning and control in Industry 4.0. Comput. Ind. Eng. 2022, 173, 108659. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, Y.; Yang, G. Smart supply chain management in Industry 4.0: The review, research agenda and strategies in North America. Ann. Oper. Res. 2023, 322, 1075–1117. [Google Scholar] [CrossRef]

- Appiah, K.M.; Odei, A.S.; Kumi-Amoah, G.; Yeboah, A.S. Modeling the Impact of Green Supply Chain Practices Environmental Performance: The Mediating Role of Ecocentricity. Afr. J. Econ. Manag. Stud. 2022, 13, 551–567. [Google Scholar] [CrossRef]

- Appiah, K.M.; Ameko, E.; Asiamah, A.T.; Duker, Q.R. Blue economy investment and sustainability of Ghana’s territorial waters: An application of structural equation modelling. Int. J. Sustain. Eng. 2023, 16, 1–15. [Google Scholar] [CrossRef]

- Hart, S.L. A Natural-Resource-Based View of the Firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Firm Capabilities, Resources and the Concept of Strategy. Economic Analysis and Policy Working Paper EAP, 38; University of California: Oakland, CA, USA, 1990. [Google Scholar]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating Dynamic Capabilities: The Nature and Micro Foundations of (Sustainable) Enterprise Performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Bueno, A.F.; Godinho Filho, M.; Frank, A.G. Smart Production Planning and Control in The Industry 4.0 Context: A Systematic Literature Review. Comput. Ind. Eng. 2020, 149, 106774. [Google Scholar] [CrossRef]

- Saad, S.M.; Bahadori, R.; Jafarnejad, H.; Putra, M.F. Smart Production Planning and Control: Technology Readiness Assessment. Procedia Comput. Sci. 2021, 180, 618–627. [Google Scholar] [CrossRef]

- De Man, J.C.; Strandhagen, J.O. Spreadsheet application still dominates enterprise resource planning and advanced planning systems. Ifac-Pap. 2018, 51, 1224–1229. [Google Scholar] [CrossRef]

- Safdarian, A.; Fotuhi-Firuzabad, M.; Lehtonen, M.; Aminifar, F. Optimal Electricity Procurement in Smart Grids with Autonomous Distributed Energy Resources. IEEE Trans. Smart Grid 2015, 6, 2975–2984. [Google Scholar] [CrossRef]

- Henneberry, B. What is Smart Procurement? Definition, Applications, and How to Implement. 2023. Available online: https://www.thomasnet.com/articles/procurement/smart-procurement/ (accessed on 22 December 2020).

- Ngatia, M.; Jomo, K. Role of Public Procurement Oversight Authority on Procurement Regulations in Kenyan State Corporations. A Case of Kenya Electricity Generating Company (KenGen). Int. J. Acad. Res. Account. Financ. Manag. Sci. 2016, 6, 190–201. [Google Scholar]

- Chalmers, B. Smart Procurement: What It Is and Where to Start. What Is Smart Procurement? 2022. Available online: https://rfp360.com/smart-procurement/ (accessed on 22 December 2022).

- Wang, T.; Deng, S. Multi-Period Energy Procurement Policies for Smart-grid Communities with Deferrable Demand and Supplementary Uncertain Power Supplies. Omega 2018, 89, 212–226. [Google Scholar] [CrossRef]

- Chen, Z.; Ming, X.; Zhou, T.; Chang, Y. Sustainable supplier selection for smart supply chain considering internal and external uncertainty: An integrated rough-fuzzy approach. Appl. Soft Comput. 2019, 87, 106004. [Google Scholar] [CrossRef]

- Gupta, S.; Drave, V.A.; Bag, S. Leveraging Smart Supply Chain and Information System Agility for Supply Chain Flexibility. Inf. Syst. Front. 2019, 21, 547–564. [Google Scholar] [CrossRef]

- Butner, K. The Smarter Supply Chain of the Future. Strategy Leadersh. 2010, 38, 22–31. [Google Scholar] [CrossRef]

- Scherbakov, V.; Silkina, G. Logistics of smart supply chains. In Proceedings of the International Conference on Digital Technologies in Logistics and Infrastructure (ICDTLI 2019), St. Petersburg, Russia, 4–5 April 2019; Atlantis Press: Amsterdam, The Netherlands, 2019; Volume 1, pp. 66–71. [Google Scholar] [CrossRef]

- Shao, X.-F.; Liu, W.; Li, Y.; Chaudhry, H.R.; Yue, X.-G. Multistage implementation framework for smart supply chain management under industry 4.0. Technol. Forecast. Soc. Chang. 2021, 162, 120354. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT Driven Service-Oriented Smart Manufacturing: Framework and Characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 81–91. [Google Scholar] [CrossRef]

- Cai, S.; Ma, Z.; Skibniewski, M.J.; Bao, S. Construction automation and robotics for high-rise buildings over the past decades: A comprehensive review. Adv. Eng. Inform. 2019, 42, 100989. [Google Scholar] [CrossRef]

- Tantawi, K.H.; Sokolov, A.; Tantawi, O. Advances in Industrial Robotics: From Industry 3.0 Automation to Industry 4.0 Collaboration. In Proceedings of the 2019 4th Technology Innovation Management and Engineering Science International Conference (TIMES-iCON), Bangkok, Thailand, 11–13 December 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Aghimien, D.O.; Aigbavboa, C.O.; Oke, A.E.; Thwala, W.D. Mapping out research focus for robotics and automation research in construction-related studies: A bibliometric approach. J. Eng. Des. Technol. 2020, 18, 1063–1079. [Google Scholar] [CrossRef]

- Enríquez, J.G.; Jiménez-Ramírez, A.; Domínguez-Mayo, F.J.; García-García, J.A. Robotic Process Automation: A Scientific and Industrial Systematic Mapping Study. IEEE Access 2020, 8, 39113–39129. [Google Scholar] [CrossRef]

- Lowenberg-DeBoer, J.; Huang, I.Y.; Grigoriadis, V. Economics of robots and automation in field crop production. Precis. Agric. 2020, 21, 278–299. [Google Scholar] [CrossRef]

- Gerovitch and Slava Automation. 2003. Available online: https://www.researchgate.net/publication/262281771_Automation/citation/download (accessed on 22 July 2020).

- Humbert, M. Technology and Workforce: Comparison between the Information Revolution and the Industrial Revolution; University of California: Berkley, CA, USA, 2007; Available online: http://infoscience.epfl.ch/record/146804/files/InformationSchool.pdf?version=1 (accessed on 22 June 2010).

- Goldberg, K. What Is Automation? IEEE Trans. Autom. Sci. Eng. 2012, 9, 1–2. [Google Scholar] [CrossRef]

- Gerovitch, S. Automation. 2019; pp. 122–126. Available online: http://web.mit.edu/slava/homepage/articles/Gerovitch-Automation.pdf (accessed on 22 December 2022).

- Groover, P.M. Fundamentals of Modern Manufacturing Materials, Processes, and Systems, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Yang, H.; Kumara, S.; Bukkapatnam, S.T.S.; Tsung, F. The internet of things for smart manufacturing: A review. IISE Trans. 2019, 51, 1190–1216. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart Manufacturing and Intelligent Manufacturing: A Comparative Review. Engineering 2020, 7, 738–757. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative Industrie 4.0: Final Report of the Industrie 4.0 Working Group; Forschungsunion: Berlin, Germany, 2013. [Google Scholar]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Tseng, M.-L. Modeling sustainable production indicators with linguistic preferences. J. Clean. Prod. 2013, 40, 46–56. [Google Scholar] [CrossRef]

- Samuel, V.B.; Agamuthu, P.; Hashim, M.A. Indicators for assessment of sustainable production: A case study of the petrochemical industry in Malaysia. Ecol. Indic. 2013, 24, 392–402. [Google Scholar] [CrossRef]

- Blok, V.; Long, T.B.; Gaziulusoy, A.I.; Ciliz, N.; Lozano, R.; Huisingh, D.; Boks, C. From best practices to bridges for a more sustainable future: Advances and challenges in the transition to global sustainable production and consumption. J. Clean. Prod. 2015, 108, 19–30. [Google Scholar] [CrossRef]

- Alayón, C.; Säfsten, K.; Johansson, G. Conceptual sustainable production principles in practice: Do they reflect what companies do? J. Clean. Prod. 2017, 141, 693–701. [Google Scholar] [CrossRef]

- O’Brien, C. Sustainable production—A new paradigm for a new millennium. Int. J. Prod. Econ. 1999, 60–61, 1–7. [Google Scholar] [CrossRef]

- Ron, A.J. Sustainable production: The ultimate result of a continuous improvement. Int. J. Prod. Econ. 1998, 56–57, 99–110. [Google Scholar] [CrossRef]

- Roome, N.; Anastasiou, I. Sustainable Production: Challenges and objectives for EU Research Policy. 2021. Available online: https://www.cairn.info/revue-reflets-et-perspectives-de-la-vie-economique-2002-1-page-35.htm (accessed on 20 June 2022).

- Rosen, M.A.; Kishawy, H.A. Sustainable Manufacturing and Design: Concepts, Practices and Needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

- Hörisch, J.; Kollat, J.; Brieger, S.A. What influences environmental entrepreneurship? A multilevel analysis of the determinants of entrepreneurs’ environmental orientation. Small Bus. Econ. 2017, 48, 47–69. [Google Scholar] [CrossRef]

- Keszey, T. Environmental orientation, sustainable behaviour at the firm-market interface and performance. J. Clean. Prod. 2019, 243, 118524. [Google Scholar] [CrossRef]

- Hirunyawipada, T.; Xiong, G. Corporate environmental commitment and financial performance: Moderating effects of marketing and operations capabilities. J. Bus. Res. 2018, 86, 22–31. [Google Scholar] [CrossRef]

- Banerjee, S.B. Corporate environmentalism: The construct and its measurement. J. Bus. Res. 2002, 55, 177–191. [Google Scholar] [CrossRef]

- Yu, Y.; Huo, B. The impact of environmental orientation on supplier green management and financial performance: The moderating role of relational capital. J. Clean. Prod. 2018, 211, 628–639. [Google Scholar] [CrossRef]

- Lin, Y.H.; Chen, Y.S. Determinants of green competitive advantage: The roles of green knowledge sharing, green dynamic capabilities, and green service innovation. Qual. Quant. 2017, 51, 1663–1685. [Google Scholar] [CrossRef]

- Xing, X.; Liu, T.; Shen, L.; Wang, J. Linking Environmental Regulation and Financial Performance: The Mediating Role of Green Dynamic Capability and Sustainable Innovation. Sustainability 2018, 12, 1007. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Martin, J.A. Dynamic capabilities: What are they? Strateg. Manag. J. 2000, 21, 1105–1121. [Google Scholar] [CrossRef]

- Nelson, R.R.; Nelson, K. Technology, institutions, and innovation systems. Res. Policy. 2002, 31, 265–272. [Google Scholar] [CrossRef]

- Qiu, L.; Jie, X.; Wang, Y.; Zhao, M. Green product innovation, green dynamic capability, and competitive advantage: Evidence from Chinese manufacturing enterprises. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 146–165. [Google Scholar] [CrossRef]

- Teece, D.J. Business model and dynamic capabilities. Long Range Plan. 2017, 51, 40–49. [Google Scholar] [CrossRef]

- Amui, L.B.L.; Jabbour, C.C.J.; de Sousa Jabbour, A.B.L.; Kannan, D. Sustainability as a dynamic organizational capability: A systematic review and a future agenda toward a sustainable transition. J. Clean. Prod. 2017, 142, 308–322. [Google Scholar] [CrossRef]

- Appiah, K.M.; Sedegah, D.; Ayisi-Addo, K.A.; Gyening, K.E. Modeling the Influence of Industry Forces on Intention to Invest in Renewable Energy Resources with the Moderating Effect of Sustainable Competitive Strategy. Cogent Eng. 2022, 9, 2138101. [Google Scholar] [CrossRef]

- Appiah, K.M. A simplified model to enhance SMEs’ investment in renewable energy sources in Ghana. Int. J. Sustain. Energy Plan. Manag. 2022, 35, 83–96. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; Sage Publications Inc.: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to Use and How to Report the Results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Hair, F.J., Jr.; Sarstedt, M.; Hopkins, L.; Kuppelwieser, V.G. Partial least squares structural equation modeling (PLS-SEM): An emerging tool in business research. Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A New Criterion for Assessing Discriminant Validity in Variance-Based Structural Equation Modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Katchasuwanmanee, K.; Bateman, R.; Cheng, K. Development of the energy-smart production management system (e-ProMan): A big data driven approach, analysis and optimization. Proc. IMechE Part B J. Eng. Manuf. 2016, 230, 972–978. [Google Scholar] [CrossRef]

- Li, P.; Cheng, K.; Jiang, P. Investigation on quantitative analysis of carbon footprint in discrete manufacturing by using the innovative energy dataspace approach. Manuf. Lett. 2021, 27, 58–62. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).