The Mediating Role of Environmental Uncertainty in the Impact of Information Technology on Supply Chain Performance

Abstract

:1. Introduction

2. Conceptual Framework

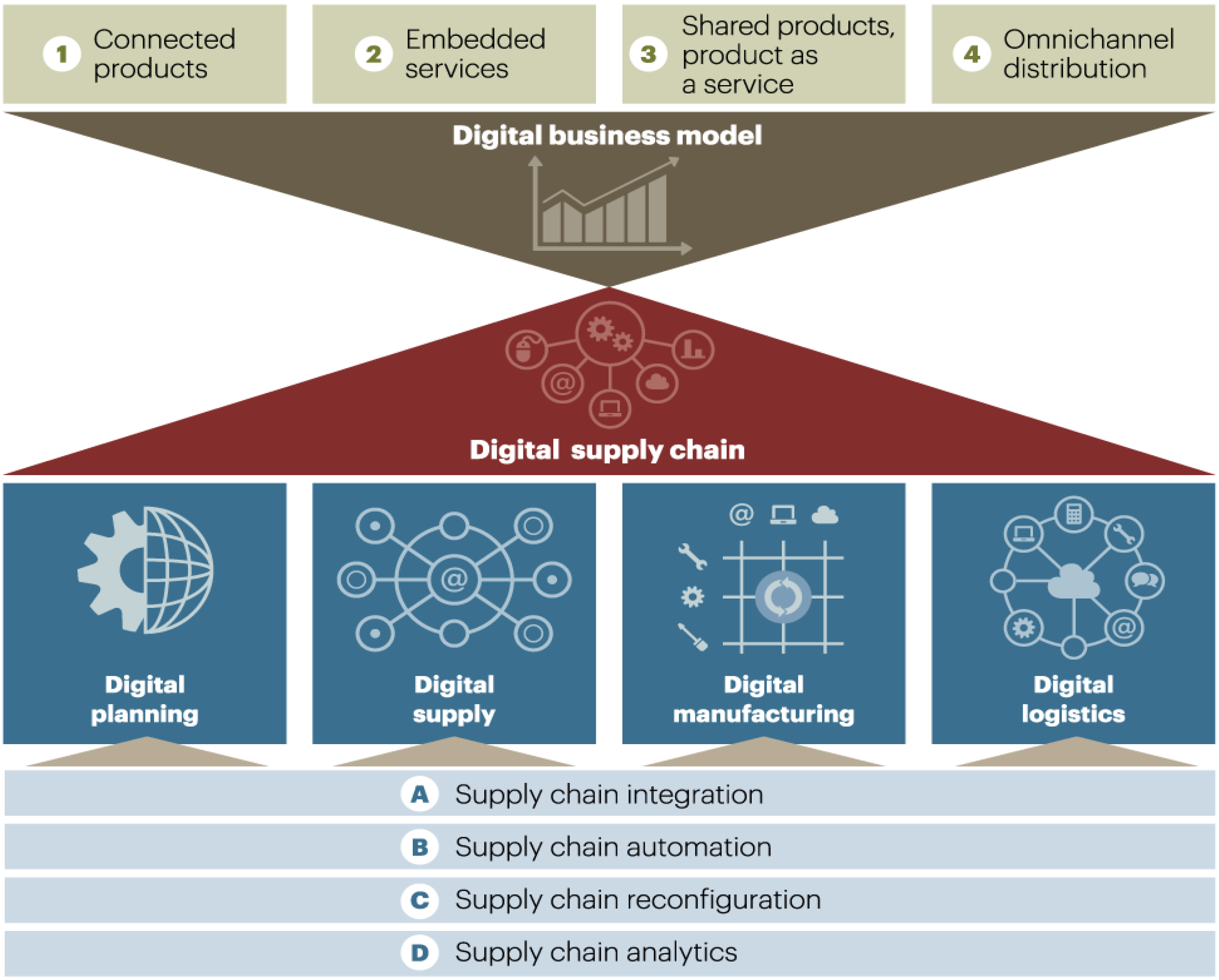

2.1. Strategic Importance of Information Technologies in Supply Chains

2.2. Supply Chain Performance

2.3. Environmental Uncertainty

3. Aim and Importance of the Study

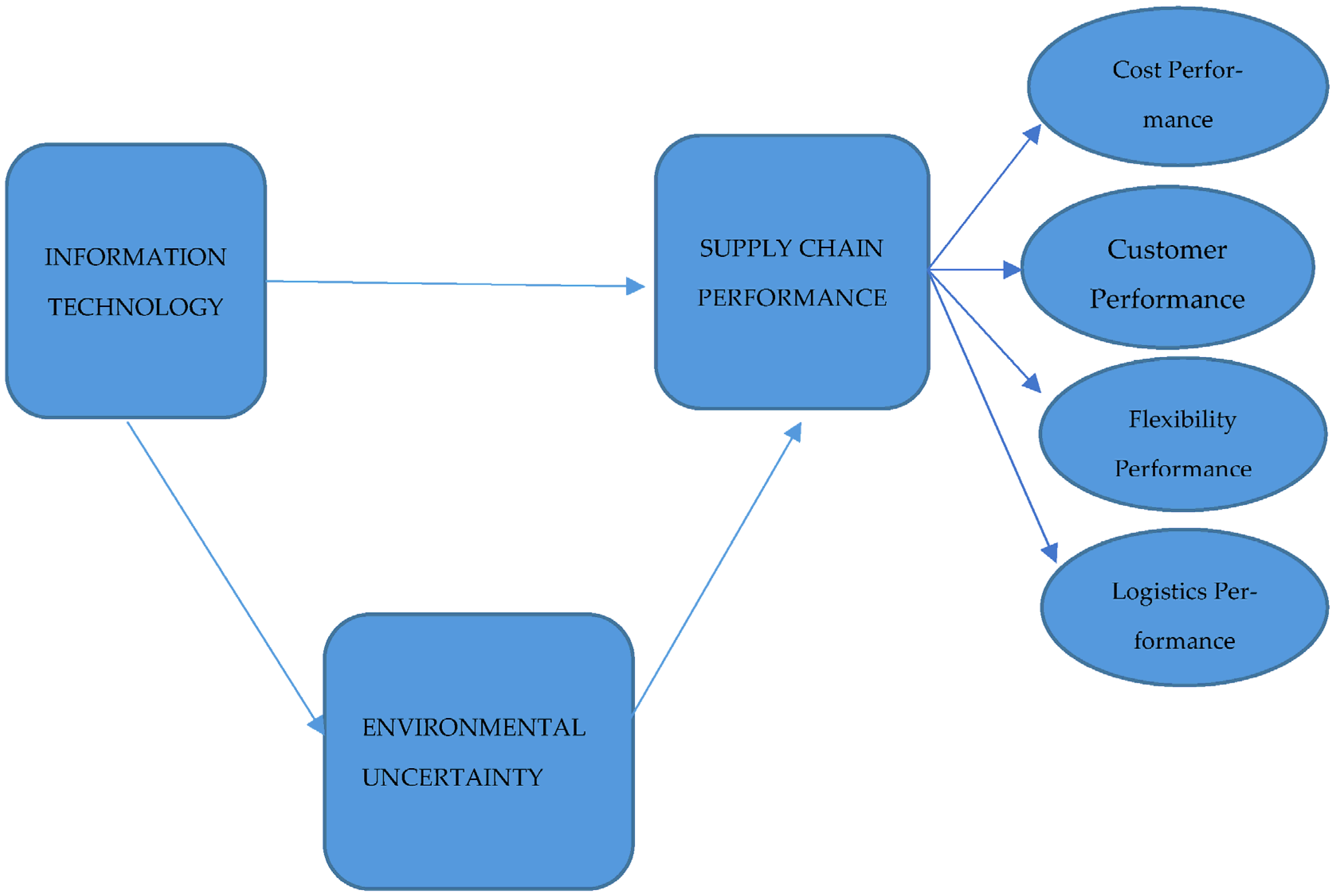

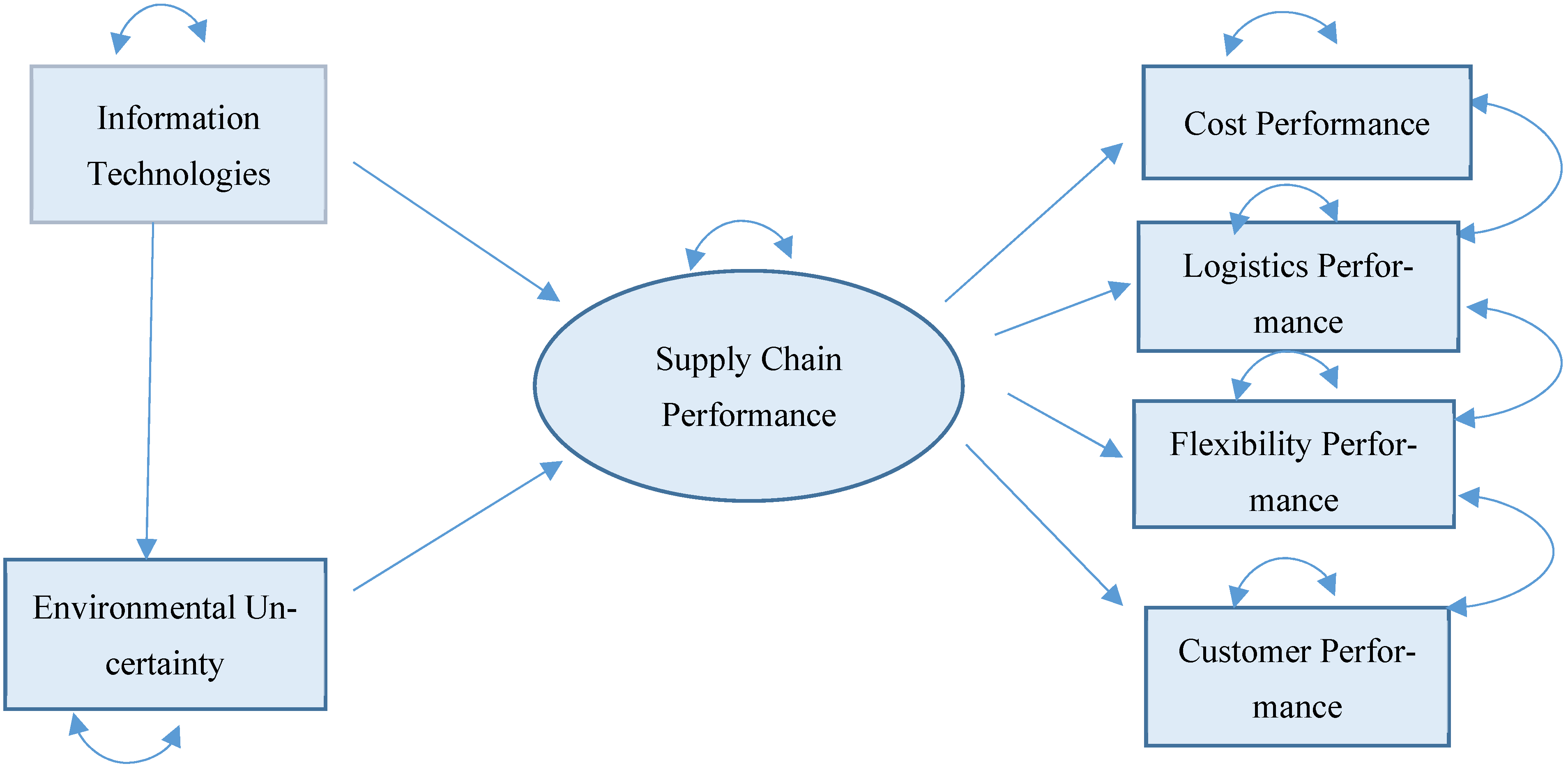

4. Research Model and Hypotheses

5. Research Population, Sample, and Data Collection Method

6. Analysis and Findings of Research Data

6.1. Demographic Findings

6.2. Reliability, Validity Analysis, and Normality Test

6.3. Results of the Relationship between Scales

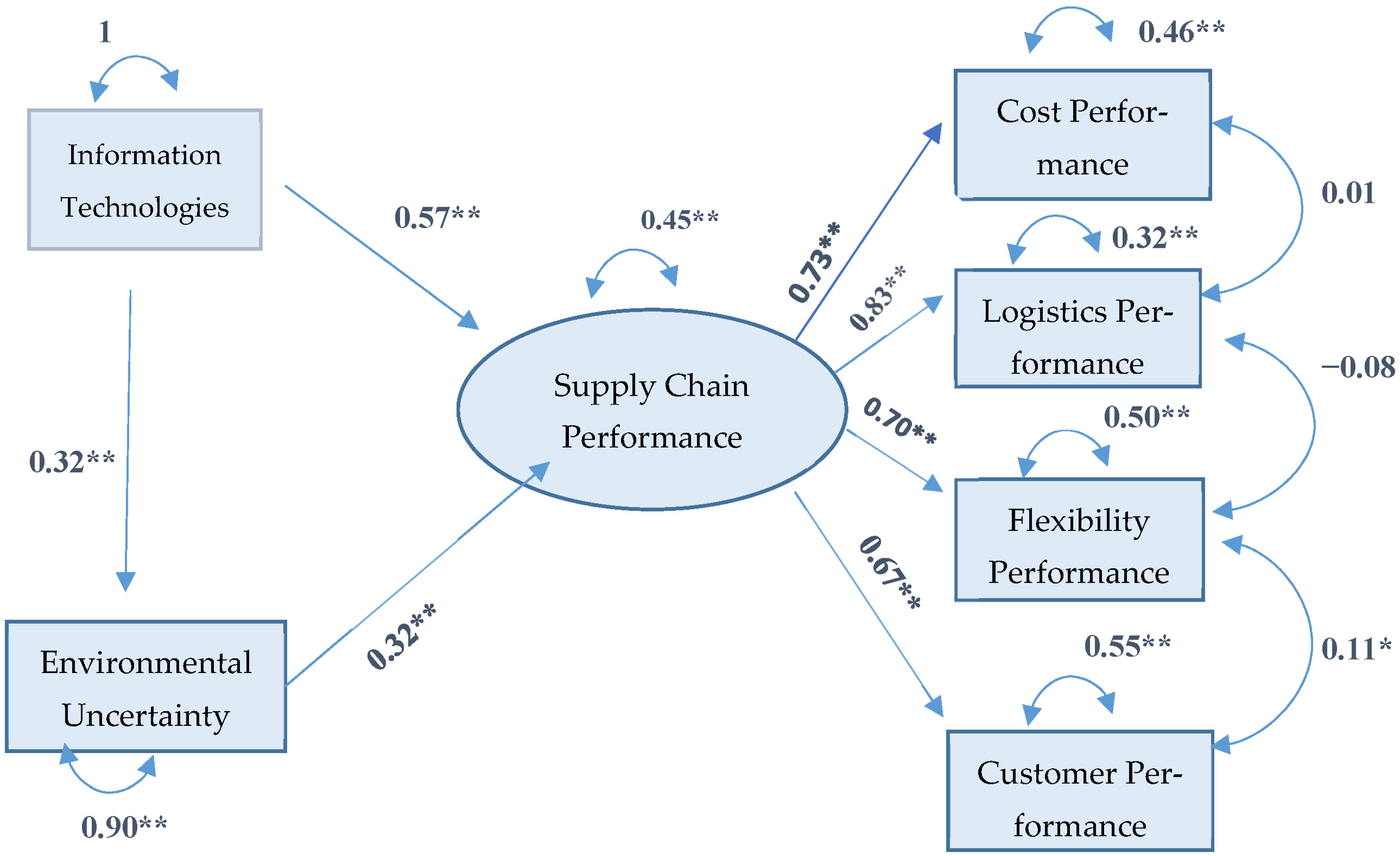

6.4. Testing the Theoretical Structural Model with Path Analysis

6.5. Confirmatory Factor Analysis Results

6.6. Convergent and Divergent Validity

6.7. Structural Equation Modeling Results

7. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Özçifçi, V. Tedarik Zinciri Yönetiminde Bilişim Teknolojileri Kullanımı ve Performans Ilişkisinin Incelenmesi. Doctoral Dissertation, University of Nigde, Nigde, Turkey, 2009. [Google Scholar]

- Bahar, S.; Özdağoğlu, A. Tedarik zinciri performansında bilgi teknolojileri faktörlerinin analiz edilmesinin önemi: AHS uygulaması. Turkuaz Uluslararası Sosyo-Ekon. Strat. Araştırmalar Derg. 2022, 4, 39–65. [Google Scholar]

- Schwab, K. The Fourth Industrial Revolution; World Economic Forum: Geneva, Switzerland, 2016. [Google Scholar]

- Tekin, M.; Öztürk, D.; Bahar, İ. Akıllı lojistik faaliyetlerinde blokzincir teknolojisi. Kent Akad. 2020, 13, 570–583. [Google Scholar] [CrossRef]

- Chan, T.; Qi, J.; Chan, H.; Lau, C.; Ip, W. A conceptual model of performance measurement for supply chains. Manag. Decis. 2003, 41, 635–642. [Google Scholar] [CrossRef]

- Sosa, L.; Alcaraz, J.L.; Macías, A.A. Evaluation of supply chain performance. In Management and Industrial Engineering; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar]

- Liao, Y. Supply Chain Flexibility: The Antecedents, Driving Forces and Impacts on Performance. Doctoral Dissertation, University of Toledo, Toledo, OH, USA, 2006. [Google Scholar]

- Bozalan, M.; Turan, İ. Bireysel yenilikçiliğin rekabetçi tutuma etkisinde çevresel belirsizliğin düzenleyici rolü. Süleyman Demirel Üniversitesi Vizyoner Derg. 2022, 13, 222–235. [Google Scholar] [CrossRef]

- Fynes, B.; Buirca, S.; Marshall, D. Environmental uncertainty, supply chain relationship quality and performance. J. Purch. Supply Manag. 2004, 10, 179–190. [Google Scholar] [CrossRef]

- Chejarla, K.C.; Vaidya, O.S.; Kumar, S. MCDM applications in logistics performance evaluation: A literature review. J. Multi-Criteria Decis. Anal. 2021, 29, 274–297. [Google Scholar] [CrossRef]

- Ahammad, M.F.; Basu, S.; Munjal, S.; Clegg, J.; Shoham, O. Strategic agility, environmental uncertainties and international performance: The perspective of Indian firms. J. World Bus. 2021, 56, 101218. [Google Scholar] [CrossRef]

- Grewal, R.; Tansuhaj, P. Building organizational capabilities for managing economic crisis: The role of market orientation and strategic flexibility. J. Mark. 2001, 65, 67–80. [Google Scholar] [CrossRef]

- Güler, Ü.; Sönmez, R. Dijitalleşmenin çevresel belirsizlik ortamında çevikliğe etkisi. J. Life Econ. 2023, 10, 233–245. [Google Scholar] [CrossRef]

- Miceli, A.; Hagen, B.; Riccardi, M.P.; Sotti, F.; Settembre-Blundo, D. Thriving, not just surviving in changing times: How sustainability, agility and digitalization intertwine with organizational resilience. Sustainability 2021, 13, 2052. [Google Scholar] [CrossRef]

- Zahra, S.A.; Covin, J.G. Contextual influences on the corporate entrepreneurship-performance relationship: A longitudinal analysis. J. Bus. Ventur. 1995, 10, 43–58. [Google Scholar] [CrossRef]

- Zahra, S.A.; Garvis, D.M. International corporate entrepreneurship and firm performance: The moderating effect of international environmental hostility. J. Bus. Ventur. 2000, 15, 469–492. [Google Scholar] [CrossRef]

- Aerts, A.; Goossenaerts, J.; Hammer, D.; Wortmann, J. Architectures in context: On the evolution of business, application software, and ict platform architectures. Inf. Manag. 2004, 41, 781–794. [Google Scholar] [CrossRef]

- Haddadzadehhendou, F. Bilişim ve Iletişim Teknolojileri Kullaniminin Işletmelerin Tedarikçileri Ile Olan Ilişkileri ve Işletme Performansi Üzerindeki Etkilerinin Belirlenmesi. Doctoral Dissertation, University of Atatürk, Erzurum, Turkey, 2020. [Google Scholar]

- Sağbaş, M. Tedarik Zinciri Yönetiminde Bilgi Teknolojileri, Çeviklik ve Entegrasyonun Operasyonel ve Finansal Performansa Etkisi. Doctoral Dissertation, University of Beykent, Istanbul, Turkey, 2015. [Google Scholar]

- Yüksel, H. Tedarik zinciri yönetiminde bilgi sistemlerinin önemi. Dokuz Eylül Üniversitesi Sos. Bilim. Enstitüsü Derg. 2002, 4, 261–279. [Google Scholar]

- Aydın, A.; Sarman, S. A management information system: Integrating GIS, GPS and ERP. In Proceedings of the 4th International Logistics and Supply Chain Management Congress, Izmir, Turkey, 29 November–1 December 2006. [Google Scholar]

- Gunasekaran, A.; Ngai, E.W. Information systems in supply chain integration and management. Eur. J. Oper. Res. 2004, 159, 269–295. [Google Scholar] [CrossRef]

- Yazgan, H. Tedarik Zinciri ve Bilgi Sistemleri Stratejilerinin Tedarik Zinciri Performansına Etkisi: Ihracat Yapan Işletmeler Üzerine Bir Araştırma. Doctoral Dissertation, University of Düzce, Düzce, Turkey, 2017. [Google Scholar]

- Zhao, M.; Dröge, C.; Stank, T.P. The effects of logistics capabilities on firm performance: Customer-focused versus information-focused capabilities. J. Bus. Logist. 2001, 22, 91–107. [Google Scholar] [CrossRef]

- Sauvage, T. The relationship between technology and logistics third-party providers. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 236–253. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Pereira, S.C.F.; Telles, R.; Machado, M.C. Industry 4.0 and digital supply chain capabilities: A framework for understanding digitalisation challenges and opportunities. Benchmarking Int. J. 2021, 28, 1761–1782. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.I. The impact of industry 4.0 on supply chains in engineer-to-order industries—An exploratory case study. IFAC-Pap. 2018, 51, 122–127. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J. Digital manufacturing-driven transformations of service supply chains for complex products. Supply Chain. Manag. Int. J. 2014, 19, 421–430. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. An extension of ARAS methodology under interval valued intuitionistic fuzzy environment for digital supply chain. Appl. Soft Comput. 2018, 69, 634–654. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. Impact of Industry 4.0 on supply chain performance. Prod. Plan. Control 2021, 32, 63–81. [Google Scholar] [CrossRef]

- MacCarthy, B.L.; Ivanov, D. The Digital Supply Chain—Emergence, concepts, definitions, and technologies. In The Digital Supply Chain; Elsevier: Amsterdam, The Netherlands, 2022; pp. 3–24. [Google Scholar]

- Zekhnini, K.; Cherrafi, A.; Bouhaddou, I.; Benghabrit, Y.; Garza-Reyes, J.A. Supply chain management 4.0: A literature review and research framework. Benchmarking Int. J. 2021, 28, 465–501. [Google Scholar] [CrossRef]

- Organisation for Economic Co-Operation and Development (OECD). OECD Dijital Economy Outlook 2017. 2017. Available online: https://www.oecd-ilibrary.org/sites/9789264276284-en/index.html?itemId=/content/publication/9789264276284-en (accessed on 12 March 2024).

- Otto Beisheim School of Managemet (WHU) Logistics Study 2015. Digital Supply Chains: Increasingly Critical for Competitive Edge. 2015. Available online: https://www.kearney.com/service/operations-performance/article/-/insights/digital-supply-chains-increasingly-critical-for-competitive-edge (accessed on 22 April 2024).

- Narasimhan, R.; Kim, S.W. Information system utilization strategy for supply chain integration. J. Bus. Logist. 2001, 22, 51–75. [Google Scholar] [CrossRef]

- Devaraj, S.; Krajewski, L.; Wei, J.C. Impact Of E-Business Technologies On Operational Performance: The Role Of Production İnformation İn The Supply Chain. J. Oper. Manag. 2007, 25, 1199–1216. [Google Scholar] [CrossRef]

- Thun, J.H. Angles of integration: An empirical analysis of the alignment of internet-based information technology and global supply chain integration. J. Supply Chain Manag. 2010, 46, 30–44. [Google Scholar] [CrossRef]

- Christopher, M. Logistics and Supply Chain Management, 4th ed.; Pearson: Harlow, UK, 2011. [Google Scholar]

- Nebol, E.; Uslu, T.; Uzel, E. Tedarik Zinciri ve Lojistik Yönetimi; Beta Yayıncılık: İstanbul, Turkey, 2014. [Google Scholar]

- Childs, T.C. The Effects of Intraorganizational Resources and Dimensions of Supply Chain Integration on Firm Performance. Doctoral Dissertation, University of Capella, Minneapolis, MN, USA, 2016. [Google Scholar]

- Terjesen, S.; Patel, P.C.; Sanders, N.R. Managing differentiation-integration duality in supply chain integration. Decis. Sci. 2012, 43, 303–339. [Google Scholar] [CrossRef]

- Yarar, C. Tedarik Zinciri Yönetiminde Bilgi Teknolojileri Kullanımının Zincir Performansına Etkisi. Doctoral Dissertation, University of Başkent, Ankara, Turkey, 2022. [Google Scholar]

- Eriş, E. Lojistik Sektöründe Pazar Yönlü—Öğrenme Yönlü Olma ve Yenilikçiliğin Işletme Performansina Etkisi. Doctoral Dissertation, University of Dokuz Eylül, İzmir, Turkey, 2008. [Google Scholar]

- Baki, B.; Şimşek, B. Lojistik faaliyetlere göre performans ölçütlerinin belirlenmesi. In Proceedings of the 24. Yöneylem Araştırması/Endüstri Mühendisliği Kongresi, Adana, Turkey, 15–18 June 2004. [Google Scholar]

- Schmıtz, J.; Platts, K.W. Supplier logistics performance measurement: Indications from a study in the automotive industry. Int. J. Prod. Econ. 2004, 89, 231–243. [Google Scholar] [CrossRef]

- Chow, G.; Heaver, T.D.; Henriksson, L.E. Logistics performance: Definition and measurement. Int. J. Phys. Distrib. Logist. Manag. 1994, 24, 17–28. [Google Scholar] [CrossRef]

- Senir, G. Ihracatçi Firmalar Açisindan Lojistik Hizmet Sağlayicilarin Performansinin Değerlendirilmesi. Doctoral Dissertation, University of Nigde Omer Halisdemir, Niğde, Turkey, 2021. [Google Scholar]

- Chan, F.T. performance measurement in a supply chain. Int. J. Adv. Manuf. Technol. 2003, 21, 534–548. [Google Scholar] [CrossRef]

- Beamon, B.M. Supply chain design and analysis: Models and methods. Int. J. Prod. Econ. 1998, 55, 281–294. [Google Scholar] [CrossRef]

- Parker, C. Performance measurement. Work Study 2000, 49, 63–66. [Google Scholar] [CrossRef]

- Niven, P.R. Balanced Scorecard Step-by-Step: Maximizing Performance and Maintaining Results; John Wiley and Sons: New York, NY, USA, 2006. [Google Scholar]

- Polat, İ. Tedarik Zinciri Entegrasyonunun Tedarik Zinciri Performansi Üzerindeki Etkisi. Master’s Dissertation, University of Bandırma Onyedi Eylül, Bandirma, Turkey, 2021. [Google Scholar]

- Poluha, G.R. The quintessence of supply chain management what you really need to know to manage your processes in procurement, manufacturing. In Warehousing And Logistics; Springer: Paris, France, 2016. [Google Scholar]

- Ghalayini, A.M.; Noble, J.S. The changing basis of performance measurement. Int. J. Oper. Prod. Manag. 1996, 16, 63–80. [Google Scholar] [CrossRef]

- Arıöz, Ö.; Yıldırım, K. Turkey’de çimento sektöründeki belirsizlikler ve Türk çimento sektörünün SWOT analizi. Dumlupınar Üniversitesi Sos. Bilim. Derg. 2012, 32, 173–190. [Google Scholar]

- Jaworski, B.J.; Kohli, A.K. Market orientation: Antecedents and consequences. J. Mark. 1993, 57, 53–70. [Google Scholar] [CrossRef]

- Lin, Z. Environmental determination or organizational design: An exploration of organizational decision making under environmental uncertainty. Simul. Model. Pract. Theory 2006, 14, 438–453. [Google Scholar] [CrossRef]

- Daft, R.L.; Murphy, J.; Willmott, H. Organization Theory and Design; South-Wester: Singapore, 2010. [Google Scholar]

- Vatansever, K. Tedarik Zinciri Esnekliğinin Firma Performansı Üzerindeki Etkileri ve Tekstil Sektöründe Bir Araştırma. Doctoral Dissertation, University of Dumlupınar, Kütahya, Turkey, 2010. [Google Scholar]

- Yang, B.; Burns, N.D.; Backhouse, C.J. Management of uncertainty through postponement. Int. J. Prod. Res. 2004, 42, 1049–1064. [Google Scholar] [CrossRef]

- Agarwal, A.; Shankar, R.; Tiwari, M.K. Modeling the metrics of lean, agile and leagile supply chain: An ANP-based approach. Eur. J. Oper. Res. 2006, 173, 211–225. [Google Scholar] [CrossRef]

- Gosling, J.; Purvis, L.; Naim, M.M. Supply chain flexibility as a determinant of supplier selection. Int. J. Prod. Econ. 2010, 128, 11–21. [Google Scholar] [CrossRef]

- Hult, G.T.M.; Craighead, C.W.; Ketchen, D.J., Jr. Risk uncertainty and supply chain decisions: A real options perspective. Decis. Sci. 2010, 41, 435–458. [Google Scholar] [CrossRef]

- Simangunsong, E.; Hendry, L.C.; Stevenson, M. Supply-chain uncertainty: A review and theoretical foundation for future research. Int. J. Prod. Res. 2012, 50, 4493–4523. [Google Scholar] [CrossRef]

- Ambulkar, S.; Blackhurst, J.; Grawe, S. Firm’s resilience to supply chain disruptions: Scale development and empirical examination. J. Oper. Manag. 2015, 33, 111–122. [Google Scholar] [CrossRef]

- Salam, M.A.; Bajaba, S. The role of supply chain resilience and absorptive capacity in the relationship between marketing–supply chain management alignment and firm performance: A moderated-mediation analysis. J. Bus. Ind. Mark. 2023, 38, 1545–1561. [Google Scholar] [CrossRef]

- Zhou, J.; Hu, L.; Yu, Y.; Zhang, J.Z.; Zheng, L.J. Impacts of IT capability and supply chain collaboration on supply chain resilience: Empirical evidence from China in COVID-19 pandemic. J. Enterp. Inf. Manag. 2024, 37, 777–803. [Google Scholar] [CrossRef]

- Meijer, I.S.; Hekkert, M.P.; Koppenjan, J.F. How perceived uncertainties influence transitions; the case of micro-CHP in the Netherlands. Technol. Forecast. Soc. Change 2007, 74, 519–537. [Google Scholar] [CrossRef]

- Çetindaş, A. İmalat İşletmelerinde Tedarik Zinciri Entegrasyonunun Lojistik Performansı Üzerindeki Etkisinde Çevresel Belirsizliğin Düzenleyici Rolü. Doctoral Dissertation, University of Hasan Kalyoncu, Gaziantep, Turkey, 2018. [Google Scholar]

- Lee, P.K.C.; Yeung, A.C.L.; Cheng, T.C.E. Supplier alliances and envioronmental uncertainty: An emprical study. Prod. Econ. 2009, 120, 190–204. [Google Scholar] [CrossRef]

- Wernerfelt, B.; Karnani, A. Competitive strategy under uncertainty. Strateg. Manag. J. 1987, 8, 187–194. [Google Scholar] [CrossRef]

- Li, S.; Lin, B. Accessing information sharing and information quality in supply chain management. Decis. Support Syst. 2006, 42, 1641–1656. [Google Scholar] [CrossRef]

- Mohr, J. The marketing of high-technology products and services: Implications for curriculum conten and design. J. Mark. Educ. 2000, 22, 246–259. [Google Scholar] [CrossRef]

- Eckbo, B. Mergers and the value of antitrust deterrence. J. Financ. 1992, 47, 1005–1028. [Google Scholar] [CrossRef]

- Chandy, R.K.; Tellis, G.J. The incumbent’s curse? Incumbency, size, and radical product innovation. J. Mark. 2000, 64, 1–17. [Google Scholar] [CrossRef]

- Asamoah, D.; Agyei-Owusu, B.; Andoh-Baidoo, F.K.; Ayaburi, E. Inter-organizational systems use and supply chain performance: Mediating role of supply chain management capabilities. Int. J. Inf. Manag. 2021, 58, 102195. [Google Scholar] [CrossRef]

- Gülaslan, M. Tedarik Zinciri Yönetiminde Bilgi Iletişim Teknolojileri Kullaniminin Tedarik Zinciri Entegrasyonuna ve Performansina Etkisi: Imalat Sanayiinde Bir Araştirma. Doctoral Dissertation, University of Marmara, Istanbul, Turkey, 2022. [Google Scholar]

- Kim, H.J. Information technology and firm performance: The role of supply chain integration. Oper. Manag. Res. 2017, 10, 1–9. [Google Scholar] [CrossRef]

- Liang, T.P.; You, J.J.; Liu, C.C. A resource-based perspective on information technology and firm performance: A meta analysis. Ind. Manag. Data Syst. 2010, 110, 1138–1158. [Google Scholar] [CrossRef]

- Zhang, X.; Van Donk, D.P.; van der Vaart, T. The different impact of inter-organizational and intra-organizational ICT on supply chain performance. Int. J. Oper. Prod. Manag. 2016, 36, 803–824. [Google Scholar] [CrossRef]

- Hou, C.K. The effects of IT infrastructure integration and flexibility on supply chain capabilities and organizational performance: An empirical study of the electronics industry in Taiwan. Inf. Dev. 2020, 36, 576–602. [Google Scholar] [CrossRef]

- Nandi, M.L.; Nandi, S.; Moya, H.; Kaynak, H. Blockchain technology-enabled supply chain systems and supply chain performance: A resource-based view. Supply Chain Manag. Int. J. 2020, 25, 841–862. [Google Scholar] [CrossRef]

- Baki, R. The Impact ofinformation technologies andtop management support on supply chain performance: An empirical approach for Turkey. Avrupa Bilim Teknol. Derg. 2019, 17, 916–926. [Google Scholar]

- Jin, B. Performance implications of information technology implementation in an apparel supply chain. Supply Chain Manag. Int. J. 2006, 11, 309–316. [Google Scholar] [CrossRef]

- Li, G.; Yang, H.; Sun, L.; Sohal, A.S. The impact of IT implementation on supply chain integration and performance. Int. J. Prod. Econ. 2009, 120, 125–138. [Google Scholar] [CrossRef]

- Öztemiz, H. Dijital tedarik zinciri yönetimi ve tedarik zincirinde dijital uygulamalar konusundaki yayınların bibliyometrik analizi (1995–2023) ve gelecek araştırmalar için fırsatlar. J. Res. Bus. 2023, 8, 377–410. [Google Scholar] [CrossRef]

- Srivastava, A.K. Modeling strategic performance factors for effective strategy execution. Int. J. Product. Perform. Manag. 2013, 62, 554–582. [Google Scholar] [CrossRef]

- Bülbül, H.; Özçifçi, V.; Özoğlu, B. Tedarik zinciri ve işletme performansına bilişim teknolojilerinin etkisi. Niğde Üniversitesi İktisadi Ve İdari Bilim. Fakültesi Derg. 2014, 7, 95. [Google Scholar]

- Vinogradova, M.; Rogulin, R.; Ermakova, M.; Okhrimenko, I. Assessing the sources of uncertainty in supply chain management. Strateg. Change 2021, 30, 453–460. [Google Scholar] [CrossRef]

- Lee, H.L. Aligning supply chain strategies with product uncertainties. Calif. Manag. Rev. 2002, 44, 105–119. [Google Scholar] [CrossRef]

- Gubbi, S.R.; Aulakh, P.S.; Ray, S.; Sarkar, M.B.; Chittoor, R. Do international acquisitions by emerging-economy firms create shareholder value? The case of Indian firms. J. Int. Bus. Stud. 2010, 41, 397–418. [Google Scholar] [CrossRef]

- Samsami, F.; Hosseini, S.H.K.; Kordnaeij, A.; Azar, A. Managing environmental uncertainty: From conceptual review to strategic management point of view. Int. J. Bus. Manag. 2015, 10, 215. [Google Scholar] [CrossRef]

- Dess, G.G.; Lumpkin, G.T.; Covin, J.G. Entrepreneurial strategy making and firm performance: Tests of contingency and configurational models. Strateg. Manag. J. 1997, 18, 677–695. [Google Scholar] [CrossRef]

- Srinivasan, M.; Mukherjee, D.; Gaur, A.S. Buyer–supplier partnership quality and supply chain performance: Moderating role of risks, and environmental uncertainty. Eur. Manag. J. 2011, 29, 260–271. [Google Scholar] [CrossRef]

- Wong, C.Y.; Boon-Itt, S.; Wong, C.W. The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. J. Oper. Manag. 2011, 29, 604–615. [Google Scholar] [CrossRef]

- Istanbul Chamber of Industry (ICI). Turkey’s Top 500 Industrial Enterprises. Available online: https://www.iso500.org.tr/500-big-industrial-institutions-of-turkey (accessed on 3 May 2024).

- Desarbo, W.S.; Benedetto, C.A.D.; Song, M.; Sinha, I. Revisiting the miles and snow strategic framework: Uncovering interrelationships between strategictypes, capabilities, environmental uncertainty and firm performance. Strateg. Manag. J. 2005, 26, 47–74. [Google Scholar] [CrossRef]

- Karagöz, I. Bilgi Teknolojisi Yeteneğinin Lojistik Yeteneğe ve Işletme Performansina Etkileri. Doctoral Dissertation, University of Gebze Teknik, Gebze, Turkey, 2016. [Google Scholar]

- Piprani, A.Z.; Mohezar, S.; Jaafar, N.I. Supply chain integration and supply chain performance: The mediating role of supply chain resilience. Int. J. Supply Chain Manag. 2020, 9, 58–73. [Google Scholar]

- Huo, B.; Haq, M.Z.U.; Gu, M. The impact of it application on supply chain learning and service performance. Ind. Manag. Data Syst. 2020, 120, 1–20. [Google Scholar] [CrossRef]

- Tao, X. Performance evaluation of supply chain based on fuzzy matter element theory. In Proceedings of the International Conference on Information Management, Innovation Management and Industrial Engineering, Xi’an, China, 26–27 December 2009. [Google Scholar]

- Çankaya, S. Tedarik Zinciri Yönetimine Sürdürülebilirlik Perspektifinden Bakiş ve Yeşil Uygulamalar. Doctoral Dissertation, University of Gebze Teknik, Darica, Turkey, 2015. [Google Scholar]

- Altunışık, R.; Coşkun, R.; Bayraktaroğlu, S.; Yıldırım, E. Sosyal Bilimlerde Araştırma Yöntemleri, 6th ed.; Sakarya Publishing House: Sakarya, Turkey, 2010. [Google Scholar]

- Hair, J.F.; Anderson, R.E.; Tatham, R.L.; Black, W.C. Multivariate Data Analysis; Macmiilan Publishing Company: New York, NY, USA, 1998. [Google Scholar]

- Brown, T.A. Confirmatory Factor Analysis for Applied Research. In Methodology in the Social Sciences; Guilford Press: New York, NY, USA, 2006. [Google Scholar]

- Tabachnick, B.G.; Fidell, L.S. Using Multivariate Statistics, 5th ed.; Pearson Allyn and Bacon: Boston, MA, USA, 2007. [Google Scholar]

- Fornell, C.; Larcker, D.F. Structural equation models with unobservable variables and measurement error: Algebra and statistics. J. Mark. Res. 1981, 18, 382–388. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R. Multivariate Data Analysis, 6th ed.; Prentice Hall: Uppersaddle River, NJ, USA, 2006. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis: A Global Perspective, 7th ed.; Pearson Education: Uppersaddle River, NJ, USA, 2010. [Google Scholar]

- Tugtekin, U.; Barut Tugtekin, E.; Kurt, A.A.; Demir, K. Associations between fear of missing out, problematic smartphone use, and social networking services fatigue among young adults. Soc. Media Soc. 2020, 6, 1–17. [Google Scholar] [CrossRef]

- Bagozzi, R.P.; Yi, Y. On the evaluation of structural equation models. J. Acad. Mark. Sci. 1988, 16, 74–94. [Google Scholar] [CrossRef]

- Salleh, N.A.M.; Jusoh, R.; Isa, C.R. Relationship between information systems sophistication and performance measurement. Ind. Manag. Data Syst. 2010, 110, 993–1017. [Google Scholar] [CrossRef]

- Yang, C.; Su, Y. The relationship between benefits of ERP systems implementation and its impacts on firm performance of SCM. J. Enterp. Inf. Manag. 2009, 22, 722–752. [Google Scholar] [CrossRef]

- Collins, J.D.; Worthington, W.J.; Reyes, P.M.; Romero, M. Knowledge management, supply chain technologies and firm performance. Manag. Res. Rev. 2010, 33, 947–960. [Google Scholar] [CrossRef]

- McFarland, F.W. Information technology changes the way you compete. Harv. Bus. Rev. 1984, 62, 98–103. [Google Scholar]

- Zheng, Z.; Xie, S.; Dai, H.; Chen, X.; Wang, H. An overview of blockchain technology: Architecture, consensus, and future trends. In Proceedings of the 2017 IEEE International Congress on Big Data, Boston, MA, USA, 11–14 June 2017. [Google Scholar]

- Çemberci, M.; Sözer, E.G.; Civelek, M.E. Firmalar arası bilgi paylaşımı ile tedarik zinciri yönetimi performansı ilişkisinde bilgi kalitesinin moderatör etkisi. Yönetim Bilim. Derg. 2015, 13, 141–159. [Google Scholar]

- Fawcett, S.E.; Osterhaus, P.; Magnan, G.M.; Brau, J.C.; McCarter, M.W. Information sharing and supply chain performance: The role of connectivity and willingness. Supply Chain Manag. Int. J. 2007, 12, 358–368. [Google Scholar] [CrossRef]

- Sevinç, D. Kamu kurumlarında bilgi teknolojileri kullanımı ve bunların çalışanların fiziksel ve psikolojik durumlarına etkileri. Bilgi Ekon. Yönetimi Derg. 2007, 2, 21–31. [Google Scholar]

- Bülbül, H.; Durna, U.; Yılmaz, N. Yenilikçiliği Geliştirmede Bilgi ve Bilgi Teknolojilerinin Önemi. In Proceedings of the Kırgızistan-Turkey Manas Üniversitesi İktisadi ve İdari Birimler Fakültesi Uluslararası Girişimcilik Kongresi, Bişkek, Kyrgyzstan, 25–27 May 2006. [Google Scholar]

- Sun, S.Y.; Hsu, M.H.; Hwang, W.J. The impact of alignment between supply chain strategy and environmental uncertainty on SCM performance. Supply Chain Manag. Int. J. 2009, 14, 201–212. [Google Scholar] [CrossRef]

| Variables | n | % | |

|---|---|---|---|

| Gender | Female | 89 | 46.4 |

| Male | 103 | 53.6 | |

| Educational status | High school and below | 15 | 7.8 |

| Associate degree | 36 | 18.8 | |

| License | 102 | 53.1 | |

| Postgraduate (Master’s/Ph.D.) | 39 | 20.3 | |

| Dealer/Retailer | 22 | 11.5 | |

| Distributor/Wholesaler | 21 | 10.9 | |

| Logistics Service Provider | 44 | 22.9 | |

| Producer | 79 | 41.1 | |

| Primary Supplier | 18 | 9.4 | |

| Secondary Supplier | 8 | 4.2 | |

| Sector in which the business operates | Food | 52 | 27.1 |

| Metal/Steel | 10 | 5.2 | |

| Energy | 8 | 4.2 | |

| Transportation and Storage | 20 | 10.4 | |

| Textile | 17 | 8.9 | |

| Heating Cooling | 6 | 3.1 | |

| Machinery/Industry | 7 | 3.6 | |

| Furniture/Wood Works | 5 | 2.6 | |

| Plastic packaging | 12 | 6.3 | |

| Logistics | 5 | 2.6 | |

| Electrical/Electronics | 5 | 2.6 | |

| Agricultural Products | 12 | 6.3 | |

| Defense Industry and Aviation | 3 | 1.6 | |

| Mining | 5 | 2.6 | |

| Automotive | 17 | 8.9 | |

| Chemistry/Medicine | 8 | 4.2 | |

| Number of employees in the enterprise | Fewer than 50 | 31 | 16.1 |

| 50–249 | 35 | 18.2 | |

| 250–500 | 60 | 31.3 | |

| More than 501 | 66 | 34.4 | |

| Status in the enterprise | Manager/General Manager | 14 | 7.3 |

| Assistant director | 13 | 6.8 | |

| Purchasing manager | 9 | 4.7 | |

| Production manager | 8 | 4.2 | |

| Supply Chain/Logistics Manager | 45 | 23.4 | |

| Planning Specialist | 10 | 5.2 | |

| Warehouse Problem | 22 | 11.5 | |

| Operations manager | 14 | 7.3 | |

| Entrepreneur | 19 | 9.9 | |

| Finance Manager | 11 | 5.7 | |

| Marketing Manager | 7 | 3.6 | |

| Human resources manager | 11 | 5.7 | |

| Others | 9 | 4.7 | |

| Total | 192 | 100.0 | |

| Mean | Std. Dev. | Minimum | Maximum | Skewness | |

|---|---|---|---|---|---|

| Cost Performance | 3.4257 | 1.1045 | 1.0000 | 5.0000 | −0.6299 |

| Customer Performance | 3.9652 | 0.8400 | 1.0000 | 5.0000 | −1.3955 |

| Flexibility Performance | 3.5729 | 1.1543 | 1.0000 | 5.0000 | −0.9523 |

| Logistics Performance | 3.7250 | 0.9169 | 1.0000 | 5.0000 | −1.1671 |

| Supply Chain Performance | 3.6992 | 0.8036 | 1.0000 | 5.0000 | −1.0288 |

| Information Technologies | 3.7847 | 1.0805 | 1.0000 | 5.0000 | −1.0550 |

| Environmental Uncertainty | 3.2395 | 0.9750 | 1.0000 | 5.0000 | −0.1593 |

| Scales | Cronbach’s Alpha |

|---|---|

| Cost Performance | 0.937559 |

| Customer Performance | 0.881852 |

| Flexibility Performance | 0.964207 |

| Logistics Performance | 0.867136 |

| Supply Chain Performance | 0.943012 |

| Information Technologies | 0.967616 |

| Environmental Uncertainty | 0.836233 |

| Cost Performance | Customer Performance | Flexibility Performance | Logistics Performance | Supply Chain Performance | Information Technologies | Environmental Uncertainty | |

|---|---|---|---|---|---|---|---|

| Cost Performance | 1.00000 | ||||||

| Customer Performance | 0.45666 | 1.00000 | |||||

| <0.0001 | |||||||

| Flexibility Performance | 0.54684 | 0.58110 | 1.00000 | ||||

| <0.0001 | <0.0001 | ||||||

| Logistics Performance | 0.61403 | 0.55262 | 0.50359 | 1.00000 | |||

| <0.0001 | <0.0001 | <0.0001 | |||||

| Supply Chain Performance | 0.78957 | 0.80538 | 0.83525 | 0.80813 | 1.00000 | ||

| <0.0001 | <0.0001 | <0.0001 | <0.0001 | ||||

| Information Technologies | 0.53163 | 0.48284 | 0.45719 | 0.54410 | 0.61690 | 1.00000 | |

| <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | |||

| Environmental Uncertainty | 0.31071 | 0.36630 | 0.32652 | 0.46112 | 0.44904 | 0.32252 | 1.00000 |

| <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Compatibility Index | Acceptance Criteria | Reference |

|---|---|---|

| χ2/sd | ≤3 = perfect fit ≤5 = acceptable fit | [105] |

| RMSEA/SRMR | ≤0.05 = perfect fit ≤0.10 = acceptable fit | [106] |

| GFI/AGFI | ≥0.90 = perfect fit ≥0.85 = acceptable fit | [107] |

| CFI | ≥0.90 = perfect fit ≥0.85 = acceptable fit | [107] |

| NFI | ≥0.90 = perfect fit ≥0.85 = acceptable fit | [107] |

| Scales and Items | Average | Std. Deviation | Standardized Loads | Std. Error | t | p | |

|---|---|---|---|---|---|---|---|

| Cost Performance | SCPCP1 | 3.3854 | 1.1610 | 0.8767 | 0.0203 | 43.046 | <0.0001 |

| SCPCP2 | 3.4791 | 1.1931 | 0.8474 | 0.0249 | 34.023 | <0.0001 | |

| SCPCP3 | 3.4375 | 1.2306 | 0.9048 | 0.0181 | 49.996 | <0.0001 | |

| SCPCP4 | 3.4010 | 1.2282 | 0.9007 | 0.0179 | 50.269 | <0.0001 | |

| Customer Performance | SCPCP1 | 4.0312 | 1.0176 | 0.8979 | 0.0196 | 45.622 | <0.0001 |

| SCPCP2 | 4.0885 | 0.9960 | 0.8977 | 0.0198 | 45.326 | <0.0001 | |

| SCPCP3 | 4.0156 | 1.0459 | 0.8044 | 0.0293 | 27.382 | <0.0001 | |

| SCPCP4 | 4.0104 | 1.0682 | 0.7446 | 0.0458 | 14.047 | <0.0001 | |

| SCPCP5 | 3.9375 | 0.9954 | 0.7176 | 0.0479 | 12.888 | <0.0001 | |

| SCPCP6 | 3.7083 | 1.2609 | 0.7853 | 0.0566 | 8.5762 | <0.0001 | |

| Flexibility Performance | SCPFP1 | 3.4791 | 1.2235 | 0.8481 | 0.0211 | 40.117 | <0.0001 |

| SCPFP2 | 3.5104 | 1.2236 | 0.8783 | 0.0174 | 50.252 | <0.0001 | |

| SCPFP3 | 3.6302 | 1.2548 | 0.9294 | 0.0111 | 83.539 | <0.0001 | |

| SCPFP4 | 3.6354 | 1.2204 | 0.9665 | 0.0072 | 133.400 | <0.0001 | |

| SCPFP5 | 3.6093 | 1.2484 | 0.9080 | 0.0140 | 64.504 | <0.0001 | |

| Logistics Performance | SCPLP1 | 3.5468 | 1.1385 | 0.8200 | 0.0319 | 25.690 | <0.0001 |

| SCPLP2 | 3.6197 | 1.2134 | 0.6815 | 0.0425 | 16.031 | <0.0001 | |

| SCPLP3 | 3.8020 | 1.0646 | 0.7483 | 0.0351 | 21.293 | <0.0001 | |

| SCPLP4 | 3.8645 | 1.0985 | 0.7576 | 0.0362 | 20.909 | <0.0001 | |

| SCPLP5 | 3.7916 | 1.1659 | 0.8042 | 0.0336 | 23.923 | <0.0001 | |

| Information Technologies | IT1 | 3.7187 | 1.1995 | 0.8878 | 0.0164 | 53.827 | <0.0001 |

| IT2 | 3.8072 | 1.1528 | 0.8997 | 0.0149 | 60.072 | <0.0001 | |

| IT3 | 3.8072 | 1.1574 | 0.9561 | 0.0078 | 121.400 | <0.0001 | |

| IT4 | 3.7864 | 1.1850 | 0.9596 | 0.0074 | 128.500 | <0.0001 | |

| IT5 | 3.7760 | 1.1653 | 0.8570 | 0.0204 | 41.987 | <0.0001 | |

| IT6 | 3.8125 | 1.1285 | 0.8910 | 0.0161 | 55.256 | <0.0001 | |

| Environmental Uncertainty | EU1 | 3.2135 | 1.1806 | 0.6760 | 0.0493 | 13.702 | <0.0001 |

| EU2 | 3.1614 | 1.1667 | 0.8312 | 0.0356 | 23.290 | <0.0001 | |

| EU3 | 3.1770 | 1.1933 | 0.8881 | 0.0327 | 27.133 | <0.0001 | |

| EU4 | 3.4062 | 1.2286 | 0.7915 | 0.0504 | 11.736 | <0.0001 |

| Compliance Measures | Perfect Fit | Acceptable Fit | Results of the Model | Compatibility |

|---|---|---|---|---|

| RMSEA | 0 ≤ RMSEA ≤ 0.05 | 0.05 ≤ RMSEA ≤ 0.10 | 0.0853 | Acceptable Fit |

| SRMR | 0 ≤ SRMR ≤ 0.05 | 0.05 ≤ SRMR ≤ 0.10 | 0.0991 | Acceptable Fit |

| GFI | 0.90 ≤ GFI ≤ 1.00 | 0.85 ≤ GFI ≤ 0.90 | 0.8640 | Acceptable Fit |

| AGFI | 0.90 ≤ AGFI ≤ 1.00 | 0.85 ≤ AGFI ≤ 0.90 | 0.8510 | Acceptable Fit |

| NFI | 0.90 ≤ NFI ≤ 1.00 | 0.85 ≤ NFI ≤ 0.90 | 0.8582 | Acceptable Fit |

| CFI | 0.90 ≤ CFI ≤ 1.00 | 0.85 ≤ CFI ≤ 0.90 | 0.9112 | Perfect Fit |

| χ2/df | 0 ≤ χ2/df ≤ 3 | 3 ≤ χ2/df ≤ 5 | 2.389 | Perfect Fit |

| Convergent Validity | Divergent Validity |

|---|---|

| Standardized factor loadings > 0.7 | AVE > MSV |

| AVE > 0.5 | AVE > ASV |

| CR > 0.7 | > interfactor correlation |

| CR > AVE | MSV > ASV |

| > 0.5 |

| CR | AVE | MSV | ASV | Supply Chain Performance | Information Technologies | Environmental Uncertainty | |

|---|---|---|---|---|---|---|---|

| Supply Chain Performance | 0.976 | 0.672 | 0.381 | 0.292 | 0.820 | 0.381 | 0.202 |

| Information Technologies | 0.966 | 0.827 | 0.381 | 0.243 | 0.617 | 0.909 | 0.104 |

| Environmental Uncertainty | 0.839 | 0.572 | 0.202 | 0.153 | 0.449 | 0.323 | 0.765 |

| Compliance Measures | Perfect Fit | Acceptable Fit | Results of the Model | Compatibility |

|---|---|---|---|---|

| RMSEA | 0 ≤ RMSEA ≤ 0.05 | 0.05 ≤ RMSEA ≤ 0.10 | 0.0795 | Acceptable Fit |

| SRMR | 0 ≤ SRMR ≤ 0.05 | 0.05 ≤ SRMR ≤ 0.10 | 0.0240 | Perfect Fit |

| GFI | 0.90 ≤ GFI ≤ 1.00 | 0.85 ≤ GFI ≤ 0.90 | 0.9849 | Perfect Fit |

| AGFI | 0.90 ≤ AGFI ≤ 1.00 | 0.85 ≤ AGFI ≤ 0.90 | 0.9206 | Perfect Fit |

| NFI | 0.90 ≤ NFI ≤ 1.00 | 0.85 ≤ NFI ≤ 0.90 | 0.9793 | Perfect Fit |

| CFI | 0.90 ≤ CFI ≤ 1.00 | 0.85 ≤ CFI ≤ 0.90 | 0.9882 | Perfect Fit |

| χ2/df | 0 ≤ χ2/df ≤ 3 | 3 ≤ χ2/df ≤ 5 | 2.2063 | Perfect Fit |

| Path | Guess | Standard Error | t | p | R2 | ||

|---|---|---|---|---|---|---|---|

| Cost Performance | ⟵ | Supply Chain Performance | 0.7344 | 0.0488 | 15.023 | <0.0001 | 0.539 |

| Customer Performance | ⟵ | Supply Chain Performance | 0.6696 | 0.0501 | 13.362 | <0.0001 | 0.448 |

| Flexibility Performance | ⟵ | Supply Chain Performance | 0.7043 | 0.0523 | 13.465 | <0.0001 | 0.496 |

| Logistics Performance | ⟵ | Supply Chain Performance | 0.8268 | 0.0454 | 18.205 | <0.0001 | 0.683 |

| Information Technologies | ⟶ | Supply Chain Performance | 0.5724 | 0.0548 | 10.445 | <0.0001 | 0.551 |

| Environmental Uncertainty | ⟶ | Supply Chain Performance | 0.3230 | 0.0599 | 5.385 | <0.0001 | |

| Information Technologies | ⟶ | Environmental Uncertainty | 0.3225 | 0.0648 | 4.974 | <0.0001 | 0.104 |

| Direct Impacts | Indirect Impacts | Total Impacts | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Environmental Uncertainty | Supply Chain Performance | Information Technologies | Environmental Uncertainty | Supply Chain Performance | Information Technologies | Environmental Uncertainty | Supply Chain Performance | Information Technologies | |

| Environmental Uncertainty | 0 | 0 | 0.3225 | 0 | 0 | 0 | 0 | 0 | 0.3225 |

| 0.0648 | 0.0648 | ||||||||

| 4.9748 | 4.9748 | ||||||||

| <0.0001 | <0.0001 | ||||||||

| Flexibility Performance | 0 | 0.7043 | 0 | 0.2275 | 0 | 0.4766 | 0.2275 | 0.7043 | 0.4766 |

| 0.0523 | 0.0452 | 0.0506 | 0.0452 | 0.0523 | 0.0506 | ||||

| 13.4659 | 5.0286 | 9.4177 | 5.0286 | 13.4659 | 9.4177 | ||||

| <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | ||||

| Logistics Performance | 0 | 0.8269 | 0 | 0.2671 | 0 | 0.5595 | 0.2671 | 0.8269 | 0.5595 |

| 0.0454 | 0.0504 | 0.0469 | 0.0504 | 0.0454 | 0.0469 | ||||

| 18.2057 | 5.2951 | 11.9411 | 5.2951 | 18.2057 | 11.9411 | ||||

| <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | ||||

| Cost Performance | 0 | 0.7345 | 0 | 0.2373 | 0 | 0.4970 | 0.2373 | 0.7345 | 0.4970 |

| 0.0489 | 0.0463 | 0.0490 | 0.0463 | 0.0489 | 0.0490 | ||||

| 15.0237 | 5.1233 | 10.1340 | 5.1233 | 15.0237 | 10.1340 | ||||

| <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | ||||

| Customer Performance | 0 | 0.6697 | 0 | 0.2163 | 0 | 0.4531 | 0.2163 | 0.6697 | 0.4531 |

| 0.0501 | 0.0438 | 0.0513 | 0.0438 | 0.0501 | 0.0513 | ||||

| 13.3620 | 4.9380 | 8.8269 | 4.9380 | 13.3620 | 8.8269 | ||||

| <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | ||||

| Supply Chain Performance | 0.3230 | 0 | 0.5725 | 0 | 0 | 0.1042 | 0.3230 | 0 | 0.6766 |

| 0.0600 | 0.0548 | 0.0280 | 0.0600 | 0.0487 | |||||

| 5.3852 | 10.4456 | 3.7223 | 5.3852 | 13.8822 | |||||

| <0.0001 | <0.0001 | 0.000197 | <0.0001 | <0.0001 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dağdeviren, I.E.; Mirza, S. The Mediating Role of Environmental Uncertainty in the Impact of Information Technology on Supply Chain Performance. Sustainability 2024, 16, 7667. https://doi.org/10.3390/su16177667

Dağdeviren IE, Mirza S. The Mediating Role of Environmental Uncertainty in the Impact of Information Technology on Supply Chain Performance. Sustainability. 2024; 16(17):7667. https://doi.org/10.3390/su16177667

Chicago/Turabian StyleDağdeviren, Ibrahim Ethem, and Sakir Mirza. 2024. "The Mediating Role of Environmental Uncertainty in the Impact of Information Technology on Supply Chain Performance" Sustainability 16, no. 17: 7667. https://doi.org/10.3390/su16177667