Experimental Investigation on the Effect of Gold Tailings as a Partial Replacement for Sand in Concrete

Abstract

:1. Introduction

2. Experimental Work

2.1. Materials

2.1.1. Mixture Proportion

2.1.2. Specimen Preparation

2.2. Fresh Concrete Tests

2.3. Compressive Strength and Splitting Tensile Strength Tests

2.4. Durability Tests

2.4.1. Oxygen Permeability Index Test

2.4.2. Water Sorptivity Index Test

2.4.3. Chloride Conductivity Index

3. Results and Discussion

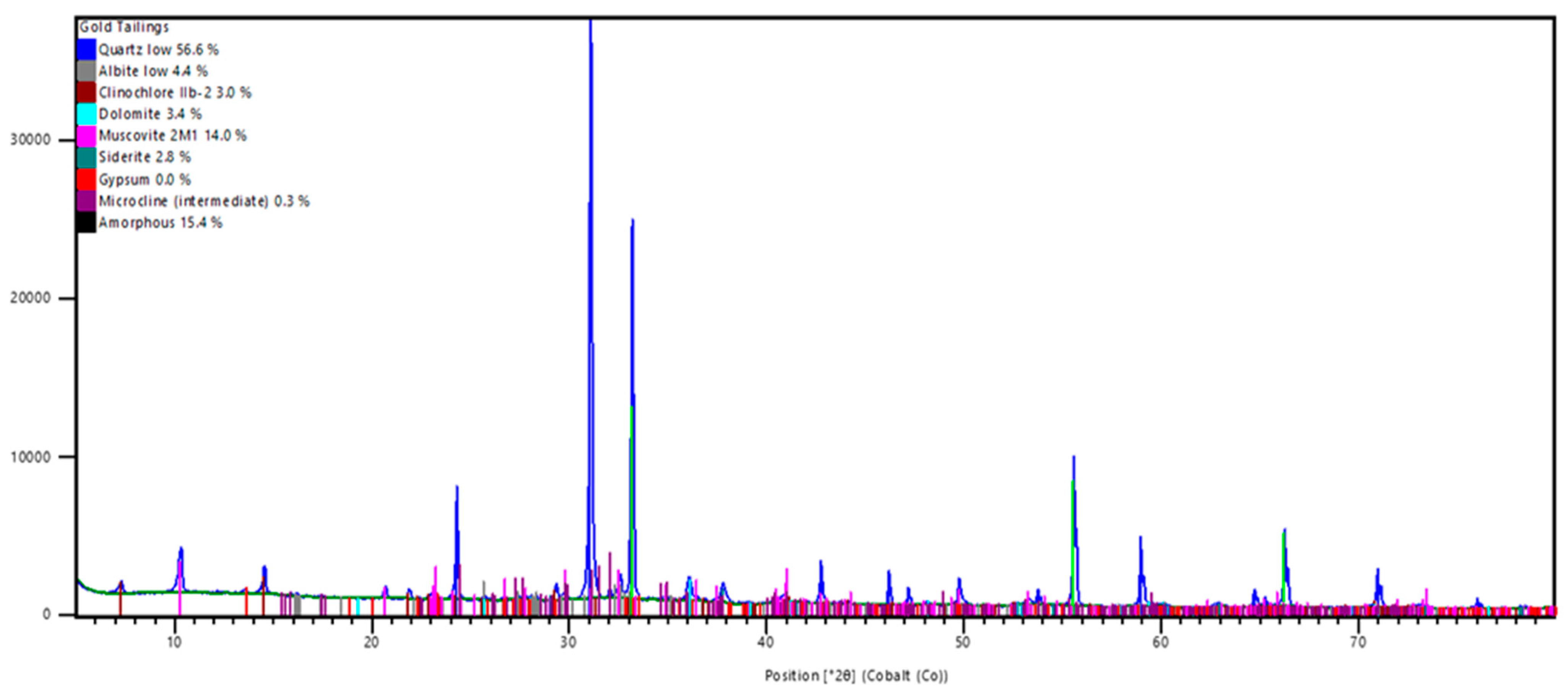

3.1. SGT and Andesite Crusher Sand Characterization

3.2. Workability

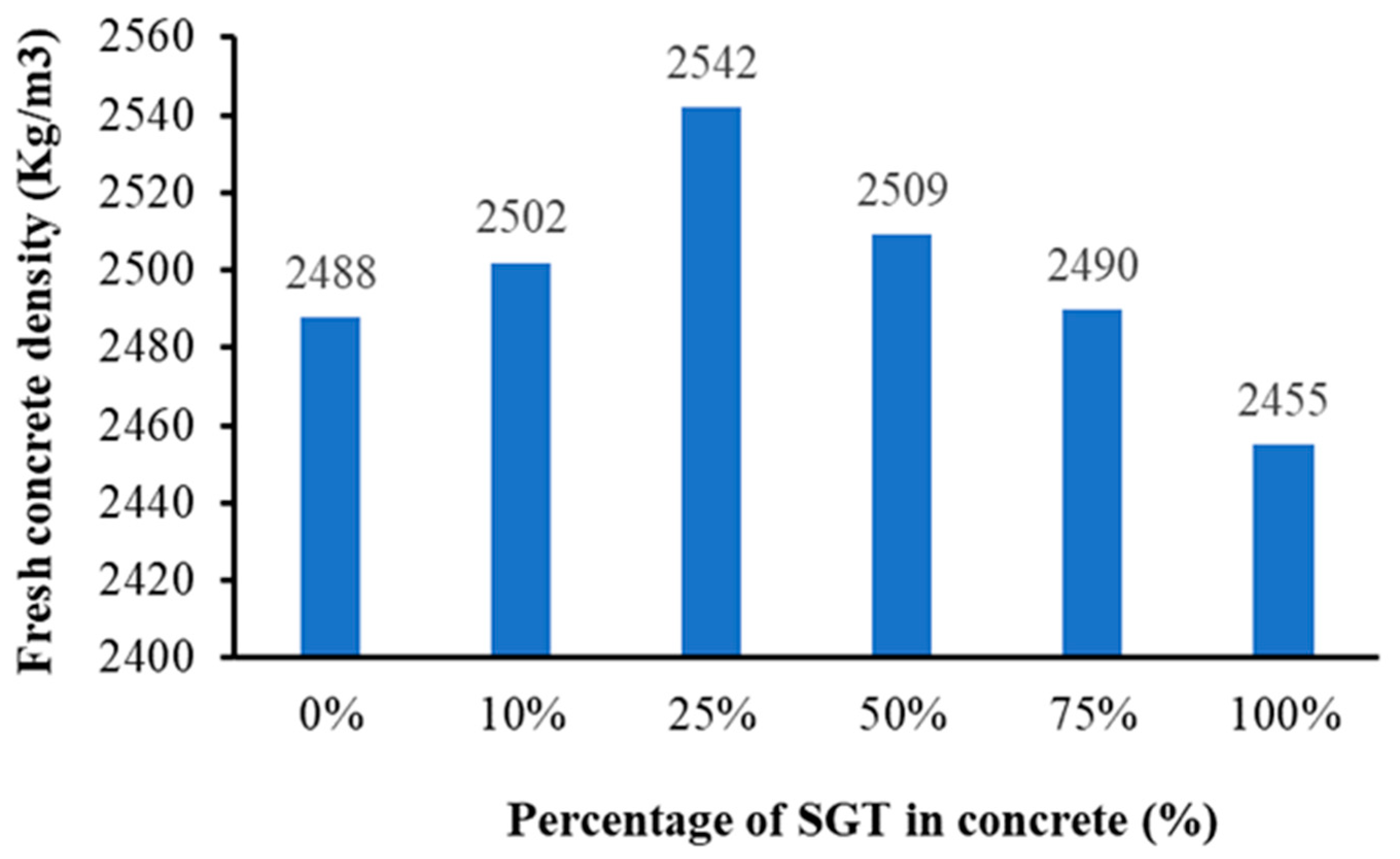

3.3. Fresh Concrete Density

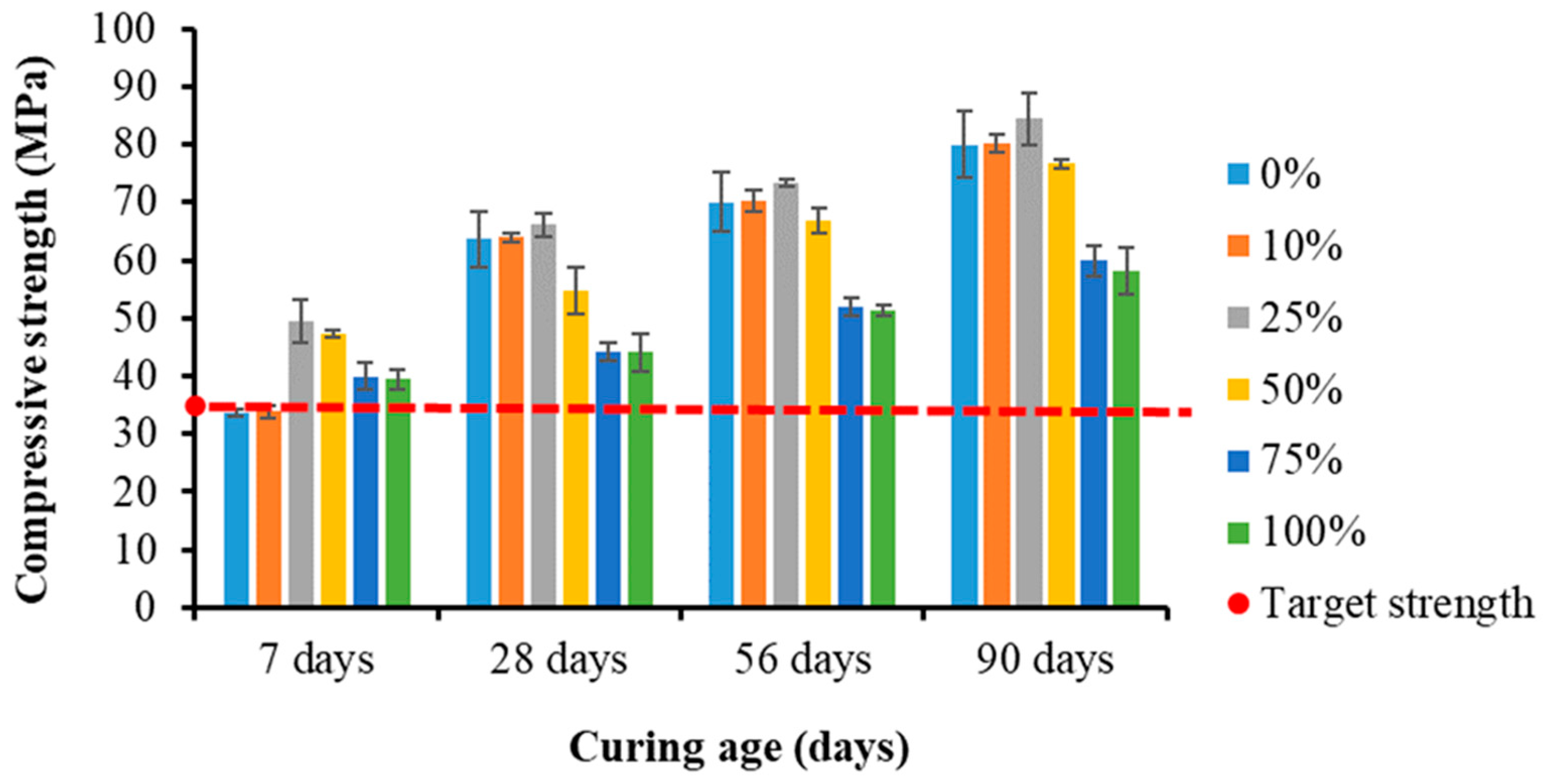

3.4. Compressive Strength

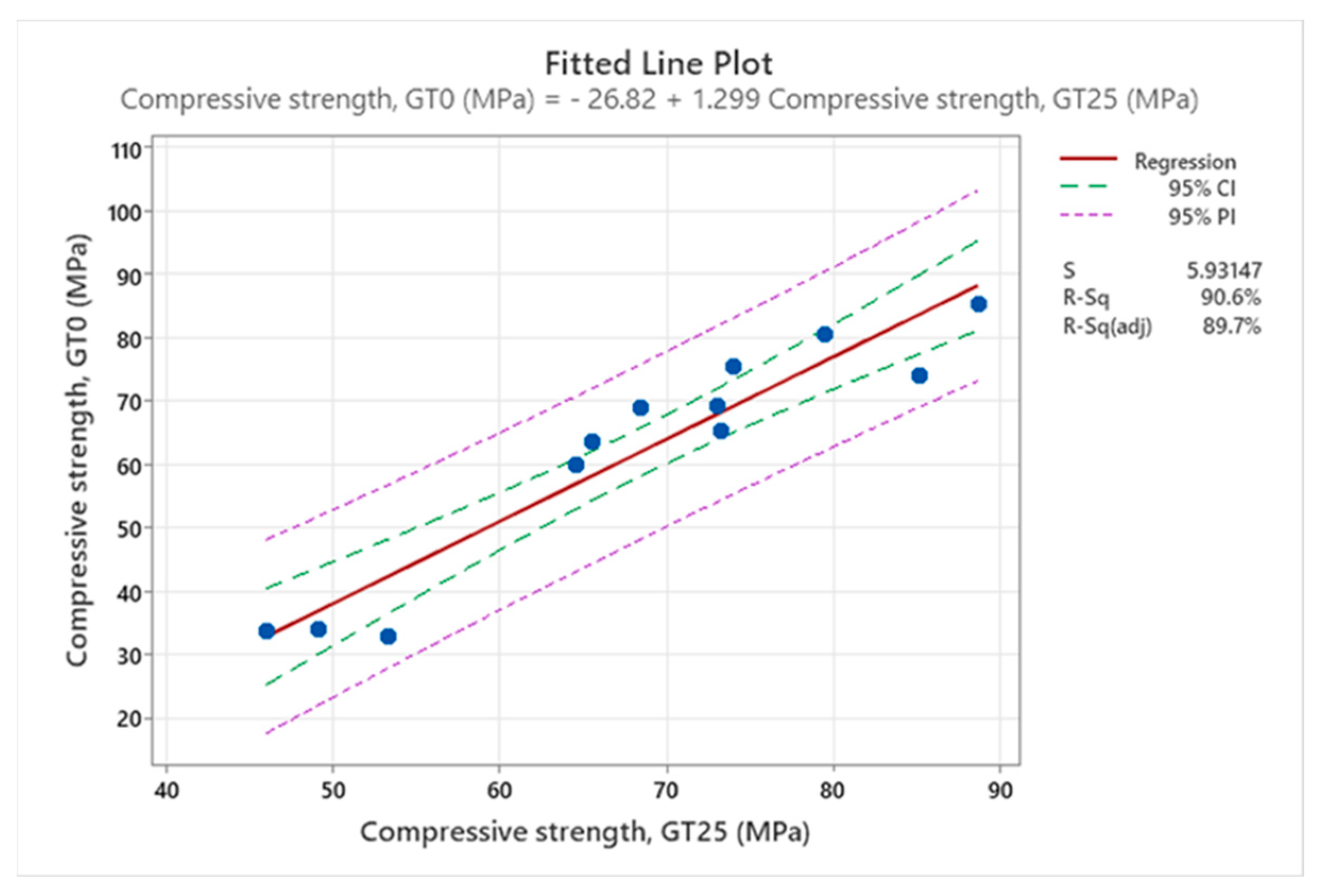

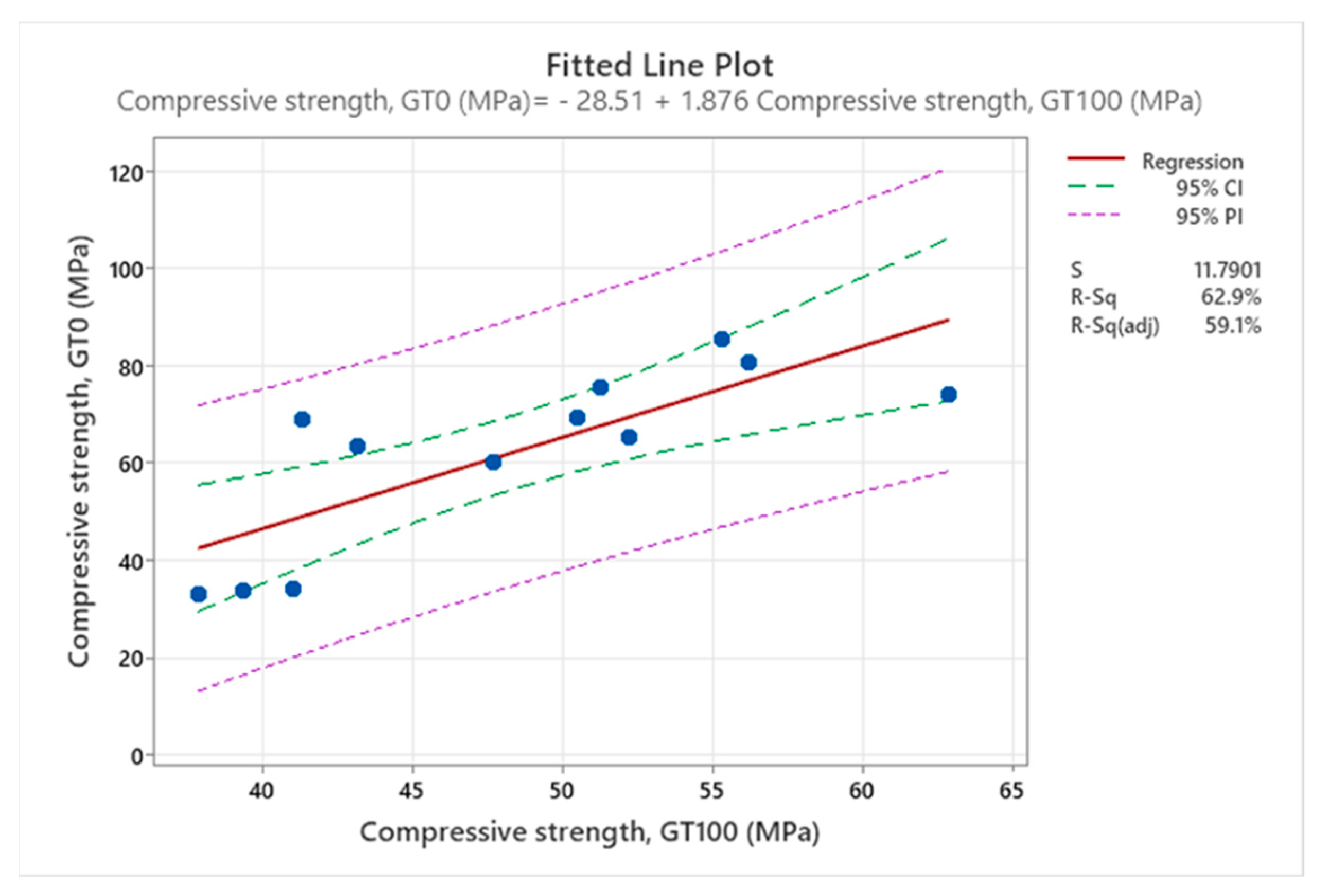

Statistical Analysis

3.5. Splitting Tensile Strength

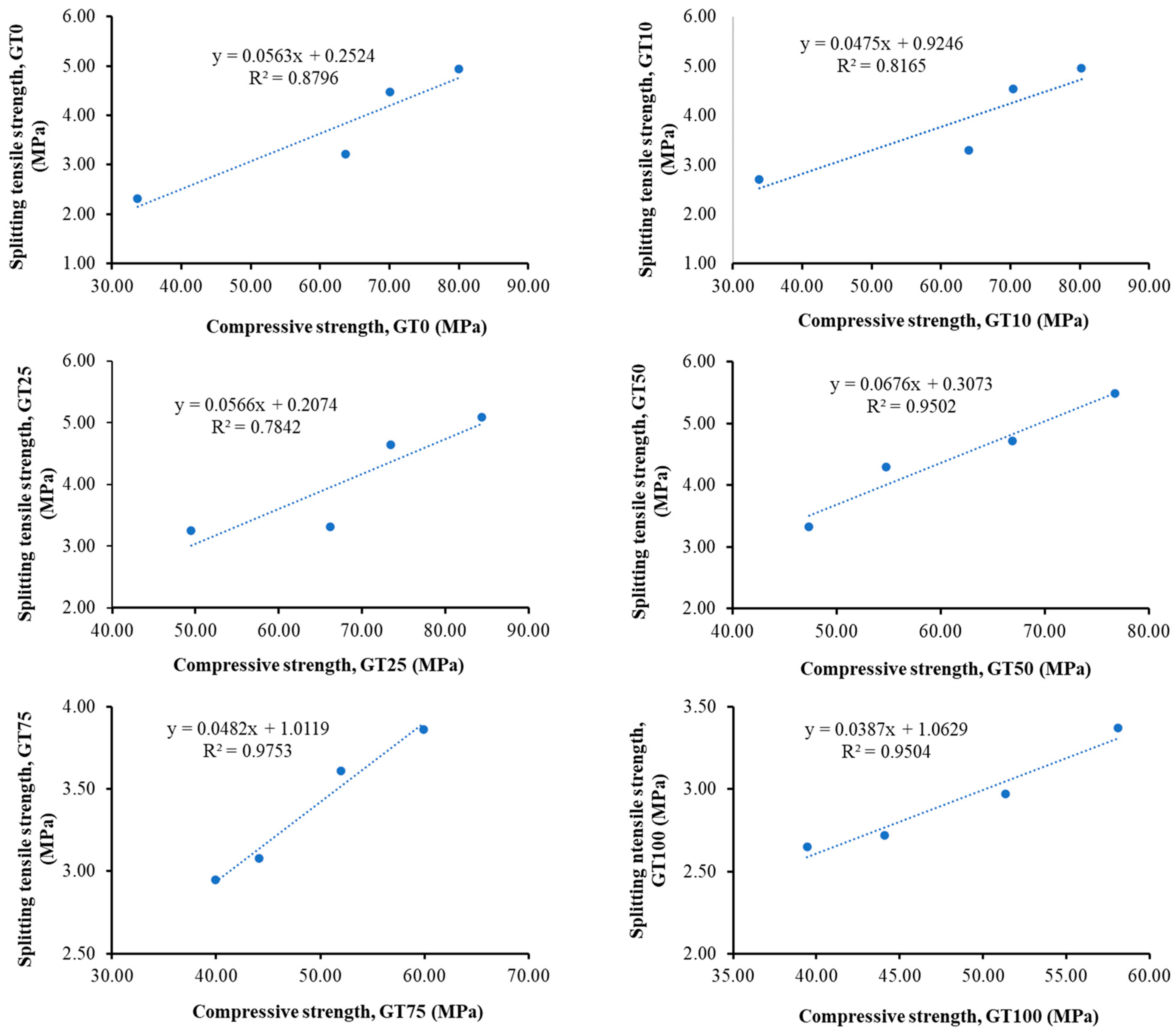

3.6. The Relationship between Splitting Tensile Strength and Compressive Strength

3.7. Durability Properties

3.7.1. Oxygen Permeability

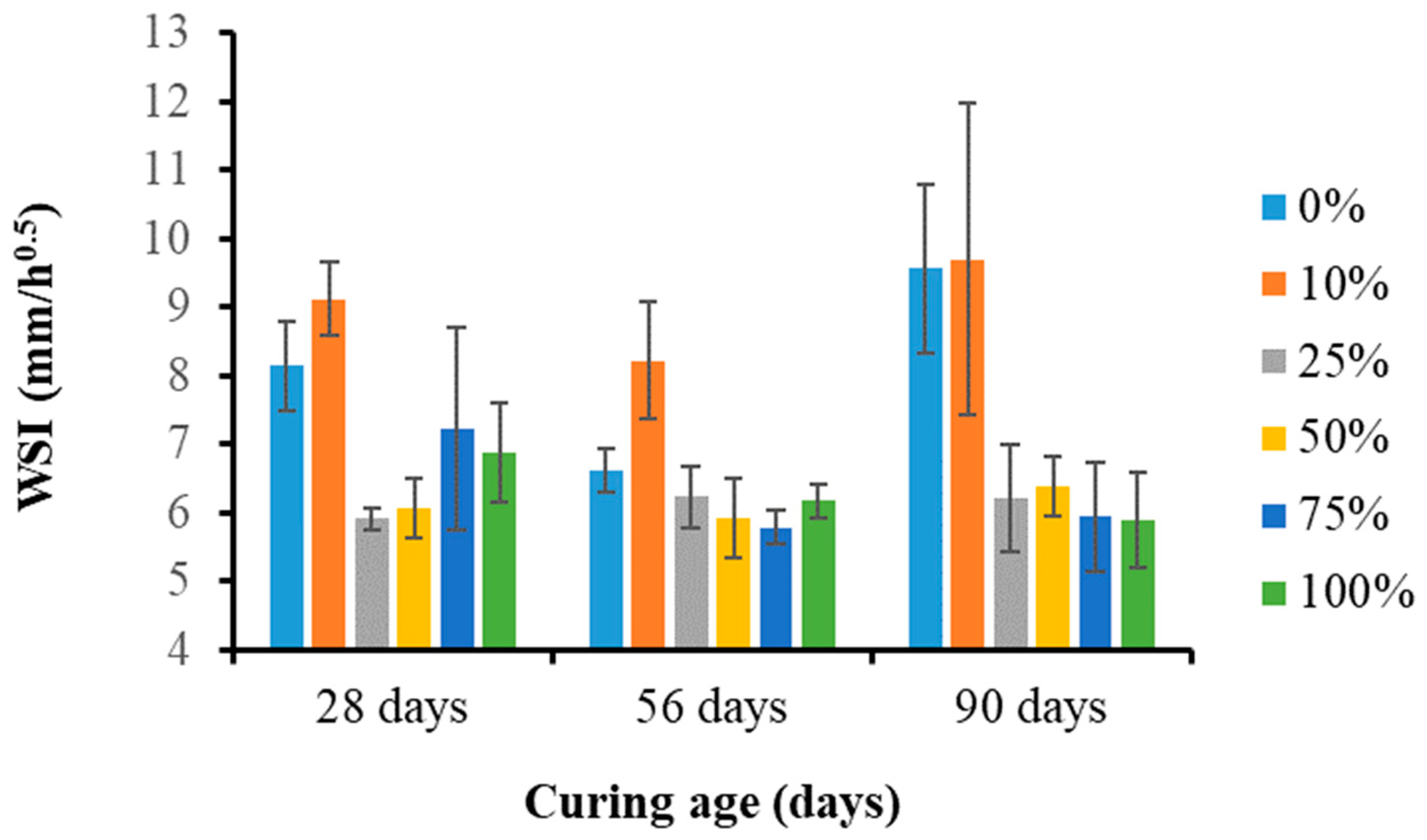

3.7.2. Water Sorptivity

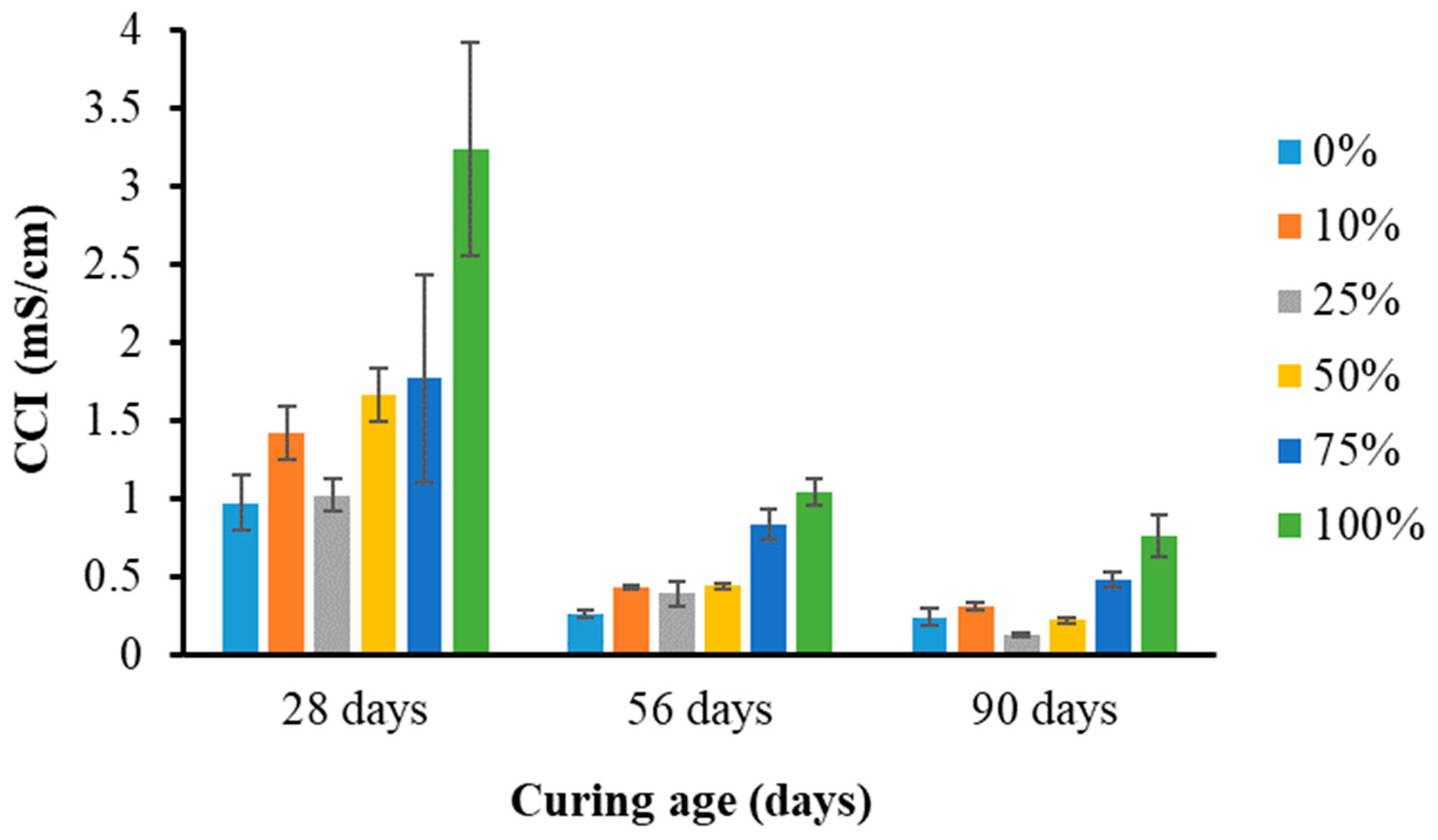

3.7.3. Chloride Conductivity

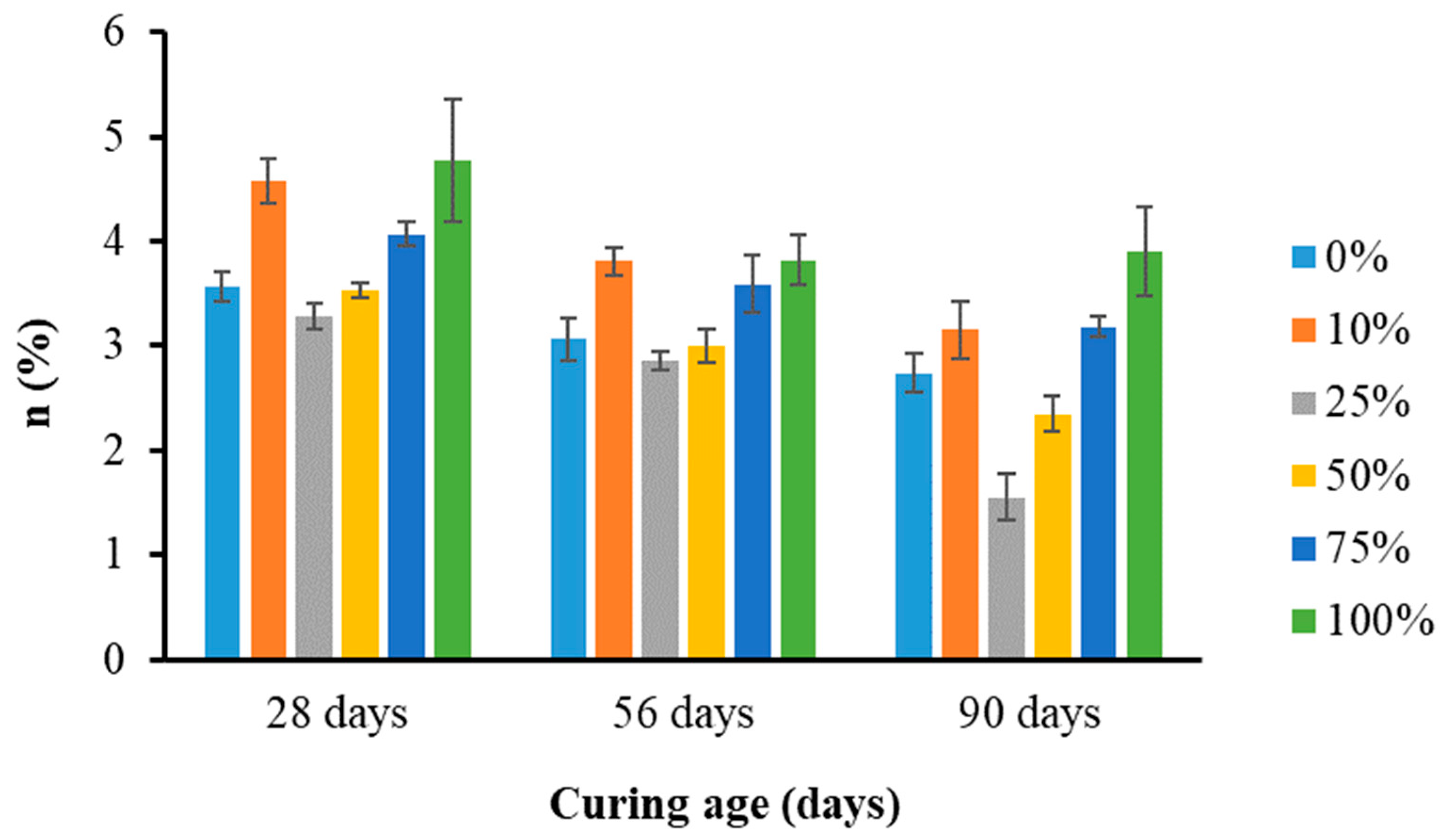

3.7.4. Porosity

4. Applications

5. Conclusions and Recommendations

- SGTs are reprocessed gold tailings from which some metals have been recovered, and they are considered relatively inert due to the absence of sulfide and pyrite, making them environmentally friendly. They contain soft minerals and a high muscovite content that could influence the properties of concrete. SGTs have finer particles, low densities, high specific surface area, and high water absorption compared with andesite crusher sand. However, the similarity in the properties of SGTs and andesite crusher sand makes SGTs a potential material for andesite crusher sand substitution in concrete production.

- The inclusion of SGTs as fine aggregate decreased the workability due to finer particles, high specific surface area, and high water absorption of the SGTs. The workability of concrete containing SGTs can be improved by adding superplasticizers, regardless of SGT content in the concrete mix. The replacement of andesite crusher sand with SGTs up to 75% enhanced the density of concrete compared with andesite crusher sand, while the highest density was obtained at a 25% replacement level.

- The compressive strength of concrete with up to 25% replacement of crusher sand with SGTs is high compared with the reference concrete, for all curing ages. Beyond the 25% replacement level, the compressive strength was lower than that of the reference concrete for all curing ages. However, all the concrete samples at 28, 56, and 90 days met the target strength. The highest compressive strength was obtained at a 25% replacement level. The ANOVA analysis results validated that the percentage of SGT significantly impacted the compressive strength of concrete for curing periods of 7, 28, 56, and 90 days. The splitting tensile strength of the concretes followed a similar trend to that of compressive strength. However, the splitting tensile strength increased up to 50% for all curing ages but then decreased. The highest splitting tensile strength was achieved at a 50% replacement level. This indicates that SGTs can partially replace crusher sand and produce concrete with desirable mechanical properties.

- Concrete made with SGTs as a replacement for crusher sand had similar OPI and WSI to reference concrete. The concrete samples’ OPI ranged from 9.95 to 11.01 and WSI ranged from 5.79–9.69, placing them within the good to excellent category for concrete quality in terms of OPI and WSI, respectively. Concrete made with SGTs showed strong resistance to oxygen permeability and water sorptivity, irrespective of the percentage replacement levels, for all curing ages. Also, after 56 and 90 days, the CCI of concretes with and without SGTs was found to reflect good to excellent concrete quality, indicating good resistance to chloride penetration. Concrete samples also showed a reduction in porosity with increasing curing periods. This indicates that concrete containing SGTs as a substitute for crusher sand is durable.

- This study demonstrates that like primary gold tailings, SGTs can be used as fine aggregate in concrete production, indicating that the substitution potential of gold tailings is not limited to river sand. The results of this study suggest that SGT is environmentally friendly and can be efficiently substituted for crusher sand in concrete. In addition to its strength performance, this study further shows the satisfactory durability performance of concrete containing gold tailings. Using SGTs as fine aggregate in concrete can reduce the space occupied by tailings disposal, conserve natural resources, and lessen environmental problems. It also reduces the use of conventional fine aggregate and lowers the cost compared with using conventional fine aggregate for concrete production, particularly in mining environments. Additionally, it would represent a reduction in carbon emissions associated with conventional fine aggregate (crusher sand) production, as SGTs require no additional processing to achieve the necessary particle size. This study can offer direction for conducting a more comprehensive investigation into utilizing secondary gold tailings in concrete.

- It is necessary to investigate other important properties such as resistance to sulfate attack, carbonation depth, alkali–silica reaction, drying shrinkage, microstructural behavior, corrosion, and thermal properties to understand the performance of the concrete from these aspects.

- Due to the satisfactory performance of concrete containing SGTs, it can be effectively employed as a construction material. This utilization of SGTs helps address sand sustainability concerns in producing sustainable concrete, promoting a greener environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Mixes | Compressive Strength (MPa) | |||

|---|---|---|---|---|

| 7 Days | 28 Days | 56 Days | 90 Days | |

| 0% | 33.71 | 63.64 | 70.05 | 80.01 |

| 10% | 33.81 | 63.93 | 70.33 | 80.21 |

| 25% | 49.49 | 66.19 | 73.40 | 84.21 |

| 50% | 47.33 | 54.77 | 66.85 | 76.73 |

| 75% | 39.96 | 44.15 | 52.01 | 59.59 |

| 100% | 39.43 | 44.08 | 51.33 | 58.12 |

| Mixes | Splitting Tensile Strength (MPa) | |||

|---|---|---|---|---|

| 7 Days | 28 Days | 56 Days | 90 Days | |

| 0% | 2.31 | 3.22 | 4.48 | 4.94 |

| 10% | 2.71 | 3.29 | 4.54 | 4.96 |

| 25% | 3.25 | 3.31 | 4.65 | 5.09 |

| 50% | 3.33 | 4.29 | 4.72 | 5.49 |

| 75% | 2.95 | 3.08 | 3.61 | 3.86 |

| 100% | 2.65 | 2.72 | 2.97 | 3.37 |

| Mixes | Oxygen Permeability Index | ||

|---|---|---|---|

| 28 Days | 56 Days | 90 Days | |

| 0% | 10. 23 | 10.81 | 10.77 |

| 10% | 10.50 | 10.60 | 10.16 |

| 25% | 9.95 | 10.60 | 11.00 |

| 50% | 10.04 | 10.70 | 11.01 |

| 75% | 10.42 | 10.64 | 10.68 |

| 100% | 10.64 | 10.13 | 10.44 |

| Mixes | Water Sorptivity Index | ||

|---|---|---|---|

| 28 Days | 56 Days | 90 Days | |

| 0% | 8.14 | 6.68 | 9.57 |

| 10% | 9.12 | 8.22 | 9.69 |

| 25% | 5.91 | 6.23 | 6.21 |

| 50% | 6.07 | 5.92 | 6.39 |

| 75% | 7.23 | 5.79 | 5.94 |

| 100% | 6.88 | 6.17 | 5.89 |

| Mixes | Chloride Conductivity Index | ||

|---|---|---|---|

| 28 Days | 56 Days | 90 Days | |

| 0% | 0.97 | 0.26 | 0.24 |

| 10% | 1.42 | 0.43 | 0.31 |

| 25% | 1.02 | 0.39 | 0.13 |

| 50% | 1.66 | 0.44 | 0.22 |

| 75% | 1.77 | 0.83 | 0.48 |

| 100% | 3.24 | 1.04 | 0.76 |

| Mixes | Porosity with Calcium Hydroxide | ||

|---|---|---|---|

| 28 Days | 56 Days | 90 Days | |

| 0% | 8.40 | 6.69 | 6.02 |

| 10% | 10.07 | 8.59 | 7.63 |

| 25% | 7.95 | 6.81 | 3.89 |

| 50% | 8.71 | 7.97 | 5.92 |

| 75% | 9.42 | 8.7 | 7.45 |

| 100% | 10.98 | 10.08 | 8.25 |

| Mixes | Porosity with Sodium Hydroxide | ||

|---|---|---|---|

| 28 Days | 56 Days | 90 Days | |

| 0% | 3.56 | 3.06 | 2.74 |

| 10% | 4.58 | 3.81 | 3.15 |

| 25% | 3.28 | 2.85 | 1.55 |

| 50% | 3.53 | 3.00 | 2.35 |

| 75% | 4.07 | 3.59 | 3.18 |

| 100% | 4.77 | 3.82 | 3.90 |

References

- Ahmad, J.; Majdi, A.; Babeker Elhag, A.; Deifalla, A.F.; Soomro, M.; Isleem, H.F.; Qaidi, S. A Step towards Sustainable Concrete with Substitution of Plastic Waste in Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Crystals 2022, 12, 944. [Google Scholar] [CrossRef]

- Tangaramvong, S.; Nuaklong, P.; Khine, M.T.; Jongvivatsakul, P. The influences of granite industry waste on concrete properties with different strength grades. Case Stud. Constr. Mater. 2021, 15, e00669. [Google Scholar] [CrossRef]

- Sankh, A.C.; Biradar, P.M.; Naghathan, S.J.; Ishwargol, M.B. Recent Trends in Replacement of Natural Sand with Different Alternatives. IOSR J. Mech. Civ. Eng. 2018, 59–66. Available online: www.iosrjournals.org (accessed on 2 September 2024).

- Khouadjia, M.L.K.; Mezghiche, B.; Drissi, M. Experimental evaluation of workability and compressive strength of concrete with several local sand and mineral additions. Constr. Build. Mater. 2015, 98, 194–203. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Martínez-García, R.; Vatin, N.I.; De-Prado-gil, J.; El-Shorbagy, M.A. Waste Foundry Sand in Concrete Production Instead of Natural River Sand: A Review. Materials 2022, 15, 2365. [Google Scholar] [CrossRef] [PubMed]

- Stempkowska, A.; Gawenda, T.; Naziemiec, Z.; Adam Ostrowski, K.; Saramak, D.; Surowiak, A. Impact of the geometrical parameters of dolomite coarse aggregate on the thermal and mechanic properties of preplaced aggregate concrete. Materials 2020, 13, 4358. [Google Scholar] [CrossRef] [PubMed]

- Nardelli, A.; Cacciari, P.P.; Futai, M.M. Sand–concrete interface response: The role of surface texture and confinement conditions. Soils Found. 2019, 59, 1675–1694. [Google Scholar] [CrossRef]

- Gondo, T.; Mathada, H.; Amponsah-Dacosta, F. Regulatory and policy implications of sand mining along shallow waters of Nzhelele River in South Africa. Jamba J. Disaster Risk Stud. 2019, 11, 1–12. [Google Scholar] [CrossRef]

- Muigai, R.; Alexander, M.G.; Moyo, P. Cradle-to-gate environmental impacts of the concrete industry in South Africa. J. S. Afr. Inst. Civ. Eng. 2014, 56, 108. [Google Scholar]

- Lee, C. How Can Environmental Impacts Be Evaluated in Aggregate Production; University of Gothenburg: Gothenburg, Sweden, 2021; Available online: https://cms.it.gu.se/infoglueDeliverWorking/digitalAssets/1792/1792496_lee-c.pdf (accessed on 25 July 2024).

- Siddique, R.; Singh, M.; Mehta, S.; Belarbi, R. Utilization of treated saw dust in concrete as partial replacement of natural sand. J. Clean. Prod. 2020, 261, 121226. [Google Scholar] [CrossRef]

- Althoey, F.; Hosen, M.A. Physical and mechanical characteristics of sustainable concrete comprising industrial waste materials as a replacement of conventional aggregate. Sustainability 2021, 13, 4306. [Google Scholar] [CrossRef]

- Sunarsih, E.S.; Patanti, G.W.; Agustin, R.S.; Rahmawati, K. Utilization of Waste Glass and Fly Ash as a Replacement of Material Concrete. IOP Conf. Ser. Earth Environ. Sci. 2021, 1808, 012004. [Google Scholar] [CrossRef]

- Thiruvenkitam, M.; Pandian, S.; Santra, M.; Subramanian, D. Use of waste foundry sand as a partial replacement to produce green concrete: Mechanical properties, durability attributes and its economical assessment. Environ. Technol. Innov. 2020, 19, 101022. [Google Scholar] [CrossRef]

- Ogola, J.; Shavhani, T.; Mundalamo, R. Possibilities of Reprocessing Tailings Dams for Gold and other Minerals: A Case Study of South Africa. J. Environ. Sci. Allied Res. 2018, 2017, 39–42. [Google Scholar] [CrossRef]

- Weiersbye, I.M.; Witkowski, E.T.F.; Reichardt, M. Floristic composition of gold and uranium tailings dams, and adjacent polluted areas, on South Africa’s deep-level mines. Bothalia 2006, 36, 101–127. [Google Scholar] [CrossRef]

- Aderinto, G.E.; Ikotun, J.O.; Madirisha, M.M.; Katte, V. Geopolymer Cement in Pavement Applications: Bridging Sustainability and Performance, an In-Depth Review. 2024, pp. 1–30. Available online: https://www.mdpi.com/2071-1050/16/13/5417 (accessed on 2 September 2024).

- Ikotun, J.O.; Aderinto, G.; Katte, V. Geo-polymerization of mining tailing for use as a pavement construction material: A review. In Young Concrete Researchers, Engineers & Technologist Symposium (YCRETS); Cement & Concrete SA: Midrand, South Africa, 2023. [Google Scholar]

- Chen, B.; Pang, L.; Zhou, Z.; Chang, Q.; Fu, P. Study on the activation mechanism and hydration properties of gold tailings activated by mechanical-chemical-thermal coupling. J. Build. Eng. 2022, 48, 104014. [Google Scholar] [CrossRef]

- Gou, M.; Zhou, L.; Then, N.W.Y. Utilization of tailings in cement and concrete: A review. Sci. Eng. Compos. Mater. 2019, 26, 449–464. [Google Scholar] [CrossRef]

- Li, S.; Chen, J.; Gao, W.; Lyu, X.; Liang, Z.; Zhou, W. Current situation and prospects for the clean utilization of gold tailings. Waste Manag. 2024, 180, 149–161. [Google Scholar] [CrossRef]

- Mashifana, T.; Sithole, T. Clean production of sustainable backfill material from waste gold tailings and slag. J. Clean. Prod. 2021, 308, 127357. [Google Scholar] [CrossRef]

- Wang, L.; Ji, B.; Hu, Y.; Liu, R.; Sun, W. A review on in situ phytoremediation of mine tailings. Chemosphere 2017, 184, 594–600. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Nielsen, M.R.; Potier, C.; Ottosen, L.M.; Jensen, P.E. Utilization of Mine Tailings as Partial Cement Replacement. Mod. Environ. Sci. Eng. 2018, 4, 365–373. [Google Scholar]

- Wu, A.; Wang, Y.; Ruan, Z.; Xiao, B.; Wang, J.; Wang, L. Key theory and technology of cemented paste backfill for green mining of metal mines. Green Smart Min. Eng. 2024, 1, 27–39. [Google Scholar] [CrossRef]

- Yang, L.; Jia, H.; Wu, A.; Jiao, H.; Chen, X.; Kou, Y.; Dong, M. Particle aggregation and breakage kinetics in cemented paste backfill. Int. J. Miner. Metall. Mater. 2024, 31, 1965–1974. [Google Scholar] [CrossRef]

- Ikotun, J.; Adeyeye, R.; Otieno, M. Application of mine tailings sand as construction material—A review. MATEC Web Conf. 2022, 364, 05008. [Google Scholar] [CrossRef]

- Reddy, R.B.M.; Satyanarayanan, K.S.; Jagannatha, H.N.; Parthasarathi, N. Use of Gold Mine Tailings in Production of Concrete—A Feasibility Study. BDL 2016, 9, 197–202. [Google Scholar]

- Preethi, A.V.; Rajendra, S.; Navneeth, P.K.L. Studies on Gold Ore Tailings as Partial Replacement of Fine Aggregates in Concrete. Int. J. Latest. Technol. Eng. Manag. Appl. Sci. 2017, 6, 30–33. Available online: www.ijltemas.in (accessed on 2 September 2024).

- Ahmed, T.; Elchalakani, M.; Basarir, H.; Karrech, A.; Sadrossadat, E.; Yang, B. Development of ECO-UHPC utilizing gold mine tailings as quartz sand alternative. Clean. Eng. Technol. 2021, 4, 100176. [Google Scholar] [CrossRef]

- Balegamire, C.; Nkuba, B.; Dable, P. Production of gold mine tailings based concrete pavers by substitution of natural river sand in Misisi, Eastern Congo. Clean. Eng. Technol. 2022, 7, 100427. [Google Scholar] [CrossRef]

- Song, Q.; Zou, Y.; Bao, J.; Zhang, P. Disposal of solid waste as building materials: A study on the mechanical and durability performance of concrete composed of gold tailings. J. Mater. Res. Technol. 2024, 30, 2111–2124. [Google Scholar] [CrossRef]

- SANS 1083:2014; Aggregates from Natural Sources—Aggregate for Concrete. South African National Standard: Pretoria, South Africa, 2014.

- SANS 5845:2006; Aggregate Tests—Bulk Density of Aggregate. South African National Standard: Pretoria, South Africa, 2006.

- SANS 5843:2008; Water Absorption of Aggregates. South African National Standard: Pretoria, South Africa, 2008.

- SANS 50197-2:2011; Cement Part 2: Conformity Evaluation. South African National Standard: Pretoria, South Africa, 2011.

- SANS 50450-1:2014; Portland Cement Extenders. Part 1 Fly Ash; South African National Standard: Pretoria, South Africa, 2014.

- BS EN 934-2:2009; Admixture for Concrete, Mortar and Grout. Concrete Admixtures. Definitions, Requirement, Conformity, Making and Labelling. British Standards Institution: London, UK, 2009.

- Alexander, M.G.; Santhanam, M.; Ballim, Y. Durability design and specification for concrete structures—The way forward. Int. J. Adv. Eng. Sci. Appl. Math. 2010, 2, 95–105. [Google Scholar] [CrossRef]

- SANS 5861-1:2006; Concrete Tests Part 1—Mixing Fresh Concrete in the Laboratory. South African National Standard: Pretoria, South Africa, 2006.

- SANS 5862-1:2006; Concrete Tests Part 1—Consistence of Freshly Mixed Concrete—Slump Test. South African National Standard: Pretoria, South Africa, 2006.

- SANS 6250:2006; Concrete Tests—Density of Compacted Freshly Mixed Concrete. South African National Standard: Pretoria, South Africa, 2006.

- SANS 5863:2006; Concrete Tests—Compressive Strength of Hardened Cocnrete. South African National Standard: Pretoria, South Africa, 2006.

- SANS 6253:2006; Concrete Tests—Tensile Splitting Strength of Concrete. South African National Standard: Pretoria, South Africa, 2006.

- Alexander, M. Durability Index Testing Procedure Manual, Ver 4.5.1; University of Cape Town: Cape Town, South Africa, 2018; Volume 2018. [Google Scholar]

- Charlaftis, D. Assessing Sandstone Reservoir Quality: Identifying the Reality. Doctoral Dissertation, Durham University, Durham, UK, 2021. [Google Scholar]

- Zhou, H.M.; Qiao, X.C.; Yu, J.G. Influences of quartz and muscovite on the formation of mullite from kaolinite. Appl. Clay Sci. 2013, 80, 176–181. [Google Scholar] [CrossRef]

- Cai, L.; Ma, B.; Li, X.; Lv, Y.; Liu, Z.; Jian, S. Mechanical and hydration characteristics of autoclaved aerated concrete (AAC) containing iron-tailings: Effect of content and fineness. Constr. Build. Mater. 2016, 128, 361–372. [Google Scholar] [CrossRef]

- Mashifana, T.P. Beneficiation of Barberton Gold Mine Tailings: The Effect of Fly Ash on the Mineralogy and Micrograph. 2018. Available online: https://core.ac.uk/download/pdf/161412668.pdf (accessed on 2 September 2024).

- Mufteeva, L.F.; Pavlova, I.A.; Farafontova, E.P. The effect of enrichment on quartz sand properties. IOP Conf. Ser. Mater. Sci. Eng. 2020, 966, 012027. [Google Scholar] [CrossRef]

- Santander, M.; Valderrama, L. Recovery of pyrite from copper tailings by flotation. J. Mater. Res. Technol. 2019, 8, 4312–4317. [Google Scholar] [CrossRef]

- Adiguzel, D.; Tuylu, S.; Eker, H. Utilization of tailings in concrete products: A review. Constr. Build. Mater. 2022, 360, 129574. [Google Scholar] [CrossRef]

- Wang, L.; Shen, L.; Sun, W.; Ji, B.; Tang, H. The effects of natural weathering ages on mineralogical, physical, and chemical properties of stacking molybdenum tailings. Environ. Sci. Pollut. Res. 2022, 29, 87817–87827. [Google Scholar] [CrossRef] [PubMed]

- Mueller, O.H. Some aspects of the effect of micaceous sand on concrete. Civ. Eng. Siviele Ingenieurswese 1971, 1971, 313–315. [Google Scholar]

- Nosrati, A.; Addai-Mensah, J.; Skinner, W. Muscovite clay mineral particle interactions in aqueous media. Powder Technol. 2012, 219, 228–238. [Google Scholar] [CrossRef]

- Sposito, R. Investigations on the Impact of Metaphyllosilicates and Calcined Common Clays on the Rheology and Early Hydration of Cements Admixed with Different Superplasticizers. Doctoral Dissertation, Universität der Bundeswehr München, Neubiberg, Germany, 2022. [Google Scholar]

- Zografou, A.; Heath, A.; Walker, P. China clay waste as aggregate in alkali-activated cement mortars. Proc. Inst. Civ. Eng. Constr. Mater. 2014, 167, 312–322. [Google Scholar] [CrossRef]

- Oritola, S.; Saleh, A.L.; Mohd Sam, A.R. Performance of Iron Ore Tailings as Partial Replacement for Sand in Concrete. Appl. Mech. Mater. 2015, 735, 122–127. [Google Scholar] [CrossRef]

- Quan, X.; Wang, S.; Li, J.; Luo, J.; Liu, K.; Xu, J.; Zhao, N.; Liu, Y. Utilization of molybdenum tailings as fine aggregate in recycled aggregate concrete. J. Clean. Prod. 2022, 372, 133649. [Google Scholar] [CrossRef]

- Thomas, B.S.; Damare, A.; Gupta, R.C. Strength and durability characteristics of copper tailing concrete. Constr. Build. Mater. 2013, 48, 894–900. [Google Scholar] [CrossRef]

- Zhao, J.; Ni, K.; Su, Y.; Shi, Y. An evaluation of iron ore tailings characteristics and iron ore tailings concrete properties. Constr. Build. Mater. 2021, 286, 122968. [Google Scholar] [CrossRef]

- Patil, M.V.; Patil, Y.D. Effect of copper slag and granite dust as sand replacement on the properties of concrete. Mater. Today Proc. 2020, 43, 1666–1677. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; Tang, Z.; Huo, X.; Lu, J.; Xu, L. Recycling spodumene flotation tailings in cement mortar: A synergy with metakaolin. In Proceedings of the 2011 International Conference on Computer Distributed Control and Intelligent Environmental Monitoring, Changsha, China, 19–20 February 2011; IEEE: Piscataway, NJ, USA, 2021; pp. 1687–1690. [Google Scholar] [CrossRef]

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Mirza, J. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Alexander, M.G.; Mackechnie, J.R.; Ballim, Y. Guide to the Use of Durability Indexes for Achieving Durability in Concrete Structures; Research Monograph No. 2; Department of Civil Engineering, University of Cape Town: Cape Town, South Africa, 1999. [Google Scholar]

- Zhang, W.; Gu, X.; Qiu, J.; Liu, J.; Zhao, Y.; Li, X. Effects of iron ore tailings on the compressive strength and permeability of ultra-high performance concrete. Constr. Build. Mater. 2020, 260, 119917. [Google Scholar] [CrossRef]

- Teggin, J.W. Corrosion of Reinforcing Steel Induced by Combined Penetration of Chlorides and Carbon Dioxide in Concrete with Construction Cold Joints; University of the Witwatersrand: Johannesburg, South Africa, 2022. [Google Scholar]

- Ince, C. Reusing gold-mine tailings in cement mortars: Mechanical properties and socio-economic developments for the Lefke-Xeros area of Cyprus. J. Clean. Prod. 2019, 238, 117871. [Google Scholar] [CrossRef]

- Siddique, S.; Jang, J.G. Assessment of molybdenum mine tailings as filler in cement mortar. J. Build. Eng. 2020, 31, 101322. [Google Scholar] [CrossRef]

- Ghazi, A.B.; Jamshidi-Zanjani, A.; Nejati, H. Utilization of copper mine tailings as a partial substitute for cement in concrete construction. Constr. Build. Mater. 2022, 317, 125921. [Google Scholar] [CrossRef]

- Pyo, S.; Tafesse, M.; Kim, B.J.; Kim, H.K. Effects of quartz-based mine tailings on characteristics and leaching behavior of ultra-high performance concrete. Constr. Build. Mater. 2018, 166, 110–117. [Google Scholar] [CrossRef]

| Mix Label | Binders (kg/m3) | Aggregates (kg/m3) | Water (kg/m3) | W/C | SP Dosage (%) | |||

|---|---|---|---|---|---|---|---|---|

| PC | FA | Andesite Crushed Stone (Uniformly Graded 19 mm Size) | Andesite Crusher Sand | Secondary Gold Tailings | ||||

| GT0 | 294 | 126 | 1084 | 842 | - | 210 | 0.5 | 0.06 |

| GT10 | 294 | 126 | 1084 | 757.8 | 84.2 | 210 | 0.5 | 0.078 |

| GT25 | 294 | 126 | 1084 | 631.5 | 210.5 | 210 | 0.5 | 0.85 |

| GT50 | 294 | 126 | 1084 | 421.0 | 210 | 210 | 0.5 | 1.23 |

| GT75 | 294 | 126 | 1084 | 210.5 | 631.5 | 210 | 0.5 | 1.58 |

| GT100 | 294 | 126 | 1084 | - | 842 | 210 | 0.5 | 1.96 |

| Element | Percentage by Weight of Secondary Gold Tailings (%) | Percentage by Weight of Andesite Crusher Sand (%) |

|---|---|---|

| Si | 20.96 | 8.78 |

| Fe | 0.54 | 2.56 |

| Al | 8.11 | 1.58 |

| Mg | 0.35 | 0.8 |

| Na | 0.00 | 0.4 |

| K | 8.06 | 0.56 |

| O | 59.33 | 42.34 |

| Ca | 0.00 | 26.58 |

| Cl | 0.00 | 0.1 |

| S | 0.00 | 0.58 |

| C | 2.65 | 15.76 |

| Property | Secondary Gold Tailings | Andesite Crusher Sand |

|---|---|---|

| Fineness modulus | 0.66 | 3.19 |

| Density (g/cm3) | 2.76 | 2.94 |

| Bulk density (kg/m3) | 1522 | 2011 |

| Water absorption (%) | 5.87 | 3.90 |

| Shape | Angular | Angular |

| Surface texture | Very Rough | Rough |

| Source | DF | MS | F Value | p Value Prob ˃ F | Adj. R Square | Significance |

|---|---|---|---|---|---|---|

| GT10 | 1 | 3632.890 | 332.532 | 0.000 | 96.8 | Yes |

| GT25 | 1 | 3390.316 | 96.364 | 0.000 | 89.7 | Yes |

| GT50 | 1 | 2714.851 | 26.427 | 0.000 | 69.8 | Yes |

| GT75 | 1 | 2672.334 | 24.980 | 0.001 | 68.6 | Yes |

| GT100 | 1 | 2352.070 | 16.921 | 0.002 | 59.1 | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ikotun, J.O.; Adeyeye, R.A.; Otieno, M. Experimental Investigation on the Effect of Gold Tailings as a Partial Replacement for Sand in Concrete. Sustainability 2024, 16, 7762. https://doi.org/10.3390/su16177762

Ikotun JO, Adeyeye RA, Otieno M. Experimental Investigation on the Effect of Gold Tailings as a Partial Replacement for Sand in Concrete. Sustainability. 2024; 16(17):7762. https://doi.org/10.3390/su16177762

Chicago/Turabian StyleIkotun, Jacob O., Rhoda A. Adeyeye, and Mike Otieno. 2024. "Experimental Investigation on the Effect of Gold Tailings as a Partial Replacement for Sand in Concrete" Sustainability 16, no. 17: 7762. https://doi.org/10.3390/su16177762

APA StyleIkotun, J. O., Adeyeye, R. A., & Otieno, M. (2024). Experimental Investigation on the Effect of Gold Tailings as a Partial Replacement for Sand in Concrete. Sustainability, 16(17), 7762. https://doi.org/10.3390/su16177762