Sustainable Operation and Management of a Dynamic Supply Chain under the Framework of a Community with a Shared Future for Mankind

Abstract

:1. Introduction

1.1. Motivation

1.2. Literature Review

1.3. Contribution of This Article

- (1)

- This article introduces the values of a community with a shared future for mankind into the operation and management of dynamic supply chains, providing new tacks and ideas for the operation and management of dynamic supply chains.

- (2)

- This article establishes an information supply chain model with self-processing capability for the first time, considering raw material inventory and finished product inventory in a hierarchical manner.

- (3)

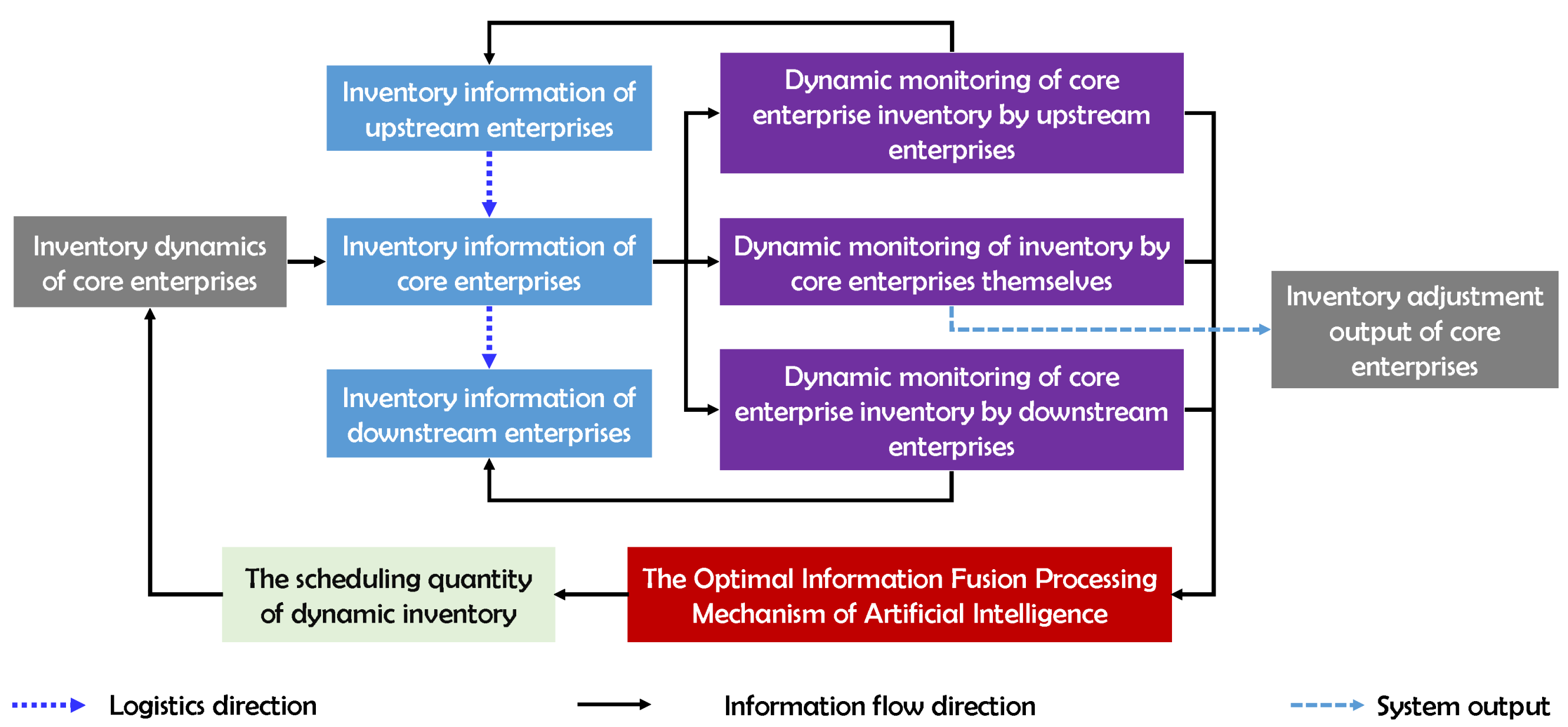

- This article establishes for the first time the static and dynamic monitoring information of core enterprises, achieving real-time data collection and providing effective strategies for real-time control of dynamic supply chains, enhancing the robustness of control algorithms.

- (4)

- This article introduces the principle of artificial intelligence optimal information fusion into the operation and management of dynamic supply chains, overcoming the public problem of traditional optimal control in dynamic supply chains that requires solving the Jacobian matrix. The design concept and process are also simple and easy.

- (5)

- In the face of the public problem of “ordering less may not be enough to meet the needs of consumers, while ordering more may bring huge losses to themselves” in agricultural product enterprises, this article establishes an order-switching model with market conditions, holidays, weather conditions, and other factors as switching factors for the first time, providing new ideas for the quantitative solution of this open problem.

1.4. Organization

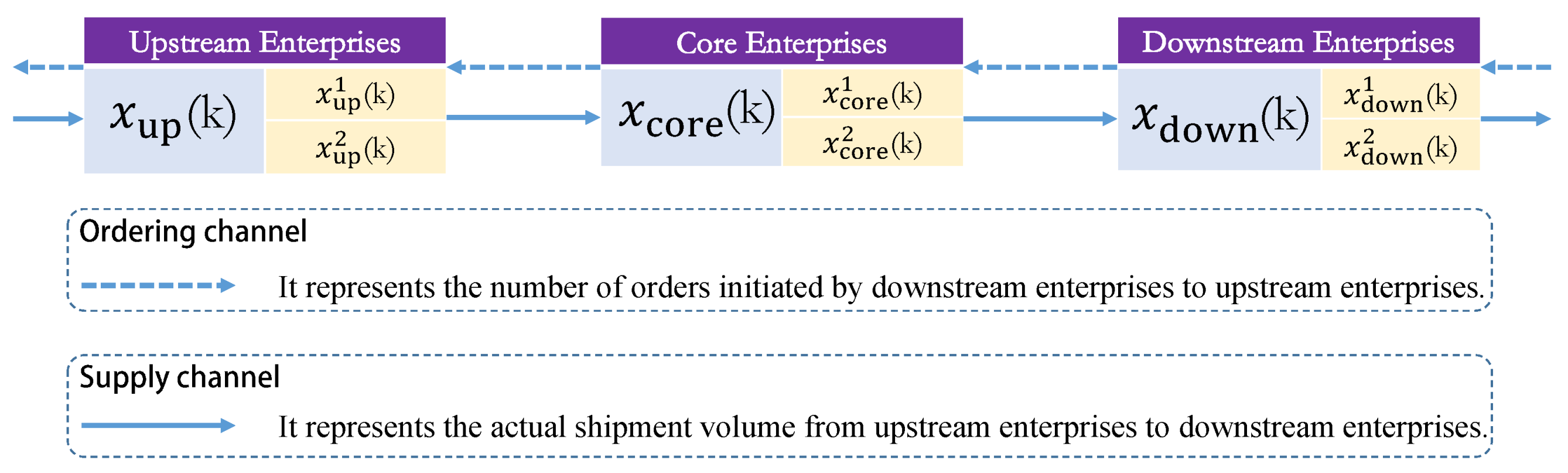

2. Dynamic Supply Chain Model

3. Artificial Intelligence Optimal Information Fusion

4. Control of Dynamic Supply Chain

4.1. Order Switching

4.2. Sufficient Conditions for Solvability in Dynamic Supply Chains

- (1)

- (2)

- Under zero initial conditions, with the action of arbitrary switching of , the tuned output satisfies

4.3. Robustness of Dynamic Supply Chains

4.4. Control Criteria for Dynamic Supply Chains

- (1)

- (2)

- At this point, the closed-loop dynamic supply chain system (26)–(28) is robust and stable under the action of the dynamic output feedback regulation signal (18), and has an disturbance attenuation degree γ. Therefore, the closed-loop dynamic supply chain system (26)–(28) satisfies the control criterion, where the norm is defined by the inner product of the discrete space.

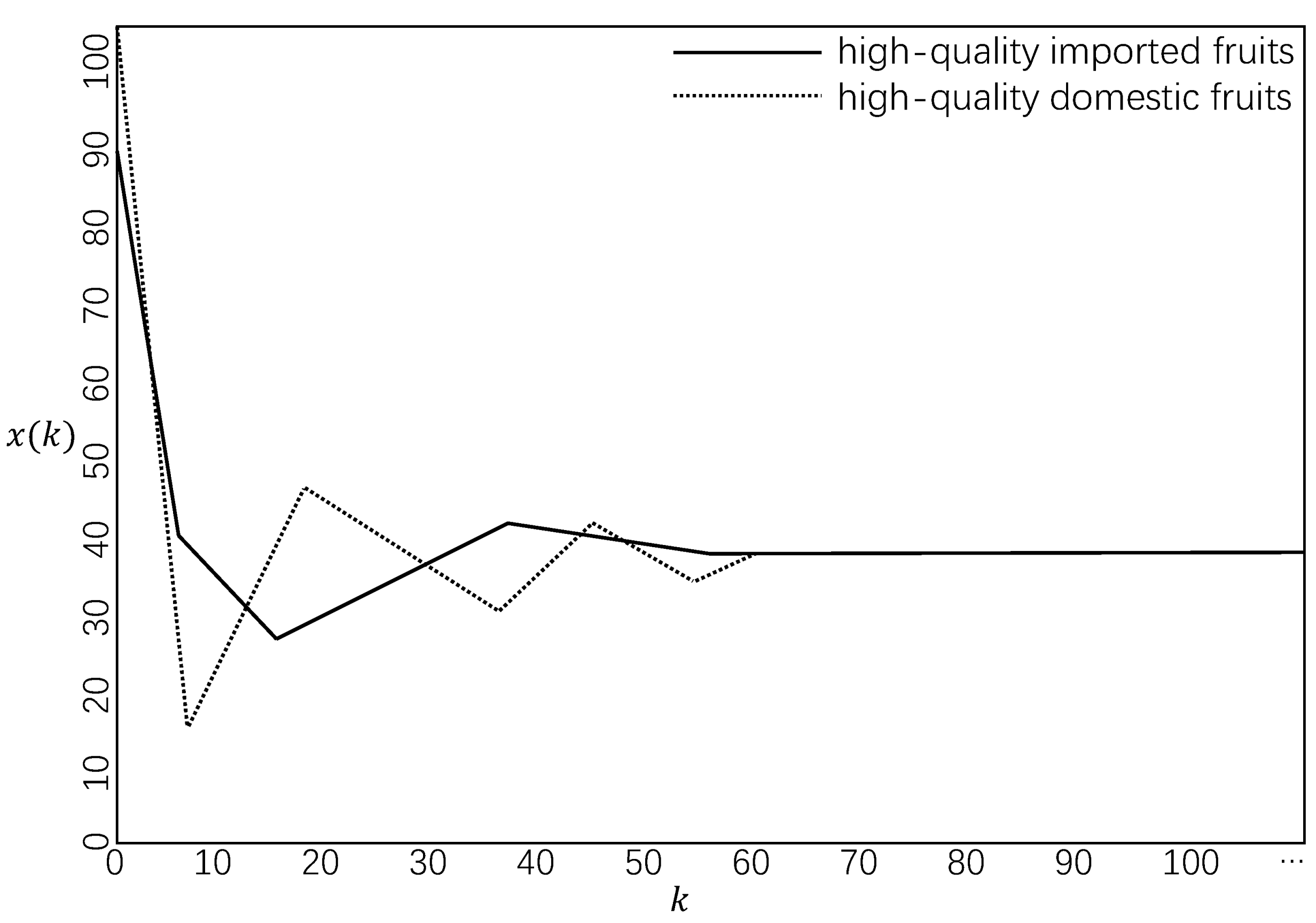

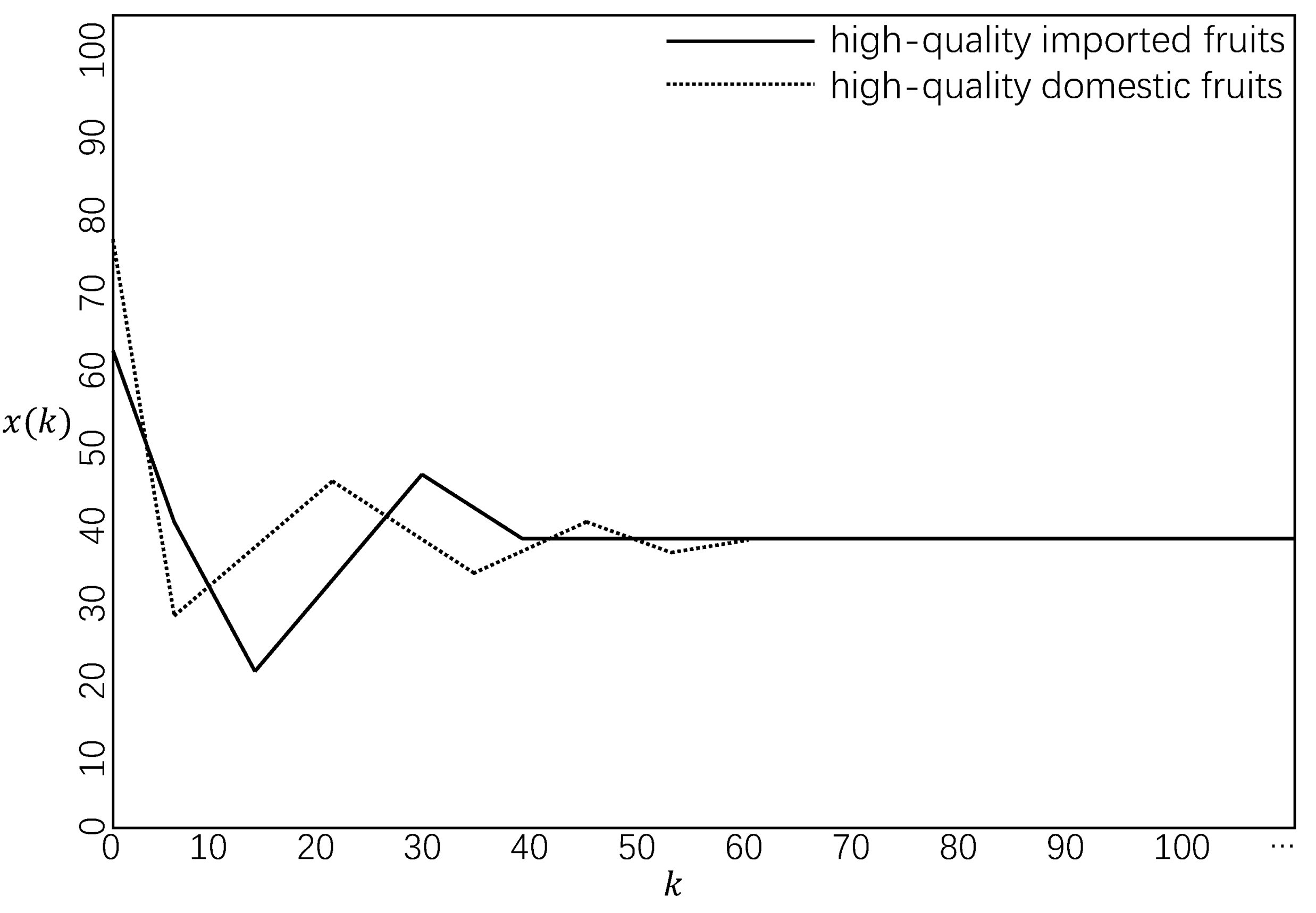

5. Empirical Research

6. Conclusions and Inspiration

6.1. Key Findings

6.2. Policy Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ivanov, D. Transformation of supply chain resilience research through the COVID-19 pandemic. Int. J. Prod. Res. 2024. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Zhong, R.Y. A supply chain disruption recovery strategy considering product change under COVID-19. J. Manuf. Syst. 2021, 60, 920–927. [Google Scholar] [CrossRef]

- Wu, D.; Li, J.; Li, S.; Zhu, L. Research on decision optimization of supply chain quality information disclosure considering stigma level. Systems 2024, 12, 229. [Google Scholar] [CrossRef]

- Xi, M.; Liu, Y.; Fang, W.; Feng, T. Intelligent manufacturing for strengthening operational resilience during the COVID-19 pandemic: A dynamic capability theory perspective. Int. J. Prod. Econ. 2024, 267, 109078. [Google Scholar] [CrossRef]

- Qian, X.; Ren, R.; Wang, Y.; Guo, Y.; Fang, J.; Wu, Z.D.; Liu, P.L.; Han, T.R.; Members of Steering Committee, Society of Global Health, Chinese Preventive Medicine Association. Fighting against the common enemy of COVID-19: A practice of building a community with a shared future for mankind. Infect. Dis. Poverty 2020, 9, 8–13. [Google Scholar] [CrossRef]

- Ngo, V.M.; Quang, H.T.; Hoang, T.G.; Binh, A.D.T. Sustainability-related supply chain risks and supply chain performances: The moderating effects of dynamic supply chain management practices. Bus. Strategy Environ. 2024, 33, 839–857. [Google Scholar] [CrossRef]

- Liu, T. The cultural construction of a community with a shared future for mankind and the addition of new energy of civilization. Wuhan Univ. J. (Philosophy Soc. Sci.) 2024, 77, 5–12. [Google Scholar]

- Stadtfeld, G.M.; Gruchmann, T. Dynamic capabilities for supply chain resilience: A meta-review. Int. J. Logist. Manag. 2024, 35, 623–648. [Google Scholar] [CrossRef]

- Ivanov, D. Cash flow dynamics in the supply chain during and after disruptions. Transp. Res. Part Logist. Transp. Rev. 2024, 185, 103526. [Google Scholar] [CrossRef]

- Du, Q.; Yang, M.; Wang, Y.; Wang, X.; Dong, Y. Dynamic simulation for carbon emission reduction effects of the prefabricated building supply chain under environmental policies. Sustain. Cities Soc. 2024, 100, 105027. [Google Scholar] [CrossRef]

- Yin, W.G. A community with a shared future for mankind: A realistic plan to real community. J. North China Electr. Power Univ. (Soc. Sci.) 2023, 4, 9–16. [Google Scholar]

- Xu, F.; Su, J. Shaping “a community of shared future for mankind”: New elements of general assembly resolution 72/250 on further practical measures for the PAROS. Space Policy 2018, 44–45, 57–62. [Google Scholar] [CrossRef]

- Hui, Z. A community of shared future for mankind—The contemporary development of the social foundations theory of international law. Soc. Sci. China 2019, 40, 186–202. [Google Scholar] [CrossRef]

- Khan, U.; Wang, H.; Ali, I. A sustainable community of shared future for mankind: Origin, evolution and Philosophical foundation. Sustainability 2021, 13, 9352. [Google Scholar] [CrossRef]

- Hu, L.; Chen, Y.; Fan, T. The influence of government subsidies on the efficiency of technological innovation: A panel threshold regression approach. Sustainability 2023, 15, 534. [Google Scholar] [CrossRef]

- Park, R.; Kutanoglu, E.; Baldea, M. Dynamics, uncertainty and control in circular supply chains. Comput. Chem. Eng. 2024, 180, 108441. [Google Scholar] [CrossRef]

- Darmawan, A. Evaluating proactive and reactive strategies in supply chain network design with coordinated inventory control in the presence of disruptions. J. Ind. Prod. Eng. 2024, 41, 307–323. [Google Scholar] [CrossRef]

- Mubarik, M.S.; Khan, S.A. Future of Digital Supply Chain Management. In The Theory, Methods and Application of Managing Digital Supply Chains; Emerald Publishing Limited: Bingley, UK, 2024; pp. 163–178. [Google Scholar]

- Sun, S.L. Distributed optimal linear fusion estimators. Inf. Fusion 2020, 63, 56–73. [Google Scholar] [CrossRef]

- Zhang, P.; Li, T.; Yuan, Z.; Deng, Z.; Wang, G.; Wang, D.; Zhang, F. A possibilistic information fusion-based unsupervised feature selection method using information quality measures. IEEE Trans. Fuzzy Syst. 2023, 31, 2975–2988. [Google Scholar] [CrossRef]

- Albahri, A.; Duhaim, A.M.; Fadhel, M.A.; Alnoor, A.; Baqer, N.S.; Alzubaidi, L.; Albahri, O.; Alamoodi, A.; Bai, J.; Salhi, A.; et al. A systematic review of trustworthy and explainable artificial intelligence in healthcare: Assessment of quality, bias risk, and data fusion. Inf. Fusion 2023, 96, 156–191. [Google Scholar] [CrossRef]

- Xu, Q.; Tan, Z. Building a maritime community with a shared future: Scholarly reflections on China’s new ocean vision. Mar. Policy 2023, 149, 105508. [Google Scholar] [CrossRef]

- Wang, C. The significance of the concept of a maritime community with a shared future in the international law-making process: Taking the BBNJ Agreement as an example. Marine Policy 2023, 149, 105509. [Google Scholar] [CrossRef]

- Zhao, X.X.; Wen, J.; Zou, X.Y.; Wang, Q.j.; Chang, C.P. Strategies for the sustainable development of China in the post-epidemic era. Sustain. Dev. 2023, 31, 426–438. [Google Scholar] [CrossRef]

- Xing, Z.; Huang, J.; Wang, J. Unleashing the potential: Exploring the nexus between low-carbon digital economy and regional economic-social development in China. J. Clean. Prod. 2023, 413, 137552. [Google Scholar] [CrossRef]

- Shen, Y.J.; Chen, R.F.; Zhu, Y.Y. On making China’s industrial and supply chains more resilient and secure: Based on Marx’s capital cycle theory. Soc. Sci. Chin. High. Educ. 2023, 2023, 64–71. [Google Scholar]

- Hu, L.; Fan, T. Guarantee stability of supply chain with dual channels under supply failure of goods. Sustainability 2023, 15, 5890. [Google Scholar] [CrossRef]

- Hu, L.; Fan, T. Hierarchical scheduling of complex dynamic supply chain. Appl. Sci. 2023, 13, 75. [Google Scholar] [CrossRef]

- Zhang, B.L.; Liu, L.P.; Wei, L. Dynamic modeling and robust state feedback stabilization of supply chains via demand combination prediction schemes. Control. Decis. 2017, 32, 695–702. [Google Scholar]

- Chen, X.; Xie, H.; Li, Z.; Cheng, G.; Leng, M.; Wang, F.L. Information fusion and artificial intelligence for smart healthcare: A bibliometric study. Inf. Process. Manag. 2023, 60, 103113. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Wang, J.; Wu, L.; Liu, Z.; Wang, L. A new data fusion driven-sparse representation learning method for bearing intelligent diagnosis in small and unbalanced samples. Eng. Appl. Artif. Intell. 2023, 117, 105513. [Google Scholar] [CrossRef]

- Hu, G.; Xu, L.; Gao, B.; Chang, L.; Zhong, Y. Robust unscented Kalman filter based decentralized multi-sensor information fusion for INS/GNSS/CNS integration in hypersonic vehicle navigation. IEEE Trans. Instrum. Meas. 2023, 72, 8504011. [Google Scholar] [CrossRef]

- Wu, B.; Guan, Z.H.; Zhan, X.S.; Zhang, X.H. H∞ control of wireless sensor networks with filtering. Control. Theory Appl. 2013, 30, 261–265. [Google Scholar]

- Deng, Z.; Qi, R. Suboptimal steady-state Kalman filter for multisensor information fusion. Chin. Sci. Abstr. 2000, 6, 183–184. [Google Scholar]

- Deng, Z.; Mao, L.; Gao, Y. Multisensor optimal information fusion steady-state Kalman filter. Sci. Technol. Eng. 2004, 4, 743–748. [Google Scholar]

- Song, Z.Y.; Zhao, J. A sufficient condition for stability with H∞ performance for linear discrete-time switched systems. J. Northeast. Univ. (Natural Sci.) 2005, 26, 213–216. [Google Scholar]

- Ma, G.; Chen, Q.; Hu, W. Robust H∞ control for a class of uncertain discrete time switched systems. J. Southeast Univ. (Natural Sci. Ed.) 2006, 36, 79–81. [Google Scholar]

- Ma, G.; Li, S.; Chen, Q.; Hu, W. H∞ robustness analysis for uncertain discrete time switched systems. Control. Decis. 2005, 20, 1304–1310. [Google Scholar]

- Li, H.; Huang, Y.; Xiao, F. Research on the “Internet +” agricultural supply chain financial model: A case study of New Hope Group. Agric. Outlook 2024, 20, 27–35. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, L.; Wang, C.; Fan, T. Sustainable Operation and Management of a Dynamic Supply Chain under the Framework of a Community with a Shared Future for Mankind. Sustainability 2024, 16, 7780. https://doi.org/10.3390/su16177780

Hu L, Wang C, Fan T. Sustainable Operation and Management of a Dynamic Supply Chain under the Framework of a Community with a Shared Future for Mankind. Sustainability. 2024; 16(17):7780. https://doi.org/10.3390/su16177780

Chicago/Turabian StyleHu, Lihua, Chengjiu Wang, and Tao Fan. 2024. "Sustainable Operation and Management of a Dynamic Supply Chain under the Framework of a Community with a Shared Future for Mankind" Sustainability 16, no. 17: 7780. https://doi.org/10.3390/su16177780