Offshore Wind Power: Progress of the Edge Tool, Which Can Promote Sustainable Energy Development

Abstract

1. Introduction

2. Technical Characteristics of Offshore Wind Power

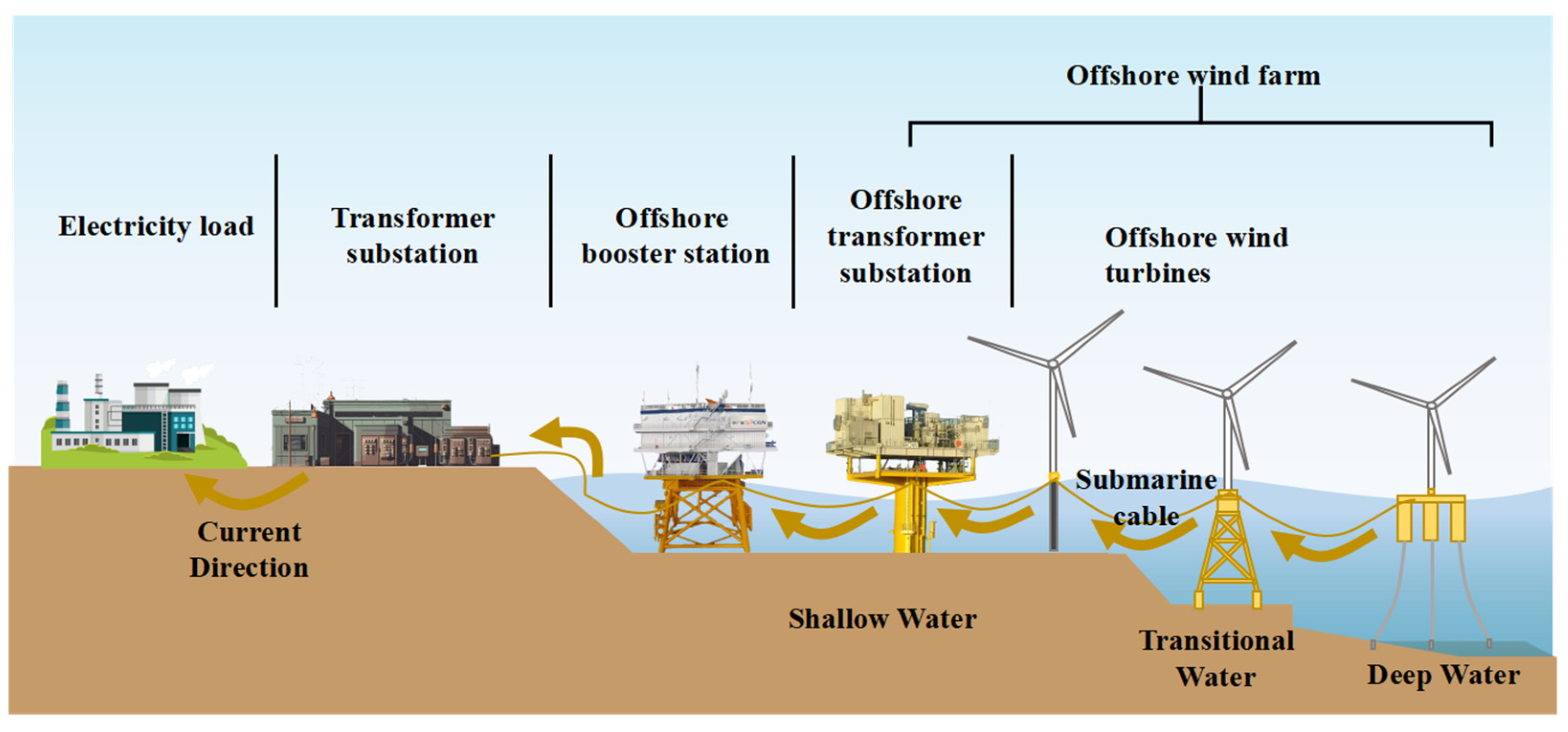

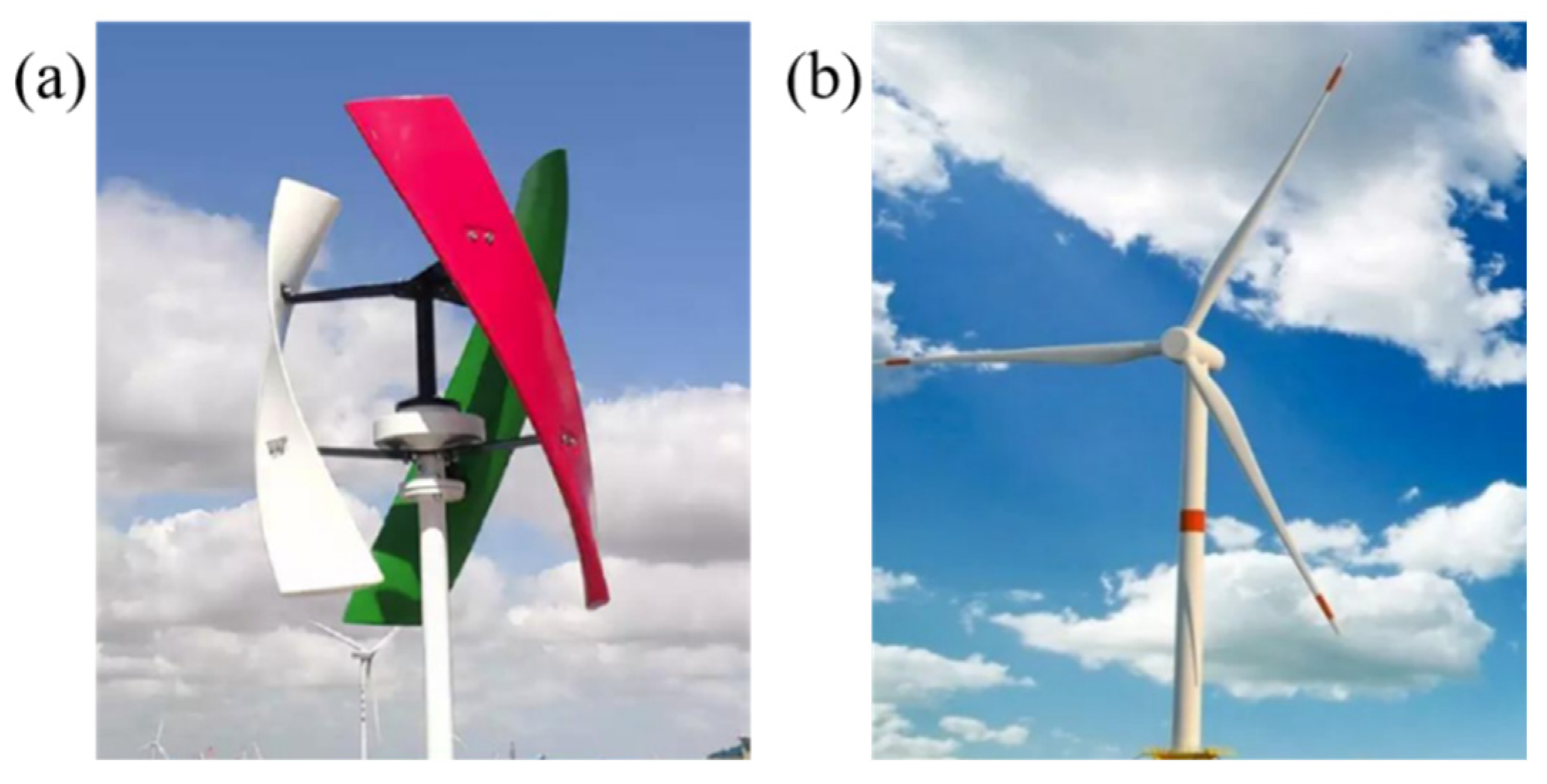

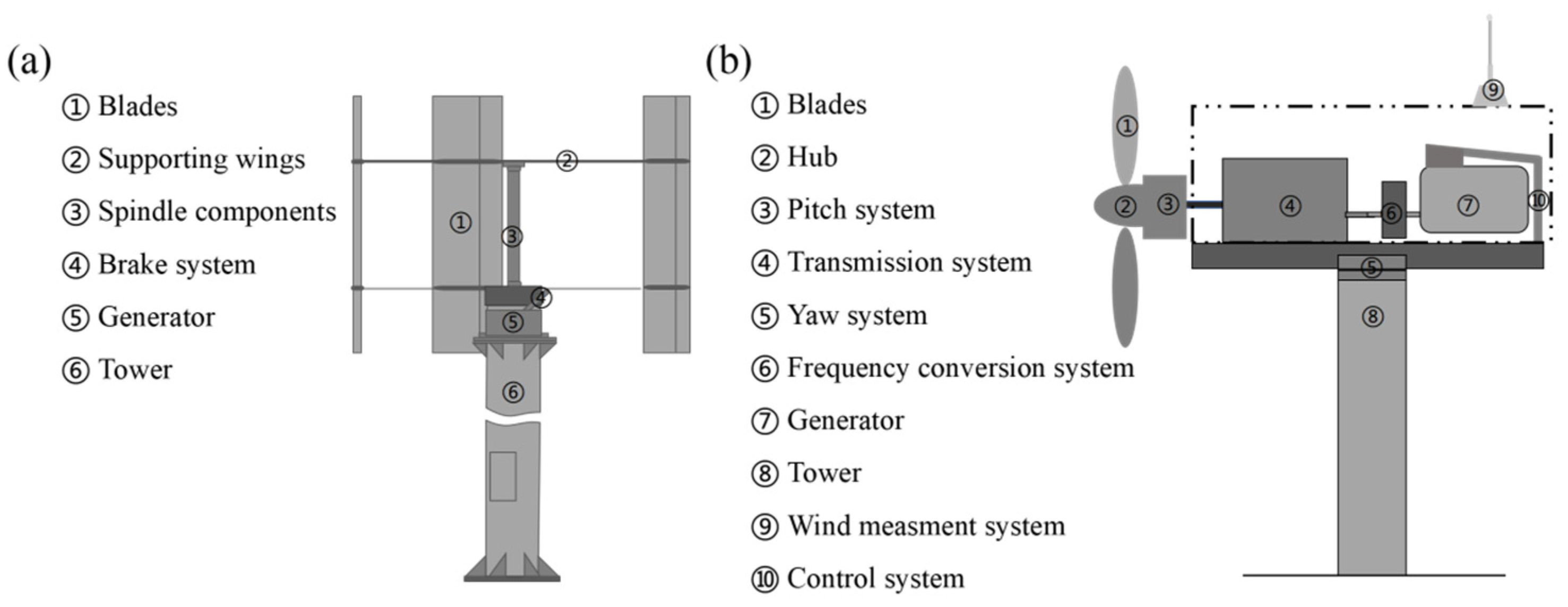

2.1. Overview of Offshore Wind Power Structure

2.2. Analysis of Advantages and Disadvantages of Offshore Wind Power

3. Development Status of Offshore Wind Power Technology

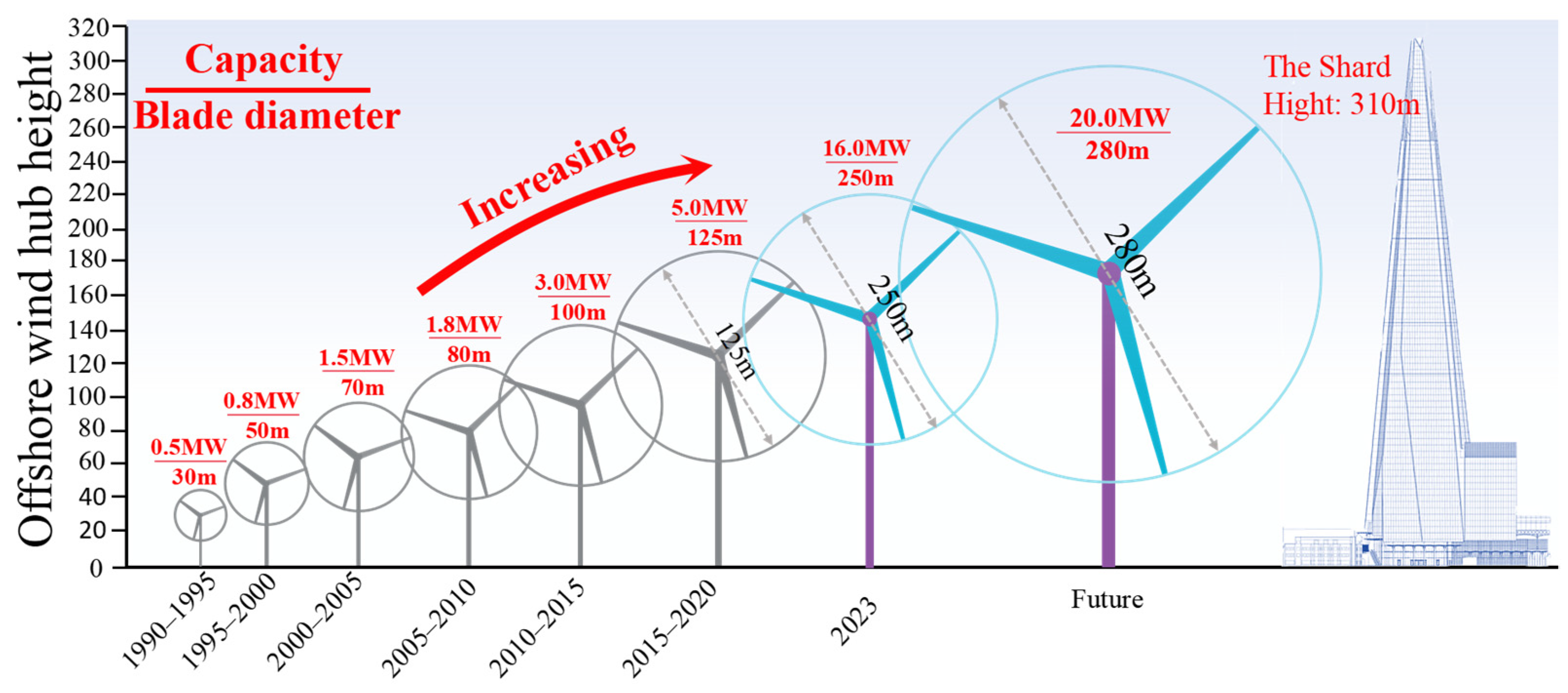

3.1. Large Wind Turbine Technology

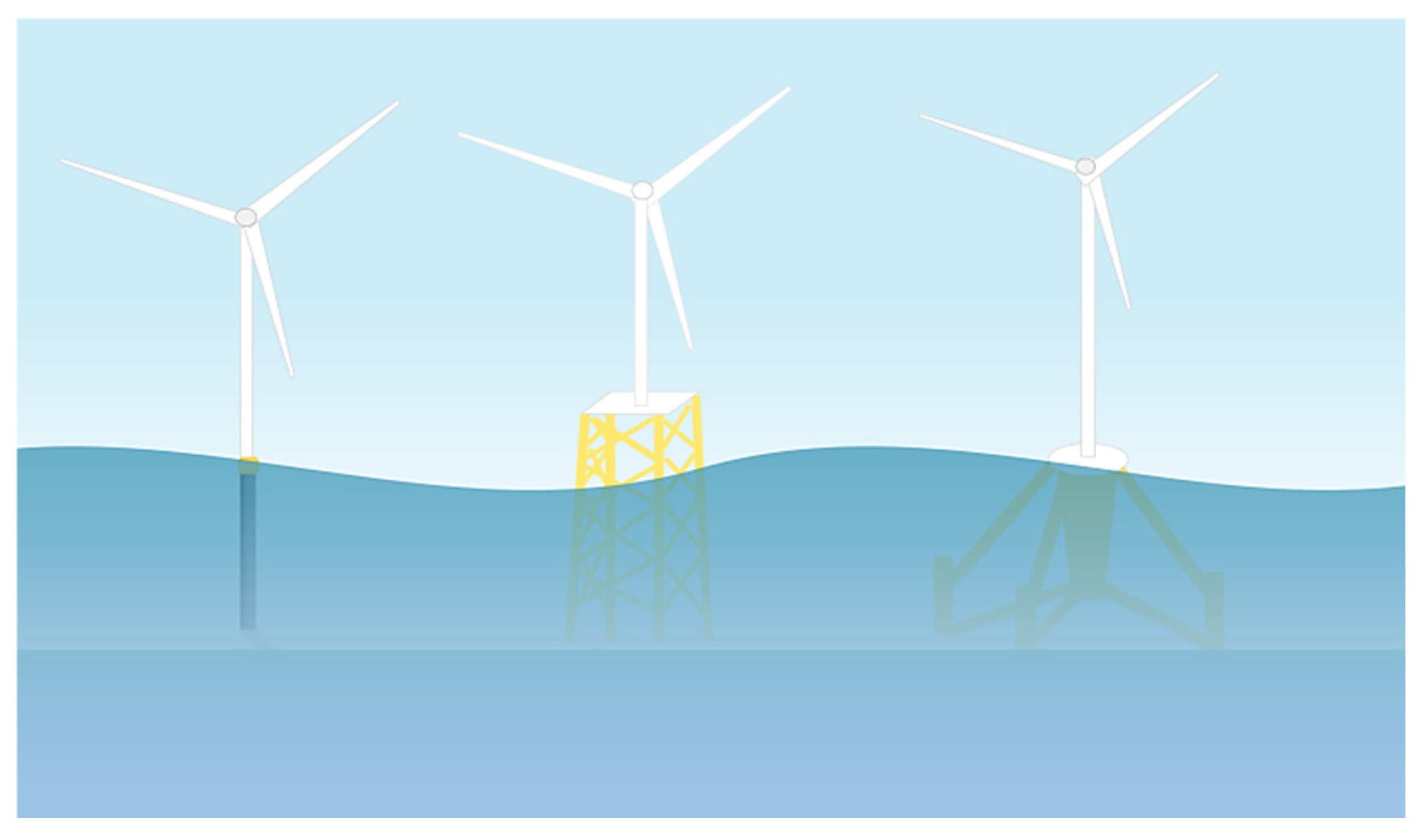

3.2. Fixed Offshore Wind Power Technology

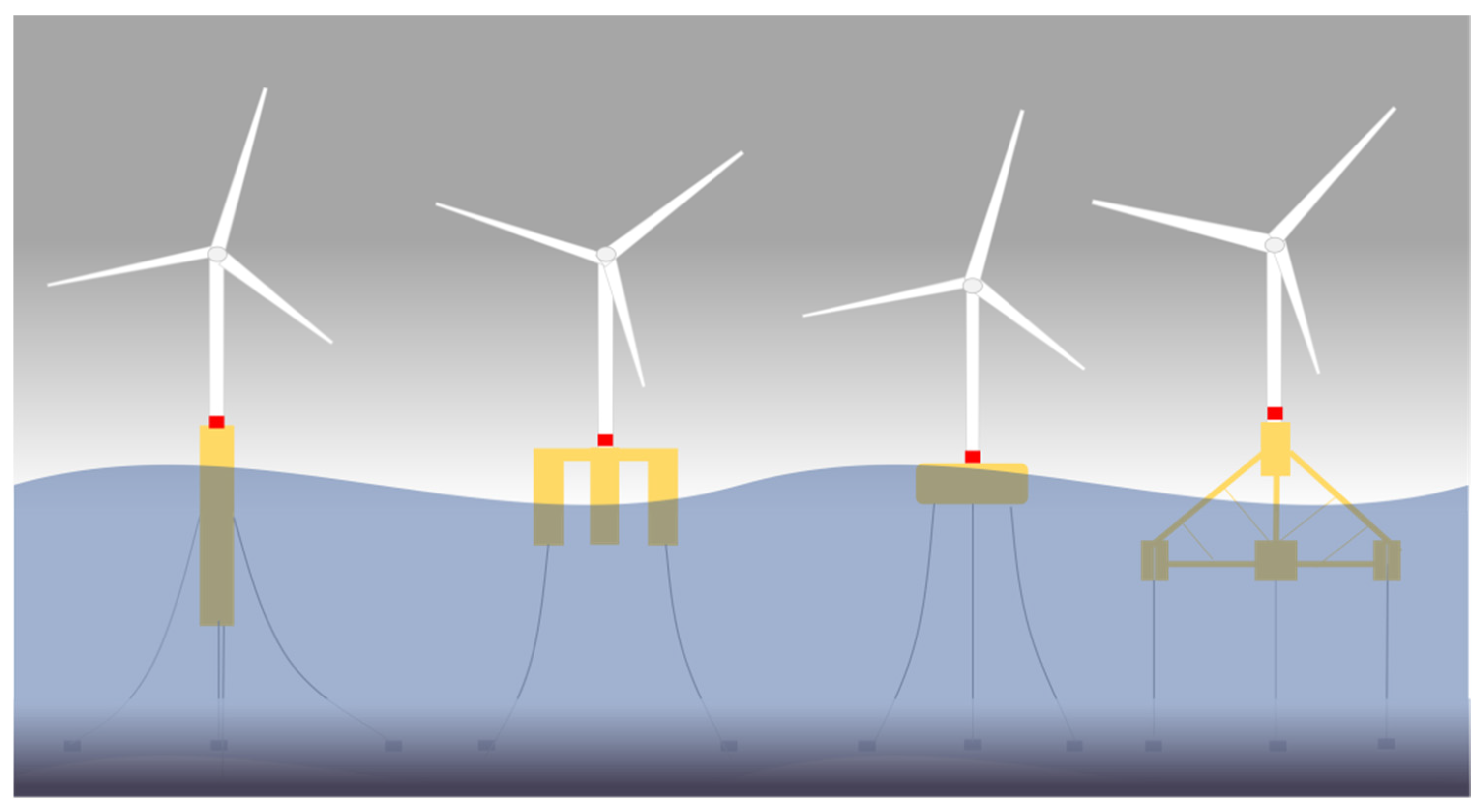

3.3. Floating Offshore Wind Power Technology

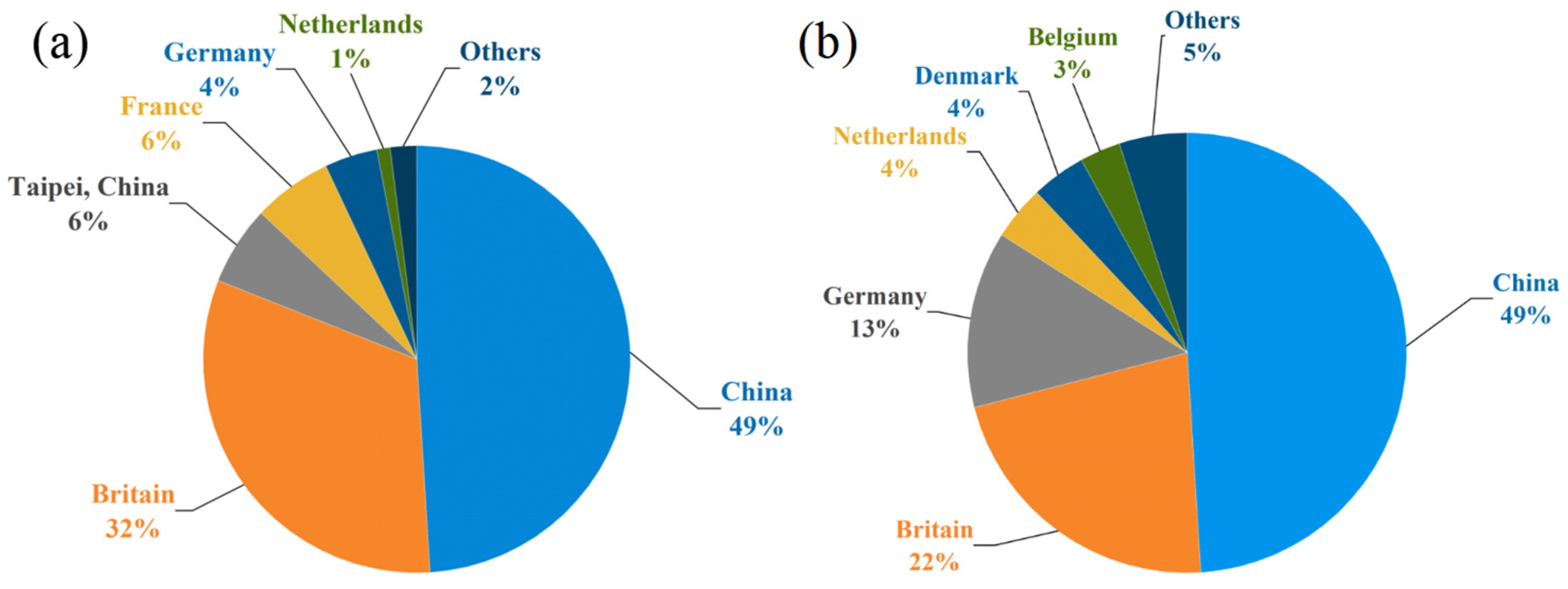

4. Development Status of Offshore Wind Power Industry

4.1. Offshore Wind Power Policy

4.2. Offshore Wind Power Market

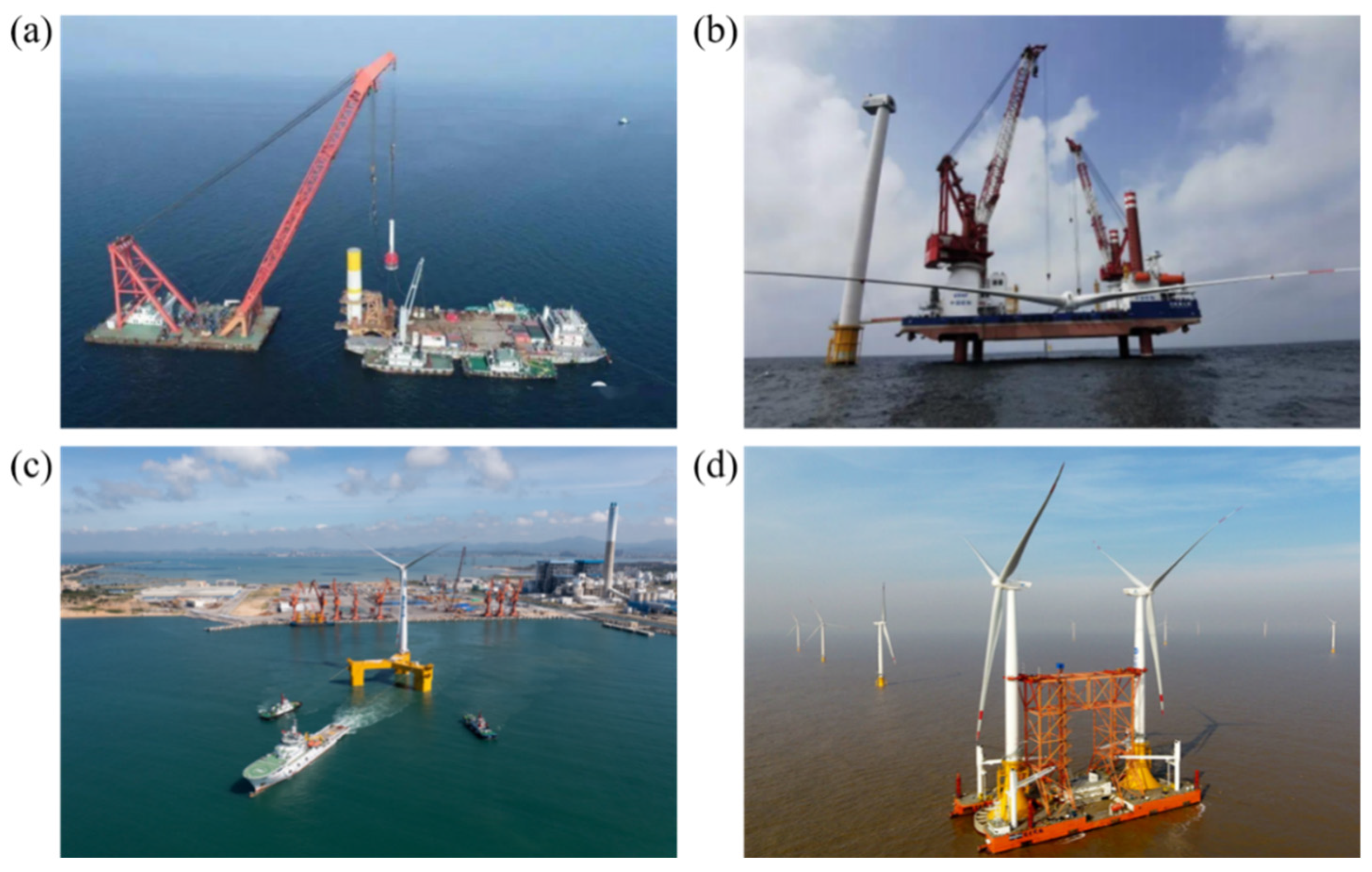

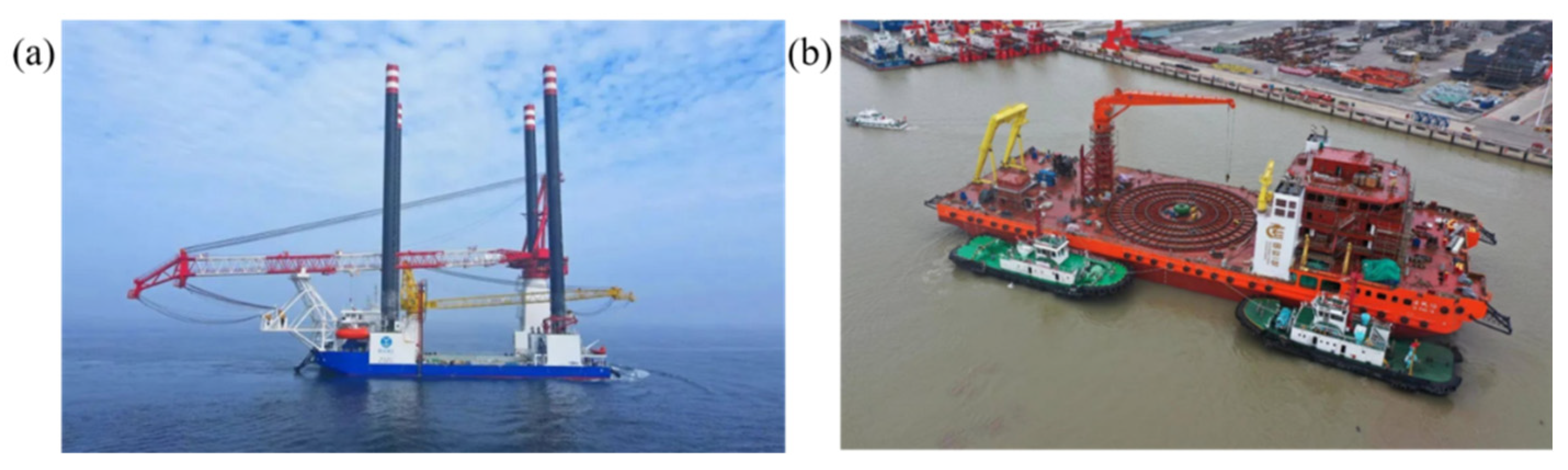

4.3. Engineering Construction

4.4. Operation and Maintenance of Offshore Wind Power

5. Discussion

5.1. Challenges in the Development of Offshore Wind Power

- The stability of offshore wind power output is insufficient. The wind direction and speed at sea are generally affected by seasonality and weather. Periods of low or zero wind generally occur every year. In certain areas, typhoon weather may occur. Both low and high wind speeds can influence the electricity generation of offshore wind power, thereby resulting in fluctuations in power output. To reduce the constraints on the use of electricity, it is necessary to smooth out the fluctuations in offshore wind power, expand the range of offshore wind power operation conditions, and improve wind power generation efficiency.

- The development of offshore wind power is subject to restrictions on maritime rights. With the intensive development of offshore wind power in the early stages, large-scale wind farms have been opened up along the coast. However, the use of marine resources needs to be considered comprehensively. If the establishment of wind farms is not restricted, it would cause a shortage of coastal sea resources by affecting the passage of waterways and the development of other industries such as fisheries, mining, and tourism. Therefore, certain regions in China have temporarily slowed down the establishment of offshore wind farms. The allocation and use of offshore wind power rights need to be determined scientifically and reasonably.

- The construction cost of offshore wind power is relatively high. The construction of offshore wind power requires the consideration of the investment cost of offshore engineering operations. A rational design of wind turbines should consider the special offshore environment, such as the high temperature, high humidity, high salt spray, high ultraviolet radiation, typhoons, and erosion caused by marine organisms. Therefore, the expenses for multiple protection modules need to be considered. The simultaneous construction of submarine cables and offshore booster stations results in higher initial construction costs than those for onshore wind power. The reduction of the cost of offshore wind power is a major challenge for its future development.

- Offshore wind power operation and maintenance needs large resource investments. Unlike onshore wind power, offshore wind power is at a distance from the coast and requires the transportation of personnel, equipment, and accessories by ship. Therefore, professional engineering ships and maintenance ships are the key to offshore wind power operation and maintenance. This results in the complexity of offshore wind power operation and maintenance involves more personnel and equipment investment and occupies and consumes more resources than those for onshore wind power.

- The offshore wind power market mechanism needs further improvement. There are indications of weakening financial support from the government for offshore wind power: China proposed in 2020 that newly established offshore wind power farms will no longer enjoy the central government subsidies. In addition, the current maritime management laws and related supporting systems are applicable only to a single industry, the approval of offshore wind power is relatively complex, and a comprehensive offshore development system is absent. The system that can scientifically and reasonably promote the steady development of offshore wind power needs to be supplemented and improved urgently.

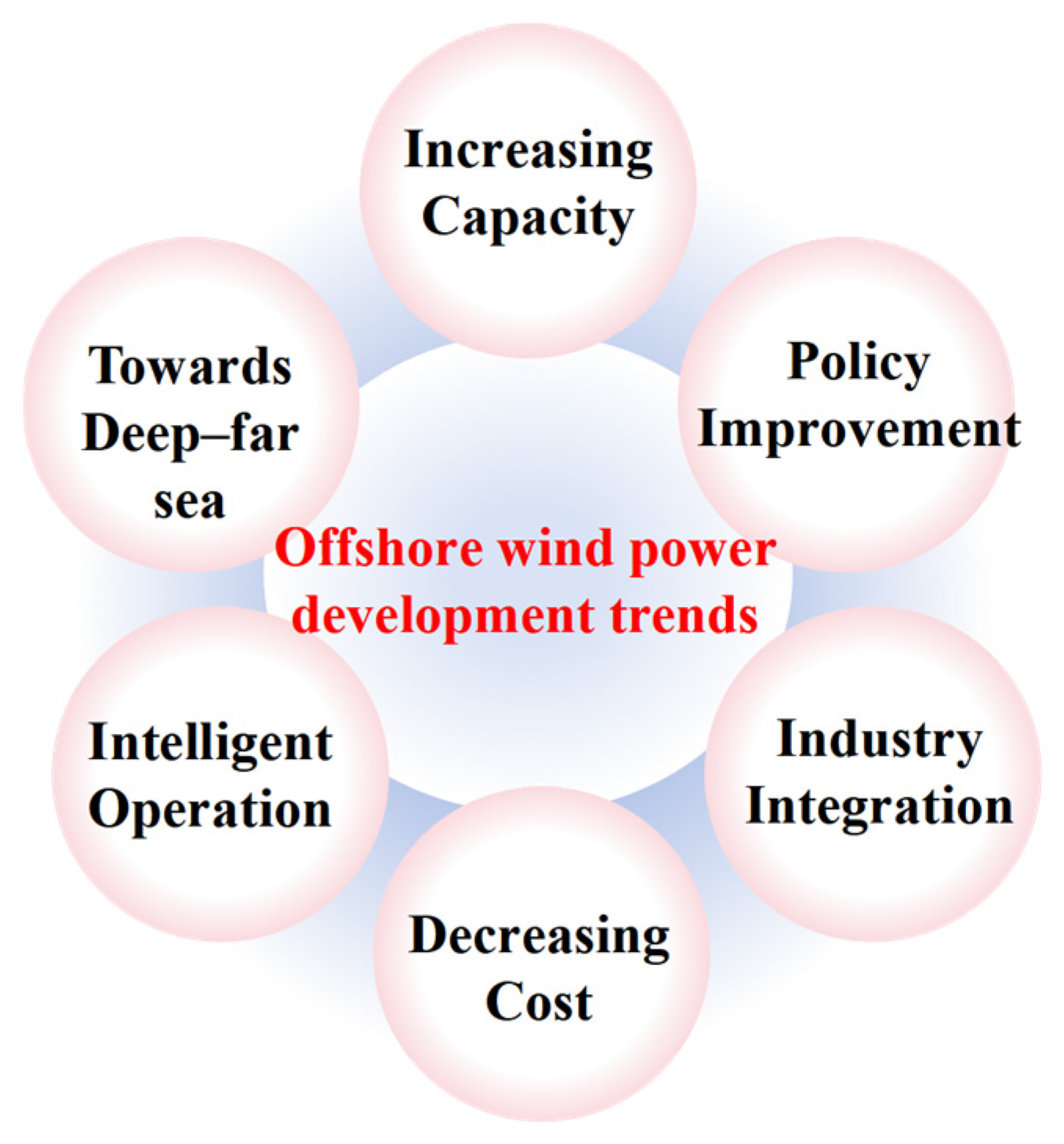

5.2. Developmental Trend of Offshore Wind Power

- The capacity of offshore wind turbines is increasing. Large wind turbines can fully utilize offshore wind resources, improve power generation efficiency, reduce the impact of wind fluctuations, effectively offset the cost increase caused by offshore construction operations, and reduce power generation costs.

- The locations of offshore wind plants are developing from near sea to deep–far sea. The wind energy resources in the deep–far sea areas with offshore distances larger than 100 km and water depths exceeding 50 m have increased in number after the saturation of wind farm resources near the coast. Offshore wind power will be large-scale, clustered, and located in deep–far seas in the future.

- Intelligent operation and maintenance. With the increasing maturity of digital twin technology, long-term maintenance-free technology, and intelligent monitoring technology for wind turbines, the frequency of maintenance and staffing efforts in offshore wind plants will decrease gradually. Thus, resource investment would be reduced when power generation is ensured.

- Overall cost reduction. With the gradual maturity of technology and industrial chains, as well as the large-scale development of the industry, the construction and operation costs of offshore wind turbines are displaying a downward trend. The production and manufacturing costs of offshore wind turbine equipment are decreasing gradually. Offshore operation and maintenance are gradually being undertaken by specialized companies. The large-scale operation and maintenance of wind power would also dilute the costs. Moreover, offshore wind power is convenient for consumption in coastal economic zones, thereby reducing power losses and transmission costs.

- Integrated development and comprehensive utilization of marine resources. Offshore wind power has been introduced gradually in conjunction with fishing, oil and gas, hydrogen production, and desalination. This shows a trend of integrated development with other resources on the same sea area or platform.

- Continuous improvement of development policies. Although the central subsidies in certain countries are decreasing gradually, local subsidy mechanisms are constantly being introduced and improved in certain provinces and cities. The integration technology of offshore wind power with other industries also provides a technical foundation for the detailed planning for the ocean and the establishment of a compatible development and utilization mechanism for the sea area. In the future, through the refined and characteristic development as well as management of marine resources, the maximum value of marine areas will be utilized. This will enable multiple industries to develop synergistically in the same marine area.

5.3. Offshore Wind Power and Sustainable Development

- Reduce environmental pollution and carbon emissions. Offshore wind power energy originates from sea wind and has good-scale economic effects. This can induce the upgrading of the energy industry, eliminate outdated high-emission energy industries, reduce the use of fossil fuels such as coal and oil, decrease the emission of greenhouse gases such as carbon dioxide, and cause a reduction in air pollutants such as sulfur and nitrogen oxide. This would reduce environmental pollution and mitigate the impact of climate change.

- Reduce the pressure on land utilization. The construction of offshore wind plants does not reduce the available land area; has a minimal impact on agriculture, forestry, and wildlife habitats; and prevents competition with residential or industrial land. This is particularly important in populated areas with limited or expensive land resources. Thereby, it would provide a broader space for the scientific development and layout of local economies.

- Contribute to sustainable energy development. As a rapidly expanding renewable energy source, offshore wind power plays an important role in sustainable energy development. By developing offshore wind power, the proportion of traditional environment-unfriendly fossil energy would be reduced gradually, and the upgrade as well as transformation of the energy industrial structure can be achieved. A scientific and rational layout of long-term construction of wind power can contribute to sustainable energy development through a stepwise establishment project of offshore wind power, from onshore, nearshore, and, finally, to deep–far sea, meeting today’s energy needs without compromising the ability of future generations to meet their needs.

- Promote the comprehensive development of industries. The development of offshore wind power involves the industry chain of wind turbines and industries such as shipbuilding, power grid, information network, energy storage, and green power trading. In addition, offshore wind power can also be integrated with offshore industries such as fisheries, mining, and tourism to utilize marine resources in a cascade manner. Therefore, the development of the offshore wind power industry has a driving effect and can effectively promote the comprehensive development of the regional economy and industry; for example, the Ocean Ranch and the Three Gorges 300 MW offshore wind power integration demonstration project in Changyi City, in which the total installed capacity is 300 MW. It can provide about 940 million kWh of clean electricity per year, which can meet the annual electricity need of about 400,000 households. It has significant economic benefits and energy saving and emission reduction benefits that can save about 290,000 tons of standard coal and reduce about 790,000 tons of carbon dioxide every year. In addition, the construction of the Ocean Ranch relied on the built wind turbine foundation, and the integrated system simultaneously provided electricity and met people’s demand for seafood products, which has had a positive impact on sustainable development.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zou, C.; Zhao, Q.; Zhang, G.; Xiong, B. Energy revolution: From a fossil energy era to a new energy era. Nat. Gas Ind. B 2016, 3, 1–11. [Google Scholar] [CrossRef]

- López-Castrillón, W.; Sepúlveda, H.H.; Mattar, C. Off-Grid Hybrid Electrical Generation Systems in Remote Communities: Trends and Characteristics in Sustainability Solutions. Sustainability 2021, 13, 5856. [Google Scholar] [CrossRef]

- Holechek, J.L.; Geli, H.M.E.; Sawalhah, M.N.; Valdez, R. A Global Assessment: Can Renewable Energy Replace Fossil Fuels by 2050? Sustainability 2022, 14, 4792. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Yang, Y. Wind energy development and its environmental impact: A review. Renew. Sustain. Energy Rev. 2012, 16, 1031–1039. [Google Scholar] [CrossRef]

- Song, D.; Fan, T.; Li, Q.; Joo, Y.H. Advances in Offshore Wind. J. Mar. Sci. Eng. 2024, 12, 359. [Google Scholar] [CrossRef]

- Gaudiosi, G. Offshore wind energy prospects. Renew. Energy 1999, 16, 828–834. [Google Scholar] [CrossRef]

- Li, G.; Wang, J.; Liu, F.; Wang, T.; Zhou, Y.; Tian, A. Regional Differences and Convergence of Technical Efficiency in China’s Marine Economy under Carbon Emission Constraints. Sustainability 2023, 15, 7632. [Google Scholar] [CrossRef]

- Council, Global Wind Energy. Global Offshore Wind Report 2020; GWEC: Brussels, Belgium, 2020; Volume 19, pp. 10–12. [Google Scholar]

- Guo, X.; Chen, X.; Chen, X.; Sherman, P.; Wen, J.; McElroy, M. Grid integration feasibility and investment planning of offshore wind power under carbon-neutral transition in China. Nat. Commun. 2023, 14, 2447. [Google Scholar] [CrossRef]

- Esteban, M.D.; Diez, J.J.; López, J.S.; Negro, V. Why offshore wind energy? Renew. Energy 2011, 36, 444–450. [Google Scholar] [CrossRef]

- Zhou, P.; Yin, P.T. An opportunistic condition-based maintenance strategy for offshore wind farm based on predictive analytics. Renew. Sustain. Energy Rev. 2019, 109, 1–9. [Google Scholar] [CrossRef]

- Sun, C.; Chen, J.; Tang, Z. New energy wind power development status and future trends. In Proceedings of the International Conference on Advanced Electrical Equipment and Reliable Operation (AEERO), Beijing, China, 15–17 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–5. [Google Scholar]

- Al-Rawajfeh, M.A.; Gomaa, M.R. Comparison between horizontal and vertical axis wind turbine. Int. J. Appl. 2023, 12, 13–23. [Google Scholar] [CrossRef]

- Roy, S.; Das, B.; Biswas, A. A comprehensive review of the application of bio-inspired tubercles on the horizontal axis wind turbine blade. Int. J. Environ. Sci. Technol. 2023, 20, 4695–4722. [Google Scholar] [CrossRef]

- Nassar, W.M.; Anaya-Lara, O.; Ahmed, K.H.; Campos-Gaona, D.; Elgenedy, M. Assessment of Multi-Use Offshore Platforms: Structure Classification and Design Challenges. Sustainability 2020, 12, 1860. [Google Scholar] [CrossRef]

- Jiang, Z. Installation of offshore wind turbines: A technical review. Renew. Sustain. Energy Rev. 2021, 139, 110576. [Google Scholar] [CrossRef]

- Pan, L.; Zhu, Z.; Shi, Z.; Wang, L. Modeling and Investigation of Blade Trailing Edge of Vertical Axis Offshore Wind Turbine. Sustainability 2021, 13, 10905. [Google Scholar] [CrossRef]

- Koh, J.H.; Ng, E.Y.K. Downwind offshore wind turbines: Opportunities, trends and technical challenges. Renew. Sustain. Energy Rev. 2016, 54, 797–808. [Google Scholar] [CrossRef]

- Peng, H.; Li, S.; Shangguan, L.; Fan, Y.; Zhang, H. Analysis of Wind Turbine Equipment Failure and Intelligent Operation and Maintenance Research. Sustainability 2023, 15, 8333. [Google Scholar] [CrossRef]

- Ali, A.; Ali, S.; Shaukat, H.; Khalid, E.; Behram, L.; Rani, H.; Altabey, W.A.; Kouritem, S.A.; Noori, M. Advancements in piezoelectric wind energy harvesting: A review. Results Eng. 2024, 21, 101777. [Google Scholar] [CrossRef]

- Wu, H.; Ke, S.; Lu, M.; Gao, M.; Tian, W.; Liu, D.; Li, Y.; Wang, T. Research on vibration suppression effect and energy dissipation mechanism of wind turbine piezoelectric blade. J. Fluid. Struct. 2023, 117, 103814. [Google Scholar] [CrossRef]

- Zhu, L.; Zheng, H.; Ji, H.; Li, G.; Li, H.; Yao, S. Development trends and suggestions on offshore wind power of China. In Proceedings of the IEEE Sustainable Power and Energy Conference (iSPEC), Nanjing, China, 23–25 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 2043–2048. [Google Scholar]

- Zhu, H.; Du, Z.; Wu, J.; Sun, Z. Innovation environment and opportunities of offshore wind turbine foundations: Insights from a new patent analysis approach. World Pat. Inf. 2022, 68, 102092. [Google Scholar] [CrossRef]

- Tian, Y.; Kou, L.; Han, Y.; Yang, X.; Hou, T.; Zhang, W. Evaluation of offshore wind power in the China sea. J. Energy Explor. Exploit. 2021, 39, 1803–1816. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Kammen, D. Greener is Cheaper: An Example Form Offshore Wind Farms. Natl. Inst. Econ. Rev. 2024, 1–17. [Google Scholar] [CrossRef]

- Pryor, S.C.; Barthelmie, R.J. Wind shadows impact planning of large offshore wind farms. Appl. Energy 2024, 359, 122755. [Google Scholar] [CrossRef]

- Wang, J.; Wei, X.; Juanatas, R. Study on the optimization strategy of offshore wind power. Int. J. Low-Carbon Technol. 2023, 18, 367–372. [Google Scholar] [CrossRef]

- Huang, J.; Huang, X.; Song, N.; Ma, Y.; Wei, D. Evaluation of the Spatial Suitability of Offshore Wind Farm—A Case Study of the Sea Area of Liaoning Province. Sustainability 2022, 14, 449. [Google Scholar] [CrossRef]

- Huang, R.; Li, H.; Fei, F.; Qi, Y.; Song, T.; Zheng, S. Research on a New Control Method of Squirrel Cage Induction Generator for Wind Turbine. In Proceedings of the 2023 3rd International Conference on New Energy and Power Engineering (ICNEPE), Huzhou, China, 24–26 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 445–449. [Google Scholar]

- Kadam, D.P.; Kushare, B.E. Overview of different wind generator systems and their comparisons. Int. J. Eng. Sci. 2012, 2, 1076–1081. [Google Scholar]

- Zhang, X.; Gao, H.; Cao, B. Research on fault causes and treatment methods of squirrel-cage asynchronous wind turbine. J. Phys. Conf. Ser. 2023, 2488, 012026. [Google Scholar] [CrossRef]

- Zhuo, Z.Y.; Chen, M.J.; Li, X.Y. A comparative analysis of carbon reduction potential for directly driven permanent magnet and doubly fed asynchronous wind turbines. Energy Sci. Eng. 2023, 11, 978–988. [Google Scholar] [CrossRef]

- Moudden, A.; Hmidat, A.; Aarib, A. Comparison of the active and reactive powers of the asynchronous cage machine and the doubly fed induction generator used in wind turbine energy in the case of decentralized production on an isolated site. Int. J. Electr. Eng. Inform. 2023, 15, 50–63. [Google Scholar] [CrossRef]

- Alexandrova, Y.; Semken, R.S.; Pyrhönen, J. Permanent magnet synchronous generator design solution for large direct-drive wind turbines. Int. Rev. Electr. Eng. (IREE) 2013, 8, 6. [Google Scholar]

- Zhang, R.; Gao, L. Research on the design and optimization of 1.5 MW semi-direct drive permanent magnet synchronous wind turbine. Energy Rep. 2022, 8, 589–598. [Google Scholar] [CrossRef]

- Jin, Y.; Zeng, Z.; Chen, Y.; Xu, R.; Ziegler, A.D.; Chen, W.; Ye, B.; Zhang, D. Geographically constrained resource potential of integrating floating photovoltaics in global existing offshore wind farms. Adv. Appl. Energy 2024, 13, 100163. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Floating Offshore Wind Outlook 2024; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2024. [Google Scholar]

- Ding, H.; Zou, G.; Wang, F.; Xu, C. Modelling and control strategies of DC offshore wind farm. In Proceedings of the 2023 8th Asia Conference on Power and Electrical Engineering (ACPEE), Tianjin, China, 14–16 April 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1224–1228. [Google Scholar]

- Ryu, G.H.; Kim, D.; Kim, D.Y.; Kim, Y.G.; Kwak, S.J.; Choi, M.S.; Jeon, W.; Kim, B.S.; Moon, C.J. Analysis of vertical wind shear effects on offshore wind energy prediction accuracy applying rotor equivalent wind speed and the relationship with atmospheric stability. Appl. Sci. 2022, 12, 6949. [Google Scholar] [CrossRef]

- O’Neill, S. Giant turbines poised to claim offshore wind. Engineering 2021, 7, 894–896. [Google Scholar] [CrossRef]

- Li, J.; Shi, W.; Zhang, L.; Michailides, C.; Li, X. Wind–wave coupling effect on the dynamic response of a combined wind–wave energy converter. J. Mar. Sci. Eng. 2021, 9, 1101. [Google Scholar] [CrossRef]

- Alnmr, A.; Mayassah, M. Innovations in Offshore Wind: Reviewing Current Status and Future Prospects with a Parametric Analysis of Helical Pile Performance for Anchoring Mooring Lines. J. Mar. Sci. Eng. 2024, 12, 1040. [Google Scholar] [CrossRef]

- O’Kelly, B.C.; Arshad, M. Offshore Wind Turbine Foundations–Analysis and Design Offshore Wind Farms; Woodhead Publishing: Cambridge, UK, 2016; pp. 589–610. [Google Scholar]

- Díaz, H.; Soares, C.G. Review of the current status, technology and future trends of offshore wind farms. Ocean. Eng. 2020, 209, 107381. [Google Scholar] [CrossRef]

- Chen, J.; Kim, M.-H. Review of Recent Offshore Wind Turbine Research and Optimization Methodologies in Their Design. J. Mar. Sci. Eng. 2022, 10, 28. [Google Scholar] [CrossRef]

- Cui, L. Current Status of Marine Energy Technology and Industry; National Ocean Technology Center: Tianjin, China, 2024. [Google Scholar]

- Yeter, B.; Garbatov, Y. Structural integrity assessment of fixed support structures for offshore wind turbines: A review. Ocean. Eng. 2022, 244, 110271. [Google Scholar] [CrossRef]

- Maienza, C.; Avossa, A.M.; Ricciardelli, F.; Scherillo, F.; Georgakis, C.T. A comparative analysis of construction costs of onshore and shallow-and deep-water offshore wind farms. In Proceedings of the XV Conference of the Italian Association for Wind Engineering: IN-VENTO 2018, Naples, Italy, 9–12 September 2018; Springer International Publishing: Berlin, Germany, 2019; pp. 440–453. [Google Scholar]

- Wang, Z.; Carriveau, R.; Ting, D.S.K.; Xiong, W.; Wang, Z. A review of marine renewable energy storage. Int. J. Energy Res. 2019, 43, 6108–6150. [Google Scholar] [CrossRef]

- Yuan, J.; Cheng, Z.; Liu, D. Design of Variable Pitch Control Method for Floating Wind Turbine. Energies 2023, 16, 821. [Google Scholar] [CrossRef]

- Hong, S.; McMorland, J.; Zhang, H.; Collu, M.; Halse, K.H. Floating offshore wind farm installation, challenges and opportunities: A comprehensive survey. Ocean. Eng. 2024, 304, 117793. [Google Scholar] [CrossRef]

- Sun, X.; Huang, D.; Wu, G. The current state of offshore wind energy technology development. Energy 2012, 41, 298–312. [Google Scholar] [CrossRef]

- Zhanga, L.; Jiang, Y.; Li, Y. Preliminary study on the interaction of two floating offshore wind turbines. In Proceedings of the International Ocean and Polar Engineering Conference–ISOPE 2020, Shanghai, China, 11–16 October 2020. ISOPE-I-20-1172. [Google Scholar]

- Day, A.H.; Babarit, A.; Fontaine, A.; He, Y.P.; Kraskowski, M.; Murai, M.; Penesis, I.; Salvatore, F.; Shin, H.K. Hydrodynamic modelling of marine renewable energy devices: A state of the art review. Ocean. Eng. 2015, 108, 46–69. [Google Scholar] [CrossRef]

- Yoshimoto, H.; Awashima, Y.; Kitakoji, Y.; Suzuki, H. Development of floating offshore substation and wind turbine for Fukushima FORWARD. In Proceedings of the International Symposium on Marine and Offshore Renewable Energy, Tokyo, Japan, 28–30 October 2013. [Google Scholar]

- Roddier, D.; Cermelli, C.; Aubault, A.; Weinstein, A. WindFloat: A floating foundation for offshore wind turbines. J. Renew. Sustain. Energy 2010, 2, 033104. [Google Scholar] [CrossRef]

- Edwards, E.C.; Holcombe, A.; Brown, S.; Ransley, E.; Hann, M.; Greaves, D. Evolution of floating offshore wind platforms: A review of at-sea devices. Renew. Sustain. Energy Rev. 2023, 183, 113416. [Google Scholar] [CrossRef]

- Luo, D.H.; He, L. The world’s first typhoon-resistant floating offshore wind turbine has been built. Science and Technology Daily, 28 July 2021. [Google Scholar]

- Li, X.Y.; Fan, K.; Yang, X. “Three Gorges Leading”: China’s floating offshore wind power technology leader. Manag. Res. Sci. Technol. Achiev. 2023, 18, 2. [Google Scholar]

- Ma, Y.; Huang, Q.P.; Dong, Y.H. China’s Independent Research and Development of Far-Reaching Sea Floating Offshore Wind Power Equipment Operation Generation—“Fuyao” Offshore “Wind”. Website of Maritime Bureau of Guangxi Zhuang Autonomous Region. 2023. Available online: https://mp.weixin.qq.com/s?__biz=MjM5MTExODIxNg==&mid=2652649268&idx=2&sn=60e1418dbcd46506112241f88c7d859f&chksm=bd52f1d38a2578c5bec2c115c16be64d9f4225be67701a47193b2cf985fbf1e5253739da9219&scene=27 (accessed on 8 August 2024).

- Zeng, X.; Shao, Y.; Feng, X.; Xu, K.; Jin, R.; Li, H. Nonlinear hydrodynamics of floating offshore wind turbines: A review. Renew. Sustain. Energy Rev. 2024, 191, 114092. [Google Scholar] [CrossRef]

- Yan, X.R.; Zhang, N.N.; Ma, K.C.; Wei, C.; Yang, S.; Pan, B.B. Overview of Current Situation and Trend of Offshore Wind Power Development in China. Power Gener. Technol. 2024, 45, 1–12. [Google Scholar]

- Lu, X.R. “Guanlan” skill, green electricity across the far-reaching sea. China Pet. Petrochem. Corp. 2023, 8, 42–45. [Google Scholar]

- Lu, C.K. “National energy sharing number” opens the integrated development mode of fish and electricity. Science and Technology Daily, 24 October 2023. [Google Scholar]

- Choisnet, T.; Rogier, E.; Percher, Y.; Courbois, A.; Le Crom, I.; Mariani, R. Performance and mooring qualification in Floatgen: The first French offshore wind turbine project. 16ième Journées l’Hydrodynamique 2018, 1, 1–10. [Google Scholar]

- Gomes, J.G.; Lin, Y.; Jiang, J.; Yan, N.; Dai, S.; Yang, T. Review of offshore wind projects status: New approach of floating turbines. In Proceedings of the International Conference on Power and Energy Applications (ICPEA), Guangzhou, China, 18–20 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 676–686. [Google Scholar]

- González, S.F.; Diaz-Casas, V. Present and Future of Floating Offshore Wind. In Floating Offshore Wind Farms; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–22. [Google Scholar]

- Henderson, A.R.; Witcher, D. Floating offshore wind energy—A review of the current status and an assessment of the prospects. Wind Eng. 2010, 34, 1–16. [Google Scholar] [CrossRef]

- Crowle, A.; Thies, P.R. Port and Installation Constraints of Tension Leg Platforms (TLP) Floating Wind Turbines. 2022. Available online: http://hdl.handle.net/10871/131320 (accessed on 8 August 2024).

- Pantusa, D.; Tomasicchio, G.R. Large-scale offshore wind production in the Mediterranean Sea. Cogent Eng. 2019, 6, 1661112. [Google Scholar] [CrossRef]

- Li, J.; Wang, G.; Li, Z.; Yang, S.; Chong, W.T.; Xiang, X. A review on development of offshore wind energy conversion system. Int. J. Energy Res. 2020, 44, 9283–9297. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, Z.; Li, G.; Yang, D.; Santos, M. Review of key technologies for offshore floating wind power generation. Energies 2023, 16, 710. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Net Zero Emissions by 2050; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Swamy, S.K.; Gonzalez-Aparicio, I.; Chrysochoidis-Antsos, N. Developing a long-lasting offshore wind business case towards a Dutch decarbonised energy system by 2050. J. Phys. Conf. Series 2022, 2151, 012010. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, H. Overview of the development of offshore wind power generation in China. Sustain. Energy Technol. 2022, 53, 102766. [Google Scholar] [CrossRef]

- Musial, W.; Spitsen, P.; Duffy, P.; Beiter, P.; Shields, M.; Mulas Hernando, D.; Sathish, S.; Hammond, R.; Marquis, M.; King, J. Offshore Wind Market Report: 2023 Edition; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2023. [Google Scholar]

- Zhang, J.; Wang, H. Development of offshore wind power and foundation technology for offshore wind turbines in China. Ocean. Eng. 2022, 266, 113256. [Google Scholar] [CrossRef]

- Hughes, L.; Longden, T. Offshore wind power in the Asia-Pacific: Expert elicitation on costs and policies. Energy Policy 2024, 184, 113842. [Google Scholar] [CrossRef]

- Frederiksen, R.D.; Bocewicz, G.; Radzki, G.; Banaszak, Z.; Nielsen, P. Cost-Effectiveness of Predictive Maintenance for Offshore Wind Farms: A Case Study. Energies 2024, 17, 3147. [Google Scholar] [CrossRef]

- Soares-Ramos, E.P.P.; de Oliveira-Assis, L.; Sarrias-Mena, R.; Fernández-Ramírez, L.M. Current status and future trends of offshore wind power in Europe. Energy 2020, 202, 117787. [Google Scholar] [CrossRef]

- Chung, C.; Lee, J.; Yang, J.S. National offshore wind strategy for late-mover countries. Renew. Energy 2022, 192, 472–484. [Google Scholar] [CrossRef]

- Gkeka-Serpetsidaki, P.; Skiniti, G.; Tournaki, S.; Tsoutsos, T. A Review of the Sustainable Siting of Offshore Wind Farms. Sustainability 2024, 16, 6036. [Google Scholar] [CrossRef]

- National Energy Administration. Transcript of the National Energy Administration’s Online Press Conference in the Third Quarter of 2023. Available online: https://www.nea.gov.cn/2023-07/31/c_1310734825.htm (accessed on 8 August 2024).

- Perveen, R.; Kishor, N.; Mohanty, S.R. Off-shore wind farm development: Present status and challenges. Renew. Sustain. Energy Rev. 2014, 29, 780–792. [Google Scholar] [CrossRef]

- Wang, W.; Bai, Y. Investigation on installation of offshore wind turbines. J. Mar. Sci. Appl. 2010, 9, 175–180. [Google Scholar] [CrossRef]

- Lacal-Arántegui, R.; Yusta, J.M.; Domínguez-Navarro, J.A. Offshore wind installation: Analysing the evidence behind improvements in installation time. Renew. Sustain. Energy Rev. 2018, 92, 133–145. [Google Scholar] [CrossRef]

- Li, Y.; Liu, L.; Li, S.; Hu, Z.-Z. The Probability of Ship Collision during the Fully Submerged Towing Process of Floating Offshore Wind Turbines. Sustainability 2024, 16, 1705. [Google Scholar] [CrossRef]

- Rippel, D.; Jathe, N.; Becker, M.; Lütjen, M.; Szczerbicka, H.; Freitag, M. A review on the planning problem for the installation of offshore wind farms. IFAC-PapersOnLine 2019, 52, 1337–1342. [Google Scholar] [CrossRef]

- Van Lynden, C.; van Winsen, I.; Westland, C.; Kana, A. Offshore Wind Installation Vessels: Generating insight about the driving factors behind the future design. Int. J. Marit. Eng. 2022, 164, 221–236. [Google Scholar]

- Scheu, M.; Matha, D.; Hofmann, M.; Muskulus, M. Maintenance strategies for large offshore wind farms. Energy Procedia 2012, 24, 281–288. [Google Scholar] [CrossRef]

- Yan, R.; Dunnett, S.; Jackson, L. Impact of condition monitoring on the maintenance and economic viability of offshore wind turbines. Reliab. Eng. Syst. Safe 2023, 238, 109475. [Google Scholar] [CrossRef]

- Kou, L.; Li, Y.; Zhang, F.; Gong, X.; Hu, Y.; Yuan, Q.; Ke, W. Review on monitoring, operation and maintenance of smart offshore wind farms. Sensors 2022, 22, 2822. [Google Scholar] [CrossRef] [PubMed]

- Rinaldi, G.; Thies, P.R.; Johanning, L. Current status and future trends in the operation and maintenance of offshore wind turbines: A review. Energies 2021, 14, 2484. [Google Scholar] [CrossRef]

| Production Company | Turbine Type | Time | Unit Capacity | Blade Length |

|---|---|---|---|---|

| Siemens Gamesa (Zamudio, Spain) | SG14-222DD | May 2020 | 14 MW | 108 m |

| General Electric (Boston, MA, USA) | Haliade-X | 2020 | 14 MW | 107 m |

| Vestas (Aarhus, Denmark) | V236-15.0 MW | February 2021 | 15 MW | 115.5 m |

| Goldwind (Beijing, China) | GWH252-16 MW | June 2023 | 16 MW | 123 m |

| Mingyang (Zhongshan, China) | MySE 16.0-242 | August 2021 | 16 MW | 118 m |

| Project | Type | Time | Unit Capacity |

|---|---|---|---|

| Huaneng Cangnan No. 2 | monopile type | 2023 | 8.5 MW |

| Ormonde | tripod type | 2012 | 5.0 MW |

| Rudong | jacket type | 2010 | 2.5 MW |

| Project | Foundation/Turbine Type | Time | Unit Capacity |

|---|---|---|---|

| Hywind Tampen | spar type Siemens (Zamudio, Spain) | August 2023 | 8.6 MW |

| WindFloat Atlantic | semi-submersible type MHI Vestas V164-8.4 MW (Aarhus, Denmark) | 2020 | 8.4 MW |

| FLOATGEN | barge type V164-10.0 MW (Aarhus, Denmark) | 2018 | 10.0 MW |

| SBM Offshore and IFP Energies Nouvelles | tension leg type SWT-8.0-154 (Zamudio, Spain) | 2020 | 8.0 MW |

| Project | Foundation Type | Time | Unit Capacity | Impeller Diameter |

|---|---|---|---|---|

| Yinling | semi-submersible type | 2021 | 5.5 MW | 158 m |

| Fuyao | semi-submersible type | 2022 | 6.2 MW | 152 m |

| Guanlan | semi-submersible type | 2023 | 7.25 MW | 158 m |

| GuonengGongxiang | semi-submersible type | 2023 | 4.0 MW | 130 m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, X.; Wang, X.; Xu, W.; Yuan, L.; Xiong, C.; Chen, J. Offshore Wind Power: Progress of the Edge Tool, Which Can Promote Sustainable Energy Development. Sustainability 2024, 16, 7810. https://doi.org/10.3390/su16177810

Su X, Wang X, Xu W, Yuan L, Xiong C, Chen J. Offshore Wind Power: Progress of the Edge Tool, Which Can Promote Sustainable Energy Development. Sustainability. 2024; 16(17):7810. https://doi.org/10.3390/su16177810

Chicago/Turabian StyleSu, Xing, Xudong Wang, Wanli Xu, Liqian Yuan, Chunhua Xiong, and Jinmao Chen. 2024. "Offshore Wind Power: Progress of the Edge Tool, Which Can Promote Sustainable Energy Development" Sustainability 16, no. 17: 7810. https://doi.org/10.3390/su16177810

APA StyleSu, X., Wang, X., Xu, W., Yuan, L., Xiong, C., & Chen, J. (2024). Offshore Wind Power: Progress of the Edge Tool, Which Can Promote Sustainable Energy Development. Sustainability, 16(17), 7810. https://doi.org/10.3390/su16177810