Optimal Hybrid Renewable Energy System to Accelerate a Sustainable Energy Transition in Johor, Malaysia

Abstract

:1. Introduction

Literature Review

- To provide valuable insights into the economic feasibility and technical compatibility of powering the Kulai residential district from renewable energy systems.

- To valorise palm biomass for energy generation, thereby promoting the circular economy of the palm oil industry.

- To demonstrate the utilisation of the HOMER tool for modelling biomass gasifiers as a potential technology in HRESs.

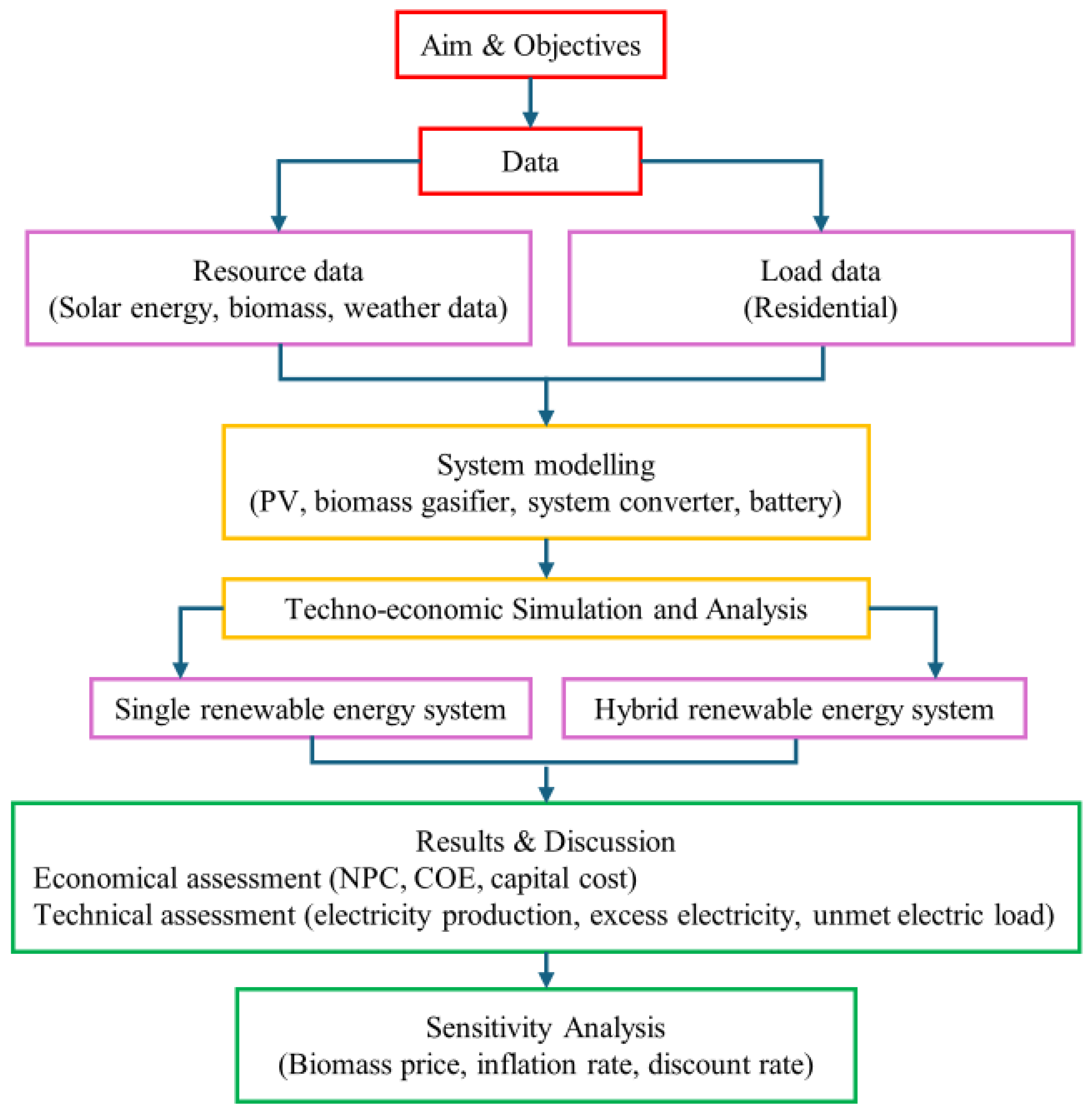

2. Materials and Methods

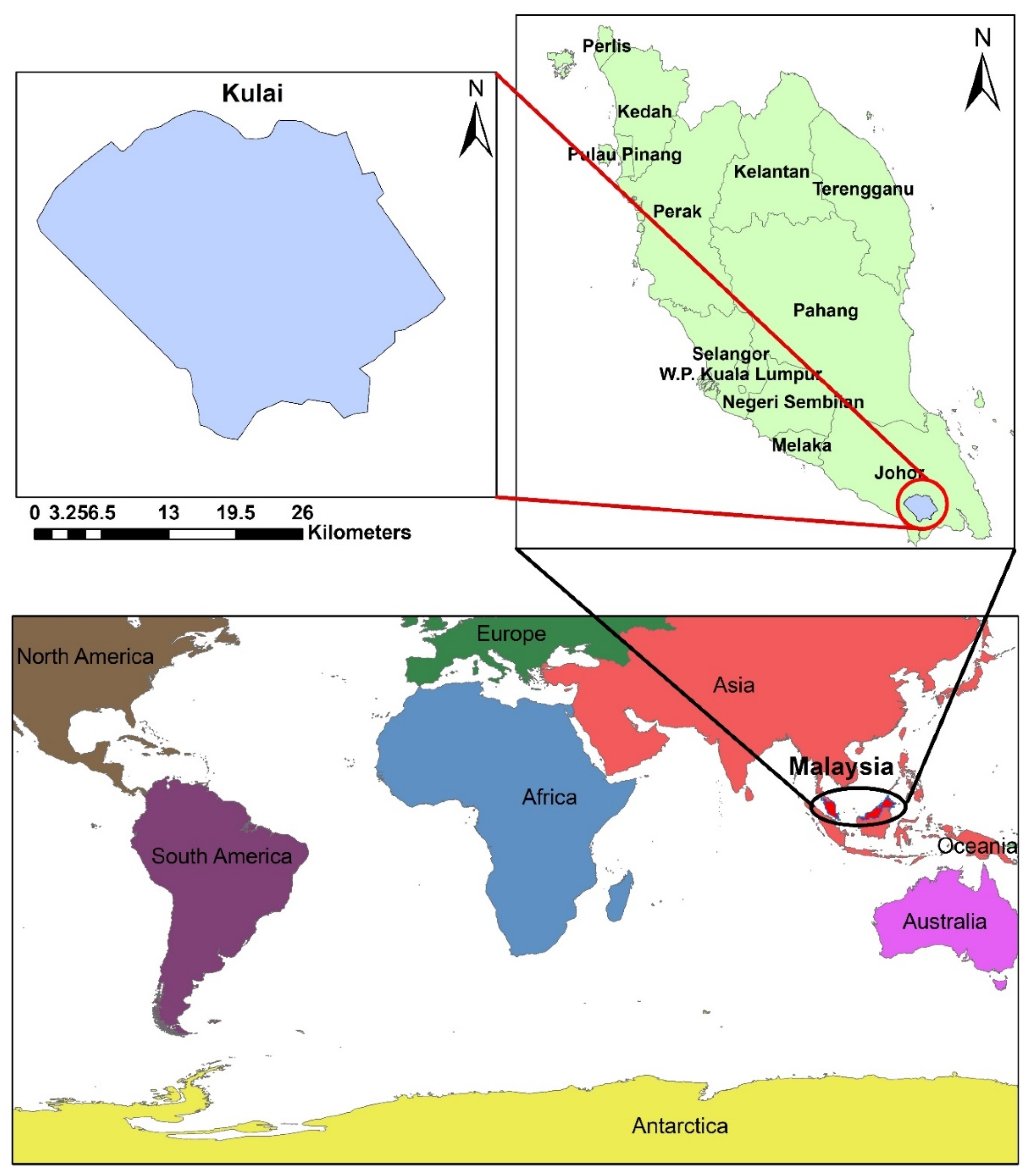

2.1. Site Description

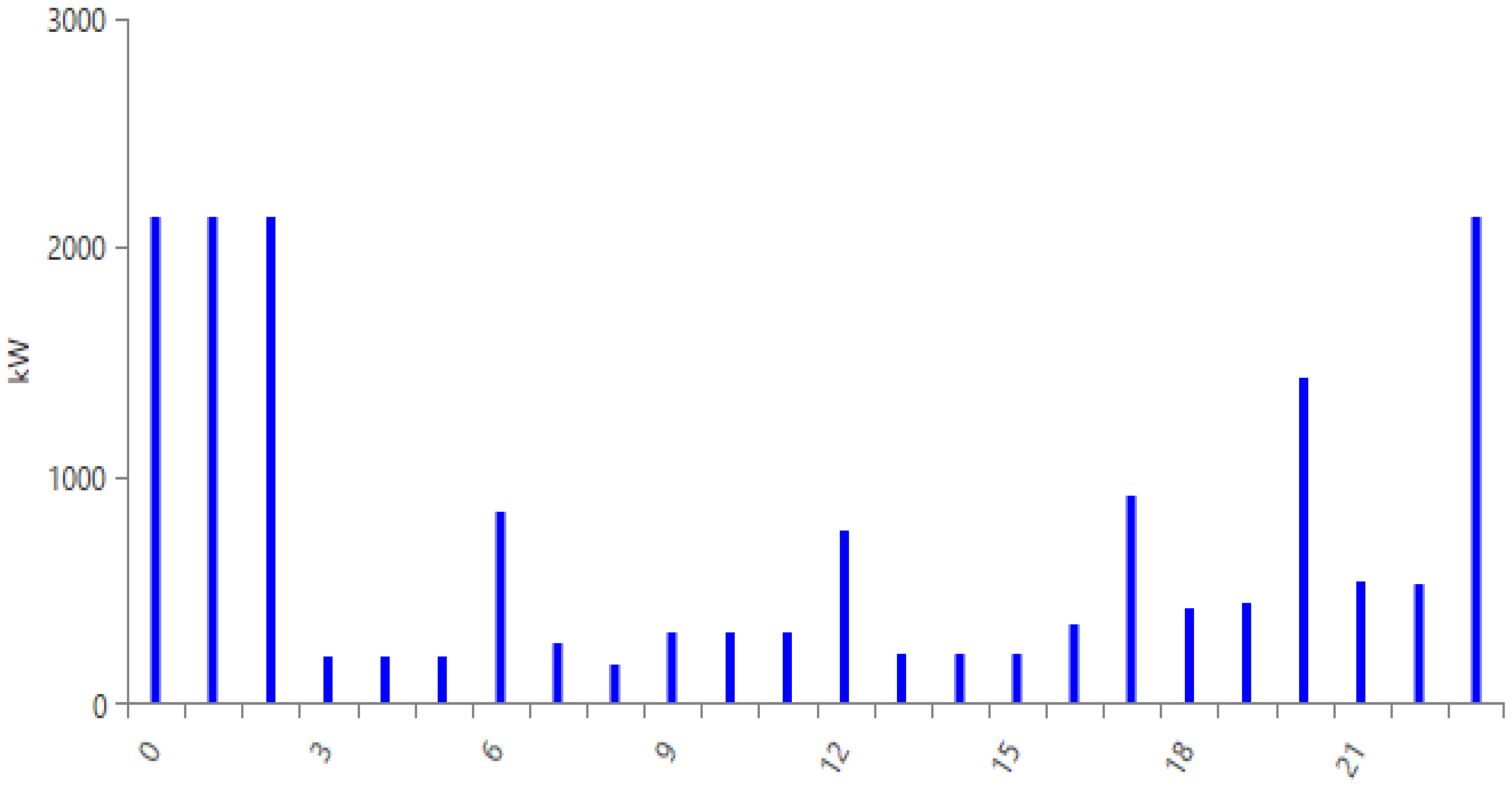

2.2. Load Profile and Resource Data

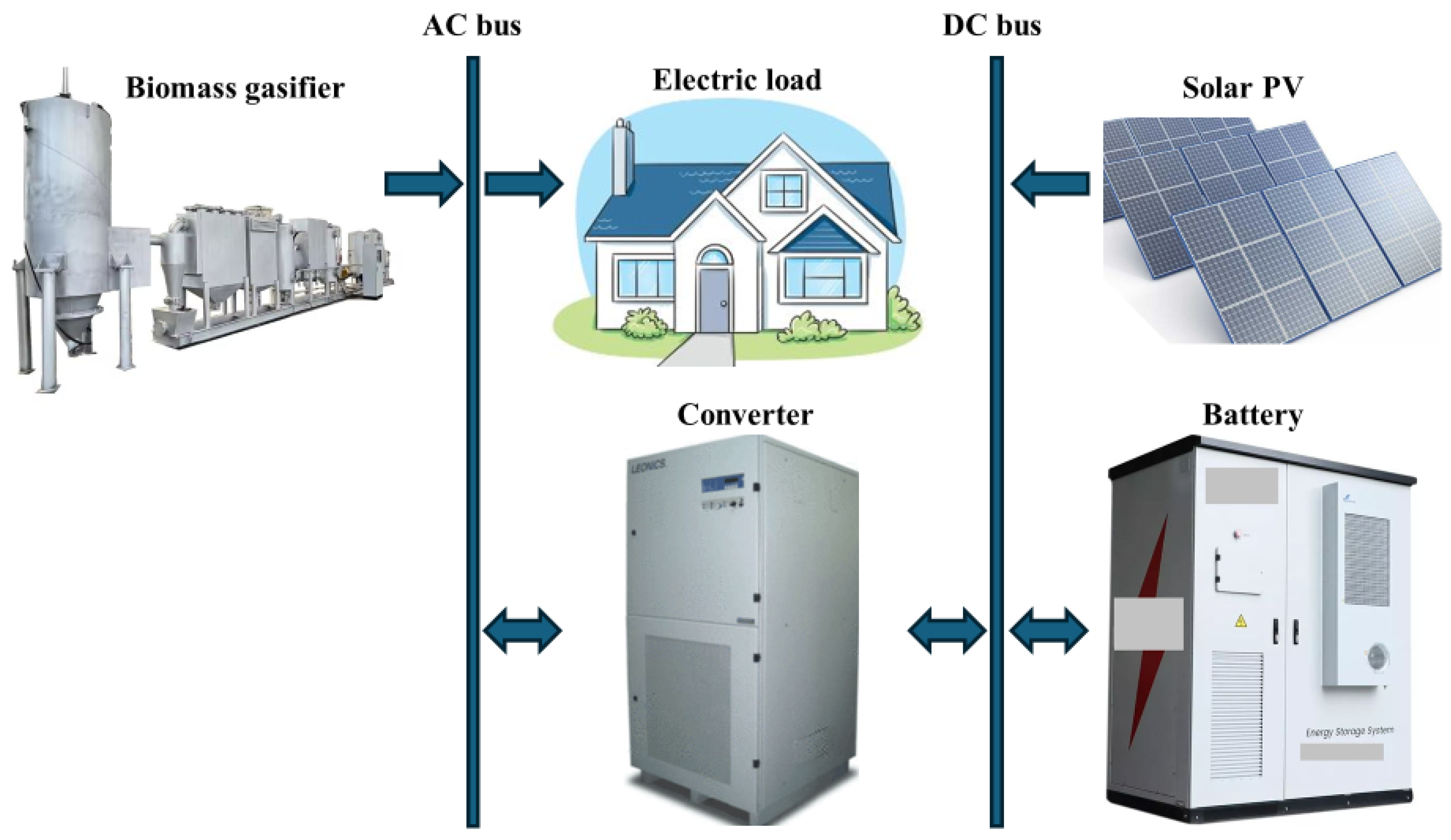

2.3. Modelling HRES Components

2.3.1. Solar Photovoltaic

2.3.2. Biomass Gasifier

2.3.3. Power Converter

2.3.4. Battery

2.4. Economic of Optimisation

2.5. Constraints

3. Results and Discussions

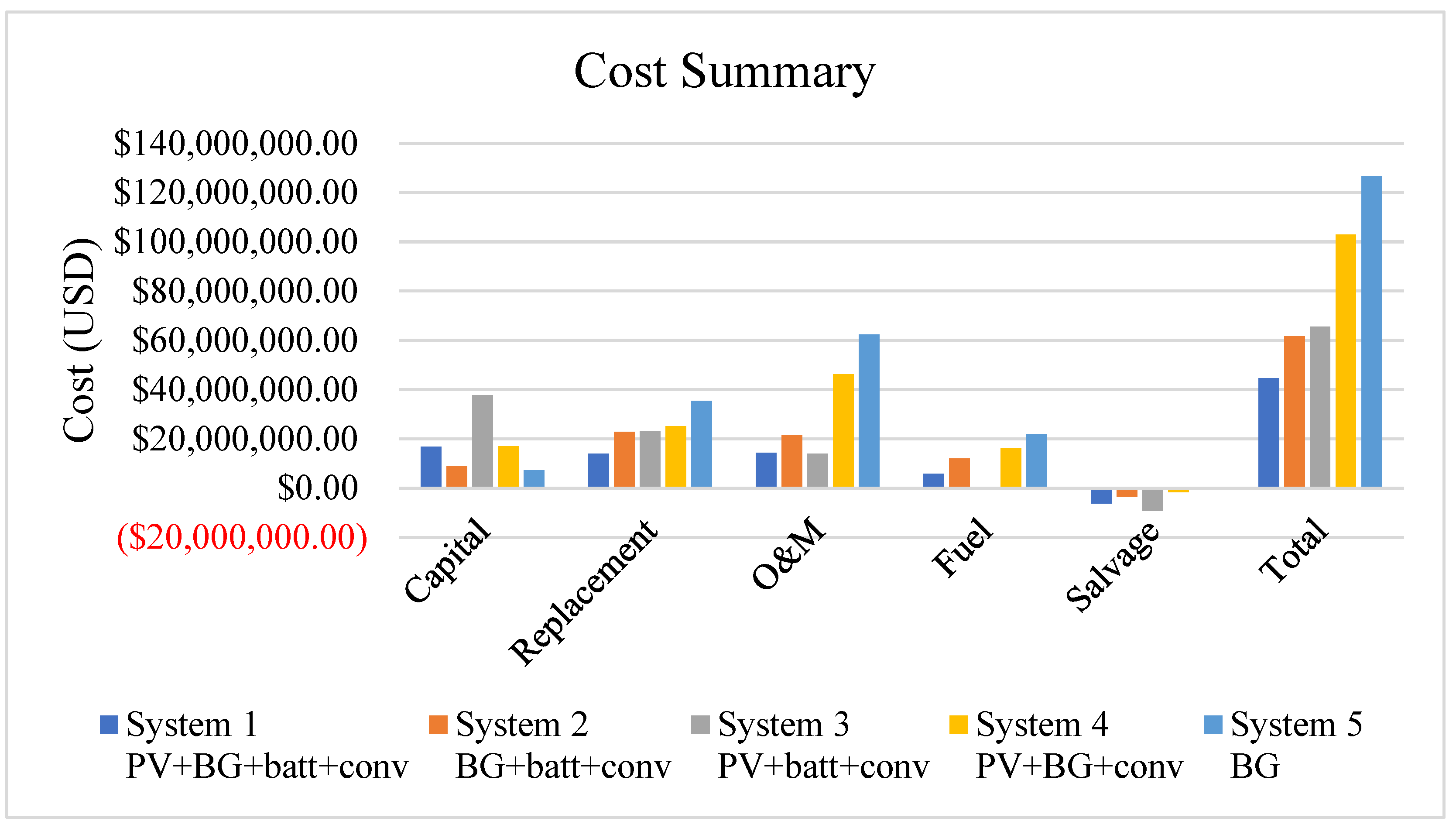

3.1. Economic Performance

3.2. Technical Performance

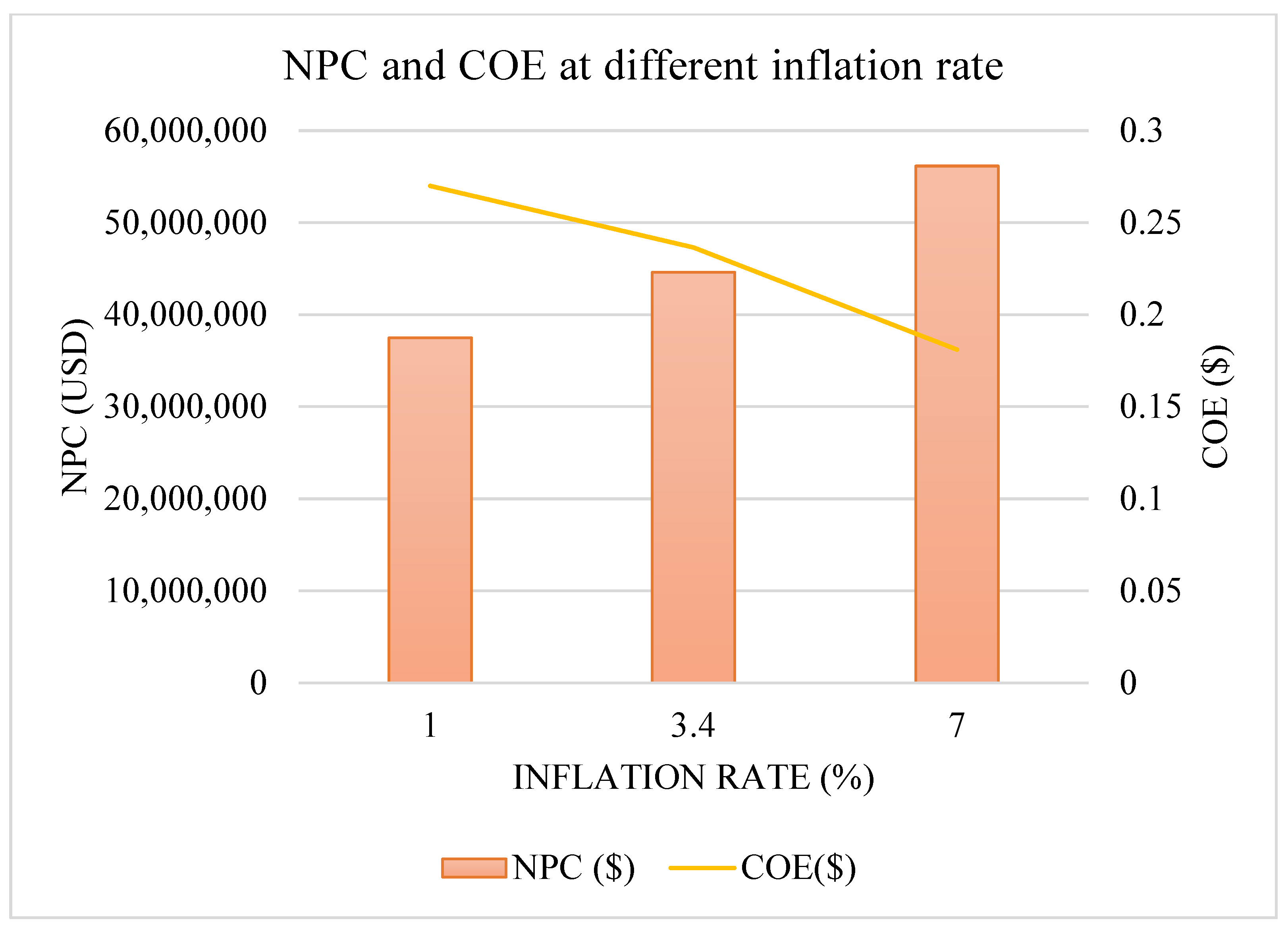

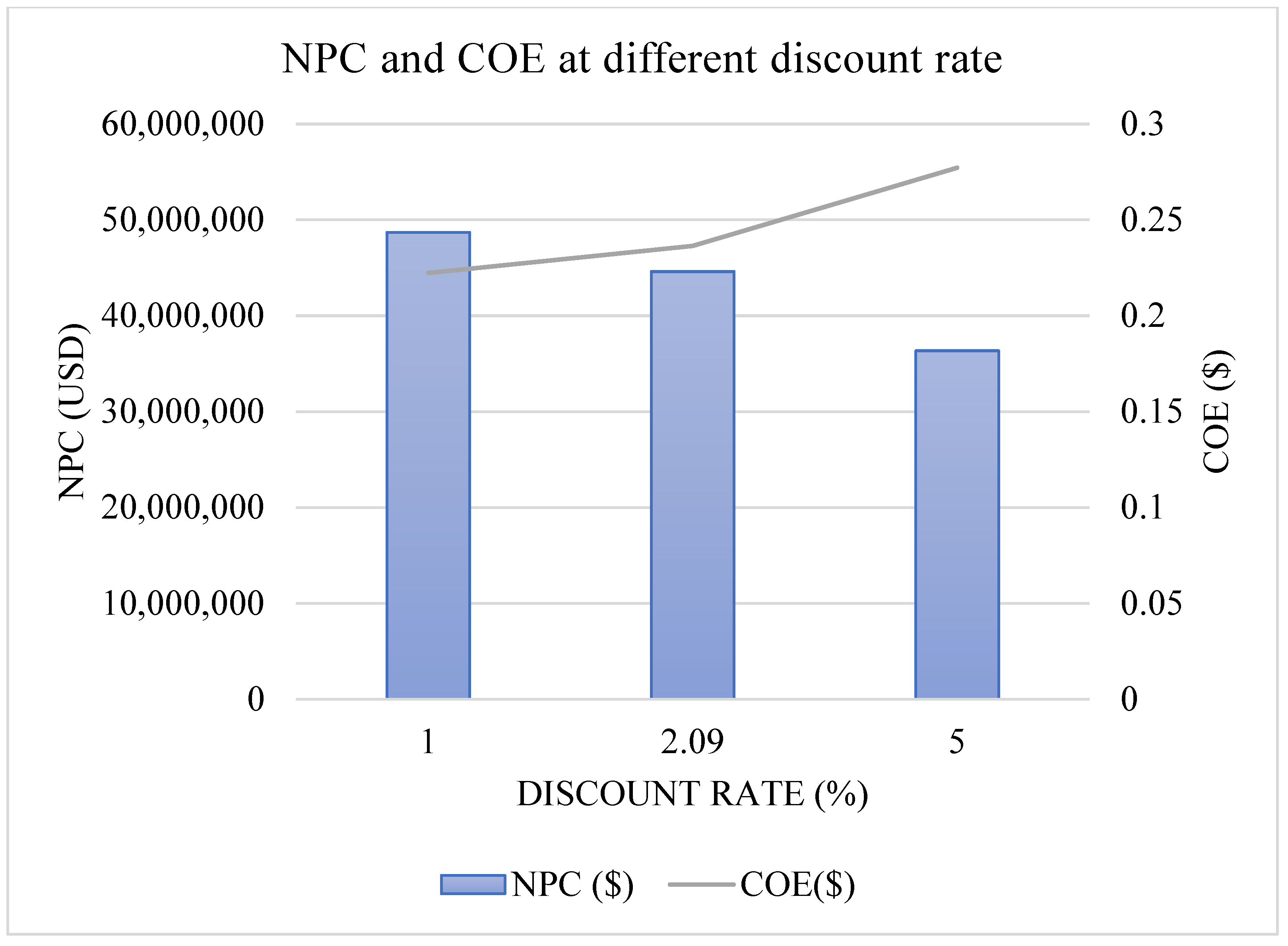

3.3. Sensitivity Analysis

4. Conclusions

5. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petinrin, J.; Shaaban, M. Renewable energy for continuous energy sustainability in Malaysia. Renew. Sustain. Energy Rev. 2015, 50, 967–981. [Google Scholar] [CrossRef]

- SEDA. Malaysia Renewable Energy Roadmap: Pathway towards Low Carbon Energy System. Sustainable Energy Development Authority (SEDA) Malaysia. 2021. Available online: https://www.seda.gov.my (accessed on 1 August 2024).

- Kamaruzaman, N.; Manaf, N.A.; Milani, D.; Abbas, A. Assessing the current state of biomass gasification technology in advancing circular economies: A holistic analysis from techno-economic-policy perspective in Malaysia and beyond. Chem. Eng. Res. Des. 2023, 199, 593–619. [Google Scholar] [CrossRef]

- Koerner, S.A.; Siew, W.S.; Salema, A.A.; Balan, P.; Mekhilef, S.; Thavamoney, N. Energy policies shaping the solar photovoltaics business models in Malaysia with some insights on COVID-19 pandemic effect. Energy Policy 2022, 164, 112918. [Google Scholar] [CrossRef]

- Tang, K.H.D. Climate change in Malaysia: Trends, contributors, impacts, mitigation and adaptations. Sci. Total. Environ. 2019, 650, 1858–1871. [Google Scholar] [CrossRef]

- IRENA. Malaysia Energy Transition Outlook. International Renewable Energy Agency, Abu Dhabi. 2023. Available online: https://www.irena.org (accessed on 1 August 2024).

- Ministry of Economy. National Energy Transition Roadmap: Energising the Nation, Powering Our Future. 2023. Available online: https://ekonomi.gov.my (accessed on 20 January 2024).

- Kammen, D.M.; Sunter, D.A. City-integrated renewable energy for urban sustainability. Science 2016, 352, 922–928. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Z.; Yuan, J.; Shao, J. Design and multi-objective comprehensive evaluation analysis of PV-WT-BG-Battery hybrid renewable energy systems in urban communities. Energy Convers. Manag. X 2023, 18, 100357. [Google Scholar] [CrossRef]

- Low Carbon Society Blueprint for Iskandar Malaysia 2025—Summary for Policymakers, Secon; UTM-Low Carbon Asia Research Center: Johor, Malaysia, 2023.

- Umar, H.; Sulaiman, S.; Said, M.M.; Gungor, A.; Shahbaz, M.; Inayat, M.; Ahmad, R. Assessing the implementation levels of oil palm waste conversion methods in Malaysia and the challenges of commercialisation: Towards sustainable energy production. Biomass-Bioenergy 2021, 151, 106179. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Utilization of palm solid residue as a source of renewable and sustainable energy in Malaysia. Renew. Sustain. Energy Rev. 2014, 40, 621–632. [Google Scholar] [CrossRef]

- Loh, S.K.; Nasrin, A.B.; Sukiran, M.A.; Bukhari, N.A.; Subramaniam, V. Oil palm biomass value chain for biofuel development in Malaysia: Part II. In Value-Chain of Biofuels: Fundamentals, Technology, and Standardization; Elsevier: Amsterdam, The Netherlands, 2021; pp. 505–534. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Martinez-Hernandez, E.; Murphy, R.J.; Ng, D.K.; Hassim, M.H.; Ng, K.S.; Kin, W.Y.; Jaye, I.F.M.; Hang, M.Y.L.P.; Andiappan, V. Role of bioenergy, biorefinery and bioeconomy in sustainable development: Strategic pathways for Malaysia. Renew. Sustain. Energy Rev. 2018, 81, 1966–1987. [Google Scholar] [CrossRef]

- Zamri, M.F.M.A.; Milano, J.; Shamsuddin, A.H.; Roslan, M.E.M.; Salleh, S.F.; Rahman, A.A.; Bahru, R.; Fattah, I.M.R.; Mahlia, T.M.I. An overview of palm oil biomass for power generation sector decarbonization in Malaysia: Progress, challenges, and prospects. WIREs Energy Environ. 2022, 11, e437. [Google Scholar] [CrossRef]

- IRENA. Scaling up Biomass for the Energy Transition: Untapped Opportunities in Southeast Asia. International Renewable Energy Agency, Abu Dhabi. 2022. Available online: https://www.irena.org (accessed on 1 August 2024).

- Cheah, W.Y.; Siti-Dina, R.P.; Leng, S.T.K.; Er, A.; Show, P.L. Circular bioeconomy in palm oil industry: Current practices and future perspectives. Environ. Technol. Innov. 2023, 30, 103050. [Google Scholar] [CrossRef]

- Abdullah, N.; Sulaiman, F. The Oil Palm Wastes in Malaysia. In Biomass Now-Sustainable Growth and Use; InTech: Rijeka, Croatia, 2013; Volume 1, pp. 75–93. [Google Scholar] [CrossRef]

- Malik, P.; Awasthi, M.; Sinha, S. Biomass-based gaseous fuel for hybrid renewable energy systems: An overview and future research opportunities. Int. J. Energy Res. 2021, 45, 3464–3494. [Google Scholar] [CrossRef]

- Ullah, Z.; Elkadeem, M.; Kotb, K.M.; Taha, I.B.; Wang, S. Multi-criteria decision-making model for optimal planning of on/off grid hybrid solar, wind, hydro, biomass clean electricity supply. Renew. Energy 2021, 179, 885–910. [Google Scholar] [CrossRef]

- Chambon, C.L.; Karia, T.; Sandwell, P.; Hallett, J.P. Techno-economic assessment of biomass gasification-based mini-grids for productive energy applications: The case of rural India. Renew. Energy 2020, 154, 432–444. [Google Scholar] [CrossRef]

- Lozano, L.; Querikiol, E.M.; Abundo, M.L.S.; Bellotindos, L.M. Techno-economic analysis of a cost-effective power generation system for off-grid island communities: A case study of Gilutongan Island, Cordova, Cebu, Philippines. Renew. Energy 2019, 140, 905–911. [Google Scholar] [CrossRef]

- Li, J.; Liu, P.; Li, Z. Optimal design and techno-economic analysis of a solar-wind-biomass off-grid hybrid power system for remote rural electrification: A case study of west China. Energy 2020, 208, 118387. [Google Scholar] [CrossRef]

- Ribó-Pérez, D.; Herraiz-Cañete, A.; Alfonso-Solar, D.; Vargas-Salgado, C.; Gómez-Navarro, T. Modelling biomass gasifiers in hybrid renewable energy microgrids; a complete procedure for enabling gasifiers simulation in HOMER. Renew. Energy 2021, 174, 501–512. [Google Scholar] [CrossRef]

- Baek, S.; Park, E.; Kim, M.-G.; Kwon, S.J.; Kim, K.J.; Ohm, J.Y.; del Pobil, A.P. Optimal renewable power generation systems for Busan metropolitan city in South Korea. Renew. Energy 2016, 88, 517–525. [Google Scholar] [CrossRef]

- Guelleh, H.; Patel, R.; Kara-Zaitri, C.; Mujtaba, I. Grid connected hybrid renewable energy systems for urban households in Djibouti: An economic evaluation. S. Afr. J. Chem. Eng. 2023, 43, 215–231. [Google Scholar] [CrossRef]

- Bagheri, M.; Shirzadi, N.; Bazdar, E.; Kennedy, C.A. Optimal planning of hybrid renewable energy infrastructure for urban sustainability: Green Vancouver. Renew. Sustain. Energy Rev. 2018, 95, 254–264. [Google Scholar] [CrossRef]

- See, A.M.K.; Mehranzamir, K.; Rezania, S.; Rahimi, N.; Afrouzi, H.N.; Hassan, A. Techno-economic analysis of an off-grid hybrid system for a remote island in Malaysia: Malawali island, Sabah. Renew. Sustain. Energy Transit. 2022, 2, 100040. [Google Scholar] [CrossRef]

- Lau, K.; Tan, C.; Ching, K. The implementation of grid-connected, residential rooftop photovoltaic systems under different load scenarios in Malaysia. J. Clean. Prod. 2021, 316, 128389. [Google Scholar] [CrossRef]

- Laajimi, M.; Go, Y.I. Energy storage system design for large-scale solar PV in Malaysia: Technical and environmental assessments. J. Energy Storage 2019, 26, 100984. [Google Scholar] [CrossRef]

- Su, G.; Jiang, P.; Ong, H.C.; Zhu, J.; Amin, N.A.S.; Zulkifli, N.W.M.; Ibrahim, S. Co-production of biochar and electricity from oil palm wastes for carbon dioxide mitigation in Malaysia. J. Clean. Prod. 2023, 423, 138749. [Google Scholar] [CrossRef]

- Wee, A.N.C.H.; Erison, A.E.; Anyek, E.H.E.; Pakpahan, G.R.; Lim, J.R.; Tiong, A.N.T. Techno-economic assessment of hydrogen production via steam reforming of palm oil mill effluent. Sustain. Energy Technol. Assess. 2022, 53, 102575. [Google Scholar] [CrossRef]

- Salehmin, M.N.I.; Tiong, S.K.; Mohamed, H.; Zainal, B.S.; Lim, S.S.; Yasin, N.H.M.; Zakaria, Z. Sustainable Bioenergy from Palm Oil Mill Effluent: Advancements in Upstream and Downstream Engineering with Techno-Economic and Environmental Assessment; Korean Society of Industrial Engineering Chemistry: Busan, Republic of Korea, 2023. [Google Scholar] [CrossRef]

- Mahmod, S.S.; Jahim, J.M.; Abdul, P.M.; Luthfi, A.A.I.; Takriff, M.S. Techno-economic analysis of two-stage anaerobic system for biohydrogen and biomethane production from palm oil mill effluent. J. Environ. Chem. Eng. 2021, 9, 105679. [Google Scholar] [CrossRef]

- Hor, C.J.; Tan, Y.H.; Mubarak, N.M.; Tan, I.S.; Ibrahim, M.L.; Yek, P.; Karri, R.R.; Khalid, M. Techno-economic assessment of hydrotreated vegetable oil as a renewable fuel from waste sludge palm oil. Environ. Res. 2023, 220, 115169. [Google Scholar] [CrossRef]

- FFB Received by Mill 2021. Available online: https://bepi.mpob.gov.my/index.php/sectoral-status/274-sectoral-status-2021/1049-ffb-received-by-mill-2021 (accessed on 22 January 2024).

- FFB Received by Mill 2022. Available online: https://bepi.mpob.gov.my/index.php/sectoral-status/288-sectoral-status-2022/1101-ffb-received-by-mill-2022 (accessed on 22 January 2024).

- Department of Statistics Malaysia. Current Population Estimates, Administrative DistricT. 2023. Available online: https://www.dosm.gov.my (accessed on 1 August 2024).

- Liew, W.L.; Kassim, M.A.; Muda, K.; Loh, S.K.; Affam, A.C. Conventional methods and emerging wastewater polishing technologies for palm oil mill effluent treatment: A review. J. Environ. Manag. 2015, 149, 222–235. [Google Scholar] [CrossRef]

- Salleh, S.F.; Rahman, A.A.; Abdullah, T.A.R.T. Potential of Deploying Empty Fruit Bunch (EFB) for Biomass Cofiring in Malaysia’s Largest Coal Power Plant. In Proceedings of the 2018 IEEE 7th International Conference on Power and Energy (PECon), Kuala Lumpur, Malaysia, 3–4 December 2018; pp. 429–433. [Google Scholar]

- Panasonic HIT+ VBHN340SA17|EnergySage. Available online: https://www.energysage.com/solar-panels/panasonic/1410/vbhn340sa17/ (accessed on 23 January 2024).

- HOMER Pro Version 3.7 User Manual. Available online: https://homerenergy.com/pdf/HOMERHelpManual.pdf (accessed on 20 December 2023).

- Samiran, N.A.; Jaafar, M.N.M.; Ng, J.-H.; Lam, S.S.; Chong, C.T. Progress in biomass gasification technique—With focus on Malaysian palm biomass for syngas production. Renew. Sustain. Energy Rev. 2016, 62, 1047–1062. [Google Scholar] [CrossRef]

- Valdés, C.F.; Montoya, J.I.; Gómez, C.A.; Chaquea, H.; Pecha, M.B.; Chejne, F. Influence of Pelletization and Moisture Content of Oil Palm Empty Fruit Bunches (EFBs) on Dynamic Gasification Performance. Energy Fuels 2021, 35, 8807–8818. [Google Scholar] [CrossRef]

- Yakub, A.O.; Same, N.N.; Owolabi, A.B.; Nsafon, B.E.K.; Suh, D.; Huh, J.-S. Optimizing the performance of hybrid renewable energy systems to accelerate a sustainable energy transition in Nigeria: A case study of a rural healthcare centre in Kano. Energy Strat. Rev. 2022, 43, 100906. [Google Scholar] [CrossRef]

- Same, N.N.; Yakub, A.O.; Nsafon, B.E.K.; Owolabi, A.B.; Mih, T.A.; Suh, D.; Huh, J.-S. Performance evaluation of renewable-based sustainable micro-grid under predictive management control strategy: A case study of Gado refugee camp in Cameroon. Front. Energy Res. 2022, 10, 987495. [Google Scholar] [CrossRef]

- Interest Rates & Volumes—Bank Negara Malaysia. Available online: https://www.bnm.gov.my/interest-rates-volumes (accessed on 22 January 2024).

- Inflation, Consumer Prices (Annual %)—Malaysia|Data. Available online: https://data.worldbank.org/indicator/FP.CPI.TOTL.ZG?end=2022&locations=MY&start=2022&view=chart (accessed on 22 January 2024).

- Ramesh, M.; Saini, R.P. Dispatch strategies based performance analysis of a hybrid renewable energy system for a remote rural area in India. J. Clean. Prod. 2020, 259, 120697. [Google Scholar] [CrossRef]

- Kumar, R.; Channi, H.K. A PV-Biomass off-grid hybrid renewable energy system (HRES) for rural electrification: Design, optimization and techno-economic-environmental analysis. J. Clean. Prod. 2022, 349, 131347. [Google Scholar] [CrossRef]

- Welcome to myTNB Portal—Pricing & Tariff. Available online: https://www.mytnb.com.my/residential/understand-your-bill/pricing-tariff (accessed on 4 March 2024).

- Malaysia Ranked Fourth Most Affordable Country—MIDA|Malaysian Investment Development Authority. Available online: https://www.mida.gov.my/mida-news/malaysia-ranked-fourth-most-affordable-country/ (accessed on 10 March 2024).

- Kumar, P.; Pal, N.; Sharma, H. Optimization and techno-economic analysis of a solar photo-voltaic/biomass/diesel/battery hybrid off-grid power generation system for rural remote electrification in eastern India. Energy 2022, 247, 123560. [Google Scholar] [CrossRef]

- Kaur, M.; Dhundhara, S.; Verma, Y.P.; Chauhan, S. Techno-economic analysis of photovoltaic-biomass-based microgrid system for reliable rural electrification. Int. Trans. Electr. Energy Syst. 2020, 30, 12347. [Google Scholar] [CrossRef]

- Islam, M.S.; Akhter, R.; Rahman, M.A. A thorough investigation on hybrid application of biomass gasifier and PV resources to meet energy needs for a northern rural off-grid region of Bangladesh: A potential solution to replicate in rural off-grid areas or not? Energy 2018, 145, 338–355. [Google Scholar] [CrossRef]

- Malaysia—Inflation Rate 2028|Statista. Available online: https://www.statista.com/statistics/319033/inflation-rate-in-malaysia/ (accessed on 7 February 2024).

| Appliance Type | No. of Appliance | Rating (W) | Hourly Consumption (W) | Total kWh/day |

|---|---|---|---|---|

| Compact fluorescent lamp | 7 | 40 | 280 | 1.640 |

| Ceiling fan | 1 | 55 | 55 | 0.770 |

| Air conditioner | 3 | 750 | 2250 | 9.000 |

| Phone charger | 4 | 18 | 72 | 0.072 |

| Laptop | 1 | 50 | 50 | 0.100 |

| Television | 1 | 120 | 120 | 1.320 |

| Refrigerator | 1 | 200 | 200 | 4.800 |

| Kettle | 1 | 1000 | 1000 | 1.500 |

| Rice cooker | 1 | 650 | 650 | 0.650 |

| Washing machine | 1 | 500 | 500 | 0.500 |

| Total | 5177 | 20.352 |

| Month | Clearness Index | Average Solar GHI (kWh/m2/day) | Average Ambient Temperature (°C) |

|---|---|---|---|

| January | 0.494 | 4.881 | 25.47 |

| February | 0.531 | 5.460 | 25.79 |

| March | 0.522 | 5.476 | 26.55 |

| April | 0.512 | 5.255 | 27.34 |

| May | 0.497 | 4.868 | 27.45 |

| June | 0.509 | 4.824 | 27.06 |

| July | 0.491 | 4.715 | 26.59 |

| August | 0.489 | 4.905 | 26.52 |

| September | 0.492 | 5.092 | 26.60 |

| October | 0.509 | 5.223 | 26.76 |

| November | 0.468 | 4.646 | 26.39 |

| December | 0.481 | 4.674 | 25.76 |

| FFB 2020 | FFB 2021 | FFB 2022 | FFB Average 2020–2022 | EFB (wet) | EFB (dry) | EFB (dry/ day) | |

|---|---|---|---|---|---|---|---|

| January | 940,263 | 927,361 | 975,030 | 947,551 | 208,461 | 72,961 | 2354 |

| February | 1,141,258 | 906,399 | 988,675 | 1,012,111 | 222,664 | 77,933 | 2783 |

| March | 1,182,731 | 1,203,375 | 1,219,022 | 1,201,709 | 264,376 | 92,532 | 2985 |

| April | 1,407,185 | 1,263,728 | 1,228,701 | 1,299,871 | 285,972 | 100,090 | 3336 |

| May | 1,361,246 | 1,241,030 | 1,247,160 | 1,283,145 | 282,292 | 98,802 | 3187 |

| June | 1,685,240 | 1,278,675 | 1,341,022 | 1,434,979 | 315,695 | 110,493 | 3683 |

| July | 1,570,828 | 1,323,265 | 1,353,206 | 1,415,766 | 311,469 | 109,014 | 3517 |

| August | 1,552,713 | 1,384,916 | 1,409,494 | 1,449,041 | 318,789 | 111,576 | 3599 |

| September | 1,553,053 | 1,315,201 | 1,431,185 | 1,433,146 | 315,292 | 110,352 | 3678 |

| October | 1,358,064 | 1,329,658 | 1,441,709 | 1,376,477 | 302,825 | 105,989 | 3419 |

| November | 1,248,860 | 1,259,877 | 1,347,453 | 1,285,397 | 282,787 | 98,976 | 3299 |

| December | 1,110,630 | 1,125,419 | 1,337,570 | 1,191,206 | 262,065 | 91,723 | 2959 |

| TOTAL | 16,112,071 | 14,558,904 | 15,320,227 | 15,330,401 | 3,372,688 | 1,180,441 | 38,800 |

| Component | Model | Cost (USD) | Replacement Cost (USD) | O&M Cost (USD) | Lifetime (years) |

|---|---|---|---|---|---|

| PV | Panasonic VBHN340SA17 | 1100/kW | 1100/kW | 10/kW/yr | 25 |

| Biomass gasifier | Biogas downdraft | 3000/kW | 1250/kW | 0.1/kW/h | 20,000 h |

| Battery | 1 kWh Li-ion | 600/unit | 600/unit | 10/yr | 15 |

| Converter | Leonics MTP-413F 25 kW | 200/kW | 200/kW | 0 | 20 |

| Feasible Options | System Configurations | Economic Performance | ||||||

|---|---|---|---|---|---|---|---|---|

| PV | BG | Battery | Converter | Total NPC (USD) | LCOE (USD/kWh) | Initial Capital (USD/yr) | Operating Cost (USD/yr) | |

| 1 | ✓ | ✓ | ✓ | ✓ | 44,596,990 | 0.2364 | 16,787,825 | 938,488 |

| 2 | ✓ | ✓ | ✓ | 61,726,390 | 0.3272 | 8,868,350 | 1,783,822 | |

| 3 | ✓ | ✓ | ✓ | 65,523,890 | 0.3476 | 37,728,454 | 938,024 | |

| 4 | ✓ | ✓ | ✓ | 102,944,100 | 0.5457 | 16,979,825 | 2,901,074 | |

| 5 | ✓ | 126,627,300 | 0.6713 | 7,200,000 | 4,030,364 | |||

| Description | Units | System 1 | System 2 | System 3 | System 4 | System 5 |

|---|---|---|---|---|---|---|

| PV + BG + batt + conv | BG + batt + conv | PV + batt + conv | PV + BG + conv | BG | ||

| Solar PV | kW | 4075 | - | 16,988 | 8721 | - |

| Biomass gasifier | kW | 2100 | 2400 | - | 2400 | 2400 |

| Battery 1 kWh Li | unit | 9363 | 2336 | 30,103 | - | - |

| Converter | kW | 1939 | 1334 | 4898 | 934 | - |

| Tariff—Domestic | Rate (USD/kWh) |

|---|---|

| 1–200 kWh | 0.046 |

| 201–300 kWh | 0.071 |

| 301–600 kWh | 0.110 |

| 601–900 kWh | 0.120 |

| 901 kWh~ | 0.120 |

| Description | Units | System 1 | System 2 | System 3 | System 4 | System 5 |

|---|---|---|---|---|---|---|

| PV + BG + batt + conv | BG + batt + conv | PV + batt + conv | PV + BG + conv | BG | ||

| PV electricity production | kWh/yr | 6,020,427 | - | 25,100,133 | 12,885,354 | - |

| BG electricity production | kWh/yr | 3,286,257 | 6,737,377 | - | 8,811,960 | 11,958,360 |

| Total feedstock consumed | tonnes | 3160 | 6473 | - | 8720 | 11,881 |

| BG operation hours | hrs/yr | 1659 | 2920 | - | 6138 | 8760 |

| Battery autonomy | hr | 9.02 | 2.25 | 29.0 | - | - |

| Excess electricity | kWh/yr | 2,613,329 | 0 | 17,932,330 | 15,297,467 | 5,592,132 |

| Unmet electric load | kWh/yr | 121 | 0 | 5128 | 0 | 0 |

| Capacity shortage | kWh/yr | 6341 | 0 | 6329 | 0 | 0 |

| No. | Parameter | Unit | Variables | ||

|---|---|---|---|---|---|

| 1 | Biomass price | USD/tonne | 62.5 | 10 | 52.9 |

| 2 | Expected inflation rate | % | 3.4 | 1 | 7 |

| 3 | Nominal discount rate | % | 2.09 | 1 | 5 |

| 4 | PV capital cost | USD/kW | 1100 | 990 | 1210 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yew, P.J.; Chaulagain, D.; Same, N.N.; Park, J.; Lim, J.-O.; Huh, J.-S. Optimal Hybrid Renewable Energy System to Accelerate a Sustainable Energy Transition in Johor, Malaysia. Sustainability 2024, 16, 7856. https://doi.org/10.3390/su16177856

Yew PJ, Chaulagain D, Same NN, Park J, Lim J-O, Huh J-S. Optimal Hybrid Renewable Energy System to Accelerate a Sustainable Energy Transition in Johor, Malaysia. Sustainability. 2024; 16(17):7856. https://doi.org/10.3390/su16177856

Chicago/Turabian StyleYew, Pei Juan, Deepak Chaulagain, Noel Ngando Same, Jaebum Park, Jeong-Ok Lim, and Jeung-Soo Huh. 2024. "Optimal Hybrid Renewable Energy System to Accelerate a Sustainable Energy Transition in Johor, Malaysia" Sustainability 16, no. 17: 7856. https://doi.org/10.3390/su16177856