Abstract

Deep-sea polymetallic nodules are associated with rich rare substances, such as rare-earth elements (REEs), Mo, Ti, Te, Li, which are currently in demand and are used in various applications. Deep-sea sediments near nodules are another important source of REEs, which will increase the resource potential of polymetallic nodules. Given the similarity of the mining technologies for deep-sea REEs and polymetallic nodules, this study proposed environmentally friendly mining options and developed a technoeconomic evaluation model by combining deep-sea polymetallic nodules and REEs. Using the Clarion-Clipperton Fracture Zone as an example, this study revealed that the development of polymetallic nodules together with REEs of nearby sediments in the form of by-products will improve the economic and environmental benefits. In addition, the effects of discount rate, cost, and price on the economic benefits of nodule mining were discussed, and a technical development direction was proposed based on scientific and technological needs.

1. Introduction

As nonrenewable terrestrial mineral resources are being depleted, marine mineral deposits, as an important area for humans to obtain strategic resources, have been increasingly valued by all countries. Australia’s manganese ore production accounts for 15% of the world’s total, but in 2024, Australia’s South32 manganese ore supply will be cut off, and the global manganese ore supply and demand balance will be broken. Australia is rich in mineral resources, with ore and metal exports accounting for a relatively high percentage of commodity exports, at 35.30% in 2023, according to the World Bank. The cut off of South32 manganese ore supply will seriously affect its domestic economic development. Pacific island countries are scarce in terrestrial manganese ore and other resources, and the percentage of ore and metal exports in commodity exports in 2018 was only 2.04%. However, Pacific island countries have certain advantages over deep-sea resources, including an estimated 12 billion tons of cobalt-rich nodules in the exclusive economic zone of the Cook Islands. Japan’s mineral resources are relatively scarce; according to the World Bank, ore and metal exports (as a percentage of commodity exports) in 2023 are relatively low, only 3.37%, while Japan’s manufacturing industry in automobiles, household appliances, precision instruments, machine tools, and other industrial products have a great demand for metal resources; these resources mainly rely on imports, especially iron ore, copper, and rare-earth resources which are almost entirely dependent on imports. The attention toward carbon neutrality has increased the demand for metals, such as cobalt (Co), nickel (Ni), and manganese (Mn), as well as rare-earth elements (REEs). Mining of minerals, such as deep-sea polymetallic nodules (also called manganese nodules or Fe-Mn nodules), cobalt-rich crusts, and rare-earth resources, will pave the way for a new development boom. Polymetallic nodules are a potential source of critical metals, such as copper (Cu), Co, and Ni, which are widely found on the abyssal plains of the global oceans and are an abundant source for rare elements such as REEs, molybdenum (Mo), phosphorus (P), thallium (Ti), tellurium (Te), and lithium (Li) [1].

There are Fe–Mn nodules throughout the global ocean, predominantly on the surface of sediment-covered abyssal plains at water depths of approximately 3500 to 6500 m. The most extensive deposits have been found in the Pacific Ocean, especially between the Clarion and Clipperton Fracture Zones (CCZ), the Peru Basin, and Penrhyn–Samoa Basins [2]. Traditionally, Ni and Cu have been the metals of greatest economic interest and have mean concentrations in the above three nodule fields that vary from 1.10% to 1.30% and 0.60 to 1.07%. The CCZ is the area of greatest economic interest, where 19 exploration contracts of about 75,000 km2 each (one exception of 58,620 km2) have been signed with the International Seabed Authority. A conservative estimate of the dry tonnage of nodules in the CCZ is 21,100 million tons. Over the last decade, research efforts have expanded to encompass additional rare metals and REEs that could potentially be extracted as by-products during the mining of primary metals of interest [3]. For instance, aside from the primary metals, Fe-Mn nodules also contain notable concentrations of Co, Li, Mo, REEs, yttrium (Y), and zirconium (Zr). The metals most enriched in these marine deposits are essential for a wide variety of high-tech, green-tech, emerging-tech, and energy applications [2].

The contents of those seabed mineral resources, which comprise deep-sea manganese nodules, cobalt-rich crusts, polymetallic sulfides, and deep-sea sediment deposits, have been evaluated as potential REE resources [4]. REE concentrate compared with land-based sources is calculated as a beneficiation multiplier of 3.25 for this REE-rich concentrate of CCZ nodules. Manganese nodules and cobalt-rich crusts are also rich in other accessory metals and REEs, and the comprehensive recovery of other accessory metals and REEs in polymetallic nodules in the conventional metallurgical process can significantly increase the economic value of polymetallic nodules and reduce the cost of resource development [2]. Compared to the Bayan Obo deposits, with REEs as a byproduct of Fe-ore mining, REEs in the nodule deposits would be extracted as a byproduct of the focus metals, Mn, Ni, Cu, and Co [2], and the cost of mining, transportation, and part of the processing of the marine deposits would be covered by the focus metals.

Equally, in addition to REEs and yttrium (REY), mud is enriched in crystal metals, including vanadium (V), Co, Ni, Cu, Zn, Mo, and Mn, by up to two orders of magnitude greater than average continental crustal contents, indicating that it is of great significance to exploiting the mud [5]. In pelagic REY-rich sediments, Fe–Mn oxides mainly exist in the form of micronodules [6,7,8,9]. Fe–Mn micronodules separated from REY-rich muds around Minamitorishima Island, Japan, in the western North Pacific Ocean, are significantly enriched in Co, Ni, and Mo, with Co and Ni contents reaching approximately 3000 and 39,000 ppm, respectively. In addition, the major portions (generally >80%) of metals associated with Fe–Mn (oxyhydr) oxides can be extracted from REY-rich muds by reductive chemical leaching [10]. Based on estimations, the most promising site for REY-rich mud development contains (9.3 ± 0.6) × 102, (1.6 ± 0.1) × 103, and (2.8 ± 0.2) × 102 t of leachable Co, Ni, and Mo, respectively, at 1 km2 × 0–10 m below the seafloor [10]. Therefore, some have proposed that for developing rare-earth mud, metal resources in Fe–Mn micronodules should also be developed in conjunction with rare-earth mining as a by-product, improving its economic benefits.

Given the absence of ongoing seabed mining operations for REEs, it is crucial to consider the current practices in seabed mining. It is plausible to envision that REY-rich mud could be extracted using mining methodologies similar to those employed for mining other deep-sea resources [11]. Typically, the mining setup for deep-sea polymetallic nodules and rare-earth resources involves a sealed resource collector, hydraulic lifting system, and mining platform. Thus, it is conceivable that existing technology utilized for exploring other seabed resources, such as systems proposed for manganese nodules, could be adapted for REEs mining, albeit with some necessary adjustments [11,12].

As a key source of metals, REEs are developed together as by-products of manganese nodule deposits in the mining process, and whether it will improve economic efficiency and mining feasibility should be determined. Similarly, micronodules in sediment muds, including REEs rich in metal elements, such as Cu, Co, and Ni, are developed as by-products of rare-earth mining, and whether they will improve the economic benefits of rare-earth mining by extracting these metal elements as by-products remains unknown. In addition, in areas rich in rare-earth mud sedimentary layers and manganese nodule resources, whether the combination of polymetallic nodules and rare-earth resources can increase the economic feasibility of mining and improve the economic benefits of deep-sea mineral resources mining remains unclear.

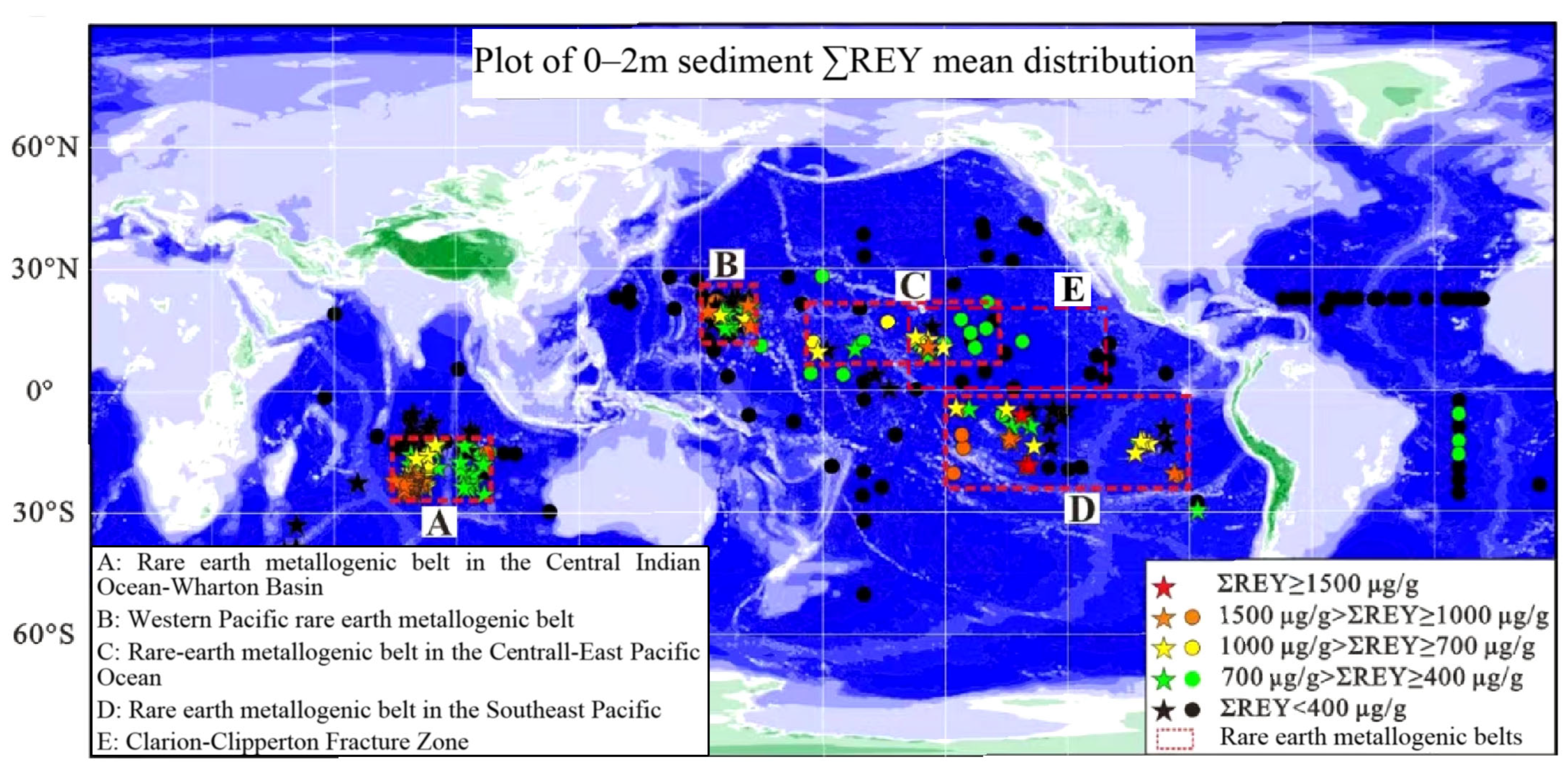

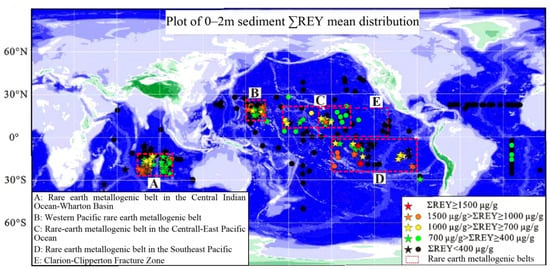

The answers to these knowledge gaps require the analysis and study of deep-sea regions rich in polymetallic nodules and rare-earth-rich sediments as research objects. The CCZ, which has the richest polymetallic nodules in the world, overlaps with the Central East Pacific rare-earth metallogenic belt, one of the four potential areas of deep-sea rare-earth mineralization in the global ocean [13,14]. This implies that the CCZ is rich in polymetallic nodules and REE-rich deposits, meeting the above research requirements (Figure 1).

Figure 1.

Distribution of ΣREY contents for deep-sea sediments (modified from Shi et al., 2021 [13]).

Nodules in the CCZ have more Tl (6000 times), Mn, Te, Ni, Co, and Y than the entire global terrestrial reserve base for these metals. The CCZ nodules also contain significant amounts of Cu, Mo, wolfram (W), Li, niobium (Nb), rare-earth oxides (REOs), yttrium (Y), and zirconium (Zr) compared with global land-based reserves [2]. Metals in CCZ nodules as a percent of the entire global terrestrial reserve base are as 88%, Mo 63%, Th 27%, V 25%, Cu 23%, W21%, Li 20%, Nb15%, TREO (total rare-earth elements) 10%, Ti 7%, and PGM (total platinum group metals) 4% [2]. In the 1990s, the geochemical characteristics of deep-sea sediments, enrichment mechanisms, and resource characteristics of polymetallic nodules in the CCZ were systematically analyzed [15,16]. In recent years, the geochemical characteristics of deep-sea sediments in this area have been continuously studied [17,18,19]. In spite of the diminished concentrations of total rare-earth oxides (TREO) within deep seabed mineral deposits, notable yields of TREO have been estimated from polymetallic nodules and REE-rich deep-sea sediments situated in Korean tenements (approximately 1 and 8 Mt, respectively). When contrasted with land-based REEs deposits, deep-sea mineral deposits emerge as low-grade mineral reservoirs boasting substantial tonnages. Rare-earth elements and critical metals sourced from deep-sea mineral deposits function as significant by-products and co-products alongside primary commodities such as Co and Ni, potentially augmenting the economic viability of their extraction [4]. The land-based deposits have less than 1% HREEs, whereas the CCZ nodules have a mean of 26% HREEs [2].

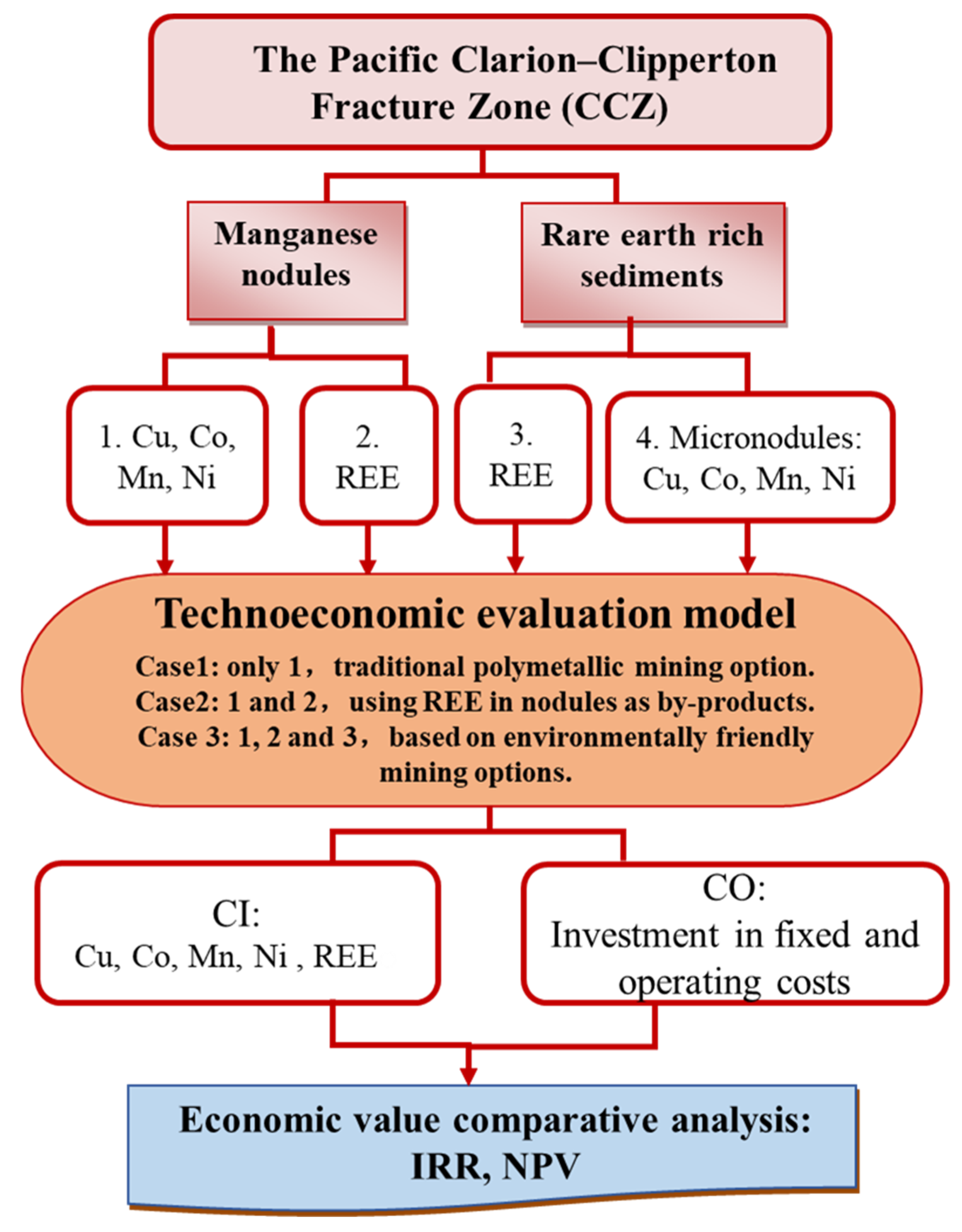

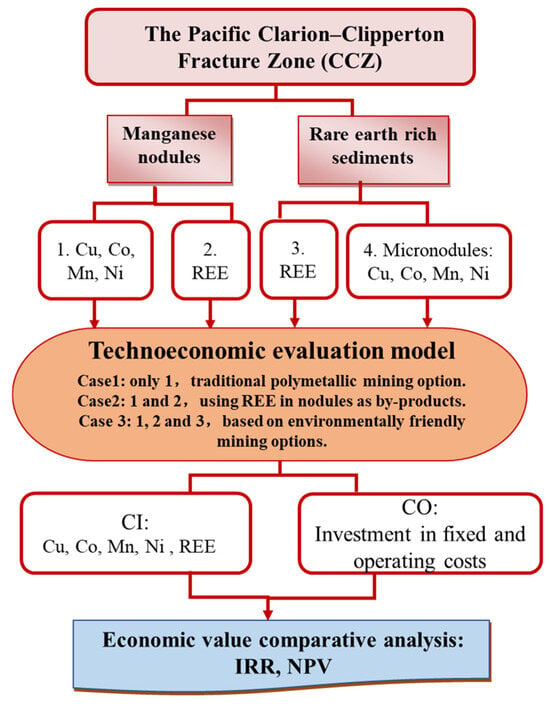

In general, the Pacific CCZ, which is a very important rare-earth-rich mineralization belt, partially coincides with the Middle East Pacific rare-earth mineralization belt, and widespread deep-sea rare-earth deposits are found in the area; although the ∑REY is medium, the thickness of rare-earth-rich deposits is large [14]. Mining of mineral resources in the CCZ requires consideration of the main metals (Cu, Co, Mn, and Ni) and REEs in polymetallic nodules. REEs and important metals in manganese micronodules in sediments also need to be considered. Therefore, this paper considered CCZ as the study area to adopt a technoeconomic evaluation method to determine whether the combined mining of polymetallic nodules and rare-earth resources will bring higher economic benefits than the separate mining of nodules or rare-earth resources in sediments. This paper also determined whether combined mining can comprehensively improve the economic benefits of deep-sea mineral resource mining, as shown in the flow chart in Figure 2.

Figure 2.

Evaluating the economic value of polymetallic nodules and rare-earth sediments in CCZ.

2. Materials and Methods

2.1. Metal and Rare-Earth Resources in Manganese Nodules

2.1.1. Main Metal Content in Manganese Nodules

Fe–Mn nodules occur throughout the global ocean, primarily found on the surface of abyssal plains covered by sediment, at water depths ranging from approximately 3500 to 6500 m. Their deposition rate is generally less than 1 × 10−5 m per annum. Given its huge resources and abundant amounts of more than ten rare and precious metal elements, such as Mn, Cu, Co, Ni, Ti, Li, Mo, Te, V, Zr, Nb, and Ta, and rare-earth and platinum groups, Fe–Mn nodules are considered to be a deep-sea mineral resource with great commercial development potential [3,20]. Particularly, the area between the Clarion and Clipperton Fracture Zones in the NE Pacific is moderately well known for its greatest economic interest, grades, and tonnages. A conservative estimate of the dry tonnage of nodules in the deep-sea basin (about 3.83 × 106 km2) in the CCZ is 21,100 million tons. The Eastern Pacific CCZ develops a mixed-genesis polymetallic nodule deposit type characterized by high levels of Mn, Ni, and Cu and medium levels of Co, Mo, and Li.

The abundance of polymetallic nodules in the Pacific CC region ranges from 0 kg/m2 to 30 kg/m2, with an average abundance of approximately 15 kg/m2 [21]. The polymetallic nodules in the CCZ contain about 6 × 109 t Mn, which is larger than the total known terrestrial manganese reserves. In addition, the Ni (270 Mt) and Co contents (44 Mt) of polymetallic nodules in the CCZ were 3 and more than 3.4 times higher than those of terrestrial reserves, respectively [20]. Despite having the most extensive resources of polymetallic nodules and other major metal elements, its distribution in the CCZ is nonuniform: resources for polymetallic nodules in the central and northern CCZ are higher than those in the southern, southwestern, and eastern areas according to the International Seabed Authority.

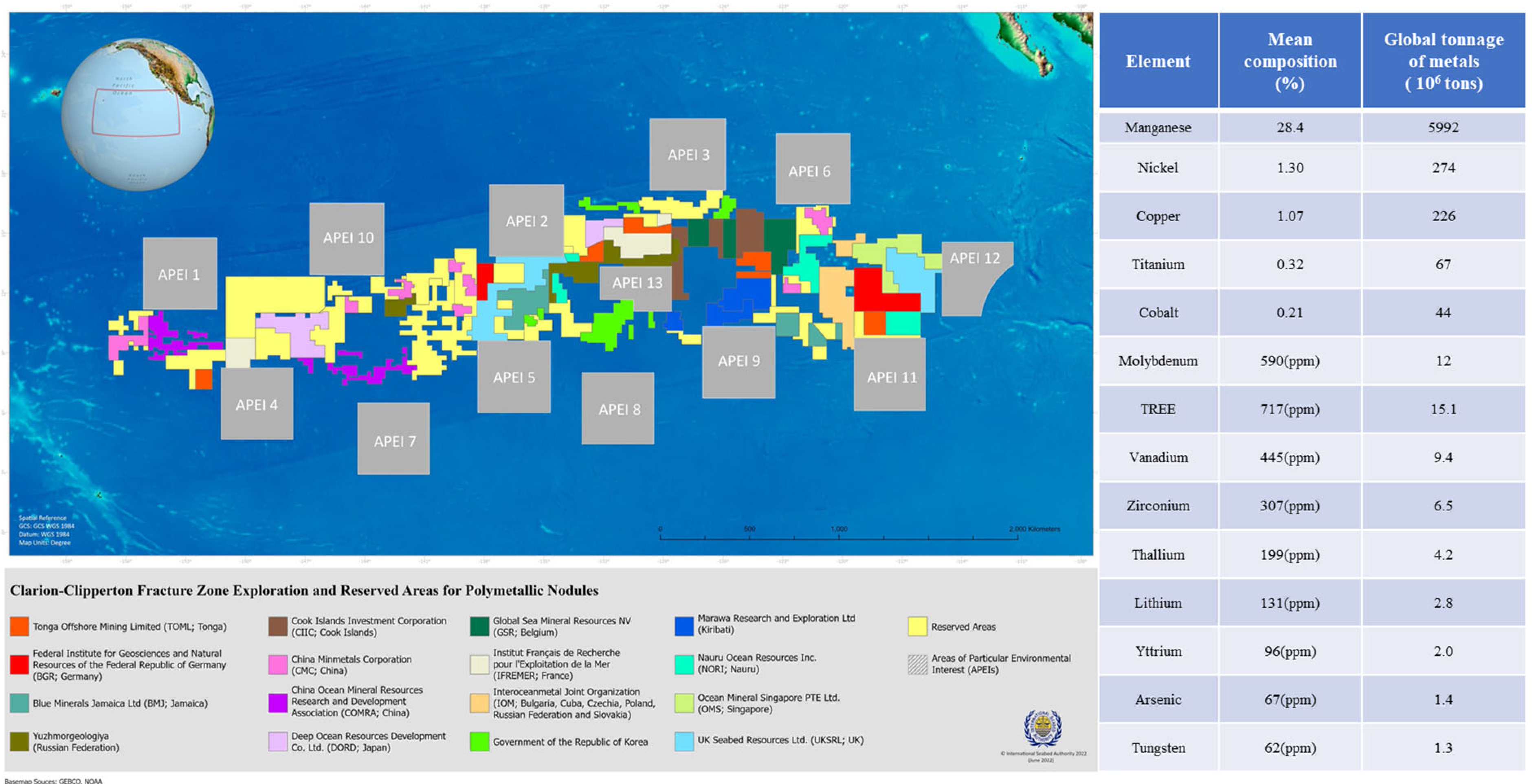

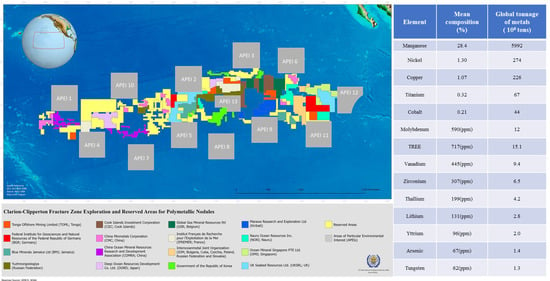

Up to April 2021, the International Seabed Authority (ISA) had granted 17 exploration contracts, each covering an area of approximately 75,000 square kilometers, with one exception of 58,620 square kilometers (Figure 3). These contracts were awarded to various countries, including China (2), Cook Islands, France, Germany, Jamaica, Japan, Kiribati, Korea, Nauru, Belgium, Russia, Singapore, Tonga, and the United Kingdom (2), as well as an intergovernmental consortium [15].

Figure 3.

Exploration and reserve area and elements for polymetallic nodules in CCZ (modified from the web of ISA and Hein et al., 2020 [3]).

Nodules generally vary in size, typically ranging from about 1 cm to 12 cm in their longest dimension. The most commonly observed sizes fall within the lower to middle range, typically between 1 and 5 cm. Morgan (2000) [22], based on measurements of 6706 nodules from CCZ, found the median maximum, middle, and minimum nodule dimensions to be 8, 6, and 4 cm, respectively. It is worth noting that nodules smaller than 2 cm were not included in his analysis. The mean specific surface area of Fe-Mn nodules is highly variable, approximately around 150 m2/g, which is significantly less than the characteristic 325 m2/g observed in crusts.

This greater economic interest is due to the high Ni and Cu concentrations found in the CCZ nodules and high nodule abundances [2]. Traditionally, economic interests for Ni and Co metals have been the greatest, and they have also been the drivers of nodule mining, with average concentrations of 1.30% and 0.21%, respectively, in the CCZ nodules, coupled with a nodule Mn abundance of up to 28.4% [23]. Nodules are also more enriched in Li and are especially high in diagenetic nodules. Lithium in CCZ nodules averages 131 ppm. The market for Li is growing because of the rapidly increased use of Li in batteries, including those in electric and hybrid cars. Although polymetallic nodules contain a considerable number of metals, not all metals can be extracted economically [24].

Extracting metals or Mn-rich slag from the nodules requires a series of complex and highly capital-intensive processing. The polymetallic–nodule matrix has to be completely destroyed to release the metals. Generally, three methods can be accomplished: ammoniacal leaching processes (“Cuprion” and others), pyrometallurgical extraction processes, and hydrometallurgical extraction processes followed by electrowinning refining. An approach first proposed in the 1970s involves a nitric acid or ammoniacal leach to create a leachate from which cobalt, nickel, and copper can be recovered by electrowinning. The resulting slag can be further processed to retrieve electrolytic manganese metal or sold as a manganese rich slag. A variety of pyrometallurgical and hydrometallurgical approaches have been proposed for the primary metals extraction: pyrometallurgy, which involves smelting the nodules at 1400–1500 °C; hydrometallurgy, the chemical dissolution of nodules in sulfuric or hydrochloric acid or in ammonium sulfate and carbonate solutions. In addition, now microbiological treatment is being applied, such as dissolution by microorganisms [3].

2.1.2. REEs Content in Manganese Nodules

REEs are precious strategic resources that are widely used in cutting-edge science and technology and the military industry and are called the “mother of new materials”. The main aspects are as follows: (1) Rare-earth permanent magnet materials. Rare-earth permanent magnet materials are not only the fastest-growing and largest sector within the entire rare-earth industry, with the most comprehensive industrial scale, but also an irreplaceable and indispensable key raw material in the defense industry. Additionally, they represent the largest application area in terms of rare-earth consumption. Sintered neodymium–iron–boron (NdFeB) magnets are widely used in advanced technology sectors such as wind power generation, hybrid and electric vehicles, energy-efficient appliances, industrial robotics, and high-speed and maglev trains. (2) Rare-earth catalytic materials. Rare-earth catalytic materials have wide-ranging applications in environmental and energy sectors, promoting the large-scale use of abundant light rare-earth elements such as lanthanum and cerium. These materials enhance energy and environmental technologies, thereby improving the human living environment. The two largest application areas for rare-earth catalytic materials are petroleum cracking catalysts and automotive exhaust purification catalysts. This includes petroleum cracking catalysts, mobile source exhaust purification catalysts (for vehicles, ships, agricultural machinery, etc.), and stationary source exhaust purification catalysts (for industrial waste gas denitrification, natural gas combustion, organic waste gas treatment, etc.). (3) Rare-earth crystal materials. Rare-earth crystal materials primarily include two categories: rare-earth laser crystals and rare-earth scintillation crystals. These materials have broad applications in defense and military industries, advanced scientific equipment, medical technology, detection systems, and security screening. (4) Rare-earth luminescent materials. Rare-earth luminescent materials are used in applications such as light sources, displays, imaging, detection, and lasers. They hold significant potential for applications in fields such as security monitoring, biometric identification, and food and medical testing [25].

REEs in manganese nodules are also of economic interest [26], with a maximum total REE plus Y of approximately 0.08% in CCZ nodules. However, certain advantages are associated with the recovery of REEs despite their low grades [26]. The TREO contents of polymetallic nodules range between 0.037% and 0.302%, with an average value of 0.13% [4]. REEs found in Fe–Mn nodules have several advantages over those produced from terrestrial mines. The total tonnage of REE metals in the CCZ nodules is comparable to that of the largest carbonatite-hosted deposits, namely, Bayan Obo in China and Mountain Pass in California, USA. However, the considerably larger complement of heavy REEs (HREEs) in marine deposits relative to terrestrial mines is more important. Large terrestrial REE deposits have less than 1% HREEs, and CCZ nodules contain 26% HREEs of the total REEs [2]. This condition is crucial because HREEs have the greatest economic value. Nearly 63.6% La and Ce (LC), 19.9% Nd, Pr, and Dy (NPD), and 16.5% Sm, Eu, Gd, Y, and Tb (SEGTY) are in the nodule RRD. The largest component (LC) boasts the least expensive price tag at 1.2 USD/kg, whereas the NPD emerges as the costliest at 13.0 USD/kg (as outlined in Table 1). Moreover, the SEGTY component exhibits the highest basket price, indicating a slightly elevated overall value of 3.7 USD/kg in comparison to the LC, notwithstanding its lower prevalence [4]. Notably, the main terrestrial deposits have less than 1% HREE, but in the Pacific polymetallic nodules, the HREE level can reach as much as 26% [2]. Many land-based mines extract REEs as the primary ore, and a part of the Bayan Obo deposit is mined with REEs as the primary ore and another part with REEs as a by-product of Fe-ore mining. Based on this example, REEs in nodules are extracted as a by-product of the focus metals Mn, Ni, Cu, and Co. Extraction operations targeting the main minerals found in Fe-Mn nodules at ocean depths hold the potential to yield a substantial quantity of REEs as by products [27]. Manganese nodules can be dissolved with simple hydrochloric acid leaching, which releases the major metals and their sorbed constituents, including REEs and rare metals, into the solution. Under the premise that the main process remains unchanged when separating REEs in deep-sea polymetallic oxide ore, REEs are transferred to the solution, in which most of the REEs in the acid leaching method enter the solution and can be directly separated. Parhi et al. studied the extraction and separation of rare earths from polymetallic nodule leachate [28]. The leachate composition was 0.094 g/L total rare earth, 0.23 g/L Mn, 0.697 g/L Cu, 0.2 g/L Fe, and 0.01g/L Ni, and the rare-earth content in the reverse extract was 5.6 g/L [28]. The expenses associated with mining, transportation, and a portion of the processing of marine deposits would likely be offset by the primary focus metals, leaving behind a residue enriched with REEs and other scarce metals, including Th [2]. Utilizing hydrochloric acid for the extraction of rare earths promises significant returns, offering a notable economic advantage for the exploitation of deep-sea polymetallic nodule resources. Spickermann (2012) emphasized the importance of comparing this REE concentrate with its terrestrial counterparts, suggesting a beneficiation multiplier of 3.25 for the REE-rich concentrate obtained from CCZ nodules. Advances in extractive metallurgy may leverage this unique characteristic of marine deposits for further development and optimization [26].

2.2. Metals and Rare-Earth Resources in Sediments

2.2.1. Metal Content in Micronodules in Pelagic REY-Rich Sediments

In pelagic REY-rich sediment samples, Fe–Mn (oxyhydr) oxides mainly exist in the form of micronodules [7,16]. The metal composition in the sediments was dominated by Cu, Ni, and Zn. According to the analysis of the geochemical and mineralogical properties of pelagic sediments obtained from the Interoceanmetal Joint Organization (IOM) claim area situated in the eastern portion of the CCZ in the eastern tropical Pacific, Zawadzki et al. in 2020 discovered certain concentrations of rare-earth elements (REEs) and other essential elements in 135 sediment samples consisting of siliceous clayey silts. Furthermore, the predominant metallic constituents in these sediments were Cu, Ni, and Zn [29].

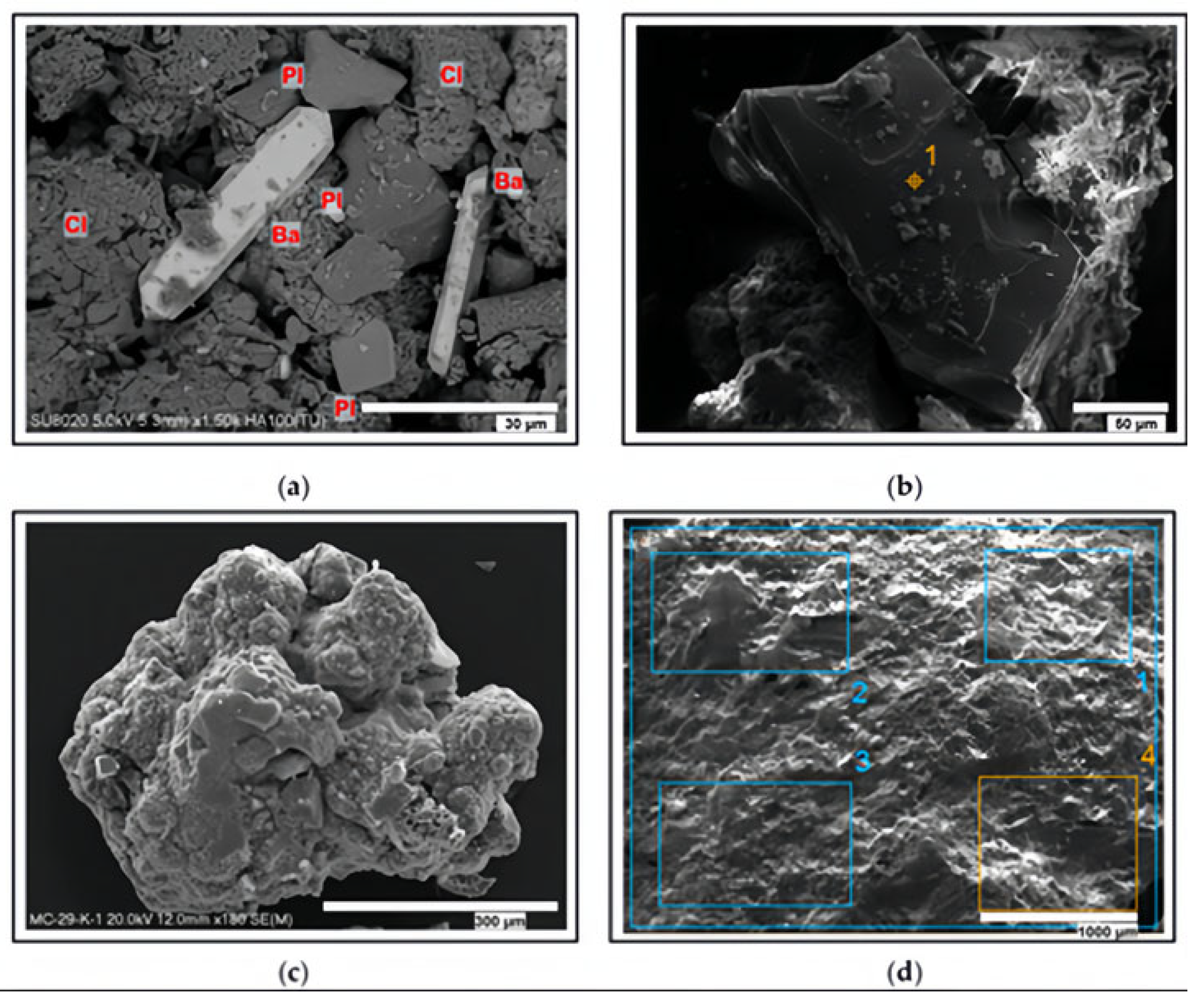

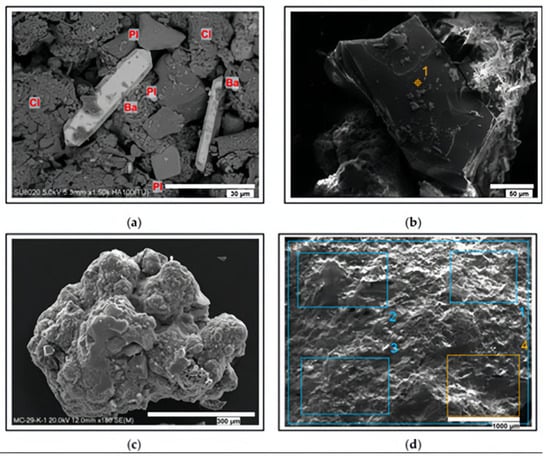

The sediment samples exhibited intricate lateral and horizontal fractionation patterns for rare-earth elements (REEs) and critical metals, primarily influenced by factors such as clay components, early diagenetic processes, admixtures of allogenic detrital minerals, or scavenging by micronodules. These micronodules, typically smaller than 2 mm in diameter, were composed of Mn–Fe particles formed in sediments through complex diagenetic-hydrogenic processes, displaying increased metal contents including Ni, Cu, Co, or REEs (Figure 4c,d) [29]. Their weight in selected sediment layers could account for a few percentage points. The weight of micronodules in the selected sediment horizons might have reached a few percentage points [9]. Analysis revealed micronodules with high Mg content, averaging 50.8%, along with 13.5% Fe and 3.0% Ni + Cu, sometimes exceeding 5%. Zn levels were also heightened, accompanied by traces of Ti, Na, Ca, Mg, K, Ba, Sr, Mo, Sc, and F. The level of phosphatization was generally low, typically below 0.1% [29]. Biogenic phosphates, represented by carbonate fluorapatite, occasionally displayed elevated REE concentrations, particularly Y and La, exceeding 0.5%. Examination of fish remains indicated traces of Fe, Mn, Si, Al, Cr, Ti, alkali, and alkaline metals. Clay-rich fractions exhibited a Si-to-Al ratio of 2.3–2.4, elevated Fe levels, with minor presence of Mn, Cr, Ti, Ba, and Ca. The contents of Na, Mg, and K averaged 3.2%, 2.4%, and 1.9%, respectively. Cl content rose from 1.5% to 2.0%, primarily due to interstitial halite crystallization.

Figure 4.

Representative scanning electron microscopy images of selected mineral components in CCZ: (a) authigenic euhedral coffin-shaped barite crystals encircled by plagioclase and clay agglomerates, with a noticeable increase in barite presence observed solely in samples exhibiting high Ba concentrations; (b) fresh surface of allogenic plagioclase debris, with the highest Na and Ca contents (5.4% and 3.8%, respectively) marked at the Na-Ca plagioclase and oligoclase location; (c) typical Mn-dominated micronodule; (d) region for chemical surface analysis of the sedimentary samples, predominantly consisting of clays and debris material, with numbers from 1 to 4 indicating the areas of analysis (adapted from Zawadzki et al., 2020 [29]).

2.2.2. REEs in Pelagic REY-Rich Sediments

In comparison to the global terrestrial (land-based) reserves, REOs, including those of Y and Sc, can reach significantly larger quantities at the Pacific deep-ocean bottom [2]. Extensive concentrations of REEs and yttrium are found in deep-sea mud across numerous locations in the eastern South and Central North Pacific [5]. Moreover, based on measurements of the elemental composition of over 2000 seafloor sediments, samples were collected at approximately 1 m depth intervals from 78 sites that span a substantial portion of the Pacific Ocean. The sediments contained high concentrations of REE in various sites across the ES and Central North Pacific, where the total REY-rich deep-sea sediments (“REY-rich mud”) were found to range from 1000 to 2230 and 400 to 1000 ppm, respectively [5,27]. Moreover, these sediments exhibited a higher ratio of HREE/LREE compared to current terrestrial REO reserves, indicating a highly promising prospect for considering ocean-floor sediments as a relatively abundant source of REY [27]. Additionally, the straightforward recovery of REEs and yttrium from Pacific deep-sea mud through simple acid leaching suggests a high potential for deep-sea mud as a valuable resource for these elements [5].

The deposits in the northeast Pacific are thick, with thicknesses mostly measuring >30 m, while some are even >70 m locally. The REY-rich mud contains moderate REY content, that is, ∑REY = 400–1000 ppm and ∑HREE = 70–180 ppm [5]. The sediments in the CCZ of the Pacific region exhibit similar characteristics, with REY-rich mud having moderate REY content, ∑REY = 352.94–812.80 ppm and ∑HREE = 117.69–343.12 ppm [30]. Thus, the CCZ is an important production area for polymetallic nodules and a relatively rich area of REEs (including Y). Similar values for the total REE content (200–577 ppm) and TREO (150–1150 ppm) were obtained after the analysis of unconsolidated seafloor sediment samples from the NE Pacific [3,30]. REEs are mainly stored in sediments, such as zeolite and pelagic clays, in the CCZ, which is affected by phosphate rock, iron manganese oxygen (hydroxide), and other substances. Based on the estimation of Pak, the sediment samples comprised 37.3% SEGTY, 33.5% LC, and 29.2% NPD, which resulted in a twice-higher cost compared with other polymetallic nodule samples [4]. The analyzed sediments from the IOM H11 polymetallic nodule field generally contained low concentrations of REE and metals, such as Ni, Cu, or Co [29]. However, the distribution of REEs in the CCZ sediments was uneven, and REE geochemical studies were conducted on the basis of 33 surface sediment samples in the CCZ in the Eastern Pacific Ocean; the REE levels were higher than the average of land-based sources [31]. The number of rare earths in the surface sediment type was determined (Table S1). The total content of light REEs (LREE), heavy rare earth and yttrium (HREY), and REEs (∑REY) in the surface sediment was (226.40–507.07) × 10−6, (117.69–343.12) × 10−6, and (352.94–812.80) × 10−6, respectively.

From the perspective of mineral resources, the REE resources in the surface sediments in the study area were preliminarily estimated, and the factors influencing their enrichment were discussed [32]. Referring to the resource grade standards in common terrestrial ores in China (Table 1) and comparing the distribution of REEs in surface sediments, the LREE of the surface sediment samples in the 74 study sites can be divided into three categories: non-enrichment, weak enrichment, and normal enrichment. The range of HREE changes exceeded the upper limit of industrial grade (106 × 10−6), in which the resource enrichment was evident and can be mainly divided into enrichment and extreme enrichment types. ∑REY also exceeded the upper limit of the cut-off grade (348 × 10−6) and can be divided into two categories: weak enrichment and enrichment types.

Table 1.

Classification and type of REE content in the surface sediments of the CCZ (modified from Huang et al., 2014 [32]).

Table 1.

Classification and type of REE content in the surface sediments of the CCZ (modified from Huang et al., 2014 [32]).

| Grade | Enrichment Type | LREE (10−6) | HREE (10−6) | ∑REY (10−6) | |||

|---|---|---|---|---|---|---|---|

| Content | Sites | Content | Sites | Content | Sites | ||

| I | Non-enriched type | ∑LREE ≤ 303 | 55 | ∑HREY ≤ 45 | 1 | ∑REY ≤ 348 | 10 |

| II | Weakly enriched type | 303 < ∑LREE ≤ 455 | 15 | 45 < ∑HREY ≤ 76 | 3 | 348 < ∑REY ≤ 530 | 47 |

| III | Enriched type | 455 < ∑LREE ≤ 910 | 4 | 76 < ∑HREY ≤ 152 | 35 | 530 < ∑REY ≤ 1060 | 16 |

| IV | Extremely Enriched type | ∑LREE > 910 | ∑HREY > 152 | 35 | ∑REY > 1060 | 1 | |

Note: I. Non-enriched type: the content of REEs is less than or equal to the upper limit of the boundary grade; II. weak enrichment type: the content of REEs is greater than the upper limit of the boundary grade and is less than or equal to the lower limit of industrial grade; III. enrichment type: the content of REEs is greater than the lower limit of industrial grade and less than or equal to two times the lower limit of industrial grade; IV. very enriched type: the content of REEs is greater than two times the lower limit of industrial grade.

When REEs are extracted from deep-sea sediments, they often take the form of REO. Some scholars have compared the REO content and economic value of polymetallic nodules in CCZ sediments [4]. The TREO concentrations in deep-sea sediments range from 0.015% to 0.015–0.115%, averaging at 0.049%. Across a wide array of sampling sites, the average TREO contents of sediment cores range from 0.026% to 0.076%, with one exception (average TREO: 0.093%). Notably, the TREO contents of the deep-sea sediments were ~1/3 of those found in polymetallic nodules (Table S2). The deep-sea sediments comprised 37.3% SEGTY, 33.5% LC, and 29.2% NPD. Despite their lower average TREO contents, the overall market value of deep-sea sediments surpasses that of nodules and crusts by approximately 200% (26.1 USD/kg). This is attributed to a doubled presence of NPD and SEGTY in the former, along with a halved proportion of LC compared to the latter. The REE concentrations in core samples exhibit vertical variation, corresponding to changes in the RRD [4]. As the development of energy-saving technology for deep-water hydraulic lifting with loading devices for vortex pulp preparation with the placement of slurry fractions in the mined-out space, it is necessary to consider issues related to the justification of the development of ferromanganese nodule deposits during the development process of the REE deep-sea mud.

Deep-sea rare earths are generally extracted by acid leaching. Sulfuric acid is used to leach rare earths from deep-sea clay samples in the central Pacific Ocean, the leaching rate of yttrium is 84.38%, the leaching rate of yttrium rare earth is 94.53% using hydrochloric acid as the leaching agent, and the extraction rate of yttrium is 98% by using P535 extractant [33].

2.3. Technoeconomic Evaluation Methods

2.3.1. Model and Theory

The technical and economic models for polymetallic nodules and other solid mineral resources are generally based on the theory of net present value (NPV) (Chen and Gu, 2007 [34]), i.e., the discounted cash flow (DCF) method. Net present value is the difference between the discounted present value of future cash flows generated by an investment and the cost of the project investment. The DCF method converts the expected cash flow of an enterprise within a specific period to its current value, which is widely used in the case of enterprise investment project valuation, as shown in Formula (1). It uses the total present value of the net cash benefit and the net cash investment to calculate the net present value, and then evaluates the investment plan according to the net present value. If the net present value is positive, the investment plan is acceptable; otherwise, it is unacceptable.

where NPV is financial NPV, CIt indicates cash inflow in year t, COt denotes cash outflow in year t, n refers to project life, and i is the base discount rate.

The internal rate of return (IRR) is the discount rate at which the total present value of capital inflows equals the total present value of capital outflows, namely, NPV = 0. In general, when the IRR of an investment project is greater than or equal to the benchmark rate of return, the project is considered feasible.

where CIt denotes the cash inflow in year t, COt stands for the cash outflow in year t, and n is the project life. (Notes: An IRR only exists if NPV can be zero. This can only happen if an actor experiences both positive and negative cash flows. In this analysis, we only assess revenues—positive cash flows—for the ISA due to administrative fees and extraction-related payments. Therefore, it is not possible to compute an IRR for the ISA and an NPV analysis is used to understand those revenues.)

In addition, this paper analyzed the sensitivity of data and results of the process of NPV calculation and showed a better analysis of how to optimize the overall mining solution through different sensitivities.

2.3.2. Model Construction Based on the Mining Process

According to the resource occurrence characteristics of the CCZ, which has both polymetallic nodules and loose deposits rich in rare earths, this paper proposes three mining cases for related minerals in the CCZ. Case 1 involves the exploitation of polymetallic nodules in which the contents of Co, Ni, Cu, Mn, and other main metal elements are proposed. Case 2 involves the mining of polymetallic nodules to extract Co, Ni, Cu, Mn, and other metallic elements and REEs as by-products. Moreover, given that polymetallic nodules and submarine sediments rich in REEs coexist in the CCZ, Case 3 simultaneously mines the polymetallic nodules and seabed sediments, extracting not only Co, Ni, Cu, and Mn, and other metallic elements and REEs from polymetallic nodules but also REEs from deep-sea sediment ooze as by-products.

In this study, the DCF method was applied to the income assessment of mineral development to evaluate the long-term investment feasibility of polymetallic nodules and deep-sea sediment mining projects in the CCZ. We assumed that the mining project was divided into two phases, including a 3-year infrastructure period and a 10-year mining period, with an average annual recovery of 3 million tons of dry manganese nodules. Three million dry tons was selected as the baseline since it is believed that this order of magnitude is needed to achieve economies of scale and thus minimize costs. The model includes mineral resource revenues and mining costs, and does not include the revenue to the ISA and the possible environmental or sustainability fund.

The NPV and IRR of Cases 1, 2, and 3 were calculated and compared to discuss the economic benefits of various mining plans and explore the optimal plan. Case 1 is the traditional polymetallic mining option, which proposed in this paper mines polymetallic nodules to extract four metallic elements: Co, Ni, Cu, and Mn, and only considered the capital cost and operating cost of these four metals in the NPV model. Case 2 is using REE in nodules as by-products, which proposed mines polymetallic nodules in the CCZ to extract metallic elements and REEs. In addition to the above four metal costs, the cost of REE is also considered.

According to Case 3, considering the actual situation of the CCZ, this study maintained a total annual mining nodule amount of 3 million tons when mining deep-sea sediment ooze as a by-product in the corresponding collection area and extracted REEs from it. According to Huang Mu [31], the study area is 1643 km2. The average water content of the study samples was 70.20%, representing the water content of surface sediments in the study area, and the average natural density of the samples was 1.25 g/cm3, representing the average density of surface sediments. Meanwhile, the average REE content of surface sediments was assumed to be the REE content of the other sediments tested, which can represent the average REE content of 60 cm thick surface sediments at the sampling site. Then, the REE content of the sediments can be expressed by the following formula:

where Wtotal is the REE content, s denotes the sediment distribution area, h refers to the thickness of sediments, ρ indicates the average natural density of the wet sample, Φ corresponds to the mean water content of the sediment; σ is the average REE content of the surface sediment. In accordance with the above formula, the ∑REE content in the surface sediments in the study area was calculated.

The ∑REE content in the surface sediments of the study area was 162,114 t. When 3 million tons of dry manganese nodules were mined annually, the mined area was approximately 450 km2.

In the formula above, Wyear indicates the annual production of mined REE, Wtotal indicates the REE content, Syear refers to the annually mined squared area, and Stotal is the total square of the research zone. The annual output of REE can be up to 44,400 t when mining 3 million tons of dry core annually.

3. Results and Discussion

3.1. Technoeconomic Evaluation Based on Environmentally Friendly Mining Options

3.1.1. Case 1 Traditional Polymetallic Mining Option

In Case 1, the relevant geological and economic model of polymetallic nodules and deep-sea sediment mining in the CCZ and its parameters refer to the authoritative economic evaluation report submitted by MIT to the International Seabed Authority (hereinafter referred to as MIT report) [34,35]. Based on the report, we divided the expenses into capital cost (CAPEX) and operating costs (OPEX). The capital cost was divided into seven parts, namely, collection, lifting system, mining vessel, process water, environmental monitoring, transportation, and metal smelting, and 50%, 30%, and 20% of the capital cost were invested in construction within three years of the construction period. Operating costs include equipment, maintenance costs, and annual metal smelting expenses. According to the MIT report, metal metallurgy involves three methods, namely, Cuprion, pyrometallurgy, and hydrometallurgy, with capital costs of USD 2.072 billion, USD 1.75 billion, and USD 2.742 billion, respectively. Considering the cost and metallurgical recovery, the pyrometallurgy solution was selected. The capital costs for environmental monitoring are calculated based on the stochastic technoeconomic assessment of the seabed mining of polymetallic nodules [24]. The total cost is shown in Table 2. According to the MIT report, the mining project will be subject to fees payable to the International Seabed Authority and the sponsoring state, including administrative fees payable to the international search unit, those payable to the international search unit related to the extraction, those payable to the environment or sustainability fund, and corporate income tax payable to the sponsoring state. The fees and scale of payments to international units are often uncertain in practice. Thus, this study ignored these costs and only considered the corporate income taxes to be paid.

Table 2.

Investment in capital and operating costs according to Case 1 (USD million).

To calculate the cash inflow required in the NPV formula, we obtained the annual income; that is, we calculated the output and price of metal elements and REEs, determined the initial ore income, subtracted the annual operating costs, then subtracted taxes and fees, and finally obtained the theoretical cash inflow. According to the MIT report, the total annual output of polymetallic nodules is set at 3 million tons. Table 3 shows the contents and prices of the four metal elements: Co, Ni, Cu, and Mn.

Table 3.

Contents and prices of the related metal elements in nodules.

The social discount rate stipulated by the economic department of China is 12%. Considering that deep-sea mining projects have higher risks compared with traditional land mining projects, this paper considered the higher risk rate of return when selecting the discount rate and set the discount rate as 15%, which is slightly higher than the prescribed social discount rate. In addition, the corporate income tax rate is 25%, with tax = profit × 25%.

3.1.2. Case 2 Using REE in Nodules as By-Products

To keep the capital and operating costs similar to those in Case 1, we controlled the total annual mining amount to be the same as Case 1, i.e., 3 million tons. Compared with Case 1 above, when keeping the total annual mining amount of 3 million tons, in Case 2, the cost of smelting REEs from nodules must be increased. For 2000 tons of REE per year, capital and annual operating costs for REE smelting are USD 6 and 31 million, respectively; hence, the capital cost for REE smelting is estimated to be USD 6.69 million, and annual operating cost is USD 34.57 million. The total cost after the increase is shown in Table 4.

Table 4.

Investment in capital and operating costs based on Case 2 (unit: USD million).

REEs are divided into light (lanthanum, cerium, praseodymium, and neodymium), medium (samarium, europium, gadolinium, terbium, and dysprosium), and heavy (holmium, erbium, thulium, ytterbium, lutetium, and scandium) rare earths. The demand and value of medium and heavy rare earths are substantially higher than those of light rare earths. Table 5 shows the contents of various rare earths in polymetallic nodules in existing studies and their price indices. The rare-earth content data of polymetallic nodules came from the conclusions of Hein et al. [2], and the rare-earth content of deep-sea sediments was based on the research of Huang and Liu [30] on the content of REEs in sediments in the CC area. The price data for yttrium, lanthanum, cerium, praseodymium, neodymium, terbium, dysprosium, and scandium were derived from the Shanghai nonferrous metal price index in the Guotai’an Database, and the annual price average of 2021 was already obtained. The price data for samarium, europium, gadolinium, holmium, erbium, thulium, ytterbium, lutetium, and other rare earths were obtained from the real-time price of gold investment net on 16 January 2023. The price of lithium metal was derived from the London Metal Exchange.

Table 5.

Classification of REEs.

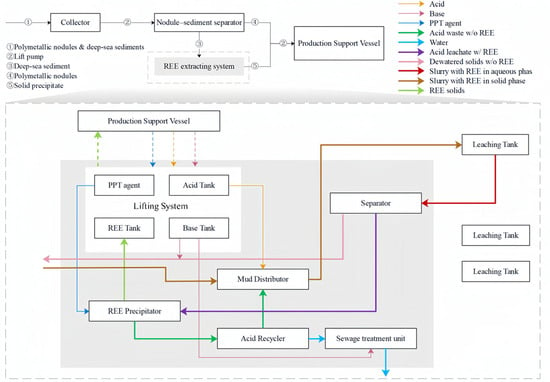

3.1.3. Case 3 Based on Environmentally Friendly Mining Options

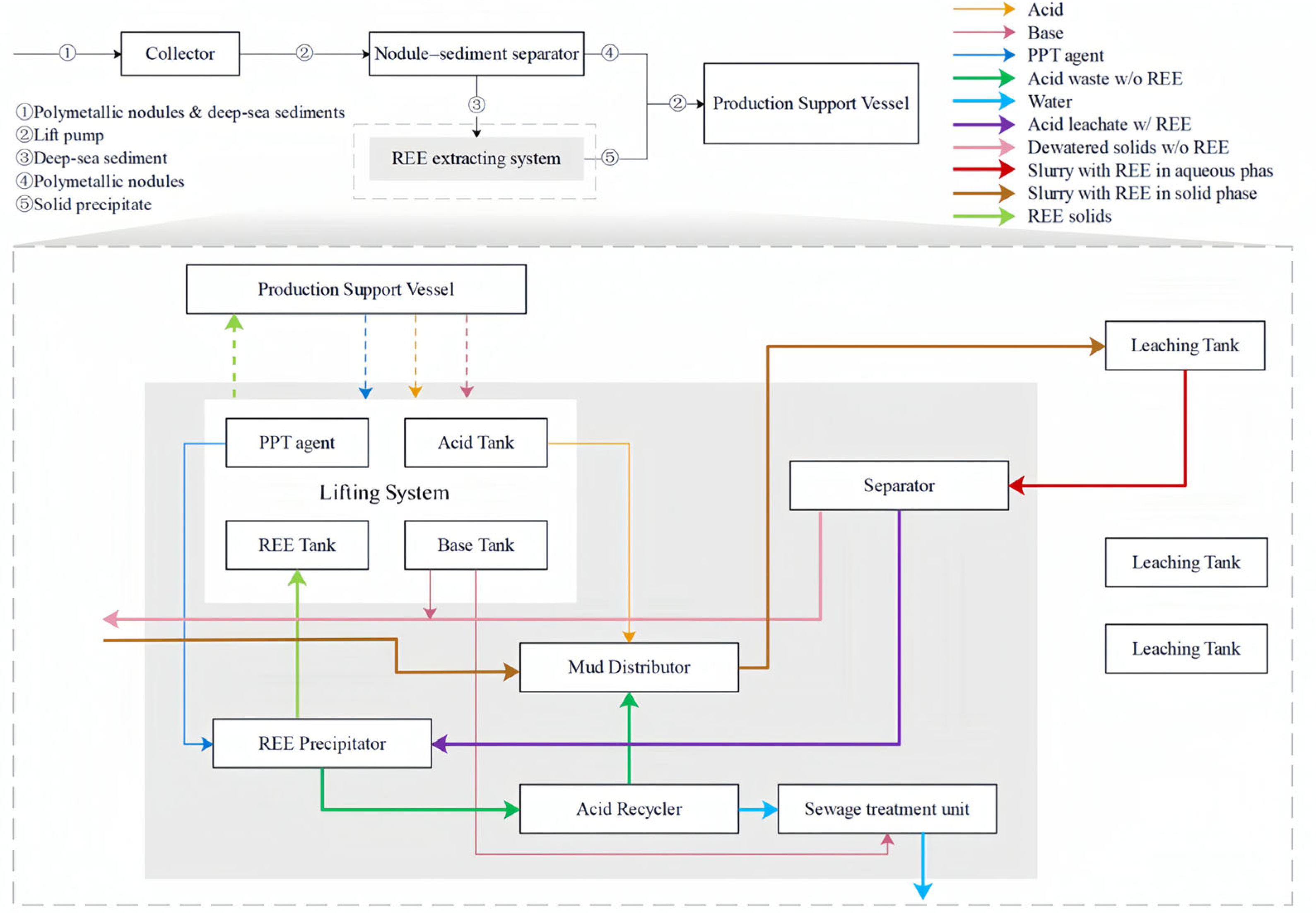

In terms of cost in Case 3, as the weight of mined REEs is extremely small compared with that of mined nodules, the cost increase caused by the weight increase was ignored here. Therefore, the main cost of Case 3 is the same as that in Case 1 (Table 6). However, when treating polymetallic nodules and deep-sea sediments, the two substances can be separated by installing a nodule–sediment separator on the seabed, which is shown in Figure 5 [36,37]. Figure 5 shows the main process of deep-sea mining. First, a collector collects polymetallic nodules and deep-sea sediments from the ocean floor. They are then lifted by a lift pump to the nodule–sediment separator. Here, the nodules and sediment will be separated: the nodule will be lifted onto the vessel by a lift pump, while the sediment will be sent to the Ree extracting system. After separation, the mud will be pumped in slurry form to the mud distributor, where concentrated acid will be added. The slurry will then be pumped to a leaching tank, remaining there until the REEs are dissolved into the solution. Next, the slurry containing the dissolved REEs will be pumped through a physical separator to separate the solids from the leachate. The leachate will be directed to the REE precipitator, while the solids will be returned as slurry to the excavation site for disposal. Finally, a reagent will be added to the leachate in the REE precipitator to precipitate the REEs as solids, which will then be transferred to a REE tank for vertical lifting to the surface. It is also worth noting that the acid can be recycled, and the wastewater can be treated within this separator.

Table 6.

Investment table of capital and operating costs set under Case 3 (unit: US $million).

Figure 5.

Assumed mining processes for REE mud (modified from Bashir et al., 2012 [36]).

This method of separating rare earths from the sediments is environmentally feasible to a certain extent, provided that the acid solution used for separating rare earths does not directly discharge into the seabed environment and must undergo strict environmental treatment. For organisms near seabed polymetallic nodules, the environmental impact of nodule mining may have profound effects on them because of the importance of the nodules for the epifaunal biodiversity of this abyssal area. So, environmental research must be invested in and promoted for deep-sea mining, to make it less polluting and more sustainable in the short term [38].

The mining, transportation, and partial processing costs of marine sediments will be borne by the major metal mining groups, leaving only the residue rich in rare earth and other rare metals for the extraction of REEs. Therefore, this part of the cost is still a nodule mining cost. Because the nodule–sediment separator technology mentioned in this method is not yet available on the market, we estimated its cost along with the cost of a deep-sea polymetallic nodule mining vehicle. Given that the nodule–sediment separator is at a relatively early end of the product lifecycle, economies of scale have not been realized, and combined with sediment production, we assumed a capital expenditure of USD 50 million. The operating costs were preliminarily estimated to be USD 2 million, which is 4% of capital costs. Meanwhile, the product plan includes four metallic elements (Co, Ni, Cu, and Mn) and REEs. The maintenance plan was the same as that in Case 1, and the cost estimate is shown in Table 6. In terms of benefits, the content and price of REEs selected in Case 3 were the same as those in Case 2 (Table 5).

3.2. Calculation Results and Sensitivity Analysis

3.2.1. Calculation Results

The best scheme was selected by comparing the difference between the financial NPV and IRR of each scheme. The formula is as follows:

where i and t together represent different schemes. The calculation results are shown in Table 7. Compared with Case 1, that is, the extraction of metal elements from metal nodules alone, for the NPV of Case 2, the extraction of metal elements and REEs from metal nodules increased by 565.38 (unit: million US dollars, the same as below) and IRR increased by 5.64%. In addition, the NPV of Case 3 was more than that of Case 1 by 968.86, and IRR increased by 9.07%; both values were considerably better than those in the first scheme.

Table 7.

Differences in NPV and IRR of the three cases (USD million).

Based on the increasing separator cost, the NPV of Case 3 still increased by 403.49 compared with that of Case 2, and IRR increased by 3.43% (Table 7). In the three hypothetical schemes, based on the natural fact that polymetallic nodules and rare-earth-rich deep-sea sediments coexist in CCZ when polymetallic nodules and seabed sediments are mined simultaneously, the corresponding project that involves the extraction of metallic elements, such as Co, Ni, Cu, Mn, and REEs in polymetallic nodules as by-products from the ooze of deep-sea sediments is the most economically valuable.

3.2.2. Sensitivity Analysis

The sensitivity factors considered in this study mainly included discount rate, tax, prices of metal elements, and REEs of economic factors, capital and operating costs jointly determined by economic and technical factors (related to each subpart of mining, transportation, and selection), annual ore output and the mining recovery rate as technical factors, and ore grade as geological factors. From the calculation formula of sales income, the annual ore output and mining recovery of technical factors had the same influence on the sensitivity of the evaluation index, and the prices of each metal element in the ore and each REE had the same direction in the sensitivity of the evaluation index.

This paper mainly focused on the sensitivity of three factors: discount rate, cost (including capital and operating costs), and price (including prices of metal elements and REEs). First, we focus on the direction of the influence of the factors. According to formula (1), we take the derivatives of the revenue factor (CI), cost factor (CO), and discount rate (i). It can be concluded that the derivative of the revenue factor is always greater than zero, while the derivatives of the cost factor and discount rate are always less than zero. This means that the influence of the revenue factor on NPV is positive, while the influence of the cost factor and discount rate is in the opposite direction.

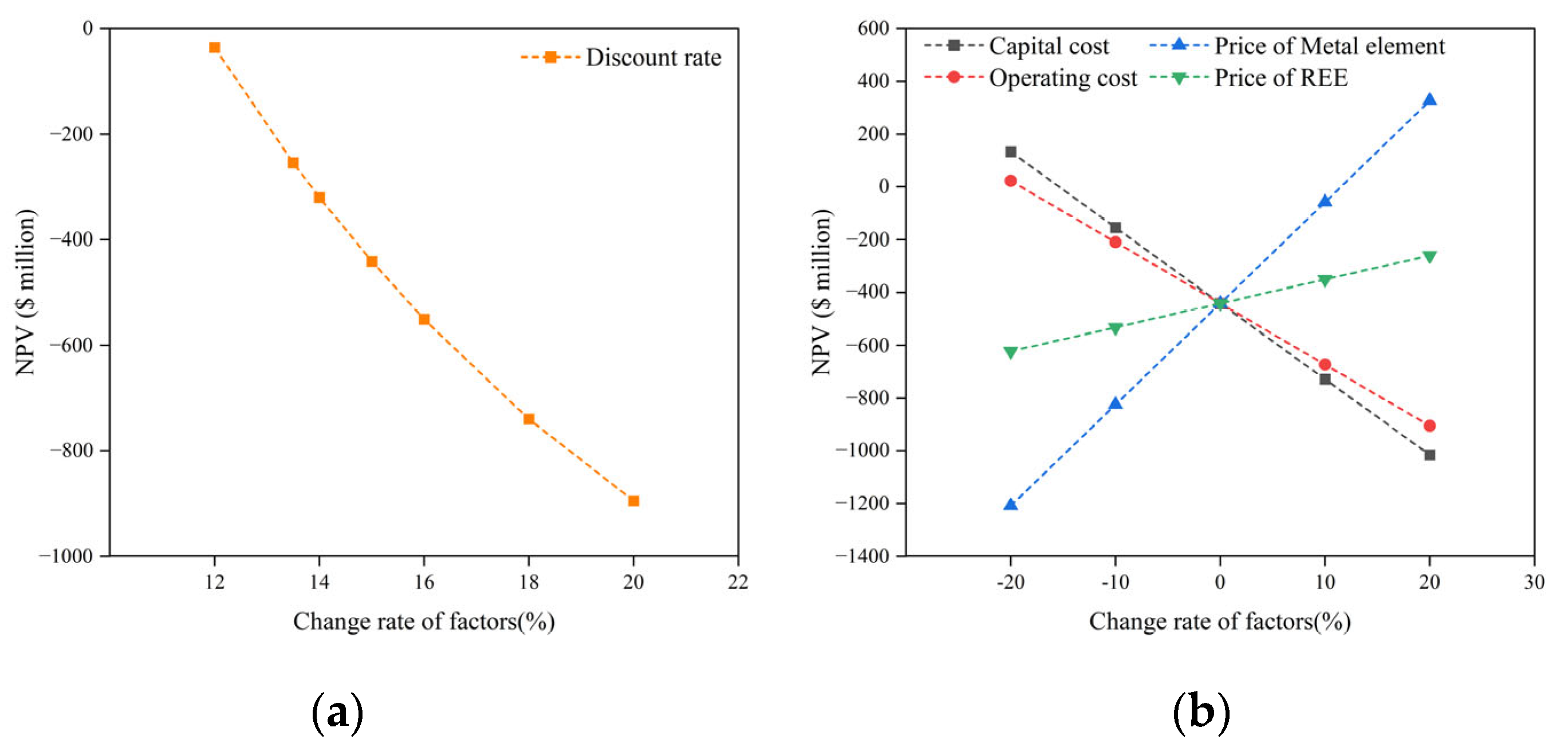

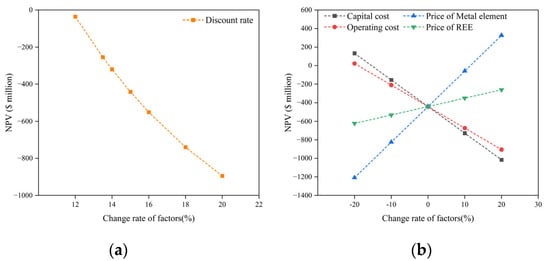

Next, we turn our attention to the magnitude of the influence of these factors, that is, their sensitivity. Case 3 was used as an example to calculate the financial NPV when the discount rates were 12%, 14%, 16%, 18%, and 20%. Figure 6 shows the influence of the change in the discount rate on NPV as the evaluation index. Financial NPVs with a continuous change of 10% in cost (capital cost and operating cost) and price (prices of metal elements and REEs) factors were calculated, which showed the impact of cost and price change on NPV.

Figure 6.

(a) Influence of different discount rates on NPV. (b) Influence of various factors on NPV.

As presented in the line chart, the influence directions of the discount rate, cost, and price on financial NPV were different. The prices of metal elements and REEs showed a positive effect on financial NPV, and the discount rate, operating cost, and capital cost exhibited a negative influence.

Based on the slope, this study ranked the influence of the above five factors on the evaluation index (Table 8). As shown in Table 8, considering both positive and negative influences, the price of metal elements in economic factors had the greatest effect on the evaluation index, and the most prominent influence was the effect on economic feasibility, followed by capital and operating costs jointly determined by economic and technical factors. Comparatively speaking, the price of REEs in terms of economic factors had the least influence on the evaluation index. Therefore, in the process of the project, we should focus on the price trends of Co, Ni, Cu, Mn, and other metal elements. Meanwhile, we should evaluate the technical factors of the project development, reduce the cost of mining equipment by developing relevant feasible technologies, such as the price of specific parts of the mining equipment (the nodule and sediment separator), and reduce the cash outflow by the input of operating costs to better accommodate the economic benefits of the project.

Table 8.

Ranking of the sensitivity factors.

4. Conclusions

(1) Joint mining of rare earth and polymetallic nodules in the deep sea will improve economic benefits.

The CCZ is rich in both polymetallic nodules and sediments of important rare earths. In addition, polymetallic nodules are rich in REEs, and the deep-sea sediment soft mud contains iron and manganese micronodules with high metal contents. By combining the two and developing suitable mining technology with low economic cost to mine a variety of metals and REEs simultaneously, the economic benefits will be significantly improved. The technical and economic evaluation model verifies that simultaneous mining of polymetallic nodules and deep-sea rare earths is more economically feasible than single mining of polymetallic nodules. Extracting REEs from sediments as by-products can help increase the economic value of mining when seabed sediments are unavoidably collected during the mining of polymetallic nodules.

(2) To significantly reduce the cost of deep-sea mining, it is essential to develop mining technology towards high-tech and environmentally friendly directions.

Based on the results of the net present value (NPV) analysis, the integrated development of polymetallic nodules and seabed sediments is projected to yield higher returns compared to their separate exploitation at the current stage. However, both capital costs and operating costs exert a negative impact on NPV, underscoring the critical importance of reducing these costs. The adoption of more environmentally sustainable mining technologies is likely a prudent approach. With ongoing advancements in extraction and smelting technologies, a reduction in overall costs appears attainable, which enhances the long-term prospects for the comprehensive development of these resources. Furthermore, considering the mining areas rich in polymetallic nodules and seabed sediments, to maximize returns, it is imperative to advance mining technologies with an emphasis on polymetallic nodules extraction, complemented by the collection of sediment. This strategy enables the efficient recovery of multiple types of deep-sea sediments within the same mining area, thereby effectively increasing profitability. Consequently, upgrading mining and separation equipment remains a key priority. This paper introduces a novel mining framework and assumes mining processes for REE mud, which is likely to contribute to advancements in deep-sea mining. Further research into optimizing the associated technologies is both necessary and deserving of close attention.

(3) Since there are more abundant resources in the deep sea than on land, continuing to explore and exploit the ocean scientifically in the future has significant benefits.

Existing research shows that there are numerous strategic resources in the deep sea, so it is necessary to develop marine resources. This paper focuses on the distribution and extraction of rare-earth elements, but it is equally important to focus on the development of other important deep-sea resources in the future. From a technical point of view, land beneficiation of some seabed resources has already had a certain technical reserve. Further, the comprehensive utilization of seabed resources in the future will focus on the possible transfer of beneficiation technology to the sea and how to maximize the harmless treating technology, e.g., acid leach, to restrain the tailings pollution. The extraction of deep-sea REEs from sediments on the seafloor and their smelting process will reduce the cost of lifting sediments to the sea surface, and direct landfill with tailings will reduce the impact on land. Beneficiation and processing technology at a rapid speed at sea will be key factors in realizing the commercial exploitation of deep-sea resources.

In conclusion, the deep ocean harbors abundant REEs, and while current technology remains in a developmental phase, advancing it towards environmentally sustainable, streamlined, cost-effective, and intelligently controlled processes could significantly enhance the efficiency of deep-sea mining. Technical and economic evaluations suggest that extracting REEs from sediments as a by-product could increase the economic value of deep-sea polymetallic nodule mining. In the case of the CCZ, which is rich in both nodules and rare-earth-laden sediments, the in situ separation of polymetallic nodules from soft seabed sediments could bolster both economic feasibility and environmental sustainability.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su16177872/s1, Table S1. REEs in different types of surface sediments in the CCZ. Table S2. Prices of REOs in deep-sea polymetallic nodules and sediments.

Author Contributions

Conceptualization, C.W.; data curation, C.W. and J.C.; formal analysis, C.W., D.L., J.C. and C.L.; funding acquisition, D.L.; investigation, J.C.; methodology, C.W., D.L., J.C. and C.L.; project administration, C.W.; resources, C.W. and J.C.; software, C.L.; supervision, C.W. and D.L.; validation, Y.Y.; visualization, D.L.; writing—original draft, C.W., D.L., J.C., C.L. and Y.Y.; writing—review and editing, C.W., D.L., J.C. and Y.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Key Project of National Natural Science Foundation of China (NO.72134008) and National Natural Science Foundation of China (NO.42276080).

Data Availability Statement

The data that support this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, Z.; Li, H.; Hein, J.R.; Dong, Y.; Wang, M.; Ren, X.; Wu, Z.; Li, X.; Chu, F. A possible link between seamount sector collapse and manganese nodule occurrence in the abyssal plains, NW Pacific Ocean. Ore Geol. Rev. 2021, 138, 104378. [Google Scholar] [CrossRef]

- Hein, J.R.; Mizell, K.; Koschinsky, A.; Conrad, T.A. Deep-ocean mineral deposits as a source of critical metals for high- and green-technology applications: Comparison with land-based resources. Ore Geol. Rev. 2013, 1, 1–14. [Google Scholar] [CrossRef]

- Hein, J.R.; Koschinsky, A.; Kuhn, T. Deep-ocean polymetallic nodules as a resource for critical materials. Nat. Rev. Earth Environ. 2020, 1, 158–169. [Google Scholar] [CrossRef]

- Pak, S.J.; Seo, I.; Lee, K.Y.; Hyeong, K. Rare Earth Elements and Other Critical Metals in Deep Seabed Mineral Deposits: Composition and Implications for Resource Potential. Minerals 2018, 9, 3. [Google Scholar] [CrossRef]

- Kato, Y.; Fujinaga, K.; Nakamura, K.; Takaya, Y.; Kitamura, K.; Ohta, J.; Toda, R.; Nakashima, T.; Iwamori, H. Deep-sea mud in the Pacific Ocean as a potential resource for rare-earth elements. Nat. Geosci. 2011, 4, 535–539. [Google Scholar] [CrossRef]

- Addy, S.K. Distribution of Fe, Mn, Cu, Ni and Co in coexisting manganese nodules and micronodules. Mar. Geol. 1978, 28, M9–M17. [Google Scholar] [CrossRef]

- Elderfield, H.; Hawkesworth, C.; Greaves, M.; Calvert, S. Rare earth element geochemistry of oceanic ferromanganese nodules and associated sediments. Geochim. Cosmochim. Acta 1981, 45, 513–528. [Google Scholar] [CrossRef]

- Menendez, A.; James, R.H.; Roberts, S.; Peel, K.; Connelly, D. Controls on the distribution of rare earth elements in deep-sea sediments in the North Atlantic Ocean. Ore Geol. Rev. 2017, 87, 100–113. [Google Scholar] [CrossRef]

- Liao, J.; Sun, X.; Wu, Z.; Sa, R.; Guan, Y.; Lu, Y.; Li, D.; Liu, Y.; Deng, Y.; Pan, Y. Fe-Mn (oxyhydr)oxides as an indicator of REY enrichment in deep-sea sediments from the central North Pacific. Ore Geol. Rev. 2019, 112, 103044. [Google Scholar] [CrossRef]

- Yasukawa, K.; Kino, S.; Azami, K.; Tanaka, E.; Mimura, K.; Ohta, J.; Fujinaga, K.; Nakamura, K.; Kato, Y. Geochemical characteristics of Fe-Mn micronodules in deep-sea sediments from the Northwest Pacific Ocean: Metal extraction potential from by-products of rich REY mud. Ore Geol. Rev. 2020, 127, 103085. [Google Scholar] [CrossRef]

- Nakamura, K.; Fujinaga, K.; Yasukawa, K.; Takaya, Y.; Ohta, J.; Machida, S.; Haraguchi, S.; Kato, Y. REY-rich mud: A deep-sea mineral resource for rare earths and yttrium. In Handbook on the Physics and Chemistry of Rare Earths; Elsevier: Amsterdam, The Netherlands, 2015; Volume 46, pp. 79–127. [Google Scholar] [CrossRef]

- Yamazaki, T.; Yamamoto, Y.; Nakatani, N.; Arai, R. Preliminary Economic Evaluation of Deep- Sea REE Mud Mining. Am. Soc. Mech. Eng. 2014, 45493, V007T05A001. [Google Scholar] [CrossRef]

- Shi, X.; Bi, D.; Huang, M.; Yu, M.; Luo, Y.; Zhou, T.; Zhang, Z.; Liu, J. Distribution and metallogenesis of deep-sea rare earth elements. Geol. Bull. China 2021, 40, 195–208. [Google Scholar]

- Huang, M.; Shi, X.; Bi, D.; Yu, M.; Li, L.; Li, J.; Zhang, P.; Zhang, X.; Liu, J.; Yang, G.; et al. Advances on study of exploration and development of deep-sea rare earth resources. Chin. J. Nonferrous Met. 2021, 31, 2665–2681. [Google Scholar] [CrossRef]

- Shen, H. Rare earth elements in deep sea sediments. Geochimica 1990, 19, 340–348. [Google Scholar]

- Addy, S.K. Rare earth element patterns in manganese nodules and micronodules from northwest Atlantic. Geochim. Cosmochim. Acta 1979, 43, 1105–1115. [Google Scholar] [CrossRef]

- Liu, J. Geochemistry of REE of deep sea sediments in the East Pacific Ocean. Mar. Geol. Quat. Geol. 1992, 12, 33–42. [Google Scholar]

- Liu, J. The Geochemistry of REEs and Nd Isotope in Deep-Sea Sediments from the Eastern Pacific and Their Geological Implications; Chinese Academy of Sciences, The Institute of Oceanology: Qingdao, China, 2004. [Google Scholar]

- Liu, J.; Liang, H.; Xia, N. REE geochemistry of <2 μm fractions in deep-sea sediments from East Pacific. Geochimica 1998, 27, 49–58. [Google Scholar] [CrossRef]

- Hein, J.R.; Spinardi, F.; Okamoto, N.; Mizell, K.; Thorburn, D.; Tawake, A. Critical metals in manganese nodules from the Cook Islands EEZ, abundances and distributions. Ore Geol. Rev. 2015, 68, 97–116. [Google Scholar] [CrossRef]

- Yu, M.; Deng, X.; Yao, H.; Liu, Y. Investigation and research progress of polymetallic nodules in the world seabed. Geol. China 2018, 45, 29–38. [Google Scholar] [CrossRef]

- Morgan, C.L. Resource estimates of the Clarion–Clipperton manganese nodule deposits. In Handbook of Marine Mineral Deposits; Cronan, D.S., Ed.; CRC Press: Boca Raton, FL, USA, 2000; pp. 145–170. [Google Scholar]

- Hein, J.R.; Koschinsky, A. Deep-Ocean Ferromanganese Crusts and Nodules, 2nd ed.; Elsevier: Oxford, UK, 2014; Volume 13, pp. 273–291. [Google Scholar] [CrossRef]

- Van Nijen, K.; Van Passel, S.; Squires, D. A stochastic techno-economic assessment of seabed mining of polymetallic nodules in the Clarion Clipperton Fracture Zone. Mar. Policy 2018, 95, 133–141. [Google Scholar] [CrossRef]

- Zhu, M.; Sun, X.; Liu, R.; Xu, H. Development Strategies for Rare Earth Functional Materials by 2035. Chin. J. Eng. Sci. 2020, 22, 37–43. [Google Scholar] [CrossRef]

- Spickermann, R. Rare earth content of manganese nodules in the Lockheed Martin Clarion–Clipperton Zone exploration areas. In Proceedings of the Offshore Technology Conference Number OTC-23084-MS, Houston, TX, USA, 30 April–3 May 2012; pp. 1–6. [Google Scholar]

- Milinovic, J.; Rodrigues, F.J.L.; Barriga, F.J.A.S.; Murton, B.J. Ocean-Floor Sediments as a Resource of Rare Earth Elements: An Overview of Recently Studied Sites. Minerals 2021, 11, 142. [Google Scholar] [CrossRef]

- Parhi, P.; Park, K.; Nam, C.; Park, J. Liquid-liquid extraction and separation of total rare earth (RE) metals from polymetallic manganese nodule leaching solution. J. Rare Earths 2015, 33, 207–213. [Google Scholar] [CrossRef]

- Zawadzki, D.; Maciąg, Ł.; Abramowski, T.; McCartney, K. Fractionation Trends and Variability of Rare Earth Elements and Selected Critical Metals in Pelagic Sediment from Abyssal Basin of NE Pacific (Clarion-Clipperton Fracture Zone). Minerals 2020, 10, 320. [Google Scholar] [CrossRef]

- Huang, M.; Liu, J.H.; Shi, X.F.; Zhu, A. Distribution characteristics and resource significance of rare earth elements in surface sediments of the Pacific Ocean. In Proceedings of the 15th Academic Annual Meeting of the Chinese Society of Mineral and Rock Geochemistry, Changchun, China, 23–29 June 2015. [Google Scholar]

- Huang, M. Preliminary Study on the Geochemical Characteristics and Resource Potential of Rare Earth Elements in DeepSea Sediments of the Pacific Ocean; The First Institute of Oceanography, State Oceanic Administration: Qingdao, China, 2014. [Google Scholar]

- Mu, H.; Jihua, L.; Xuefa, S.; Aimei, Z.; Huahua, L.; Limin, H. Geochemical characteristics and material sources of rare earth elements in sediments from the CCZ in the eastern Pacific ocean. Adv. Mar. Sci. 2014, 32, 175–187. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, Y.M.; Zhang, K.; Zhu, Y.; Zhu, K.; Li, W.; Zhu, W. Acid Leaching of Rare Earth Yttrium in Pelagic Clay from Central Pacific Ocean. Min. Eng. 2017, 37, 94–100. [Google Scholar] [CrossRef]

- Chen, J.; Gu, D. Mining Economics; Central South University Press: Changsha, China, 2017; pp. 166–194. [Google Scholar]

- Kirchain, R.; Roth, R.; Field, F.R.; Muñoz-Royo, C.; Peacock, T. Report to the International Seabed Authority on the Development of an Economic Model and System of Payments for the Exploitation of Polymetallic Nodules in the Area; Massachusetts Institute of Technology: Cambridge, MA, USA, 2019; pp. 77–90. [Google Scholar]

- Bashir, M.B.; Kim, S.H.; Kiosidou, E.; Wolgamot, H.; Zhang, W. A Concept for Seabed Rare Earth Mining in the Eastern South Pacific; University of Southampton: Southampton, Britain, 2012; pp. 66–96. [Google Scholar]

- Zhang, K.; Wei, B.; Tao, J.; Zhong, X.; Zhu, W.; Wang, R.; Liu, Z. Recovery of rare earth elements from deep-sea mud using acid leaching followed by selective solvent extraction with N1923 and TBP. Sep. Purif. Technol. 2023, 318, 124013. [Google Scholar] [CrossRef]

- Toro, N.; Gálvez, E.; Saldaña, M.; Jeldres, R.I. Submarine mineral resources: A potential solution to political conflicts and global warming. Miner. Eng. 2022, 179, 107441. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).