Applicability of Paper and Pulp Industry Waste for Manufacturing Mycelium-Based Materials for Thermoacoustic Insulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Physicochemical and Microstructural Characterization of Sludge

2.3. Preparation of Biomaterial

2.3.1. Fungal Inoculum

2.3.2. Substrate Preparation

2.3.3. Mycelium Cultivation and Deactivation

2.4. Hyphae Growth Rate

2.5. Characterization of MBM

2.6. Thermal and Acoustic Analysis

2.7. Data Analysis

3. Results and Discussion

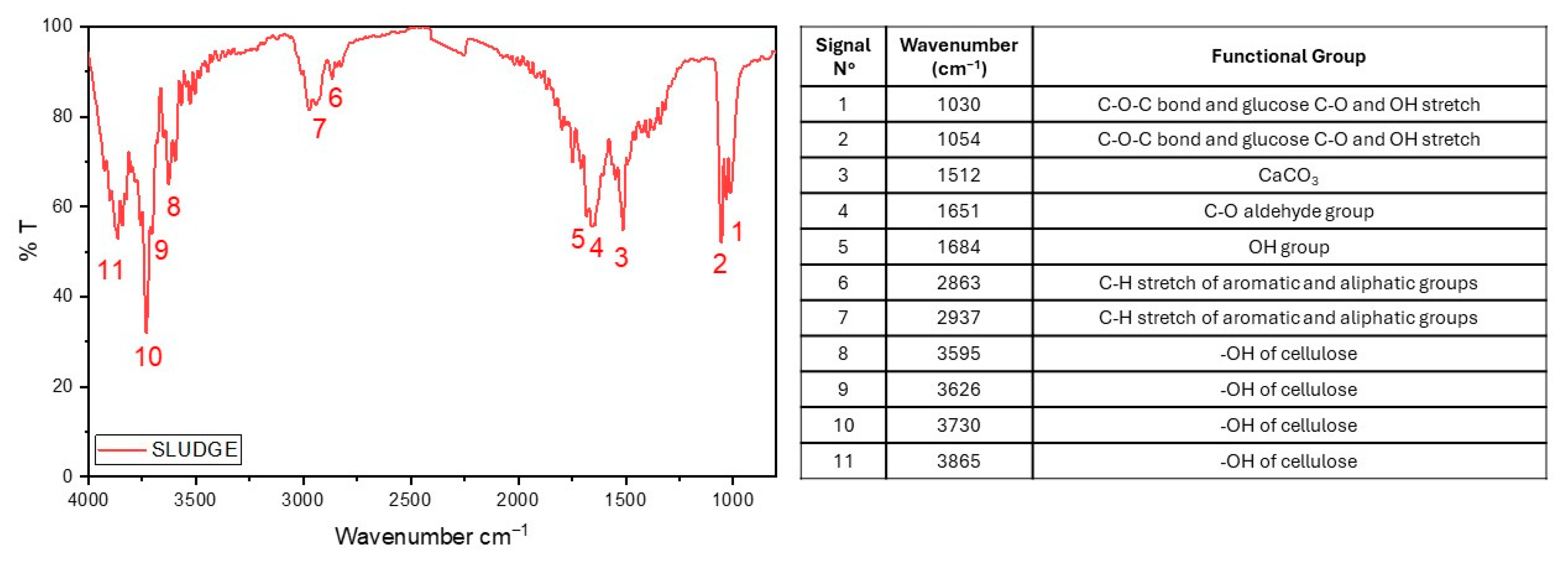

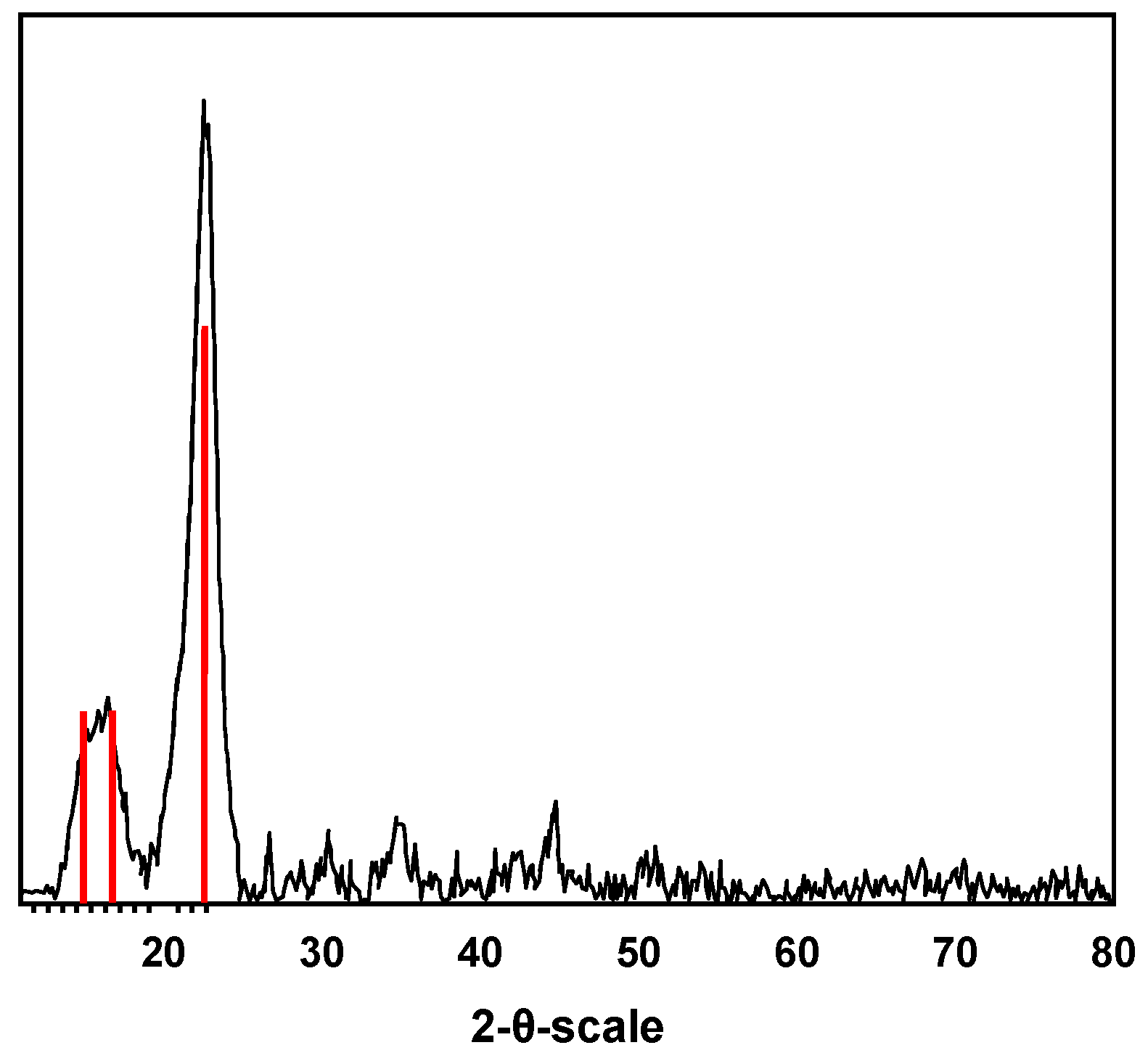

3.1. Physicochemical Characterization of Sludge

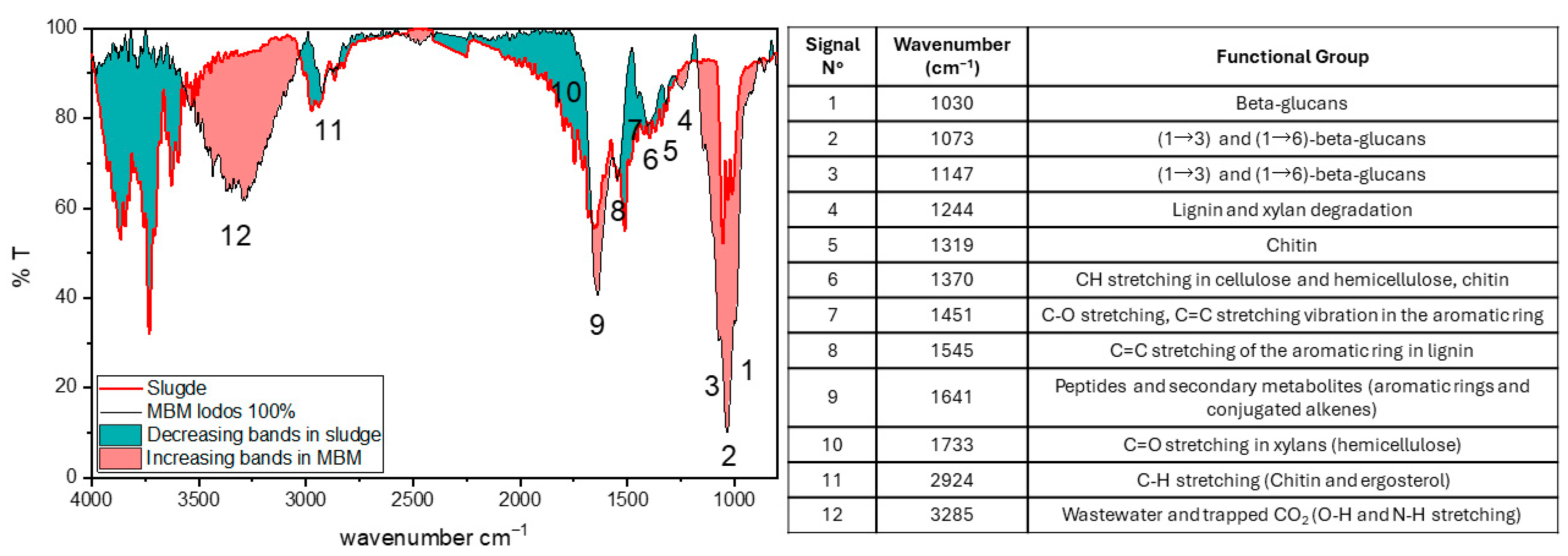

3.2. Physicochemical Analysis of Biomaterials

3.3. Thermoacoustic Analysis of Biomaterials

3.4. Prospect for Large-Scale Industrial Use

- The selection of fungal species: Using native fungi adapted to local conditions could make the production process more efficient and sustainable [32,54]. These fungi thrive in their local environment, leading to better and more consistent growth on forest debris. Alternatively, using economically damaging fungi such as Trametes versicolor [55], known for their efficiency in breaking down lignocellulosic materials, could reduce the energy required for incubation.

- The optimization of growth parameters: The optimization of parameters such as temperature, humidity, aeration, and modularity to allow the exchange of energy and matter during the growth process could improve the properties and consistency of the final product [56].

- Sterilization: For large-scale production, it is essential to investigate methods that enable the rapid sterilization of substrates, such as nuclear radiation, to ensure the development of microbiologically contamination-free biomaterials [59].

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ardente, F.; Beccali, M.; Cellura, M.; Mistretta, M. Building Energy Performance: A LCA Case Study of Kenaf-Fibres Insulation Board. Energy Build. 2008, 40, 1–10. [Google Scholar] [CrossRef]

- Kulakovskaya, A.; Wiprächtiger, M.; Knoeri, C.; Bening, C.R. Integrated Environmental-Economic Circular Economy Assessment: Application to the Case of Expanded Polystyrene. Resour. Conserv. Recycl. 2023, 197, 107069. [Google Scholar] [CrossRef]

- Vila-Cortavitarte, M.; Lastra-González, P.; Calzada-Pérez, M.Á.; Indacoechea-Vega, I. Analysis of the Influence of Using Recycled Polystyrene as a Substitute for Bitumen in the Behaviour of Asphalt Concrete Mixtures. J. Clean. Prod. 2018, 170, 1279–1287. [Google Scholar] [CrossRef]

- Oswald, F. Recycling and Reutilisation Opportunities and Techniques of the Insulation Material EPS (Expanded Polystyrene) after the Lifetime of EIFS (Exterior Insulation Finishing System). In Sustainability and Toxicity of Building Materials—Manufacture, Use and Disposal Stages; Elsevier: Amsterdam, The Netherlands, 2024; ISBN 9780323983365. [Google Scholar]

- Cerimi, K.; Akkaya, K.C.; Pohl, C.; Schmidt, B.; Neubauer, P. Fungi as Source for New Bio-Based Materials: A Patent Review. Fungal Biol. Biotechnol. 2019, 6, 1–10. [Google Scholar] [CrossRef]

- Al-Qahtani, S.; Koç, M.; Isaifan, R.J. Mycelium-Based Thermal Insulation for Domestic Cooling Footprint Reduction: A Review. Sustainability 2023, 15, 13217. [Google Scholar] [CrossRef]

- Volk, R.; Schröter, M.; Saeidi, N.; Steffl, S.; Javadian, A.; Hebel, D.E.; Schultmann, F. Life Cycle Assessment of Mycelium-Based Composite Materials. Resour. Conserv. Recycl. 2024, 205, 107579. [Google Scholar] [CrossRef]

- Charpentier-Alfaro, C.; Benavides-Hernández, J.; Poggerini, M.; Crisci, A.; Mele, G.; Della Rocca, G.; Emiliani, G.; Frascella, A.; Torrigiani, T.; Palanti, S. Wood-Decaying Fungi: From Timber Degradation to Sustainable Insulating Biomaterials Production. Materials 2023, 16, 3547. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Farrokhsiar, P.; Vieira, F.; Pecchia, J.; Gursoy, B. Mycelium-Based Bio-Composites for Architecture. Mater. Res. Innov. 2019, 2, 505–514. [Google Scholar]

- Attias, N.; Reid, M.; Mijowska, S.C.; Dobryden, I.; Isaksson, M.; Pokroy, B.; Grobman, Y.J.; Abitbol, T. Biofabrication of Nanocellulose–Mycelium Hybrid Materials. Adv. Sustain. Syst. 2021, 5, 2000196. [Google Scholar] [CrossRef]

- Teixeira, J.L.; Matos, M.P.; Nascimento, B.L.; Griza, S.; Holanda, F.S.R.; Marino, R.H. Production and Mechanical Evaluation of Biodegradable Composites by White Rot Fungi. Ciênc. Agrotecnol. 2018, 42, 676–684. [Google Scholar] [CrossRef]

- Huang, D.; Guo, X.; Peng, Z.; Zeng, G.; Xu, P.; Gong, X.; Deng, R.; Xue, W.; Wang, R.; Yi, H.; et al. White Rot Fungi and Advanced Combined Biotechnology with Nanomaterials: Promising Tools for Endocrine-Disrupting Compounds Biotransformation. Crit. Rev. Biotechnol. 2018, 38, 671–689. [Google Scholar] [CrossRef]

- Harshvardhan, A.; Saikia, P. Microbial Bioremediation: A Sustainable Approach for Restoration of Contaminated Sites. In Microbes in Agri-Forestry Biotechnology; CRC Press: Boca Raton, FL, USA, 2022; ISBN 9789811518119. [Google Scholar]

- Nussbaumer, M.; Van Opdenbosch, D.; Engelhardt, M.; Briesen, H.; Benz, J.P.; Karl, T. Material Characterization of Pressed and Unpressed Wood–Mycelium Composites Derived from Two Trametes Species. Environ. Technol. Innov. 2023, 30, 103063. [Google Scholar] [CrossRef]

- Xing, Y.; Brewer, M.; El-Gharabawy, H.; Griffith, G.; Jones, P. Growing and Testing Mycelium Bricks as Building Insulation Materials. IOP Conf. Ser. Earth Environ. Sci. 2018, 121, 022032. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Damsin, B.; Van Wylick, A.; Peeters, E.; De Laet, L. Mechanical Characteristics of Bacterial Cellulose-Reinforced Mycelium Composite Materials. Fungal Biol. Biotechnol. 2021, 8, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Hu, J.; Fan, X.; Yu, X. Naturally Grown Mycelium-Composite as Sustainable Building Insulation Materials. J. Clean. Prod. 2022, 342, 130784. [Google Scholar] [CrossRef]

- Bhagavathi, L.R.; Deshpande, A.P.; Ram, G.D.J.; Panigrahi, S.K. Effect of Cellulosic Fillers Addition on Curing and Adhesion Strength of Moisture-Curing One-Component Polyurethane Adhesives. Int. J. Adhes. Adhes. 2021, 108, 102871. [Google Scholar] [CrossRef]

- Marcuello, C.; Foulon, L.; Chabbert, B.; Molinari, M.; Aguié-Béghin, V. Langmuir-Blodgett Procedure to Precisely Control the Coverage of Functionalized AFM Cantilevers for SMFS Measurements: Application with Cellulose Nanocrystals. Langmuir 2018, 34, 9376–9386. [Google Scholar] [CrossRef]

- Blauwhoff, D.; La Bianca, I. From Biomass to Mycelium Composite: An Exploration on Cellulose and Weed Residues; Stichting Toegepast Onderzoek Waterbeheer (STOWA): Amersfoort, The Netherlands, 2019. [Google Scholar]

- Sayfutdinova, A.; Samofalova, I.; Barkov, A.; Cherednichenko, K.; Rimashevskiy, D.; Vinokurov, V. Structure and Properties of Cellulose/Mycelium Biocomposites. Polymers 2022, 14, 1519. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Gürsoy, B. Mycelium-Based Composite Graded Materials: Assessing the Effects of Time and Substrate Mixture on Mechanical Properties. Biomimetics 2022, 7, 48. [Google Scholar] [CrossRef]

- Sun, W.; Tajvidi, M.; Hunt, C.G.; McIntyre, G.; Gardner, D.J. Fully Bio-Based Hybrid Composites Made of Wood, Fungal Mycelium and Cellulose Nanofibrils. Sci. Rep. 2019, 9, 3766. [Google Scholar] [CrossRef]

- Quintana, E.; Valls, C.; Roncero, M.B. Valorization of Waste Paper Sludge as a Sustainable Source for Packaging Applications. Polym. Bull. 2024, 81, 9321–9345. [Google Scholar] [CrossRef]

- Faubert, P.; Barnabé, S.; Bouchard, S.; Côté, R.; Villeneuve, C. Pulp and Paper Mill Sludge Management Practices: What Are the Challenges to Assess the Impacts on Greenhouse Gas Emissions? Resour. Conserv. Recycl. 2016, 108, 107–133. [Google Scholar] [CrossRef]

- Turner, T.; Wheeler, R.; Oliver, I.W. Evaluating Land Application of Pulp and Paper Mill Sludge: A Review. J. Environ. Manag. 2022, 317, 115439. [Google Scholar] [CrossRef]

- Hazarika, J.; Khwairakpam, M. Evaluation of Biodegradation Feasibility through Rotary Drum Composting Recalcitrant Primary Paper Mill Sludge. Waste Manag. 2018, 76, 275–283. [Google Scholar] [CrossRef]

- Jackson, M.J.; Line, M.A. Organic Composition of a Pulp and Paper Mill Sludge Determined by FTIR, 13 C CP MAS NMR, and Chemical Extraction Techniques. J. Agric. Food Chem. 1997, 45, 2354–2358. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Park, S.C. Pretreatment of Wastepaper and Pulp Mill Sludge by Aqueous Ammonia and Hydrogen Peroxide. Appl. Biochem. Biotechnol. 2000, 84, 129–139. [Google Scholar] [CrossRef]

- Aiduang, W.; Chanthaluck, A.; Kumla, J.; Jatuwong, K.; Srinuanpan, S.; Waroonkun, T.; Oranratmanee, R.; Lumyong, S.; Suwannarach, N. Amazing Fungi for Eco-Friendly Composite Materials: A Comprehensive Review. J. Fungi 2022, 8, 1–28. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, Physical and Chemical Characterisation of Mycelium-Based Composites with Different Types of Lignocellulosic Substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.; Huynh, T.; John, S. Inherent Species Characteristic Influence and Growth Performance Assessment for Mycelium Composite Applications. Adv. Mater. Lett. 2018, 9, 71–80. [Google Scholar] [CrossRef]

- Collins, T.J. ImageJ for Microscopy. Biotechniques 2007, 43, S25–S30. [Google Scholar] [CrossRef]

- ISO 9427:2003; Wood-Based Panels—Determination of Density. The International Organization for Standardization: Geneva, Switzerland, 2003.

- ISO 16979:2003; Wood-Based Panels—Determination of Moisture Content. The International Organization for Standardization: Geneva, Switzerland, 2003.

- ASTM C1585-04; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D5334-08; Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. ASTM International: Conshohocken, PA, USA, 2005.

- Abdullah, A.; Mohamad, I.S.; Bani Hashim, A.Y.; Abdullah, N.; Wei, P.B.; Isa, M.H.M.; Abidin, S.Z. Thermal conductivity and viscosity of deionised water and ethylene glycol-based nanofluids. J. Mech. Eng. Sci. 2016, 10, 2249–2261. [Google Scholar] [CrossRef]

- ASTM E1050-24; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System. ASTM International: Conshohocken, PA, USA, 2024.

- Tao, J.; Wang, P.; Qiu, X.; Pan, J. Static flow resistivity measurements based on the ISO 10534.2 standard impedance tube. Build. Environ. 2015, 94, 853–858. [Google Scholar] [CrossRef]

- Hernández -Hernández, R.N.; Vázquez-García, R.Á.; Hernández-Ávila, J.; Veloz-Rodríguez, M.A.; Villagomez-Ibarra, J.R. Obtención de Celulosa Cristalina de Hoja de Maíz de Metztitlán Hidalgo. Pädi Bol. Cient. Cienc. Básicas Ing. ICBI 2021, 9, 7–12. [Google Scholar] [CrossRef]

- Yaras, A.; Arslanoğlu, H. Valorization of Paper Mill Sludge as Adsorbent in Adsorption Process of Copper (II) Ion from Synthetic Solution: Kinetic, Isotherm and Thermodynamic Studies. Arab. J. Sci. Eng. 2018, 43, 2393–2402. [Google Scholar] [CrossRef]

- Han, J.S.; Kang, D.S.; Seo, Y.B. Application of In Situ Calcium Carbonate Process for Producing Papermaking Fillers from Lime Mud. ACS Omega 2021, 6, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Clausi, M.; Pinto, D. Valorisation of Water Potabilization Sludges as Precursors for Alkali-Activated Binders: Characterization and Feasibility Study. Materials 2023, 16, 1998. [Google Scholar] [CrossRef]

- Padmanabhan, S.K.; Lionetto, F.; Nisi, R.; Stoppa, M.; Licciulli, A. Sustainable Production of Stiff and Crystalline Bacterial Cellulose from Orange Peel Extract. Sustainability 2022, 14, 2247. [Google Scholar] [CrossRef]

- Ren, W.; Guo, F.; Zhu, J.; Cao, M.; Wang, H.; Yu, Y. A Comparative Study on the Crystalline Structure of Cellulose Isolated from Bamboo Fibers and Parenchyma Cells. Cellulose 2021, 28, 5993–6005. [Google Scholar] [CrossRef]

- Sydor, M.; Cofta, G.; Doczekalska, B.; Bonenberg, A. Fungi in Mycelium-Based Composites: Usage and Recommendations. Materials 2022, 15, 6283. [Google Scholar] [CrossRef]

- Schoder, K.A.; Krümpel, J.; Müller, J.; Lemmer, A. Effects of Environmental and Nutritional Conditions on Mycelium Growth of Three Basidiomycota. Mycobiology 2024, 52, 124–134. [Google Scholar] [CrossRef]

- Alves, R.M.; Alves, M.L.; Campos, M.J. Morphology and Thermal Behaviour of New Mycelium-Based Composites with Different Types of Substrates. In Progress in Digital and Physical Manufacturing, Proceedings of the ProDPM’19, Leiria, Portugal, 2–4 October 2019; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 189–197. ISBN 9783030290405. [Google Scholar]

- Pedroso, M.; de Brito, J.; Silvestre, J.D. Characterization of Eco-Efficient Acoustic Insulation Materials (Traditional and Innovative). Constr. Build. Mater. 2017, 140, 221–228. [Google Scholar] [CrossRef]

- Yucel, K.T.; Basyigit, C.; Ozel, C. Thermal Insulation Properties of Expanded Polystyrene as Construction and Insulating Materials. In Proceedings of the 15th Symposium on Thermophysical Properties, Boulder, CO, USA, 22–27 June 2003; pp. 54–66. [Google Scholar]

- Lafond, C.; Blanchet, P. Technical Performance Overview of Bio-Based Expanded Polystyrene. Buildings 2020, 10, 81. [Google Scholar] [CrossRef]

- Shakir, M.A.; Ahmad, M.I. Bioproduct Advances: Insight into Failure Factors in Mycelium Composite Fabrication. Biofuels Bioprod. Biorefining 2024, 1–16. [Google Scholar] [CrossRef]

- Livne, A.; Pearlmutter, D.; Gal, E.; Wösten, H.A.B. Increased CO2 Fixation and Reduced Embodied Energy of Mycelium Bio-Composite Materials Grown on a Mixed Substrate over Diurnal Temperature Cycles. Constr. Build. Mater. 2024, 421, 135566. [Google Scholar] [CrossRef]

- Tišma, M.; Žnidaršič-Plazl, P.; Šelo, G.; Tolj, I.; Šperanda, M.; Bucić-Kojić, A.; Planinić, M. Trametes Versicolor in Lignocellulose-Based Bioeconomy: State of the Art, Challenges and Opportunities. Bioresour. Technol. 2021, 330, 124997. [Google Scholar] [CrossRef]

- Bonga, K.B.; Bertolacci, L.; Contardi, M.; Paul, U.C.; Zafar, M.S.; Mancini, G.; Marini, L.; Ceseracciu, L.; Fragouli, D.; Athanassiou, A. Mycelium Agrowaste-Bound Biocomposites as Thermal and Acoustic Insulation Materials in Building Construction. Macromol. Mater. Eng. 2024, 309, 2300449. [Google Scholar] [CrossRef]

- Manan, S.; Ullah, M.W.; Ul-Islam, M.; Atta, O.M.; Yang, G. Synthesis and Applications of Fungal Mycelium-Based Advanced Functional Materials. J. Bioresour. Bioprod. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Van Wylick, A.; Elsacker, E.; Yap, L.L.; Peeters, E.; de Laet, L. Mycelium Composites and Their Biodegradability: An Exploration on the Disintegration of Mycelium-Based Materials in Soil. Constr. Technol. Archit. 2022, 1, 652–659. [Google Scholar]

- Williams, E.; Cenian, K.; Golsteijn, L.; Morris, B.; Scullin, M.L. Life Cycle Assessment of MycoWorks’ ReishiTM: The First Low-Carbon and Biodegradable Alternative Leather. Environ. Sci. Eur. 2022, 34, 120. [Google Scholar] [CrossRef]

| Apparent Density (g/cm3) | Humidity (%) | pH | Cellulose (%) | Hemicellulose (%) | Lignin (%) |

|---|---|---|---|---|---|

| 0.419–0.598 | 50–75 | 6.8–8.2 | 57–72 | 8.0–12.4 | 19.7–32.5 |

| Humidity (%) | pH | Organic Matter Content (%) | Ash Content (%) | Color |

|---|---|---|---|---|

| 85 ± 2 | 7.49 ± 0.07 | 11.45 ± 0.02 | 1.44 ± 0.1 | Grayish |

| Ca | Na | K | As | Ba | B | Cd | V | Hg |

| 1100.2 ± 5.7 | 3730 ± 1.7 | 1378 ± 4.0 | 4.3 ± 0.1 | 781.4 ± 2.2 | 135.5 ± 1.2 | 0.5 ± 0.01 | 38.7 ± 0.6 | <0.25 |

| Co | Cr | Cu | Mo | Ni | Pb | Se | Zn | Au |

| 1.3 ± 0.01 | 5.6 ± 0.02 | 12.3 ± 0.1 | 3.2 ± 0.04 | 9.3 ± 0.2 | 1.5 ± 0.02 | <0.22 | 94.7 ± 0.2 | <0.23 |

| Material | Density (g/cm3) | Noise Reduction Coefficient (NRC) | Sound Absorption (SAA) |

|---|---|---|---|

| Sludge biomaterial with T. versicolor | 0.689 | 0.25 ± 0.02 | 0.25 ± 0.02 |

| Expanded polyurethane | 0.028 | 0.50 | - |

| Extruded polyurethane | 0.025 | 0.33 | - |

| Material | Substrate | Thermal Conductivity Coefficient (W/m K) |

|---|---|---|

| Mycelium-based material | Sludge | 0.052 ± 0.003 |

| Fiberglass | Not applicable | 0.033–0.045 |

| Extruded polystyrene | Not applicable | 0.025–0.035 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muñoz, H.; Molina, P.; Urzúa-Parra, I.A.; Vasco, D.A.; Walczak, M.; Rodríguez-Grau, G.; Chateau, F.; Sancy, M. Applicability of Paper and Pulp Industry Waste for Manufacturing Mycelium-Based Materials for Thermoacoustic Insulation. Sustainability 2024, 16, 8034. https://doi.org/10.3390/su16188034

Muñoz H, Molina P, Urzúa-Parra IA, Vasco DA, Walczak M, Rodríguez-Grau G, Chateau F, Sancy M. Applicability of Paper and Pulp Industry Waste for Manufacturing Mycelium-Based Materials for Thermoacoustic Insulation. Sustainability. 2024; 16(18):8034. https://doi.org/10.3390/su16188034

Chicago/Turabian StyleMuñoz, Hugo, Paulo Molina, Ignacio A. Urzúa-Parra, Diego A. Vasco, Magdalena Walczak, Gonzalo Rodríguez-Grau, Francisco Chateau, and Mamié Sancy. 2024. "Applicability of Paper and Pulp Industry Waste for Manufacturing Mycelium-Based Materials for Thermoacoustic Insulation" Sustainability 16, no. 18: 8034. https://doi.org/10.3390/su16188034

APA StyleMuñoz, H., Molina, P., Urzúa-Parra, I. A., Vasco, D. A., Walczak, M., Rodríguez-Grau, G., Chateau, F., & Sancy, M. (2024). Applicability of Paper and Pulp Industry Waste for Manufacturing Mycelium-Based Materials for Thermoacoustic Insulation. Sustainability, 16(18), 8034. https://doi.org/10.3390/su16188034