Robust Load Frequency Control of Interconnected Power Systems with Back Propagation Neural Network-Proportional-Integral-Derivative-Controlled Wind Power Integration

Abstract

1. Introduction

- (1)

- In the context of high wind power penetration, it is essential to address issues such as frequency instability due to the participation of wind power in power grids. Therefore, in response to the non-dispatchability and stochastic nature of wind power output, a rated wind power tracking controller based on BPNN-PID is proposed.

- (2)

- To mitigate the impacts of fluctuant wind power on system frequency of the main grid, an adaptive robust controller is presented by incorporating the H∞ performance criteria.

2. Modeling and Controller Design

2.1. Wind Turbine Modelling

2.2. BPNN-Based PID Controller for Rated Wind Power Tracking

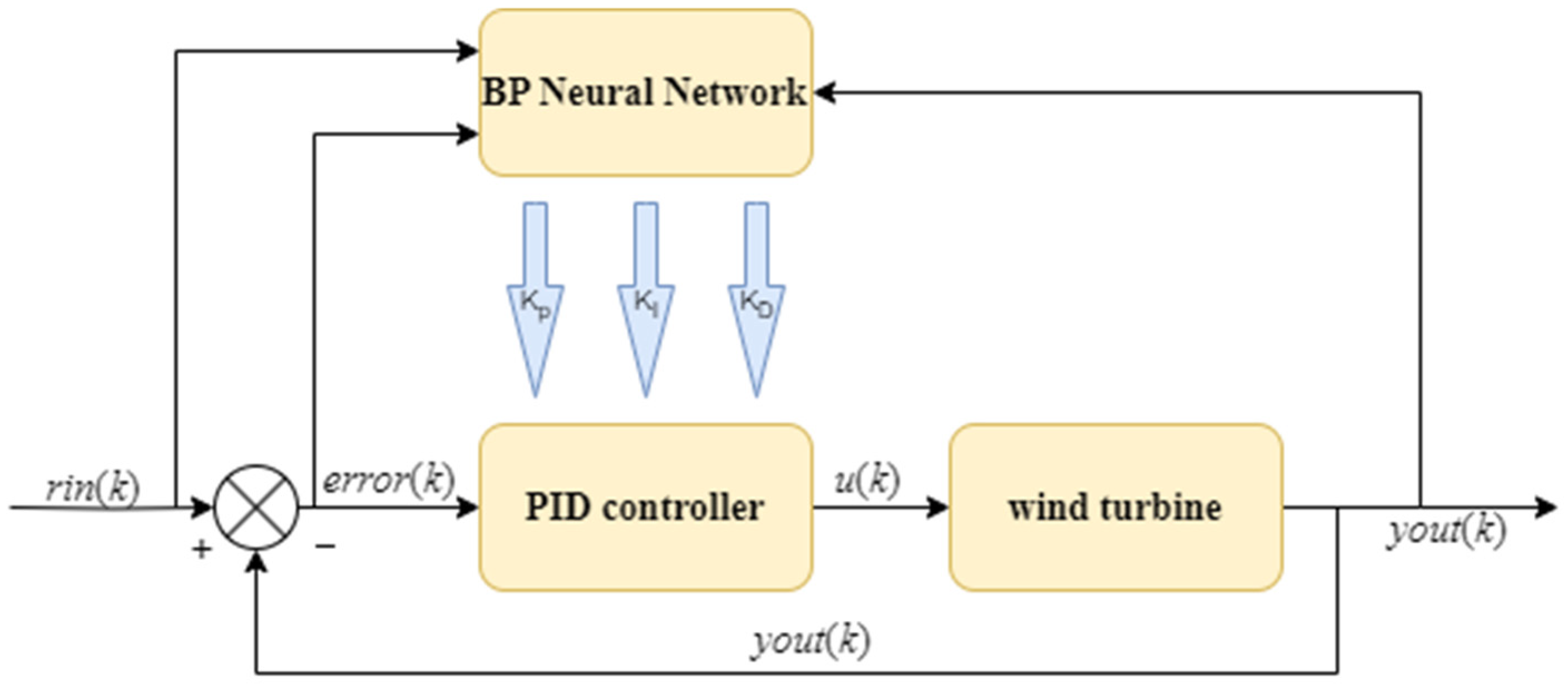

2.2.1. Structure of the Wind Turbine Controller Based on BPNN-PID

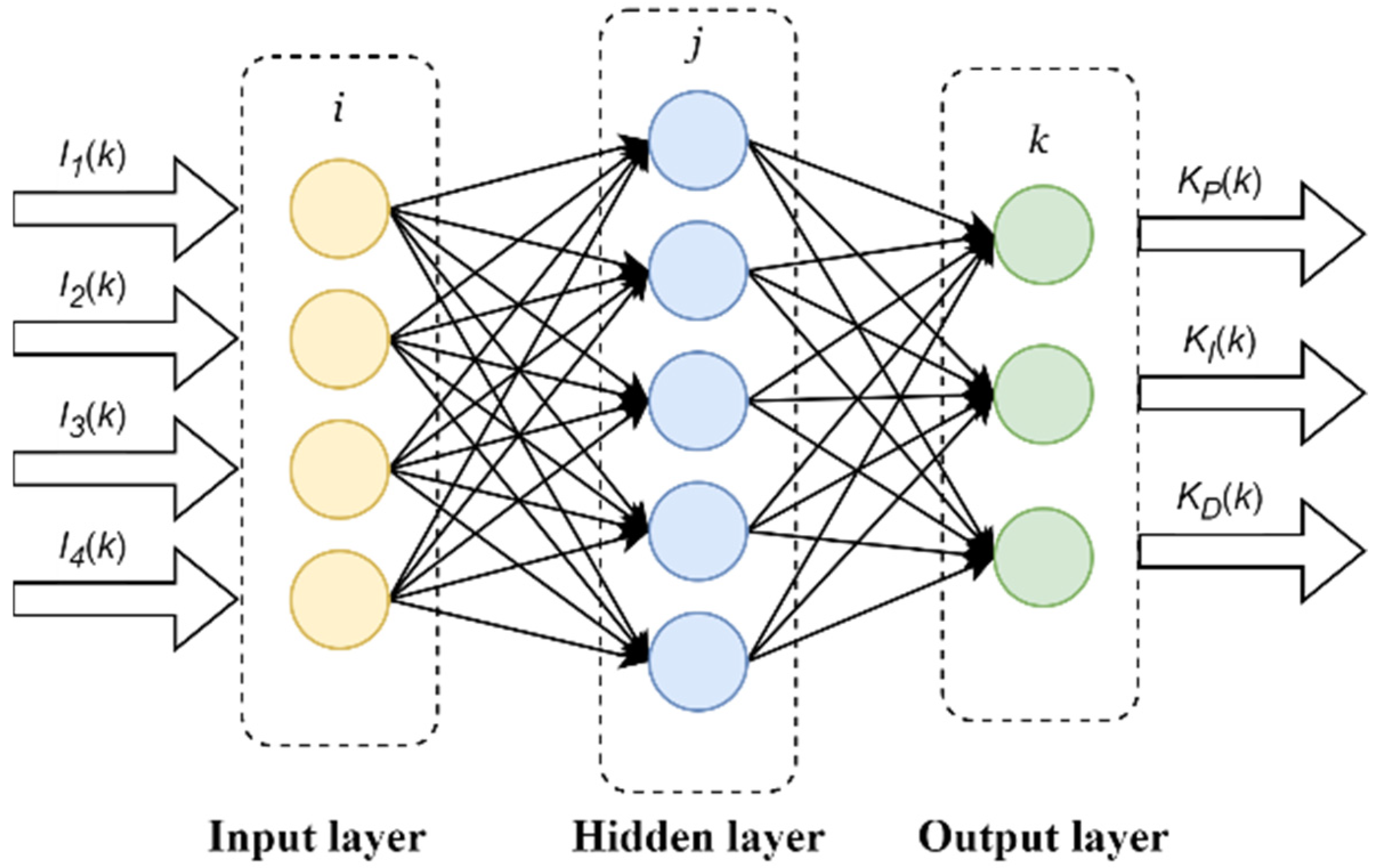

2.2.2. Forward Propagation of BPNN-PID Control

2.2.3. Back Propagation of BPNN-PID Control

2.3. Thermal Plant Modelling

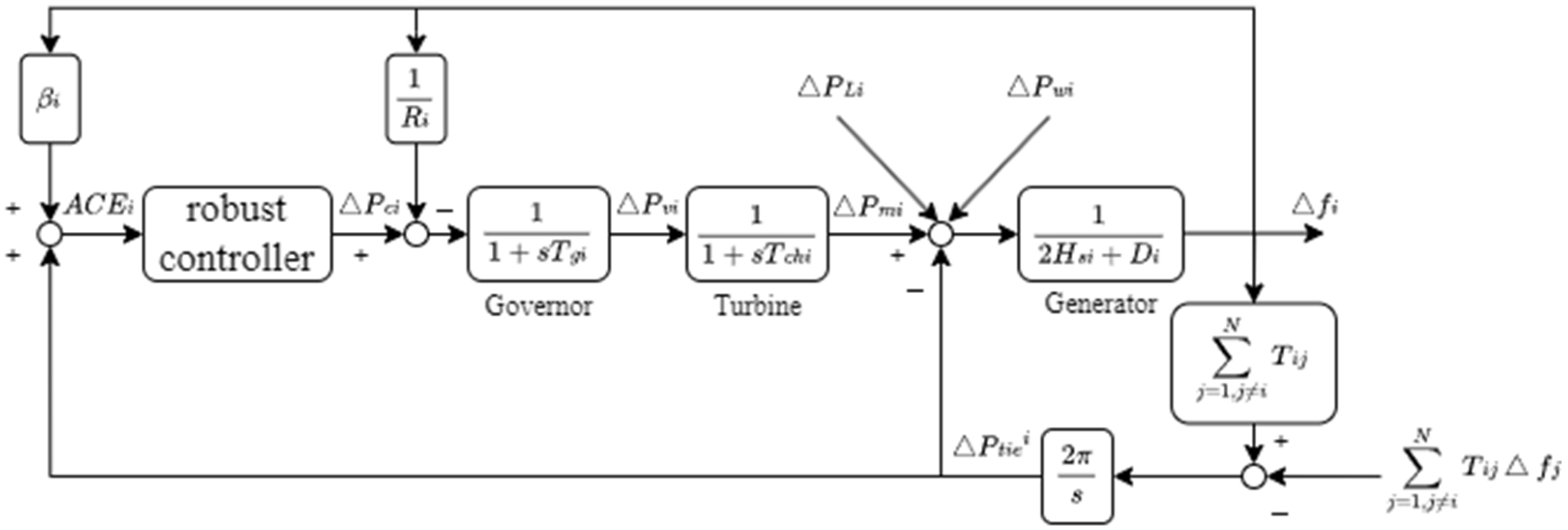

2.4. Robust LFC with Wind Turbine Power Penetration

3. Results

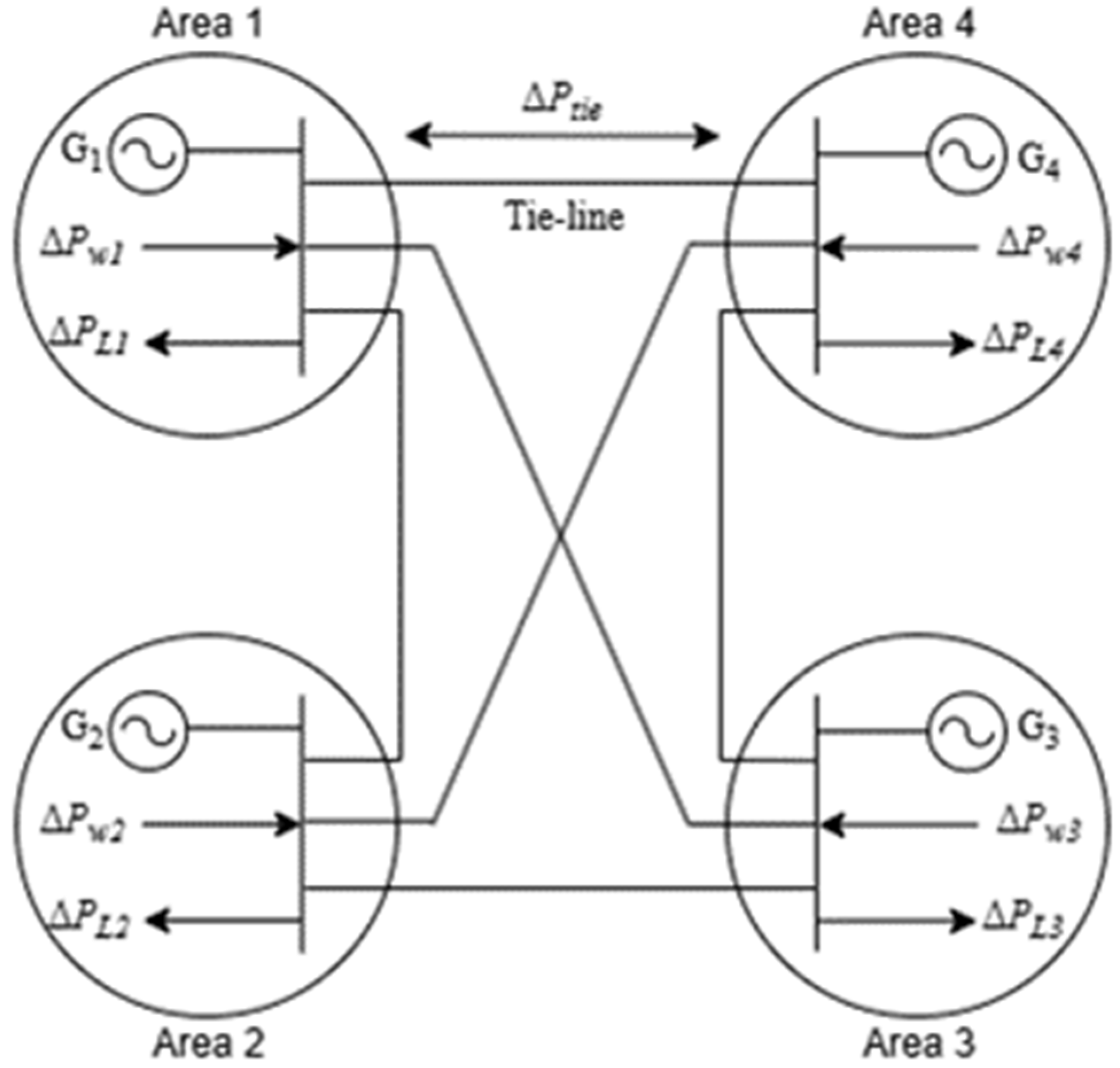

3.1. System Structure and Parameters

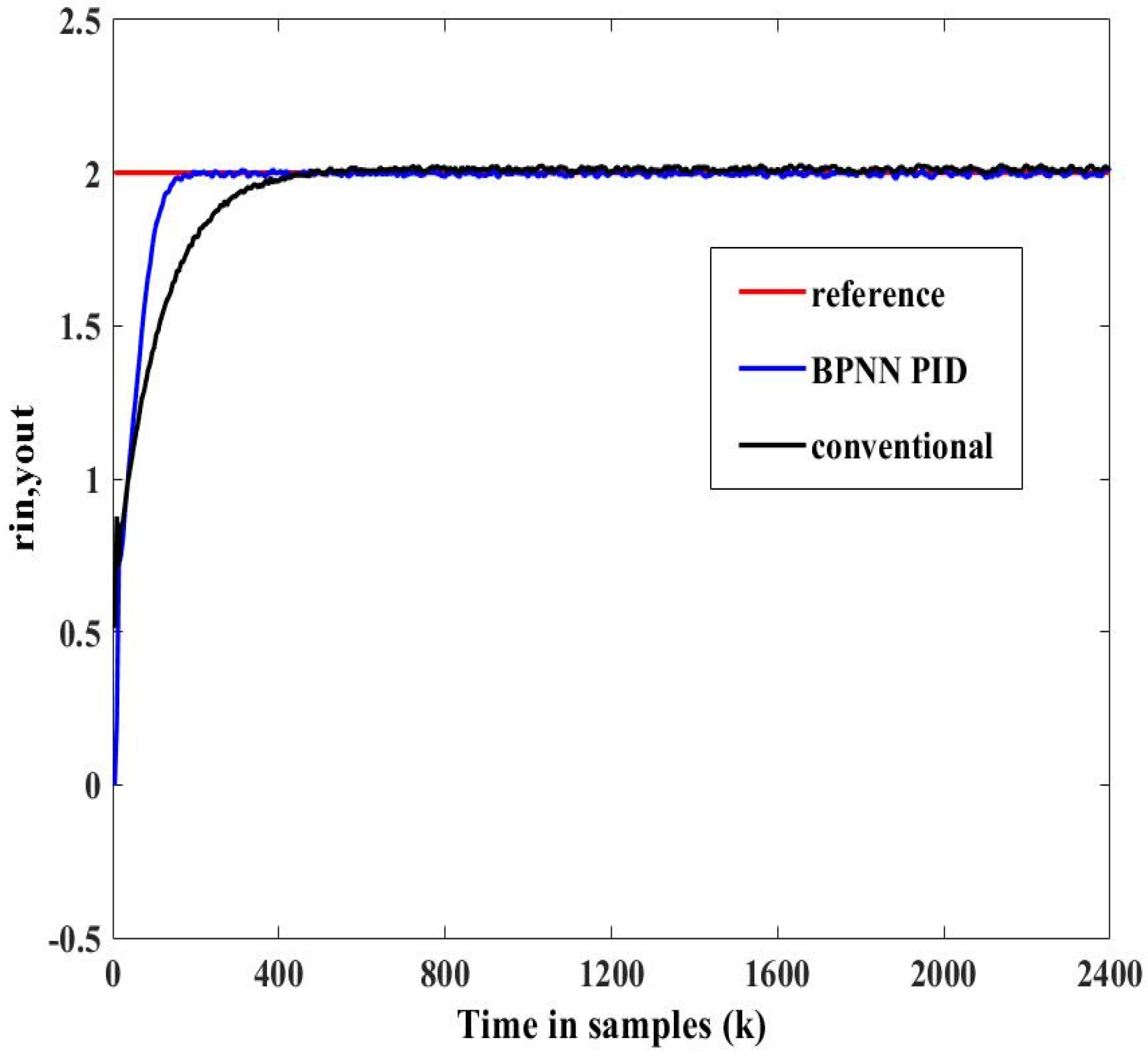

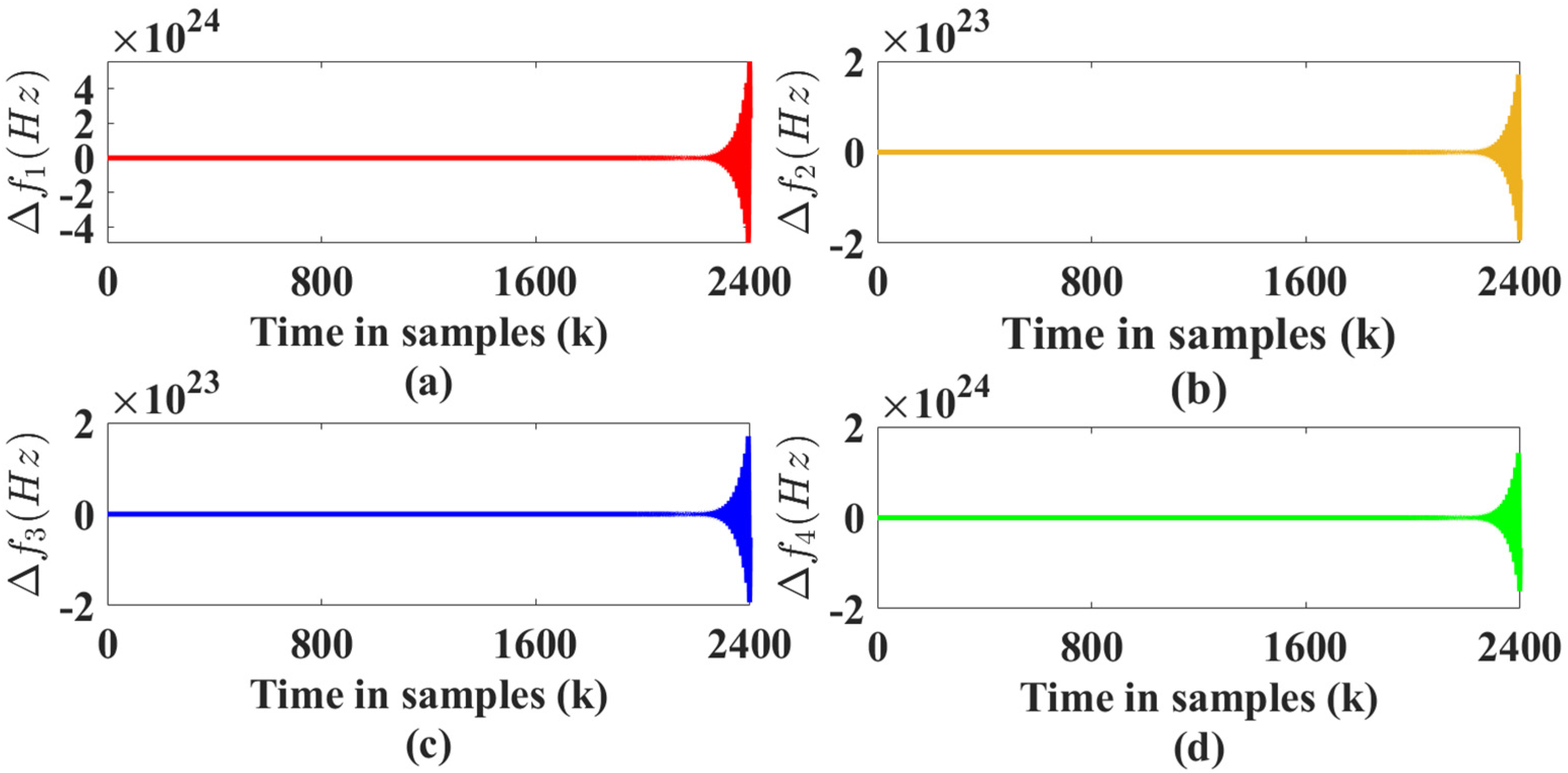

3.2. Validations on BPNN-Based PID Control for Wind Turbine

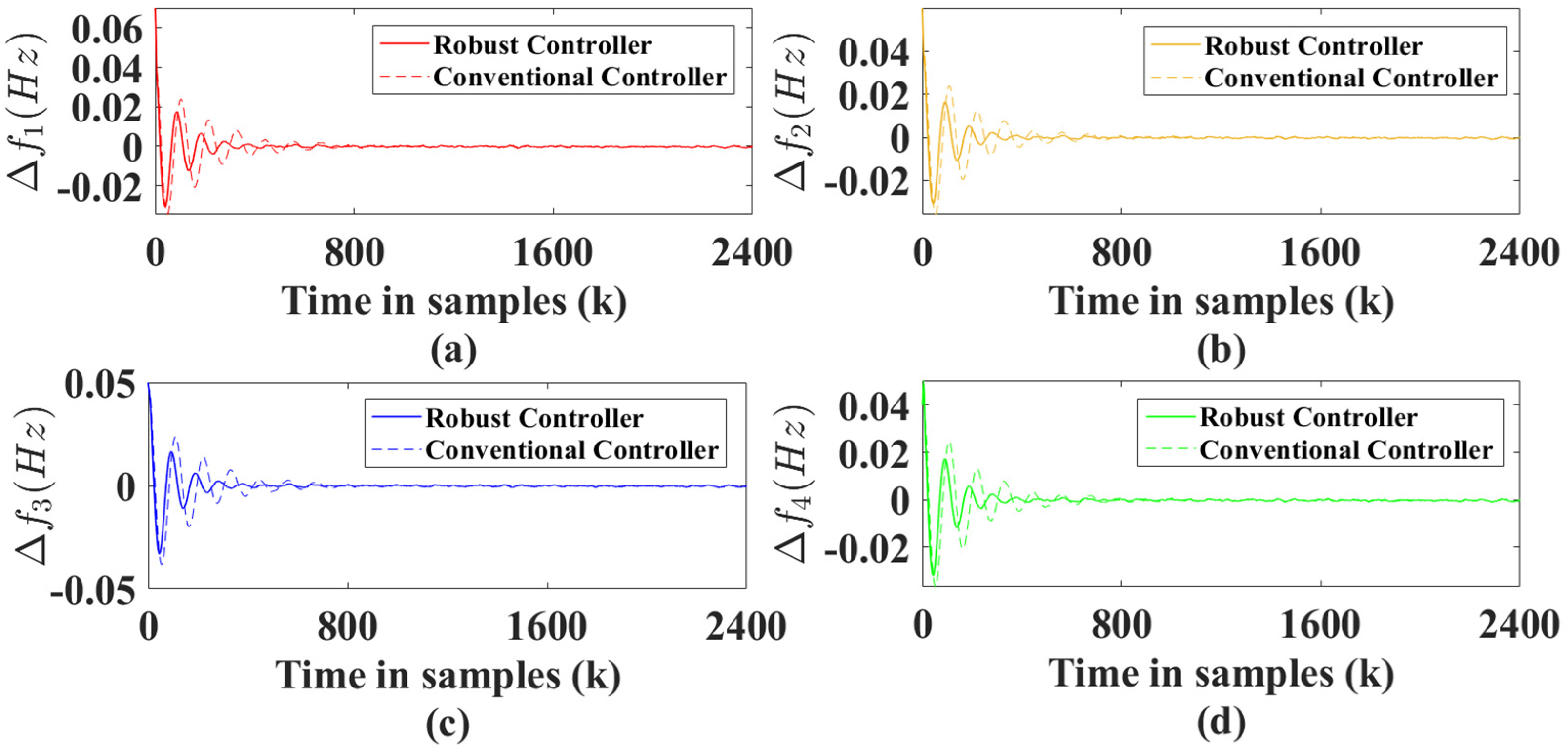

3.3. Robust Validations on LFC with Wind Turbine Integration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Renewables. Available online: www.iea.org/energy-system/renewables (accessed on 20 June 2024).

- Gayen, D.; Chatterjee, R.; Roy, S. A review on environmental impacts of renewable energy for sustainable development. Int. J. Environ. Sci. Technol. 2024, 21, 5285–5310. [Google Scholar] [CrossRef]

- Hanwate, S.; Hote, Y.V.; Saxena, S. Adaptive policy for load frequency control. IEEE Trans. Power Syst. 2017, 33, 1142–1144. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, K.; Geng, J.; Yuan, K.; Yang, Z.; Li, L. Multiobjective-based optimal allocation scheme for load frequency control. Int. Trans. Electr. Energy Syst. 2017, 27, e2334. [Google Scholar] [CrossRef]

- Fan, Q.; Wang, X.; Yuan, J.; Liu, X.; Hu, H.; Lin, P. A review of the development of key technologies for offshore wind power in China. J. Mar. Sci. Eng. 2022, 10, 929. [Google Scholar] [CrossRef]

- Neya, N.M.; Saberi, S.; Rezaie, B. Design of an adaptive controller to capture maximum power from a variable speed wind turbine system without any prior knowledge of system parameters. Trans. Inst. Meas. Control 2022, 44, 609–619. [Google Scholar] [CrossRef]

- Wang, Y.; Guan, Y.; Li, H.; Chen, M. Spiking-free disturbance observer-based fixed-time sliding mode control of maximum power extraction from wind turbine. Trans. Inst. Meas. Control 2024, 46, 555–565. [Google Scholar] [CrossRef]

- Mahvash, H.; Taher, S.A.; Rahimi, M.; Shahidehpour, M. Enhancement of DFIG performance at high wind speed using fractional order PI controller in pitch compensation loop. Int. J. Electr. Power Energy Syst. 2019, 104, 259–268. [Google Scholar] [CrossRef]

- Mahvash, H.; Taher, S.A.; Shahidehpour, M. Fractional order control scheme in pitch control loop of synchronous generator wind turbine type 4 at high wind speed operation in a microgrid. J. Renew. Sustain. Energy 2019, 11, 013305. [Google Scholar] [CrossRef]

- Varzaneh, S.G.; Gharehpetian, G.B.; Abedi, M. Output power smoothing of variable speed wind farms using rotor-inertia. Electr. Power Syst. Res. 2014, 116, 208–217. [Google Scholar] [CrossRef]

- Bernard, M.Z.; Mohamed, T.H.; Ali, R.; Mitani, Y.; Qudaih, Y.S. PI-MPC frequency control of power system in the presence of DFIG wind turbines. Engineering 2013, 5, 43. [Google Scholar] [CrossRef]

- Chapaloglou, S.; Varagnolo, D.; Marra, F.; Tedeschi, E. Data-driven energy management of isolated power systems under rapidly varying operating conditions. Appl. Energy 2022, 314, 118906. [Google Scholar] [CrossRef]

- Qian, D.; Fan, G. Neural-network-based terminal sliding mode control for frequency stabilization of renewable power systems. IEEE/CAA J. Autom. Sin. 2018, 5, 706–717. [Google Scholar] [CrossRef]

- Iqbal, A.; Ying, D.; Saleem, A.; Hayat, M.A.; Mateen, M. Proposed particle swarm optimization technique for the wind turbine control system. Meas. Control 2020, 53, 1022–1030. [Google Scholar] [CrossRef]

- Deng, Z.; Xu, Y.; Gu, W.; Fei, Z. Finite-time convergence robust control of battery energy storage system to mitigate wind power fluctuations. Int. J. Electr. Power Energy Syst. 2017, 91, 144–154. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, J.; Hua, L.; Ma, K. Enhancing performances on wind power fluctuation mitigation by optimizing operation schedule of battery energy storage systems with considerations of operation cost. IEEE Access 2019, 7, 94072–94083. [Google Scholar] [CrossRef]

- Alam, M.J.E.; Muttaqi, K.M.; Sutanto, D. Battery energy storage to mitigate rapid voltage/power fluctuations in power grids due to fast variations of solar/wind outputs. IEEE Access 2021, 9, 12191–12202. [Google Scholar] [CrossRef]

- Ma, D.; Niculescu, S.; Guo, L.; Chen, J. Special issue on PID control in the information age: Theoretical advances and applications. Int. J. Robust Nonlinear Control 2022, 32, 9384–9388. [Google Scholar] [CrossRef]

- Indulkar, C.; Raj, B. Application of fuzzy controller to automatic generation control. Electr. Mach. Power Syst. 1995, 23, 209–220. [Google Scholar] [CrossRef]

- Karnavas, Y.; Papadopoulos, D. AGC for autonomous power system using combined intelligent techniques. Electr. Power Syst. Res. 2002, 62, 225–239. [Google Scholar] [CrossRef]

- Ramakrishna, K.; Bhatti, T. Discrete data load frequency control of two-area power system with multi-source power generation. Int. Energy J. 2008, 9, 145–154. [Google Scholar]

- Hu, Z.; Liu, S.; Luo, W.; Wu, L. Intrusion-detector-dependent distributed economic model predictive control for load frequency regulation with PEVs under cyber attacks. IEEE Trans. Circuits Syst. I Regul. Pap. 2021, 68, 3857–3868. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, K.; Su, R. Robust Cooperative Load Frequency Control for Enhancing Wind Energy Integration in Multi-Area Power Systems. IEEE Trans. Autom. Sci. Eng. 2024, 1–11. [Google Scholar] [CrossRef]

- Hu, Z.; Su, R.; Wang, R. Robust Distributed Load Frequency Control for Multi-Area Wind Energy-Dominated Microgrids Considering Phasor Measurement Unit Failures. IEEE Internet Things J. 2024, 11, 23475–23484. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, S.; Luo, W.; Wu, L. Resilient distributed fuzzy load frequency regulation for power systems under cross-layer random denial-of-service attacks. IEEE Trans. Cybern. 2022, 52, 2396–2406. [Google Scholar] [CrossRef]

- Ancuti, M.-C.; Musuroi, S.; Sorandaru, C.; Dordescu, M.; Erdodi, G.M. Wind turbines optimal operation at time variable wind speeds. Appl. Sci. 2020, 10, 4232. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, W.; Zhao, X. Current status and future prospects of continuously variable speed wind turbines: A systematic review. Mech. Syst. Signal Process. 2019, 120, 326–340. [Google Scholar] [CrossRef]

- Li, D.; Sang, Y.; Fang, S.; Sun, C.; Wang, H. Wind tunnel test research on the aerodynamic behavior of concrete-filled double-skin steel (CFDST) wind turbine towers. Buildings 2024, 14, 2372. [Google Scholar] [CrossRef]

- Li, D.; Zhang, Z.; Zhou, X.; Zhang, Z.; Yang, X. Cross-wind dynamic response of concrete-filled double-skin wind turbine towers: Theoretical modelling and experimental investigation. J. Vib. Control 2023, 30, 2881–2893. [Google Scholar] [CrossRef]

- Bedoud, K.; Rhif, A.; Bahi, T.; Merabet, H. Study of a double fed induction generator using matrix converter: Case of wind energy conversion system. Int. J. Hydrog. Energy 2018, 43, 11432–11441. [Google Scholar] [CrossRef]

- Ekanayake, J.; Jenkins, N.; Strbac, G. Frequency response from wind turbines. Wind. Eng. 2008, 32, 573–586. [Google Scholar] [CrossRef]

- Garrido, J.; Ruz, M.L.; Morilla, F.; Vázquez, F. Interactive tool for frequency domain tuning of PID controllers. Processes 2018, 6, 197. [Google Scholar] [CrossRef]

- Son, Y.-D.; Bin, S.-D.; Jin, G.-G. Stability Analysis of a Nonlinear PID Controller. Int. J. Control Autom. Syst. 2021, 19, 3400–3408. [Google Scholar] [CrossRef]

- Dey, R.; Dhar, R.S.; Mondal, U. Artificial neural network–based modelling of pacemaker and its pace tracking using discrete wavelet transform–based finite dimension repetitive controller. Trans. Inst. Meas. Control 2024, 46, 1410–1417. [Google Scholar] [CrossRef]

- Yu, T.; Liu, J.; Zeng, Y.; Zhang, X.; Zeng, Q.; Wu, L. Stability analysis of genetic regulatory networks with switching parameters and time delays. IEEE Trans. Neural Netw. Learn. Syst. 2017, 29, 3047–3058. [Google Scholar] [CrossRef]

- Wang, M.; Chen, J.; Wen, C.; Qin, S. Adaptive generalized Nash equilibrium seeking algorithm for non-smooth aggregative game under dynamic event-triggered mechanism. Automatica 2024, 169, 111835. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Qi, S. Generalized Nash equilibrium seeking for noncooperative game with different monotonicity by adaptive neurodynamic algorithm. IEEE Trans. Neural Netw. Learn. Syst. 2024, 95, 266–272. [Google Scholar] [CrossRef]

- Wang, L.; Ye, W.; Zhu, Y.; Yang, F.; Zhou, Y. Optimal parameters selection of back propagation algorithm in the feedforward neural network. Eng. Anal. Bound. Elem. 2023, 151, 575–596. [Google Scholar] [CrossRef]

- Wu, Y.; Feng, J. Development and application of artificial neural network. Wirel. Pers. Commun. 2018, 102, 1645–1656. [Google Scholar] [CrossRef]

- Hu, Z.; Su, R.; Ling, K.-V.; Guo, Y.; Ma, R. Resilient event-triggered MPC for load frequency regulation with wind turbines under false data injection attacks. IEEE Trans. Autom. Sci. Eng. 2023, 1–11. [Google Scholar] [CrossRef]

| Area 1 | Area 2 | Area 3 | Area 4 |

|---|---|---|---|

| D1 = 0.4 | D2 = 1 | D3 = 0.8 | D4 = 0.5 |

| 2H1 = 10 | 2H2 = 12 | 2H3 = 15 | 2H4 = 13 |

| Tch1 = 1.6 | Tch2 = 1.2 | Tch3 = 1.9 | Tch4 = 1.4 |

| Tg1 = 0.7 | Tg2 = 0.9 | Tg3 = 0.5 | Tg4 = 0.8 |

| R1 = 0.04 | R2 = 0.06 | R3 = 0.08 | R4 = 0.05 |

| T12 = 0.04 | T21 = 0.04 | T31 = 0 | T41 = 0.12 |

| T13 = 0 | T23 = 0.08 | T32 = 0.08 | T42 = 0.1 |

| T14 = 0.12 | T24 = 0.1 | T34 = 0.2 | T43 = 0.2 |

| ωs | Rr | Rs | Ls | Lm | Lr | Ht |

|---|---|---|---|---|---|---|

| 1.17 | 0.00552 | 0.00491 | 0.09273 | 3.9654 | 0.1 | 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, F.; Hu, Z. Robust Load Frequency Control of Interconnected Power Systems with Back Propagation Neural Network-Proportional-Integral-Derivative-Controlled Wind Power Integration. Sustainability 2024, 16, 8062. https://doi.org/10.3390/su16188062

Ye F, Hu Z. Robust Load Frequency Control of Interconnected Power Systems with Back Propagation Neural Network-Proportional-Integral-Derivative-Controlled Wind Power Integration. Sustainability. 2024; 16(18):8062. https://doi.org/10.3390/su16188062

Chicago/Turabian StyleYe, Fang, and Zhijian Hu. 2024. "Robust Load Frequency Control of Interconnected Power Systems with Back Propagation Neural Network-Proportional-Integral-Derivative-Controlled Wind Power Integration" Sustainability 16, no. 18: 8062. https://doi.org/10.3390/su16188062

APA StyleYe, F., & Hu, Z. (2024). Robust Load Frequency Control of Interconnected Power Systems with Back Propagation Neural Network-Proportional-Integral-Derivative-Controlled Wind Power Integration. Sustainability, 16(18), 8062. https://doi.org/10.3390/su16188062