Characterization of Geopolymer Masonry Mortars Incorporating Recycled Fine Aggregates

Abstract

1. Introduction

2. Materials and Methods

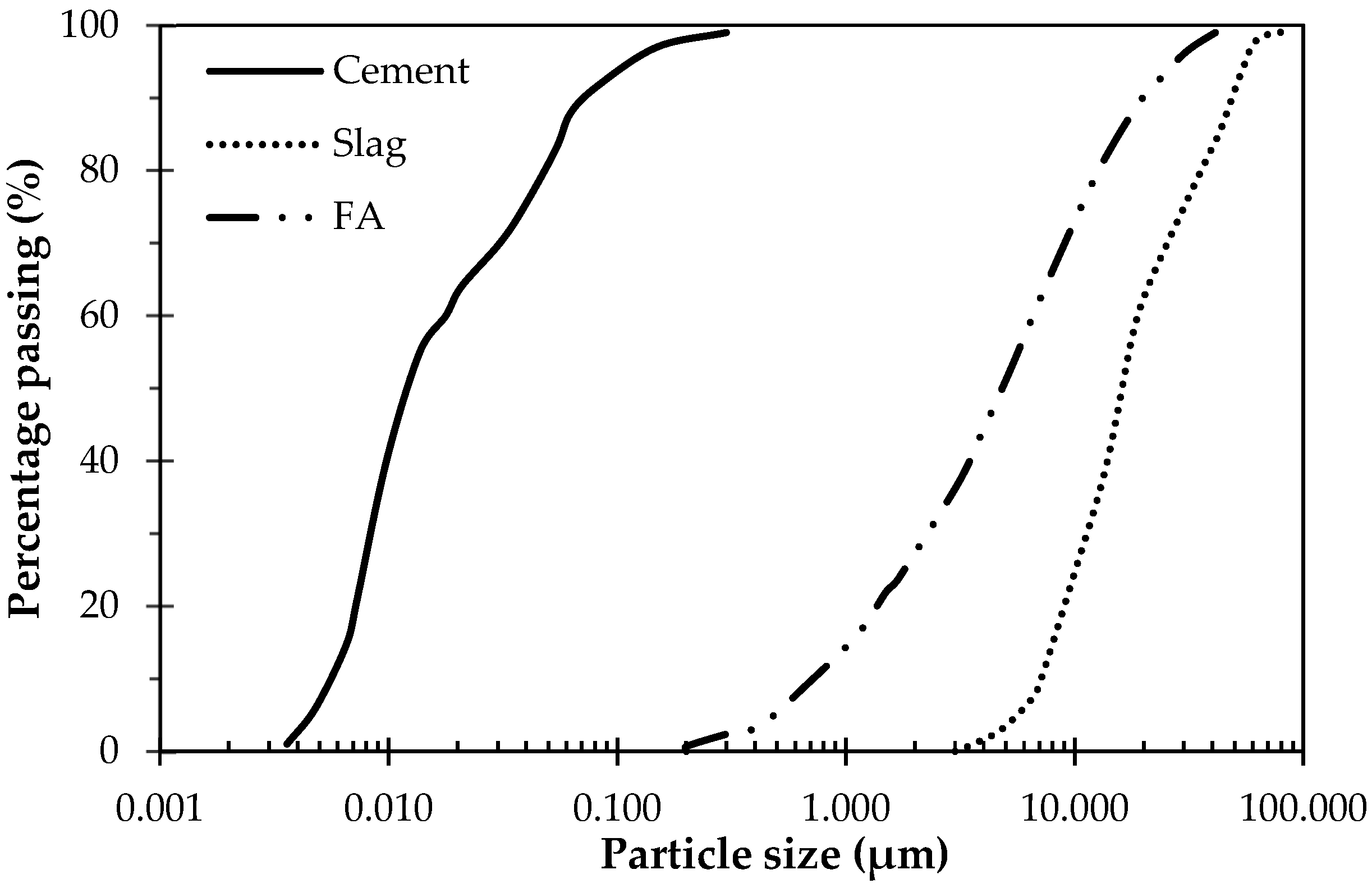

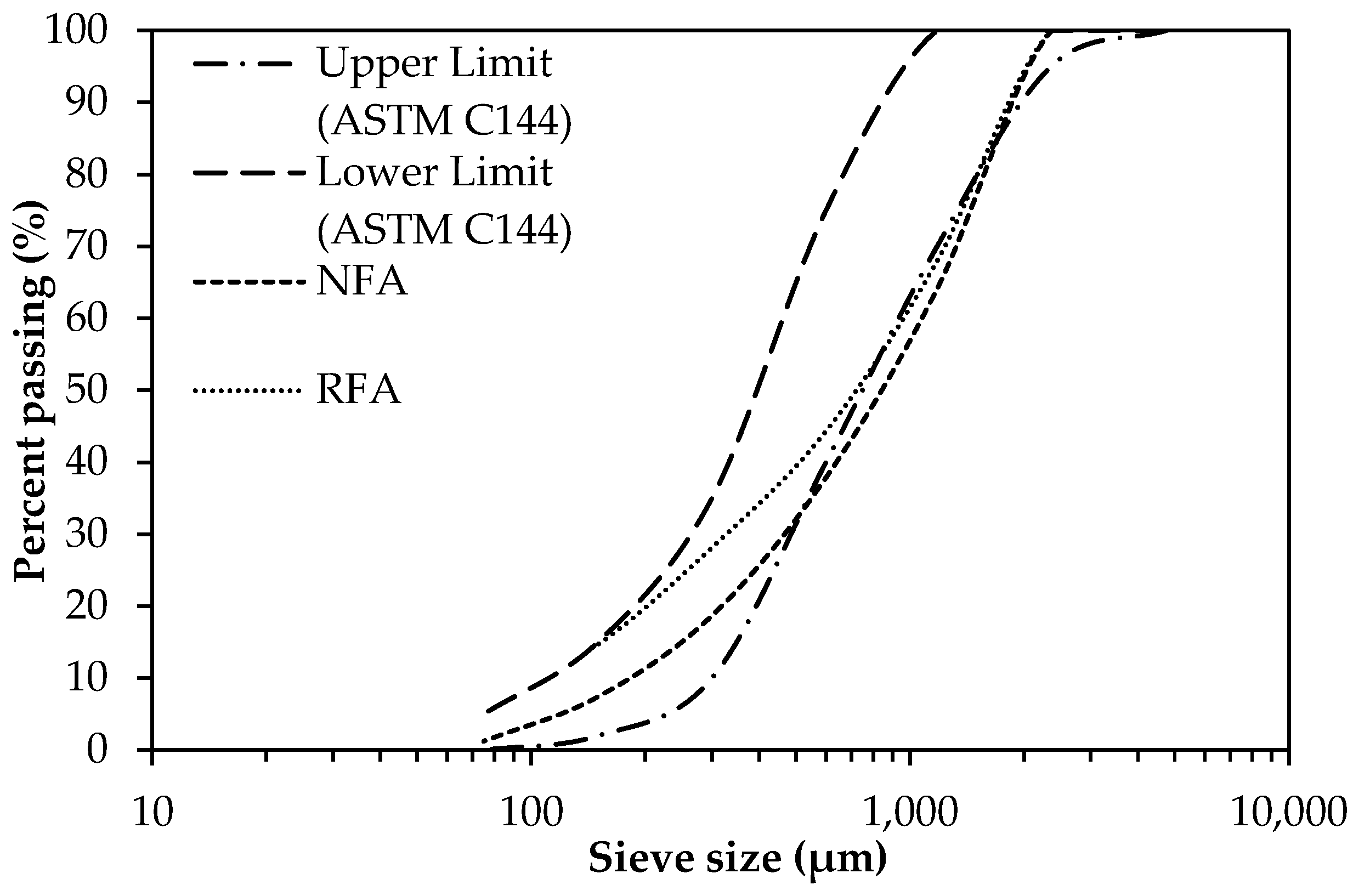

2.1. Materials

2.2. Mixture Proportioning

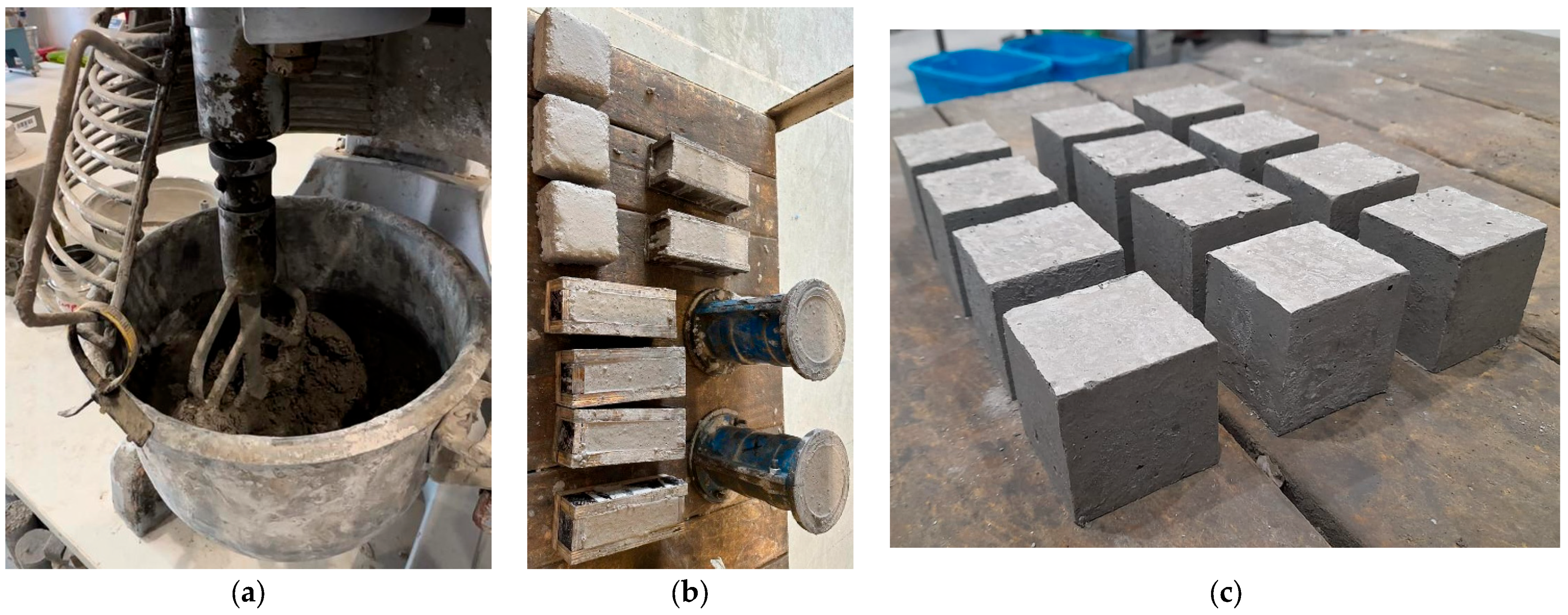

2.3. Sample Preparation

2.4. Test Methods

3. Results and Discussion

3.1. Fresh Properties

3.1.1. Flow

3.1.2. Air Content

3.1.3. Water Retention

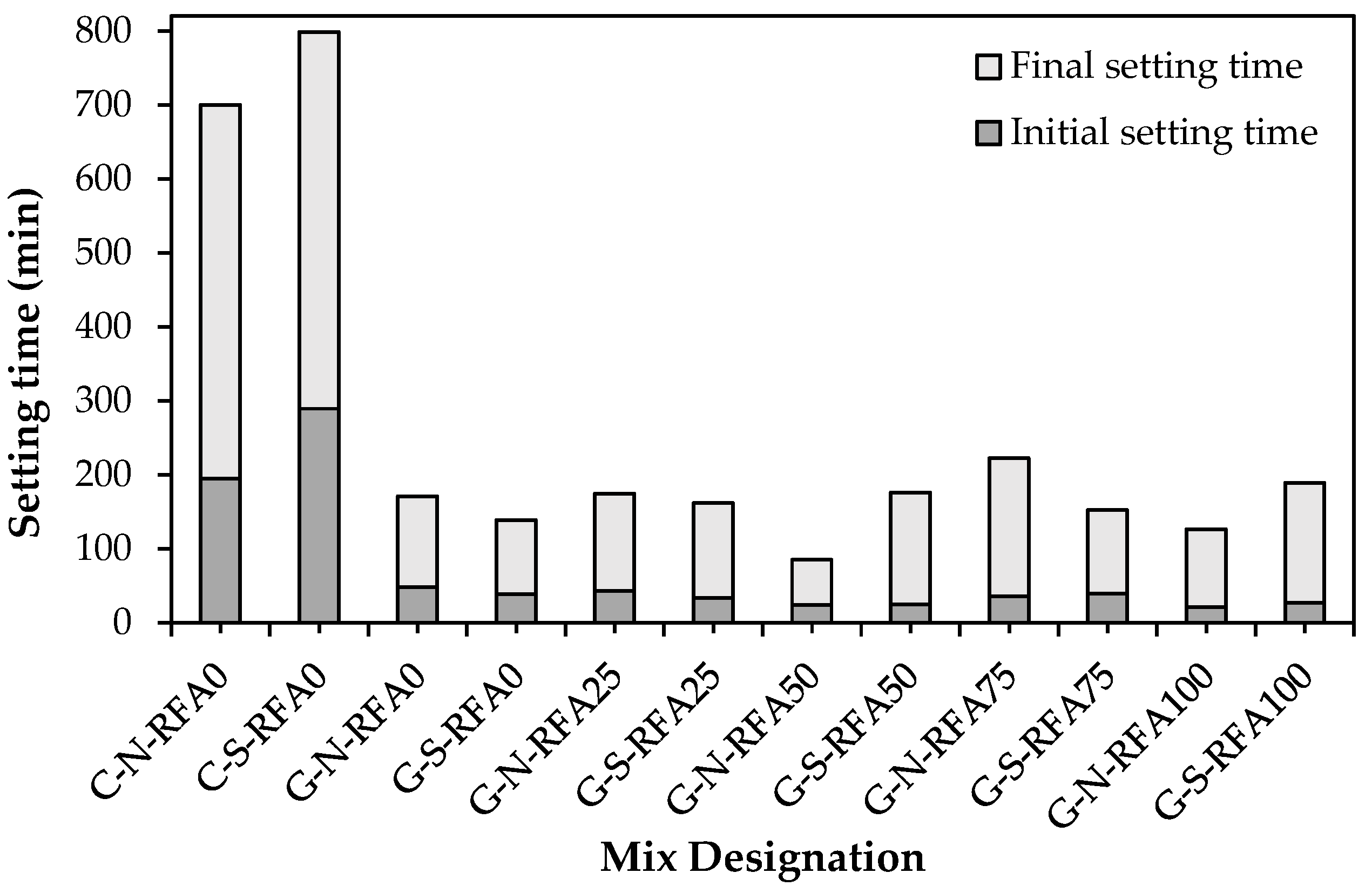

3.1.4. Setting Time

3.2. Mechanical Properties

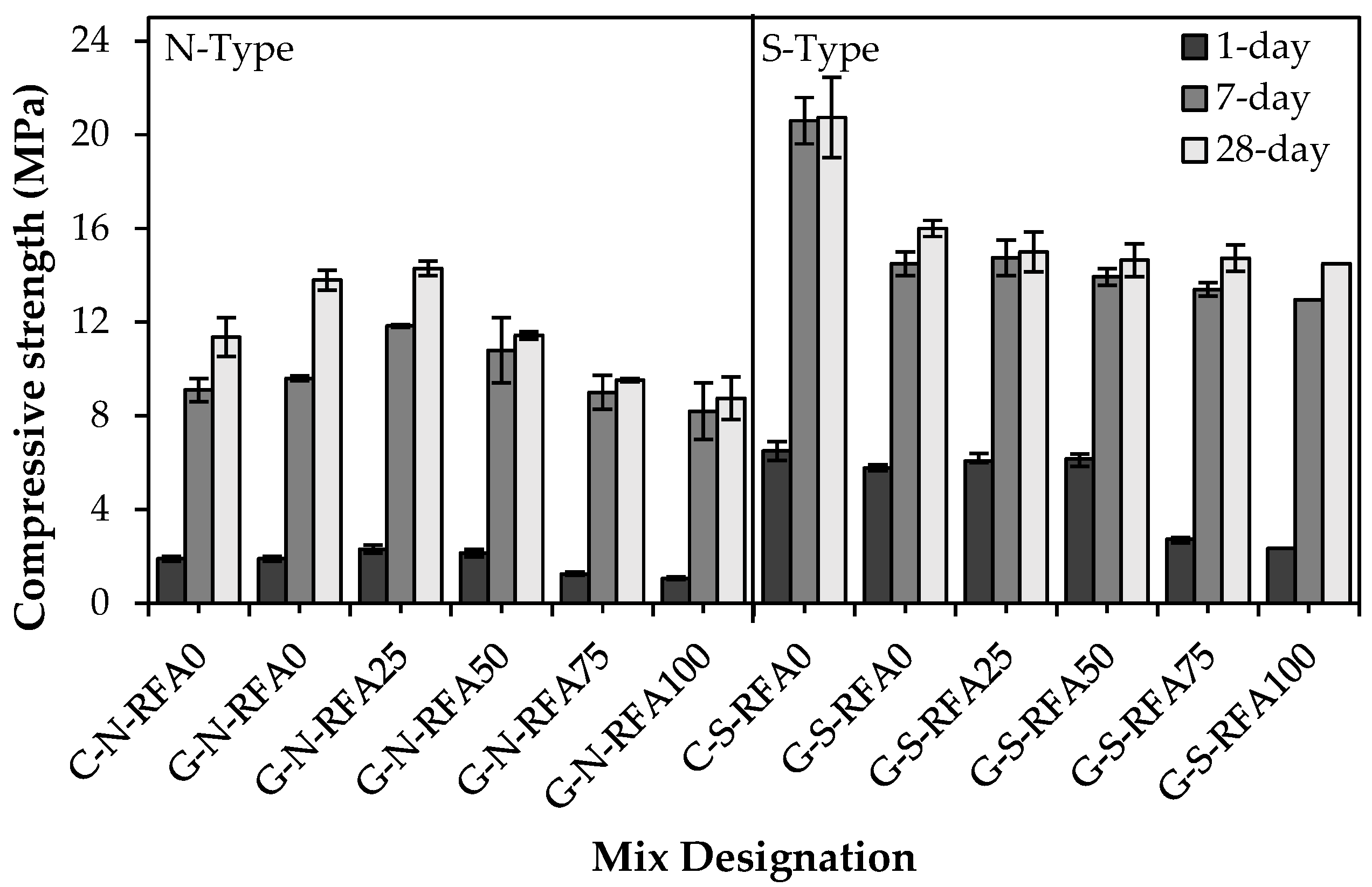

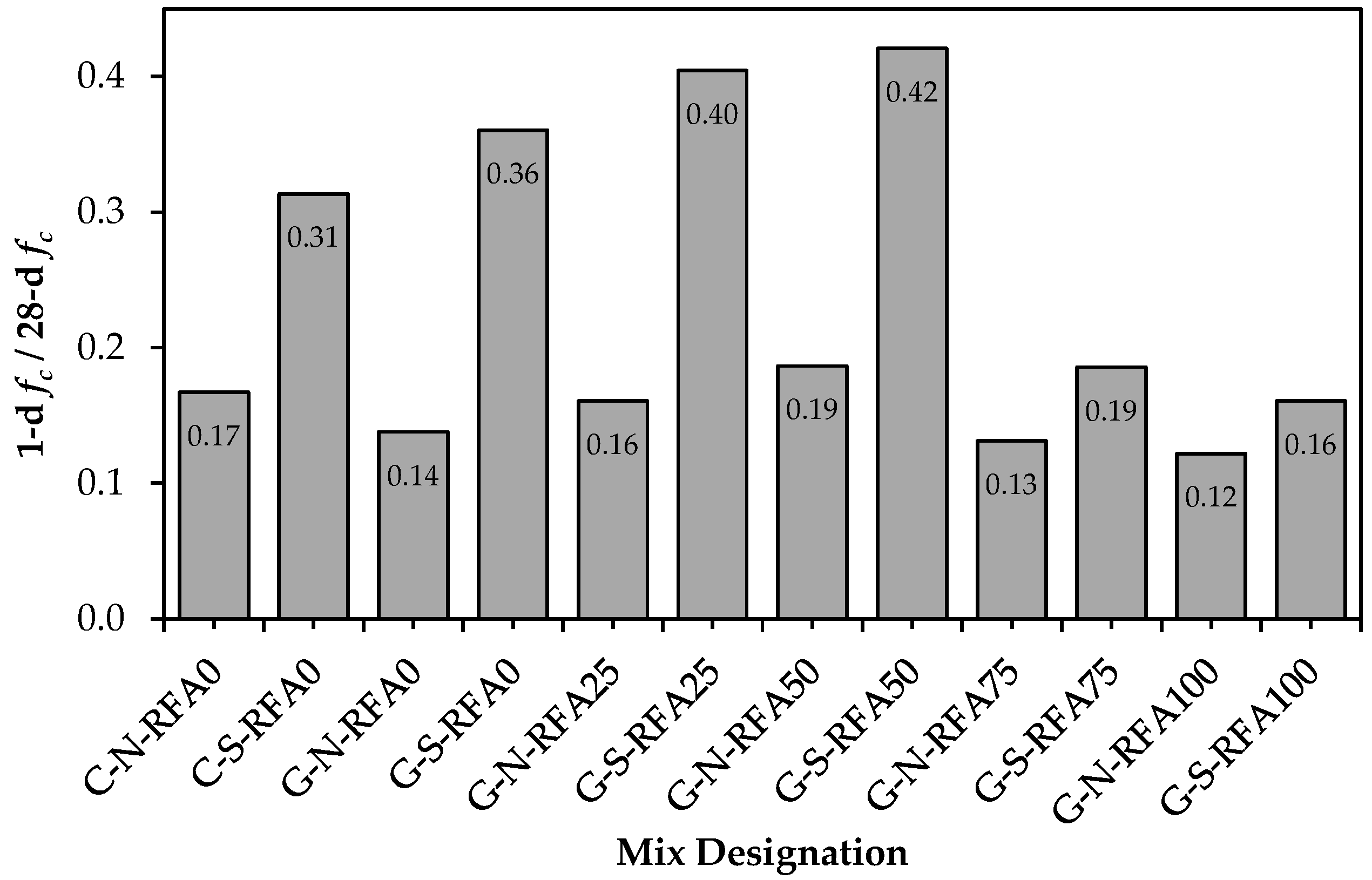

3.2.1. Compressive Strength

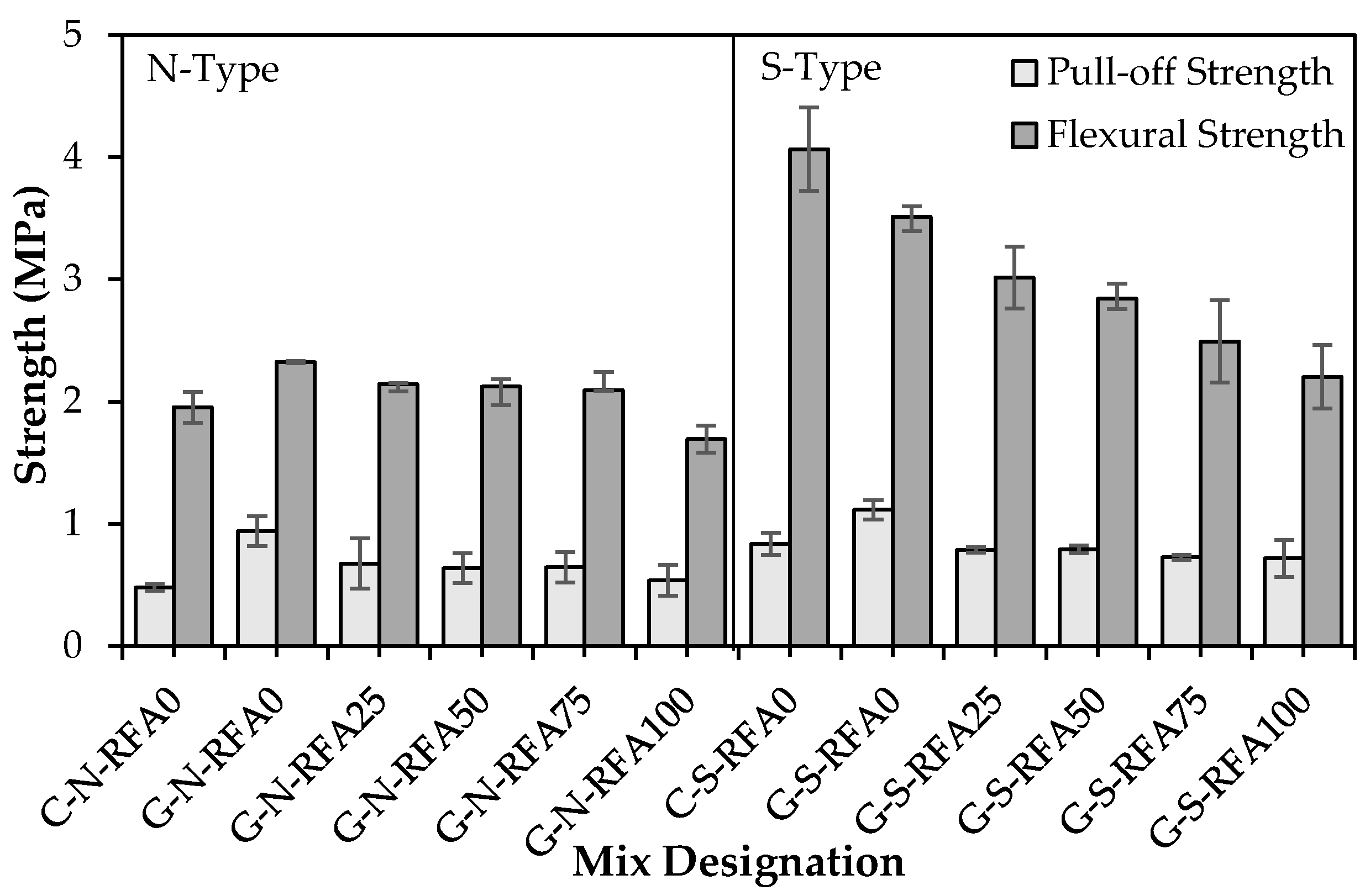

3.2.2. Pull-Off Strength

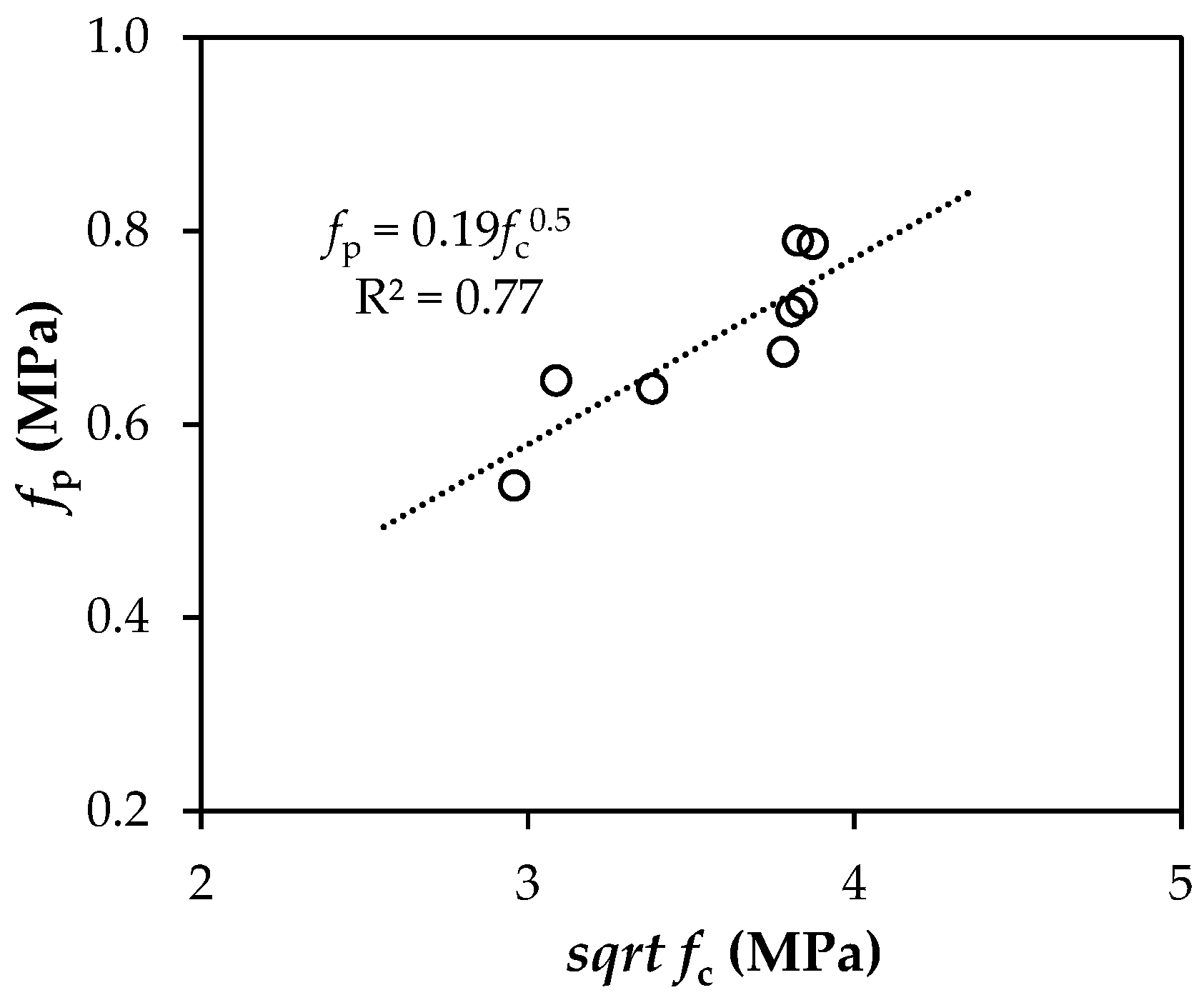

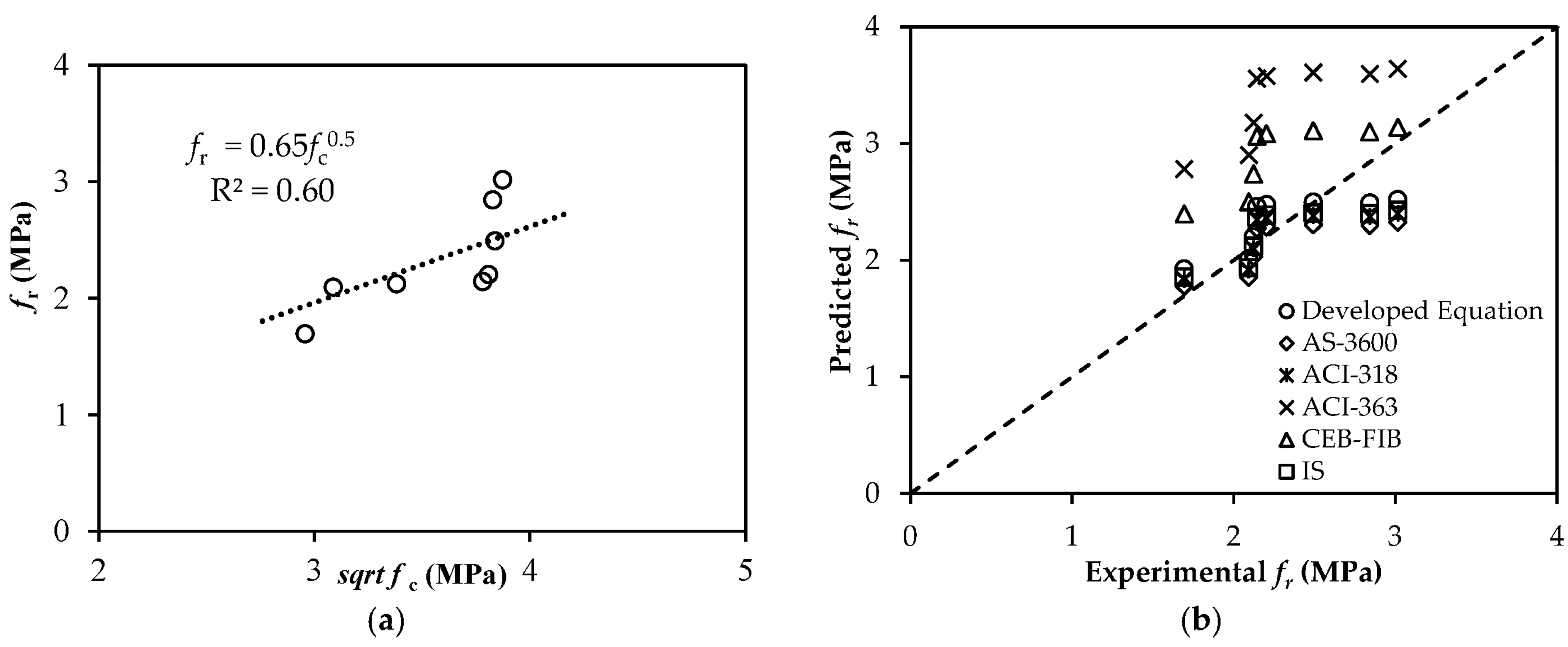

3.2.3. Flexural Strength

3.3. Physical and Durability Properties

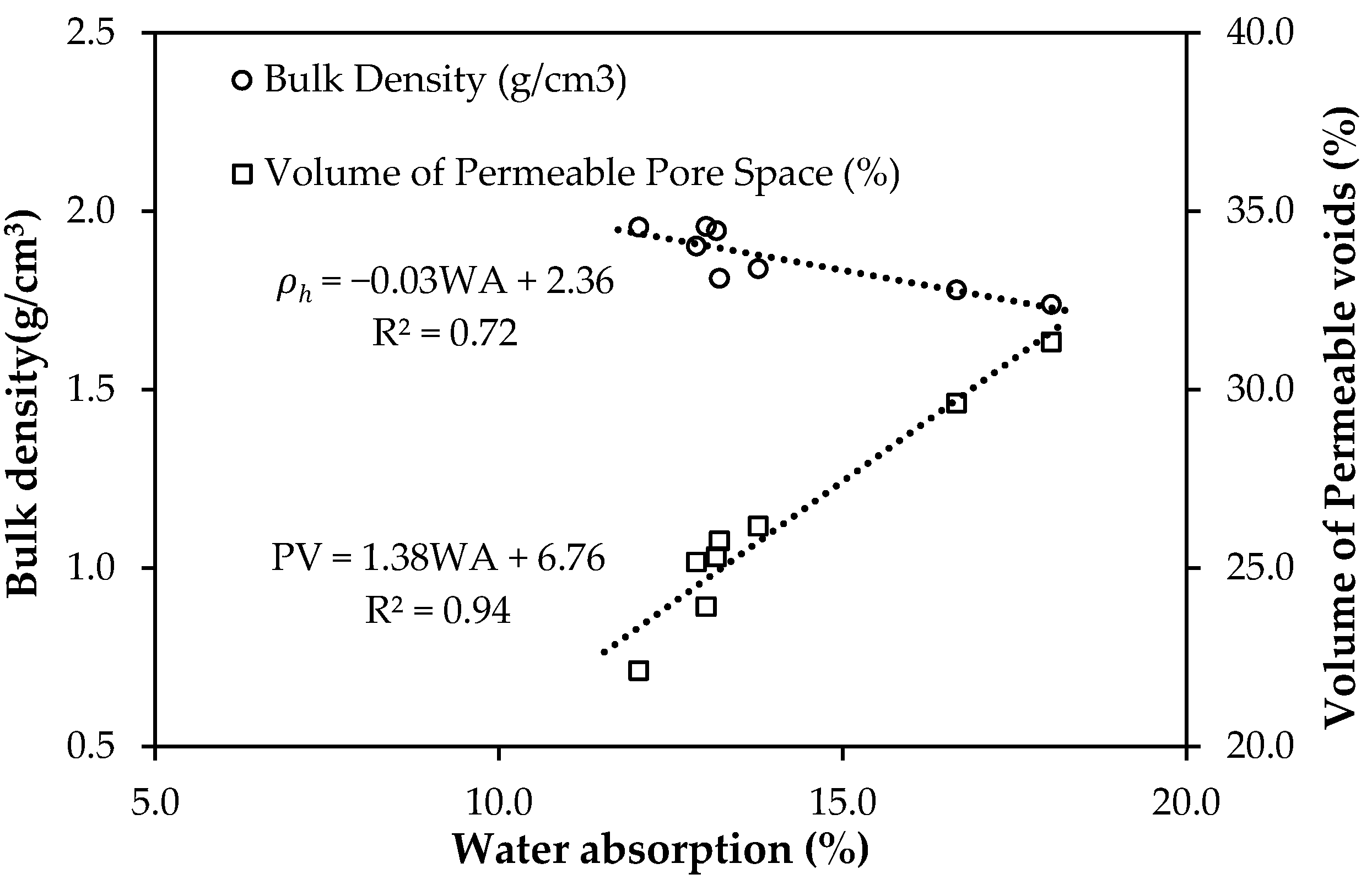

3.3.1. Bulk Density, Absorption, and Volume of Permeable Voids

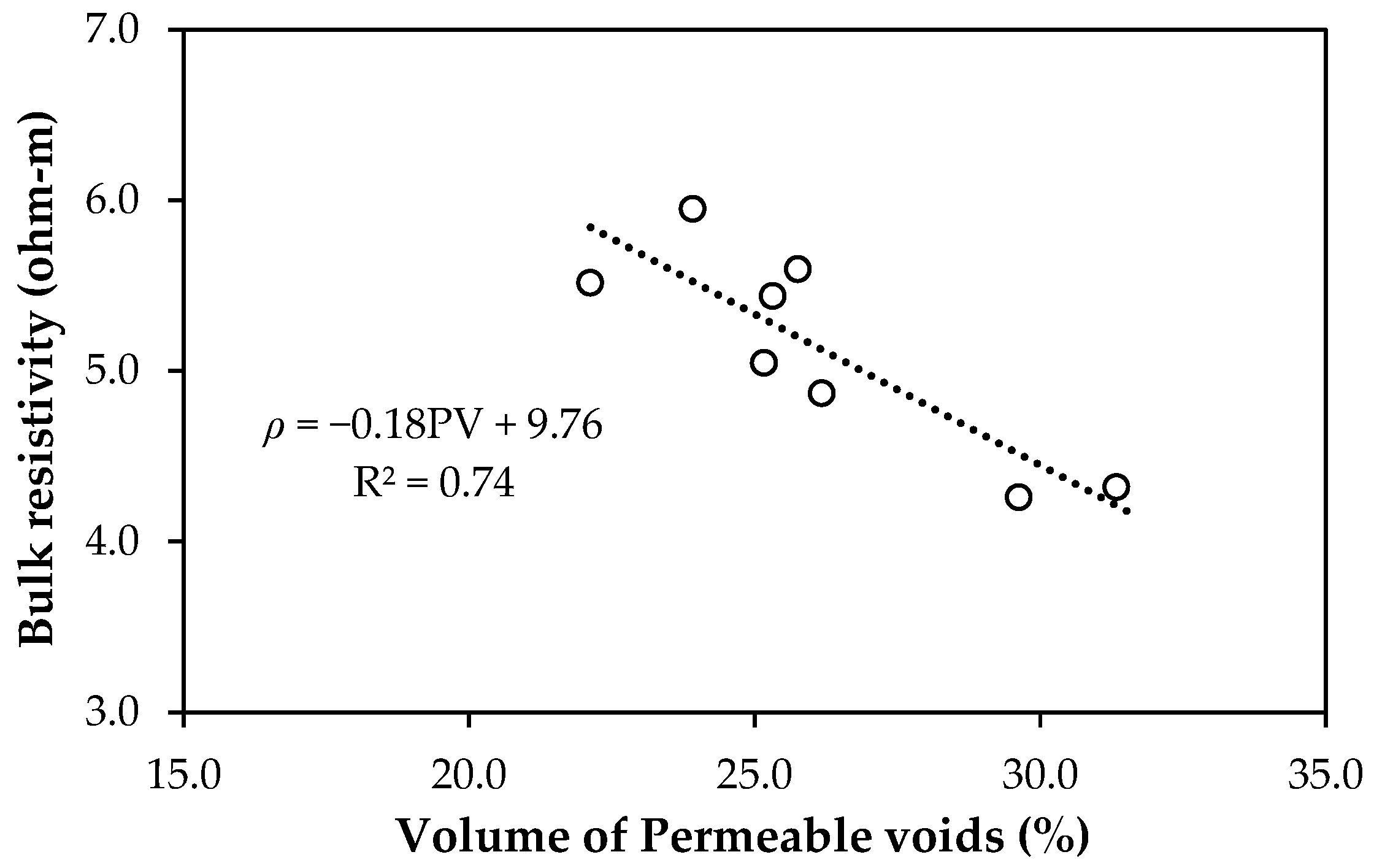

3.3.2. Bulk Electrical Resistivity

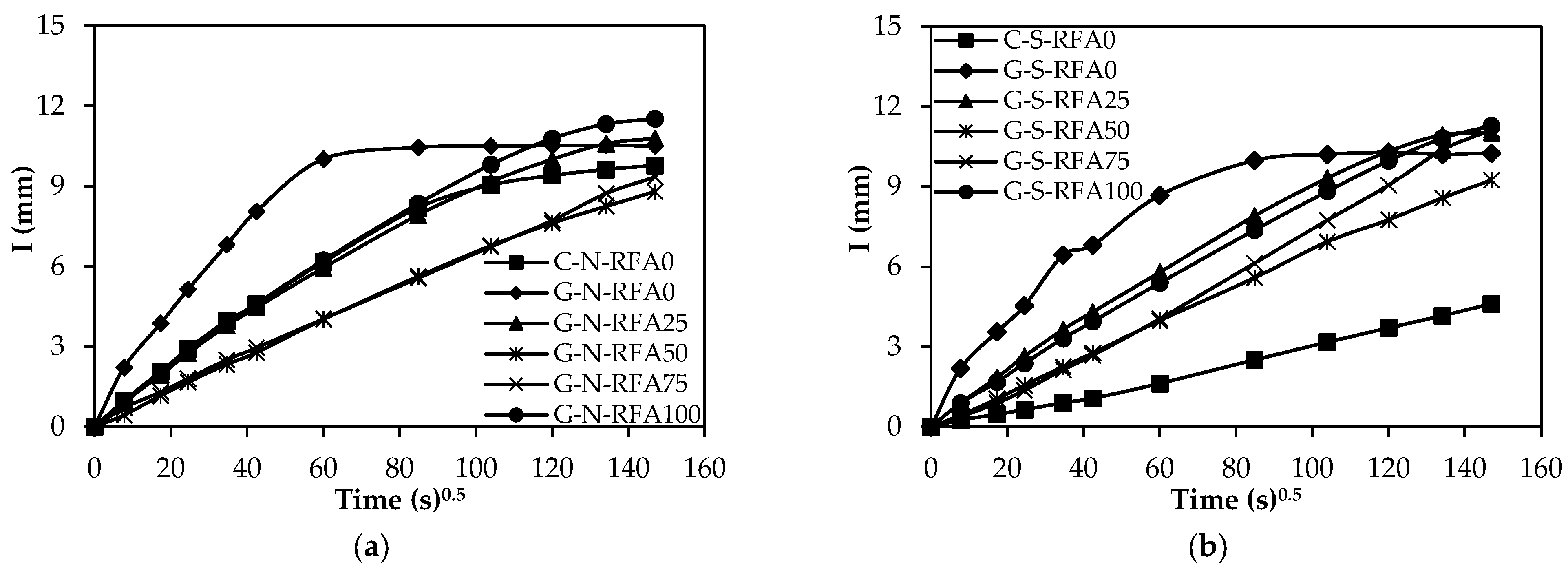

3.3.3. Sorptivity

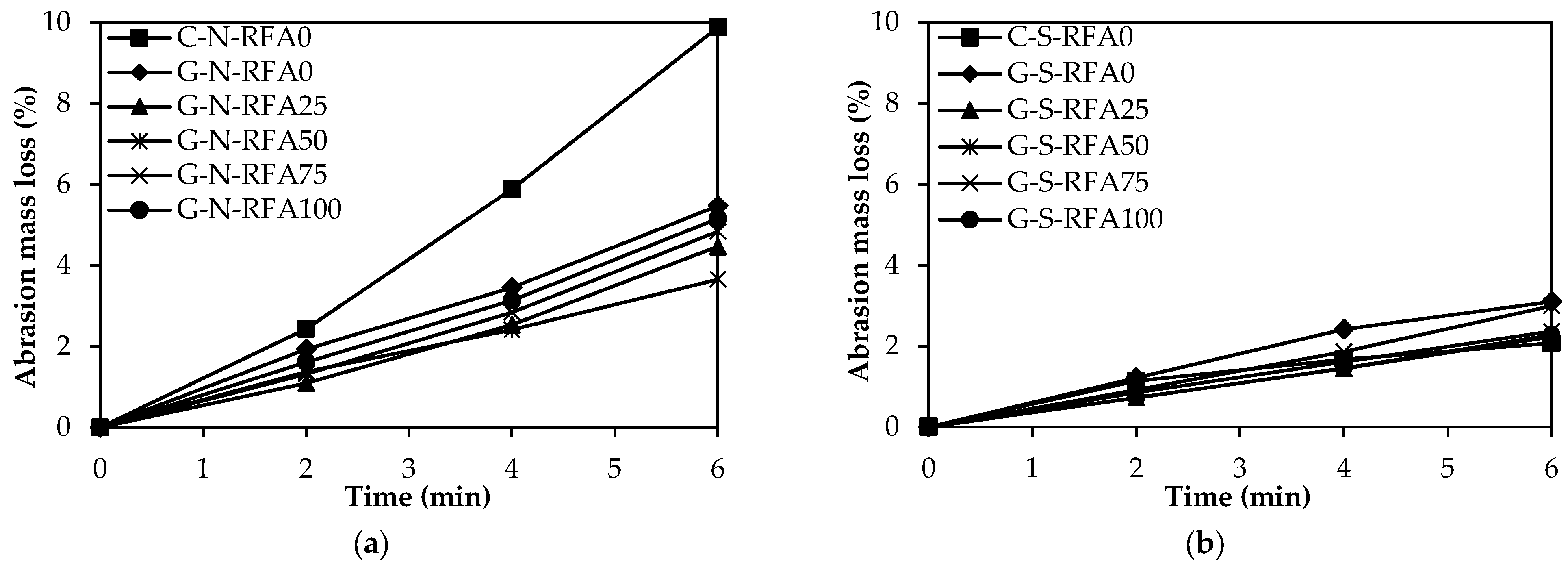

3.3.4. Abrasion Resistance

3.4. Environmental Impact Assessment

3.5. Economic Impact Assessment

3.6. Performance Index

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cement: Production Ranking Top Countries. 2023. Available online: https://www.statista.com/statistics/267364/world-cement-production-by-country/ (accessed on 20 May 2024).

- Abuowda, E.; El-Hassan, H.; El-Maaddawy, T. Effect of Recycled Fine Aggregates on the Performance of Slag-Fly Ash Blended Geopolymer Masonry Mortar. In Proceedings of the 9th International Conference on Civil, Structural and Transportation Engineering (ICCSTE 2024), Toronto, Canada, 13–15 June 2024. [Google Scholar]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global Strategies and Potentials to Curb CO2 Emissions in Cement Industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Labaran, Y.H.; Mathur, V.S.; Muhammad, S.U.; Musa, A.A. Carbon Footprint Management: A Review of Construction Industry. Clean. Eng. Technol. 2022, 9, 100531. [Google Scholar] [CrossRef]

- Shen, L.-Y.; Lu, W.-S.; Yao, H.; Wu, D.-H. A Computer-Based Scoring Method for Measuring the Environmental Performance of Construction Activities. Autom. Constr. 2005, 14, 297–309. [Google Scholar] [CrossRef]

- Stoner, J.A.F.; Wankel, C. (Eds.) Global Sustainability Initiatives: New Models and New Approaches; Illustrated edition; Information Age Publishing: Charlotte, NC, USA, 2008; ISBN 978-1-59311-813-6. [Google Scholar]

- U.S. Environmental Protection Agency. Sustainable Management of Construction and Demolition Materials. Available online: https://www.epa.gov/smm/sustainable-management-construction-and-demolition-materials (accessed on 20 May 2024).

- Alzard, M.H.; El-Hassan, H.; El-Maaddawy, T. Environmental and Economic Life Cycle Assessment of Recycled Aggregates Concrete in the United Arab Emirates. Sustainability 2021, 13, 10348. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Horpibulsuk, S.; Chanprasert, P.; Sukmak, P.; Arulrajah, A. Compressive Strength Development in Fly Ash Geopolymer Masonry Units Manufactured from Water Treatment Sludge. Constr. Build. Mater. 2015, 82, 597–607. [Google Scholar] [CrossRef]

- Yedage, D.M.; Gosavi, S.A.; Velapurkar, P.S. Assessment of Study on Geopolymer Concrete Block. IJNTR 2022, 8, 12–24. [Google Scholar]

- Radhakrishna; Venugopal, K.; Sasalatti, V.; Venumadhav, T. Study on Geopolymer Masonry as Sustainable Building Material. J. Environ. Res. Dev. 2015, 9, 925–932. [Google Scholar]

- Patil, S.; Rathi, K.; Budihal, M.O.; Dhadekar, A.; Salecha, D. Production of Cost Effective and High Strength Geopolymer Concrete Masonry Blocks. IJASE 2019, 5, 1099–1105. [Google Scholar] [CrossRef]

- Niphadkar, A. Geopolymer Masonry Block: A Substitute Material for Cement Concrete Block. SSRN Scholarly Paper 2020. Available online: https://ssrn.com/abstract=3533668 (accessed on 13 August 2024).

- Abuowda, E.; El-Hassan, H.; El-Maaddawy, T. Evaluation of Early-Age Compressive Strength of Geopolymer Concrete Masonry Units. Proc. Int. Struct. Eng. Constr. 2024, 11, CGC05. [Google Scholar] [CrossRef]

- ASTM C91/C91M-23; Standard Specification for Masonry Cement. ASTM International: West Conshohocken, PA, USA, 2023.

- Komljenović, M.; Baščarević, Z.; Bradić, V. Mechanical and Microstructural Properties of Alkali-Activated Fly Ash Geopolymers. J. Hazard. Mater. 2010, 181, 35–42. [Google Scholar] [CrossRef]

- Öz, H.Ö.; Doğan-Sağlamtimur, N.; Bilgil, A.; Tamer, A.; Günaydin, K. Process Development of Fly Ash-Based Geopolymer Mortars in View of the Mechanical Characteristics. Materials 2021, 14, 2935. [Google Scholar] [CrossRef] [PubMed]

- Adam, A.A.; Horianto, X.X.X. The Effect of Temperature and Duration of Curing on the Strength of Fly Ash Based Geopolymer Mortar. Procedia Eng. 2014, 95, 410–414. [Google Scholar] [CrossRef]

- Yankwa Djobo, J.N.; Elimbi, A.; Kouamo Tchakouté, H.; Kumar, S. Mechanical Properties and Durability of Volcanic Ash Based Geopolymer Mortars. Constr. Build. Mater. 2016, 124, 606–614. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Alengaram, U.J.; Jumaat, M.Z. Compressive Strength and Microstructural Analysis of Fly Ash/Palm Oil Fuel Ash Based Geopolymer Mortar. Mater. Des. 2014, 59, 532–539. [Google Scholar] [CrossRef]

- Shang, J.; Dai, J.-G.; Zhao, T.-J.; Guo, S.-Y.; Zhang, P.; Mu, B. Alternation of Traditional Cement Mortars Using Fly Ash-Based Geopolymer Mortars Modified by Slag. J. Clean. Prod. 2018, 203, 746–756. [Google Scholar] [CrossRef]

- Sathonsaowaphak, A.; Chindaprasirt, P.; Pimraksa, K. Workability and Strength of Lignite Bottom Ash Geopolymer Mortar. J. Hazard. Mater. 2009, 168, 44–50. [Google Scholar] [CrossRef]

- Kwasny, J.; Soutsos, M.N.; McIntosh, J.A.; Cleland, D.J. Comparison of the Effect of Mix Proportion Parameters on Behaviour of Geopolymer and Portland Cement Mortars. Constr. Build. Mater. 2018, 187, 635–651. [Google Scholar] [CrossRef]

- Jiménez, J.R.; Ayuso, J.; López, M.; Fernández, J.M.; De Brito, J. Use of Fine Recycled Aggregates from Ceramic Waste in Masonry Mortar Manufacturing. Constr. Build. Mater. 2013, 40, 679–690. [Google Scholar] [CrossRef]

- Silva, J.; De Brito, J.; Veiga, R. Recycled Red-Clay Ceramic Construction and Demolition Waste for Mortars Production. J. Mater. Civ. Eng. 2010, 22, 236–244. [Google Scholar] [CrossRef]

- Martínez, I.; Etxeberria, M.; Pavón, E.; Díaz, N. A Comparative Analysis of the Properties of Recycled and Natural Aggregate in Masonry Mortars. Constr. Build. Mater. 2013, 49, 384–392. [Google Scholar] [CrossRef]

- Mora-Ortiz, R.S.; Del Angel-Meraz, E.; Díaz, S.A.; Magaña-Hernández, F.; Munguía-Balvanera, E.; Pantoja Castro, M.A.; Alavez-Ramírez, J.; Alejandro Quiroga, L. Effect of Pre-Wetting Recycled Mortar Aggregate on the Mechanical Properties of Masonry Mortar. Materials 2021, 14, 1547. [Google Scholar] [CrossRef] [PubMed]

- Saba, M.; Assaad, J.J. Effect of Recycled Fine Aggregates on Performance of Geopolymer Masonry Mortars. Constr. Build. Mater. 2021, 279, 122461. [Google Scholar] [CrossRef]

- De Rossi, A.; Ribeiro, M.J.; Labrincha, J.A.; Novais, R.M.; Hotza, D.; Moreira, R.F.P.M. Effect of the Particle Size Range of Construction and Demolition Waste on the Fresh and Hardened-State Properties of Fly Ash-Based Geopolymer Mortars with Total Replacement of Sand. Process Saf. Environ. Prot. 2019, 129, 130–137. [Google Scholar] [CrossRef]

- Gholampour, A.; Ho, V.D.; Ozbakkaloglu, T. Ambient-Cured Geopolymer Mortars Prepared with Waste-Based Sands: Mechanical and Durability-Related Properties and Microstructure. Compos. Part B Eng. 2019, 160, 519–534. [Google Scholar] [CrossRef]

- Deng, P.; Zheng, Z. Mechanical Properties of One-Part Geopolymer Masonry Mortar Using Alkali-Fused Lead–Zinc Tailings. Constr. Build. Mater. 2023, 369, 130522. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Bashar, I.I. The Development of Compressive Strength of Ground Granulated Blast Furnace Slag-Palm Oil Fuel Ash-Fly Ash Based Geopolymer Mortar. Mater. Des. (1980–2015) 2014, 56, 833–841. [Google Scholar] [CrossRef]

- ASTM C150/C150M-24; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C29/C29M-23; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C128-22; Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- Venugopal, K. Radhakrishna Development of Solid and Hollow Geopolymer Masonry Blocks. GSTF J. Eng. Technol. 2016, 4, 65–71. [Google Scholar] [CrossRef]

- Venugopal, K.; Radhakrishna; Sasalatti, V.M. Ambient Cured Alkali Activated Flyash Masonry Units. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012073. [Google Scholar] [CrossRef]

- Hwalla, J.; El-Hassan, H.; Assaad, J.J.; El-Maaddawy, T. Performance of Cementitious and Slag-Fly Ash Blended Geopolymer Screed Composites: A Comparative Study. Case Stud. Constr. Mater. 2023, 18, e02037. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Farhan, N.A.; Sheikh, M.N. Design of Geopolymer Concrete with GGBFS at Ambient Curing Condition Using Taguchi Method. Constr. Build. Mater. 2017, 140, 424–431. [Google Scholar] [CrossRef]

- Gugulothu, V.; Gunneswara Rao, T.D. Effect of Binder Content and Solution/Binder Ratio on Alkali-Activated Slag Concrete Activated with Neutral Grade Water Glass. Arab. J Sci Eng 2020, 45, 8187–8197. [Google Scholar] [CrossRef]

- Li, H.; Gao, P.; Xu, F.; Sun, T.; Zhou, Y.; Zhu, J.; Peng, C.; Lin, J. Effect of Fine Aggregate Particle Characteristics on Mechanical Properties of Fly Ash-Based Geopolymer Mortar. Minerals 2021, 11, 897. [Google Scholar] [CrossRef]

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020.

- BS EN 1015-7; Methods of Test for Mortar for Masonry Determination of Air Content of Fresh Mortar. British Standard Institution: London, UK, 1999.

- ASTM C1506-17; Standard Test Method for Water Retention of Hydraulic Cement-Based Mortars and Plasters. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C403/C403M-16; Standard Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C109/C109M-21; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 Mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D7234-22; Standard Test Method for Pull-Off Strength of Coatings on Concrete Using Portable Pull-Off Adhesion Testers. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C348-21; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C1876-19; Standard Test Method for Bulk Electrical Resistivity or Bulk Conductivity of Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C1585-20; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C944/C944M-19; Standard Test Method for Abrasion Resistance of Concrete or Mortar Surfaces by the Rotating-Cutter Method. ASTM International: West Conshohocken, PA, USA, 2019.

- Kumar, S.; Sekhar Das, C.; Lao, J.; Alrefaei, Y.; Dai, J.-G. Effect of Sand Content on Bond Performance of Engineered Geopolymer Composites (EGC) Repair Material. Constr. Build. Mater. 2022, 328, 127080. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The Effects of Ground Granulated Blast-Furnace Slag Blending with Fly Ash and Activator Content on the Workability and Strength Properties of Geopolymer Concrete Cured at Ambient Temperature. Mater. Des. (1980–2015) 2014, 62, 32–39. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. The Properties of the Self-Compacting Concrete with Fly Ash and Ground Granulated Blast Furnace Slag Mineral Admixtures. J. Clean. Prod. 2015, 95, 66–74. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on Setting, Workability and Early Strength Properties of Fly Ash Geopolymer Concrete Cured in Ambient Condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Fauzi, A.; Nuruddin, M.F.; Malkawi, A.B.; Al Bakri Abdullah, M.M.; Mohammed, B.S. Effect of Alkaline Solution to Fly Ash Ratio on Geopolymer Mortar Properties. KEM 2017, 733, 85–88. [Google Scholar] [CrossRef]

- Tiwari, A.; Singh, S.; Nagar, R. Feasibility Assessment for Partial Replacement of Fine Aggregate to Attain Cleaner Production Perspective in Concrete: A Review. J. Clean. Prod. 2016, 135, 490–507. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X. Relationship between Flowability, Entrapped Air Content and Strength of UHPC Mixtures Containing Different Dosage of Steel Fiber. Appl. Sci. 2016, 6, 216. [Google Scholar] [CrossRef]

- Vegas, I.; Azkarate, I.; Juarrero, A.; Frías, M. Design and Performance of Masonry Mortars Made with Recycled Concrete Aggregates. Mater. De Constr. 2009, 59, 5–18. [Google Scholar] [CrossRef]

- Saiz Martínez, P.; González Cortina, M.; Fernández Martínez, F.; Rodríguez Sánchez, A. Comparative Study of Three Types of Fine Recycled Aggregates from Construction and Demolition Waste (CDW), and Their Use in Masonry Mortar Fabrication. J. Clean. Prod. 2016, 118, 162–169. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Effects of Different Kinds of Recycled Fine Aggregate on Properties of Rendering Mortar. J. Sustain. Cem.-Based Mater. 2013, 2, 43–57. [Google Scholar] [CrossRef]

- Shekhovtsova, J.; Kovtun, M.; Kearsley, E.P. Temperature Rise and Initial Shrinkage of Alkali-Activated Fly Ash Cement Pastes. Adv. Cem. Res. 2016, 28, 3–12. [Google Scholar] [CrossRef]

- Assaad, J.; Daou, Y. Behavior of Structural Polymer-Modified Concrete Containing Recycled Aggregates. J. Adhes. Sci. Technol. 2017, 31, 874–896. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Performance of Cementitious Renderings and Masonry Mortars Containing Recycled Aggregates from Construction and Demolition Wastes. Constr. Build. Mater. 2016, 105, 400–415. [Google Scholar] [CrossRef]

- ASTM C270-19a; Standard Specification for Mortar for Unit Masonry. ASTM International: West Conshohocken, PA, USA, 2019.

- Garcia-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A. 2—An Overview of the Chemistry of Alkali-Activated Cement-Based Binders. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Pacheco-Torgal, F., Labrincha, J.A., Leonelli, C., Palomo, A., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 19–47. ISBN 978-1-78242-276-1. [Google Scholar]

- Wang, Y.; Wang, Y.; Zhang, M. Effect of Sand Content on Engineering Properties of Fly Ash-Slag Based Strain Hardening Geopolymer Composites. J. Build. Eng. 2021, 34, 101951. [Google Scholar] [CrossRef]

- Wongsa, A.; Siriwattanakarn, A.; Nuaklong, P.; Sata, V.; Sukontasukkul, P.; Chindaprasirt, P. Use of Recycled Aggregates in Pressed Fly Ash Geopolymer Concrete. Environ. Prog. Sustain. Energy 2020, 39, e13327. [Google Scholar] [CrossRef]

- Zemajtis, J.Z. Role of Concrete Curing. Available online: https://www.cement.org/learn/concrete-technology/concrete-construction/curing-in-construction (accessed on 30 October 2023).

- Park, J.-S.; Kim, Y.J.; Cho, J.-R.; Jeon, S.-J. Early-Age Strength of Ultra-High Performance Concrete in Various Curing Conditions. Materials 2015, 8, 5537–5553. [Google Scholar] [CrossRef]

- Uddin, M.A.; Jameel, M.; Sobuz, H.R.; Hasan, N.M.S.; Islam, M.S.; Amanat, K.M. The Effect of Curing Time on Compressive Strength of Composite Cement Concrete. Appl. Mech. Mater. 2017, 204–208, 4105–4109. [Google Scholar] [CrossRef]

- Ejiogu, I.K.; Mamza, P.A.P.; Nkeonye, P.O.; Yaro, S.A. Effects of Water-Cement Ratio and Cure Days on the Strength and Workability of Normal Concrete Blocks. Int. J. Innov. Sci. Eng. Technol. Res. 2018, 6, 11–18. [Google Scholar]

- De Juan, M.S.; Gutiérrez, P.A. Study on the Influence of Attached Mortar Content on the Properties of Recycled Concrete Aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Braga, M.; de Brito, J.; Veiga, R. Incorporation of Fine Concrete Aggregates in Mortars. Constr. Build. Mater. 2012, 36, 960–968. [Google Scholar] [CrossRef]

- Neno, C.; de Brito, J.; Veiga, R. Using Fine Recycled Concrete Aggregate for Mortar Production. Mater. Res. 2014, 17, 168–177. [Google Scholar] [CrossRef]

- Zuaiter, M.; El-Hassan, H.; El-Maaddawy, T.; El-Ariss, B. Properties of Slag-Fly Ash Blended Geopolymer Concrete Reinforced with Hybrid Glass Fibers. Buildings 2022, 12, 1114. [Google Scholar] [CrossRef]

- Hu, Y.; Tang, Z.; Li, W.; Li, Y.; Tam, V.W.Y. Physical-Mechanical Properties of Fly Ash/GGBFS Geopolymer Composites with Recycled Aggregates. Constr. Build. Mater. 2019, 226, 139–151. [Google Scholar] [CrossRef]

- Rakhimova, N.R.; Rakhimov, R.Z. Reaction Products, Structure and Properties of Alkali-Activated Metakaolin Cements Incorporated with Supplementary Materials—A Review. J. Mater. Res. Technol. 2019, 8, 1522–1531. [Google Scholar] [CrossRef]

- Huseien, G.; Mirza, J.; Ismail, M.; Ghoshal, S.K.; Ariffin, M.A. Effect of Metakaolin Replaced Granulated Blast Furnace Slag on Fresh and Early Strength Properties of Geopolymer Mortar. Ain Shams Eng. J. 2016, 9, 1557–1566. [Google Scholar] [CrossRef]

- Vegas, I.; Ibañez, J.A.; Lisbona, A.; Sáez de Cortazar, A.; Frías, M. Pre-Normative Research on the Use of Mixed Recycled Aggregates in Unbound Road Sections. Constr. Build. Mater. 2011, 25, 2674–2682. [Google Scholar] [CrossRef]

- Jiménez, J.R.; Ayuso, J.; Galvín, A.P.; López, M.; Agrela, F. Use of Mixed Recycled Aggregates with a Low Embodied Energy from Non-Selected CDW in Unpaved Rural Roads. Constr. Build. Mater. 2012, 34, 34–43. [Google Scholar] [CrossRef]

- AS3600; Concrete Structures. Standards Australia: Sydney, Australia, 2009.

- ACI 318-19; Building Code Requirements for Structural Concrete (ACI 318-19): An ACI Standard and Commentary on Building Code Requirements for Structural Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- ACI Committee 363; State-of-the Art Report on High-Strength Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1992.

- Comité Euro-International du Béton. CEB-FIB Model Code 1990 Design Code; Thomas Telford, Ltd.: London, UK, 1993. [Google Scholar]

- IS 456: 2000; Plain and Reinforced Concrete Code of Practice. BIS: New Delhi, India, 2007.

- Görhan, G.; Kürklü, G. The Influence of the NaOH Solution on the Properties of the Fly Ash-Based Geopolymer Mortar Cured at Different Temperatures. Compos. Part B Eng. 2014, 58, 371–377. [Google Scholar] [CrossRef]

- Wei, X.; Xiao, L.; Li, Z. Prediction of Standard Compressive Strength of Cement by the Electrical Resistivity Measurement. Constr. Build. Mater. 2012, 31, 341–346. [Google Scholar] [CrossRef]

- El-Hassan, H.; Shehab, E.; Al-Sallamin, A. Influence of Different Curing Regimes on the Performance and Microstructure of Alkali-Activated Slag Concrete. J. Mater. Civ. Eng. 2018, 30, 04018230. [Google Scholar] [CrossRef]

- Ameen, B.M.; Al-Numan, B. Corrosion Rate of Reinforced Concrete Incorporating Recycled Concrete Aggregates. IOP Conf. Ser. Earth Environ. Sci. 2021, 871, 012004. [Google Scholar] [CrossRef]

- Horsakulthai, V. Effect of Recycled Concrete Powder on Strength, Electrical Resistivity, and Water Absorption of Self-Compacting Mortars. Case Stud. Constr. Mater. 2021, 15, e00725. [Google Scholar] [CrossRef]

- Layssi, H.; Ghods, P.; Alizadeh, A.R.; Salehi, M. Electrical Resistivity of Concrete. Concr. Int. 2015, 37, 41–46. [Google Scholar]

- Mermerdaş, K. Effect of Glass Fiber Addition on the Strength Properties and Pore Structure of Fly Ash Based Geopolymer Composites. Eskişehir Tech. Univ. J. Sci. Technol. A-Appl. Sci. Eng. 2019, 20, 427–435. [Google Scholar] [CrossRef][Green Version]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H. A Review on Effects of Limestone Powder on the Properties of Concrete. Constr. Build. Mater. 2018, 192, 153–166. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Salem, H.A. Effect of Water Addition, Plasticizer and Alkaline Solution Constitution on Fly Ash Based Geopolymer Concrete Performance. Constr. Build. Mater. 2016, 121, 694–703. [Google Scholar] [CrossRef]

- Ramujee, K.; Potharaju, M. Abrasion Resistance of Geopolymer Composites. Procedia Mater. Sci. 2014, 6, 1961–1966. [Google Scholar] [CrossRef]

- De Brito, J. Abrasion Resistance of Concrete Made with Recycled Aggregates. Int. J. Sustain. Eng. 2010, 3, 58–64. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Influence of Recycled Aggregate on Fly Ash Geopolymer Concrete Properties. J. Clean. Prod. 2016, 112, 2300–2307. [Google Scholar] [CrossRef]

- Mohamed, A.Y.; Canpolat, O.; Al-Mashhadani, M.M.M. Assessment of Strength and Abrasion Resistance of Elasto-Plastic Fiber Reinforced Concrete Using Geopolymer Based Recycled Aggregates. Environ. Res. Technol. 2021, 4, 244–248. [Google Scholar] [CrossRef]

| Oxide | Cement | Slag | FA |

|---|---|---|---|

| CaO, % | 66.3 | 59.7 | 8.3 |

| SiO2, % | 21.5 | 27.0 | 52.7 |

| Al2O3, % | 4.0 | 7.5 | 18.6 |

| SO3, % | 2.7 | 2.5 | 1.1 |

| Fe2O3, % | 2.7 | 1.2 | 14.3 |

| Loss on ignition, % | 0.9 | 1.1 | 1.1 |

| Others, % | 1.9 | 1.0 | 3.9 |

| Property | ASTM Test | NFAs | RFAs |

|---|---|---|---|

| Dry-Rodded Density (kg/m3) | C29 [34] | 1898 | 1510 |

| Absorption (%) | C128 [35] | 0.22 | 6.63 |

| Median particle size d50 (µm) | C136 [36] | 880 | 745 |

| Surface Area (cm2/g) | C136 [36] | 66.8 | 113.5 |

| Fineness Modulus | C136 [36] | 2.7 | 2.5 |

| Specific Gravity | C128 [35] | 2.69 | 2.63 |

| Mix No. | Mix Designation | Binder-to-Aggregates | FA-to-Slag | AAS-to-Binder | SS/SH | Water-to-Binder |

|---|---|---|---|---|---|---|

| 1 | C-N-RFA0 | 1:3 | - | - | - | 0.60 |

| 2 | C-S-RFA0 | 1:2.75 | - | - | - | 0.60 |

| 3 | G-N-RFA0 | 1:3 | 5:1 | 0.5 | 1.5 | 0.20 |

| 4 | G-S-RFA0 | 1:3 | 4:1 | 0.5 | 1.5 | 0.20 |

| 5 | G-N-RFA25 | 1:3 | 4:1 | 0.6 | 1.5 | 0.15 |

| 6 | G-S-RFA25 | 1:3 | 3:1 | 0.6 | 1.5 | 0.15 |

| 7 | G-N-RFA50 | 1:3 | 3:1 | 0.6 | 1.5 | 0.10 |

| 8 | G-S-RFA50 | 1:3 | 3:1 | 0.7 | 1.5 | 0.00 |

| 9 | G-N-RFA75 | 1:3 | 3:1 | 0.7 | 1.5 | 0.00 |

| 10 | G-S-RFA75 | 1:2 | 3:1 | 0.7 | 1.5 | 0.00 |

| 11 | G-N-RFA100 | 1:3 | 3:1 | 0.7 | 1.5 | 0.00 |

| 12 | G-S-RFA100 | 1:2 | 3:1 | 0.7 | 1.5 | 0.00 |

| Mix ID | Flow (cm) | Air Content (%) | Water Retention (%) | Setting Time (min) | |

|---|---|---|---|---|---|

| Initial | Final | ||||

| C-N-RFA0 | 13.7 | 10.5 | 83 | 195 | 700 |

| C-S-RFA0 | 18.2 | 8.5 | 80 | 290 | 799 |

| G-N-RFA0 | 19.5 | 15.0 | 89 | 48 | 171 |

| G-S-RFA0 | 20.1 | 7.3 | 89 | 39 | 168 |

| G-N-RFA25 | 18.5 | 13.8 | 92 | 43 | 175 |

| G-S-RFA25 | 16.8 | 8.5 | 90 | 34 | 134 |

| G-N-RFA50 | 18.3 | 9.2 | 96 | 24 | 86 |

| G-S-RFA50 | 17.6 | 8.8 | 96 | 25 | 176 |

| G-N-RFA75 | 15.7 | 10.3 | 98 | 36 | 149 |

| G-S-RFA75 | 19.5 | 7.8 | 98 | 39 | 226 |

| G-N-RFA100 | 15.7 | 11.5 | 98 | 21 | 127 |

| G-S-RFA100 | 19.0 | 6.5 | 98 | 27 | 189 |

| Mix ID | Compressive Strength (MPa) | Pull-Off Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|

| 1-Day | 7-Day | 28-Day | 28-Day | Failure Mode | 28-Day | |

| C-N-RFA0 | 1.9 ± 0.1 | 9.1 ± 0.5 | 11.4 ± 0.8 | 0.5 ± 0.0 | Cohesive | 1.95 ± 0.13 |

| C-S-RFA0 | 6.5 ± 0.4 | 20.6 ± 1.0 | 20.7 ± 1.7 | 0.8 ± 0.1 | Adhesive | 4.06 ± 0.34 |

| G-N-RFA0 | 1.9 ± 0.1 | 9.6 ± 0.1 | 13.8 ± 0.4 | 0.9 ± 0.1 | Cohesive | 2.33 ± 0.01 |

| G-S-RFA0 | 5.8 ± 0.2 | 14.5 ± 0.3 | 16.0 ± 0.6 | 1.1 ± 0.1 | Cohesive | 3.51 ± 0.09 |

| G-N-RFA25 | 2.3 ± 0.2 | 11.8 ± 0.1 | 14.3 ± 0.3 | 0.7 ± 0.0 | Cohesive | 2.14 ± 0.01 |

| G-S-RFA25 | 6.1 ± 0.3 | 14.8 ± 0.4 | 15.0 ± 0.7 | 0.8 ± 0.2 | Adhesive | 3.02 ± 0.25 |

| G-N-RFA50 | 2.1 ± 0.2 | 10.8 ± 1.4 | 11.4 ± 0.2 | 0.6 ± 0.1 | Cohesive | 2.12 ± 0.06 |

| G-S-RFA50 | 6.2 ± 0.2 | 13.9 ± 1.5 | 14.7 ± 0.6 | 0.8 ± 0.2 | Adhesive | 2.84 ± 0.12 |

| G-N-RFA75 | 1.3 ± 0.1 | 9.0 ± 1.2 | 9.5 ± 0.9 | 0.6 ± 0.0 | Cohesive | 2.09 ± 0.15 |

| G-S-RFA75 | 2.7 ± 0.1 | 13.4 ± 0.8 | 14.7 ± 0.9 | 0.7 ± 0.1 | Adhesive | 2.49 ± 0.34 |

| G-N-RFA100 | 1.1 ± 0.1 | 8.2 ± 0.7 | 8.8 ± 0.1 | 0.5 ± 0.1 | Cohesive | 1.69 ± 0.11 |

| G-S-RFA100 | 2.3 ± 0.1 | 13.0 ± 0.5 | 14.5 ± 0.0 | 0.7 ± 0.0 | Adhesive | 2.20 ± 0.26 |

| Reference | Flexural Strength | Correction Factor | Modified Equation |

|---|---|---|---|

| AS3600 [84] | 0.6 fc0.5 | 1.08 | 0.65 fc0.5 |

| ACI 318-19 [85] | 0.62 fc0.5 | 1.05 | 0.65 fc0.5 |

| ACI 363 [86] | 0.94 fc0.5 | 0.69 | 0.65 fc0.5 |

| CEB-FIP [87] | 0.81 fc0.5 | 0.80 | 0.65 fc0.5 |

| IS-456 [88] | 0.626 fc0.5 | 1.04 | 0.65 fc0.5 |

| Mix ID | Dry Bulk Density (g/cm3) | Absorption (%) | Volume of Permeable Pore Space (%) | Bulk Electrical Resistivity (Ω∙m) | Sorptivity (mm/s0.5) | Abrasion Resistance (%) |

|---|---|---|---|---|---|---|

| C-N-RFA0 | 2.01 ± 0.01 | 13.1 ± 0.03 | 26.4 ± 0.1 | 28.9 ± 1.4 | 0.102 | 9.9 |

| C-S-RFA0 | 2.08 ± 0.01 | 12.0 ± 0.27 | 24.2 ± 0.4 | 37.3 ± 0.7 | 0.026 | 2.1 |

| G-N-RFA0 | 2.03 ± 0.01 | 11.8 ± 0.26 | 23.9 ± 0.5 | 6.5 ± 0.0 | 0.164 | 5.5 |

| G-S-RFA0 | 2.02 ± 0.02 | 10.8 ± 0.20 | 22.4 ± 0.3 | 7.0 ± 0.0 | 0.138 | 3.1 |

| G-N-RFA25 | 1.96 ± 0.01 | 12.0 ± 0.67 | 22.1 ± 1.2 | 5.5 ± 0.0 | 0.099 | 4.5 |

| G-S-RFA25 | 1.96 ± 0.02 | 13.0 ± 0.10 | 23.9 ± 0.3 | 5.9 ± 0.2 | 0.096 | 2.2 |

| G-N-RFA50 | 1.90 ± 0.01 | 12.9 ± 0.17 | 25.2 ± 0.2 | 5.0 ± 0.0 | 0.067 | 3.7 |

| G-S-RFA50 | 1.95 ± 0.01 | 13.2 ± 0.17 | 25.3 ± 0.1 | 5.4 ± 0.2 | 0.066 | 2.4 |

| G-N-RFA75 | 1.84 ± 0.00 | 13.8 ± 0.14 | 26.2 ± 0.2 | 4.9 ± 0.1 | 0.066 | 4.8 |

| G-S-RFA75 | 1.81 ± 0.01 | 13.2 ± 0.26 | 25.8 ± 0.2 | 5.6 ± 0.1 | 0.067 | 3.0 |

| G-N-RFA100 | 1.78 ± 0.01 | 16.7 ± 0.09 | 29.6 ± 0.1 | 4.3 ± 0.0 | 0.104 | 5.2 |

| G-S-RFA100 | 1.74 ± 0.01 | 18.0 ± 0.09 | 31.3 ± 0.3 | 4.3 ± 0.2 | 0.089 | 2.3 |

| Mix Designation | Component | Total | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Cement | Slag | Fly Ash | NFAs | RFAs | SS | SH(s) | Water 1 | ||

| C-N-RFA0 | 412.18 | 0.00 | 0.00 | 7.16 | 0.00 | 0.00 | 0.00 | 3.47 | 422.81 |

| C-S-RFA0 | 431.94 | 0.00 | 0.00 | 6.87 | 0.00 | 0.00 | 0.00 | 3.63 | 442.44 |

| G-N-RFA0 | 0.00 | 3.06 | 9.92 | 6.88 | 0.00 | 56.05 | 18.99 | 1.93 | 96.83 |

| G-S-RFA0 | 0.00 | 3.67 | 9.53 | 6.88 | 0.00 | 56.10 | 18.99 | 1.93 | 97.09 |

| G-N-RFA25 | 0.00 | 3.49 | 9.07 | 4.91 | 0.19 | 64.07 | 21.73 | 2.05 | 105.51 |

| G-S-RFA25 | 0.00 | 4.37 | 8.51 | 4.92 | 0.19 | 64.11 | 21.73 | 2.05 | 105.87 |

| G-N-RFA50 | 0.00 | 4.31 | 8.39 | 3.23 | 0.37 | 63.26 | 21.48 | 2.08 | 103.13 |

| G-S-RFA50 | 0.00 | 4.36 | 8.49 | 3.27 | 0.38 | 74.67 | 25.29 | 1.73 | 118.20 |

| G-N-RFA75 | 0.00 | 4.21 | 8.19 | 1.58 | 0.55 | 72.04 | 24.46 | 1.97 | 113.01 |

| G-S-RFA75 | 0.00 | 5.22 | 10.15 | 1.30 | 0.45 | 89.29 | 30.27 | 2.07 | 138.76 |

| G-N-RFA100 | 0.00 | 4.06 | 7.91 | 0.00 | 0.70 | 69.62 | 23.64 | 2.20 | 108.14 |

| G-S-RFA100 | 0.00 | 5.07 | 9.87 | 0.00 | 0.58 | 86.75 | 29.44 | 2.25 | 133.96 |

| Mix Designation | Component | Total | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Cement | Slag | Fly Ash | NFAs | RFAs | SS | SH(s) | Water 1 | ||

| C-N-RFA0 | 34.7 | 0.0 | 0.0 | 9.3 | 0.0 | 0.0 | 0.0 | 0.6 | 44.6 |

| C-S-RFA0 | 36.4 | 0.0 | 0.0 | 8.9 | 0.0 | 0.0 | 0.0 | 0.6 | 45.9 |

| G-N-RFA0 | 0.0 | 5.6 | 32.7 | 8.9 | 0.0 | 38.5 | 15.0 | 0.3 | 101.0 |

| G-S-RFA0 | 0.0 | 6.7 | 31.4 | 8.9 | 0.0 | 38.5 | 15.0 | 0.3 | 100.8 |

| G-N-RFA25 | 0.0 | 6.4 | 29.9 | 6.4 | 1.7 | 44.0 | 17.1 | 0.3 | 105.8 |

| G-S-RFA25 | 0.0 | 7.9 | 28.1 | 6.4 | 1.7 | 44.0 | 17.1 | 0.3 | 105.5 |

| G-N-RFA50 | 0.0 | 7.8 | 27.7 | 4.2 | 3.4 | 43.4 | 16.9 | 0.3 | 103.8 |

| G-S-RFA50 | 0.0 | 7.9 | 28.0 | 4.2 | 3.4 | 51.2 | 19.9 | 0.3 | 115.1 |

| G-N-RFA75 | 0.0 | 7.7 | 27.0 | 2.0 | 4.9 | 49.4 | 19.3 | 0.3 | 110.7 |

| G-S-RFA75 | 0.0 | 9.5 | 33.5 | 1.7 | 4.1 | 61.3 | 23.8 | 0.3 | 134.2 |

| G-N-RFA100 | 0.0 | 7.4 | 26.1 | 0.0 | 6.3 | 47.8 | 18.6 | 0.4 | 106.6 |

| G-S-RFA100 | 0.0 | 9.2 | 32.6 | 0.0 | 5.3 | 59.5 | 23.2 | 0.4 | 130.1 |

| Mix Designation | Weight (W) | Score (S) | PI | |||

|---|---|---|---|---|---|---|

| Environment | Cost | Waste | fc | |||

| C-N-RFA0 | 0.23 | 1.00 | 0.09 | 0.80 | 172.73 | 7.50 |

| G-N-RFA0 | 1.00 | 0.44 | 0.10 | 0.97 | 419.82 | 18.22 |

| G-N-RFA25 | 0.92 | 0.42 | 0.13 | 1.00 | 514.35 | 22.32 |

| G-N-RFA50 | 0.94 | 0.43 | 0.19 | 0.80 | 606.34 | 26.31 |

| G-N-RFA75 | 0.86 | 0.40 | 0.32 | 0.66 | 738.02 | 32.03 |

| G-N-RFA100 | 0.90 | 0.42 | 1.00 | 0.62 | 2304.30 | 100.00 |

| Mix Designation | Weight (W) | Score (S) | PI | |||

|---|---|---|---|---|---|---|

| Environment | Cost | Waste | fc | |||

| C-S-RFA0 | 0.22 | 1.00 | 0.08 | 1.00 | 179.74 | 10.04 |

| G-S-RFA0 | 1.00 | 0.46 | 0.08 | 0.77 | 288.04 | 16.08 |

| G-S-RFA25 | 0.92 | 0.43 | 0.11 | 0.72 | 319.20 | 17.83 |

| G-S-RFA50 | 0.82 | 0.40 | 0.15 | 0.71 | 360.48 | 20.13 |

| G-S-RFA75 | 0.70 | 0.34 | 0.32 | 0.71 | 550.44 | 30.74 |

| G-S-RFA100 | 0.72 | 0.35 | 1.00 | 0.70 | 1790.74 | 100.00 |

| Property | Parameter | ||||

|---|---|---|---|---|---|

| N-Type to S-Type | N-Type | S-Type | |||

| Cement to Geopolymer | RFA Replacement | Cement to Geopolymer | RFA Replacement | ||

| Flow | ↑ * | ↑ | ↓ ** | ↑ | ↓ |

| Air Content | ↓ | - *** | - | - | - |

| Water Retention | ↓ | ↑ | ↑ | ↑ | ↑ |

| Setting time | - | ↓ | ↓ | ↓ | ↓ |

| Compressive Strength | ↑ | ↑ | ↓ | ↓ | ↓ |

| Pull-off Strength | ↑ | ↑ | ↓ | ↑ | ↓ |

| Flexural Strength | ↑ | ↑ | ↓ | ↓ | ↓ |

| Bulk Density | - | - | ↓ | - | ↓ |

| Water Absorption | - | ↓ | ↑ | ↓ | ↑ |

| Permeable voids | - | ↓ | ↑ | ↓ | ↑ |

| Bulk Resistivity | ↑ | ↓ | ↓ | ↓ | ↓ |

| Sorptivity | ↓ | ↑ | ↓ | ↑ | ↓ |

| Abrasion Resistance | ↑ | ↑ | ↑ | ↓ | ↑ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abuowda, E.; El-Hassan, H.; El-Maaddawy, T. Characterization of Geopolymer Masonry Mortars Incorporating Recycled Fine Aggregates. Sustainability 2024, 16, 8147. https://doi.org/10.3390/su16188147

Abuowda E, El-Hassan H, El-Maaddawy T. Characterization of Geopolymer Masonry Mortars Incorporating Recycled Fine Aggregates. Sustainability. 2024; 16(18):8147. https://doi.org/10.3390/su16188147

Chicago/Turabian StyleAbuowda, Elen, Hilal El-Hassan, and Tamer El-Maaddawy. 2024. "Characterization of Geopolymer Masonry Mortars Incorporating Recycled Fine Aggregates" Sustainability 16, no. 18: 8147. https://doi.org/10.3390/su16188147

APA StyleAbuowda, E., El-Hassan, H., & El-Maaddawy, T. (2024). Characterization of Geopolymer Masonry Mortars Incorporating Recycled Fine Aggregates. Sustainability, 16(18), 8147. https://doi.org/10.3390/su16188147