Abstract

The decentralization of production processes organized in global supply chains has made it possible to connect the different levels through industrial digitalization, an evolution derived from the Fourth Industrial Revolution which incorporates enabling technologies. This context raises the need to analyze sectors that, due to the complexity of their projects, require more efficient supply chain management. Two clear examples of these sectors are aerospace and shipbuilding, which demand greater efficiency and sustainability in their operations. The main objective of this study is to compare these two sectors to evaluate the degree of sustainability of their supply chains and how Industry 4.0 technologies have contributed to achieving these goals. To perform this, the Delphi method will be used, a tool that collects information through expert opinions, which will provide key indicators for the comparison. The use of this method will facilitate the identification of convergences and divergences in the management of sustainability in both sectors. Through this analysis, the expected results will reflect the specific needs of each industry in terms of productivity and sustainability. Thus, the study will offer a comprehensive view of how the aerospace and shipbuilding sectors can move toward more sustainable and efficient production models, integrating Industry 4.0 concepts and improving the management of their global supply chains.

1. Introduction

Today, production processes are fragmented across different companies, organized into global supply chains that are structured at various levels.

The global supply chain is understood as the worldwide network of activities that encompass the design, production, distribution, and delivery of a company’s products and services. This chain involves multiple participants, including suppliers, manufacturers, distributors, and retailers, collaborating at an international level [1]. This international working model is related to geographically decentralized manufacturing, involving the production of complex components using industrial plants distributed across the globe. The global supply chain allows for the coordinated management of all aspects related to the factories involved in this manufacturing process [2].

This is the result of a first wave of globalization that, among other factors, was made possible by the dissemination of Information and Communication Technologies (ICTs) through the Internet in the early 2000s. Currently, a new wave of technologies, leading to the Fourth Industrial Revolution, is still in full swing, the so-called Industry 4.0, which is further multiplying opportunities [3]. Each industrial revolution has brought significant improvements in terms of manufacturing. This Fourth Industrial Revolution introduces new advanced production models with new technologies that enable the digitalization of processes, services, and even business models. Among other innovations, Industry 4.0 (I4.0) includes the social aspect in defining the performance model of manufacturing processes, thus completing the economic, energy, environmental, and functional aspects considered so far.

From the aspects mentioned above, it is deduced that the society of today needs a sustainable system that allows for business growth without compromising the ability of future generations to meet their needs and demands. Economic perspectives, ecological balance, and social responsibility are the three essential parameters for achieving sustainability. It is the harmonious interaction between these dimensions that ensures balanced growth and proper societal development [4]. In the literature, this collective approach aimed at simultaneously addressing the three dimensions is known as the ‘Triple Bottom Line’ [5]. In the past, these dimensions have been studied individually, but now it seems that the time has come to address a joint strategy that combines different manufacturing strategies to build a unified structure. The most advocated case in the literature is the one that works with the Lean, Green, and Agile models [4]. The “Lean” manufacturing strategy acts at the system level to save costs by reducing waste in the production system, thus addressing the economic dimension. The “Green” manufacturing strategy acts at the process level, saving the environment by reducing emissions and resource use, thus addressing the environmental dimension, and the “Agile” manufacturing strategy acts at the product level, satisfying the customer by providing the required product on time, thus addressing the social dimension.

The interaction between environmental management practices and numerous company performance factors is mainly related through the concept of sustainability. Thus, the implementation of environmental management practices is primarily based on reducing resource consumption and improving stakeholder relationships, so improvements in companies’ environmental performance also have a positive impact on social and financial performance [4]. The three dimensions of the LGAMS (Lean, Green, and Agile Manufacturing System) for production processes also have their representation within supply chain management paradigms thanks to the LARG (Lean, Agile, Green, and Resilient) concept, which advocates for the integration of these four models to obtain benefits derived from their synergies and to better meet the demands, not only of their customers, but of society in general. It is important to highlight the inclusion of the “Resilient” paradigm, which is not included in the LGAMS system. This is because the LARG paradigm is an even broader and more diverse approach, considering resilience as another key concept for achieving a sustainable supply chain. As will be seen later, resilience refers to the supply chain’s ability to cope with unexpected disruptions [6]. This is fundamental in a changing and constantly evolving society like the current one, where countless factors can affect the proper development of the supply chain.

The deployment of LARG practices within companies and their respective supply chains aims to achieve compatibility between the application of Lean production principles (based on zero-stock, no-waste, or non-value-added activities) with Agility (which assumes adjustment to constantly changing markets), while also considering the necessary resilience of the production system in the face of possible disruptions and risks (some can be predictable, but others occur completely unexpectedly) and also “Green” principles to reduce environmental impacts [7].

Focusing on two construction sectors, such as shipbuilding and aerospace, there are important similarities between them. The shipbuilding sector has the following two distinct fields of work: one dedicated to the repair, maintenance, or improvement of already-built ships, and the second dedicated to new ships. As for the new construction, it could be considered a case of distributed manufacturing, where the different blocks that make up the ship, built in different workshops belonging to the same manufacturing center, are later assembled at the dock. This highlights how both sectors, shipbuilding and aerospace, can be discussed in terms of distributed manufacturing. Therefore, both sectors can be considered complex manufacturing processes that must adapt to I4.0 to progress.

In the framework of Industry 4.0, the main goal of the supply chain in both sectors should be the total visibility of all product movements for each member of the chain, as well as complete integration to achieve the improved competitiveness and sustainability of the company [8]. The most important supply chain paradigms found in the literature, from the perspective of sustainability, are in the LARG paradigm, and among its components, focus will be on the Green paradigm.

This Green paradigm encompasses the management of sustainable products from the perspective of risks as well as the performance of managing various suppliers, even simultaneously [9]. The consideration that this Green term has in the supply chain consists of including the environmental aspect within supply chain management from the product design stages, through the manufacturing process itself, to the delivery to the end-consumer, and even managing the end-of-life of the manufactured product [10]. This paradigm even leads to the determination that, by greening the various stages of the supply chain, an integrated Green supply chain can be achieved, which would lead to increased competitiveness and economic performance [11,12]. The sustainable supply chain also considers the coordination of economic, environmental, and social considerations [13,14].

In the case at hand, and based on previous studies, we use the Delphi method as a strategic information collection tool suitable for analyzing the sustainable aspect of the supply chain in both sectors [7] and establish a comparison between them that leads us to establish convergences and divergences for both sectors.

This study compares the aerospace industry and the shipbuilding sector from the Green point of view. These industries present complex projects that provide for more efficient supply chain management, which will allow us to determine the sustainability of these projects and how I4.0 technologies have helped to achieve the results. This study presents indicators to obtain comparative information through expert opinion using the Delphi method. The results obtained reflect the specific needs of each industry.

Therefore, the goal of the article is to merge and expand the concepts of sustainability in Industry 4.0, the global supply chain in the aerospace industry, and shipbuilding, providing a comprehensive and detailed view of how companies can move towards a more sustainable and efficient production model.

2. Materials and Methods

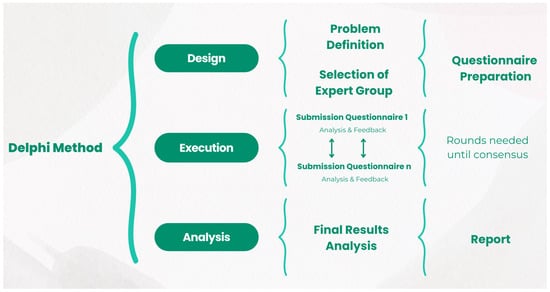

As already mentioned, the experimental methodology used in this case study will follow the Delphi method. This method has been previously used in the literature to address various studies on the supply chain [15,16,17,18]. Likewise, its use in the analysis oriented to the shipbuilding sector [19] has been used as the basis to try to obtain comparable results for the comparison between sectors. Figure 1 shows a general scheme developed below.

Figure 1.

Methodology.

As can be seen, the methodology consists of three phases, starting with the definition of the problem. In this case, the aim is to learn about the technological advances related to the global supply chain from the perspective of sustainability in two industries related to the transport sector, namely, the aeronautical and shipbuilding sectors. In the case of shipbuilding, the focus is on new work, i.e., the manufacture of new ships, carried out in shipyards. In the case of aerospace, on the other hand, it focuses on an aerostructure manufacturing plant, and specifically on an assembly line for aeronautical components. Therefore, the sample has been divided to identify the existence of possible connections between the type of manufacturing process and the results of the survey.

Once the case studies were defined, the Industry 4.0 enabling technologies best suited to the case study were defined according to their contribution to the sustainability of the supply chain in the sector studied. Specifically, additive manufacturing, Big Data, cloud computing, augmented reality, autonomous robots, automated guided vehicles (AGVs), Blockchain, cybersecurity, horizontal and vertical integration systems, artificial intelligence, the Internet of Things (IoT), and simulation were selected, since these technologies have already been studied in previous cases for shipbuilding [20] and will be the same ones used for the aerospace sector.

Regarding the selection of participating experts, the aim was to involve individuals from each sector with knowledge and interest in the subject and whose professional development has been related to the topic of study. In addition, a blind treatment of the data was carried out to achieve the greatest objectivity in the results obtained. Therefore, 40 participants were selected for each sector. In the shipbuilding sector, half of the participants belonged to different areas within the parent company studied, and the other half corresponded to professionals who, without belonging to the company directly, collaborated through contracts and research agreements in this field. In the aerospace sector, half of the participants belonged to different areas within the parent company and the other half belonged to other professionals involved in the plant as suppliers of the parent company.

To complete the first phase, the questionnaires were defined. These were divided into three parts, with the first one measuring, between “not important at all” and “extremely important”, the importance of the inclusion of sustainability in the supply chain. In other words, we used the 5-point Likert scale adapted to the context, in which the importance was assessed, that is, the assessment of the issue addressed, ranging from “not at all important”, represented with the value “1”, and “extremely important”, represented with the value “5”.

The second part of the questionnaire tried to evaluate the implementation of sustainable practices in the supply chain. Finally, the third part of the questionnaire tried to evaluate the weight/importance of the 12 Industry 4.0 Key Enabling Technologies (KETs) for the achievement of sustainability in the supply chain for each of the sectors.

Once the questionnaire was designed, we continued with the next phase, which was the execution and launch of the first round of surveys to all participants. The questionnaire was carried out through computerized forms that were shared via e-mail for ease of use. After the first round, the data were collected and analyzed through basic statistical indicators; given that it was concluded that there was not enough consensus among the answers of the professionals analyzed through Kendall’s coefficient of concordance, it was necessary to perform a second round of surveys.

This proceeded in the same way as the first round, except that, on this occasion, the participants were informed of the results of the first round. Consequently, the results were more consistent among the professionals, and it was decided to conclude the survey phase to proceed with the data analysis.

The last phase was the data analysis. For this analysis, the final responses obtained were used. Since this was a lengthy process, the number of responses may not be the same for each sector; however, the process included the use of weighted averages, which ensured that the analysis of different amounts of data did not influence the outcome.

The analysis phase consisted of three parts. In the first part, the importance of sustainability for the supply chain of each of the sectors studied was analyzed individually. Through the evaluation of the answers obtained to the question “How relevant do you consider the “Green” aspect for the supply chain in the sector?” asked to the experts, we obtained the average of the answers obtained.

In the second part, an analysis was performed of how these sustainable practices have been implemented in the supply chain, which made it possible to compare how sustainable the supply chains of both sectors were. For this, the questionnaire consisted of four questions, as shown in Table 1.

Table 1.

Questions concerning the Green supply chain behavior.

The weight of each of the practices was conducted following Equation (1), as follows:

where Wx represents the weighting of the Green practice x, MRx represents the average rate of that practice, and represents the sum of the averages of each practice.

Following this point, an analysis of the behavior of the Green paradigm in both sectors was conducted by Equation (2) as follows:

where Dixj is the response of expert “i” to practice “j” of the Green paradigm. Similarly, the behavior of this paradigm was carried out by Equation (3) as follows:

Finally, the third section evaluated and compared the importance of each of the twelve enabling technologies (KETs) for the supply chain in each sector. To determine the technological advances in the supply chains of both sectors, a weighting of the responses of the experts in this regard was used. Table 2 shows the questions asked relating each of the Industry 4.0 enabling technologies to the paradigm studied for the global supply chain. In the same way as the mean rating, the weights are calculated using Equation (1).

Table 2.

Questionnaire on technological advances for global supply chain sustainability.

With these weights, it was possible to calculate the relevance of the Green aspect in the supply chain through the technologies studied by following Equation (4), whose sum, Equation (5), will allow for the calculation of the Green 4.0 performance of each supply chain, as follows:

These calculations yielded the data used in the analysis of the results.

3. Results

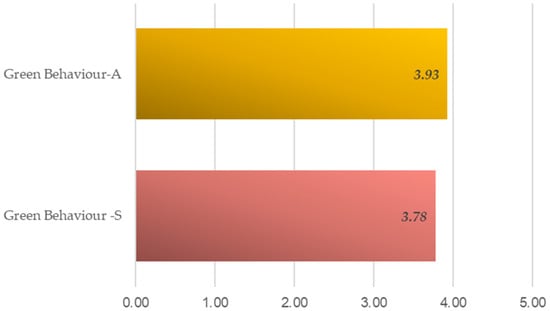

The first aspect that was analyzed was the importance of sustainability for the supply chain in both sectors (Figure 2), where, from now on, the shipbuilding sector will be referred to as “S” and the aerospace sector will be referred to as “A” in all of the figures and graphs.

Figure 2.

Importance of sustainability in the supply chain for both sectors.

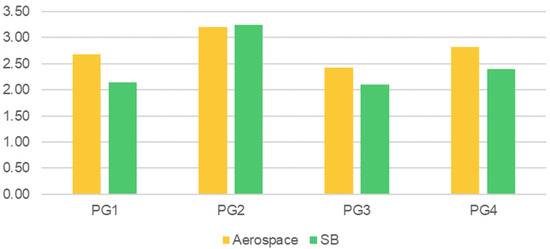

As mentioned previously, the second part of the analysis leads us to evaluate the level of implementation of Green practices in each of the sectors. Table 3 shows the mean rating and weights of the level of implementation of Green practices in the supply chain for both sectors, while Figure 3 shows the comparison of these values.

Table 3.

Mean rating and weights of the Green supply chain behavior for the shipbuilding (S) and aerospace (A) sectors.

Figure 3.

Level of implementation of Green practices in the supply chain.

It can be observed that, in most cases, the aerospace industry has a higher level of implementation of Green practices compared to the shipbuilding industry, except for Practice 2, “ISO 14001 Certification.” This could be because the experts consulted in the shipbuilding industry often work on defense-related projects, where the regulations are very strict, whereas, in the aerospace sector, the experts have more diverse profiles, although they still assign equal importance to this certification.

When these data are analyzed (Figure 4), it can be observed that, overall, the aerospace sector shows a higher level of implementation, at around 5%, which is not a significantly differentiating value. However, it is worth noting that, in both cases, the total value exceeds 50%, which suggests that these are established and consolidated practices in the current industry.

Figure 4.

Green paradigm behavior.

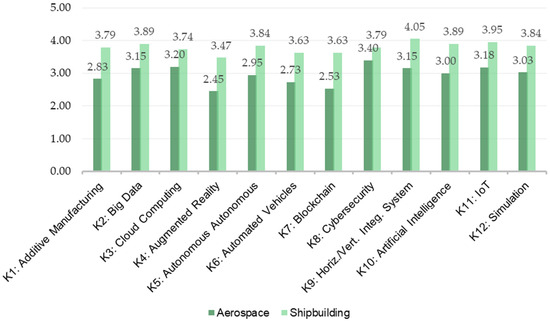

Furthermore, the importance of each of the twelve enabling technologies (KETs) for the supply chain in each sector are compared with the behavior of the KETs that were calculated in the same way as above according to the behavior of the experts, as shown in Table 4 and Figure 5.

Table 4.

Mean rating and weight of each KET studied by sectors.

Figure 5.

Behavior of each KET for each sector according to the response of the experts.

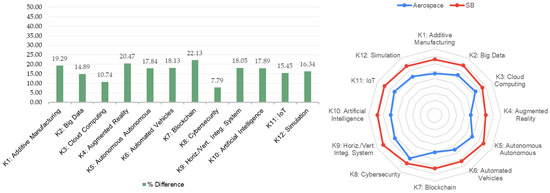

However, these results are contrary to the previous ones, as it can be observed that, when analyzing the practices related to Industry 4.0, the shipbuilding sector shows a higher degree of implementation. This may be due to the development of specific Industry 4.0 models tailored to the shipbuilding sector, which have facilitated the incorporation and advancement of these technologies. Combined with a good level of implementation of Green practices in the sector, this has led to a high level of adoption of these technologies for their Green application. Analyzing the percentage difference between the technologies studied in both sectors, Figure 6 clarifies the current situation with respect to the sustainability of the supply chain.

Figure 6.

Percentage difference between the KETs of both sectors.

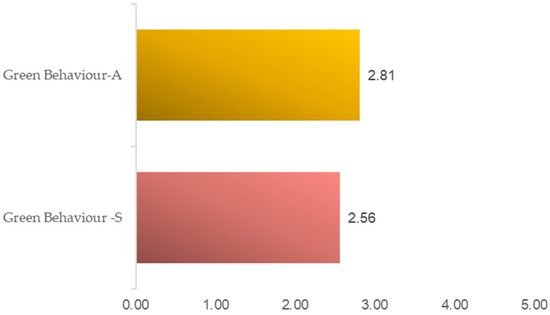

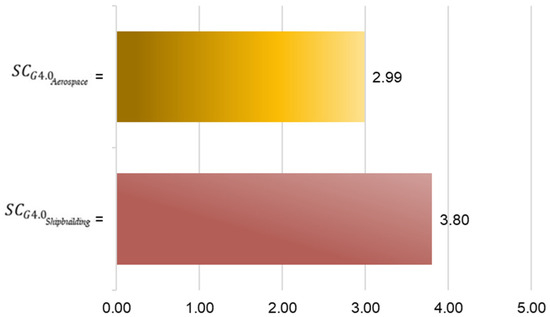

At this point, it is possible to calculate the relevance of the Green aspect in the global supply chain through the Industry 4.0 technologies studied in each sector. These values are shown in Figure 7.

Figure 7.

General KET behavior in each sector.

These data show that, in the case of shipbuilding, the value of the index is significantly higher than that of the aerospace sector, at around 15%. This reveals that, although the aerospace sector has more practices applied with respect to the Green paradigm, the advancement of enabling technologies makes the shipbuilding sector better prepared for the technological transition in this paradigm, and therefore better prepared for future sustainability management.

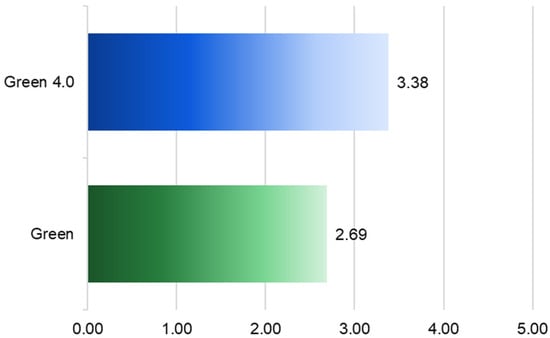

However, if the data of the two sectors are analyzed together to know the state of sustainability in the manufacture of highly complex mass transportation systems (ships and aircraft), it can be seen that, although the Green paradigm is extremely important, the industry is aware of this impact, and therefore works toward technological advances that will enable the proper management of sustainability in the future through KETs. For this reason, the global index 4.0 (3.38) is higher than the one for the current state (2.69), as shown in Figure 8.

Figure 8.

Green level of the supply chain of both sectors with and without KETs.

This is an excellent response from these sectors, a priori, of the most polluting technologies, who are aware of this and of the importance of sustainability and Industry 4.0, and how they will provide solutions to improve these aspects in a sustainable way.

4. Discussion

In the shipbuilding and aerospace sectors, sustainability has emerged as a key component, driven by both international regulations and growing environmental awareness. In the aerospace industry, the pursuit of sustainability has materialized through practices integrated into supply chains, adopting Green technologies and management methods that promote energy efficiency and emission reductions. A notable example is the use of composite materials in aircraft manufacturing, which reduces the weight of structures, thereby improving the fuel consumption-to-load capacity ratio. This strategy not only reduces the environmental impact throughout the aircraft’s life cycle but also optimizes the long-term operational costs [21].

On the other hand, in the shipbuilding sector, there has been increased attention toward sustainability in recent decades, especially in maritime logistics and transportation. The International Maritime Organization (IMO) has driven regulations that require ships to reduce emissions and improve interactions between ports and cities, forcing the industry to adopt more sustainable practices in its operations. Although this sector has historically been slower to implement these measures compared to aviation, the trend toward cleaner maritime transport is quickly gaining momentum [22]. This aligns with the data presented in previous sections, where Industry 4.0 technologies have rapidly advanced in the shipbuilding sector. A clear example of this application is in the use of large-format additive manufacturing in the shipbuilding sector, where the inherently sustainable characteristics of the technology are leveraged [23,24].

Similarly, in the aerospace industry, advancements in supply chain management have enabled the integration of Green practices, promoting a more resilient and sustainable approach. These practices not only enhance the environmental performance but also optimize the operational efficiency and profitability, making them a crucial tool for addressing the sector’s current challenges [25].

As a result, both the shipbuilding and aerospace sectors have made significant strides in adopting sustainable practices, albeit at different paces. The implementation of Green technologies, the optimization of supply chains, and compliance with environmental regulations are key pillars in achieving greater sustainability in both industries. Although challenges remain, the efforts made thus far demonstrate the commitment of these sectors to a more sustainable future [26].

The implementation of Industry 4.0 in the shipbuilding and aerospace sectors has brought about a significant shift, promoting the digitization and automation of production processes. In the aerospace field, the adoption of these technologies has facilitated the integration of cyber–physical systems, enabling the creation of more agile and efficient supply chains, which improves the competitiveness and reduces the operational costs. The concept of the “smart factory” has been key in the modernization of these sectors by introducing sensors and real-time data analysis systems, allowing for better decision making and resource optimization. This approach also drives sustainability, as optimizing processes reduces energy consumption and emissions [27].

In the shipbuilding sector, the concept of “Shipyard 4.0” has been developed to integrate digital technologies into the construction and management of naval platforms. A notable example is Navantia, a Spanish company that has implemented a digital transformation plan, including automation and the integration of functional and business requirements. This strategy has proven to improve the operational efficiency and sustainability in complex projects, such as the construction of naval platforms, through the digitization of key processes [28]. This model exemplifies the push for Industry 4.0 in the shipbuilding sector, as previously discussed.

Additionally, models have been developed to facilitate the implementation of Industry 4.0 in both sectors, with an emphasis on simulations and maturity models. These tools allow companies to assess their current state and efficiently plan their digital transformation [29,30]. However, the degree of technology implementation in the aerospace sector does not seem to be as advanced as in the shipbuilding sector.

The differences in the importance of the technologies considered in the study between the aerospace and shipbuilding sectors reflect the specific needs and challenges of each industry. It seems that the data obtained in the results indicate that shipbuilding tends to value these technologies more highly due to the scale and complexity of its projects, as well as the opportunities to improve the efficiency and coordination through advanced technologies. However, in this study, each of the technologies has been analyzed independently.

As indicated previously, horizontal and vertical integrated systems are the highest rated according to the responses of experts in the shipbuilding sector, although slightly ahead of the rest, followed by IoT.

The Internet of Things (IoT) is crucial in both sectors for monitoring and controlling systems. In shipbuilding, the IoT enables the efficient management of ship operations, monitoring equipment status, environmental conditions, and operational performance in real time. This is vital for predictive maintenance and route optimization, improving safety, and reducing operating costs. In aerospace, the IoT is also important for aircraft monitoring and fleet management, but the integration of the IoT into aircraft systems faces greater challenges due to the need for robust cybersecurity and device certification [19,31].

Big Data continues as the third KET, together with artificial intelligence, in the score. Big Data analysis is crucial in both sectors to optimize processes and predict failures. In shipbuilding, the integration of large volumes of data from various sources (maintenance, operations, and design) is essential for fleet management and route optimization. The ability to analyze historical and real-time data significantly improves the operational efficiency and safety. In aerospace, Big Data is also critical, but the complexity of systems and data integration across multiple systems and platforms can be an additional challenge [32,33].

Artificial intelligence (AI) plays a key role in process optimization, predictive analytics, and improved decision making. In shipbuilding, AI is used for optimized ship design, operations simulation, and predictive maintenance, which increases the efficiency and reduces costs. In aerospace, AI is used in autonomous navigation, fault detection, and air traffic management. However, the implementation of AI in manned aircrafts requires rigorous certifications and extensive testing to ensure safety [34,35].

Following the order marked by shipbuilding, simulation appears as a powerful tool for the design and evaluation of complex systems in shipbuilding. Simulation is used to evaluate ship performance under various conditions, optimize design, and train crew. In aerospace, simulations are critical for aircraft testing, mission planning, and pilot training. While both industries highly value simulation, aerospace applications can face greater challenges due to the need for high fidelity and accuracy in simulated models [36].

Robotics is essential in automating processes and performing dangerous or repetitive tasks. In shipbuilding, robots are used for welding, cutting, and inspection in harsh environments, improving worker safety and task accuracy. In aerospace, robotics is applied in component manufacturing and assembly, as well as in space exploration [35,37].

Additive manufacturing and cybersecurity follow. Additive manufacturing is especially useful in shipbuilding because of the need to create large, customized parts efficiently. In addition, parts can be produced on-site, which reduces costs and lead times. In aerospace, while also important, high precision and certification requirements may limit its wider application compared to shipbuilding. Although additive manufacturing allows for the creation of lighter and more complex parts, ideal for aircraft fuel economy, strict regulations and the need for safety certifications are major obstacles in this sector [38,39].

Cybersecurity is critical in both sectors to protect sensitive systems and data. In shipbuilding, the protection of navigation, communication, and operational systems is vital to prevent cyber-attacks that could compromise the safety of vessels. In aerospace, cybersecurity is even more crucial due to the high sensitivity of the data and the interconnection of multiple critical systems. The implementation of cybersecurity measures must comply with rigorous international regulations and standards [40,41].

Cloud computing follows the ranking, which enables the management and analysis of large amounts of data and facilitates remote collaboration. In the marine industry, where projects can involve multiple stakeholders in various geographic locations, cloud computing is essential for effective coordination. In addition, the ability to access real-time data and applications from anywhere improves efficiency and reduces costs. In aerospace, cloud computing is also valuable, especially for predictive maintenance and flight simulation, although concerns about data security may be heightened [33,42].

Within the study on supply chain sustainability, Blockchain technology is evident in both sectors, where top management is responsible for strategic decision making and thus for designing and implementing sustainability in the organization [43,44]. Together with augmented reality (AR), it has significant applications in shipbuilding for visualizing complex designs and training workers. Operators can use AR devices to overlay digital information on top of the physical environment, making tasks easier to understand and improving accuracy. In aerospace, while AR is useful for training and maintenance, its implementation may be more limited, again, by high demands for accuracy and safety. The need for specialized hardware and integration with existing information systems can also be a challenge [20,45].

Autonomous systems are vital in shipbuilding for tasks such as autonomous maintenance and navigation. These systems can operate in challenging marine environments and perform repetitive or hazardous tasks without human intervention, improving safety and efficiency. In aerospace, autonomous systems are also important, especially in drones and unmanned aerial vehicles. However, the integration and regulation of autonomous systems in manned aircraft presents additional challenges due to stringent aviation safety regulations and the need for complex interactions with air traffic control systems [45,46].

5. Conclusions

The current industrial context, characterized by the decentralization of production processes and the increasing globalization of supply chains, has been transformed by digitalization and the enabling technologies of Industry 4.0. Within this framework, the shipbuilding and aerospace sectors face similar challenges regarding the efficiency and sustainability of their operations, although with specific characteristics unique to each industry.

The study results show that, while both sectors have advanced in implementing sustainable practices in their supply chains, the aerospace sector tends to have a slightly higher level of implementation. However, the shipbuilding sector demonstrates the greater adoption of Industry 4.0 technologies, providing it with better preparedness to face future sustainability challenges. Key technologies such as additive manufacturing, Big Data, and cybersecurity are essential for both sectors, but it is in shipbuilding where a more extensive use of their potential is observed due to the complexity and scale of its projects.

Industry 4.0 has profoundly transformed how industrial sectors approach sustainability by integrating advanced technologies that improve efficiency and reduce the environmental impact of global supply chains.

The use of sustainable practices in supply chains is already well established in both sectors, with more than 50% implementation in both cases. However, further progress is needed in adopting Green technologies and enhancing collaboration with suppliers to optimize results.

While both sectors recognize the importance of Industry 4.0 technologies, shipbuilding appears to be more advanced in its integration, suggesting that it is better positioned to handle the technological transition toward more sustainable and resilient models.

Both the aerospace and shipbuilding sectors continue to focus on implementing Industry 4.0 technologies, with a special attention on cybersecurity, IoT, and artificial intelligence, to ensure efficient sustainability management in their global supply chains, and on additive manufacturing as a key production technology.

These results highlight the importance of technological innovation in the evolution toward a more sustainable and efficient industry, where digitalization and Green practices play a fundamental role in the future competitiveness of both sectors.

Author Contributions

Conceptualization, M.B. and M.R.-P.; methodology, M.B., P.P.-M. and M.R.-P.; validation, M.R.-P. and M.O.-M.; formal analysis, P.P.-M. and M.R.-P.; investigation, P.P.-M. and M.R.-P.; data curation, P.P.-M., M.B. and M.R.-P.; writing—original draft preparation, M.R.-P.; writing—review and editing, M.B. and M.O.-M.; project administration, M.R.-P. and M.O.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

Acknowledgments

This work has been developed under the support of the Mechanical Engineering and Industrial Design department and the Vice-Rector’s Office for Scientific Policy of the University of Cadiz. The authors wish to provide special thanks to the research group TEP-027 “Engineering and Technology of Materials and Manufacturing” of the University of Cadiz.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rodrigue, J.P. The Geography of Global Supply Chains: Evidence from Third-Party Logistics. J. Supply Chain. Manag. 2012, 48, 15–23. [Google Scholar] [CrossRef]

- Shamsuzzoha, A.H.M.; Helo, P.T. Distributed Supply Chain in a Global Environment. Int. J. Logist. Syst. Manag. 2010, 7, 393–411. [Google Scholar] [CrossRef]

- Hu, A.H.; Hsu, C.W. Empirical Study in the Critical Factors of Green Supply Chain Management (GSCM) Practice in the Taiwanese Electrical and Electronics Industries. In Proceedings of the ICMIT 2006 Proceedings—2006 IEEE International Conference on Management of Innovation and Technology, Singapore, 21–23 June 2006; Volume 2, pp. 853–857. [Google Scholar]

- Rao, P.; Holt, D. Do Green Supply Chains Lead to Competitiveness and Economic Performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Confirmation of a Measurement Model for Green Supply Chain Management Practices Implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Holt, D.; Ghobadian, A. An Empirical Study of Green Supply Chain Management Practices amongst UK Manufacturers. J. Manuf. Technol. Manag. 2009, 20, 933–956. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G. Exploring Industry 4.0 Technologies to Enable Circular Economy Practices in a Manufacturing Context: A Business Model Proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, Y.; Zhang, N.; Huang, T. An Optimization Model for Green Supply Chain Management by Using a Big Data Analytic Approach. J. Clean. Prod. 2017, 142, 1085–1097. [Google Scholar] [CrossRef]

- Wang, K.Q.; Liu, H.C.; Liu, L.; Huang, J. Green Supplier Evaluation and Selection Using Cloud Model Theory and the QUALIFLEX Method. Sustainability 2017, 9, 688. [Google Scholar] [CrossRef]

- Sony, M. Industry 4.0 and Lean Management: A Proposed Integration Model and Research Propositions. Prod. Manuf. Res. 2018, 6, 416–432. [Google Scholar] [CrossRef]

- Yuan, Z.; Gong, Y. Improving the Speed Delivery for Robotic Warehouses. IFAC-PapersOnLine 2016, 49, 1164–1168. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Iakovou, E. Sustainable Supply Chain Management in the Digitalisation Era: The Impact of Automated Guided Vehicles. J. Clean. Prod. 2017, 142, 3970–3984. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Sarkis, J. Blockchain Practices, Potentials, and Perspectives in Greening Supply Chains. Sustainability 2018, 10, 3652. [Google Scholar] [CrossRef]

- Maccari, M.; Polzonetti, A.; Sagratella, M. Proceedings of the Future Technologies Conference (FTC) 2018; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; Volume 881, ISBN 978-3-030-02682-0. [Google Scholar]

- Lara, M. Sistemas de Integración Horizontal y Vertical En Industria 4.0: Evaluación y Desarrollo; Autonomous University of Nuevo León San Nicolás de los Garza, Nuevo León, Mexico Join Institution: San Nicolás de los Garza, Mexico, 2018. [Google Scholar]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated Fuzzy Multi Criteria Decision Making Method and Multiobjective Programming Approach for Supplier Selection and Order Allocation in a Green Supply Chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Chen, R.Y. Intelligent IoT-Enabled System in Green Supply Chain Using Integrated FCM Method. Int. J. Bus. Anal. 2015, 2, 47–66. [Google Scholar] [CrossRef]

- Vlachos, D.; Georgiadis, P.; Iakovou, E. A System Dynamics Model for Dynamic Capacity Planning of Remanufacturing in Closed-Loop Supply Chains. Comput. Oper. Res. 2007, 34, 367–394. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A Survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Nee, A.Y.C.; Ong, S.K.; Chryssolouris, G.; Mourtzis, D. Augmented Reality Applications in Design and Manufacturing. CIRP Ann. Manuf. Technol. 2012, 61, 657–679. [Google Scholar] [CrossRef]

- Fera, M.; Abbate, R.; Caterino, M.; Manco, P.; Macchiaroli, R.; Rinaldi, M. Economic and Environmental Sustainability for Aircrafts Service Life. Sustainability 2020, 12, 10120. [Google Scholar] [CrossRef]

- Lee, P.T.W.; Kwon, O.K.; Ruan, X. Sustainability Challenges in Maritime Transport and Logistics Industry and Its Way Ahead. Sustainability 2019, 11, 1331. [Google Scholar] [CrossRef]

- Sánchez, D.M.; de la Mata, M.; Delgado, F.J.; Casal, V.; Molina, S.I. Development of Carbon Fiber Acrylonitrile Styrene Acrylate Composite for Large Format Additive Manufacturing. Mater. Des. 2020, 191, 108577. [Google Scholar] [CrossRef]

- Moreno-Sanchez, D.; Rodriguez, J.D.; Dominguez-Calvo, A.; Molina, S.I.; Corrales-Estárico, E.; Casal, V.; Abad, F. On Board Additive Manufacturing of Spare Parts for the Naval Sector. In Proceedings of the RINA, Royal Institution of Naval Architects—International Conference on Marine Design 2020, Cadiz, Spain, 15–16 January 2020; pp. 75–81. [Google Scholar]

- Ruiz-Benitez, R.; López, C.; Real, J.C. Environmental Benefits of Lean, Green and Resilient Supply Chain Management: The Case of the Aerospace Sector. J. Clean. Prod. 2017, 167, 850–862. [Google Scholar] [CrossRef]

- Ramirez-Peña, M.; Mayuet, P.F.; Vazquez-Martinez, J.M.; Batista, M. Sustainability in the Aerospace, Naval, and Automotive Supply Chain 4.0: Descriptive Review. Materials 2020, 13, 5625. [Google Scholar] [CrossRef]

- Pop, G.I.; Titu, A.M.; Pop, A.B. Enhancing Aerospace Industry Efficiency and Sustainability: Process Integration and Quality Management in the Context of Industry 4.0. Sustainability 2023, 15, 16206. [Google Scholar] [CrossRef]

- Cerezo-Narváez, A.; Otero-Mateo, M.; Rodríguez-Pecci, F.; Pastor-Fernández, A. Digital Transformation of Requirements in the Industry 4.0: Case of Naval Platforms. Dyna 2018, 93, 448–456. [Google Scholar] [CrossRef]

- Ivanov, K.A.; Gostilovich, A.O. Developing a Model for the Introduction of Industry 4.0 Technologies into the Production Processes of Aviation Industry Enterprises. Econ. Manag. 2022, 28, 584–594. [Google Scholar] [CrossRef]

- Sujova, E.; Cierna, H.; Bambura, R. Simulation Model of Production as Tool for Industry 4.0 Implementation into Practice. Eng. Rural. Dev. 2019, 18, 1192–1197. [Google Scholar] [CrossRef]

- Li, S.; Xu, L.D.; Zhao, S. The Internet of Things: A Survey. Inf. Syst. Front. 2015, 17, 243–259. [Google Scholar] [CrossRef]

- Kambatla, K.; Kollias, G.; Kumar, V.; Grama, A. Trends in Big Data Analytics. J. Parallel Distrib. Comput. 2014, 74, 2561–2573. [Google Scholar] [CrossRef]

- Stallings, W. Overview of Cloud Computing. In Cloud Computing Security: Foundations and Challenges; CRC Press: Boca Raton, FL, USA, 2016; pp. 13–30. [Google Scholar] [CrossRef]

- Lecun, Y.; Bengio, Y.; Hinton, G. Deep Learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Siciliano, B.; Khatib, O. Robotics and the Handbook; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 9783319325521. [Google Scholar]

- Johnson, R.B.; Christensen, L. Simulation Modeling and Analysis; McGraw-Hill Education: New York, NY, USA, 2014; ISBN 5951801567. [Google Scholar]

- Thrun, S. Probabilistic Robotics. Commun. ACM 2002, 45, 52–57. [Google Scholar] [CrossRef]

- Diegel, O.; Nordin, A.; Motte, D. Additive Manufacturing Technologies; Springer Nature: Berlin/Heidelberg, Germany, 2019; ISBN 9781441911193. [Google Scholar]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Stallings, W. Network Security Essentials, 6th ed.; Edition, G., Ed.; Pearson: Halow, UK, 2021; ISBN 9780134527338. [Google Scholar]

- Nguyen, T.T.; Lee, H. High-Speed Low-Complexity Elliptic Curve Cryptographic Processor; IEEE: Piscataway, NJ, USA, 2016; ISBN 9781467393089. [Google Scholar]

- Osorio, G.A.; Del Real, C.S.; Valdez, C.A.F.; Miranda, M.C.; Garay, A.H. Effect of Inclusion of Cactus Pear Cladodes in Diets for Growing-Finishing Lambs in Central Mexico. Acta Hortic. 2006, 728, 269–274. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the Future of Sustainable Supply Chain Management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Nayak, G.; Dhaigude, A.S. A Conceptual Model of Sustainable Supply Chain Management in Small and Medium Enterprises Using Blockchain Technology. Cogent Econ. Financ. 2019, 7, 1667184. [Google Scholar] [CrossRef]

- Bhouri, I. On the Projections of Generalized Upper Lq-Spectrum. Chaos Solitons Fractals 2009, 42, 1451–1462. [Google Scholar] [CrossRef]

- Thrun, S. Toward Robotic Cars. Commun. ACM 2010, 53, 99–106. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).