Utilization of Earthquake Demolition Wastes and Afşin–Elbistan Fly Ash for Soil Improvement after the Kahramanmaraş Earthquake (6 February 2023)

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Methods

3. Results

3.1. Atterberg Limit Tests

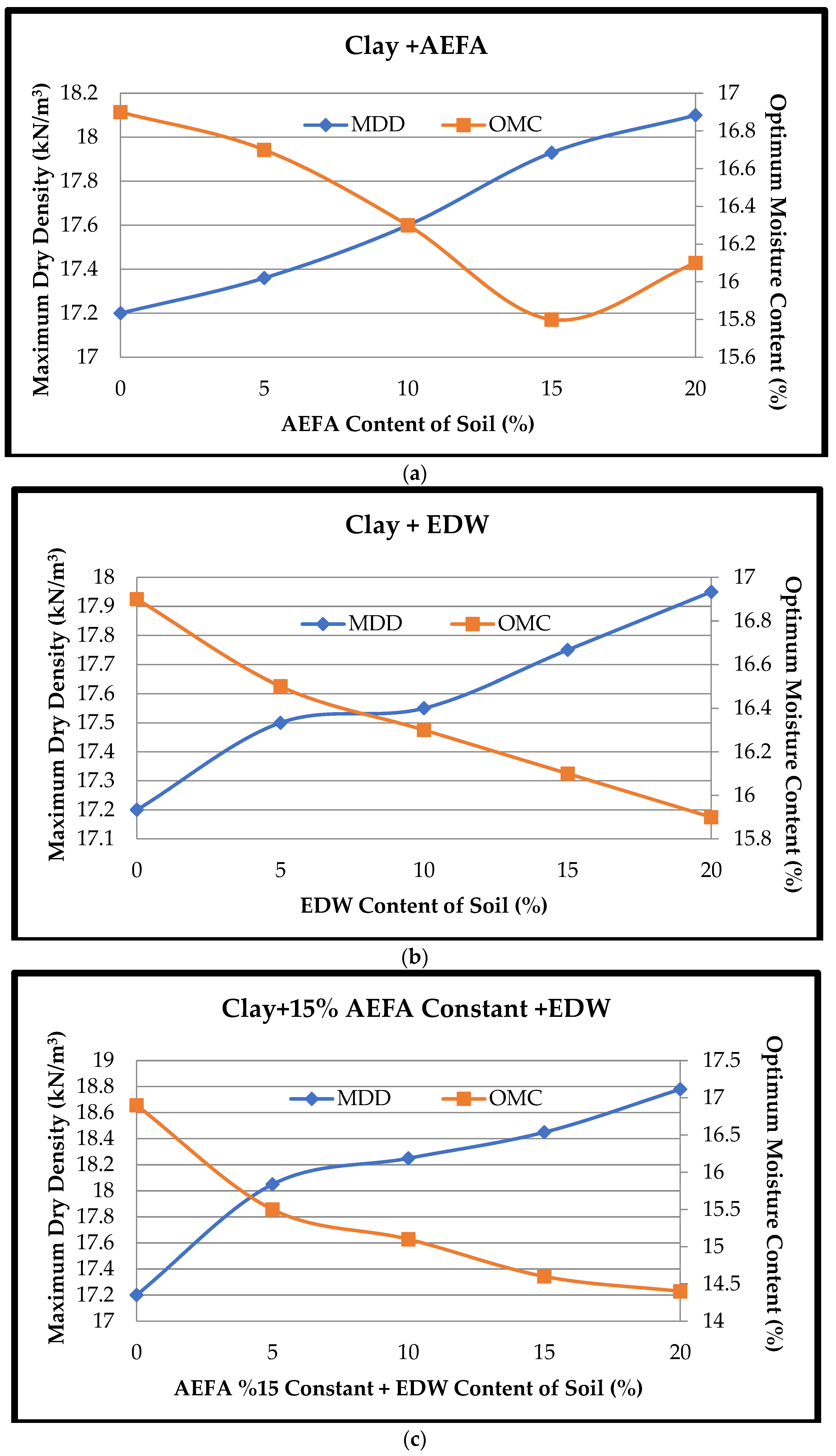

3.2. Compaction Tests

3.3. Uniaxial Compressive Strength (UCS) Tests

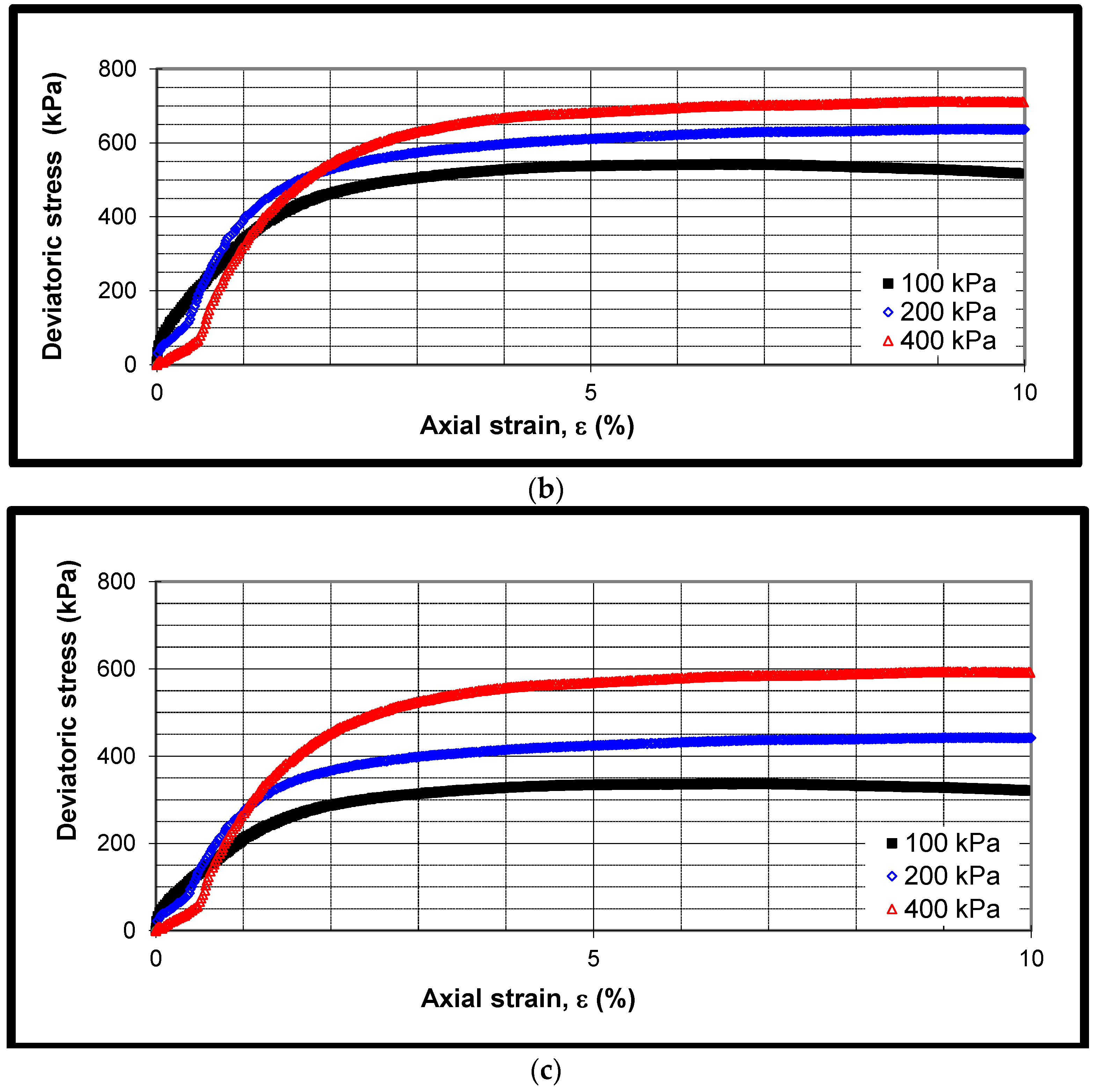

3.4. Triaxial Tests

3.5. California Bearing Ratio (CBR) Tests

4. Discussion

4.1. Atterberg Limit Tests

4.2. Compaction Tests

4.3. Uniaxial Compressive Strength (UCS) Tests

4.4. Triaxial Tests

4.5. California Bearing Ratio (CBR) Tests

5. Conclusions

- For all mixtures, as the waste material ratio increases, LL and PI values decrease and the PL value increases. Clayey soil taken from the field, according to LL and PI values, was determined as CH. The classification of the clay samples mixed with AEFA was found to be CL for mixtures of 5 and 10%, ML for mixtures of 15 and 20%. The classification of EDW-mixed clay samples was found to be CL. In the ternary mixture (AEFA 15% constant + EDW + clay), the classification was found to be ML for all ratios.

- According to the compression test results, MDD increases and OMC decreases in samples with AEFA added. Additionally, it was observed that the sample with 15% AEFA additive gave the best results. MDD increased and OMC decreased similarly in the EDW mixture. Also shown was that the highest MDD value was reached in the mixture with 15% fixed AEFA + 20% EDW ratio.

- The 28-day UCS test result for natural clay was 215 kPa, the highest result in the mixture with AEFA addition was 305 kPa at 20% mixture ratio, and the highest result in the EDW mixture was found to be 710 kPa with 20% mixture ratio. In addition, the highest UCS test result in the ternary mixture was found in the 15% AEFA + 20% EDW mixture ratio, at 1250 kPa. According to the natural clay 28-day UCS test results, when the results mixed with AEFA and EDW are compared, a 42% increase was observed in AEFA mixtures and a 230% increase was observed in EDW mixtures.

- Clay specimens stabilized with AEFA illustrated ductile stress–strain response with increasing confining pressure. In EDW-stabilized samples, the stress–strain behavior transformed from ductile to brittle response with increasing confining pressure. A brittle strain-softening behavior was observed for samples stabilized with EDW + AEFA. The brittle strain-softening behavior is due to a slight structural degradation that occurs in the EDW + AEFA-stabilized soil during the consolidation phase, leading to behavior governed by cementitious bonds and friction.

- The cohesion of EDW-added clay samples initially increased but then decreased. In the ternary mix with AEFA + EDW admixture, cohesion increased at low mix proportions and then decreased in admixtures of 15% and above. The internal friction angle increased for EDW and AEFA binary and ternary mixture ratios. EDW and AEFA mixtures reduced the clay content and increased the average particle size of the mixture. In particular, it contributed to the improvement of the shear resistance angle due to EDW.

- The CBR test results increased for all ratios of AEFA and EDW added to clay samples. The increase in CBR value in the clay sample with AEFA added was relatively less than in the clay sample with EDW added. It was determined that an AEFA mixture ratio of 20%, EDW mixture ratios of 10% and above, and all ratios for AEFA + EDW mixtures can be used as road sub-base material.

- After the major earthquake disaster, the use of EDW is of great importance for the environment. AEFA and EDW were found to improve the engineering and geotechnical characteristics of the clay. As a consequence, this experimental work demonstrated an environmentally friendly and sustainable approach.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Çınar, M.; Karpuzcu, M.; Çanakçı, H. The measurement of fresh properties of cement-based grout containing waste marble powder. Measurement 2020, 150, 106833. [Google Scholar] [CrossRef]

- Çelik, F.; Çınar, M.; Akcuru, O. Utilization of waste bottom ash as mineral additive with partial replacement of cement in geotechnical grouting works based on mechanical features. Arab. J. Geosci. 2022, 15, 1290. [Google Scholar] [CrossRef]

- Kumar, P.G.; Harika, S. Stabilization of expansive subgrade soil by using fly ash. Mater. Today Proc. 2021, 45, 6558–6562. [Google Scholar] [CrossRef]

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular Economy of Construction and DemolitionWaste: A Literature Review on Lessons, Challenges, and Benefits. Materials 2022, 15, 76. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhou, Y.; Nagarajaiah, S.; Shi, W. Bi-directional semi-active tuned mass damper for torsional asymmetric structural seismic response control. Eng. Struct. 2023, 294, 116744. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Shi, W. Seismic control of adaptive variable stiffness intelligent structures using fuzzy control strategy combined with LSTM. J. Build. Eng. 2023, 78, 107549. [Google Scholar] [CrossRef]

- Ceyhan, Z.N.; Diş, M.Ö. Çoklu Projeksiyon Yöntemleri ile Kahramanmaraş’ın Gelecek Nüfusunun Belirlenmesi. Çukurova Üniversitesi Mühendislik Fakültesi Dergisi 2022, 37, 1155–1164. [Google Scholar] [CrossRef]

- Akgönen, A.İ.; Özbek, A. A CASE study on pile design of wind turbine foundation (Kahramanmaras-Turkey). Eskişehir Tech. Univ. J. Sci. Technol. A-Appl. Sci. Eng. 2020, 21, 407–420. [Google Scholar] [CrossRef]

- Kop, A.; Ezer, M.; Bodur, M.N.; Darbaş, G.; Inan, S.; Ergintav, S.; Seyis, C.; Yalçin, C. Geochemical Monitoring Along the Türkoğlu (Kahramanmaraş)-Gölbaşı (Adıyaman) Segments of the East Anatolian Fault System. Arab. J. Sci. Eng. 2014, 39, 5521–5536. [Google Scholar] [CrossRef]

- Över, S.; Demirci, A.; Özden, S. Tectonic implications of the February 2023 Earthquakes (Mw7. 7, 7.6 and 6.3) in south-eastern Türkiye. Tectonophysics 2023, 866, 230058. [Google Scholar] [CrossRef]

- Doğdu, G.; Alkan, S.N. Deprem Sonrası Oluşan İnşaat ve Yıkıntı Atıklarının Değerlendirilmesi: 6 Şubat 2023 Kahramanmaraş Depremleri. Artvin Çoruh Üniversitesi Mühendislik ve Fen Bilimleri 2023, 1, 38–50. [Google Scholar]

- Temiz, H.; Tandirci, E. Investigation of mechanical and insulation properties of Sorel cement binding light concrete. Constr. Build. Mater. 2023, 379, 131270. [Google Scholar] [CrossRef]

- Türker, P.; Erdoğan, B.; Katnaş, F.; Yeğinobalı, A. Türkiye’deki Uçucu Küllerin Siniflandirilmasi Ve Özellikleri; Tçmb: Ankara, Turkey, 2009. [Google Scholar]

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society of Testing Materials: West Conshohocken, PA, USA, 2019.

- Vural, I.; Akgül, T.; Aydin, E. İnşaat Yıkıntı Atıkları Kullanılarak Zeminlerin Serbest Basınç Dayanımının Iyilestirilmesi. In Proceedings of the 5th International Symposium on Innovative Technologies in Engineering and Science, Baku, Azerbaijan, 29–30 September 2017. [Google Scholar]

- Çimen, Ö.; Günaydin, H.İ.; Keskin, S.N. Yüksek plastisiteli kil zeminin mühendislik özelliklerine inşaat atıklarının etkisi. Pamukkale Üniversitesi Mühendislik Bilimleri Dergisi 2017, 23, 250–253. [Google Scholar]

- Sharma, A.; Sharma, R.K. Effect of addition of construction–demolition waste on strength characteristics of high plastic clays. Innov. Infrastruct. Solut. 2019, 4, 27. [Google Scholar] [CrossRef]

- Leiva, C.; Solís-Guzmán, J.; Marrero, M.; García Arenas, C. Recycled blocks with improved sound and fire insulation containing construction and demolition waste. Waste Manag. 2013, 33, 663–671. [Google Scholar] [CrossRef] [PubMed]

- Sari, A.B.; Gadouri, H.; Ghrici, M.; Harichane, K. Best-fit models for predicting the geotechnical properties of FA–stabilised problematic soils used as materials for earth structures. Int. J. Pav. Eng. 2020, 21, 939–953. [Google Scholar] [CrossRef]

- Hakan, G. Influence of Afşin-Elbistan highly lime fly ash on engineering behavior of a cohesive soil. Sci. Res. Essays 2010, 5, 1307–1316. [Google Scholar]

- Çimen, Ö.; Keleş, E. Yüksek Plastisiteli Bir Kilin Mühendislik Özelliklerine Uçucu Kül ve Kireç Katkılarının Etkisi. İleri Müh. Çalış. Tek. Derg. 2020, 1, 80–90. [Google Scholar]

- ASTM C136/C136M; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D422; Standard Test Method for Particle-Size Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. American Society for Testing and Materials: Philadelphia, PA, USA, 2018.

- ASTMD698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D2166/D2166M-16; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D2850-15; Standard Test Method for Uncosnolidated-Undrained Triaxial Compression Test on Cohesive Soils. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D1883-16; Standard Test Method for California Bearing Ratio (CBR) of Laboratory Compacted Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- Islam, S.; Islam, J.; Hoque, N.M.R. Improvement of consolidation properties of clay soil using fine-grained construction and demolition waste. Heliyon 2022, 8, e11029. [Google Scholar] [CrossRef]

- Hu, Q.; Song, W.; Hu, J. Study of the Mechanical Properties and Water Stability of Microbially Cured, Coir-Fiber-Reinforced Clay Soil. Sustainability 2023, 15, 13261. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.A.; Vinai, R.; Beig Zali, R. Geotechnical Characteristics of Fine-Grained Soils Stabilized with Fly Ash, a Review. Sustainability 2022, 14, 16710. [Google Scholar] [CrossRef]

- Tanyıldızı, M.; Uz, V.E.; Gökalp, İ. Utilization of waste materials in the stabilization of expansive pavement subgrade: An extensive review. Constr. Build. Mater. 2023, 398, 132435. [Google Scholar] [CrossRef]

- Diallo, M.L.; Ünsever, Y.S. An experimental study on the stabilization of a clay soil with construction wastes and lime. Pamukkale Univ. J. Eng. Sci. 2020, 26, 1030–1034. [Google Scholar] [CrossRef]

- Vitales, V.V.; Amaludin, A.E.; Ho, Y.; Amaludin, N.A. Soil plasticity and standard proctor compaction characteristics of stabilized Kota Kinabalu clay using biomass silica (SH-85). IOP Conf. Ser. Mater. Sci. Eng. 2022, 1217, 012006. [Google Scholar] [CrossRef]

- Cinar, M. Investigation of Mechanical and Physical Features of Cementitious Jet Grout Applications for Various Soil Types. Buildings 2023, 13, 2833. [Google Scholar] [CrossRef]

- Tastan, E.O.; Edil, T.B.; Benson, C.H.; Aydilek, A.H. Stabilization of Organic Soils with Fly Ash. J. Geotech. Geoenviron. Eng. 2011, 137, 819–833. [Google Scholar] [CrossRef]

- Lukiantchuki, J.A.; Oliveira, J.R.M.D.S.D.; Almeida, M.D.S.S.D.; dos Reis, J.H.C.; Silva, T.B.; Guideli, L.C. Geotechnical behavior of Construction Waste (CW) as a partial replacement of a lateritic soil in fiber-reinforced cement mixtures. Geotechnol. Geol. Eng. 2021, 39, 919–942. [Google Scholar] [CrossRef]

- Sharma, R.K.; Hymavathi, J. Effect of fly ash, construction demolition waste and lime on geotechnical characteristics of a clayey soil: A comparative study. Environ. Earth Sci. 2016, 75, 377. [Google Scholar] [CrossRef]

- Binal, A. The Effects of High Alkaline Fly Ash on Strength Behaviour of a Cohesive Soil. Adv. Mater. Sci. Eng. 2016, 2016, 3048716. [Google Scholar] [CrossRef]

- National Cooperative Highway Research Program (NCHRP). Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures; National Cooperative Highway Research Program 1-37 A; NCHRP: Washington, DC, USA, 2004. [Google Scholar]

- Look, B.G. Handbook of Geotechnical Investigation and Design Tables; CRC Press: London, UK, 2014. [Google Scholar]

| Chemical Content (%) | Clay | AEFA | EDW |

|---|---|---|---|

| Al2O3 | 12.10 | 8.40 | 10.25 |

| CaO | 6.37 | 54.30 | 22.10 |

| Cl | - | 0.01 | 0.05 |

| Cr2O3 | - | - | 0.03 |

| Fe2O3 | 5.05 | 2.36 | 7.23 |

| K2O | 1.12 | 0.45 | 1.79 |

| MgO | 1.15 | 1.54 | 1.48 |

| Na2O | 0.39 | 0.09 | 1.03 |

| NiO | - | - | 0.01 |

| P2O5 | - | 0.54 | 0.10 |

| SO3 | 0.10 | 11.20 | 3.15 |

| SiO2 | 62.10 | 18.50 | 42.43 |

| TiO2 | - | 0.25 | 0.48 |

| LOI | 11.62 | 2.36 | 9.87 |

| Parameters | Clay | AEFA | EDW |

|---|---|---|---|

| Plasticity Index (%) | 30.7 | - | - |

| Plastic limit (%) | 21.3 | - | - |

| Liquid limit (%) | 52.1 | - | - |

| MDD (kN/m3) | 17.2 | 11.52 | 15.65 |

| OMC (%) | 16.9 | 20 | 13 |

| Specific Gravity (%) | 2.70 | 2.75 | 2.55 |

| Finer Component (%) | 52.50 | - | - |

| USCS Classification | CH | - | - |

| Soil (%) | AEFA (%) | EDW (%) | |

|---|---|---|---|

| CH0FA | 100 | 0 | 0 |

| CH5FA | 95 | 5 | 0 |

| CH10FA | 90 | 10 | 0 |

| CH15FA | 85 | 15 | 0 |

| CH20FA | 80 | 20 | 0 |

| CH5EDW | 95 | 0 | 5 |

| CH10EDW | 90 | 0 | 10 |

| CH15EDW | 85 | 0 | 15 |

| CH20EDW | 80 | 0 | 20 |

| CH15FA5EDW | 80 | 15 | 5 |

| CH15FA10EDW | 75 | 15 | 10 |

| CH15FA15EDW | 70 | 15 | 15 |

| CH15FA20EDW | 65 | 15 | 20 |

| LL (%) | PL (%) | PI (%) | |

|---|---|---|---|

| CH0FA | 52.1 | 21.3 | 30.7 |

| CH5FA | 42.1 | 23.3 | 18.8 |

| CH10FA | 41.5 | 25.5 | 16.0 |

| CH15FA | 40 | 25.9 | 14.1 |

| CH20FA | 40.1 | 26.3 | 13.8 |

| CH5EDW | 39.5 | 24 | 15.5 |

| CH10EDW | 38.4 | 23.5 | 14.9 |

| CH15EDW | 37.2 | 23.1 | 14.1 |

| CH20EDW | 36.5 | 22.8 | 13.7 |

| CH15FA5EDW | 38.1 | 27.7 | 10.4 |

| CH15FA10EDW | 37.4 | 28.1 | 9.3 |

| CH15FA15EDW | 35 | 28.5 | 6.5 |

| CH15FA20EDW | 34.5 | 28.8 | 5.7 |

| c (kPa) | ø (Deg.) | |

|---|---|---|

| CH0FA | 107 | 3.5 |

| CH5FA | 165 | 7 |

| CH10FA | 175 | 10.5 |

| CH15FA | 199 | 13 |

| CH20FA | 182 | 11 |

| CH5EDW | 140 | 11.2 |

| CH10EDW | 125 | 11.9 |

| CH15EDW | 110 | 12.4 |

| CH20EDW | 103 | 13.5 |

| CH15FA5EDW | 198.1 | 14.2 |

| CH15FA10EDW | 176 | 10.6 |

| CH15FA15EDW | 135 | 15.6 |

| CH15FA20EDW | 95.8 | 17.4 |

| Unsoaked Samples (%) | Soaked Samples (%) | |

|---|---|---|

| CH0FA | 5 | 2 |

| CH5FA | 5.8 | 3.5 |

| CH10FA | 10.5 | 5.9 |

| CH15FA | 12.4 | 8.5 |

| CH20FA | 14.2 | 10.5 |

| CH5EDW | 9.4 | 7.6 |

| CH10EDW | 12.6 | 10.1 |

| CH15EDW | 13.9 | 12.5 |

| CH20EDW | 15.5 | 13.4 |

| CH15FA5EDW | 13.5 | 10.9 |

| CH15FA10EDW | 14.2 | 12.4 |

| CH15FA15EDW | 14.6 | 13.1 |

| CH15FA20EDW | 20.1 | 15.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cinar, M. Utilization of Earthquake Demolition Wastes and Afşin–Elbistan Fly Ash for Soil Improvement after the Kahramanmaraş Earthquake (6 February 2023). Sustainability 2024, 16, 538. https://doi.org/10.3390/su16020538

Cinar M. Utilization of Earthquake Demolition Wastes and Afşin–Elbistan Fly Ash for Soil Improvement after the Kahramanmaraş Earthquake (6 February 2023). Sustainability. 2024; 16(2):538. https://doi.org/10.3390/su16020538

Chicago/Turabian StyleCinar, Muhammet. 2024. "Utilization of Earthquake Demolition Wastes and Afşin–Elbistan Fly Ash for Soil Improvement after the Kahramanmaraş Earthquake (6 February 2023)" Sustainability 16, no. 2: 538. https://doi.org/10.3390/su16020538

APA StyleCinar, M. (2024). Utilization of Earthquake Demolition Wastes and Afşin–Elbistan Fly Ash for Soil Improvement after the Kahramanmaraş Earthquake (6 February 2023). Sustainability, 16(2), 538. https://doi.org/10.3390/su16020538