Abstract

The objective of this research is to assess the influence of effective supply chain management on the success of transport infrastructure projects, considering the moderating effects of building information modeling (BIM) and environmental factors. Data were collected through questionnaires from construction projects and subjected to analysis to gain insights into the contributions of various supply chain management strategies to the overall performance of transport infrastructure projects, as well as how the presence of BIM and environmental considerations affect this relationship. The data were subjected to analysis using partial least squares structural equation modeling (PLS-SEM). The results of this investigation revealed a significant impact of supply chain management practices in the construction industry on the performance of transport infrastructure projects, with BIM and environmental considerations acting as moderators in this association. This study holds both practical and theoretical significance, as it contributes to the existing body of knowledge by shedding light on the role of supply chain management in construction and its influence on the success of transport infrastructure projects while also exploring the moderating influence of BIM and environmental factors. The findings provide valuable perspectives for improving supply chain management practices in construction, thereby enhancing the outcomes of transport infrastructure projects.

1. Introduction

As the major industry that creates jobs and is essential to the economic growth of Pakistan, construction is of utmost significance there [1]. Construction has boomed in several economic sectors, including Energy, Architecture and Planning, Industrial, and Transportation [2]. As a result, these sectors have seen significant advancements.

This study addresses the need to comprehensively assess how effective supply chain management practices impact the outcomes of transport infrastructure projects. The complexity and scale of such projects demand efficient supply chain management. However, what makes this research significant is its focus on understanding how two specific factors, namely building information modeling (BIM) and environmental considerations, may moderate or influence the relationship between supply chain management and project success. As BIM continues to transform the construction and infrastructure sectors and environmental concerns play a growing role in project decision-making, it is essential to explore how these factors interact with supply chain practices. This study aims to provide insights into these dynamics, offering valuable guidance for professionals and researchers in infrastructure project management. Despite the growing importance of supply chain management in construction projects, limited research explores the intersection of supply chain management practices and the outcomes of transport infrastructure projects. Maqsoom, Charoenngam [1] explored that although the sector is expanding, the rate and scope of development are still unsatisfactory. There are still problems with project quality and achieving success criteria [3]. As a result, many projects go over budget and on schedule, making it difficult for businesses to achieve government development goals [4]. Shehu, Endut [5] both emphasize the importance of the construction industry in a country’s social and economic development and how it affects other industrial sectors. The economy, ecology, and society are all significantly impacted by construction projects [6]. Infrastructure-related projects are particularly vulnerable to several risks that might harm their performance [7]. Previous studies focused on studying the major industry that creates jobs and is essential to the economic growth of Pakistan; construction is of extreme significance there [8]. The timely and cost-effective completion of projects is difficult for Pakistan’s construction business, just like for construction industries in other nations [2,9]. Stroumpoulis and Kopanaki [10] explored the reputation of the construction business in a country’s social and efficient development and how it affects other industrial sectors. Construction projects all significantly impact the economy, ecology, and society. Infrastructure-related projects are particularly vulnerable to several risks that might harm their performance [11].

Concerns regarding reduced productivity and efficiency have been documented at various stages of construction projects [12]. BIM stands out as a highly promising recent innovation in architecture, engineering, and construction (AEC) [13]. Additionally, in the realm of building, off-site manufacturing has been validated as an effective alternative to the conventional on-site construction approach [14]. Most recent research has primarily concentrated on qualitative examinations of the amalgamation of BIM and OSM in specific areas of enhancement. For instance, these studies have explored improved construction efficiency using graph-based methodologies [15], enhanced energy consumption management through operational performance [16], the development of a simulation game to enhance the learning process [17], the establishment of a framework for information delivery in modular construction [18], heightened visibility and traceability in prefabricated construction [19], and augmented productivity resulting from BIM-based multitrade prefabrication via a case study analysis of complex building projects [20]. Additionally, these studies have explored improved collaboration and information exchange facilitated by a BIM-based interdisciplinary approach [12], the optimization of assembly sequences in concrete construction projects [20], and the development of an initial framework for integrating the last planner system with BIM and OSM [21]. It is worth noting that the focus of these prior studies has been primarily on the technological aspects of BIM integration.

The study’s knowledge gap relates to integrating BIM and EI’s potential to modify the link between construction supply chain management responsibilities and the performance of transportation infrastructure projects (TIP). While there is literature on supply chain management in construction and its effect on project performance [22], comprehensive research examining the combined influence of supply chain management, BIM, and environmental considerations on TIP is lacking. Studying this subject is important for several reasons. To pinpoint crucial elements and tactics that result in more successful and efficient projects, it is important to first comprehend the function of supply chain management roles in construction with TIP. Second, with an increased emphasis on sustainability and environmental responsibility, research is being conducted to determine how BIM and environmental issues affect supply chain management methods that support using eco-friendly and sustainable practices in building projects. Third, the study’s findings give contractors, designers, and government organizations useful information about improving supply chain management procedures and producing better project results. Fourth, the relevance of technology adoption in contemporary construction methods is shown by the study’s focus on incorporating BIM as a moderator. Additionally, it motivates the sector to use cutting-edge digital technologies for improved project management and teamwork. Finally, by examining novel viewpoints and connections that have not been thoroughly studied, this research adds to the knowledge already known in construction and supply chain management [21]. The study’s practical applications can help guide decision-making in actual construction projects, resulting in more effective supply chain management and improved overall performance of transportation infrastructure.

Balancing economic interests with environmental responsibilities in information modeling and environmental considerations in transportation supply chain management is a nuanced challenge. Integrating environmental considerations can yield benefits such as cost savings, improved brand reputation, regulatory compliance, risk mitigation, increased customer loyalty, innovation, collaboration, and long-term value creation. However, achieving the optimal balance between economic and environmental goals poses difficulties involving trade-offs, uncertainties, and the involvement of multiple stakeholders [23]. The use of information modeling proves beneficial in optimizing transportation routes, inventory management, and risk mitigation for enhanced project outcomes. Integrating environmental considerations into flexible supply chains aids in mitigating negative environmental impacts while maintaining cost-effectiveness. Stakeholders must navigate these complexities to achieve comprehensive and effective sustainability outcomes in the transportation sector [24].

The integration of information modeling and environmental considerations in supply chain management faces some potential limitations, such as increased costs for sustainable practices, a lack of a well-defined sustainability framework leading to inconsistencies, and difficulties in uniformly implementing practices across the supply chain. Additionally, limited awareness, lack of regulations, and the need for transparency pose obstacles. Despite these challenges, integrating these elements holds the potential to reduce environmental impact, enhance sustainability, and create long-term value. Overcoming these limitations is essential for contributing to environmental preservation and fulfilling social responsibility objectives [23].

This study aims to evaluate the impact of efficient supply chain management on the success of transport infrastructure projects, particularly with regard to project timelines, budgets, and quality. Additionally, it investigates how the integration of BIM technology enhances supply chain coordination, information sharing, and decision-making. Furthermore, the research assesses how environmental factors, including sustainability and regulations, influence and potentially modify traditional supply chain practices within these projects.

Effective supply chain management is essential for the timely and cost-effective completion of transport infrastructure projects. Key research areas encompass supply chain optimization, risk management, sustainability, information technology adoption, procurement strategies, collaboration, infrastructure resilience, logistics modes, regulatory compliance, best practices, cost management, human resources, international projects, and technological trends.

The study of effective supply chain management in transport infrastructure projects offers significant contributions, including enhanced project efficiency, cost savings, risk mitigation, sustainability, innovation, stakeholder collaboration, regulatory compliance, human resource development, a global perspective for international projects, and the derivation of best practices. These contributions collectively ensure timely, cost-effective, and environmentally friendly project completion while improving collaboration and compliance, benefiting stakeholders, the environment, and the broader community.

The investigation of how building supply chain management positions affects TIP, together with the moderation study of BIM adoption and EI, is supported by some ideas. Supply chain management theory emphasizes the necessity of effective supply chain management in raising project performance. It implies that well-coordinated supply chain roles can favor the overall effectiveness and timely completion of building projects, including transport infrastructure [25]. These roles can involve suppliers, contractors, and other stakeholders. Building information modeling (BIM) theory is a collaborative method that uses digital depictions of a project’s structural and functional elements. The adoption of BIM is anticipated to boost supply chain participant decision-making, project coordination, and performance in building projects, particularly transportation infrastructure projects [26]. Environmental impact theory emphasizes the importance of considering environmental considerations while planning building projects. The goal of environmental impact moderation analysis is to understand how sustainability practices and considerations affect the link between supply chain management responsibilities and the performance of the transportation infrastructure [27]. By incorporating these theories, the study seeks to shed light on the intricate connections between the management of the supply chain for building materials, the adoption of BIM, environmental impact, and the performance of the transportation infrastructure, ultimately assisting in the improvement of construction practices for the efficient and sustainable development of infrastructure.

Key objectives of this study were to:

- Evaluate the impact of effective supply chain management practices on the overall success of transport infrastructure projects.

- Identify the critical success factors in transport infrastructure projects, such as project scope, cost control, quality, and time management, and understand how supply chain management practices influence these factors.

- Investigate the moderating role of BIM in the relationship between supply chain management and project success.

- Explore how environmental factors, such as sustainability initiatives, regulations, and resource constraints, may influence the relationship between supply chain management and project success.

Supply chain management and networks are strategic frameworks employed to optimize the flow of products or services from suppliers to end customers. This process comprises planning, sourcing, production, distribution, logistics, and information systems [28]. Effective management of these components ensures the seamless movement of goods and information within the supply chain, contributing to timely, cost-efficient deliveries, quality assurance, and sustainability efforts [21]. Moreover, risk management is crucial for identifying and mitigating potential disruptions, such as natural disasters or economic fluctuations, while globalization necessitates adapting to the complexities of international operations and regulations. Collaboration, as emphasized by [13], fosters coordination and communication with partners, suppliers, and customers, enhancing visibility and overall supply chain performance. These principles collectively underpin the dynamic field of supply chain management, continually evolving in response to technological advancements and shifting global market dynamics.

The integration of information modeling and supply chain management in transportation infrastructure has been exemplified by key entities such as the Karachi Port Trust (KPT) and Port Qasim Authority (PQA), as well as projects like the Karachi–Lahore Motorway (M-9) and the Allama Iqbal International Airport [29]. These initiatives aimed to optimize operations and enhance environmental sustainability. For instance, the Pakistani authorities are urged to implement green packaging, transportation, and supply chain design to promote green economic growth [30]. Additionally, research has analyzed the impact of different transport infrastructure types on industrial output in Pakistan, contributing to the understanding of the country’s transportation dynamics [29].

2. Literature Review and Hypotheses Development

This study is structured with a dual framework, incorporating both a hypothetical and theoretical foundation. Hypothetical framing primarily deals with formulating research questions, hypotheses, and predictions. It focuses on developing testable statements or educated guesses about the relationships or outcomes you expect to find in your research. It is about creating a structure for empirical investigation and experimentation. Theoretical framing, on the other hand, revolves around establishing the intellectual context and grounding for a research study. It involves delving into existing theories, models, and concepts in the field to understand how your research fits within a broader academic discourse.

2.1. Linking Reducing Cost of Site Activities and Transport Infrastructure Projects Success

According to [31], supply chain management comprises a range of organizational efforts to achieve diverse objectives, such as lowering costs, reducing lead times, enhancing profitability, and ensuring customer satisfaction. In response to challenges related to lead times, delivery uncertainty, and logistics expenses, the construction sector anticipates a growing need for logistics centers. [32]. Cost overrun is the word used when the actual cost of a project is higher than the initial projections [33]. Cost overruns are major obstacles to project development, and they are especially common in the building sector, especially in developing nations [34]. Project costs increase due to overruns, harming customers and contractors [35]. According to Saidu and Shakantu [36], the construction sector suffers several difficulties, including poor financial performance, high project delivery costs, delays, and material waste. Pakistani infrastructure projects frequently incur debts double what they originally cost [37]. Due to societal sustainability difficulties, such as land issues, the China–Pakistan Economic Corridor (CPEC) project under the one belt, one road (OBOR) plan is experiencing cost inflation and delays [38]. By increasing productivity, meeting deadlines, and producing effective results, cutting expenses in site activities improves project performance [38]. These academic works offer actual data supporting the claim that improving TIP performance is associated with cost-cutting in site operations. Effective cost control may result in better financial results, the prevention of cost overruns, increased project efficiency, and the successful completion of projects [18]. Based on the literature mentioned above, we may hypothesize that:

Hypothesis 1 (H1).

Reducing the cost of site activities has a positive relationship with the success of transport infrastructure projects.

2.2. Linking Reducing Cost of Logistics Activities Lead Time and Inventory with Transport Infrastructure Projects’ Success

Logistics expenses impact a nation’s national, regional, and business GDP [39]. According to IT management, the entire logistics cost should be reduced before specific activity expenses. Lead time is now used to qualify orders and is critical to how customers see a company’s performance [40]. Logistics performance includes logistics productivity and service performance [41]. The primary goals of evaluating logistics performance are to reduce operational expenses, stimulate revenue growth, and enhance shareholder value [42]. The incoming logistics chain should evaluate factors including manufacturing, shipping, customs brokerage, and delivery in terms of overall lead time to increase efficiency [14]. Project failures in Pakistan’s construction sector result from time and expense overruns, which impede development by government goals [43]. Lead time efficiency may be increased by better coordination across supply chain activity phases. According to research by [44], which looked at the effect of logistics performance on the success of construction projects, effective logistics operations favorably impact project performance and enhance overall project outcomes. Major transportation infrastructure projects’ performance is heavily influenced by lead time. Reducing lead time can lead to greater resource utilization, on-time project completion, and increased project efficiency. According to [45], good inventory control benefits project outcomes, including cost, schedule, and quality. The study looked at the effect of inventory management on construction project performance. Based on the above, we can hypothesize the following.

Hypothesis 2 (H2).

Reducing the cost of logistic activities, lead time, and inventory has a positive relationship with the success of transport infrastructure projects.

2.3. Linking Transferring Activities from the Site to Earlier Stages of the Supply Chain and Transport Infrastructure Projects Success

Coordination, cooperation, and agility must be prioritized by businesses to improve their supply chain capabilities [18]. This will boost performance and lead time efficiency [46]. The client/owner, designer, general contractor, subcontractor, and suppliers are just a few stakeholders responsible for the construction process [47]. Although supply chain management may be employed on a project-by-project basis, it offers its greatest potential gains when used throughout several projects, at the enterprise level, and with the participation of numerous companies [31]. Project results can be improved in terms of cost, time, and quality by moving tasks from the site to earlier phases of the supply chain, such as pre-construction planning and design. According to research by [7], engaging the supply chain at an early stage positively influences project success factors, encompassing cost management, adhering to schedules, and mitigating risks. The research investigated how early supply chain involvement affects project performance, indicating that major transportation infrastructure projects could achieve better outcomes by shifting operations from the construction site to the pre-construction planning phase. The study also explored the effectiveness of design optimization in enhancing the performance of substantial infrastructure projects [48], and it was discovered that early design optimization had a favorable impact on project success variables, including cost savings, increased project delivery, and improved project quality. We can propose the following hypothesis.

Hypothesis 3 (H3).

Transferring activities from the site to earlier stages of the supply chain has a positive relationship with the success of transport infrastructure projects.

2.4. Linking Management and Improvement of Supply Chain and Site Production with the Success of Transport Infrastructure Projects

Clients, suppliers, or contractors may adopt this emphasis and incorporate the site’s output into supply chain management [49]. Supply chain integration improves cooperation, resource allocation, and responsiveness, contributing to total project performance. It helps businesses respond to shifting consumer needs and market conditions, boosting customer happiness and competitiveness [50]. The coordination of information, materials, funds, and services is performed by several parties and organizations, including the owner, general contractor, subcontractors, and suppliers. This network experiences several information transformations [51]. Open buildings and sequential processes have been suggested as new methods for integrated management of the construction site and supply chain [52]. Effective supply chain management is a prerequisite for the success of major transportation infrastructure projects. It enhances project performance by optimizing cost control, ensuring timely delivery, and facilitating the use of higher-quality materials and components [14]. According to [53], efficient supply chain management enhances project outcomes by reducing expenses, optimizing resource utilization, and improving project coordination. According to [54], effective on-site production management contributes positively to project success factors, such as labor efficiency, cost-efficiency, and meeting project schedule milestones. Furthermore, [55] found that successful supply chain integration positively impacts key success factors in construction projects, including cost control, adherence to project schedules, and stakeholder satisfaction. We can hypothesize the following statement according to above mentioned literature.

Hypothesis 4 (H4).

Management and improvement of the supply chain and site production have a positive relationship with the success of transport infrastructure projects.

2.5. Linking Building Information Modeling, Supply Chain Management, and Transport Infrastructure Projects Success

BIM enhances collaboration and inter-professional teamwork, reducing the likelihood of conflicts and errors during design and construction [19]. Improved communication can lead to more effective project coordination and planning, ultimately reducing the necessity for rework and associated expenses [56]. BIM enables the early identification of conflicts between various building components and infrastructure systems in the design phase. This early conflict detection helps reduce costs and delays by avoiding expensive modifications during the construction phase [57]. BIM enhances building operation visualization and coordination, integrating logistics planning [12]. BIM fosters collaboration between manufacturers, suppliers, and transportation companies, providing valuable insights for streamlining operations, reducing expenses, and improving the performance of transport infrastructure [58]. BIM assists in lowering transportation costs, fuel consumption, and emissions related to site delivery and garbage collection by simulating and optimizing transportation routes and timetables [59]. Enhanced coordination positively impacts transportation infrastructure performance by streamlining operations and reducing delays [60]. There is a chance for cost savings through economies of scale and resource efficiency by moving operations from the site to earlier supply chain stages. BIM eliminates waste and enhances resource usage by allocating materials, equipment, and personnel [61]. This has a favorable effect on the entire supply chain and transportation infrastructure performance. The possibilities of BIM go beyond the realm of construction to enable asset management across the course of an infrastructure’s lifetime. According to [62], BIM plays a moderating role in enhancing the relationship between supply chain management practices and the performance of transport infrastructure projects. BIM helps optimize supply chain activities, improves coordination, and ultimately positively influences the overall performance of transport infrastructure projects [14]. We can hypothesize the following statement according to above mentioned literature.

Hypothesis 5 (H5).

Building information modeling moderates the relationship between supply chain management and the success of transport infrastructure projects.

2.6. Linking Environmental Consideration, Supply Chain Management, and Transport Infrastructure Projects’ Success

According to the study [63], the environmental aspects of the infrastructure project play a moderating role in the extent to which cost savings in site operations lead to performance enhancements. Shifting supply chain operations positively influences the effectiveness of logistics and transportation systems, according to a previous study by [64], focusing on transportation infrastructure’s efficiency and effectiveness. According to [65], numerous environmental factors pose greater organizational structure and project management challenges. These factors encompass political, legal, institutional, cultural, sociological, technical resources, economic, financial, and physical (infrastructure) dimensions. As mentioned by [66], it is essential to engage in activities that improve resource management, including reducing environmental impact [67]. Reducing carbon emissions, energy use, and waste production can be accomplished by including environmental considerations in supply chain choices [68]. An efficient transportation infrastructure, such as well-maintained highways, railroads, and ports, is essential for supply chain management and on-site production. Lead times are shortened, logistics costs are decreased, and supply chain efficiency is generally improved by high-quality infrastructure [69].

Additionally, timely delivery of building supplies is made possible by improved transportation infrastructure, lessening transportation operations’ carbon footprint [70]. The environmental effect of supply chain operations has been studied, emphasizing sustainable packaging, eco-friendly transport methods, and route optimization [71]. We can hypothesize the following statement according to above mentioned literature.

Hypothesis 6 (H6).

Environmental considerations moderate the relationship between supply chain management and the success of transport infrastructure projects.

Table 1 below summarizes and lists some theories connected to this study.

Table 1.

Supportive Theories [72].

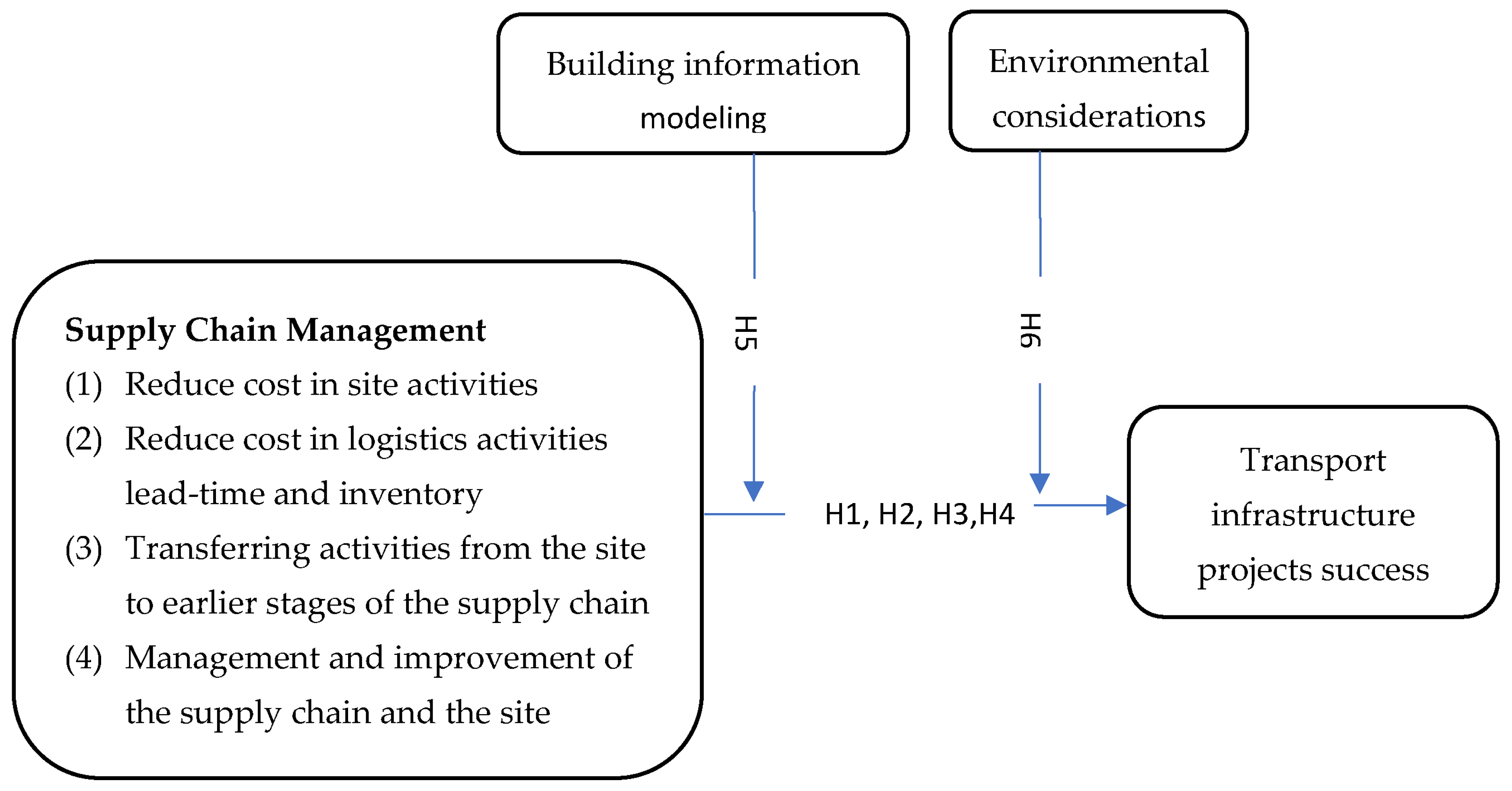

Figure 1 presents our proposed hypothesis and the underlying theoretical framework. This model has been developed by the authors and is based on comprehensive elaboration.

Figure 1.

Theoretical Framework.

3. Methodology

3.1. Study Design

This study used a research approach focused on collecting and analyzing numerical data. The research was structured to test specific hypotheses, allowing for investigations from the relevant industry.

3.2. Study Participants

The research involved individuals employed at construction companies. The study’s participants were also individuals working on projects related to transportation infrastructure. Addresses were acquired through participants who voluntarily supplied their social media information when choosing to engage in surveys, demonstrating their readiness to be contacted for research purposes. Online panels, frequently employed by research organizations, involved individuals signing up for various studies, with panel members offering their social media participants’ information as part of their profiles.

3.3. Data Collection Tool

Data were gathered through an adopted structured questionnaire administered to the participants. Incorporating an adopted questionnaire, the researcher initiated the process by conducting a comprehensive literature review to find a questionnaire that suited this research’s needs. The researcher delved deeply into the original context and purpose of the questionnaire, assessing its alignment with this research objective. Customization and adjustments were made as necessary, followed by a pilot test for clarity. The researcher also ensured the questionnaire’s validity and reliability before administering it to the intended participants. To ensure valid questionnaire responses, the researcher defined clear research objectives, conducted a pretest to identify and resolve issues, used clear language to minimize misinterpretation, and avoided leading questions. These steps collectively enhance response validity and data quality. RCSA, with 6 associated items; RCLATI, with 5 associated items; TASC, with 5 associated items; MISCSP, with 5 associated items; TIP, with 5 associated items; BIM, with 8 associated items; and EC, with 5 associated items were scored on a 5-Point Likert scale (from “1—strongly disagree” to “5—strongly agree”). The survey used a scale to assess the participants’ responses, ranging from strongly disagree to strongly agree. This instrument is appropriate for research objectives and aligns with the constructs intended to measure. Researchers demonstrated that the selected questionnaire has been used in prior research and cited studies that have successfully employed a similar instrument. Tools and instruments used for data measurement are explained in Table 2.

Table 2.

Survey Stats with Demographics Stats with Percentage.

The questionnaire includes vital components: a clear title defining its purpose, an introduction explaining objectives and ensuring anonymity, precise instructions for completion, a demographic data section, structured main questions tailored to research objectives, well-defined response options, closing remarks expressing gratitude and contact details, and an informed consent statement for sensitive data.

3.4. Data Collection Procedure

The potential respondents for the study were selected from a roster comprising individuals and entities directly engaged in or impacted by transport infrastructure projects in Pakistan. Random sampling methodology was selected to collect data. Different construction companies and transport infrastructure projects operating in Pakistan were chosen for study. Participants were selected randomly to ensure the sample was representative of the population. To generate a randomized sample, all projects in Pakistan were precisely delineated to form a comprehensive understanding of the population. Subsequently, a thorough list of these projects was developed, serving as the sampling frame. The sample size was determined by establishing the number of projects for the study based on available resources and desired precision. Random sampling methods were employed for unbiased selection. Finally, the chosen method was implemented to systematically choose projects from the established frame, ensuring a representative and unbiased sample for further analysis. The survey questionnaires were sent to participants electronically via Google Forms, email, and WhatsApp. The survey contained detailed and specific questions relating to each variable under investigation. The participants were supply chain professionals, supply chain managers, supply chain directors, contractors, and suppliers.

Random sampling was chosen because it ensures fairness by giving all population elements an equal chance in the sample, minimizes selection bias, leading to more impartial and less skewed results, supports the use of statistical methods for reliable population-wide conclusions, and is straightforward to implement, even when population details are limited. In survey research, preventing the completion of multiple questionnaires by the same respondent is a prevalent consideration to uphold data integrity and mitigate biases. It was crucial to transparently inform participants that their responses would be kept anonymous and confidential, ensuring that their individual answers remained unlinked to their identity. To further safeguard against duplicates, time constraints were imposed between survey submissions originating from the same IP address or device. Survey responses were regularly investigated for any discernible patterns or anomalies that might have suggested repeated submissions from a single individual, and subsequently, any identified duplicate entries were investigated and eliminated.

Participants were given prior notice regarding the expected duration for completing the questionnaire. The anticipated completion time was communicated as being approximately 10 to 15 min, offering prospective respondents transparency and the opportunity to plan accordingly. There was no incentive provided for participants in this study because of budgetary limitations, and participation was ensured through multiple requests.

All potential respondents were ensured anonymity; various steps were taken to safeguard the privacy and identity of each participant. Measures included identifying responses, assuring confidentiality, implementing robust data security, and undergoing ethical review to align with privacy standards. Participants were granted the freedom to stop or discontinue their involvement in the survey at any stage without facing any negative consequences or penalties. This flexibility acknowledges and respects the autonomy of respondents, allowing them to select out without being subject to adverse actions or repercussions. This practice is often employed to ensure a voluntary and non-coercive survey experience for participants.

3.5. Data Quality Check Procedure

The study began with an initial group of 245 participants. Efforts were made to encourage participants to provide accurate and complete information. Data collection between January and March 2023 resulted in the acquisition of 245 questionnaires. Among these, 17 were deemed incomplete, leading to 228 valid questionnaires. Within the 17 incomplete questionnaires, 6 outlier responses were identified and subsequently excluded, as these incomplete forms accounted for over 5% of the missing data. Consequently, our final data set consists of 228 fully completed and accurate questionnaires.

When comparing the characteristics outlined in this study to the broader SCM industry in Pakistan, it is crucial to recognize industry norms. The SCM sector in Pakistan, aligning with global standards, prioritizes efficient goods and services management, cost reduction, and product delivery. Professionals in Pakistan’s SCM industry likely share similar skills and engage in analogous activities to those in the study. However, the representativeness of the sample depends on the study’s focus, sample size, sector representation, and geographic distribution, influencing the findings’ generalizability to the entire SCM industry in Pakistan.

An applied t-test yielded no significant differences (p < 0.05) in industry-based responses, indicating that the type of industry had no discernible impact. Employing the method outlined by [79], no significant differences were observed between early and late respondents, suggesting the absence of systematic non-response bias. To mitigate social desirability response bias, the research team utilized anonymous questionnaires to encourage candid responses. The questions were framed as impartial and non-leading, and confidentiality was guaranteed. The study also refrained from discussing socially desirable answers and conducted pilot testing to address potential bias issues. To evaluate the presence of common method variance, the recommendations put forth by [80] were followed. The results indicated that no single factor could explain variance in the variables, suggesting the absence of significant common method variance.

Furthermore, a thorough assessment was carried out to address multicollinearity, adhering to the criteria outlined by [81]. The results revealed that the model was free from multicollinearity, as all variance inflation factor (VIF) values fell below the established threshold of 3.3. The VIF values are presented in Table 3.

Table 3.

Descriptive Statistics.

3.6. Data Analysis

The data were analyzed using the partial least squares method, chosen for its suitability with small sample sizes and its ability to work with various measurement scales. PLS was chosen because it can effectively analyze data despite a limited sample size. PLS does not assume that data need to be measured on a particular scale. PLS was employed to test hypotheses and clarify relationships between different variables.

Demographic statistics and data evaluations are presented in Table 2 of the study for a comprehensive understanding of the data.

Table 3 provides summary statistics for each variable, including the mean, standard deviation, and sample size. The mean is a measure of central tendency that represents the average value of the variable. For example, RCSA has a mean of 3.36, RCLATI has a mean of 4.38, TASC has a mean of 3.19, and so on. The standard deviation measures the dispersion or variability of the data points around the mean. It indicates how much the values deviate from the average. For instance, RCSA has a standard deviation of 0.054, RCLATI has a standard deviation of 0.061, TASC has a standard deviation of 0.072, and so forth.

Table 4 explains the source of measurement instruments and detailed questions used for various variables. The abbreviations in the table represent the latent constructs being studied: reduce cost in site activities (RCSA); reduce cost in logistics activities, lead time, and inventory (RCLATI); transfer activities from the site to earlier stages of the supply chain (TASC); management and improvement of the supply chain and the site production (MISCSP); transport infrastructure performance (TIP); building information modeling (BIM); and environmental consideration (EC).

Table 4.

Source of measurement instruments.

4. Results and Discussions

Partial least squares structural equation modeling (PLS-SEM) is a statistical method used in social sciences, business, and related disciplines to analyze and model complex relationships between variables. It is particularly valuable when dealing with small sample sizes, non-normal data, and complex models. PLS-SEM combines elements of partial least squares regression and structural equation modeling to examine the measurement (reflective and formative) and structural relationships between latent constructs and observed variables.

Below, in Table 5, is a breakdown of the key steps involved in partial least squares structural equation modeling (PLS-SEM), from data preprocessing to reporting findings.

Table 5.

Key Steps in PLS-SEM.

PLS-SEM differs from other structural equation modeling techniques, such as covariance-based SEM.

PLS-SEM is considered more flexible and versatile in terms of model specification, allows for both reflective and formative measurement models, employs a non-parametric method to estimate path coefficients, is more tolerant of missing data and can handle missing values through techniques such as mean imputation, and is often chosen when the primary focus is on predictive modeling, model development, and exploring relationships between variables.

CB-SEM is often used for confirmatory research where a priori models with well-established relationships are tested, mainly uses reflective measurement models, uses maximum likelihood estimation to estimate path coefficients, typically requires complete data for each case, and CB-SEM is often chosen when the focus is on model validation and hypothesis testing within well-established theoretical frameworks.

PLS-SEM excels in scenarios where sample sizes are limited, and data do not meet multivariate normality assumptions. Researchers are exploring complex or evolving models when predictive modeling is the primary objective. Its flexibility, robustness, and applicability across various domains make it a preferred choice.

4.1. Composite Reliability and Cronbach’s Alpha

The questionnaire instrument’s robustness was evaluated using Cronbach’s alpha and composite reliability. The lowest acceptable value for both factors was usually between 0.70 and 0.95 [94]. Using Smart PLS 3.0, the findings of the composite reliability testing and the results of determining Cronbach’s alpha value for the four constructs evaluated in this study are shown in Table 6. The table displays the results of composite reliability testing for the variables in the study. Composite reliability and Cronbach’s alpha were calculated to assess each construct’s internal consistency and reliability. All constructs achieved satisfactory levels of reliability.

Table 6.

Composite Reliability Test Results.

4.2. Average Variance Extracted (AVE)

By looking at the AVE values in Table 7, it is possible to evaluate the convergence validity. A strong level of convergent validity is indicated by an AVE score of greater than 0.5, which implies that latent variables often explain more than half of the variation in the indicators. The table presents the results of the convergent validity assessment using average variance extracted (AVE) for the variables in the study. The AVE values were computed to evaluate the convergent validity of each construct. All constructs achieved good convergent validity.

Table 7.

Convergent Validity Assessment Using Average Variance Extracted (AVE).

4.3. Discriminant Validity

Discriminant validity is important in research and statistical modeling as it guarantees the differentiation of various constructs or variables within a study. It involves evaluating how effectively the items intended to measure one specific construct can be distinguished from those designed for other constructs. Multiple techniques can be applied to assess discriminant validity, including correlation analysis, the Fornell-Larcker criterion, and the heterotrait–monotrait ratio (HTMT). Below, in Table 8, Table 9 and Table 10, are the findings of the discriminant validity test. When evaluating discriminant validity, the Fornell-Larcker criteria compares the square root of each construct’s average variance extracted (AVE) to correlations between that construct and every other construct in the model. According to the Fornell-Larcker criterion, each construct’s square root of the AVE needs to be higher than the correlation between it and all other constructs [95].

Table 8.

Correlation Matrix.

Table 9.

Discriminant Validity (Fornell-Larcker) Test Results.

Table 10.

Heterotrait–Monotrait Ratio (HTMT) as a Measure of Discriminant Validity.

In structural equation modeling (SEM), the heterotrait–monotrait ratio (HTMT) is a statistical tool for evaluating discriminant validity. The HTMT ratio contrasts the mean correlation of items measuring many constructs (heterotrait) with the mean correlation of items measuring a single construct (monotrait).

4.4. Cross Loading

The cross-loading test results table shows the correlation coefficients between different variables and their respective indicators. VIF values below 5 suggest no significant multicollinearity issues in our estimation model. The table appears to be part of a factor analysis or structural equation modeling (SEM) analysis. The results of the cross-loading test and VIF are shown in Table 11 below.

Table 11.

Cross-Loading Test and VIF Results.

4.5. Evaluation of Structural Model (Inner Model)

The R2 test findings are shown in Table 12 below, showing how much external influences can explain the variability of the endogenous variable. Changes in the R2 value can be used to detect significant effects of external latent factors on endogenous latent variables.

Table 12.

Coefficient Determination.

The R2 value in the table shows that factors such as “reduce cost in logistics activities and inventory”, “transfer activities from the site to earlier stages of the supply chain”, and “management and improvement of the supply chain and the site production” have an impact on 42.2% of TIP in construction companies. However, additional factors not investigated in this study are responsible for 57.8% of TIP in construction enterprises.

4.6. Path Coefficients

Direct and moderation effect analysis yielded the results shown in Table 13 below.

Table 13.

Direct and Moderation Effect Analysis.

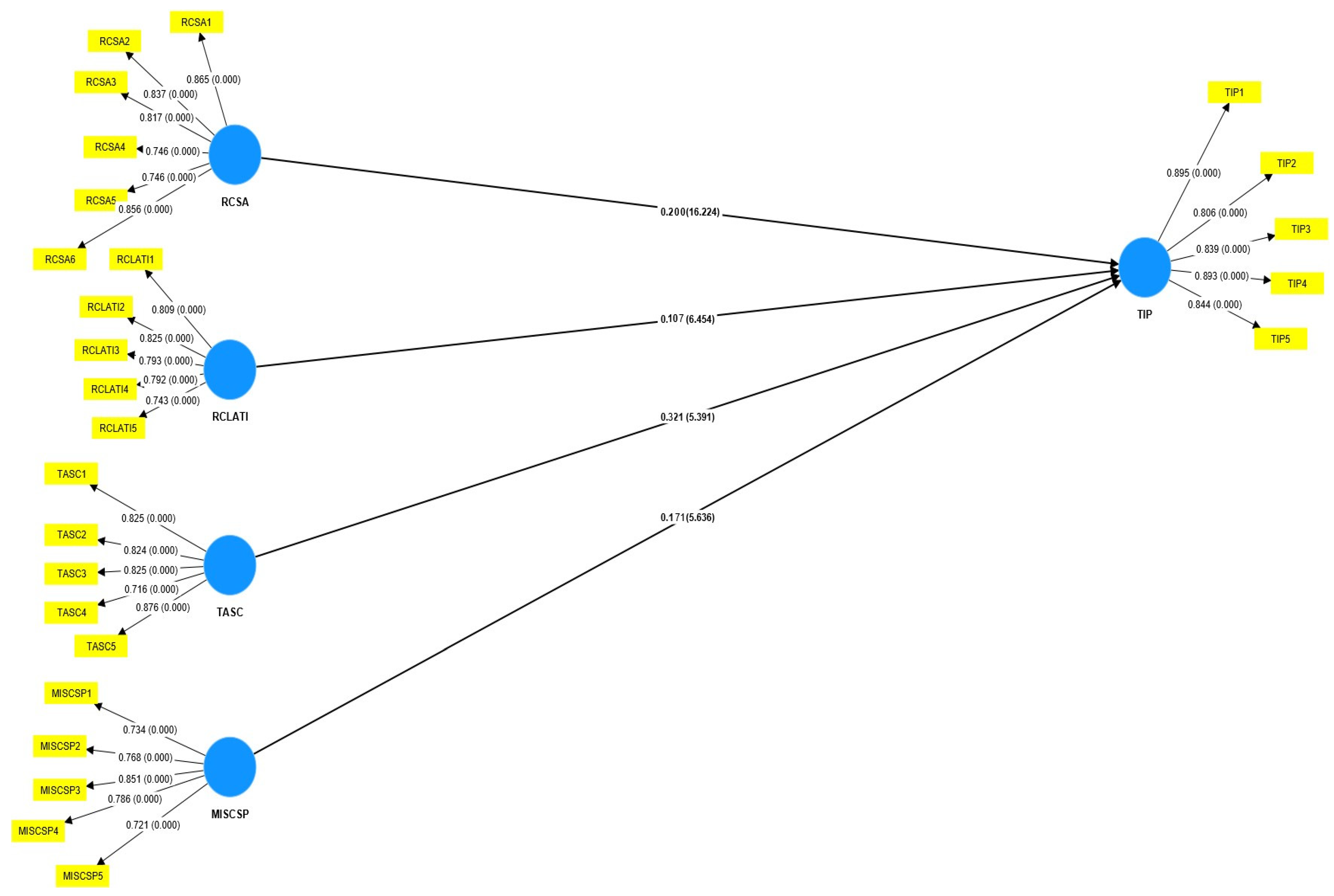

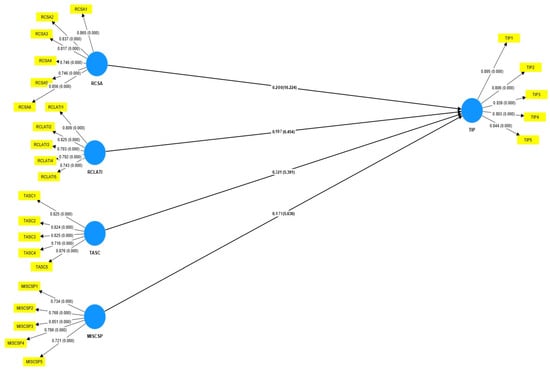

According to the direct effect analysis findings, the independent variables RCSA, RCLATI, TASC, and MISCSP all appear to have a statistically significant effect on the dependent TIP, shown in Figure 2.

Figure 2.

Path Coefficients Test Results (Direct Effect).

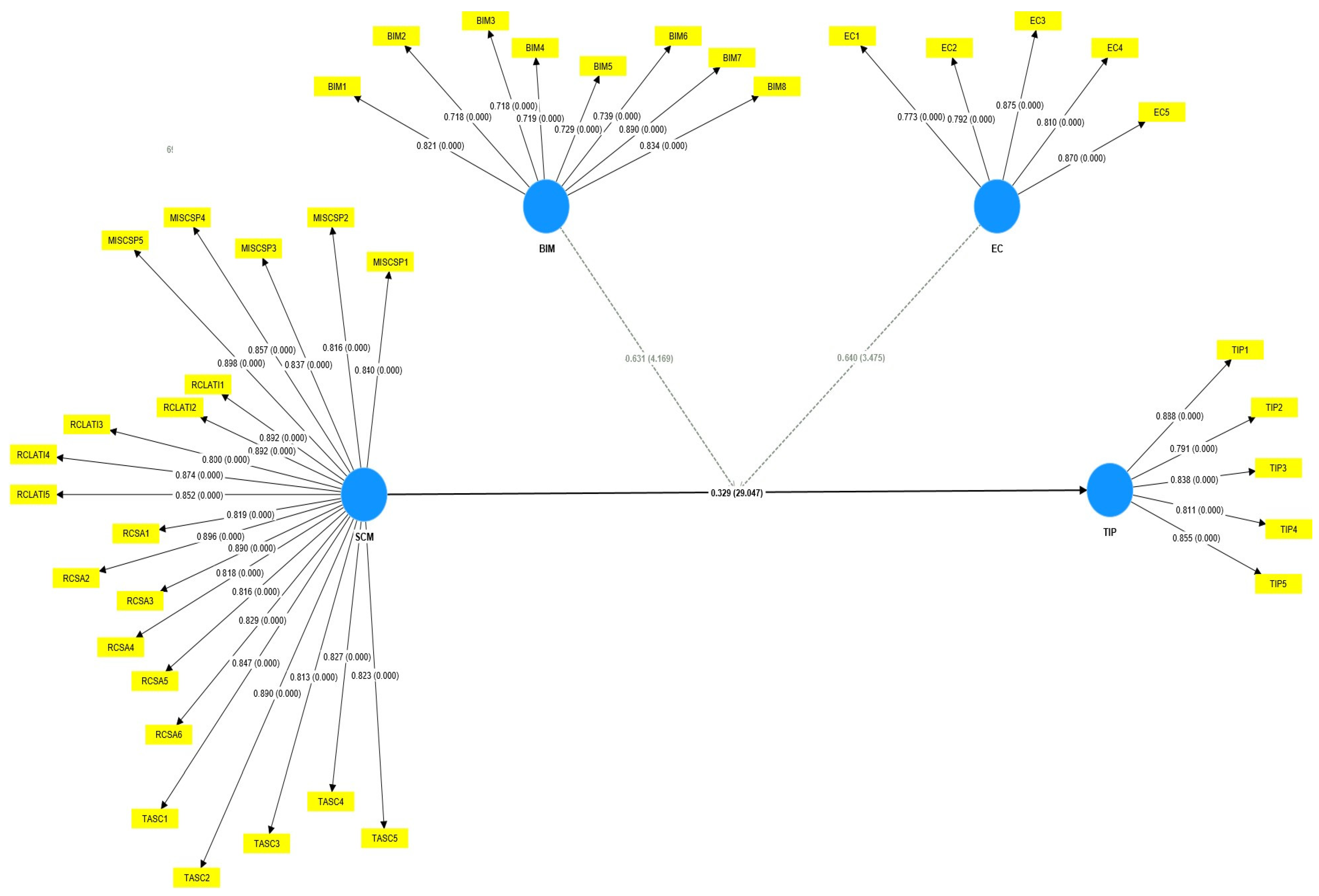

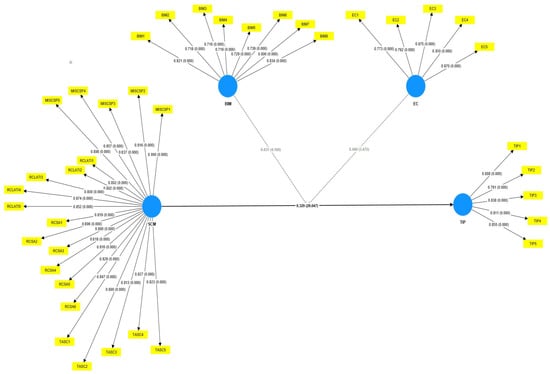

According to the results of the moderation effect study, the moderator variables (BIM and EC) strongly moderate the interactions between the independent factors and the dependent variable, providing new information about the model’s overall impact, as shown in Figure 3. This study includes six proposed hypotheses, and their associated discussions are shown below.

Figure 3.

Path Coefficients Test Results (Moderation Effect).

4.7. Critical Analysis

The examination of the interconnection between reducing the costs of site activities, logistic activities, and the success of transportation infrastructure projects reveals noteworthy insights. The reduction in site activity costs exhibits a positive correlation with project success, emphasizing the importance of efficient site management for favorable outcomes and stakeholder satisfaction. Similarly, lowering the costs associated with logistic activities is positively linked to project success, achievable through route optimization, inventory management, and shipment consolidation, ultimately enhancing project efficiency. The positive relationship between transferring activities to earlier stages of the supply chain and project success underscores the advantages of early engagement with supply chain partners in identifying risks and streamlining processes. Additionally, the effective management and improvement of the supply chain and site production demonstrate a positive influence on project success by fostering coordination, waste reduction, and improved outcomes. Building information modeling acts as a moderating factor in the relationship between supply chain management and project success, offering optimization tools for transportation routes, inventory management, and risk mitigation. In conclusion, the critical analysis affirms the positive relationship between reducing site and logistic activity costs, transferring activities to earlier supply chain stages, and the success of transport infrastructure projects, with the management and improvement of the supply chain and site production, along with BIM, exerting a moderate influence on this relationship.

The decision not to implement demographic and behavioral characteristics from the study’s model was influenced by factors such as the unavailability or difficulty in obtaining relevant data. Avoiding overfitting, where including too many variables could hinder the generalization to new data, may also drive the exclusion of certain characteristics. Additionally, ethical considerations regarding the collection and use of demographic and behavioral information could lead researchers to limit the scope of variables in the study.

4.8. Discussions

The findings of the hypothesis test showed that RCSA significantly and favorably affects TIP, as indicated by the t-value of 16.224. The findings of this study are consistent with those of [96,97]; efficient site activity cost management in transportation infrastructure projects offers several key advantages. It enhances project efficiency by streamlining construction processes, ensuring smoother execution and quicker progress. Effective cost control optimizes resource allocation, boosting productivity and overall project performance. Additionally, it leads to substantial cost reductions by monitoring and implementing cost-saving measures, reducing the project’s financial burden. These benefits highlight the significance of cost control in ensuring the efficiency and financial sustainability of transportation infrastructure projects.

RCLATI and TIP have a 6.454 t-value association. The findings of this study run counter to research by [97,98], which revealed that efficient cost reduction in logistics operations offers significant advantages. It shortens project lead times, ensuring quicker completion and minimizing costly delays. It also optimizes resource management, enhancing productivity and project progress. Additionally, reduced logistics expenses lead to substantial cost savings, promoting financial efficiency and contributing to the project’s overall success.

TASC and TIP are correlated, with a t-value of 5.391. According to [99], transferring tasks from the construction site to earlier supply chain stages positively impacts transportation infrastructure projects. This strategic shift enhances project efficiency, optimizes resource allocation, shortens construction timelines, and leads to cost savings, all collectively contributing to project success. This reorganization streamlines processes, improves productivity, accelerates project completion, and ensures financial efficiency.

TIP and MISCSP have a 5.636 t-value association. The findings of this study are consistent with studies by [100,101], which discovered that effective supply chain management and improved site manufacturing processes yield several key benefits in transport infrastructure projects. Firstly, operations become more efficient, ensuring smoother material and information flow, resulting in quicker task completion and shorter project timelines. Secondly, there are fewer delays, as effective supply chain management and enhanced manufacturing processes minimize potential bottlenecks, keeping projects on schedule and avoiding costly disruptions. Furthermore, resource utilization is optimized, enhancing productivity and project progress. Lastly, cost savings are realized through efficient supply chain management and improved manufacturing processes, reducing labor, materials, and logistics expenses, ultimately bolstering the project’s financial efficiency and sustainability.

The findings indicate that BIM significantly moderates the association between SCM and TIP. This shows that the availability of efficient risk control self-assessment methods affects how BIM impacts TIP. According to earlier research [102,103], combining BIM with effective risk management methods may enhance project results, reduce uncertainty, and improve decision-making; how well logistical operations are handled and regulated impacts how successful BIM is at improving TIP performance. Prior studies have shown that BIM-based logistics optimization may increase project efficiency, decrease delays, and cut transportation costs [56]. According to [103,104], early integration of supply chain operations with BIM integration offers multiple advantages in construction and infrastructure projects. It simplifies project execution by providing a comprehensive understanding of project components, streamlining planning and execution for smoother implementation. BIM enhances stakeholder coordination, reducing errors and rework, resulting in seamless project alignment. It often leads to shorter project durations through efficient planning and visualization, meeting timelines effectively. When combined with efficient project management, BIM optimizes resource allocation, reduces costs, and ensures on-time and on-budget projects. This efficient coordination and resource management improves financial performance. Additionally, BIM and efficient management practices yield higher-quality results by preventing errors and aligning project components with design and performance standards, emphasizing the pursuit of quality in construction and infrastructure projects [105].

The findings demonstrate the statistical significance of the moderating impact of EC on the association between SCM and TIP. EC plays a significant role in shaping how SCM impacts TIP. This suggests that environmental considerations are not just a passive factor but actively affect and potentially enhance or diminish the relationship between supply chain management practices and the overall performance of transport infrastructure projects. According to an earlier study, using environmentally friendly techniques at construction sites can result in cost savings, resource efficiency, and enhanced project results [106]. EC on TIP may be contingent on how well logistical activities related to cost, lead time, and inventory management are managed. In simpler terms, the extent to which environmental considerations influence the performance of transport infrastructure projects could be linked to how efficiently logistics operations, such as managing costs, reducing lead times, and optimizing inventory, are carried out. In other words, the success of environmental initiatives in transportation projects may depend on how effectively logistics and supply chain practices are executed in terms of cost, time, and resource management. Efficient logistics operations can amplify the positive impact of environmental considerations on project performance. According to prior studies, effective logistics procedures can result in lower project costs, shorter lead times, and better inventory management, improving overall project performance [107]. Earlier research demonstrated how early supply chain integration may enhance project results by improving resource allocation, reducing site-related effects, and reducing project costs [108]. Strong supply chain and production management techniques may enhance project performance, resource efficiency, and environmental sustainability [109]. That research has validated this result. The research results highlight the significance of well-organized collaboration and resource allocation, which substantially impact project success. Integration of BIM was crucial in improving project visualization and teamwork, which led to better results [104,110]. Project performance was improved by considering environmental effects, in line with sustainability principles.

Organizations face several challenges when implementing environmental considerations in transportation supply chain management, including inadequate resources, a lack of technical and process expertise, limited knowledge and experience in sustainable practices, difficulties in managing standard environmental control policies, and the complexity of global supply chains [111]. Additionally, resistance to change among employees and stakeholders, often driven by cost concerns, and the significant environmental impact of the transportation industry pose obstacles to achieving sustainability goals. These multifaceted challenges underscore the importance of addressing resource, knowledge, and process-related barriers for the successful integration of environmental considerations in transportation supply chain management [112].

Organizations can seize various opportunities in implementing environmental considerations in transportation supply chain management. These include optimizing transportation routes, employing fuel-efficient vehicles, and exploring alternative modes of transportation to reduce emissions and enhance logistics efficiency. Promoting collaboration and information sharing among supply chain partners fosters sustainability while ensuring transparency and measuring environmental performance. Adhering to environmental regulations and standards mitigates legal risks, and efficient ordering practices reduce transportation emissions. Partnering with sustainable suppliers and prioritizing eco-friendly packaging contributes to environmental stewardship. Leveraging these opportunities enables organizations to minimize their environmental impact, improve operational efficiency, cut costs, and contribute to a cleaner and more sustainable future [112].

5. Conclusions

Efficient cost management of site activities significantly enhances project performance, underscoring the critical role of effective cost control measures in project management. In contrast to previous research, this study establishes that reducing logistic activity costs, especially lead times and inventory management, positively correlates with the success of transport infrastructure projects. This relationship is substantiated by a coefficient of 0.107 and a t-value of 6.454. Streamlined logistics operations lead to shorter lead times, fewer delays, optimized resource utilization, and cost savings, ultimately improving project outcomes. Shifting activities from on-site construction to earlier stages in the supply chain is positively linked to the success of transport infrastructure projects. This strategic shift is supported by a substantial coefficient of 0.321 and a moderately high t-value of 5.391. It enhances efficiency, resource allocation, and overall project performance, resulting in shorter construction timelines and significant cost reductions.

The study confirms that managing and enhancing supply chain and on-site production has a positive relationship with the success of transport infrastructure projects, as indicated by a coefficient of 0.171 and a t-value of 5.636. Effective supply chain management practices and improved on-site manufacturing processes lead to increased efficiency, reduced delays, optimal resource utilization, cost savings, and overall project success. The role of BIM in moderating the relationship between supply chain management and the success of transport infrastructure projects is pivotal, supported by a substantial coefficient of 0.631 and a t-value of 4.169. This suggests that the combination of BIM and SCM enhances transport infrastructure performance (TIP). Effective risk management and BIM integration enhance project outcomes by reducing uncertainty and improving decision-making. Well-managed logistics operations maximize the impact of BIM, resulting in increased efficiency, fewer delays, and reduced transportation costs. Furthermore, environmental considerations act as a significant moderator in the relationship between supply chain management and project success, as evidenced by a substantial coefficient of 0.640 and a t-value of 3.475. This implies that considering environmental factors within SCM positively influences TIP. Implementing eco-friendly practices at construction sites leads to cost savings, resource efficiency, and improved project outcomes. Effective logistical operations, especially in terms of cost, lead time, and inventory management, are crucial to ensuring that environmental considerations positively impact project success, resulting in cost reductions and shorter lead times.

The vital role of information modeling in enhancing supply chain management within the transportation sector is evident through its contributions, such as real-time data visibility, decision-making support, and optimization of transportation routes and inventory. This integration fosters improved coordination, efficiency, and customer satisfaction. Additionally, combining information modeling with environmental considerations yields various benefits, including reduced environmental impact, cost savings, enhanced brand reputation, regulatory compliance, risk mitigation, increased customer loyalty, and long-term value creation. Together, these approaches create a comprehensive strategy for organizations to achieve sustainability, efficiency, and positive environmental and business outcomes in their supply chain management practices.

The integration of environmental considerations and information modeling has significant impacts on supply chain management. Environmental considerations in supply chain management practices, such as lean, resilient, and green practices, can improve supply chain sustainability. The integration of environmental considerations across supply, production, and distribution chains emerged as a much more effective strategy in the 1990s. A sustainable supply chain model emphasizes ethical, environmental, and economic considerations and requires transparency and traceability throughout the supply chain. BIM is one of the tools in advancing construction technology today and has the potential to be applied to construction supply chain management. Activity analysis-based modeling approaches can facilitate spatially differentiated sustainability assessments of global supply chains.

This research’s originality lies in its unique focus on supply chain management in the context of transport infrastructure projects, technology integration, environmental considerations, and its interdisciplinary approach. Its value is evident in the practical applications that can improve project efficiency, reduce costs, promote sustainability, and advance our understanding of supply chain management in complex construction projects.

5.1. Implications of the Study

This study has significant theoretical implications in multiple key areas. It advances supply chain theory by applying it to transport infrastructure projects, offering insights into adapting supply chain management principles to the industry’s unique challenges. Additionally, it enhances our understanding of supply chain roles, emphasizing the need for more comprehensive theories that address construction and transportation complexities. The research highlights the moderating role of technology, specifically BIM, underscoring the importance of technology in supply chain management models. It also brings environmental considerations to the forefront, prompting the inclusion of sustainability in supply chain models, reflecting the industry’s green practices. Furthermore, the study uncovers complex relationships between supply chain roles and project performance, laying the foundation for more nuanced models that account for diverse factors influencing project success in infrastructure settings. Lastly, it underscores the value of an interdisciplinary approach, merging supply chain management with construction, transportation, technology, and sustainability, encouraging the development of holistic theoretical frameworks recognizing the intersections of these fields.

Managing supply chains in transport infrastructure projects has various practical implications. The study provides tangible benefits for the construction industry, enabling experts to fine-tune supply chain management. Understanding the roles of different supply chain components in infrastructure performance paves the way for informed decision-making, effective strategies, and the streamlining of supply chains. Implementing best practices and utilizing tools like BIM can expedite project completion, reduce delays, improve quality, and lower costs. Furthermore, prioritizing sustainability through environmental considerations promotes the adoption of eco-friendly construction techniques and adherence to sustainability goals. The emphasis on technology integration, particularly with BIM, enhances project coordination and decision-making. It is important to note that contextual elements such as project location and regulations influence the relationship between supply chain management and infrastructure performance. Supply chain optimization is crucial in minimizing waste, resource allocation, and financial efficiency.

Additionally, stakeholder collaboration is essential for facilitating better communication and knowledge transfer. This collaboration can influence policymakers and promote environmentally friendly practices in the construction sector. Therefore, incorporating supply chain management into transport infrastructure projects is a practical approach that can lead to more efficient, cost-effective, and environmentally sustainable construction practices, benefiting project stakeholders and the broader society.

Incorporating information modeling and environmental considerations in transportation supply chain management offers numerous benefits, including enhanced operational efficiency, cost reduction, and environmental impact reduction. Efficient information flow enables real-time coordination and communication, optimizing routes and streamlining processes. Improved data utilization leads to resource efficiency, lowering costs in fuel consumption, maintenance, and inventory management. Environmental considerations identify eco-friendly transportation options, aligning with sustainability goals and reducing carbon emissions. Information modeling aids in risk mitigation by identifying and addressing disruptions and delays. This fosters a resilient supply chain. Regulatory compliance is ensured through alignment with environmental standards, reducing legal and reputational risks. Accurate tracking enhances customer satisfaction and loyalty. Information modeling promotes technology adoption, fostering continuous innovation. Additionally, integrating environmental considerations encourages long-term sustainability by incorporating eco-friendly practices into strategic planning, including renewable energy investments and sustainable packaging initiatives.

5.2. Limitations and Future Research

Limitations of this study include potential constraints on generalizability due to the specific context, the need for robust data and sample quality, limitations in measurement and variables capturing complex constructs, potential time-related factors not accounted for within the study’s timeframe, and challenges in establishing causality and directionality. To address these limitations and further advance research in this field, future studies should consider longitudinal research to track long-term effects, conduct comparative analyses across various regions and project types, employ qualitative research methods for a deeper contextual understanding, investigate the specific technological aspects of BIM that impact project success, explore standardized sustainability metrics, study government policies and regulations’ influence, and leverage advanced analytics and machine learning for more comprehensive insights into complex relationships within infrastructure projects.

Author Contributions

Conceptualization, S.M. and J.F.; methodology, I.S.D.; software, S.N.; validation, S.N., S.M. and Z.N.; formal analysis, S.M.; investigation, S.M.; resources, S.M.; data curation, S.M.; writing—original draft preparation, S.M. and I.S.D.; writing—review and editing, S.M., J.F. and Z.N.; funding acquisition, S.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Saqib Mehmood and Jianqiang Fan.

Institutional Review Board Statement

The study was conducted according to the guidelines of the Declaration of Helsinki and approved by the Ethics Committee of Chang’an University, China.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data can be obtained through email at rooqash86chd@gmail.com.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Maqsoom, A.; Charoenngam, C.; Awais, M. Internationalization process of Pakistani contractors: An exploratory study. In ICCREM 2013: Construction and Operation in the Context of Sustainability; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 59–72. [Google Scholar]

- Gardezi, S.S.S.; Manarvi, I.A.; Gardezi, S.J.S. Time extension factors in construction industry of Pakistan. Procedia Eng. 2014, 77, 196–204. [Google Scholar] [CrossRef]

- Siddiqui, S.Q.; Ullah, F.; Thaheem, M.J.; Gabriel, H.F. Six Sigma in construction: A review of critical success factors. Int. J. Lean Six Sigma 2016, 7, 171–186. [Google Scholar] [CrossRef]

- Maqsoom, A.; Charoenngam, C. Motives and competitive assets of Pakistani international construction contracting firms: Impact of size and international experience. J. Financ. Manag. Prop. Constr. 2014, 19, 138–151. [Google Scholar] [CrossRef]

- Shehu, Z.; Endut, I.R.; Akintoye, A. Factors contributing to project time and hence cost overrun in the Malaysian construction industry. J. Financ. Manag. Prop. Constr. 2014, 19, 55–75. [Google Scholar] [CrossRef]

- Zuo, J.; Read, B.; Pullen, S.; Shi, Q. Achieving carbon neutrality in commercial building developments–Perceptions of the construction industry. Habitat Int. 2012, 36, 278–286. [Google Scholar] [CrossRef]

- El-Sayegh, S.M.; Mansour, M.H. Risk assessment and allocation in highway construction projects in the UAE. J. Manag. Eng. 2015, 31, 04015004. [Google Scholar] [CrossRef]

- Rad, F.F.; Oghazi, P.; Palmié, M.; Chirumalla, K.; Pashkevich, N.; Patel, P.C.; Sattari, S. Industry 4.0 and supply chain performance: A systematic literature review of the benefits, challenges, and critical success factors of 11 core technologies. Ind. Mark. Manag. 2022, 105, 268–293. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; de Soto, B.G. Revamping construction supply chain processes with circular economy strategies: A systematic literature review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Stroumpoulis, A.; Kopanaki, E. Theoretical perspectives on sustainable supply chain management and digital transformation: A literature review and a conceptual framework. Sustainability 2022, 14, 4862. [Google Scholar] [CrossRef]

- Le, T.T.; Vo, X.V.; Venkatesh, V. Role of green innovation and supply chain management in driving sustainable corporate performance. J. Clean. Prod. 2022, 374, 133875. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Zhang, Q. Impact of sustainable practices on sustainable performance: The moderating role of supply chain visibility. J. Manuf. Technol. Manag. 2021, 32, 1421–1443. [Google Scholar] [CrossRef]

- Saeed, M.; Yas, H. Building information modelling (BIM) and knowledge management in implementation for con-struction projects. Manag. Sci. Lett. 2023, 13, 277–286. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Qin, L.; Menhas, R.; Lei, G. Strategic Sustainability and Operational Initiatives in Small-and Medium-Sized Manufacturers: An Empirical Analysis. Sustainability 2023, 15, 6330. [Google Scholar] [CrossRef]

- LaVeist, T.A.; Pérez-Stable, E.J.; Richard, P.; Anderson, A.; Isaac, L.A.; Santiago, R.; Okoh, C.; Breen, N.; Farhat, T.; Assenov, A. The economic burden of racial, ethnic, and educational health inequities in the US. JAMA 2023, 329, 1682–1692. [Google Scholar] [CrossRef] [PubMed]

- Hassanain, M.A.; Akbar, A.E.; Sanni-Anibire, M.O.; Alshibani, A. Challenges of utilizing BIM in facilities management in Saudi Arabia. Facilities 2023, 41, 890–909. [Google Scholar] [CrossRef]

- Chen, D.; Zhou, J.; Duan, P.; Zhang, J. Integrating knowledge management and BIM for safety risk identification of deep foundation pit construction. Eng. Constr. Archit. Manag. 2023, 30, 3242–3258. [Google Scholar] [CrossRef]

- Sriyanto, S.; Lodhi, M.S.; Salamun, H.; Sardin, S.; Pasani, C.F.; Muneer, G.; Zaman, K. The role of healthcare supply chain management in the wake of COVID-19 pandemic: Hot off the press. foresight 2021, 24, 429–444. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, X.; Darbandi, M. A comprehensive and bibliometric review on the blockchain-enabled IoT technology for designing a secure supply chain management system. J. Manag. Organ. 2023, 29, 745–762. [Google Scholar] [CrossRef]

- Sreenivasan, R.A.; Lee, H.-R.; Jeong, Y.; Jang, J.; Shim, D.; Lee, C.-G. A Learnable Similarity Metric for Transfer Learning with Dynamics Mismatch. In PRL Workshop Series—Bridging the Gap Between AI Planning and Reinforcement Learning; OpenReview; 2023; Available online: https://openreview.net/forum?id=78n3SG6xMY (accessed on 4 October 2023).

- Nureen, N.; Liu, D.; Irfan, M.; Malik, M.; Awan, U. Nexuses among green supply chain management, green human capital, managerial environmental knowledge, and firm performance: Evidence from a developing country. Sustainability 2023, 15, 5597. [Google Scholar] [CrossRef]

- Wibowo, M.A.; Sholeh, M.N. The analysis of supply chain performance measurement at construction project. Procedia Eng. 2015, 125, 25–31. [Google Scholar] [CrossRef]

- Xia, H.; Liu, Z.; Efremochkina, M.; Liu, X.; Lin, C. Study on city digital twin technologies for sustainable smart city design: A review and bibliometric analysis of geographic information system and building information modeling integration. Sustain. Cities Soc. 2022, 84, 104009. [Google Scholar] [CrossRef]

- Dolatabad, M.J.; Azhdarifard, M.; Acwin Dwijendra, N.K.; Ali Sharhan Al-Sudani, A.Q. Evaluating agile practices in green supply chain management using a fuzzy multicriteria approach. Discret. Dyn. Nat. Soc. 2022, 2022, 4290848. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Edwards, D.J.; Li, H.; Papadonikolaki, E.; Cao, D. Collaboration barriers in BIM-based construction networks: A conceptual model. Int. J. Proj. Manag. 2019, 37, 839–854. [Google Scholar] [CrossRef]

- Li, J.; Kassem, M.; Ciribini, A.; Bolpagni, M. A proposed approach integrating DLT, BIM, IOT and smart contracts: Demonstration using a simulated installation task. In International Conference on Smart Infrastructure and Construction 2019 (ICSIC) Driving Data-Informed Decision-Making; ICE Publishing: London, UK, 2019. [Google Scholar]

- Xue, L.; Yang, Y.; Dong, D. Roadside infrastructure planning scheme for the urban vehicular networks. Transp. Res. Procedia 2017, 25, 1380–1396. [Google Scholar] [CrossRef]

- Sharabatia, A.-A.A.; Almokdada, N.M.; Mareia, A.; Abusaimehb, H. Competitive strategy development through green supply chain practices. Uncertain Supply Chain. Manag. 2023, 11, 1507–1518. [Google Scholar] [CrossRef]

- Shoukat, R.; Xiaoqiang, Z. Sustainable Logistics Network Optimization from Dry Ports to Seaport: A Case Study from Pakistan. Transp. Res. Rec. 2023, 2677, 302–318. [Google Scholar] [CrossRef]

- Mahmud, K.K.; Chowdhury, M.M.H.; Shaheen, M.M.A. Green port management practices for sustainable port operations: A multi method study of Asian ports. Marit. Policy Manag. 2023, 1–36. [Google Scholar] [CrossRef]

- Arbulu, R.; Tommelein, I.; Walsh, K.; Hershauer, J. Value stream analysis of a re-engineered construction supply chain. Build. Res. Inf. 2003, 31, 161–171. [Google Scholar] [CrossRef]

- Janowski, T.; Kozak, S.; Malinowski, H.; Wojtasiewicz, G.; Kondratowicz-Kucewicz, B.; Kozak, J. Properties comparison of superconducting fault current limiters with closed and open core. IEEE Trans. Appl. Supercond. 2003, 13, 2072–2075. [Google Scholar] [CrossRef]

- Avotos, I. Cost-relevance analysis for overrun control. Int. J. Proj. Manag. 1983, 1, 142–148. [Google Scholar] [CrossRef]

- Endut, R.; Akintoye, A.; Kelly, J. Cost and Time Overrun in construction in Malaysia. In Proceedings of the Conference of Postgraduate Researchers in the Built Environment (Probe), Glasgow Caledonian University, Glasgow, UK, 16–17 November 2005. [Google Scholar]

- Azhar, N.; Farooqui, R.U.; Ahmed, S.M. Cost overrun factors in construction industry of Pakistan. In Proceedings of the First International Conference on Construction in Developing Countries (ICCIDC–I), Advancing and Integrating Construction Education, Research & Practice, Karachi, Pakistan, 4–5 August 2008. [Google Scholar]

- Saidu, I.; Shakantu, M. Management of Material Waste and Cost Overrun in the Nigerian Construction Industry. Ph.D. Thesis, Nelson Mandela Metropolitan University, Gqeberha, South Africa, 2016. [Google Scholar]

- Choudhry, R.M.; Aslam, M.A.; Hinze, J.W.; Arain, F.M. Cost and schedule risk analysis of bridge construction in Pakistan: Establishing risk guidelines. J. Constr. Eng. Manag. 2014, 140, 04014020. [Google Scholar] [CrossRef]

- An, H.; Razzaq, A.; Nawaz, A.; Noman, S.M.; Khan, S.A.R. Nexus between green logistic operations and triple bottom line: Evidence from infrastructure-led Chinese outward foreign direct investment in Belt and Road host countries. Environ. Sci. Pollut. Res. 2021, 28, 51022–51045. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Chu, W.; Kim, C.Y. The impact of logistics infrastructure development in China on the promotion of Sino-Korea trade: The case of Inland port under the Belt and Road Initiative. J. Korea Trade 2020, 24, 68–82. [Google Scholar] [CrossRef]

- Croucher, P.; Baker, P.; Rushton, A. The Handbook of Logistics and Distribution Management: Understanding the Supply Chain; Kogan Page: London, UK, 2014. [Google Scholar]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring supply chain resilience: Development of a conceptual framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Forslund, H. The size of a logistics performance measurement system. Facilities 2011, 29, 133–148. [Google Scholar] [CrossRef]