The Management of Food Waste Recycling for a Sustainable Future: A Case Study on South Korea

Abstract

:1. Introduction

2. Methodology

3. Waste Management Acts and Policies in South Korea

3.1. Changes in Acts and Policies by Era

3.1.1. Filth Cleaning Act (1961–1977)

3.1.2. Environmental Conservation Act (1978–1986)

3.1.3. Waste Management Act (1986–1992)

3.1.4. Division (1993–Present)

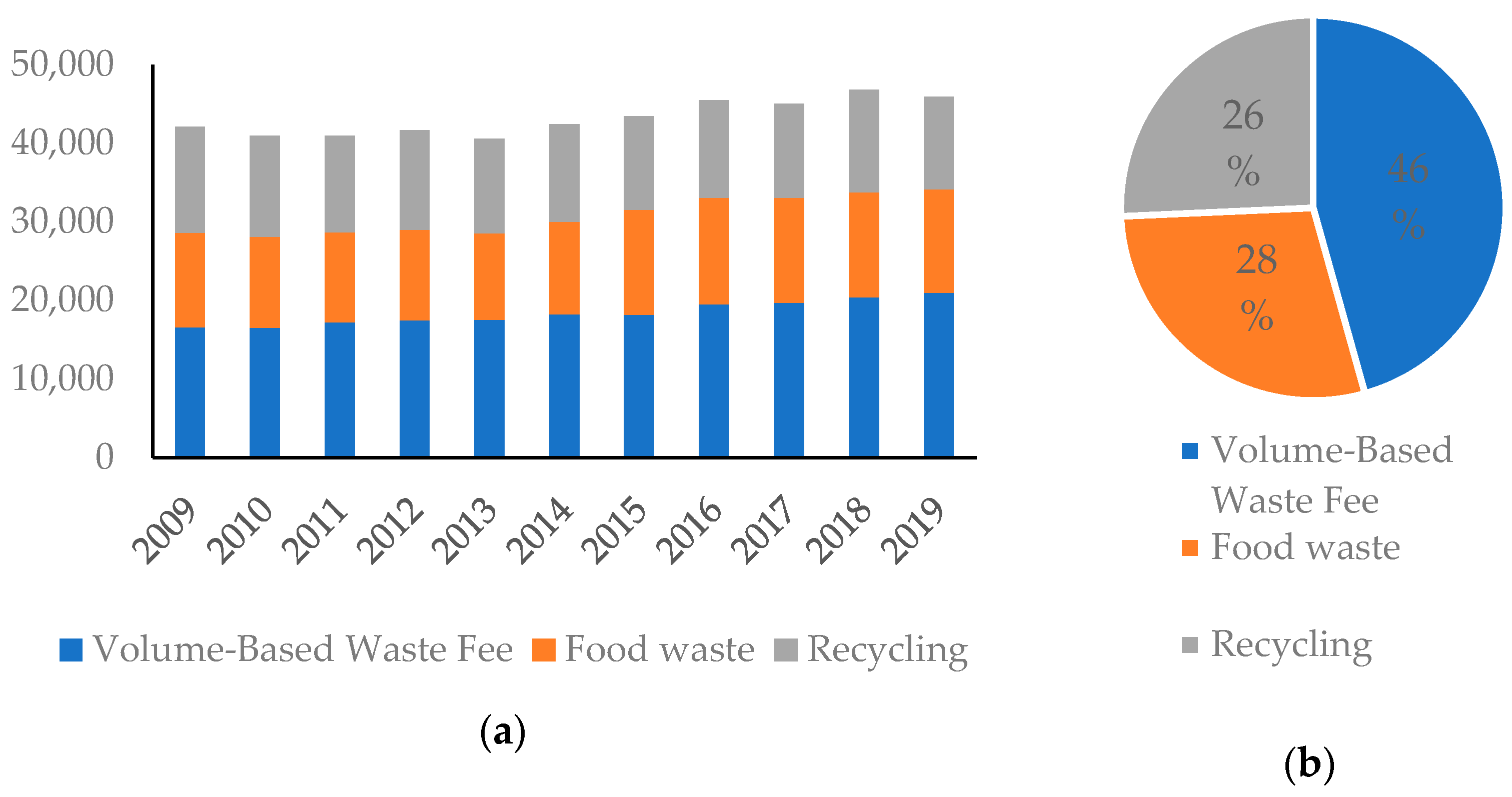

4. The Generation and Management of Food Waste

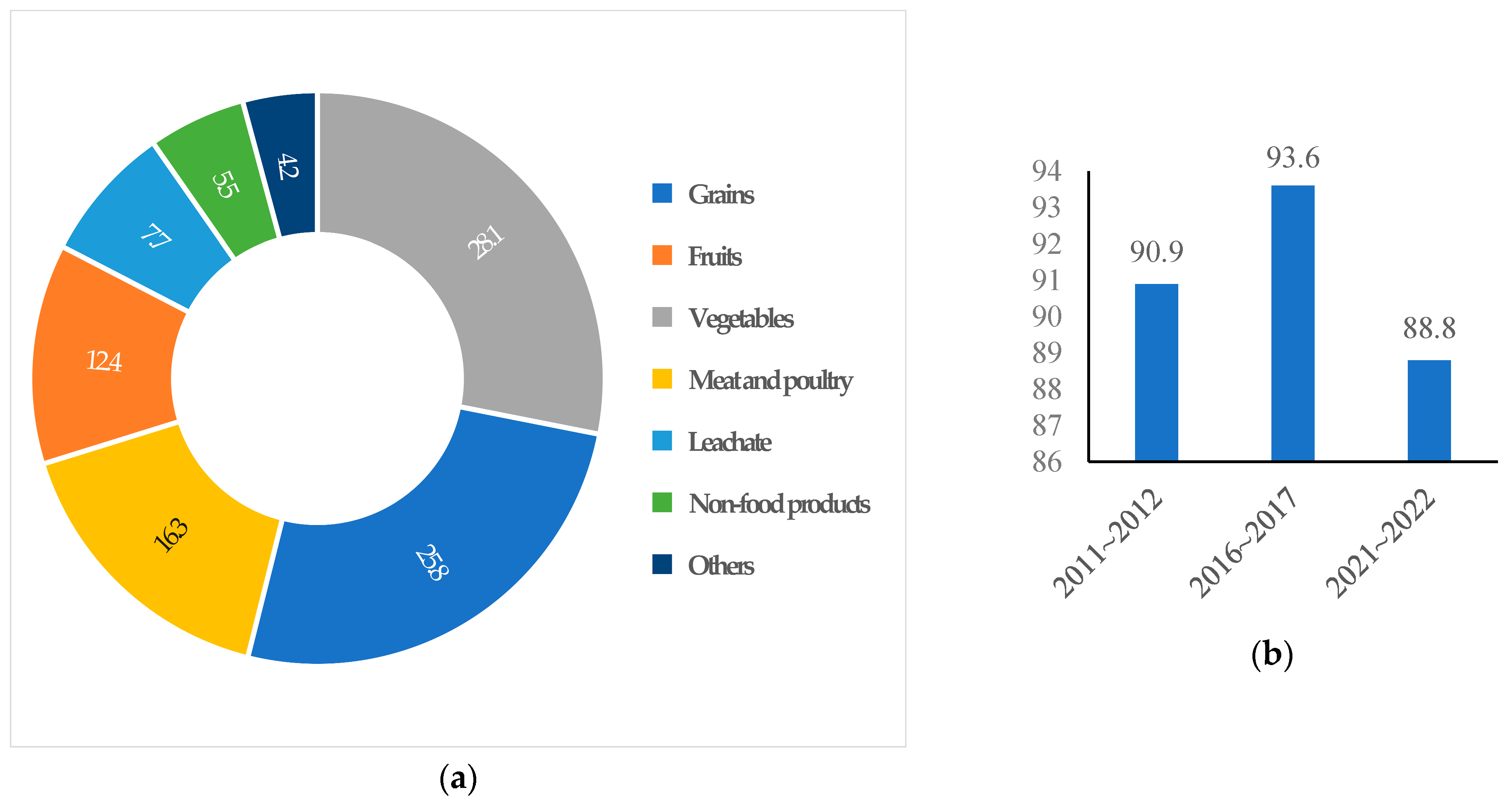

4.1. Food Waste Disposal and Classification

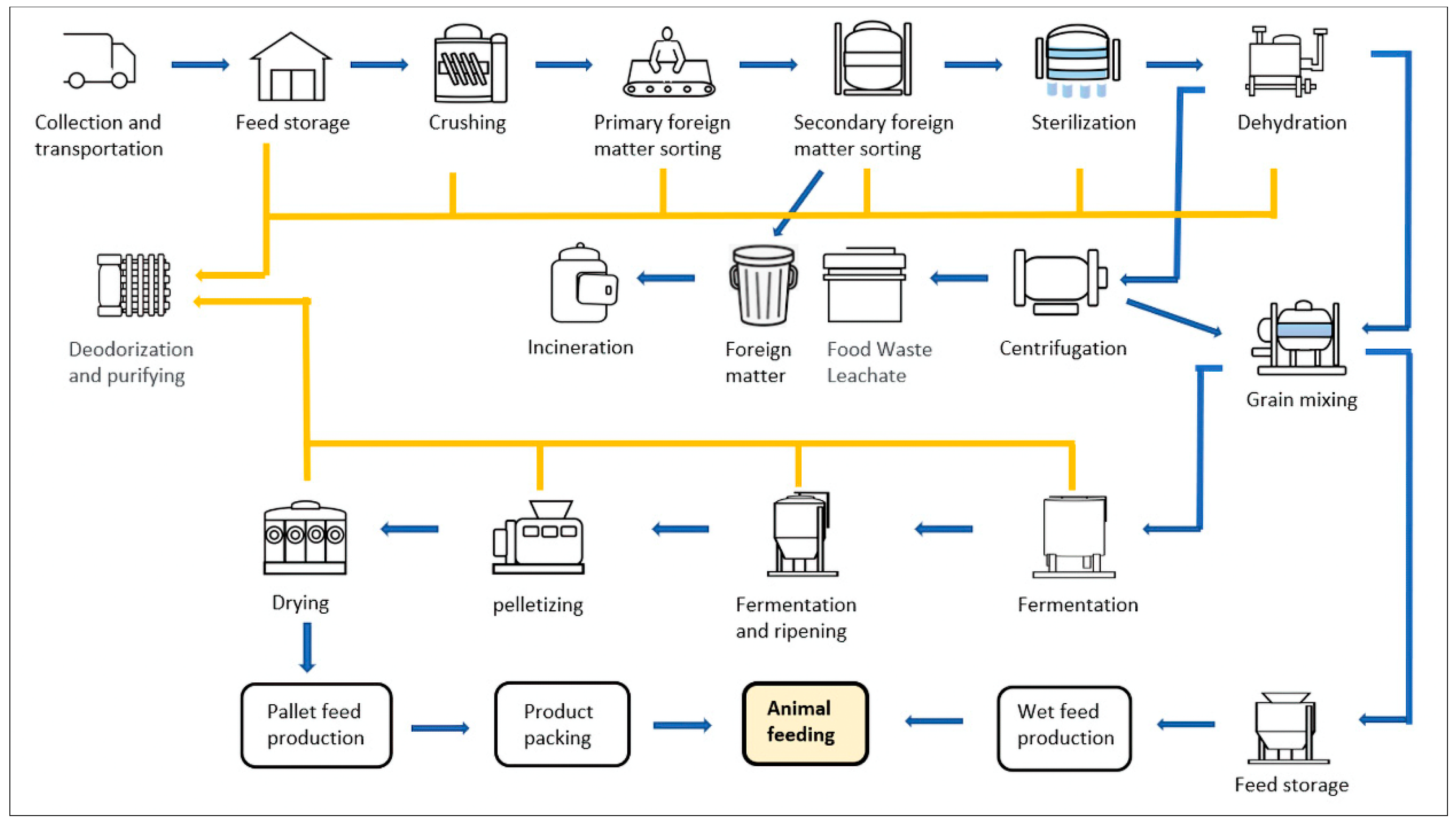

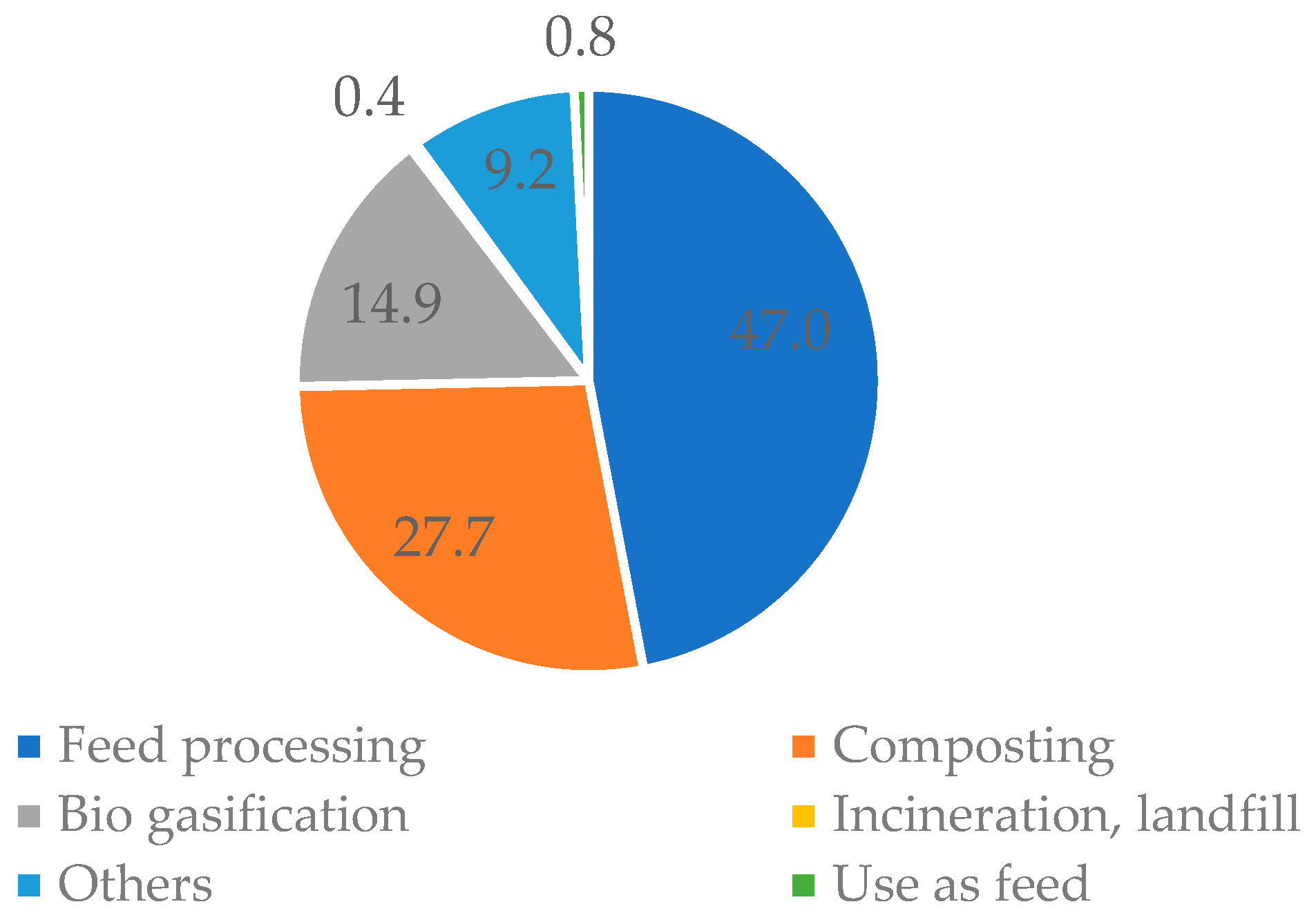

4.2. The Types of Food Waste Recycling Processes

Facilities Used to Process Food Waste into Animal Feed and Compost

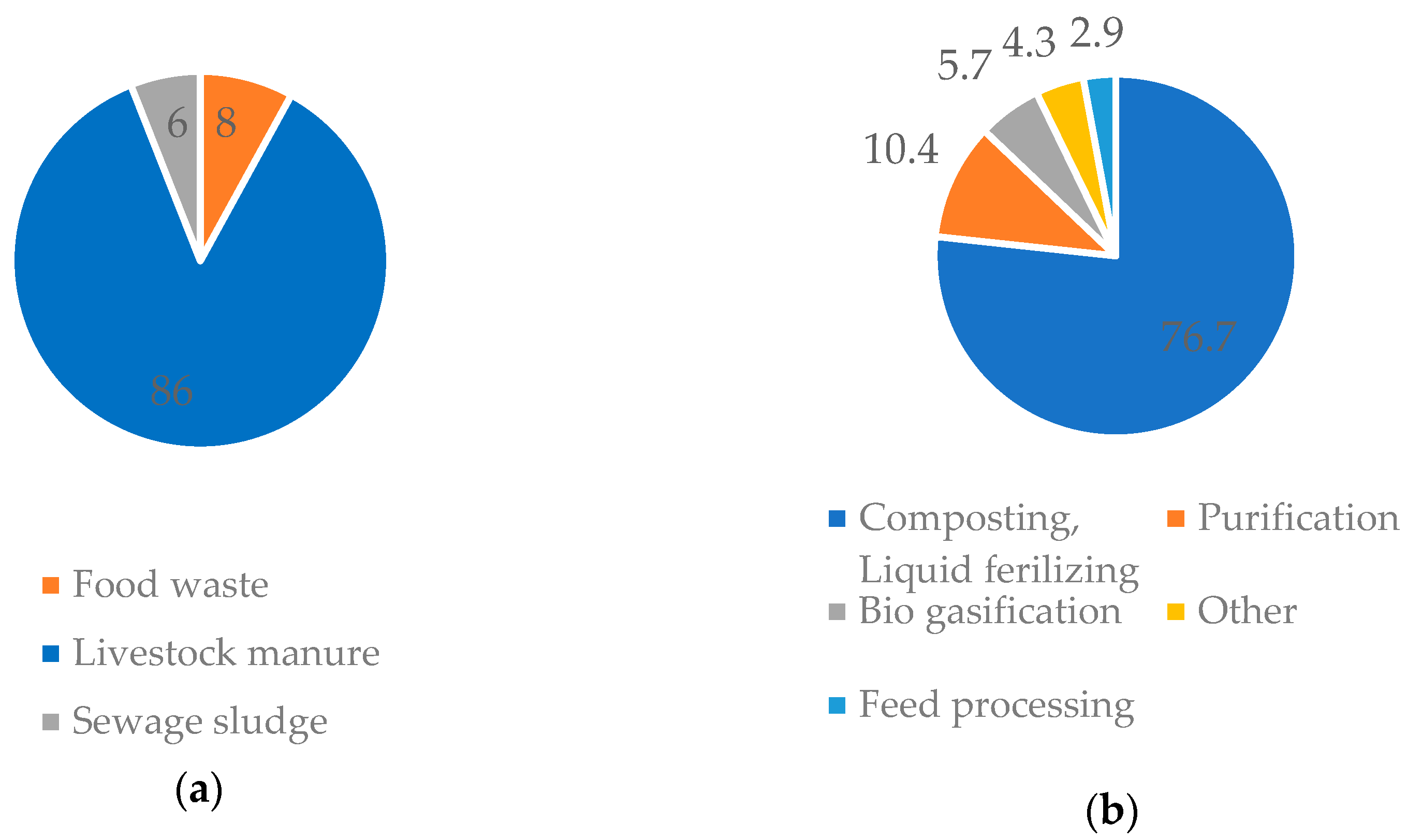

4.3. Methods Used to Process Food Waste into Compost, Animal Feed, and Biogas

4.3.1. Compost

4.3.2. Animal Feed

4.3.3. Biogas

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jacob-John, J.; D’Souza, C.; Marjoribanks, T.; Singaraju, S.P. Sustainable Development Goals: A review of SDG 12.3 in food supply chain literature. Benchmarking Int. J. 2023, 30, 3465–3481. [Google Scholar] [CrossRef]

- Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S.L.; Péan, C.; Berger, S.; Caud, N.; Chen, Y.; Goldfarb, L.; Gomis, M.I.; et al. The Sixth Assessment Report of the Intergovernmental Panel Climate Change (IPCC). 2021. Available online: https://www.ipcc.ch/report/ar6/wg1/downloads/report/IPCC_AR6_WGI_SPM_final.pdf (accessed on 3 October 2023).

- Climate Change 2021: The Physical Science Basis–IPCC. Available online: https://www.ipcc.ch/report/ar6/wg1/chapter/summary-for-policymakers/ (accessed on 3 October 2023).

- UNFCCC. A Beginner’s Guide to bu Neutrality. 2021. Available online: https://unfccc.int/blog/a-beginner-s-guide-to-climate-neutrality (accessed on 7 September 2023).

- Tonini, D.; Albizzati, P.F.; Astrup, T.F. Environmental impacts of food waste: Learnings and challenges from a case study on UK. J. Waste Manag. 2018, 76, 744–766. [Google Scholar] [CrossRef] [PubMed]

- Khalid, A.; Arshad, M.; Anjum, M.; Mahmood, T.; Dawson, L. The Anaerobic Digestion of Solid Organic Waste. J. Waste Manag. 2011, 31, 1737–1744. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Park, S.Y.; Zhu, J. Solid-State Anaerobic Digestion for Methane Production from Organic Waste. Renew. Sust. Energ. Rev. 2011, 15, 821–826. [Google Scholar] [CrossRef]

- DiGiacomo, A.; Wu, D.; Lenkic, P.; Fraser, B.; Zhao, J.; Kingstone, A. Convenience improves composting and recycling rates in high-density residential buildings. J. Environ. Plan. Manag. 2018, 61, 309–331. [Google Scholar] [CrossRef]

- Shekdar, A.V. Sustainable solid waste management: An integrated approach for Asian countries. Waste Manag. 2009, 29, 1438–1448. [Google Scholar] [CrossRef] [PubMed]

- Sakai, S.; Yoshida, H.; Hirai, Y. International comparative study of 3R and waste management policy developments. J. Mater. Cycles Waste Manag. 2011, 13, 86–102. [Google Scholar] [CrossRef]

- Clercq, D.; Wen, Z.; Gottfried, O.; Schmidt, F.; Fei, F. A review of global strategies promoting the conversion of food waste to bioenergy via anaerobic digestion. Renew. Sust. Energ. Rev. 2017, 79, 204–221. [Google Scholar] [CrossRef]

- Lee, S.; Hur, G.Y. Volume Based Waste Fee (VBWF) System for Municipal Solid Waste. Seoulsolution. 2017. Available online: https://www.seoulsolution.kr/sites/default/files/policy/%ED%99%98%EA%B2%BD_9_p181_Volume%20Based%20Waste%20Fee%20%28VBMF%29%20System%20for%20Municipal%20Solid%20Waste.pdf (accessed on 3 October 2023).

- Adelodun, B.; Kim, H.S.; Choi, S.K. Assessment of food waste generation and composition among Korean households using novel sampling and statistical approaches. Waste Manag. 2021, 122, 71–80. [Google Scholar] [CrossRef]

- Korea Land Corporation. Food Waste Composting and Fodder Facility Survey Report. 1998. Available online: https://www.codil.or.kr/filebank/original/RK/OTKLRK010349//OTKLRK010349.pdf?stream=T (accessed on 3 October 2023).

- Ko, J.Y.; Phae, C.G.; Park, J.S. Effect of Food Waste Direct Landfilling Prohibition on Characteristics of Landfill Gas and Leachate. Korean Ind. Eng. Chem. 2007, 18, 612–617. [Google Scholar]

- Ministry of Environment. Prohibition of Direct Landfilling of Food Waste Since 2005. Available online: https://me.go.kr/home/web/policy_data/read.do;jsessionid=amcz5G0ZkFShk-owLWheYPEO.mehome1?pagerOffset=4370&maxPageItems=10&maxIndexPages=10&searchKey=&searchValue=&menuId=92&orgCd=&condition.deleteYn=N&seq=1939 (accessed on 3 October 2023).

- Yoo, Y.K. Seoul Waste Management Policy, Seoul Archive. 2015. Available online: https://seoulsolution.kr/ko/content/3028 (accessed on 18 September 2023).

- Kim, I.G.; Kwon, P.S.; Kang, G.M.; Kim, O.S.; Choi, Y.K. 50 years of Korean environment. Korea Environmental Technology Research Institute. 1996. Available online: http://repository.kei.re.kr/handle/2017.oak/18886 (accessed on 7 September 2023).

- Cho, O.B. Waste Treatment and Management. National Archives of Korea. 2006. Available online: https://www.archives.go.kr/next/newsearch/listSubjectDescription.do?id=003876&sitePage= (accessed on 7 September 2023).

- National Law Information Center. The Filth Cleaning Act. Law No. 914 Enacted on 30 December 1961. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=455#0000 (accessed on 7 September 2023).

- National Law Information Center. The Filth Cleaning Act Law No. 2584 Enacted on 9 March 1973. Available online: https://glaw.scourt.go.kr/wsjo/lawod/sjo192.do?lawodNm=%EC%98%A4%EB%AC%BC%EC%B2%AD%EC%86%8C%EB%B2%95&jomunNo=20&jomunGajiNo= (accessed on 4 January 2024).

- Lee, H.S. Major Air Conservation Policy Initiatives and Future Directions. Ministry of Economy and Finance and Korea Research Institute for Human Settlements. 1997. Available online: https://www.hri.co.kr/upload/board/HER199703_02.PDF (accessed on 10 September 2023).

- National Law Information Center. The Environmental Conservation Act Enforcement Regulations [Appendix 3], Revised on 7 January 1981. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsiSeq=48948#J13624147 (accessed on 7 September 2023).

- Kim, J.D.; Kim, D.K.; Lee, H.K. The Story of the Ministry of Environment through Records. Ministry of Environment. 2015. Available online: http://www.me.go.kr/home/web/board/read.do?pagerOffset=10&maxPageItems=10&maxIndexPages=10&searchKey=&searchValue=&menuId=10181&orgCd=&boardMasterId=54&boardCategoryId=&boardId=502230&decorator= (accessed on 10 September 2023).

- Korea Institute for Health and Social Affairs. Measures for Cultivating Improved Dietary Habits. 1998. Available online: http://repository.kihasa.re.kr/bitstream/201002/1183/1/%EC%A0%95%EC%B1%85%EB%B3%B4%EA%B3%A0%EC%84%9C%201998-09.pdf (accessed on 10 September 2023).

- Ministry of Environment. Food Waste Reduction and Recycling, Achievements and Future. 2017. Available online: https://school.jbedu.kr/_cmm/fileDownload/puan-m/M01030402/bb4f827b39ae849d7d7747a8ba0b31fe (accessed on 3 October 2023).

- Ministry of Environment. 1st Basic Plan of Resource Circulation in South Korea (2018–2027). 2018. Available online: http://www.me.go.kr/home/web/policy_data/read.do?menuId=10265&seq=7193 (accessed on 3 October 2023).

- National Law Information Center. Promotion of Biogas Production and Utilization from Organic Waste Resources (Notice No. 19151). 2022b. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EC%9C%A0%EA%B8%B0%EC%84%B1%ED%8F%90%EC%9E%90%EC%9B%90%EC%9D%84%ED%99%9C%EC%9A%A9%ED%95%9C%EB%B0%94%EC%9D%B4%EC%98%A4%EA%B0%80%EC%8A%A4%EC%9D%98%EC%83%9D%EC%82%B0%EB%B0%8F%EC%9D%B4%EC%9A%A9%EC%B4%89%EC%A7%84%EB%B2%95/(19151,20221230) (accessed on 3 October 2023).

- Ministry of Environmental and Korea Environmental Corporation. National Waste Generation and Disposal Status. 2014–2019. Available online: https://www.recycling-info.or.kr/rrs/stat/envStatList.do?menuNo=M13020201 (accessed on 10 September 2023).

- Lee, J.D.; Yoon, M.Y.; Choi, W.I.; Bae, S.J.; Seo, C.D. Effect of seasonal variations of organic loading rate and acid phase on methane yield of food waste leachate in South Korea. Appl. Biol. Chem. 2017, 60, 87–93. [Google Scholar] [CrossRef]

- Korean Resource recirculation Information System. The 6th National Waste Statistics Survey (2021~2022). 2022. Available online: https://www.recycling-info.or.kr/rrs/stat/envStatDetail.do;jsessionid=xfpHnAidOc6ytjXQc6EKwYIE7rHdjXFtRtDm0ElispUHas8gxZM8z6YBvIs8B8lB.RCIS-WAS_servlet_engine1?bbsId=BBSMSTR_000000000002&nttId=1331&s_nttSj=KEC011 (accessed on 10 September 2023).

- Nongsaro. Organic Compost Manufacturing Technology. 2017. Available online: https://www.nongsaro.go.kr/portal/ps/psz/psza/contentSub.ps?menuId=PS04185&cntntsNo=207210 (accessed on 25 September 2023).

- Kim, H.J. Efficient Food Waste Treatment Plan. Incheon Green Environment Support Center. 2020. Available online: https://igec.re.kr/r_b_year/%EC%9D%8C%EC%8B%9D%EB%AC%BC%EC%93%B0%EB%A0%88%EA%B8%B0%EC%9D%98-%ED%9A%A8%EC%9C%A8%EC%A0%81-%EC%B2%98%EB%A6%AC-%EB%B0%A9%EC%95%88/?sca=%EC%A0%95%EC%B1%85&page=9 (accessed on 18 September 2023).

- Ministry of Environment. 2015 Waste Treatment Business and Waste Treatment Facility Installation and Operation Status Evaluation Result Report. 2016. Available online: http://www.me.go.kr/home/web/policy_data/read.do?pagerOffset=23&maxPageItems=10&maxIndexPages=10&searchKey=&searchValue=&menuId=10259&orgCd=&condition.orderSeqId=6843&condition.rnSeq=749&condition.deleteYn=N&seq=6845 (accessed on 15 September 2023).

- Ministry of Environment. 2022 Waste Treatment Business and Waste Treatment Facility Installation and Operation Status Evaluation Result Report. 2023. Available online: http://www.me.go.kr/home/web/policy_data/read.do?menuId=10265&seq=8016 (accessed on 7 September 2023).

- Ministry of Environmental and Korea Environmental Corporation. National Waste Generation and Disposal Status. 2021. Available online: https://www.recycling-info.or.kr/rrs/stat/envStatDetail.do?menuNo=M13020201&pageIndex=1&bbsId=BBSMSTR_000000000002&s_nttSj=KEC005&nttId=1296&searchBgnDe=&searchEndDe= (accessed on 7 September 2023).

- Lee, J.H.; Yeom, K.R.; Yang, J.W.; Choi, Y.J.; Hwang, H.C.; Jeon, Y.J.; Lee, C.H.; Choi, B.S.; Oh, T.K.; Park, S.J. Comparing the composting characteristics of food waste supplemented with various bulking agents. Korean J. Agric. Sci. 2019, 46, 897–905. [Google Scholar] [CrossRef]

- Korea Institute of Science and Technology Information. Food Waste Composting. 2002. Available online: https://scienceon.kisti.re.kr/commons/util/originalView.do?dbt=TRKO&cn=TRKO201000015694 (accessed on 21 September 2023).

- Jong, D.H. Activation Plan for the Use of Food Compost in Daejeon. Daejeon Development Institute. 2013. Available online: https://www.dsi.re.kr/board.es?mid=a10101000000&bid=0001&act=view&list_no=3104&nPage=79&sel_date= (accessed on 21 September 2023).

- Yun, R.J. Fertilization by Anaerobic Bacteria in Plant Growth. Korea Institute of Science and Technology. 2004. Available online: https://www.reseat.or.kr/portal/bbs/B0000261/view.do?nttId=159550&menuNo=200019&pageIndex=6028 (accessed on 18 September 2023).

- Yang, S.I.; Ji, K.M.; Jeon, H.B. A Review on Efficient Operation Technology of Compost Depot). Clean Technol. 2017, 23, 345–356. [Google Scholar]

- Domínguez, J. State of the art and new perspectives on vermicomposting research. In Earthworm Ecology, 2nd ed.; Edwards, C.A., Ed.; CRC Press LLC.: Boca Raton, FL, USA, 2004; pp. 401–424. [Google Scholar]

- Enebe, M.C.; Erasmus, M. Vermicomposting technology—A perspective on vermicompost production technologies, limitations and prospects. J. Environ. Manag. 2023, 345, 118585. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Ma, L.W.; Martinez, G.A. Comparison of methods for evaluating stability and maturity of biosolids compost. J. Environ. Qual. 2000, 29, 424–429. [Google Scholar] [CrossRef]

- Rupani, P.F.; Alkarkhi, A.F.M.; Shahadat, M.; Embrandiri, A.; El-Mesery, H.S.; Wang, H.; Shao, W. Bio-Optimization of Chemical Parameters and Earthworm Biomass for Efficient Vermicomposting of Different Palm Oil Mill Waste Mixtures. Int. J. Environ. Res. Public Health 2019, 16, 2092. [Google Scholar] [CrossRef]

- Othman, N.; Irwan, J.M.; Roslan, M.A. Vermicomposting of Food Waste. Int. J. Integr. Eng. 2012, 4, 39–48. [Google Scholar]

- National Law Information Center. Article 4 of the Fertilizer Management Act. 2013. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EB%B9%84%EB%A3%8C%EA%B4%80%EB%A6%AC%EB%B2%95 (accessed on 16 September 2023).

- Rural Development Administration. Opening the Way to Industrialize Food Waste Disposal Using ‘Black Solider Fly’. 2018. Available online: http://www.rda.go.kr/board/board.do?mode=view&prgId=day_farmprmninfoEntry&dataNo=100000744772 (accessed on 16 September 2023).

- National Law Information Center. Article 11 of the Feed Management Act. 2022a. Available online: https://www.law.go.kr/lsSc.do?section=&menuId=1&subMenuId=15&tabMenuId=81&eventGubun=060101&query=%EC%82%AC%EB%A3%8C%EA%B4%80%EB%A6%AC%EB%B2%95+%EC%A0%9C+11%EC%A1%B0%28%EC%82%AC%EB%A3%8C%EC%9D%98+%EA%B3%B5%EC%A0%95+%EB%93%B1%292020.3.24+%ED%83%80%EB%B2%95%EA%B0%9C%EC%A0%95#J11:0 (accessed on 16 September 2023).

- Manuel, C.R.; Carlos, Q.F.; Carmen, P.C.; Marisela, V.D.; Iván, M.A. Fungal solid-state fermentation of food waste for biohydrogen production by dark fermentation. Int. J. Hydrogen Energy 2022, 47, 30062–30073. [Google Scholar] [CrossRef]

- Rasool, K.; Hussain, S.; Shahzad, A. Comprehensive insights into sustainable conversion of agricultural and food waste into microbial protein for animal feed production. Rev. Environ. Sci. Biotechnol. 2023, 22, 527–562. [Google Scholar] [CrossRef]

- Saleh, A.A.; Shukry, M.; Farrag, F.; Soliman, M.M.; Abdel-Moneim, A.E. Effect of Feeding Wet Feed or Wet Feed Fermented by Bacillus licheniformis on Growth Performance, Histopathology and Growth and Lipid Metabolism Marker Genes in Broiler Chickens. Animals 2021, 11, 83. [Google Scholar] [CrossRef]

- Jee, S.K.; Baik, H.Y.; Kwak, S.W. Evaluation on Feed-Nutritional Change of Food Waste According to Different Processing Methods and Trouble-shooting Strategy. J. Anim. Sci. Technol. 2005, 47, 513–524. [Google Scholar]

- Korea Waste Association. Manufacturing Process Diagram of Wet and Dry Feed Production. Available online: http://www.kwaste.or.kr/bbs/content.php?co_id=sub040205(kwaste.or.kr) (accessed on 12 July 2023).

- Bu, A.S. Let’s Realize Carbon Negative by Turning Leftover Food into Resources. Korea Food Logistics Waste Collection and Transportation Industry Association. 2021. Available online: https://m.ecomedia.co.kr/news/newsview.php?ncode=1065579852072175 (accessed on 28 September 2023).

- Park, G.L.; Yun, S.M.; Ju, S.W.; Long, F.H.; Park, Y.H.; Kim, Y.Y. Effects of Fermented Food Waste Supplementation on Growth Performance and Pork Quality in Pig. J. Anim. Sci. Technol. 2006, 48, 361–374. [Google Scholar]

- Park, H.K.; Choi, C.Y.; Nam, H.S.; Kim, H.S.; Kim, Y.S.; Ma, J.Y.; No, K.S. Nutritional value of black soldier fly, Hermetia illucens (Diptera: Stratiomyidae) as a feed supplement for fish. J. Seric. Entomol. Sci. 2013, 51, 95–98. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, Y.J. Removal Efficiency of Organic Waste Resources using Black Soldier Fly. J. Korea Soc. Waste Manag. 2015, 32, 276–280. [Google Scholar] [CrossRef]

- Oonincx, D.G.A.B.; van Itterbeeck, J.; Heetkamp, M.J.W.; van den Brand, H.; van Loon, J.J.A.; van Huis, A. An Exploration on Greenhouse Gas and Ammonia Production by Insect Species Suitable for Animal or Human Consumption. PLoS ONE 2010, 5, e14445. [Google Scholar] [CrossRef] [PubMed]

- Diener, S.; Studt Solano, N.M.; Roa Gutiérrez, F. Biological Treatment of Municipal Organic Waste using Black Soldier Fly Larvae. Waste Biomass Valor 2011, 2, 357–363. [Google Scholar] [CrossRef]

- Rural Development Administration. Establishment and Designation of Fertilizer Process Standards (Full Revision). 2019. Available online: https://www.rda.go.kr/board/board.do?ccatgId=&menu_id=ofc&boardId=rdalw&searchKey=&userJumin=&searchVal=&searchSDate=&prgId=law_rdalwEntry&portlet_kind=default&portlet_rowCnt=4&mode=view&portlet_gubun=1&currPage=1&CONTENT2=&searchEDate=&CONTENT1=&nckUserNm=&list_kind=news&CONTENT3=&dataNo=100000753723&CONTENT5=&menu_nm=%C7%E0%C1%A4%C1%A4%BA%B8 (accessed on 16 September 2023).

- Awe, O.W.; Zhao, Y.; Nzihou, A.; Minh, D.P.; Lyczko, N. A Review of Biogas Utilisation, Purification and Upgrading Technologies: Review. Waste Biomass Valori 2017, 8, 267–283. [Google Scholar] [CrossRef]

- Otun, T.F.; Ojo, O.M.; Ajibade, F.O.; Babatola, J.O. Evaluation of biogas production from the digestion and co-digestion of animal waste, food waste and fruit waste. Int. J. Environ. 2015, 3, 12–24. [Google Scholar]

- Przygocka-Cyna, K.; Grzebisz, W. Biogas digestate–benefits and risks for soil fertility and crop quality–an evaluation of grain maize response. Open Chem. 2018, 16, 258–271. [Google Scholar] [CrossRef]

- Andreottola, G.; Ragazzi, M.; Foladori, P.; Villa, R.; Langone, M.; Rada, E.C. The unit intregrated approch for OFMSW Treatment. Univ. Politeh. Buchar. Sci. Bull. 2012, 74, 19–26. [Google Scholar]

- Schiavon, M.; Rada, E.C.; Cioca, L.; Torrett, V. Environmental and managerial advantages of treatment plants exploiting biogas from food waste. J. Energy Prod. Mgmt. 2018, 3, 292–306. [Google Scholar] [CrossRef]

- Park, J.H.; Kang, Y.J. Biofuel. Korea Institute of S&T Evaluation and Planning. 2022. Available online: https://www.kistep.re.kr/board.es?mid=a10306010000&bid=0031&list_no=42590&act=view (accessed on 10 September 2023).

- Ministry of Environment. Policy Direction for Bio Gasification of Organic Waste Resources. 2022. Available online: https://me.go.kr/home/web/policy_data/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=title&searchValue=%ED%8F%90%EC%9E%90%EC%9B%90&menuId=10259&orgCd=&condition.toInpYmd=null&condition.fromInpYmd=null&condition.deleteYn=N&condition.deptNm=null&seq=7923 (accessed on 10 September 2023).

- Ministry of Environment. Status of Organic Waste Bio Gasification Facilities. 2020. Available online: http://www.me.go.kr/home/web/policy_data/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=title&searchValue=%EC%9C%A0%EA%B8%B0%EC%84%B1%ED%8F%90%EC%9E%90%EC%9B%90+%EB%B0%94%EC%9D%B4%EC%98%A4%EA%B0%80%EC%8A%A4%ED%99%94%EC%8B%9C%EC%84%A4+%ED%98%84%ED%99%A9&menuId=10263&orgCd=&condition.toInpYmd=null&condition.fromInpYmd=null&condition.deleteYn=N&condition.deptNm=null&seq=7683 (accessed on 10 September 2023).

- Ministry of Environment. Operation Status of Food Waste Handling Facilities. 2021. Available online: https://me.go.kr/home/web/policy_data/read.do;jsessionid=9F0ba0rkxccsS0qlFLpGLhhj.mehome1?pagerOffset=30&maxPageItems=10&maxIndexPages=10&searchKey=&searchValue=&menuId=10259&orgCd=&condition.toInpYmd=null&condition.fromInpYmd=null&condition.deleteYn=N&condition.deptNm=null&seq=7916 (accessed on 10 September 2023).

| Categories | Number of Facilities | Distribution of Facilities Based on Capacity | |

|---|---|---|---|

| >30 Tonnes/Day | <30 Tonnes/Day | ||

| Feed | 26 | 25 | 1 |

| Compost | 28 | 19 | 9 |

| Others | 21 | 9 | 12 |

| Categories | Number of Productions (Thousand Tonnes/Year) | Method of Usage (Thousand Tonnes/Year) | Usage Rate (%) | ||

|---|---|---|---|---|---|

| Paid Sales | Provided Free of Charge | Self-Generated and Use 1 | |||

| Feed | 67.0 | 2.8 | 44.3 | - | 37.3 |

| Compost | 59.4 | 1.0 | 57.1 | 0.003 | 49.8 |

| Others 2 | 115.3 | - | 55.5 | - | 24.1 |

| Category | Principle | Advantage | Disadvantage |

|---|---|---|---|

| Aerobic composting | For a home that carries out composting using aerobic microorganisms, a continuous air supply is required | Short time required for composting | High energy consumption; odors |

| Anaerobic composting | Food stays for a long time in an enclosed space to decompose; compost and methane gas are produced as by-products | Degree of loss is large | Decomposition is slow |

| Vermicomposting | Compost production by fermenting food waste and providing it as food for earthworms | Low initial facility investment | Limitation of application in urban areas due to odors |

| Classification | Hazardous Substances | Acceptance Criteria |

|---|---|---|

| Management target: heavy metal | Lead (Pb) | 20 ppm |

| Mercury (Hg) | 0.5 ppm | |

| Cadmium (Cd) | 50 ppm | |

| Management target: major mycotoxin | Aflatoxin B1, B2, G1, G2 | 50 ppb |

| Ochratoxin | 250 ppb | |

| Management target: minor mycotoxin | Deoxynivalenol (vomitoxin) | 10,000 ppb |

| Zearalenone | 3000 ppb | |

| Fusarium B1 and B2 | 60,000 ppb | |

| T-2/HT-2 | 500 ppb | |

| Management target: other safety concerns | Free gossypol | 1200 ppm |

| Cyanide | 50 ppm | |

| Salmonella | Not detected |

| Category | Total | Feed Processing | Composting/ Liquid Fertilizing | Bio Gasification | Purification | Others (e.g., Incineration) |

|---|---|---|---|---|---|---|

| Total | 65.37 (100) | 1.89 (2.9) | 50.15 (76.7) | 3.75 (5.7) | 6.80 (10.4) | 2.78 (4.3) |

| Food waste | 5.22 (100) | 1.89 (36.2) | 1.99 (38.1) | 65 (12.5) | - | 69 (13.2) |

| Livestock excretion | 55.93 (100) | - | 48.16 (86.1) | 92 (1.6) | 6.80 (12.2) | 5 (0.1) |

| Sewage sludge | 4.22 (100) | - | - | 2.18 (51.7) | - | 2.04 (48.3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, E.; Shurson, G.; Oh, S.-H.; Jang, J.-C. The Management of Food Waste Recycling for a Sustainable Future: A Case Study on South Korea. Sustainability 2024, 16, 854. https://doi.org/10.3390/su16020854

Lee E, Shurson G, Oh S-H, Jang J-C. The Management of Food Waste Recycling for a Sustainable Future: A Case Study on South Korea. Sustainability. 2024; 16(2):854. https://doi.org/10.3390/su16020854

Chicago/Turabian StyleLee, Esther, Gerald Shurson, Sang-Hyon Oh, and Jae-Cheol Jang. 2024. "The Management of Food Waste Recycling for a Sustainable Future: A Case Study on South Korea" Sustainability 16, no. 2: 854. https://doi.org/10.3390/su16020854