Carbon Carriers Driving the Net-Zero Future: The Role of Torrefied Biomass Pellets in Power-To-X

Abstract

:1. Introduction

2. Sustainable Carbon

3. Investigation of a Sustainable Carbon Carrier

- Global Scalability: The carbon carrier process should be universally viable, cost-effective, and adaptable to various biomass types and climates. Its scalability must meet global sustainability demands.

- Standardized Production: Standardized carbon carriers are crucial for consistent quality, performance assessment, and regulatory compliance, regardless of geographic origin.

- Universal Applicability: The process should enable global inclusivity, letting countries use local biomass to create a standardized carbon carrier, provided they meet sustainability criteria.

- Transportability: The carbon carrier’s design should facilitate global shipping and integrate easily with existing logistic infrastructure, avoiding the need for major changes. Transport costs vary; they are location-dependent and also depend on the carrier physical state—solid (e.g., wood logs, pellets, or torrefied biomass pellets), liquid (e.g., biocrude), or gaseous (e.g., CO2 or CO). Solid carriers like pellets offer higher volumetric density and are generally easier and cheaper to transport using conventional logistics infrastructure. Liquid and gaseous forms require more specialized handling, with liquids like biocrude offering medium transport costs and gases like CO2 or CO demanding high costs due to pressurization or refrigeration needs.

- Simplicity and Accessibility: The beauty of the ideal carbon carrier lies in its simplicity. Especially for upstream processes typically situated in remote areas often in the developing world, the technology should be straightforward, durable, and not reliant on high-tech apparatus or specialized expertise.

- Flexibility in End Use: The initial production should not be tethered to a specific end fuel or chemical. Given that the Fischer–Tropsch synthesis, methanol synthesis, and methanation are based on COx and hydrogen, the carbon carrier should be versatile enough to serve all the above process.

- Immediate Technological Feasibility: Only technologies that are commercially available and ready to be deployed should be integrated into its production process.

- Wood Chips: These have low carbon content and bulk density. Their quality can be impacted by many factors like humidity, storage conditions, and more. Transporting wood chips over long distances would be inefficient due to these factors.

- Wood Pellets: More standardized than wood chips, wood pellets are easier to transport and handle. However, they still have issues, such as sensitivity to moisture and high volatile matter content, which can cause challenges in fuel synthesis.

- Charcoal: It has a higher carbon content, and it is already produced at significant scales in numerous countries around the world. However, the pyrolysis process used to produce charcoal is carbon inefficient, and the charcoal’s low bulk density makes it costly to transport.

- Activated Carbon: This form of charcoal has undergone treatments to increase its surface area, making it highly absorbent. This very feature could be problematic if the activated carbon were to absorb other materials during transport.

- Charcoal Briquettes: By adding a binding agent, charcoal can be formed into briquettes. These have increased bulk density although still requiring large volumes due to large porosity, reducing some of charcoal’s transport challenges. However, the need for binding agents could introduce new issues.

- Torrefied Biomass: It serves as a promising carbon carrier due to its high carbon content, energy density, and renewability. While torrefaction improves many characteristics, the lack of uniform shape or size complicates handling and transport.

- Torrefied Biomass Pellets: An approach bridging the benefits and drawbacks of “white” wood pellets and torrefied biomass, which also benefit from the fact that they do not require binding agents for pelletizing [41].

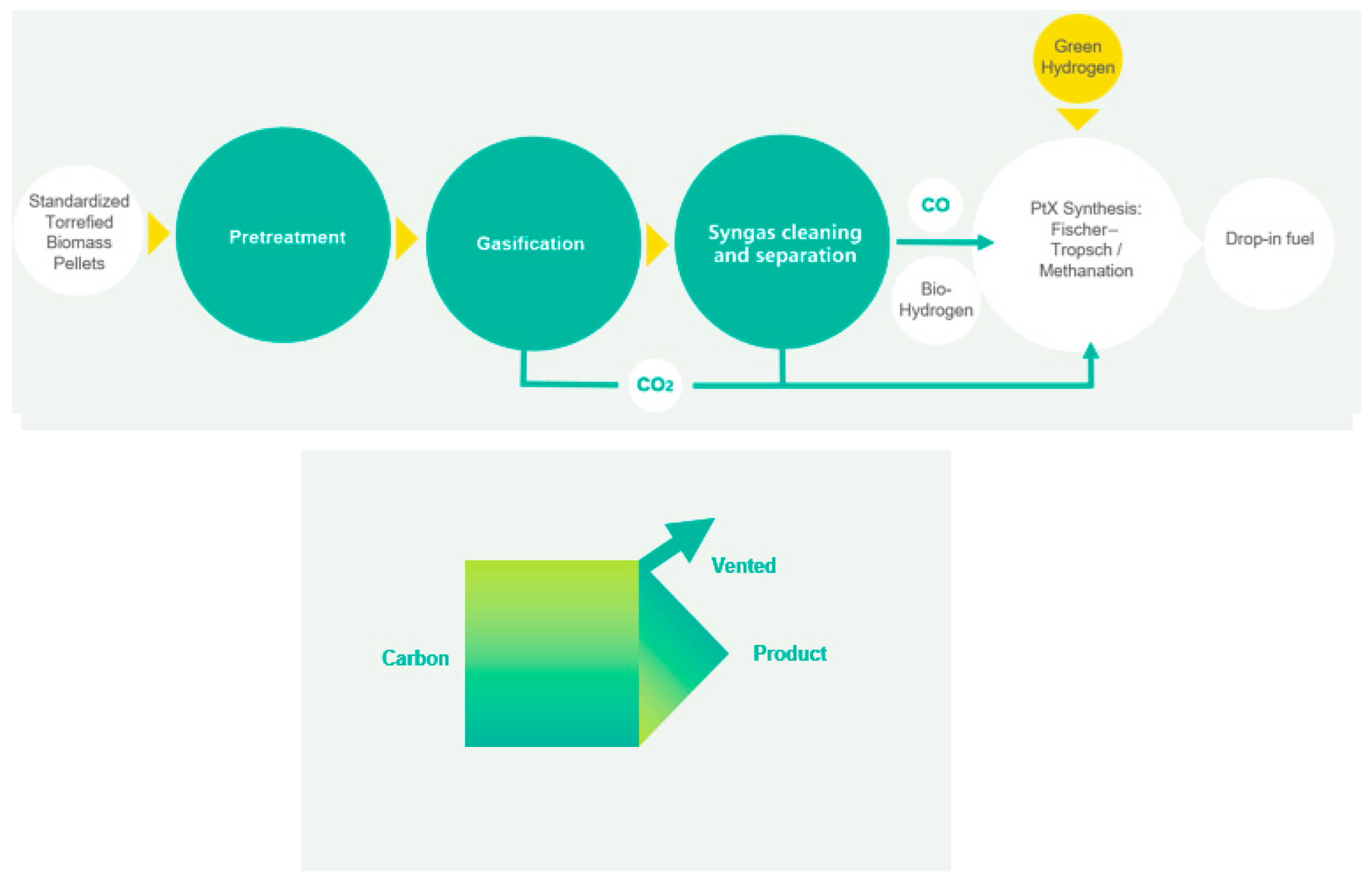

4. Incorporating Biomass in PtX

- Harvesting and Preparation:

- This phase serves as the foundation of the entire chain. Biomass is harvested in line with sustainability requirements that are met following a standard.

- To ensure efficiency and control costs, research studies recommend a 100 km harvesting radius, serving dual purposes of sustainability and economic feasibility [40].

- The biomass is subsequently chipped.

- Torrefaction and Pelletization:

- Biomass undergoes torrefaction.

- Pelletization follows, transforming the torrefied biomass into uniformly shaped entities.

- Transportation:

- The torrefied pellets redefine transportation efficiency. Their physical and chemical properties allow integration with existing global logistic infrastructures, negating the need for specific, customized transportation systems. The ability to use standard grain handling equipment is an added bonus.

- Gasification:

- The torrefied pellets are converted into syngas and any CO2 byproduct is also captured for use.

- Synthesis of Renewable Fuels:

- Using processes like Fischer–Tropsch, methanol synthesis, or methanation, the syngas is transformed into renewable fuels and chemicals.

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IPCC. Climate Change 2023: Synthesis Report. Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Lee, H., Romero, J., Eds.; IPCC: Geneva, Switzerland, 2023; p. 184. [Google Scholar]

- Cabrera, E.; de Sousa, J.M.M. Use of sustainable fuels in aviation—A review. Energies 2022, 15, 2440. [Google Scholar] [CrossRef]

- Nøland, J.K. Hydrogen Electric Airplanes: A disruptive technological path to clean up the aviation sector. IEEE Electrif. Mag. 2021, 9, 92–102. [Google Scholar] [CrossRef]

- Timmons, D.; Terwel, R. Economics of aviation fuel decarbonization: A preliminary assessment. J. Clean. Prod. 2022, 369, 133097. [Google Scholar] [CrossRef]

- Kalghatgi, G.; Levinsky, H.; Colket, M. Future transportation fuels. Prog. Energy Combust. Sci. 2018, 69, 103–105. [Google Scholar] [CrossRef]

- Psaraftis, H.N. Decarbonization of maritime transport: To be or not to be? Marit. Econ. Logist. 2019, 21, 353–371. [Google Scholar] [CrossRef]

- Wang, Y.; Wright, L.A. A Comparative Review of Alternative Fuels for the Maritime Sector: Economic, Technology, and Policy Challenges for Clean Energy Implementation. World 2021, 2, 456–481. [Google Scholar] [CrossRef]

- Bilgili, L.; Ölçer, A.I. IMO 2023 strategy-Where are we and what’s next? Mar. Policy 2024, 160, 105953. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy use in open-field agriculture in the EU: A critical review recommending energy efficiency measures and renewable energy sources adoption. Renew. Sustain. Energy Rev. 2022, 158, 112098. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in Greenhouses in the EU: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 5150. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Tyris, D.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in the EU Livestock Sector: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 2142. [Google Scholar] [CrossRef]

- Reganold, J.P.; Wachter, J.M. Organic agriculture in the twenty-first century. Nat. Plants 2016, 2, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Kassam, A.; Friedrich, T.; Derpsch, R. Global spread of conservation agriculture. Int. J. Environ. Stud. 2019, 76, 29–51. [Google Scholar] [CrossRef]

- O’donoghue, T.; Minasny, B.; McBratney, A. Regenerative agriculture and its potential to improve farmscape function. Sustainability 2022, 14, 5815. [Google Scholar] [CrossRef]

- Kyriakarakos, G.; Petropoulos, T.; Marinoudi, V.; Berruto, R.; Bochtis, D. Carbon Farming: Bridging Technology Development with Policy Goals. Sustainability 2024, 16, 1903. [Google Scholar] [CrossRef]

- Katta, A.K.; Davis, M.; Kumar, A. Assessment of greenhouse gas mitigation options for the iron, gold, and potash mining sectors. J. Clean. Prod. 2020, 245, 118718. [Google Scholar] [CrossRef]

- Dalvi, A.D. Decarbonization of Mining and Metals Industry. A Critical Overview. In Conference of Metallurgists; Springer International Publishing: Cham, Switzerland, 2022; pp. 917–937. [Google Scholar]

- Wollensack, L.; Budzinski, K.; Backmann, J. Defossilization of pharmaceutical manufacturing. Curr. Opin. Green Sustain. Chem. 2022, 33, 100586. [Google Scholar] [CrossRef]

- Lange, J.-P. Towards circular carbo-chemicals–the metamorphosis of petrochemicals. Energy Environ. Sci. 2021, 14, 4358–4376. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Bjørn, A. Pathways to sustainable plastics. Nat. Sustain. 2023, 6, 487–488. [Google Scholar] [CrossRef]

- Palamutcu, S. Sustainable Textile Technologies. In Textiles and Clothing Sustainability: Sustainable Technologies; Muthu, S.S., Ed.; Springer: Singapore, 2017; pp. 1–22. [Google Scholar]

- Schiffer, Z.J.; Manthiram, K. Electrification and decarbonization of the chemical industry. Joule 2017, 1, 10–14. [Google Scholar] [CrossRef]

- Hanel, A.; Seibold, A.; Fendt, S.; Spliethoff, H. Impact of Power-to-X on Energy Systems as a Key Technology to Defossilization. In Proceedings of the 34th International Conference On Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Taormina, Italy, 28 June–2 July 2021. [Google Scholar]

- Socolow, R.; Desmond, M.; Aines, R.; Blackstock, J.; Bolland, O.; Kaarsberg, T.; Lewis, N.; Mazzotti, M.; Pfeffer, A.; Sawyer, K. Direct Air Capture of CO2 with Chemicals: A Technology Assessment for the APS Panel on Public Affairs. 2011. Available online: https://www.aps.org/publications/reports/direct-air-capture-co2 (accessed on 18 September 2024).

- Keith, D.W.; Holmes, G.; Angelo, D.S.; Heidel, K. A process for capturing CO2 from the atmosphere. Joule 2018, 2, 1573–1594. [Google Scholar] [CrossRef]

- Gallucci, M. CO2-Removal Leader Climeworks Says New Tech Can Halve Costs, Energy Use. Available online: https://www.canarymedia.com/articles/carbon-capture/co2-removal-leader-climeworks-says-new-tech-can-halve-costs-energy-use (accessed on 7 October 2024).

- Sievert, K.; Schmidt, T.S.; Steffen, B. Considering technology characteristics to project future costs of direct air capture. Joule 2024, 8, 979–999. [Google Scholar] [CrossRef]

- de Temmerman, G.; de Rochette, F. The CDR Series: Direct Air Capture (DAC); Zenon Research: Paris, France, 2023. [Google Scholar]

- Sabatino, F.; Grimm, A.; Gallucci, F.; van Sint Annaland, M.; Kramer, G.J.; Gazzani, M. A comparative energy and costs assessment and optimization for direct air capture technologies. Joule 2021, 5, 2047–2076. [Google Scholar] [CrossRef]

- Lu, H.; Ma, X.; Huang, K.; Fu, L.; Azimi, M. Carbon dioxide transport via pipelines: A systematic review. J. Clean. Prod. 2020, 266, 121994. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Hayajneh, M.T. A hierarchy weighting preferences model to optimise green composite characteristics for better sustainable bio-products. Int. J. Sustain. Eng. 2021, 14, 1043–1048. [Google Scholar] [CrossRef]

- Wilberforce, T.; Baroutaji, A.; Soudan, B.; Al-Alami, A.H.; Olabi, A.G. Outlook of carbon capture technology and challenges. Sci. Total Environ. 2019, 657, 56–72. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Garcia, G.; Fernandez, M.C.; Armstrong, K.; Woolass, S.; Styring, P. Analytical Review of Life-Cycle Environmental Impacts of Carbon Capture and Utilization Technologies. ChemSusChem 2021, 14, 995–1015. [Google Scholar] [CrossRef]

- IRENA. Innovation Outlook: Renewable Methanol; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Pavanan, K.C.; Bosch, R.A.; Cornelissen, R.; Philp, J.C. Biomass sustainability and certification. Trends Biotechnol. 2013, 31, 385–387. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Wang, Y. Recent progress in the conversion of biomass wastes into functional materials for value-added applications. Sci. Technol. Adv. Mater. 2020, 21, 787–804. [Google Scholar] [CrossRef]

- Bentsen, N.S.; Felby, C.; Thorsen, B.J. Agricultural residue production and potentials for energy and materials services. Prog. Energy Combust. Sci. 2014, 40, 59–73. [Google Scholar] [CrossRef]

- Hakala, K.; Kontturi, M.; Pahkala, K. Field biomass as global energy source. Agric. Food Sci. 2009, 18, 347–365. [Google Scholar] [CrossRef]

- Hoogwijk, M.; Faaij, A.; van den Broek, R.; Berndes, G.; Gielen, D.; Turkenburg, W. Exploration of the ranges of the global potential of biomass for energy. Biomass Bioenergy 2003, 25, 119–133. [Google Scholar] [CrossRef]

- Kyriakarakos, G.; Lindeque, C.; Shaffudah, N. Development of a Sustainable Carbon Carrier for PtX Use: From Namibia to a Global Market; GIZ: Berlin, Germany, 2023. [Google Scholar]

- Nunes, L.J.R. A Case Study about Biomass Torrefaction on an Industrial Scale: Solutions to Problems Related to Self-Heating, Difficulties in Pelletizing, and Excessive Wear of Production Equipment. Appl. Sci. 2020, 10, 2546. [Google Scholar] [CrossRef]

- Thengane, S.K.; Kung, K.S.; Gomez-Barea, A.; Ghoniem, A.F. Advances in biomass torrefaction: Parameters, models, reactors, applications, deployment, and market. Prog. Energy Combust. Sci. 2022, 93, 101040. [Google Scholar] [CrossRef]

- ISO 17225-8:2023; Solid Biofuels—Fuel Specifications and Classes—Part 8: Graded Thermally Treated and Densified Biomass Fuels for Commercial and Industrial Use. International Organization for Standardization: Geneva, Switzerland, 2023.

- Wappler, M.; Unguder, D.; Lu, X.; Ohlmeyer, H.; Teschke, H.; Lueke, W. Building the green hydrogen market—Current state and outlook on green hydrogen demand and electrolyzer manufacturing. Int. J. Hydrogen Energy 2022, 47, 33551–33570. [Google Scholar] [CrossRef]

- Poluzzi, A.; Guandalini, G.; d’Amore, F.; Romano, M.C. The Potential of Power and Biomass-to-X Systems in the Decarbonization Challenge: A Critical Review. Curr. Sustain./Renew. Energy Rep. 2021, 8, 242–252. [Google Scholar] [CrossRef]

- Hanssen, S.V.; Daioglou, V.; Steinmann, Z.J.N.; Doelman, J.C.; Van Vuuren, D.P.; Huijbregts, M.A.J. The climate change mitigation potential of bioenergy with carbon capture and storage. Nat. Clim. Chang. 2020, 10, 1023–1029. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kyriakarakos, G.; Lindeque, C.; Shafudah, N.; Balafoutis, A.Τ. Carbon Carriers Driving the Net-Zero Future: The Role of Torrefied Biomass Pellets in Power-To-X. Sustainability 2024, 16, 9200. https://doi.org/10.3390/su16219200

Kyriakarakos G, Lindeque C, Shafudah N, Balafoutis AΤ. Carbon Carriers Driving the Net-Zero Future: The Role of Torrefied Biomass Pellets in Power-To-X. Sustainability. 2024; 16(21):9200. https://doi.org/10.3390/su16219200

Chicago/Turabian StyleKyriakarakos, George, Colin Lindeque, Natangue Shafudah, and Athanasios Τ. Balafoutis. 2024. "Carbon Carriers Driving the Net-Zero Future: The Role of Torrefied Biomass Pellets in Power-To-X" Sustainability 16, no. 21: 9200. https://doi.org/10.3390/su16219200

APA StyleKyriakarakos, G., Lindeque, C., Shafudah, N., & Balafoutis, A. Τ. (2024). Carbon Carriers Driving the Net-Zero Future: The Role of Torrefied Biomass Pellets in Power-To-X. Sustainability, 16(21), 9200. https://doi.org/10.3390/su16219200