Abstract

The purpose of this paper was to address the compatibility of management strategies with the competitive needs of textile waste recycling companies by applying Porter’s model. In conjunction with Porter’s model, it is appropriate to assess the attractiveness of the industry based on the balance of opportunities and threats, which determines whether the industry is attractive or less attractive. From this assessment, it is possible to decide whether to remain in the given industry and to identify strategies that indicate success. In terms of the European Green Agreement, it is necessary to ensure the faster and more efficient development of the circular economy, with a focus on resource-intensive sectors, including the textile industry. Given the adoption of the EU Strategy for Sustainable and Circular Textiles in June 2023, it is essential to address the issue of sustainable textile waste recycling. The importance of this strategy lies in strengthening the industry through reuse and repairs, as well as addressing the problem of textile waste. The prioritization of textile waste recycling has gained even greater importance with the arrival of the new automotive company, Volvo Cars, in eastern Slovakia. This development underscores the need for enhanced recycling efforts to manage the expected increase in industrial textile waste associated with the automotive sector’s expansion in the region. In Slovakia, four companies are involved in textile waste recycling: SK-TEX s.r.o., PR Krajné s.r.o., HOVEBA s.r.o., and LYKOTEX Slovakia s.r.o. This paper provides information on the possibility of expanding textile waste recycling capacities in eastern Slovakia. The quadratic graph method was used to identify an optimal location for textile waste recycling. The results of this analysis will help determine which enterprise in eastern Slovakia can enhance its competitiveness by leveraging this strategic location.

1. Introduction

Textile waste has become a pressing environmental issue in the Slovak Republic. This significant volume underscores the urgent need for effective waste management strategies. Despite the growing awareness of the problem, only 22% of textile waste is sorted for reuse or recycling; the remaining 78% is unfortunately sent to landfills or incinerated [1].

According to data from the European Commission, approximately 12.6 million tons of textile waste are produced annually across Europe, with 5.2 million tons consisting of clothing and footwear. This averages out to around 12 kg per person. In Slovakia, around 8500 tons of textile waste are sorted each year, contributing to a total of approximately 16,000 tons of sorted textile waste annually. This translates to each Slovak sorting about 1.6 kg of textiles yearly. However, the potential for sorting is significantly higher, as indicated by data from the Ministry of the Environment and the Statistical Office of the Slovak Republic for 2021 and 2022, which suggests that this could reach 12 kg per person [1].

The issue of textile waste in Slovakia is compounded by the fact that a considerable amount of this waste—estimated to be between 16,000 and 60,000 tons—is found in mixed municipal waste, further complicating waste management efforts [1].

In 2018, Slovakia collected 18,700 tons of textile waste, as reported in the “Waste Management Program” for the years 2021 to 2025. On average, the country gathers 3700 tons of selectively collected textile waste each year. However, this is insufficient compared to the total generated waste. The anticipated distribution of textile waste indicates that 65% originates from households, while 35% comes from industrial sources. This highlights the critical challenge that textile waste from households poses, as it frequently ends up in mixed municipal waste and landfills [1].

Addressing the urgent need for improved textile waste management is essential not only for environmental sustainability but also for enhancing resource recovery and reducing landfill dependence. This study aimed to contribute valuable insights into textile waste generation and management strategies in the Slovak Republic, emphasizing the practical significance of effective interventions in this area. Currently, an amendment to the Waste Act is being proposed in Slovakia, which includes extensive modifications. One key amendment aims to extend selective collection to include the textile category. This is brought into line with the amendment to Act No. 79/2015 Coll. on waste, which establishes the obligation for municipalities to facilitate the selective collection of textiles from 1 January 2025. The upcoming amendment clarifies that the processes of sorting and collecting textile waste will fall under the scope of extended producer responsibility (EPR). As a result, producers who market textiles will take control of the sorting and collection system. The selective method of collecting components of municipal waste, such as paper, plastics, and glass, has been operating in the Slovak Republic since 2016.

The results of the Report by the European Environmental Agency (EEA) on “Textiles in the European Circular Economy” present evidence of how the consumption of textile products negatively affects the environment and climate. In terms of the European Green Deal, which emphasizes the protection and quality of the environment, it is necessary to focus on the circular economy in the production and consumption of textiles, which is al-so related to the reduction of greenhouse gas emissions [2]. The primary task of the EU Action Plan for the Circular Economy involves measures that lead to [2]:

- Minimizing pressure on the environment and natural resources;

- Changing consumer behavior;

- Promoting recycling and the use of secondary raw materials;

- Minimizing the amount of waste generated;

- Transitioning to sustainable models of production and consumption.

2. Literature Review

Textile waste management has become a critical concern, especially in the European Union, where current practices are deemed inadequate. “In the European Union (EU), the current management of textile waste is considered suboptimal in respect of the waste management hierarchy, as landfilling and incineration are the predominant treatment methods”. Recycling technologies play a vital role in addressing textile waste. Mechanical recycling is one of the preferred methods, providing a viable option for reducing waste while maintaining resource integrity. “Overall, mechanical recycling is the second-most preferred pathway for most environmental impact categories [3]”.

The complexity and heterogeneity of textile waste complicate effective management strategies, as “the heterogeneity and complexity of textile waste due to the diverse blends, dyes, finishes and accessories on textiles render the sorting and separation of waste difficult [4]”. The economic benefits of effective textile waste management and recycling are significant. It is estimated that “an estimated USD 500 billion is lost annually due to underutilization of clothing and lack of recycling [4]”.

The environmental ramifications of textile waste are profound. The fashion industry is responsible for a significant portion of global pollution, with “the fashion industry alone was reported to produce 10% of the total greenhouse gas emissions and 20% of global wastewater”. Additionally, “the environmental impact of textile waste is compounded by the use of toxic dyes and chemicals in textile production”. To mitigate these impacts, sustainable textile management practices must be adopted, focusing on reducing waste and promoting a circular economy [5,6].

Despite advancements in recycling technologies, challenges remain, especially in implementing efficient sorting technologies. As noted, “while the amount of separately collected textile waste going to landfills decreased from 21% in 2010 to 11% in 2020, the amount of textile waste being redirected towards energy recovery increased from 9% to 16% during the same period”. Investing in textile recycling infrastructures can lower costs associated with landfill disposal and waste management [5].

Environmental pollution from textile production and disposal has become a major concern, prompting research into sustainable recycling alternatives. Increased awareness has spurred efforts to manage textile waste sustainably, as traditional methods like landfilling are costly and environmentally risky [7]. Fast fashion exacerbates this issue, with an estimated 75% of clothing materials ending up in landfills or incinerated. Furthermore, the lack of effective collection schemes can exacerbate the issue, leading to substantial amounts of textile waste ending up in landfill [8].

Textile reuse and recycling offer significant environmental benefits over incineration and landfilling [9]. Reuse is particularly advantageous as it avoids new production, though effectiveness varies with factors like transportation. More research on collection and sorting processes is needed, and exploring renewable energy for end-of-life treatments could improve recycling systems.

Recycling is a promising strategy despite technological and awareness barriers, offering potential for affordable material recovery [10]. Reuse also helps mitigate environmental impacts and can address social inequalities by providing lower-cost consumer alternatives. There is a need for awareness and education on circular economy principles throughout the textile value chain.

The environmental impact of textile waste and recycling challenges stresses the urgency of adopting a circular economy model due to fast fashion’s waste generation [11]. Life cycle assessments (LCAs) are crucial for sustainability evaluation and effective recycling strategies can support global sustainability targets.

Furthermore, the lack of effective collection schemes can exacerbate the issue, leading to substantial amounts of textile waste ending up in landfills [8]. The development of new business models, such as clothing rental and circular fashion, can enhance the economic viability of textile recycling initiatives [12].

The goal of the leadership strategy is to proactively acquire resources ahead of time, through overprovision or early investment. If demand is not met, costs will ultimately increase and resources may remain unused. This proactive approach ensures that capacity is readily available, thus avoiding the risks of resource exhaustion. The positives of the leadership strategy [2]:

- Proactive approach: This aims to increase capacity in advance of demand, ensuring resource availability to meet customer requirements, thereby minimizing the risk of stockouts or delays;

- Competitive advantage: It enhances the ability to respond flexibly to increased demand, providing a competitive edge and ensuring high levels of customer satisfaction and retention;

- Continuous operation: With certain capacity in place, businesses can maintain continuous operations during peak demand periods without bottlenecks or overburdening resources.

The negatives of the leadership strategy [2]:

- 4.

- Existence of excess capacity: If demand does not meet expectations, there is a risk of investing in excess capacity, leading to underutilization of resources and increased costs;

- 5.

- Cost consequence: Expanding capacity in advance may incur additional costs for infrastructure, equipment, and personnel, while revenues are generated only from in-creased demand;

- 6.

- Uncertainty: Accurate demand prediction can be challenging, with incorrect estimates of future demand trends resulting in inadequate and suboptimal capacity decisions.

The management strategy focuses on capacity planning, where the organization in-creases its production and service capacity in anticipation of future demand growth. This leads to investments in additional resources, such as equipment, machines, and personnel, when current capacity is exhausted or demand increases [13]. The role of this strategy is to secure the organization against expected demand growth, ensuring customer needs are met without delays or capacity constraints. If the organization is proactively prepared, it will be ready for future demand growth [14].

The use of a leadership strategy relies on a high degree of confidence in future demand trends. It is in the organization’s interest to gain a competitive advantage by being prepared to capture market share. This strategy is applicable in industries with long de-livery times to expand capacities, such as manufacturing, where building new production facilities requires significant time [14]. Addressing the leadership strategy requires significant initial investment to expand capacity. However, there is a risk that the expected demand growth will not meet expectations, leading to excess capacity, underutilization, and increased costs [14].

Linking management strategy and Porter’s Five Forces model can be applied to textile waste recycling. A textile recycling company decides to build a new production facility to increase its annual production capacity by 20% in anticipation of strong growth in textile recycling over the next five years. This proactive approach allows the company to prepare for the expected increase in demand [14].

It can be concluded that the leadership strategy in capacity planning involves investing in additional capacity ahead of expected growth in demand. While this can set an organization up for success, it requires detailed analysis, forecasting, and risk assessment to justify initial investments and minimize the potential downsides of excess capacity. When businesses expect an increase in demand, management strategy suggests adding additional resources to meet the anticipated level of demand. This approach becomes more effective when there is high certainty of future demand. By taking this proactive step, businesses ensure the availability of the necessary capacity and resources to meet customer needs [15].

The novelty and relevance of the topic lie in its focus on waste processing and recycling, which is becoming increasingly critical due to rapid industrial developments, including the fast-growing automotive industry in Slovakia. As automotive production expands, the demand for sustainable materials also rises, creating opportunities for recycled textiles to serve as components such as sound insulation, seat padding, or linings. This underscores the need for efficient waste management systems that can meet both environmental and industrial requirements.

The combination of textile recycling strategies with Porter’s Five Forces model is another innovative aspect of this research. By analyzing supplier power, competition, and market entry barriers, the model helps companies in Slovakia optimize their processes, ensuring a stable supply of waste materials and identifying competitive advantages. For instance, securing long-term contracts with suppliers ensures reliable raw material availability and reduces disruptions, which aligns with circular economy goals.

Furthermore, textile recycling supports Slovakia’s compliance with EU environmental policies aimed at reducing landfill waste and promoting sustainable production. With increasing legislative pressure, companies must not only adjust their production models but also actively explore market expansion opportunities and partnerships to stay competitive.

This research provides practical strategies for businesses to adapt to evolving policy demands, optimize operations, and support industrial sectors like automotive manufacturing through sustainable practices. The focus on linking recycling efforts to economic and competitive factors makes the topic both timely and relevant in today’s regulatory and industrial landscape.

3. Problem Formulation

Due to rapidly changing conditions, challenges related to developing a vision and understanding the relationship between management strategies are becoming more defined. Every company’s goal is to focus on competitiveness and market share to earn customer trust.

A key issue is selecting an appropriate company for textile waste recycling, considering geographical, product, and competitive factors. In eastern Slovakia, two companies operate in the textile waste recycling sector. Strategically selecting the right company can provide a significant competitive advantage, though external factors may influence this choice.

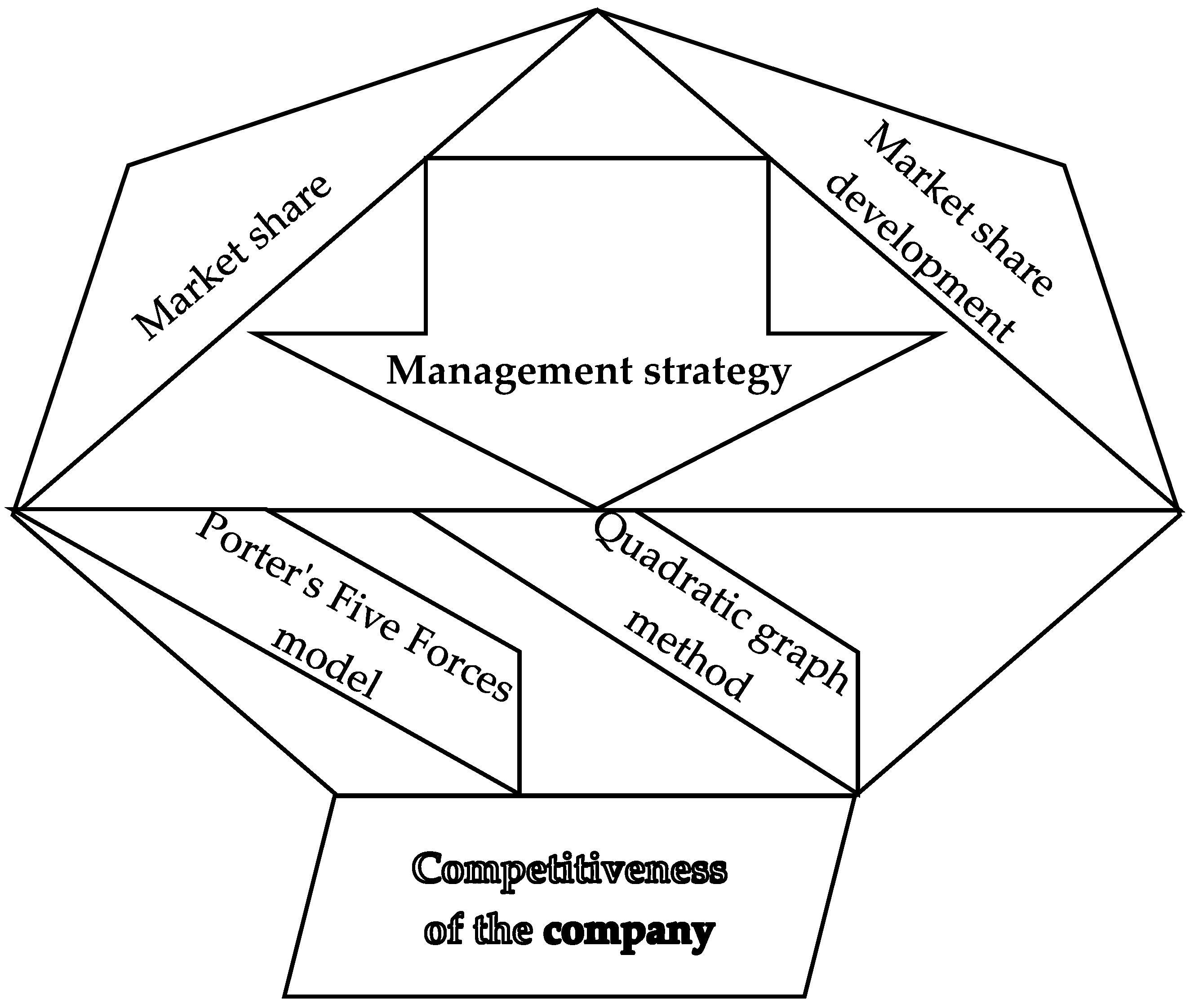

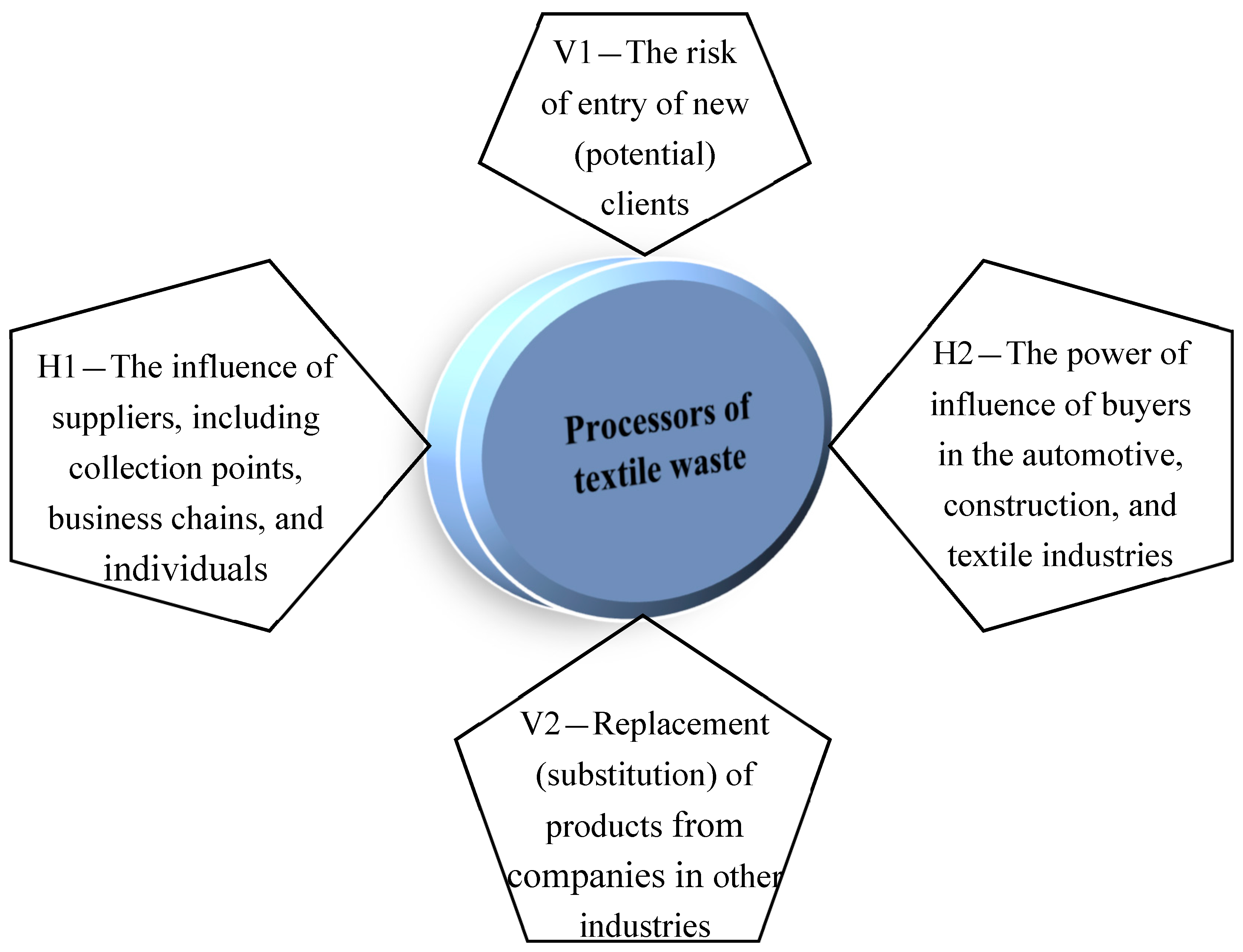

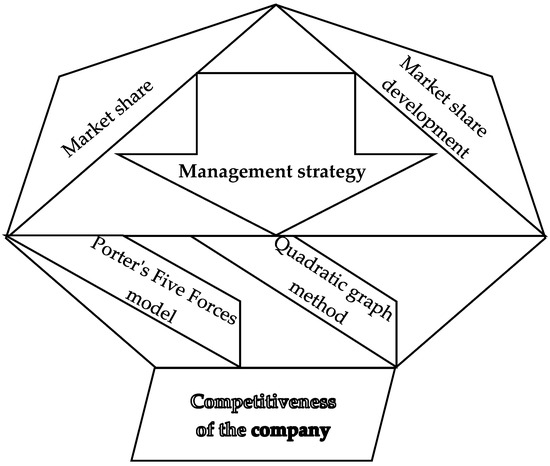

Several criteria, such as the availability of textile waste suppliers, the potential use of recycled materials, and managerial experience, impact the decision-making process. Porter’s Five Forces model and the quadratic graph method are employed to guide this selection. The application of these methods (Figure 1) helps determine the most efficient allocation of operations for textile waste recycling. Ultimately, the results point to the optimal location for recycling activities.

Figure 1.

Implementation Porter’s five forces model and quadratic graph method.

4. Materials and Methods

4.1. Porter’s Five Forces Model

Porter’s Five Forces model remains a pivotal framework for analyzing industry competitiveness and developing corporate strategies. The model allows businesses to dissect the major forces that influence and determine industry profitability, offering a structured way to assess market dynamics [16]. Porter originally categorized these forces into horizontal threats, including the threat of new entrants, substitutes, and competitive rivalry, alongside vertical forces such as the bargaining power of buyers and suppliers [13]. This framework is particularly effective in helping companies shape strategies that enhance their competitive advantage by navigating these forces [16].

The application of Porter’s Five Forces model is evident across different industries and geographical contexts. For example, in the Kenyan telecommunications sector, the model has been used to analyze how industry rivalry and the bargaining power of suppliers and buyers affect firm performance [6]. While the threat of new entrants was found to be minimal due to high entry barriers, rivalry among existing competitors and the presence of substitute products were significant factors influencing profitability [17,18]. Moreover, the model’s utility in understanding the distribution of profits within an industry underscores its relevance in strategic management, even in modern, innovation-driven environments [19].

Despite its widespread use, Porter’s model has faced criticism, particularly regarding its applicability in rapidly changing and innovative markets. Some researchers argue that technological advancements and new strategic thinking have shifted the focus from competing within an existing environment to exploring opportunities in new markets [8]. This is particularly evident in the Chinese entrepreneurial context, where factors such as Guanxi (relationship-based networks) and technology integration necessitate a modified approach to using Porter’s framework [9]. While Porter’s Five Forces model remains relevant, its application requires adaptation to account for unique regional and industry-specific dynamics [20].

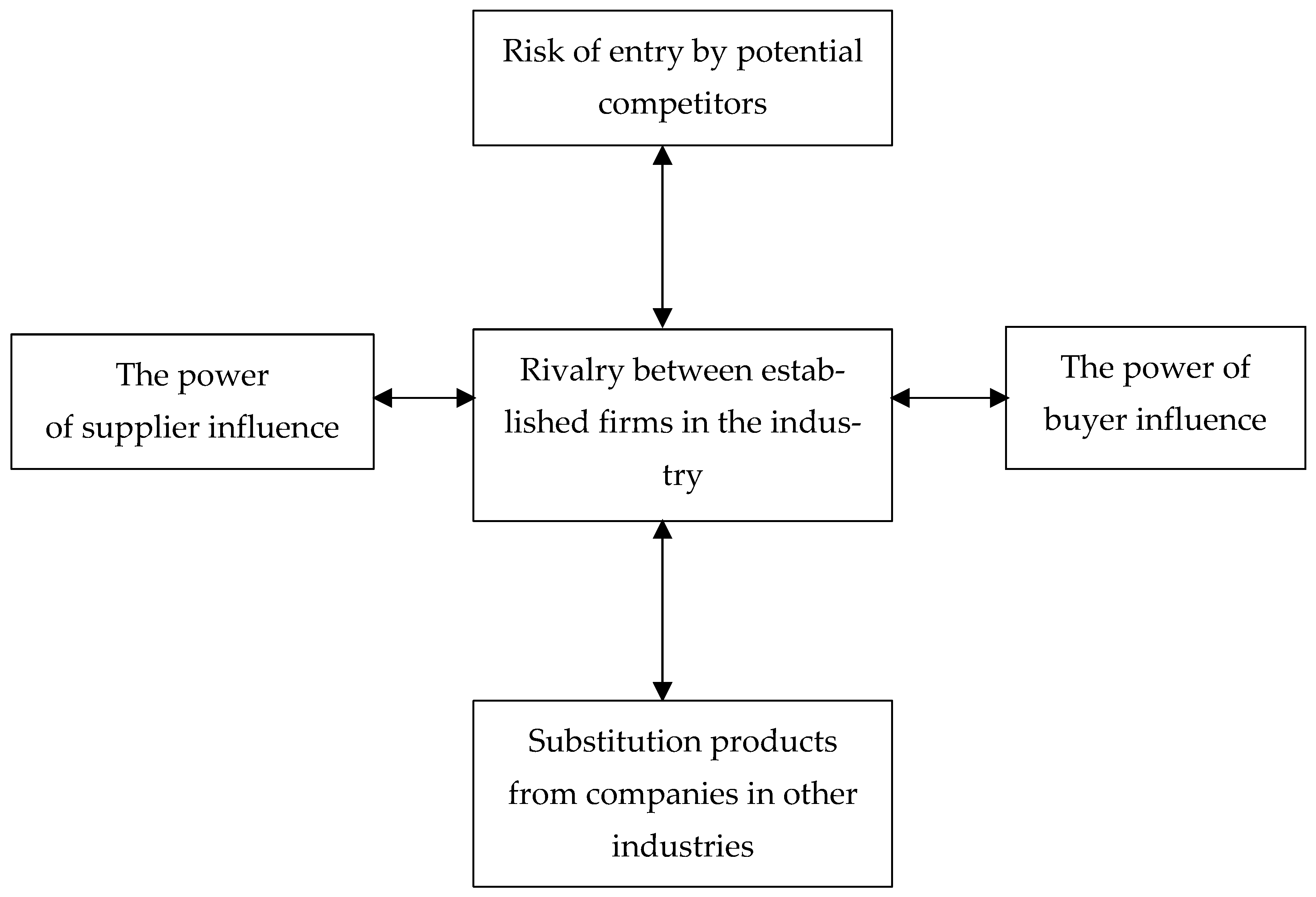

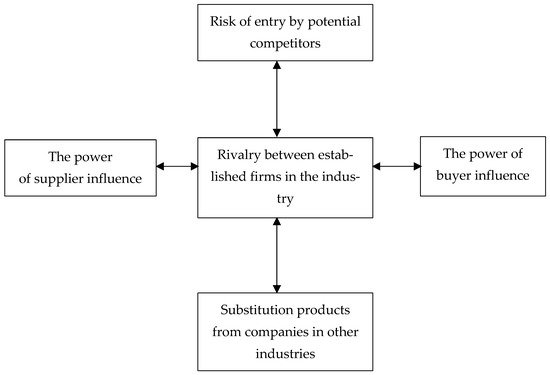

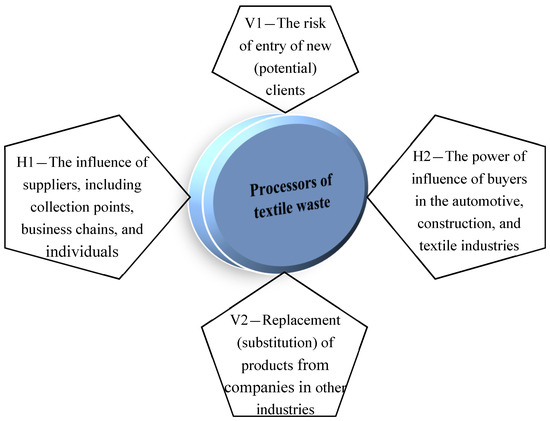

The creation of Porter’s Five Forces model in Figure 2 involves examining the interactions between five key factors, with a focus on understanding how all five forces operate simultaneously [21]. The core of this model lies in strategies that strengthen a company’s position relative to suppliers and buyers. Porter’s Five Forces model was developed to enhance methods aimed at connecting a company with its external environment [22]. The model focuses on the following [22]:

Figure 2.

Porter’s Five Forces model.

- Analyzing the impact of five key indicators (factors) within the relevant industry and identifying the opportunities and threats associated with these influences, which simultaneously affect enterprises;

- Assessing the attractiveness of the industry by weighing the balance of opportunities and threats;

- Monitoring and evaluating opportunities that the company can leverage when preparing its strategy, as well as implementing measures to prevent potential threats from arising.

4.2. Quadratic Graph Method

To evaluate different options based on individual criteria, the goal is to maximize the evaluation of relevant criteria while minimizing the total utility value using the quadratic graph method. This method requires the determination of specific criteria for assessing the appropriate value of the company [23]. Each criterion is assigned a weight on a scale from 0 to 10.

The evaluation for each company is then carried out based on these criteria using the following formula:

where:

VCC—the value of the relevant criteria for specific company accession numbers,

OV—the optimal value,

Wi—the assigned weight from the cardinal scale.

In the final stage, the values of individual options are compared. The most suitable option (or company) is the one that best balances all criteria with minimal deviations from the optimal values.

4.3. Case Study

In the socio-economic structure of both human and industrial society, textiles play an essential role. They are used not only in familiar applications but also in less visible and technical areas, such as the automotive industry. Western Europe, a global leader in car manufacturing, consumes around 1,500,000 tons of textiles annually for automotive purposes. The United States and Japan follow as the second and third largest markets focused on the automotive industry. According to estimates from the world’s largest manufacturer of non-woven textiles, 42% of its revenue comes from the automotive sector [24].

Today, every vehicle contains approximately 25 to 35 kg of components made from synthetic composite, combined, or monostructural textiles. The production of these parts generates around 10–12% in technological waste, equivalent to about 3 kg per vehicle. Calculations show that for every 1,000,000 new cars produced, around 3000 tons of clean technological waste are generated. Similarly, processing 100,000 end-of-life vehicles results in approximately 3000 tons of used textile waste [24].

Automotive textile waste represents a significant share of the total textile waste stream. With millions of vehicles manufactured and scrapped each year, the automotive sector contributes substantially to textile waste volumes. Proper recycling of this waste is essential to reduce environmental impact and ensure valuable materials are recovered. This highlights the importance of recycling car textiles, especially as synthetic materials dominate automotive applications, posing challenges for waste management and sustainability efforts. Addressing this issue is key to reducing the environmental burden of the automotive industry and supporting circular economy goals.

In the Slovak Republic, there is currently no uniform processing system or recovery of textile waste, as only four companies in Slovakia are dedicated to recycling textile waste from households and industry. The total processing capacity is 12,850 tons of textiles, with 8850 tons coming from industry and 4000 tons from households. Most of this is imported textiles from abroad. The range of recycled products is used in construction and industry. Currently, according to company representatives, the capacities are sufficient [24], but with the planned change in legislation, it is expected that these capacities will need to be significantly increased. As for the household textile processing segment, company representatives specify the problems mainly in the following areas [24,25]:

- Fragmentation of resources (collection);

- Quality and variety of materials (sorting);

- Recycling capacities (increase);

- Sale of products (legislative support).

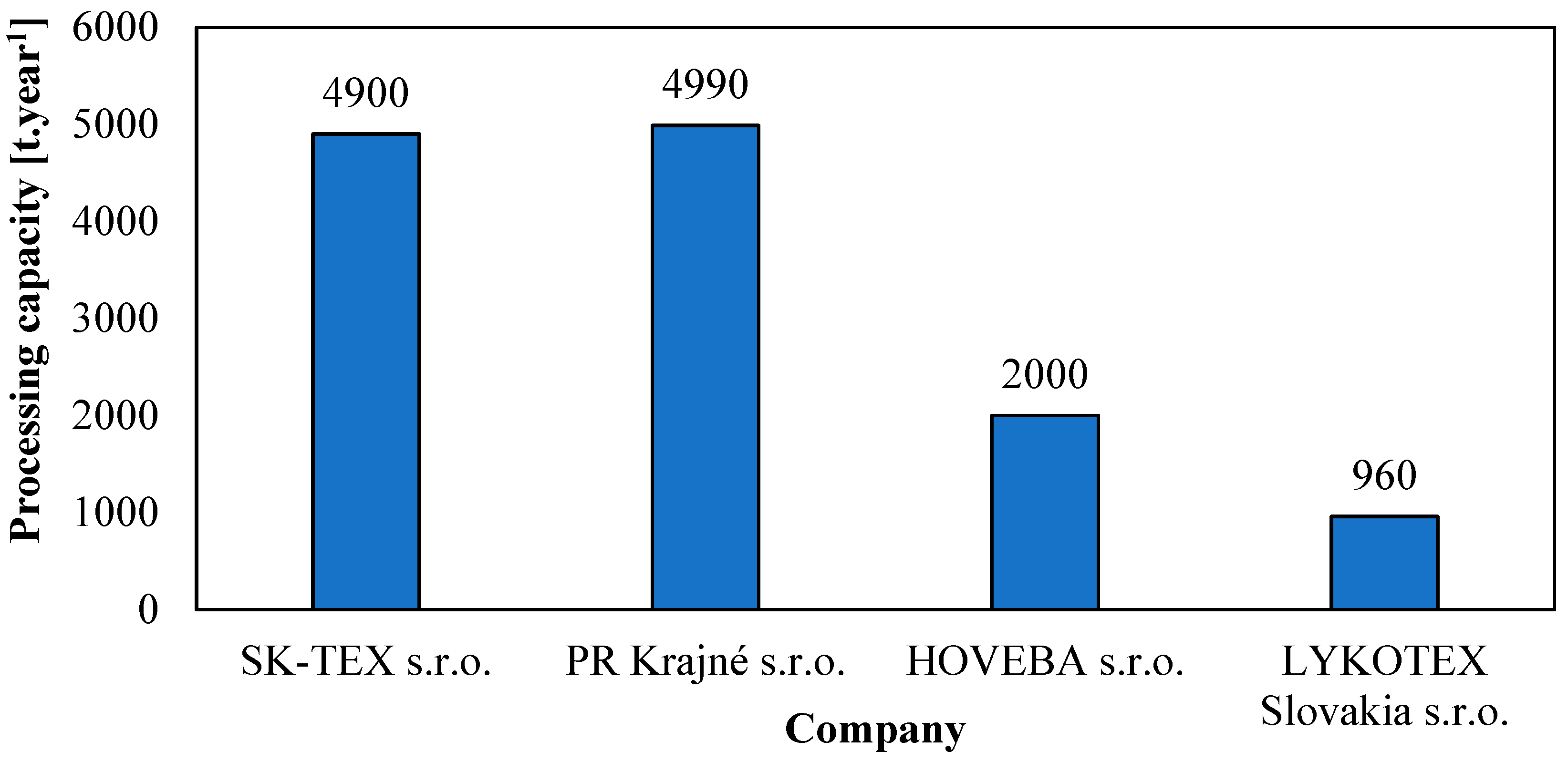

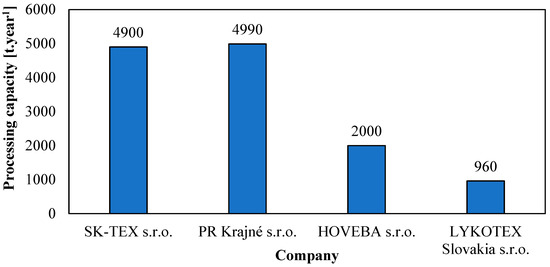

Textile waste recycling in Slovakia is managed by the following companies: SK-TEX s.r.o., PR Krajné s.r.o., HOVEBA s.r.o., and LYKOTEX Slovakia s.r.o. SK-TEX s.r.o. is the largest processor of textile waste in Slovakia. The company’s primary focus is on processing industrial textiles, but it also handles consumer textiles from households. A significant portion of the textiles processed by SK-TEX, up to 90%, is imported from abroad.

PR Krajné s.r.o. specializes in the processing of both industrial and consumer textiles. The company’s main suppliers of industrial textiles are car manufacturers, primarily based in Slovakia.

LYKOTEX Slovakia s.r.o. processes both industrial and consumer textiles. The consumer textiles are mainly sourced from second-hand stores, with a strong emphasis on quality. Notably, non-textile parts are removed from garments before processing.

HOVEBA s.r.o. recycles the smallest amount of textile waste, approximately 960 tons per year, with a focus on industrial textiles.

Figure 3 presents the recycling capacities of the relevant processors. From Figure 3 it is evident that Slovakia can process 12,850 tons of textile waste per year.

Figure 3.

Textile recycling capacities of key companies in Slovakia.

The average car consists of 2 to 2.5% textile parts of its total weight, which represents 23 to 26 kg of textile. Currently, the emphasis is on increasing user comfort, and for this reason, an increase in the amount of textiles in cars is expected to reach up to 35 kg by 2025. Almost 10% of technological waste is produced during the production of a new car, including clippings from moldings and various other offcuts [26,27].

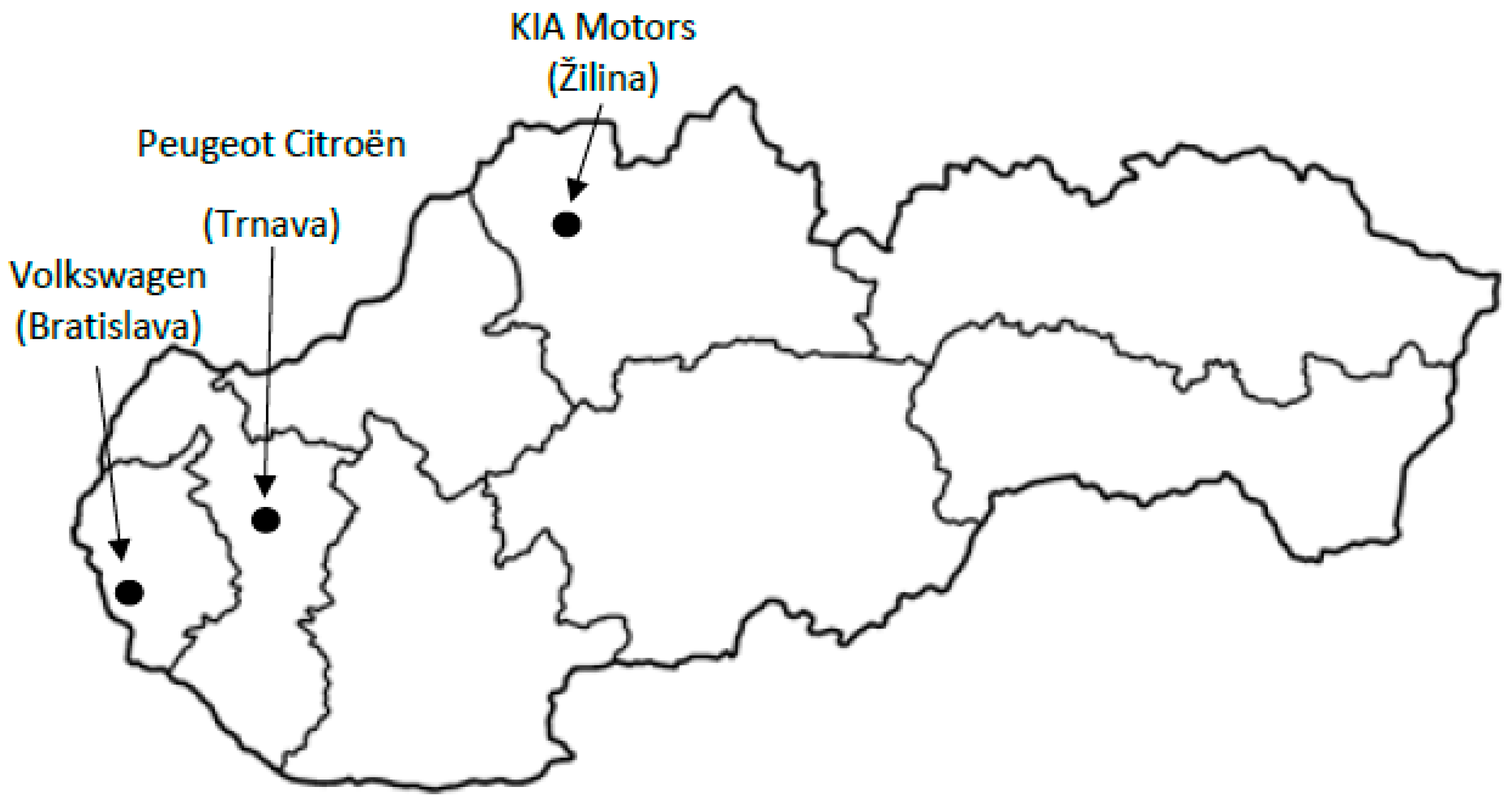

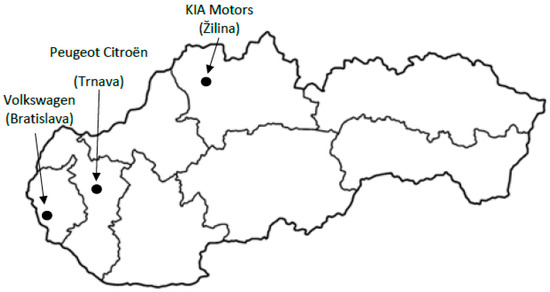

The largest car companies in Slovakia are Volkswagen, headquartered in Bratislava; PSA Peugeot Citroën, based in Trnava; and KIA Motors, based in Žilina. The graphical location of these companies on the map of Slovakia is presented in Figure 4. Currently, these car companies produce 200 to 250 tons of technological waste per month. It should be noted that this technological waste is a high-quality secondary raw material. This category of waste also includes separated textile parts from end-of-life vehicles [28].

Figure 4.

Allocation of automotive companies in Slovakia.

The special properties of technical synthetic textiles from the automotive industry are [26]:

- Long-term service life;

- High resistance to mechanical stress;

- Resistance to water;

- Resistance to mineral oils;

- Very good thermal and acoustic insulation properties;

- Non-toxicity;

- Friendliness to human organisms and the environment.

However, the disadvantage of these textiles is that they are mostly difficult to recycle due to being combined materials. This limitation restricts their straightforward recycling back into the textile industry. Technical textiles used in cars meet the stringent requirements of the automotive industry, often outlasting the vehicle itself, typically lasting up to 10 years. Until recently, these textiles were often incinerated or sent to landfills as waste.

In Slovakia, company PR Krajné has pioneered a solution to this problem by developing a method to recycle these mixed wastes into new products under the designation STERED. STERED stands for the processing of textile recyclates into boards. This innovative product, technology, and production method are protected by patents in the European Union, China, Korea, and India. This technology has demonstrated the practical use of technical textile waste from the automotive industry to create valuable products, conserving non-renewable raw materials and improving environmental quality. It helps mitigate the negative impact associated with motorization and car production.

Products manufactured using STERED technology require 3 to 5 times less energy for processing compared to the production of stone-based or glass insulating materials, making the process significantly more energy-efficient. This aligns perfectly with the European Commission’s Energy Efficiency Action Plan. The reduced energy consumption not only lowers energy costs but also has a positive impact on the environment and financial expenses [29].

STERED technology products are used in various applications, including [29]:

- Anti-noise walls;

- Rail noise absorbers;

- Hall soundproofing;

- Vegetated roofs;

- Retention walkways on-toxicity;

- Retention parking areas.

The final products of STERED technology, used in construction, help reduce heat loss from buildings, thus contributing to the goals of the Energy Efficiency Action Plan [18]. STERED construction materials are characterized by:

- Soundproofing properties;

- Thermal insulation properties.

These features introduce innovative solutions in the construction industry, enhancing the quality of various structural elements. The use of STERED products improves construction quality and reduces labor effort. By implementing STERED technology, labor productivity can be increased, offering significant benefits to the end user. Examples of applications of STERED technology [29] include:

- Thermal insulation of floors and footfall attenuation;

- Thermal and acoustic insulation of walls and partitions;

- Structural systems for partitions;

- Thermal insulation of attics and spaces between rafters;

- Sound-absorbing interior accessories;

- Sound-absorbing fences.

5. Results

To solve the competitiveness of textile waste recycling companies, applying Porter’s Five Forces model is appropriate. Implementing Porter’s model involves examining the influence of several indicators (factors) and focusing on evaluating the impact of all five indicators (factors). In rapidly changing conditions, these indicators (factors) also undergo changes [29,30]. The Five Forces model helps companies understand the dynamics of their industry and identify sources of competitive advantage and weaknesses. For instance, analyzing competition among existing firms reveals the intensity of market share competition.

Analyzing the threat of new competitors helps firms understand barriers to entry in the industry. These barriers may include factors such as high startup costs, the need for specific resources, or regulatory restrictions affecting new firms’ ability to enter the market.

5.1. Application of Porter’s Model to a Textile Waste Recycling Company

5.1.1. Horizontal Axis

The horizontal axis of Porter’s Five Forces model (Figure 5) examines the interaction between suppliers and buyers in the textile waste processing industry.

Figure 5.

Horizontal and vertical lines of Porter’s Five Forces model.

H1—Increase in Suppliers’ Influence

Four companies in Slovakia are dedicated to recycling textile waste. Company SK-TEX s.r.o. is the largest, primarily focusing on recycling textile waste from the automotive industry. Company PR Krajné s.r.o. is the second-largest textile waste recycler in Slovakia. Both companies are located in western Slovakia, while companies HOVEBA s.r.o. and LYKOTEX Slovakia s.r.o. are smaller operations based in eastern Slovakia.

SK-TEX s.r.o. and PR Krajné s.r.o. have the most extensive network of textile waste suppliers, giving them a near-monopoly in the Slovak market. Their strong market positions enable them to set product prices. Additionally, these larger companies can exert pressure on smaller competitors, potentially threatening integration. As dominant players in the textile waste recycling industry, they hold significant market power.

SK-TEX s.r.o. supplies its products in large quantities to the construction, automotive, and textile industries and exports to countries such as Poland, France, and Germany. PR Krajné s.r.o. primarily recycles textiles from the automotive industry and has received several awards for its innovative STERED technology, including the ENERGY GLOBE Winner Slovakia 2020 certificate. This strong market position allows PR Krajné s.r.o. to influence product pricing as well.

PR Krajné s.r.o. supplies its products to both the automotive and construction industries. Thanks to STERED technology, it stands out as a unique textile waste processing company. The bargaining power of suppliers increases when there are no viable substitute products, a condition that STERED technology meets. This technology also offers energy savings compared to traditional insulating materials based on stone or glass.

H1—Decline in Suppliers’ Influence

Supplier power decreases when customer dissatisfaction rises or when a company cannot produce sufficient quantities. Insufficient or inadequate supply to meet demand further weakens supplier power. Another issue is poor communication, which can lead to a reduction in supplier influence.

H2—Increase in Buyers’ Influence

Few suppliers operate in Slovakia in the recycled textile waste industry. SK-TEX s.r.o. produces various products such as acoustic insulation, thermal insulation, technical insulation, blown insulation, and recycled fibers. Buyers have limited choices of suppliers in the textile waste processing industry, making it difficult to switch to other competing suppliers.

H2—Decline in Buyers’ Influence

A larger number of buyers indicates the absence of a buyer monopoly or oligopoly. Purchasing in small quantities reduces buyer power. Lower buyer power negatively im-pacts businesses and affects value creation within the industry.

5.1.2. Vertical Axis

The vertical axis (Figure 5) addresses the entry risk posed by potential competitors in the textile waste recycling industry and the impact of substitute products from other industries.

V1—Risk of entry of potential competitors

The threat of entry by potential competitors is low due to the high barriers to entry that prevent the emergence of new competitors in the industry. The high entry costs of a new competitor relate mainly to the cost of new employees as well as the investment requirement for technology. Legislative rules and regulations as well as administration constitute limits for the entry of new companies. SK-TEX s.r.o. is an established company with skilled, experienced managers and employees, and thus creates a certain standard that makes it difficult for competitors to enter this industry. The resulting products of company SK-TEX s.r.o. are fully ecological and easily recycled.

V2—Substitution products from companies in other industries

Currently, customers are increasingly interested in more ecological variants of products, which STERED technology meets, but there is still the option of choosing a less eco-logical variant, which is made from glass or stone. A customer chooses another company because of the services offered by another company.

The influence of suppliers on competitiveness is crucial for integrating circular economy principles into the textile waste recycling industry. By prioritizing recycling and reducing dependence on raw materials, suppliers play a vital role in driving sustainable practices. Innovative processes from companies like PR-Krajné s.r.o., HOVEBA s.r.o., SK-TEX s. r. o., and LYKOTEX Slovakia s.r.o. are instrumental in decarbonizing the textile sector. The following paragraphs explore how the factors of Porter’s Five Forces model (Figure 5) evolve with changing market dynamics.

Supplier Bargaining Power: As buyers increasingly pressure suppliers to prioritize the quality and cost of recycled materials, those with advanced recycling technologies gain significant bargaining power. This shift not only enhances the suppliers’ position but also fosters strategic partnerships that can bolster the competitiveness of textile waste recycling companies.

Buyer Bargaining Power: Buyers are becoming more selective, actively seeking suppliers who demonstrate strong sustainability practices. This growing preference for eco-friendly products intensifies competition among suppliers and significantly impacts the overall competitiveness of recycling companies. As buyers negotiate favorable terms, recycling firms must continually improve their offerings to meet these evolving demands.

Threat of New Entrants: The entry of new competitors who introduce innovative textile materials with advanced properties poses a substantial threat to established recycling companies. These newcomers, particularly those leveraging technological advancements or responding proactively to regulatory changes, can disrupt the market landscape and challenge the competitiveness of existing firms.

Threat of Substitutes: Recycling companies also face threats from textile waste with similar functional properties sourced from related industries. If these substitutes become more attractive due to lower costs or superior technological features, established firms must innovate and adapt their processes to retain market share.

Industry Rivalry: In the competitive landscape of textile waste recycling, some materials are gaining traction while others are losing relevance. This intense rivalry requires companies to stay agile and responsive to changing market dynamics, including shifts in consumer preferences and regulatory pressures.

In summary, the application of Porter’s Five Forces model (Figure 5) reveals how supplier and buyer dynamics, threats from new entrants and substitutes, and industry rivalry will influence the competitiveness of textile waste recycling companies over time. By understanding and adapting to these factors, businesses in the textile recycling sector can position themselves effectively amid technological advancements and evolving regulations.

Following Porter’s Five Forces model, the quadratic graph method was applied. The implementation of this method specified the following criteria: supplier behavior (position in supplying textile waste), innovations in the field of textile waste recycling, managerial experience, utilization of recycled textiles, and entry of competitors into the textile waste processing sector. The optimal value was set at 50 points. The respective variants represent companies focused on textile waste recycling. Weights from the cardinal scale <0, 10> were assigned based on quadratic graph calculations.

Table 1 results indicate that HOVEBA s.r.o., operating in eastern Slovakia, emerges as the most suitable variant (company). From a strategic perspective, expanding HOVEBA’s existing operation for textile waste recycling is competitive. The competitive advantage of HOVEBA s.r.o. lies in its proprietary know-how, extensive managerial experience, favorable relationships with suppliers and customers, provision of necessary equipment, and adequate infrastructure.

Table 1.

Quadratic graph method for specified criteria and companies.

The evaluation results in Table 1 reveal the following key findings:

- The second criterion emphasizes that innovations in textile waste recycling are essential for increasing the competitiveness of LYKOTEX Slovakia s.r.o. To further enhance its position, the company must adopt more effective and flexible marketing strategies, which are crucial for reducing costs and keeping pace with technological advancements.

- The third criterion highlights the need for LYKOTEX Slovakia s.r.o. to improve management training and raise awareness among its managers in order to strengthen its position in the market.

- The fourth criterion suggests that LYKOTEX s.r.o. should expand the market for recycled textiles to regions beyond EU member states.

The fifth criterion points out that competitors like SK-TEX s.r.o. and PR Krajné s.r.o. could pose a threat by focusing on product quality, durability, and efforts to reduce price competition within the industry. To delineate its competitive advantage, it is crucial to define the value chain precisely. Each value-creating activity within the value chain is interconnected. The linkages between supplier value chains and the enterprise value chain enhance the enterprise’s competitive advantage.

Porter’s Five Forces are connected, and these connections influence a company’s competitive position. For example, when buyer power increases, companies often feel pressure to innovate quickly to keep their market share and compete against substitutes. Strong suppliers can also affect this situation by raising costs, which forces businesses to improve their processes or create unique products to stay competitive.

Additionally, for vertical axes, if new competitors threaten to enter the market, established companies may work harder to build strong relationships with suppliers and buyers, using long-term contracts or loyalty programs to create barriers. However, conflicts can occur; for instance, if suppliers have too much power, it might limit a company’s ability to lower costs, making it harder to respond to new competitors. Understanding how these forces interact helps businesses create effective strategies that address multiple challenges and maintain their competitiveness.

6. Conclusions

New legislative changes concerning the sorting and processing of textile waste bring both challenges and opportunities for the whole of Slovakia. These changes will require all regions to adapt to the new standards and streamline recycling processes. An even distribution of recycling capacities across the country is therefore crucial to ensure that all areas have sufficient opportunities to recover textile waste. This will not only reduce the environmental burden, but also support regional development and employment. The research highlights key findings regarding the textile waste recycling industry and the strategic positioning of companies within it.

The study underscores that PR Krajné s.r.o. and SK-TEX s.r.o. are the most competitive players in the textile recycling sector. PR Krajné s.r.o. stands out due to its extensive experience and the global recognition of its STERED technology, which significantly enhances its competitive edge. SK-TEX s.r.o., also a major player, benefits from its substantial network and efficient recycling practices. The research reveals that optimizing the existing recycling capabilities of HOVEBA s.r.o. in eastern Slovakia is a more effective approach compared to establishing new facilities. HOVEBA s.r.o. has a proven recycling technology and expanding its current operations could provide a more balanced distribution of recycling capacity across Slovakia. This expansion aligns with the anticipated in-crease in textile waste, driven by new developments like the arrival of Volvo Cars in the region.

The evaluation using the quadratic graph method suggests that HOVEBA s.r.o. is the most suitable candidate for expanding recycling capacities. This is due to its established technology, advantageous location, and existing infrastructure, which collectively provide a strong foundation for increasing its recycling output. Currently, the largest recycling operations are concentrated in western Slovakia, which causes an imbalance in the availability of recycling capacities for other parts of the country This will achieve a better use of existing resources, a balanced load on the infrastructure and a more efficient processing of textile waste in accordance with the new legislation. To address these findings, companies must focus on enhancing their relationships with suppliers and buyers, rather than just competing on price or customer service. It is Porter’s model (Figure 5) that presents the findings that companies must focus on to improve their relationships with suppliers and buyers, rather than just competing on price or customer service. Strategic development should prioritize creating added value and leveraging existing strengths.

Overall, the research points to a need for a proactive approach to expanding recycling capacities. By anticipating industry changes and strategically developing existing facilities, companies like HOVEBA s.r.o. can better position themselves to meet the growing demands of the textile waste recycling market while contributing to sustainable waste management practices.

Future research should focus on new technologies and strategies to improve the competitiveness of textile waste recycling. Although this study discusses innovation, efficiency, and market trends, some challenges remain. One key area is assessing how scalable technologies like AI-based sorting and closed-loop water systems are for businesses of different sizes.

Future studies could also analyze how changing policies affect supplier relationships and the risks of new competitors. Researchers might explore business partnerships, such as collaborations with eco-conscious fashion brands, to promote circular models.

Considering strategic recommendations for businesses, companies should start to extend predictive tools to forecast market changes and regulations. Additionally, expanding into new markets such as eco-friendly insulation or technical textiles can increase resilience to market changes. These efforts would not only improve knowledge in the area of recycling but also help businesses adapt to fast evolving regulations and market demands.

To respond to new regulations in textile waste recycling, companies can do more than production process adjustments, where technological innovation should play a key role. For example, advanced sorting systems can improve fiber separation and reduce contamination. Energy-efficient equipment, like low-temperature washers or closed-loop water systems, can lower both costs and energy use.

Optimizing production processes can also help meet regulations and boost efficiency. Circular production models, which reuse recycled textiles, can further reduce the need for new materials. Additionally, lean manufacturing can cut waste, while life cycle assessments (LCA) help find inefficiencies and environmental impacts.

An alternative approach might be expanding into new markets which also supports adaptation. Companies can create products from recycled textiles, such as eco-friendly fabrics or insulation, opening new revenue streams. Long-term contracts with waste suppliers can ensure a stable raw material supply, supporting circular economy goals, and reducing supply risks. Partnerships with municipalities can further strengthen supply chains. By focusing on innovation, improving processes, and finding new markets, companies can meet regulations and stay competitive in a market that values sustainability and responsibility.

Author Contributions

Conceptualization, M.M. and T.Š.; methodology, M.M. and D.M.; software, M.M.; validation, D.M. and T.Š.; formal analysis, M.M. and D.M.; investigation, M.M. and T.Š.; resources, M.M.; data curation, M.M. and D.M.; writing—original draft preparation, M.M. and T.Š.; writing—review and editing, M.M. and D.M.; visualization, M.M. and T.Š.; supervision, M.M.; project administration, M.M. and D.M.; funding acquisition, M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Slovak Cultural and Educational grant agency under the grants project KEGA 020TUKE-4/2024: adaptability of education with a focus on strategic support of companies to ensure the sustainable quality of processes.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this article are available on request from the corresponding author.

Acknowledgments

The authors would like to thank the anonymous referees for their valuable comments that improved the quality of the manuscript.

Conflicts of Interest

Author Dusan Malindzak was employed by the company AT&T. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- V SR sa Ročne Vytriedi cez Osemtisíc ton Textilu, Odpadu ale v Skutočnosti Vzniká Oveľa Viac. Available online: https://www.trend.sk/spravy/sr-rocne-vytriedi-cez-osemtisic-ton-textilu-odpadu-ale-skutocnosti-vznika-ovela-viac (accessed on 23 September 2024).

- Delivering the European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_sk#transform%C3%A1cia-n%C3%A1%C5%A1ho-hospod%C3%A1rstva-spolo%C4%8Dnosti (accessed on 18 April 2024).

- Solis, M.; Huygens, D.; Tonini, D.; Astrup, T.F. Management of textile waste in Europe: An environmental and a socio-economic assessment of current and future scenarios. Resour. Conserv. Recycl. 2024, 207, 107693. [Google Scholar] [CrossRef]

- Tang, K.H.D. State of the Art in TextileWaste Management: A Review. Textiles 2023, 3, 454–467. [Google Scholar] [CrossRef]

- Deckers, J.; Duhoux, T.; Due, S. Current practices and perspectives on separate collection and management of textile waste. In Textile Waste Management in Europe’s Circular Economy, 1st ed.; European Topic Centre on Circular Economy and Resource Use: Brussels, Belgium, 2024; pp. 10–20. [Google Scholar]

- Das, B.; Dwivedi, S. Post-Consumer textile waste management practices and challenges in India: A systematic literature review. J. Scientometr. Res. 2024, 13, 419–429. [Google Scholar] [CrossRef]

- Baloyi, R.B.; Gbadeyan, O.J.; Sithole, B.; Chunilall, V. Recent advances in recycling technologies for waste textile fabrics: A review. Text. Res. J. 2024, 94, 508–529. [Google Scholar] [CrossRef]

- European Regional Development Fund. Strategic Agenda on Textile Waste Management and Recycling, 1st ed.; European Union: Brussels, Belgium, 2018; pp. 3–35. [Google Scholar]

- Sandin, G.; Peters, G.M. Environmental impact of textile reuse and recycling—A review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Ramírez-Escamilla, H.G.; Martínez-Rodríguez, M.C.; Padilla-Rivera, A.; Domínguez-Solís, D.; Campos-Villegas, L.E. Advancing Toward Sustainability: A Systematic Review of Circular Economy Strategies in the Textile Industry. Recycling 2024, 9, 95. [Google Scholar] [CrossRef]

- Anjimoon, S.; Asha, V.; Gurnani, J.; Khan, I.; Surovi, P.; Al-Jawahry, M. Innovations and Opportunities in Sustainable Textile Recycling. In Proceedings of the ICFTEST-2024, Nagpur, India, 23–24 February 2024. [Google Scholar]

- Directorate General for Communication. The Impact of Textile Production and Waste on the Environment (Infographics), 1st ed.; European Union: Brussels, Belgium, 2024; pp. 1–7. [Google Scholar]

- A Creative Magazine for Digital Project Managers. Available online: https://www.pmcolumn.com/capacity-planning-strategies/ (accessed on 25 May 2024).

- Rafael, V.A. Manufacturing Logistics. Streamlining Production and Distribution, 2nd ed.; Insight Publishing: Victoria, Australia, 2023; pp. 118–126. [Google Scholar]

- Capacity Planning Strategies for Supply Chains—Everything You Need to Know in 2024. Available online: https://throughput.world/blog/capacity-planning-strategy/ (accessed on 25 May 2024).

- Hole, Y.; Pawar, S.; Bhaskar, M.P. Porter’s five forces model: Gives you a competitive advantage. J. Adv. Res. Dyn. Control Syst. 2019, 11, 1436–1448. [Google Scholar]

- Bensecilas, T.K.; Ombui, K.A. Influence of the Porter’s five forces model strategy on performance of selected telecommunication companies in Kenya. Int. J. Sci. Res. Publ. 2016, 6, 558–568. [Google Scholar]

- Mugo, P. Porter’s five forces influence on competitive advantage in telecommunication industry in Kenya. Eur. J. Bus. Strateg. Manag. 2020, 5, 30–49. [Google Scholar] [CrossRef]

- Brujil, G.H. The Relevance of Porter’s Five Forces in Today’s Innovative and Changing Business Environment. 2018, pp. 1–21. Available online: https://www.researchgate.net/publication/326026986_The_Relevance_of_Porter’s_Five_Forces_in_Today’s_Innovative_and_Changing_Business_Environment (accessed on 22 September 2024).

- Shi, C.; Afi Agbaku, C.; Zhang, F. How do upper echelons perceive Porter’s five forces? Evidence from strategic enterpreneurship in China. Front. Psychol. 2021, 12, 649574. [Google Scholar] [CrossRef] [PubMed]

- Malindzakova, M. Porterov model piatich síl zameraný na riadenie dodávateľských reťazcov. In Strategická Logistika, 1st ed.; TU v Košiciach, Fakulta BERG: Košice, Slovakia, 2023; pp. 21–27. [Google Scholar]

- Papula, J.; Papulová, Z.; Papula, J. Aktuálny koncept pre rýchlo sa približujúcu spoločnosť. In Strategický Manažment, 2nd ed.; Wolters Kluwer ČR: Praha, Czech Republic, 2019; pp. 44–96. [Google Scholar]

- Straka, M. Distribution and Supply Logistics, 1st ed.; Cambridge Scholars Publishing: Cambridge, UK, 2019; pp. 76–106. [Google Scholar]

- Technical Textile. Net. Available online: https://technicaltextile.net/articles/upholstery-in-automobiles-3100 (accessed on 16 October 2024).

- Štúdia na Posúdenie Zavedenia Systému pre Nakladanie s Odpadom z Textilu, Vrátanie Posúdenia Zavedenia Rozšírenej Zodpovednosti Výrobcov (RZV) pre Textil a Zber Dát o Opätovnom Použití Textilu. Available online: https://www.minzp.sk/files/sekcia-enviromentalneho-hodnotenia-riadenia/odpady-a-obaly/registre-a-zoznamy/studia_textil_mzpsr2.pdf (accessed on 4 October 2023).

- Syntetický Textil má Viacero Osobitných Vlastností. Available online: https://hnonline.sk/focus/ekonomika/1990811-rozhovor-synteticky-textil-ma-viacero-osobitnych-vlastnosti (accessed on 17 November 2023).

- STERED®—Patentovo Chránená Unikátna Technológia a Produkt zo Slovenska—Spojenie Príležitosti s Environmentálnu Zodpovednosťou. Available online: http://www.hospodarskyklub.sk/docs/ankety16/Plesnik.pdf (accessed on 9 December 2023).

- Ďurišková, J. Specification of Requirements for the Creation of a New Operation with a Focus on Textile Waste Recycling. Diploma Thesis, Technical University of Košice, Košice, Slovakia, 19 April 2024. [Google Scholar]

- STERED®. Available online: http://www.stered.sk/uvod (accessed on 9 December 2023).

- Malindzakova, M.; Stofkova, J.; Majernik, M. Economic–environmental performance of reverse logistics of disposable beverage packaging. Sustainability 2022, 14, 7544. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).