Photovoltaic Modules’ Cleaning Method Selection for the MENA Region

Abstract

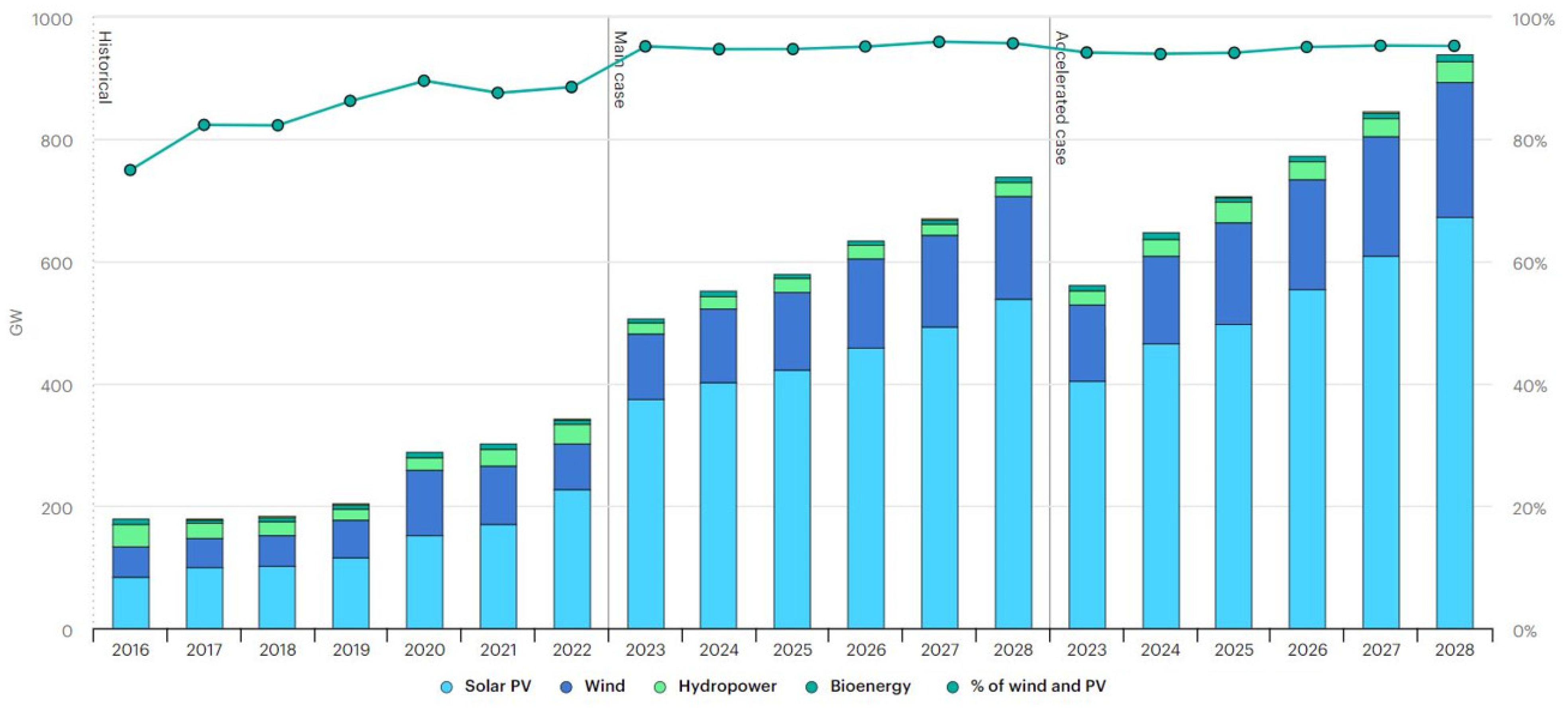

:1. Introduction

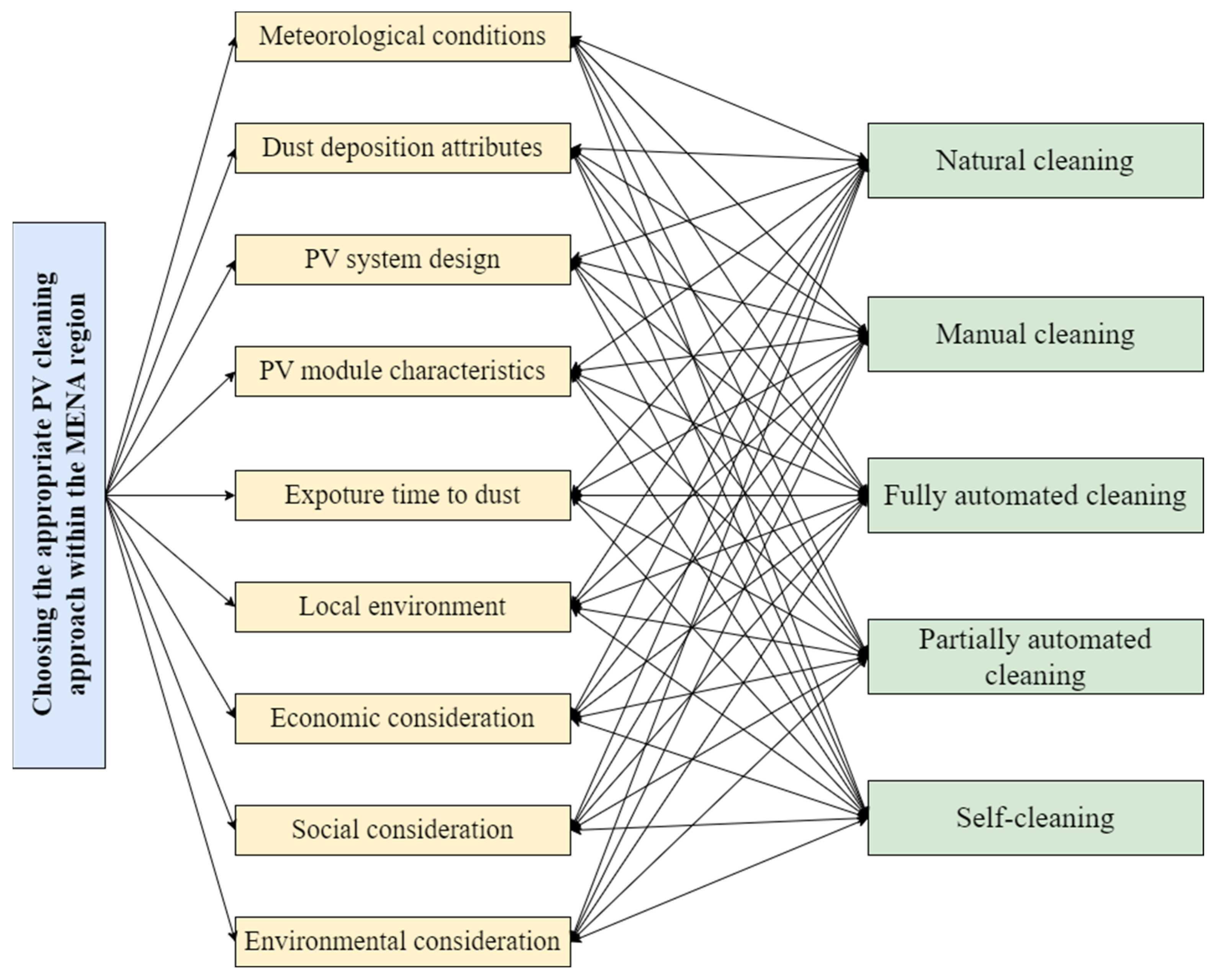

- -

- How do relevant influential factors affect PV cleaning techniques and dust accumulation on PV modules?

- -

- What are the current PV cleaning methods? How do they align with sustainability pillars?

- -

- Which socio-economic and environmental factors are relevant to the PV cleaning process within the MENA region?

- -

- What is the ranking of current cleaning techniques within the MENA region?

2. Literature Review

2.1. Influential Factors Impacting PV Cleaning Techniques and Dust Accumulation on Modules

2.1.1. Meteorological Factors

2.1.2. Dust Depositions Attributes

2.1.3. PV System Design

2.1.4. PV Module Characteristics

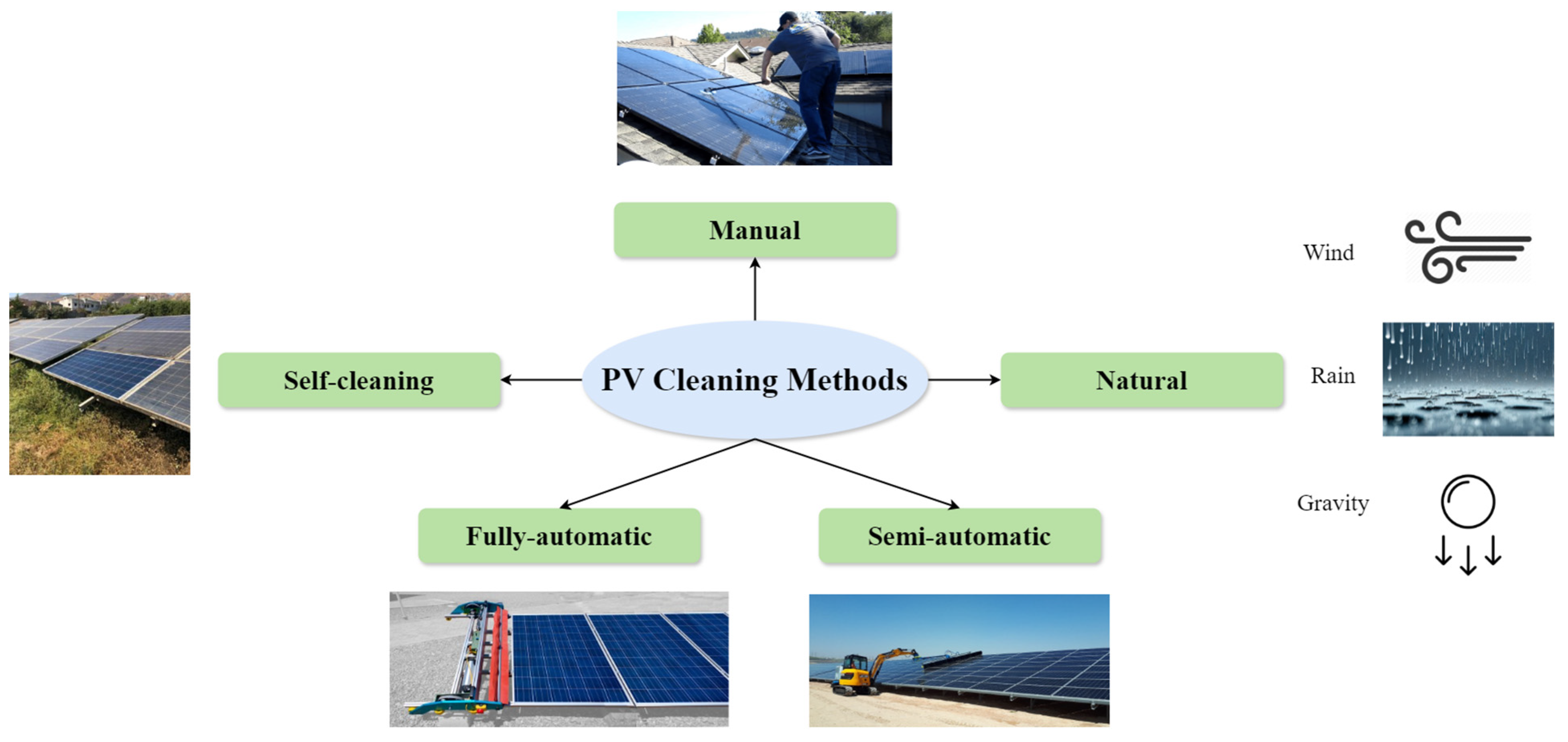

2.2. Current Methods and Techniques for PV Module Cleaning

2.2.1. Natural Cleaning

2.2.2. Self-Cleaning

2.2.3. Manual Cleaning

2.2.4. Automated Cleaning

2.3. Photovoltaic Systems in the MENA Region: PV Capacities, Climate Challenges, and Associated Costs

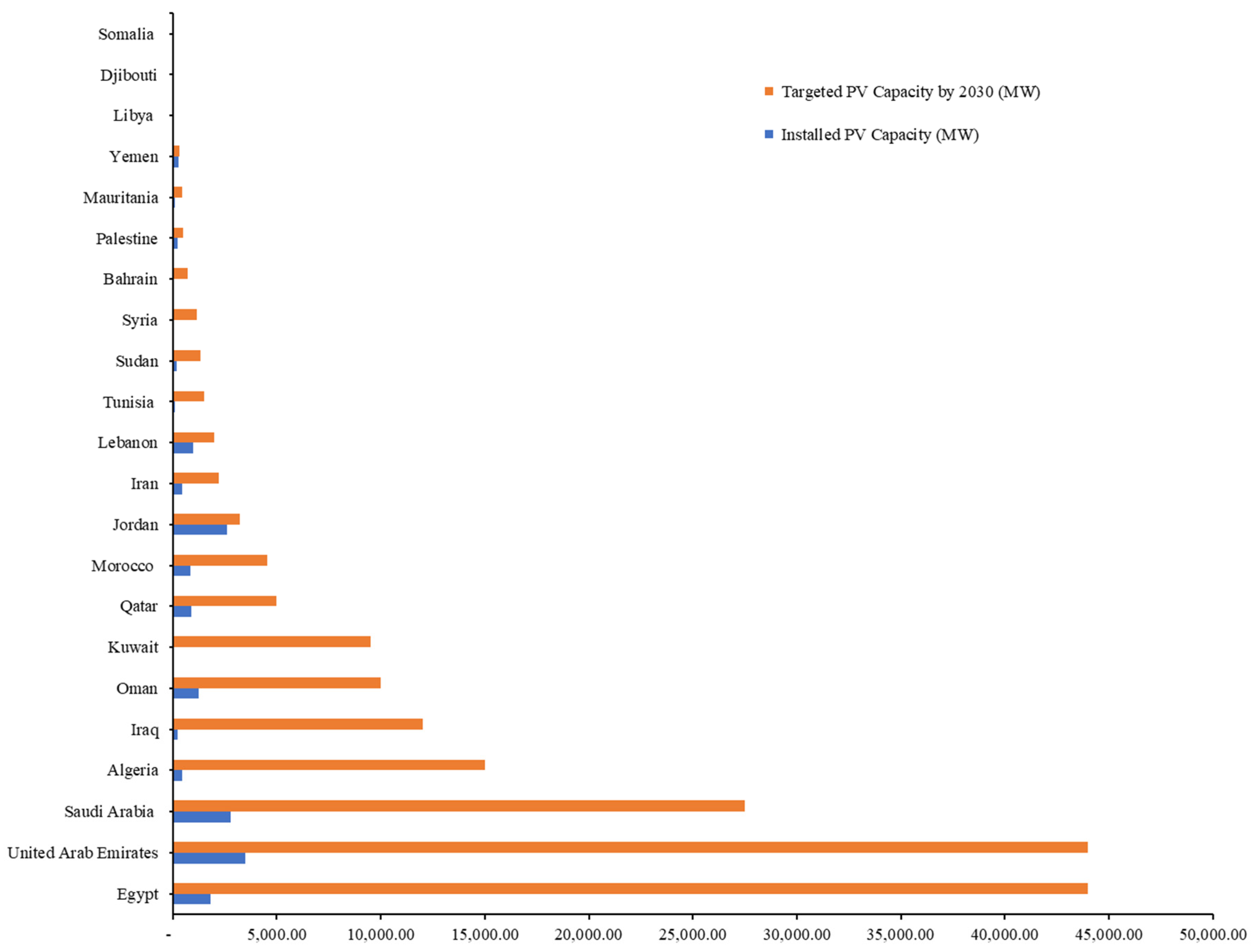

2.3.1. PV Systems’ Capacity in the MENA Region

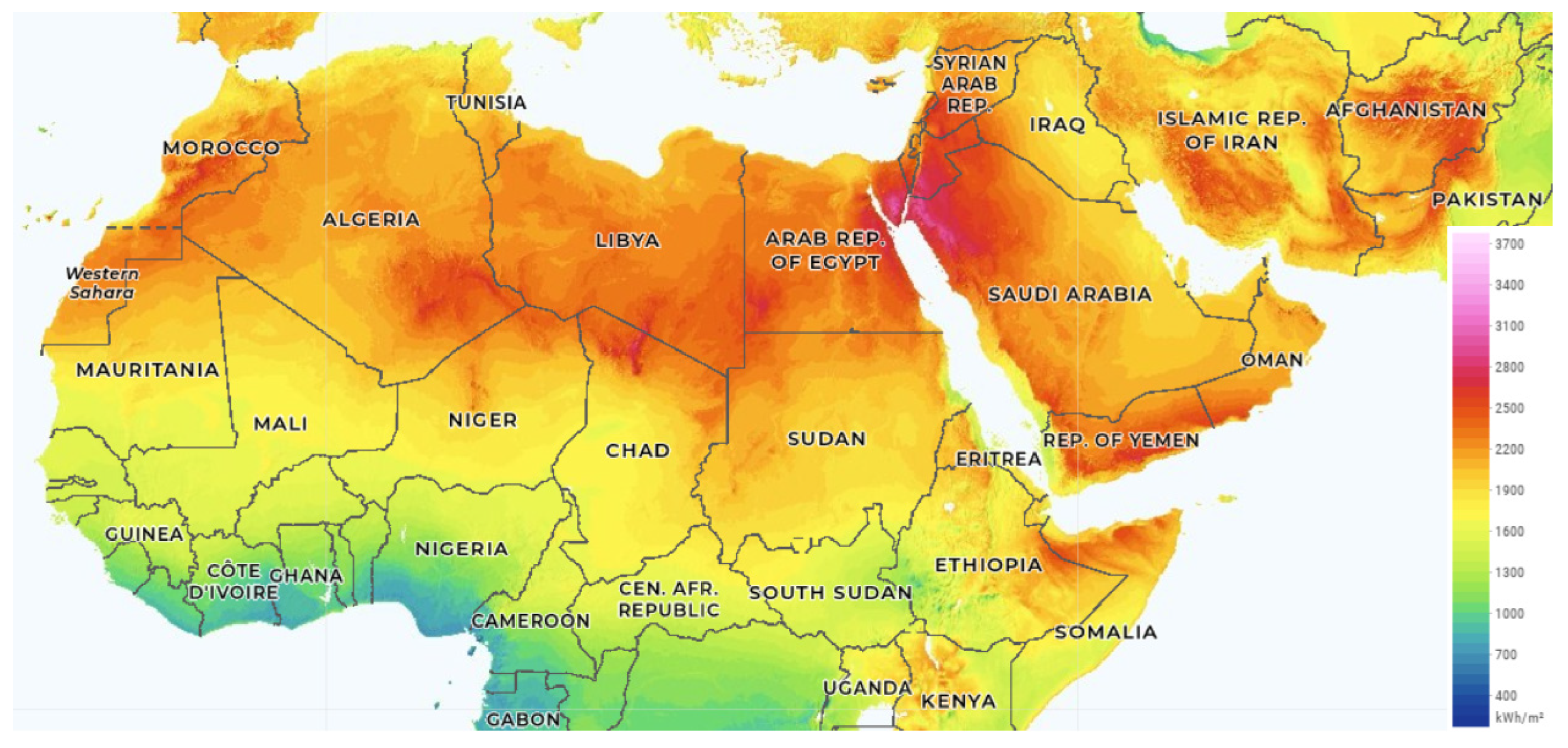

2.3.2. Climate-Related Challenges in the MENA Region

2.3.3. Associated Costs for PV Cleaning Systems in the MENA Region

2.4. Sustainability Pillars and PV Cleaning

2.5. Multi-Criteria Decision-Making for Ranking PV Cleaning Methods

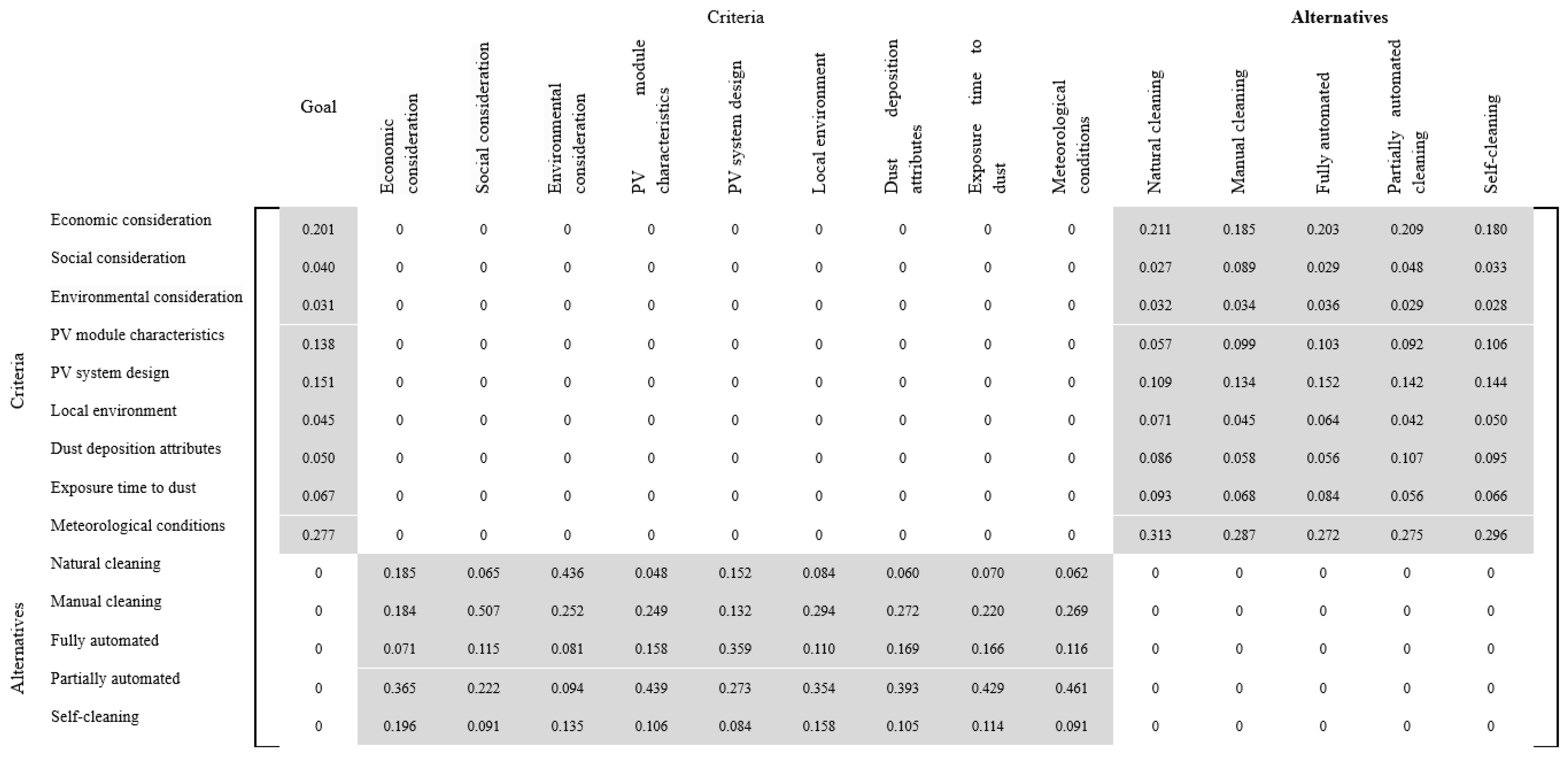

3. Methodology

| Criteria | Alternatives | ||||||||||||

| Goal | Goal | C1 | C2 | C3 | Cn | A1 | A2 | Ap | |||||

| Criteria | C1 | W1 | 0 | W11 | W12 | W1p | |||||||

| C2 | W2 | 0 | W21 | W22 | W2p | ||||||||

| C3 | W3 | 0 | W31 | W32 | W3p | ||||||||

| 0 | |||||||||||||

| Cn | W4 | 0 | Wn1 | Wn2 | Wnp | ||||||||

| Alternatives | A1 | 0 | U11 | U12 | U13 | U1n | 0 | ||||||

| A2 | 0 | U21 | U22 | U23 | U2n | 0 | |||||||

| 0 | 0 | ||||||||||||

| Ap | 0 | Up1 | Up2 | Up3 | Upn | 0 | |||||||

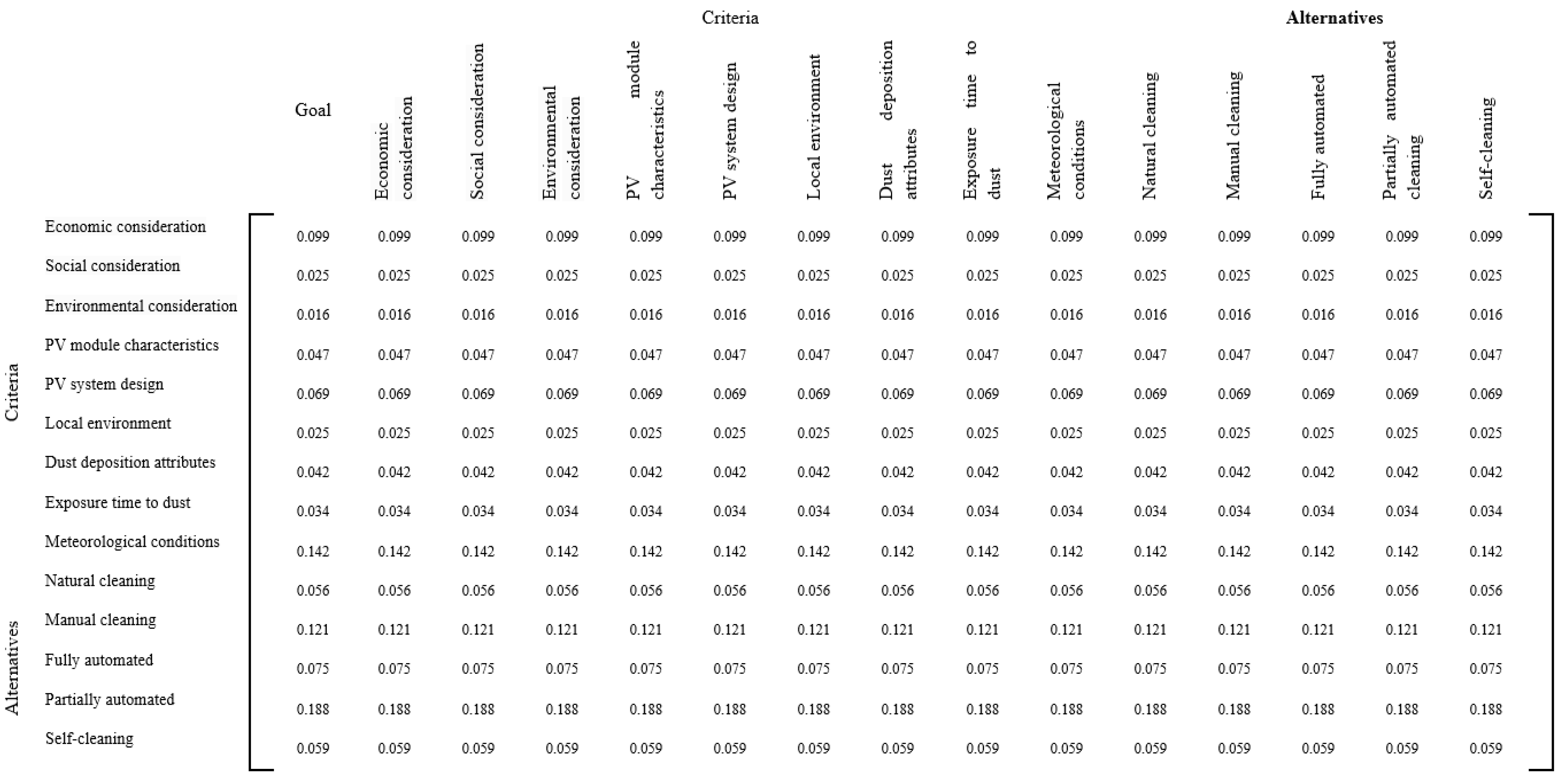

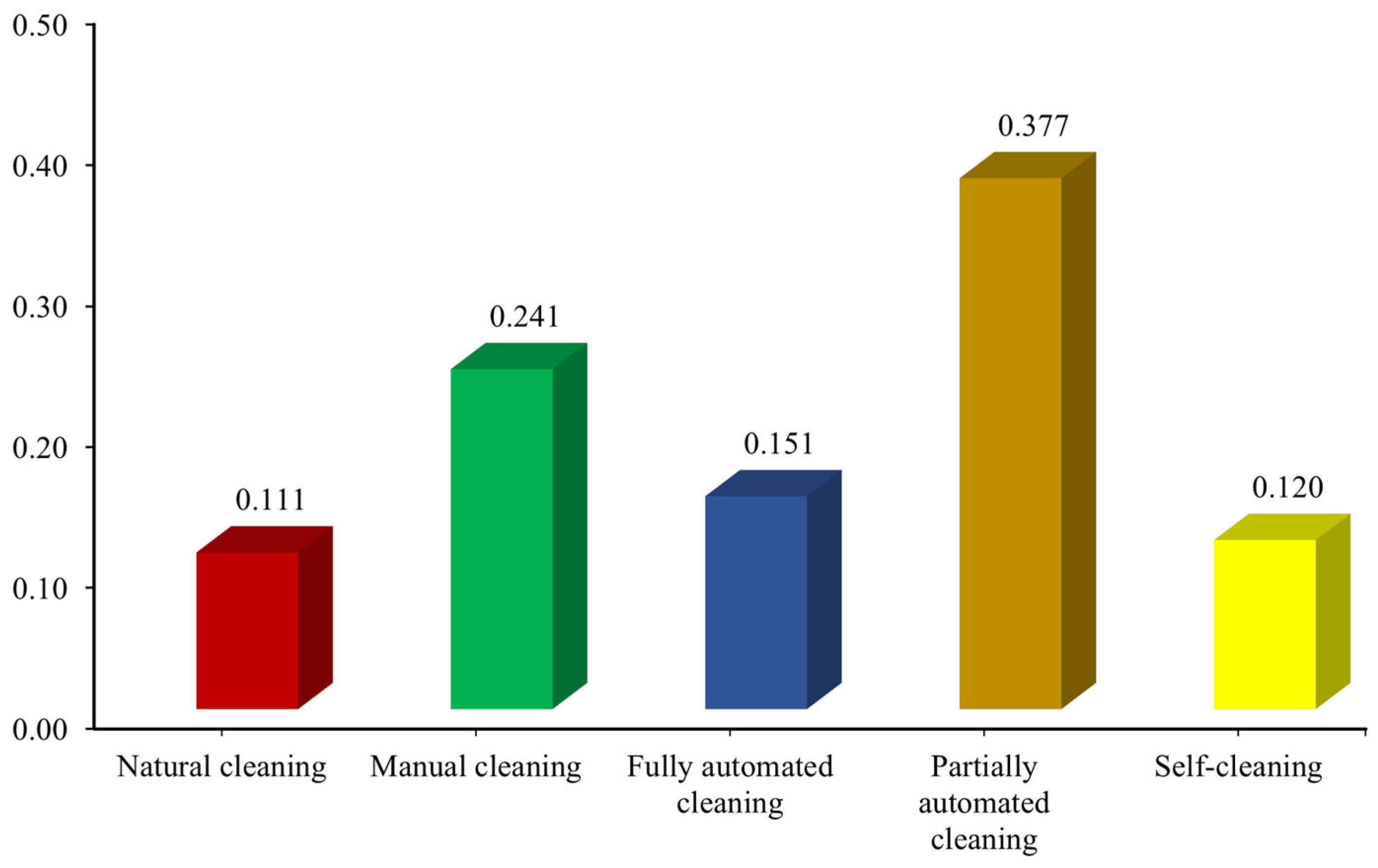

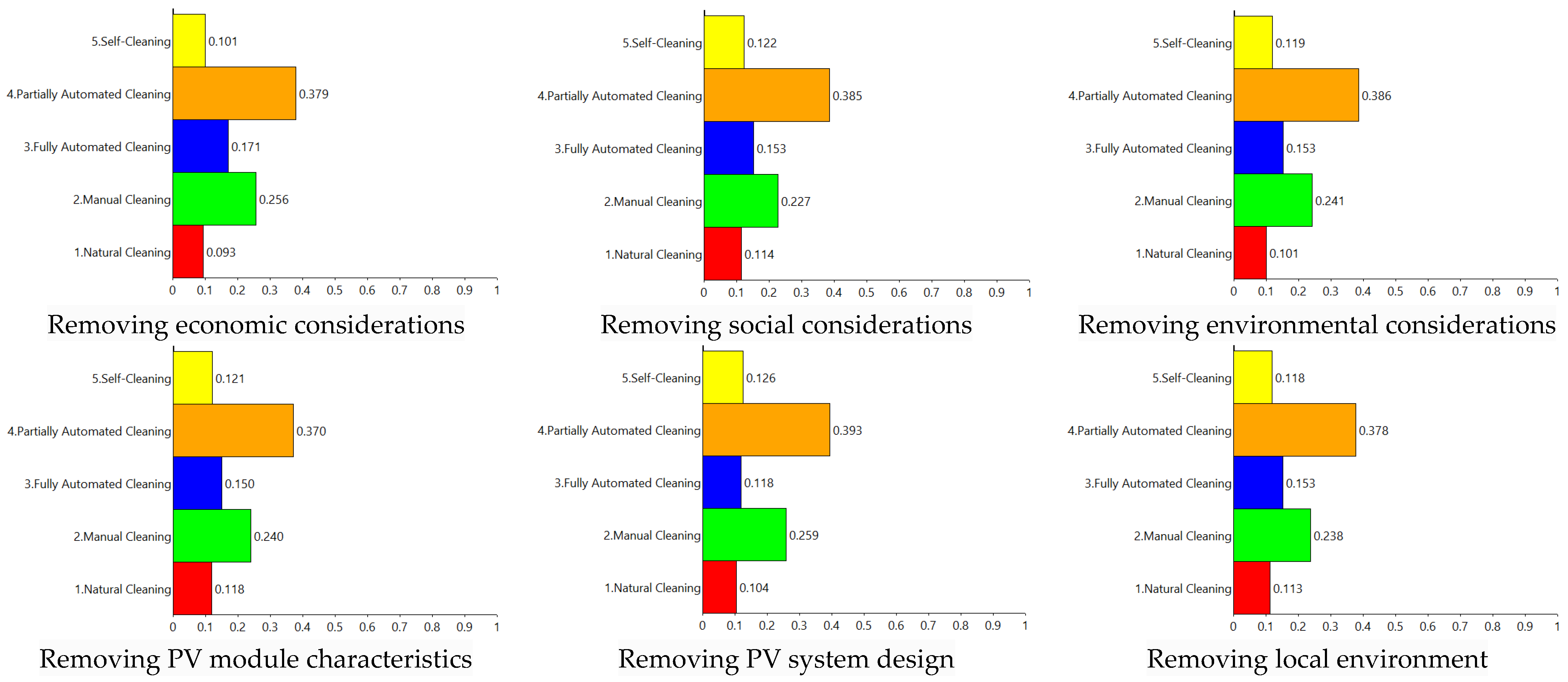

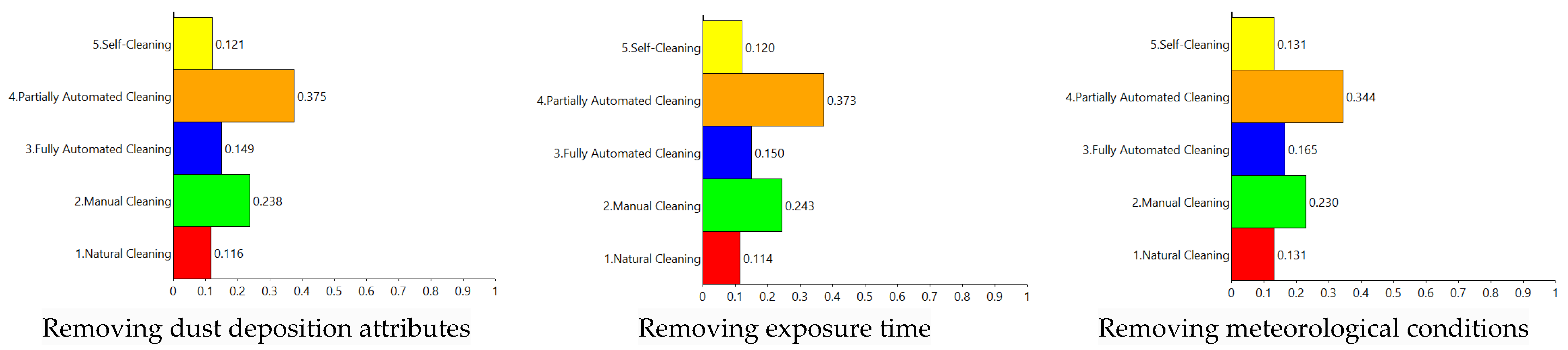

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- REN21. RENEWABLES 2023. GLOBAL STATUS REPORT. 2023. Available online: https://www.ren21.net/wp-content/uploads/2019/05/GSR-2023_Energy-Supply-Module.pdf (accessed on 23 November 2023).

- Kassem, Y.; Gokcekus, H.; Aljatlawe, A. Utilization of Solar Energy for Electric Vehicle Charging and the Energy Consumption of Residential Buildings in Northern Cyprus: A Case Study. Eng. Technol. Appl. Sci. Res. 2023, 13, 11598–11607. [Google Scholar] [CrossRef]

- Gaur, M.; Shrivastava, A.; Pandit, R.K. Performance analysis and sustainability assessment of a building integrated solar PV system. Int. J. Ambient Energy 2024, 45, 2283762. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Al-Othman, A.; Kafiah, F.; Abdelsalam, E.; Almomani, F.; Alkasrawi, M. Environmental impacts of solar photovoltaic systems: A critical review of recent progress and future outlook. Sci. Total Environ. 2021, 759, 143528. [Google Scholar] [CrossRef] [PubMed]

- Mohammad, A.; Mahjabeen, F. Revolutionizing solar energy: The impact of artificial intelligence on photovoltaic systems. Int. J. Multidiscip. Sci. Arts 2023, 2. [Google Scholar] [CrossRef]

- Hess, D.J. Conflict and uneven development in the multidecade distributed solar energy transition in the United States. Proc. Natl. Acad. Sci. USA 2023, 120, e2206200119. [Google Scholar] [CrossRef] [PubMed]

- IEA. Renewable Electricity Capacity Additions by Technology and Segment, 2016–2028. 2024; Renewables 2023. Available online: https://www.iea.org/data-and-statistics/charts/renewable-electricity-capacity-additions-by-technology-and-segment-2016-2028 (accessed on 19 February 2024).

- Abuzaid, H.; Awad, M.; Shamayleh, A. Impact of dust accumulation on photovoltaic panels: A review paper. Int. J. Sustain. Eng. 2022, 15, 264–285. [Google Scholar] [CrossRef]

- Salamah, T.; Ramahi, A.; Alamara, K.; Juaidi, A.; Abdallah, R.; Abdelkareem, M.A.; Amer, E.-C.; Olabi, A.G. Effect of dust and methods of cleaning on the performance of solar PV module for different climate regions: Comprehensive review. Sci. Total Environ. 2022, 827, 154050. [Google Scholar] [CrossRef]

- Kazmerski, L.L.; Diniz, A.S.A.; Braga, D.S.; Maia, C.B.; Viana, M.M.; Costa, S.C.; Brito, P.P.; Campos, C.D.; de Morais Hanriot, S.; de Oliveira Cruz, L.R. Interrelationships among non-uniform soiling distributions and PV module performance parameters, climate conditions, and soiling particle and module surface properties. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 2307–2311. [Google Scholar]

- Jiang, Y.; Lu, L.; Ferro, A.R.; Ahmadi, G. Analyzing wind cleaning process on the accumulated dust on solar photovoltaic (PV) modules on flat surfaces. Sol. Energy 2018, 159, 1031–1036. [Google Scholar] [CrossRef]

- Zereg, K.; Gama, A.; Aksas, M.; Rathore, N.; Yettou, F.; Panwar, N.L. Dust impact on concentrated solar power: A review. Environ. Eng. Res. 2022, 27, 210345. [Google Scholar] [CrossRef]

- Khalid, H.M.; Rafique, Z.; Muyeen, S.M.; Raqeeb, A.; Said, Z.; Saidur, R.; Sopian, K. Dust accumulation and aggregation on PV panels: An integrated survey on impacts, mathematical models, cleaning mechanisms, and possible sustainable solution. Sol. Energy 2023, 251, 261–285. [Google Scholar] [CrossRef]

- Chibani, A. Sand and Dust Storms in the MENA Region: A Problem Awaiting Mitigation. Available online: https://arabcenterdc.org/resource/sand-and-dust-storms-in-the-mena-region-a-problem-awaiting-mitigation/ (accessed on 31 January 2021).

- NASA. Fine Particulate Maps with and without Dust. NASA: Washington, DC, USA, 2015. [Google Scholar]

- Mousavi, S.V.; Karami, K.; Tilmes, S.; Muri, H.; Xia, L.; Rezaei, A. Future dust concentration over the Middle East and North Africa region under global warming and stratospheric aerosol intervention scenarios. Atmos. Chem. Phys. 2023, 23, 10677–10695. [Google Scholar] [CrossRef]

- Univdatos. MENA Solar Photovoltaic Market: Current Analysis and Forecast (2023–2030). 2022. Available online: https://univdatos.com/report/mena-solar-photovoltaic-market/#:~:text=The%20MENA%20Solar%20Photovoltaic%20Market,roadmap%20for%20solar%20energy%20expansion (accessed on 31 January 2024).

- Hernández-Callejo, L.; Gallardo-Saavedra, S.; Alonso-Gómez, V. A review of photovoltaic systems: Design, operation and maintenance. Sol. Energy 2019, 188, 426–440. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.A.; Sopian, K. Effect of dust and cleaning methods on mono and polycrystalline solar photovoltaic performance: An indoor experimental study. Sol. Energy 2022, 236, 626–643. [Google Scholar] [CrossRef]

- Hafner, M.; Raimondi, P.P.; Bonometti, B. Low-carbon energy strategies in mena countries. In The Energy Sector and Energy Geopolitics in the MENA Region at a Crossroad: Towards a Great Transformation? Springer: Berlin/Heidelberg, Germany, 2023; pp. 175–261. [Google Scholar]

- Santhakumari, M.; Sagar, N. A review of the environmental factors degrading the performance of silicon wafer-based photovoltaic modules: Failure detection methods and essential mitigation techniques. Renew. Sustain. Energy Rev. 2019, 110, 83–100. [Google Scholar] [CrossRef]

- Zarei, T.; Abdolzadeh, M.; Yaghoubi, M. Comparing the impact of climate on dust accumulation and power generation of PV modules: A comprehensive review. Energy Sustain. Dev. 2022, 66, 238–270. [Google Scholar] [CrossRef]

- Nadia, M.; Lassad, H.; Abderrahmen, Z.; Abdelkader, C. Influence of temperature and irradiance on the different solar PV panel technologies. Int. J. Energy Sect. Manag. 2021, 15, 421–430. [Google Scholar] [CrossRef]

- Atsu, D.; Dhaundiyal, A. Effect of ambient parameters on the temperature distribution of photovoltaic (PV) modules. Resources 2019, 8, 107. [Google Scholar] [CrossRef]

- Hadidi, A.; Blal, M.; Saba, D. The study of the arid climate effect on the performance of photovoltaic system. Energy Syst. 2021, 15, 565–584. [Google Scholar] [CrossRef]

- Al Siyabi, I.; Al Mayasi, A.; Al Shukaili, A.; Khanna, S. Effect of Soiling on Solar Photovoltaic Performance under Desert Climatic Conditions. Energies 2021, 14, 659. [Google Scholar] [CrossRef]

- Yao, W.; Kong, X.; Xu, A.; Xu, P.; Wang, Y.; Gao, W. New models for the influence of rainwater on the performance of photovoltaic modules under different rainfall conditions. Renew. Sustain. Energy Rev. 2023, 173, 113119. [Google Scholar] [CrossRef]

- Liu, L.; Qian, H.; Sun, E.; Li, B.; Zhang, Z.; Miao, B.; Li, Z. Power reduction mechanism of dust-deposited photovoltaic modules: An experimental study. J. Clean. Prod. 2022, 378, 134518. [Google Scholar] [CrossRef]

- Dhaouadi, R.; Al-Othman, A.; Aidan, A.A.; Tawalbeh, M.; Zannerni, R. A characterization study for the properties of dust particles collected on photovoltaic (PV) panels in Sharjah, United Arab Emirates. Renew. Energy 2021, 171, 133–140. [Google Scholar] [CrossRef]

- Isaifan, R.J.; Johnson, D.; Ackermann, L.; Figgis, B.; Ayoub, M. Evaluation of the adhesion forces between dust particles and photovoltaic module surfaces. Sol. Energy Mater. Sol. Cells 2019, 191, 413–421. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Dust and PV Performance in Nigeria: A review. Renew. Sustain. Energy Rev. 2020, 121, 109704. [Google Scholar] [CrossRef]

- Abderrezek, M.; Fathi, M. Experimental study of the dust effect on photovoltaic panels’ energy yield. Sol. Energy 2017, 142, 308–320. [Google Scholar] [CrossRef]

- Zhao, W.; Lv, Y.; Zhou, Q.; Yan, W. Investigation on particle deposition criterion and dust accumulation impact on solar PV module performance. Energy 2021, 233, 121240. [Google Scholar] [CrossRef]

- Lay-Ekuakille, A.; Ciaccioli, A.; Griffo, G.; Visconti, P.; Andria, G. Effects of dust on photovoltaic measurements: A comparative study. Measurement 2018, 113, 181–188. [Google Scholar] [CrossRef]

- Javed, W.; Guo, B.; Figgis, B.; Aïssa, B. Dust potency in the context of solar photovoltaic (PV) soiling loss. Sol. Energy 2021, 220, 1040–1052. [Google Scholar] [CrossRef]

- Wu, Z.; Yan, S.; Ming, T.; Zhao, X.; Zhang, N. Analysis and modeling of dust accumulation-composed spherical and cubic particles on PV module relative transmittance. Sustain. Energy Technol. Assess. 2021, 44, 101015. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T. The effect of dust accumulation and cleaning methods on PV panels’ outcomes based on an experimental study of six locations in Northern Oman. Sol. Energy 2019, 187, 30–38. [Google Scholar] [CrossRef]

- Aghaei, M.; Kumar, N.M.; Eskandari, A.; Ahmed, H.; de Oliveira, A.K.V.; Chopra, S.S. Solar PV systems design and monitoring. In Photovoltaic Solar Energy Conversion; Elsevier: Amsterdam, The Netherlands, 2020; pp. 117–145. [Google Scholar]

- Aslam, A.; Ahmed, N.; Qureshi, S.A.; Assadi, M.; Ahmed, N. Advances in solar PV systems; A comprehensive review of PV performance, influencing factors, and mitigation techniques. Energies 2022, 15, 7595. [Google Scholar] [CrossRef]

- Hachicha, A.A.; Al-Sawafta, I.; Said, Z. Impact of dust on the performance of solar photovoltaic (PV) systems under United Arab Emirates weather conditions. Renew. Energy 2019, 141, 287–297. [Google Scholar] [CrossRef]

- Semaoui, S.; Arab, A.H.; Boudjelthia, E.K.; Bacha, S.; Zeraia, H. Dust effect on optical transmittance of photovoltaic module glazing in a desert region. Energy Procedia 2015, 74, 1347–1357. [Google Scholar] [CrossRef]

- Aksoy, M.H.; Ispir, M.; YEŞİL, E. Impact of tilt angle on the performance of the photovoltaic systems for different row spacing. Politek. Derg. 2023, 26, 1573–1585. [Google Scholar] [CrossRef]

- AlMallahi, M.N.; El Haj Assad, M.; AlShihabi, S.; Alayi, R. Multi-criteria decision-making approach for the selection of cleaning method of solar PV panels in United Arab Emirates based on sustainability perspective. Int. J. Low-Carbon Technol. 2022, 17, 380–393. [Google Scholar] [CrossRef]

- Younis, A.; Onsa, M. A brief summary of cleaning operations and their effect on the photovoltaic performance in Africa and the Middle East. Energy Rep. 2022, 8, 2334–2347. [Google Scholar] [CrossRef]

- Chiteka, K.; Arora, R.; Sridhara, S.; Enweremadu, C. Cleaning cycle optimisation in non-tracking ground mounted solar PV systems using Particle Swarm Optimisation. Int. J. Simul. Multidiscip. Des. Optim. 2020, 11, 9. [Google Scholar] [CrossRef]

- Amber, K.P.; Hussain, I.; Kousar, A.; Bashir, M.A.; Aslam, M.W.; Akbar, B. A self-cleaning device for pole mounted solar photovoltaic installations. Therm. Sci. 2019, 23, 739–749. [Google Scholar]

- Zahedi, R.; Ranjbaran, P.; Gharehpetian, G.B.; Mohammadi, F.; Ahmadiahangar, R. Cleaning of floating photovoltaic systems: A critical review on approaches from technical and economic perspectives. Energies 2021, 14, 2018. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. An analytical indoor experimental study on the effect of soiling on PV, focusing on dust properties and PV surface material. Sol. Energy 2020, 203, 46–68. [Google Scholar] [CrossRef]

- Wu, Y.; Du, J.; Liu, G.; Ma, D.; Jia, F.; Klemeš, J.J.; Wang, J. A review of self-cleaning technology to reduce dust and ice accumulation in photovoltaic power generation using superhydrophobic coating. Renew. Energy 2022, 185, 1034–1061. [Google Scholar] [CrossRef]

- Younis, A.; Alhorr, Y. Modeling of dust soiling effects on solar photovoltaic performance: A review. Sol. Energy 2021, 220, 1074–1088. [Google Scholar] [CrossRef]

- Khan, R.A.; Farooqui, S.A.; Khan, M.H.; Sarfraz, M.; Luqman, M.; Khan, M.F. Dust deposition on PV module and its characteristics. In The Effects of Dust and Heat on Photovoltaic Modules: Impacts and Solutions; Springer: Berlin/Heidelberg, Germany, 2022; pp. 59–95. Available online: https://www.researchgate.net/publication/355856773_Dust_Deposition_on_PV_Module_and_Its_Characteristics (accessed on 31 January 2024).

- Kayri, İ.; Bayar, M.T. A new approach to determine the long-term effect of efficiency losses due to different dust types accumulation on PV modules with artificial neural networks. J. Clean. Prod. 2024, 434, 140282. [Google Scholar] [CrossRef]

- Alnasser, T.M.A.; Mahdy, A.M.J.; Abass, K.I.; Chaichan, M.T.; Kazem, H.A. Impact of dust ingredient on photovoltaic performance: An experimental study. Sol. Energy 2020, 195, 651–659. [Google Scholar] [CrossRef]

- Said, S.A.; Hassan, G.; Walwil, H.M.; Al-Aqeeli, N. The effect of environmental factors and dust accumulation on photovoltaic modules and dust-accumulation mitigation strategies. Renew. Sustain. Energy Rev. 2018, 82, 743–760. [Google Scholar] [CrossRef]

- Qasem, H.; Betts, T.R.; Müllejans, H.; AlBusairi, H.; Gottschalg, R. Dust-induced shading on photovoltaic modules. Prog. Photovolt. Res. Appl. 2014, 22, 218–226. [Google Scholar] [CrossRef]

- Ali, A. Photovoltaic Module Dust Cleaning Techniques. In The Effects of Dust and Heat on Photovoltaic Modules: Impacts and Solutions; Springer: Berlin/Heidelberg, Germany, 2022; pp. 97–112. Available online: https://www.researchgate.net/publication/355856834_Photovoltaic_Module_Dust_Cleaning_Techniques (accessed on 23 November 2023).

- Smith, M.K.; Wamser, C.C.; James, K.E.; Moody, S.; Sailor, D.J.; Rosenstiel, T.N. Effects of natural and manual cleaning on photovoltaic output. J. Sol. Energy Eng. 2013, 135, 034505. [Google Scholar] [CrossRef]

- Cruz, G.; Vorobiev, P. Dust adhesion physics on photovoltaic surfaces and its application on assisted natural cleaning of solar trackers. J. Phys. Conf. Ser. 2022, 2238, 012013. [Google Scholar] [CrossRef]

- Pawluk, R.E.; Chen, Y.; She, Y. Photovoltaic electricity generation loss due to snow–A literature review on influence factors, estimation, and mitigation. Renew. Sustain. Energy Rev. 2019, 107, 171–182. [Google Scholar] [CrossRef]

- Ghazi, S.; Sayigh, A.; Ip, K. Dust effect on flat surfaces—A review paper. Renew. Sustain. Energy Rev. 2014, 33, 742–751. [Google Scholar] [CrossRef]

- Quan, Z.; Lu, H.; Zhao, W.; Zheng, C.; Zhu, Z.; Qin, J.; Yue, M. A Review of Dust Deposition Mechanism and Self-Cleaning Methods for Solar Photovoltaic Modules. Coatings 2022, 13, 49. [Google Scholar] [CrossRef]

- Jaswal, A.; Sinha, M.K. A review on solar panel cleaning through chemical self-cleaning method. In Proceedings of the International Conference on Advanced Production and Industrial Engineering, Delhi, India, 21–22 December 2019; Springer: Berlin/Heidelberg, Germany, 2021; pp. 835–844. [Google Scholar]

- Guo, B.; Javed, W.; Khoo, Y.S.; Figgis, B. Solar PV soiling mitigation by electrodynamic dust shield in field conditions. Sol. Energy 2019, 188, 271–277. [Google Scholar] [CrossRef]

- Kawamoto, H.; Shibata, T. Electrostatic cleaning system for removal of sand from solar panels. J. Electrost. 2015, 73, 65–70. [Google Scholar] [CrossRef]

- Mazumder, M.; Sharma, R.; Biris, A.; Horenstein, M.; Zhang, J.; Ishihara, H.; Stark, J.; Blumenthal, S.; Sadder, O. Electrostatic removal of particles and its applications to self-cleaning solar panels and solar concentrators. In Developments in Surface Contamination and Cleaning; Elsevier: Amsterdam, The Netherlands, 2011; pp. 149–199. [Google Scholar]

- Sakhuja, M.; Son, J.; Yang, H.; Bhatia, C.S.; Danner, A.J. Outdoor performance and durability testing of antireflecting and self-cleaning glass for photovoltaic applications. Sol. Energy 2014, 110, 231–238. [Google Scholar] [CrossRef]

- Deb, D.; Brahmbhatt, N.L. Review of yield increase of solar panels through soiling prevention, and a proposed water-free automated cleaning solution. Renew. Sustain. Energy Rev. 2018, 82, 3306–3313. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, Q.; Hu, J. A linear piezoelectric actuator based solar panel cleaning system. Energy 2013, 60, 401–406. [Google Scholar] [CrossRef]

- Ullah, A.; Amin, A.; Haider, T.; Saleem, M.; Butt, N.Z. Investigation of soiling effects, dust chemistry and optimum cleaning schedule for PV modules in Lahore, Pakistan. Renew. Energy 2020, 150, 456–468. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, S.; Cao, S.; Zhao, Q. Cleaning cycle optimization and cost evaluation of module dust for photovoltaic power plants in China. Clean Technol. Environ. Policy 2019, 21, 1645–1654. [Google Scholar] [CrossRef]

- Alazbe, K.; Roy, H.A.; Alremeithi, A.; Saif, A.; AlHashmi, M.; Daccache, L.; Alnuaimi, A. Insight into dust soiling characteristics and cleaning solutions to investigate impact on PV systems performance across the globe. Prog. Energy 2023, 6, 012004. [Google Scholar] [CrossRef]

- Derakhshandeh, J.F.; AlLuqman, R.; Mohammad, S.; AlHussain, H.; AlHendi, G.; AlEid, D.; Ahmad, Z. A comprehensive review of automatic cleaning systems of solar panels. Sustain. Energy Technol. Assess. 2021, 47, 101518. [Google Scholar] [CrossRef]

- Khadka, N.; Bista, A.; Adhikari, B.; Shrestha, A.; Bista, D. Smart Solar Photovoltaic Panel Cleaning System. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Bangkok, Thailand, 11–14 December 2019; IOP Publishing: Bristol, UK, 2019; p. 012121. [Google Scholar]

- Bouaddi, S.; Fernández-García, A.; Sansom, C.; Sarasua, J.A.; Wolfertstetter, F.; Bouzekri, H.; Sutter, F.; Azpitarte, I. A review of conventional and innovative-sustainable methods for cleaning reflectors in concentrating solar power plants. Sustainability 2018, 10, 3937. [Google Scholar] [CrossRef]

- Mohandes, M.; Schulze, F.; Rehman, S.; Suliman, W. Cleaning PhotoVoltaic Solar Panels by Drone Aerodynamic. In Proceedings of the 2021 4th International Symposium on Advanced Electrical and Communication Technologies (ISAECT), Alkhobar, Saudi Arabia, 6–8 December 2021; pp. 1–5. [Google Scholar]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.A.; Sopian, K. A review of dust accumulation and cleaning methods for solar photovoltaic systems. J. Clean. Prod. 2020, 276, 123187. [Google Scholar] [CrossRef]

- Al-Housani, M.; Bicer, Y.; Koç, M. Experimental investigations on PV cleaning of large-scale solar power plants in desert climates: Comparison of cleaning techniques for drone retrofitting. Energy Convers. Manag. 2019, 185, 800–815. [Google Scholar] [CrossRef]

- IRENA. Energy Profile. 2024. Available online: https://www.irena.org/Data/Energy-Profiles (accessed on 1 August 2024).

- Santos, B. MENA’s Leading Solar PV Markets. 2023. Available online: https://www.pv-magazine.com/2023/01/17/menas-leading-solar-pv-markets/ (accessed on 31 January 2024).

- Serrudo, A. The Sun is Brighter in the MENA Region. 2019. Available online: https://www.ie.edu/school-politics-economics-global-affairs/sun-brighter-mena-region/ (accessed on 31 January 2024).

- Direct Normal Irradiation Map. Available online: https://globalsolaratlas.info/map?c=16.701493,37.324229,3&m=site (accessed on 23 November 2023).

- WorldBank. MIDDLE EAST & NORTH AFRICA CLIMATE ROADMAP (2021–2025). 2021. Available online: https://thedocs.worldbank.org/en/doc/6f868d4a875db3ef23ef1dc747fcf2ca-0280012022/original/MENA-Roadmap-Final-01-20.pdf (accessed on 31 January 2024).

- WorldBank. Climate and Development in the Middle East and North Africa. 2023. Available online: https://www.worldbank.org/en/region/mena/brief/climate-and-development-in-the-middle-east-and-north-africa#:~:text=The%20Middle%20East%20and%20North%20Africa%20(MENA)%20region%20is%20one,water%20scarcity%20and%20polluted%20air (accessed on 31 January 2024).

- de Waal, D.; Khemani, S.; Barone, A.; Borgomeo, E. The Economics of Water Scarcity in the Middle East and North Africa. 2023. Available online: https://openknowledge.worldbank.org/entities/publication/ab35b03a-23fa-4457-aebd-0f4a89848be1 (accessed on 31 January 2024).

- IEA. Climate Resilience is Key to Energy Transitions in the Middle East and North Africa. 2023. Available online: https://www.iea.org/commentaries/climate-resilience-is-key-to-energy-transitions-in-the-middle-east-and-north-africa (accessed on 31 January 2024).

- Ezzeldin, K.; Adshead, D.; Smith, P. Adapting to a New Climate in the MENA Region. 2023. Available online: https://www.uncclearn.org/wp-content/uploads/library/Adapting-to-a-new-climate-MENA.pdf (accessed on 31 January 2024).

- WorldBank. Average Precipitation by Country. 2021. Available online: https://tradingeconomics.com/country-list/precipitation (accessed on 31 January 2024).

- FAO. Precipitation—Country Ranking. 2020. Available online: https://www.theglobaleconomy.com/rankings/precipitation/MENA/ (accessed on 31 January 2024).

- WorldBank. Somalia–Precipitation. 2020. Available online: https://climateknowledgeportal.worldbank.org/country/somalia/climate-data-historical#:~:text=The%20average%20annual%20rainfall%20is,rainfall%20on%20an%20annual%20average (accessed on 31 January 2024).

- ECOFLOW. How Much Does Solar Panel Cleaning Cost? A Quick Guide. 2023; Volume 2024. Available online: https://blog.ecoflow.com/us/how-much-does-solar-panel-cleaning-cost/ (accessed on 31 January 2024).

- Maftouh, A.; El Fatni, O.; Fayiah, M.; Liew, R.; Lam, S.; Bahaj, T.; Butt, M. The application of water–energy nexus in the Middle East and North Africa (MENA) region: A structured review. Appl. Water Sci. 2022, 12, 83. [Google Scholar] [CrossRef]

- Boudekhdekh, K. A Comparative Analysis of Energy Subsidy in the MENA Region. Econ. Insights Trends Chall. 2022, 2022, 37–56. [Google Scholar] [CrossRef]

- Poudineh, R.; Sen, A.; Fattouh, B. An integrated approach to electricity sector reforms in the resource rich economies of the MENA. Energy Policy 2020, 138, 111236. [Google Scholar] [CrossRef]

- Aghahosseini, A.; Bogdanov, D.; Breyer, C. Towards sustainable development in the MENA region: Analysing the feasibility of a 100% renewable electricity system in 2030. Energy Strategy Rev. 2020, 28, 100466. [Google Scholar] [CrossRef]

- Griffiths, S. A review and assessment of energy policy in the Middle East and North Africa region. Energy Policy 2017, 102, 249–269. [Google Scholar] [CrossRef]

- Mertzanis, C.; Said, M. Access to skilled labor, institutions and firm performance in developing countries. Int. J. Manpow. 2019, 40, 328–355. [Google Scholar] [CrossRef]

- Al Abri, I.; Al Hinai, O.; Al Raisi, S.; Al Harrasi, A.; Al Jabri, Z.; Al Maskari, M. Economic growth and the demand for foreign labor in the oil-exporting and labor-importing states of the Arab Gulf: Case of Oman. Cogent Bus. Manag. 2023, 10, 2256083. [Google Scholar] [CrossRef]

- Myovella, G.; Karacuka, M.; Haucap, J. Digitalization and economic growth: A comparative analysis of Sub-Saharan Africa and OECD economies. Telecommun. Policy 2020, 44, 101856. [Google Scholar] [CrossRef]

- BloombergNEF Power Prices and Costs. 2024. Available online: https://climatescope.github.io/climatescope.org/markets/ (accessed on 31 January 2024).

- Mallahi, A.; Nooman, M.; Assad, M.E.H.; Rejeb, O.; Delnava, H.; Asaad, S.; Tan, Y.C. A review on cleaning techniques of solar photovoltaic panels. AIP Conf. Proc. 2023, 2847, 040010. [Google Scholar]

- Duran, A.S.; Atasu, A.; Van Wassenhove, L.N. Cleaning after solar panels: Applying a circular outlook to clean energy research. Int. J. Prod. Res. 2022, 60, 211–230. [Google Scholar] [CrossRef]

- Yalcin, A.S.; Kilic, H.S.; Delen, D. The use of multi-criteria decision-making methods in business analytics: A comprehensive literature review. Technol. Forecast. Soc. Chang. 2022, 174, 121193. [Google Scholar] [CrossRef]

- Taherdoost, H.; Madanchian, M. Multi-criteria decision making (MCDM) methods and concepts. Encyclopedia 2023, 3, 77–87. [Google Scholar] [CrossRef]

- Aljaghoub, H.; Abumadi, F.; AlMallahi, M.N.; Obaideen, K.; Alami, A.H. Solar PV cleaning techniques contribute to Sustainable Development Goals (SDGs) using Multi-criteria decision-making (MCDM): Assessment and review. Int. J. Thermofluids 2022, 16, 100233. [Google Scholar] [CrossRef]

- Saaty, T.L.; Vargas, L.G. The Analytic Network Process; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Saaty, T.L.; Vargas, L.G. Decision Making with the Analytic Network Process; Springer: Berlin/Heidelberg, Germany, 2006; Volume 282. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Aljdaeh, E.; Kamwa, I.; Hammad, W.; Abuashour, M.I.; Sweidan, T.e.O.; Khalid, H.M.; Muyeen, S.M. Performance Enhancement of Self-Cleaning Hydrophobic Nanocoated Photovoltaic Panels in a Dusty Environment. Energies 2021, 14, 6800. [Google Scholar] [CrossRef]

- Abdallah, R.; Juaidi, A.; Abdel-Fattah, S.; Qadi, M.; Shadid, M.; Albatayneh, A.; Çamur, H.; García-Cruz, A.; Manzano-Agugliaro, F. The Effects of Soiling and Frequency of Optimal Cleaning of PV Panels in Palestine. Energies 2022, 15, 4232. [Google Scholar] [CrossRef]

- Alghamdi, A.S.; Bahaj, A.S.; Blunden, L.S.; Wu, Y. Dust Removal from Solar PV Modules by Automated Cleaning Systems. Energies 2019, 12, 2923. [Google Scholar] [CrossRef]

- Le, N.T.; Nguyen, M.D.; Phan, T.D.; Truong, C.T.; Duong, V.T.; Nguyen, H.H.; Nguyen, T.T. Development of a Multi-Suspension Unit for Solar Cleaning Robots to Mitigate Vibration Impact on Photovoltaic Panels. Appl. Sci. 2023, 13, 12104. [Google Scholar] [CrossRef]

| Case Study | Location | Size | Installation Type | Current Cleaning Technique | Feedback from O&M Team |

|---|---|---|---|---|---|

| 1 | UAE | 1.8 MWp | Rooftop | Manual | Effective, reliable, and feasible cleaning. |

| 2 | UAE | 785 kWp | Car parking | Fully automated | Reliability issues, frequent shutdowns, required human interference. Need to shift to manual cleaning with water management system. |

| 3 | Jordan | 10 MWp | Ground-mounted | Partially automated | Effective, reliable, and feasible cleaning. |

| 4 | Jordan | 23 MWp | Ground-mounted, Tracking | Fully automated | Reliability issues, frequent shutdowns, required human interference, accessibility concerns. Need to shift to manual cleaning. |

| 5 | Jordan | 2.7 MWp | Rooftop | Manual | Effective, reliable, and feasible cleaning. |

| 6 | UAE | 1.2 GWp | Ground-mounted | Fully automated | Reliability issues, frequent shutdowns, required human interference, frequent need to replace broken PV modules due to vibration problems from cleaning robotics, |

| 7 | UAE | 2.1 MWp | Rooftop | Manual | Effective, reliable, and feasible cleaning. |

| 8 | UAE | 870 kWp | Rooftop | Manual | Effective, reliable, and feasible cleaning. |

| 9 | Jordan | 591 kWp | Car parking | Manual | Effective, reliable, and feasible cleaning. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abuzaid, H.; Awad, M.; Shamayleh, A. Photovoltaic Modules’ Cleaning Method Selection for the MENA Region. Sustainability 2024, 16, 9331. https://doi.org/10.3390/su16219331

Abuzaid H, Awad M, Shamayleh A. Photovoltaic Modules’ Cleaning Method Selection for the MENA Region. Sustainability. 2024; 16(21):9331. https://doi.org/10.3390/su16219331

Chicago/Turabian StyleAbuzaid, Haneen, Mahmoud Awad, and Abdulrahim Shamayleh. 2024. "Photovoltaic Modules’ Cleaning Method Selection for the MENA Region" Sustainability 16, no. 21: 9331. https://doi.org/10.3390/su16219331

APA StyleAbuzaid, H., Awad, M., & Shamayleh, A. (2024). Photovoltaic Modules’ Cleaning Method Selection for the MENA Region. Sustainability, 16(21), 9331. https://doi.org/10.3390/su16219331