Valorization of Sugarcane Bagasse Ash as an Alternative SCM: Effect of Particle Size, Temperature-Crossover Effect Mitigation & Cost Analysis

Abstract

1. Introduction

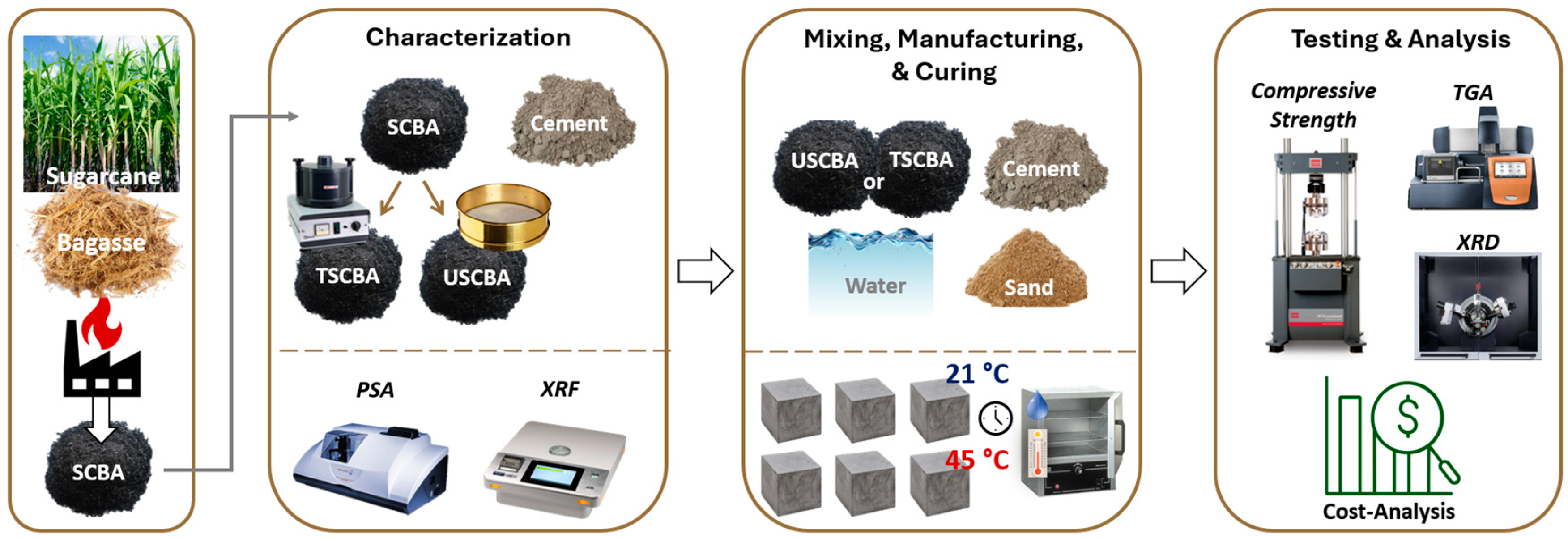

2. Materials and Methods

2.1. Materials

Mix Design, Sample Manufacturing, and Curing Conditions

2.2. Methods

2.2.1. Binders

- Particle size analysis (PSA)

- X-ray fluorescence (XRF)

- Specific gravity and Loss on ignition (LOI)

2.2.2. Pastes

- Thermogravimetric analysis (TGA)

- X-ray powder diffraction (XRD)

2.2.3. Mortars

- Compressive strength

- Modified Strength Activity Index (MSAI)

- Cost Analysis

3. Results and Discussion

3.1. Binders

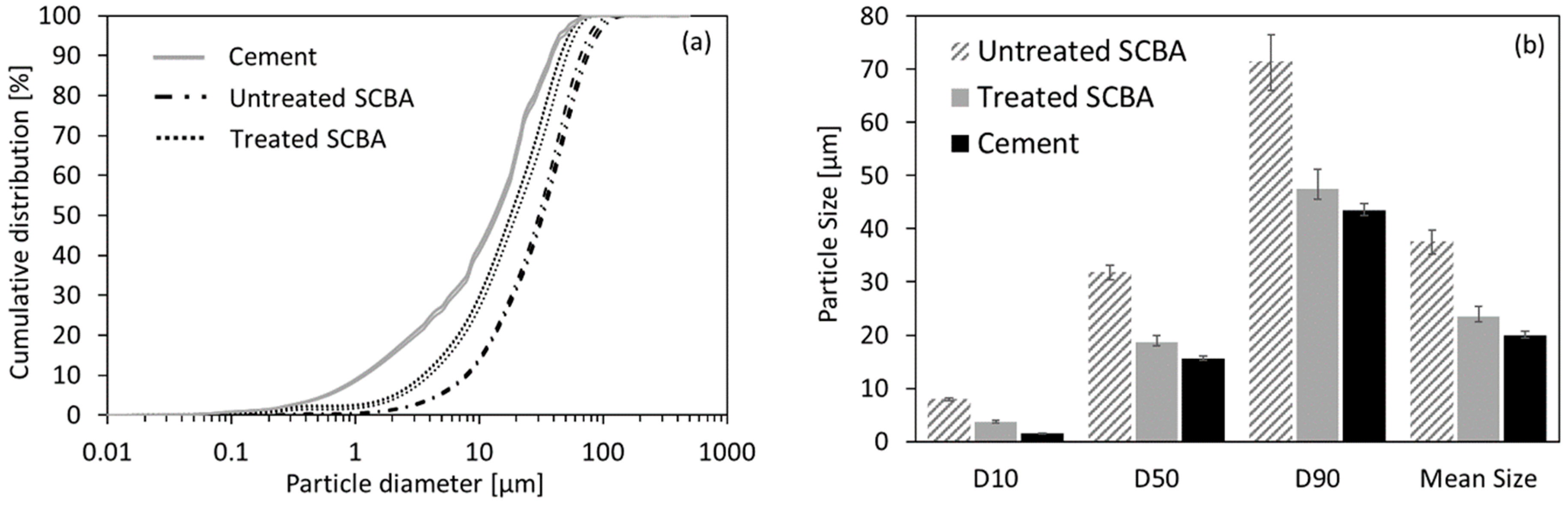

3.1.1. Particle Size Analysis (PSA)

3.1.2. Chemical Composition and Loss on Ignition (LOI)

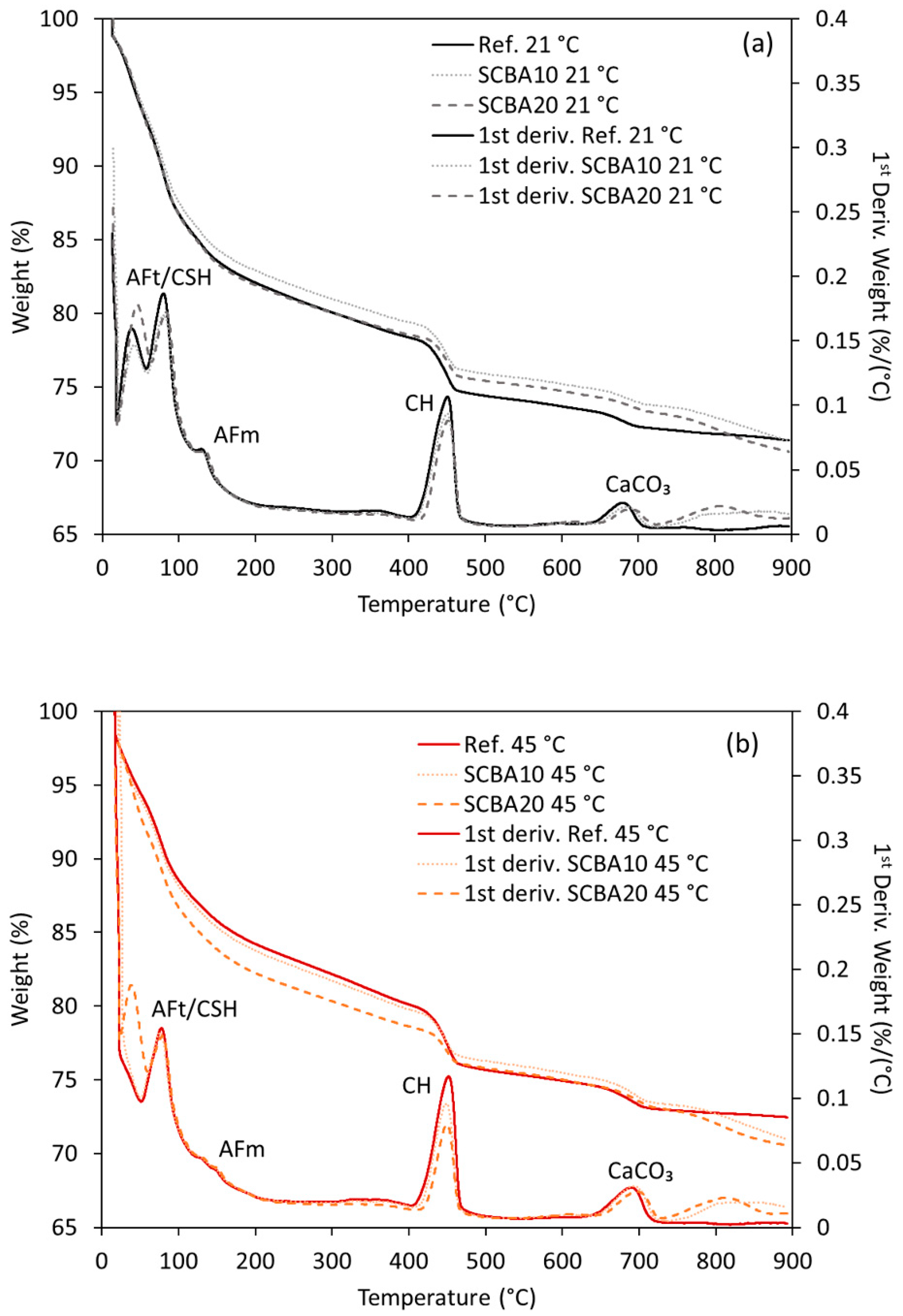

3.2. Pastes

3.2.1. Thermogravimetric Analysis (TGA)

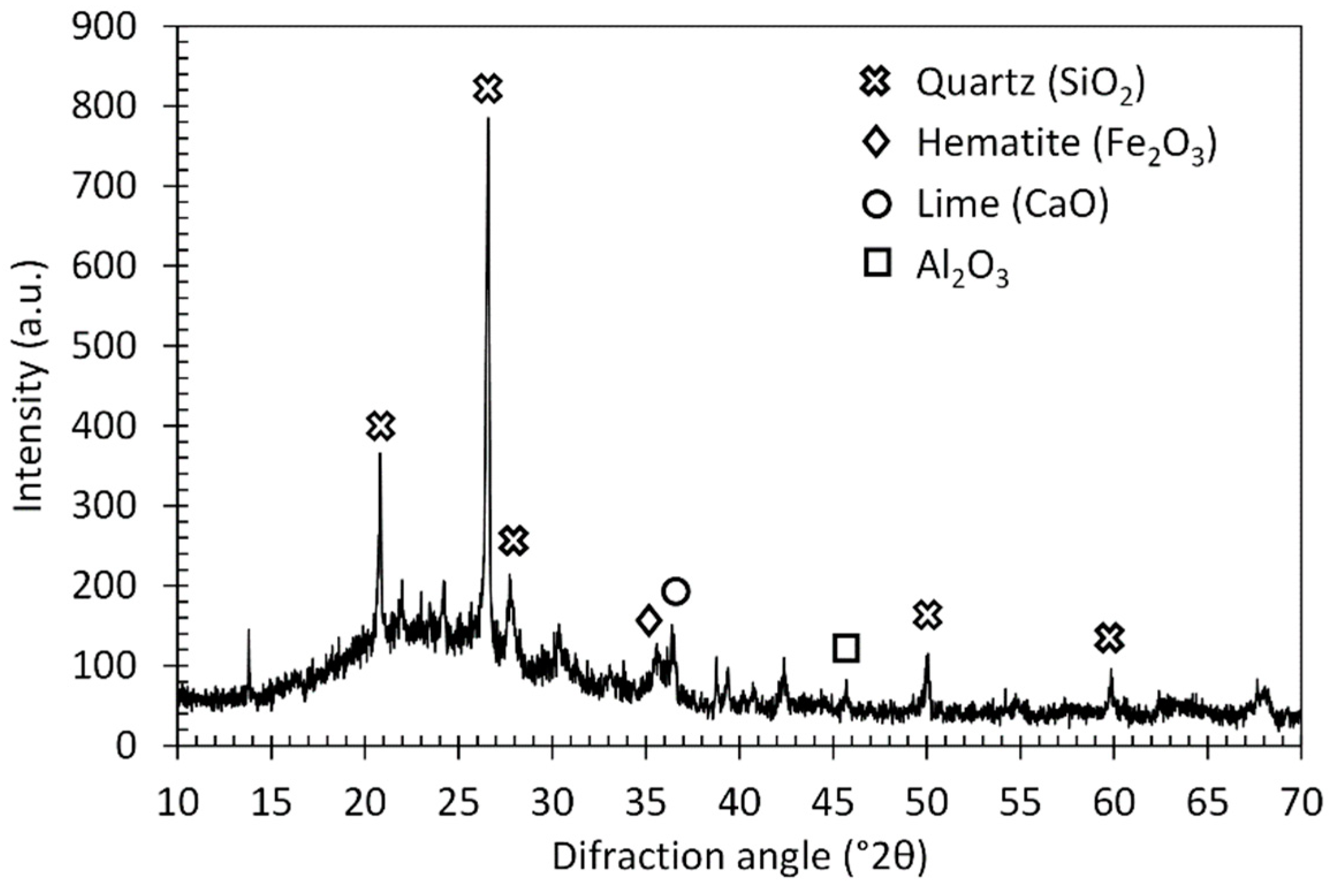

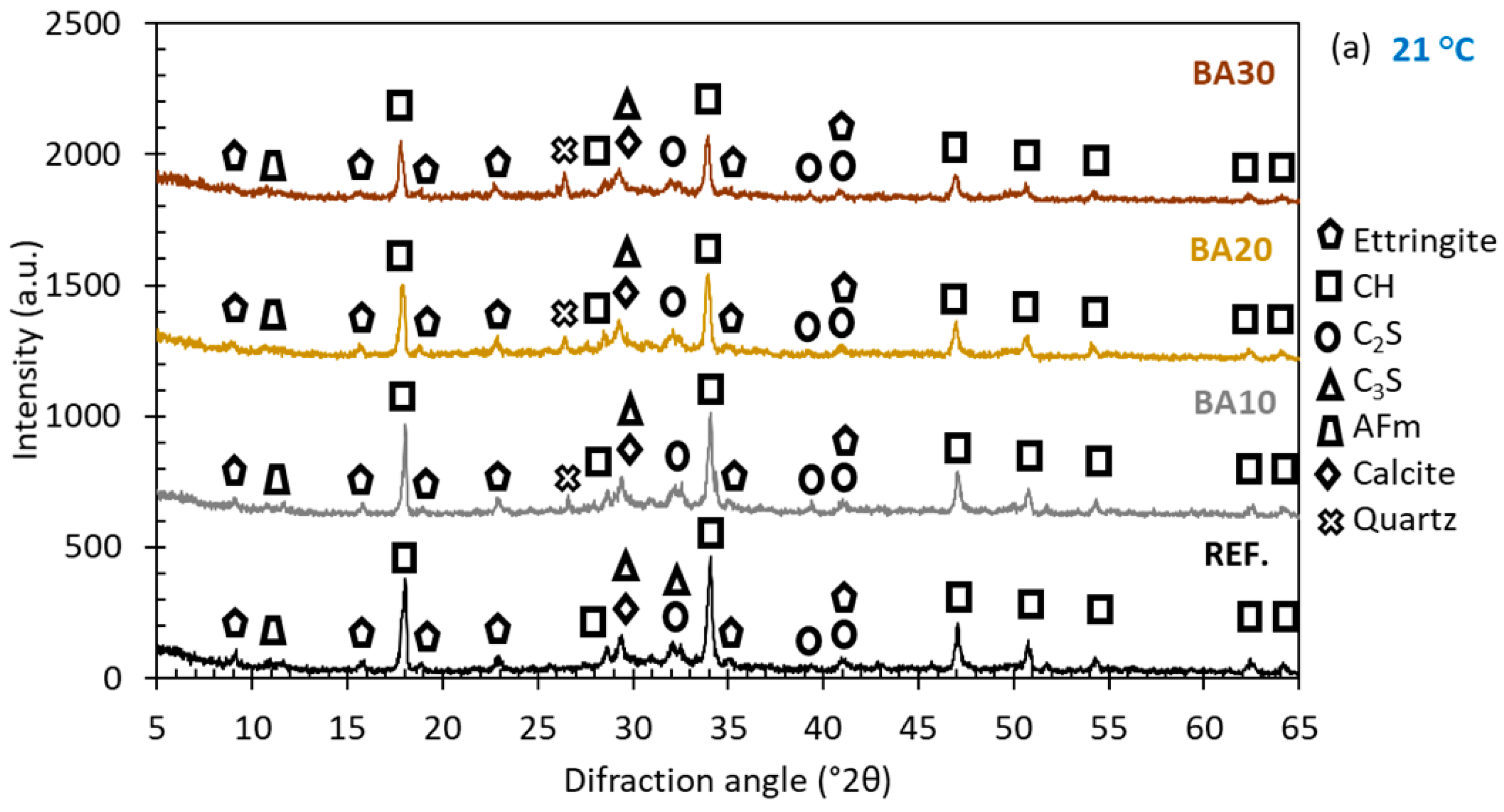

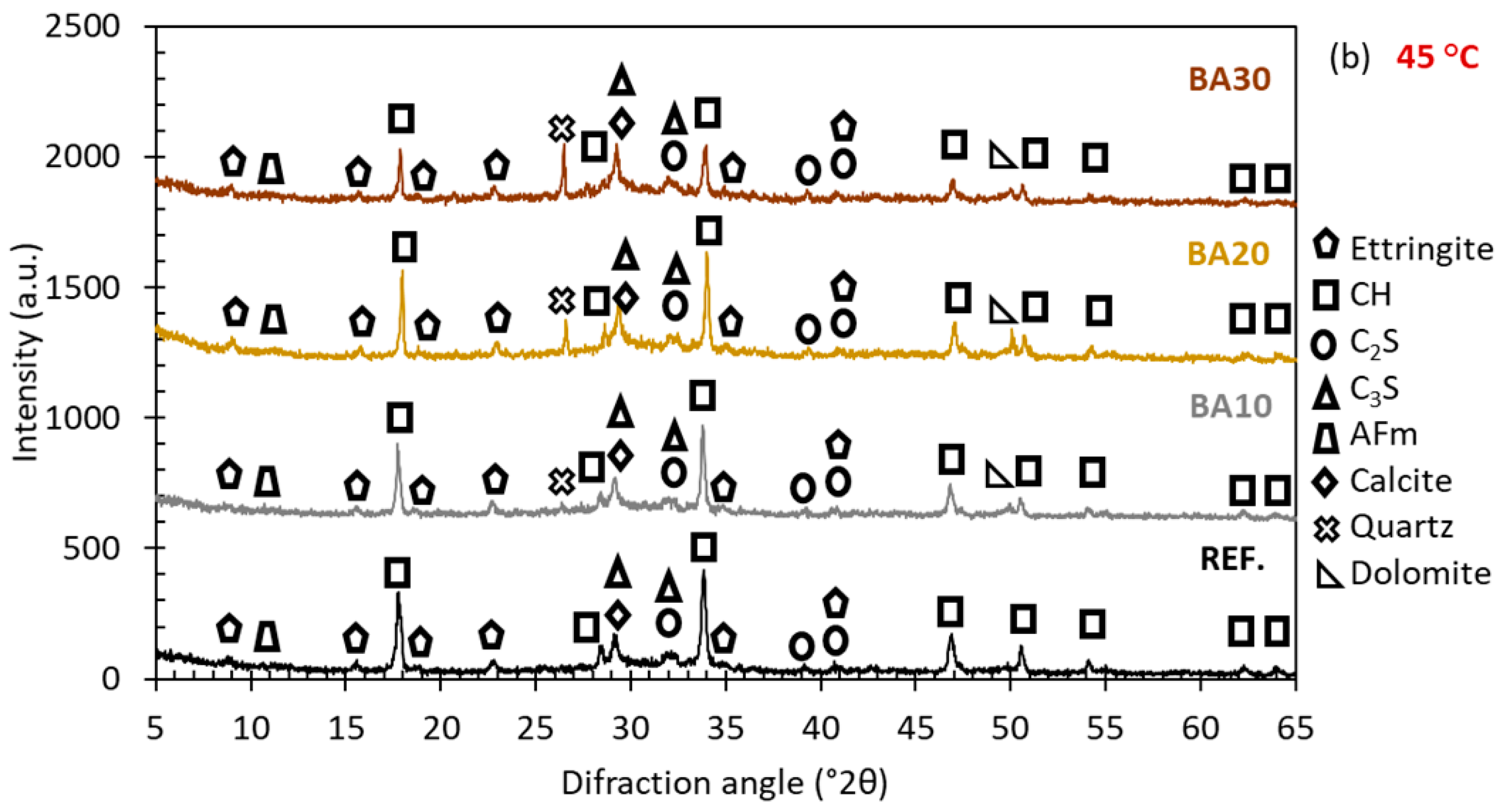

3.2.2. X-Ray Powder Diffraction (XRD)

3.3. Mortars

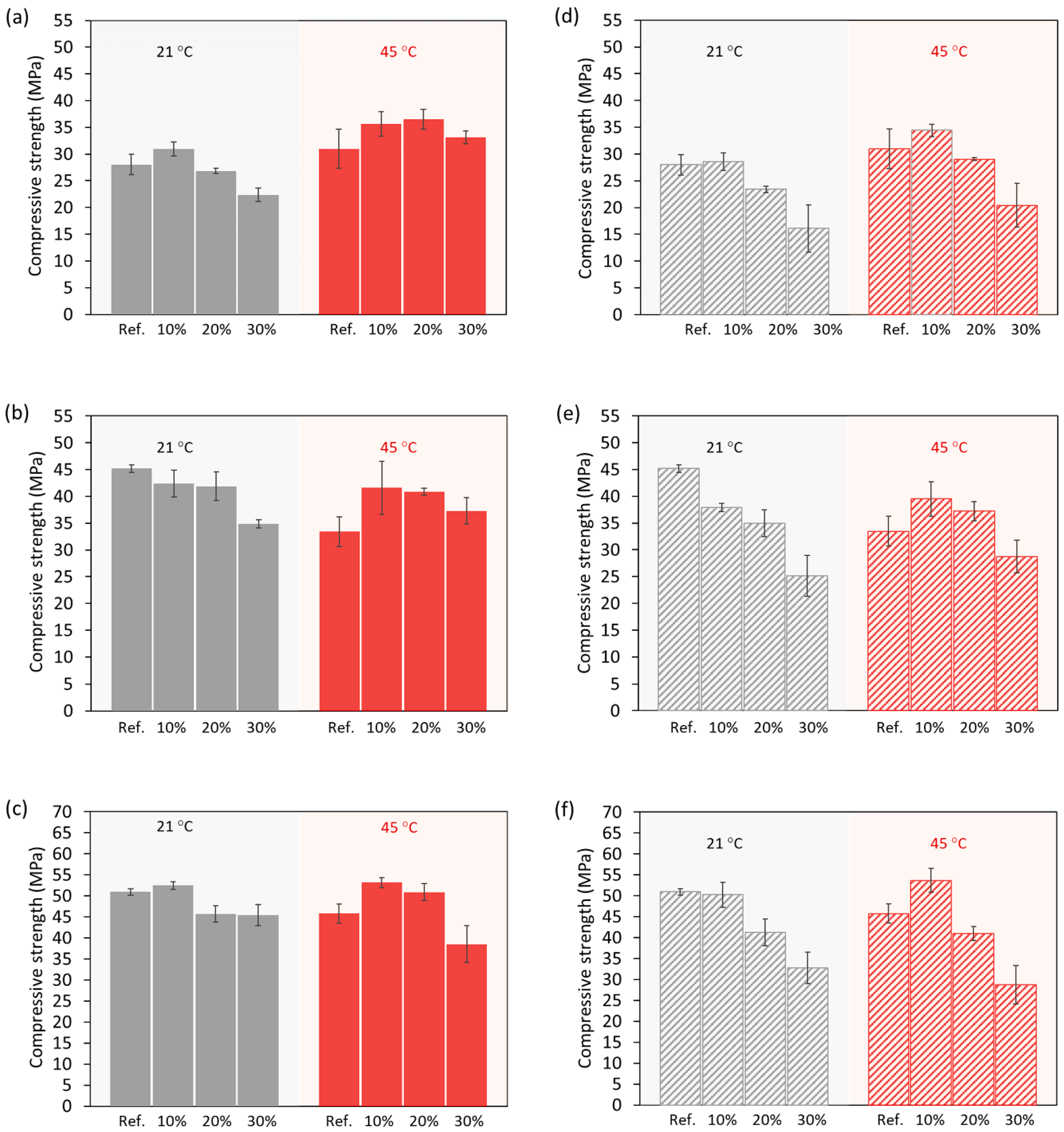

3.3.1. Compressive Strength of Mortars

3.3.2. Cross-Over Effect

3.3.3. Modified Strength Activity Index (MSAI)

3.3.4. Cost-Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cement Production Global 2021|Statista. Available online: https://www.statista.com/statistics/1087115/global-cement-production-volume/ (accessed on 31 May 2022).

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; Deford, H.D.; Townsend, T.G. A Review of Waste Products Utilized as Supplements to Portland Cement in Concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of Coal- and Biomass-Fired Ash in the Production of Self-Consolidating Concrete: A Literature Review. J. Clean. Prod. 2015, 100, 59–76. [Google Scholar] [CrossRef]

- Kolawole, J.T.; Babafemi, A.J.; Fanijo, E.; Chandra Paul, S.; Combrinck, R. State-of-the-Art Review on the Use of Sugarcane Bagasse Ash in Cementitious Materials. Cem. Concr. Compos. 2021, 118, 103975. [Google Scholar] [CrossRef]

- Yadav, A.L.; Sairam, V.; Muruganandam, L.; Srinivasan, K. An Overview of the Influences of Mechanical and Chemical Processing on Sugarcane Bagasse Ash Characterisation as a Supplementary Cementitious Material. J. Clean. Prod. 2020, 245, 118854. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Kurtis, K.E. Effect of Mechanical Processing on Sugar Cane Bagasse Ash Pozzolanicity. Cem. Concr. Res. 2017, 97, 41–49. [Google Scholar] [CrossRef]

- Khan, M.I.; Sayyed, M.A.A.; Ali, M.M.A. Examination of Cement Concrete Containing Micro Silica and Sugarcane Bagasse Ash Subjected to Sulphate and Chloride Attack. Mater. Today Proc. 2020, 39, 558–562. [Google Scholar] [CrossRef]

- Quedou, P.G.; Wirquin, E.; Bokhoree, C. Sustainable Concrete: Potency of Sugarcane Bagasse Ash as a Cementitious Material in the Construction Industry. Case Stud. Constr. Mater. 2021, 14, e00545. [Google Scholar] [CrossRef]

- Larissa, L.C.; Marcos, M.A.; Maria, M.V.; de Souza, N.S.L.; de Farias, E.C. Effect of High Temperatures on Self-Compacting Concrete with High Levels of Sugarcane Bagasse Ash and Metakaolin. Constr. Build. Mater. 2020, 248, 118715. [Google Scholar] [CrossRef]

- ASTM C618-22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use. ASTM International: West Conshohocken, PA, USA, 2022.

- Kamalakar Mali, A.; Nanthagopalan, P. Development of a Framework for the Selection of Best Sugarcane Bagasse Ash from Different Sources for Use in the Cement-Based System: A Rapid and Reliable Path. Constr. Build. Mater. 2021, 293, 123386. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Fairbairn, E.M.R. Effect of Calcination Temperature on the Pozzolanic Activity of Sugar Cane Bagasse Ash. Constr. Build. Mater. 2009, 23, 3301–3303. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Santhanam, M. Influence of Different Processing Methods on the Pozzolanic Performance of Sugarcane Bagasse Ash. Cem. Concr. Compos. 2015, 56, 32–45. [Google Scholar] [CrossRef]

- Jha, P.; Sachan, A.K.; Singh, R.P. Agro-Waste Sugarcane Bagasse Ash (ScBA) as Partial Replacement of Binder Material in Concrete. Mater. Today Proc. 2021, 44, 419–427. [Google Scholar] [CrossRef]

- Barbosa, F.L.; Cordeiro, G.C. Partial Cement Replacement by Different Sugar Cane Bagasse Ashes: Hydration-Related Properties, Compressive Strength and Autogenous Shrinkage. Constr. Build. Mater. 2021, 272, 8–11. [Google Scholar] [CrossRef]

- Lyra, G.P.; Borrachero, M.V.; Soriano, L.; Payá, J.; Rossignolo, J.A. Comparison of Original and Washed Pure Sugar Cane Bagasse Ashes as Supplementary Cementing Materials. Constr. Build. Mater. 2021, 272, 122001. [Google Scholar] [CrossRef]

- Praveenkumar, S.; Sankarasubramanian, G.; Sindhu, S. Strength, Permeability and Microstructure Characterization of Pulverized Bagasse Ash in Cement Mortars. Constr. Build. Mater. 2020, 238, 117691. [Google Scholar] [CrossRef]

- Subedi, S.; Arce, G.; Hassan, M.; Kumar, N.; Barbato, M.; Gutierrez-Wing, M.T. Influence of Production Methodology on the Pozzolanic Activity of Sugarcane Bagasse Ash. MATEC Web Conf. 2019, 271, 07003. [Google Scholar] [CrossRef]

- Soares, M.M.N.S.; Poggiali, F.S.J.; Bezerra, A.C.S.; Figueiredo, R.B.; Aguilar, M.T.P.; Cetlin, P.R. The Effect of Calcination Conditions on the Physical and Chemical Characteristics of Sugar Cane Bagasse Ash. REM Rev. Esc. Minas 2014, 67, 33–39. [Google Scholar] [CrossRef]

- Embong, R.; Shafiq, N.; Kusbiantoro, A.; Nuruddin, M.F. Effectiveness of Low-Concentration Acid and Solar Drying as Pre-Treatment Features for Producing Pozzolanic Sugarcane Bagasse Ash. J. Clean. Prod. 2016, 112, 953–962. [Google Scholar] [CrossRef]

- Mali, A.K.; Nanthagopalan, P. Thermo-Mechanical Treatment of Sugarcane Bagasse Ash with Very High LOI: A Pozzolanic Paradigm. Constr. Build. Mater. 2021, 288, 122988. [Google Scholar] [CrossRef]

- Montakarntiwong, K.; Chusilp, N.; Tangchirapat, W.; Jaturapitakkul, C. Strength and Heat Evolution of Concretes Containing Bagasse Ash from Thermal Power Plants in Sugar Industry. Mater. Des. 2013, 49, 414–420. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Andreão, P.V.; Tavares, L.M. Pozzolanic Properties of Ultrafine Sugar Cane Bagasse Ash Produced by Controlled Burning. Heliyon 2019, 5, e02566. [Google Scholar] [CrossRef] [PubMed]

- Katare, V.D.; Madurwar, M.V. Process Standardization of Sugarcane Bagasse Ash to Develop Durable High-Volume Ash Concrete. J. Build. Eng. 2021, 39, 102151. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; de Moraes Rego Fairbairn, E. Ultrafine Grinding of Sugar Cane Bagasse Ash for Application as Pozzolanic Admixture in Concrete. Cem. Concr. Res. 2009, 39, 110–115. [Google Scholar] [CrossRef]

- Chajec, A.; Chowaniec, A.; Królicka, A.; Sadowski, Ł.; Żak, A.; Piechowka-Mielnik, M.; Šavija, B. Engineering of Green Cementitious Composites Modified with Siliceous Fly Ash: Understanding the Importance of Curing Conditions. Constr. Build. Mater. 2021, 313, 125209. [Google Scholar] [CrossRef]

- Francioso, V.; Moro, C.; Martinez-Lage, I.; Velay-Lizancos, M. Curing Temperature: A Key Factor That Changes the Effect of TiO2 Nanoparticles on Mechanical Properties, Calcium Hydroxide Formation and Pore Structure of Cement Mortars. Cem. Concr. Compos. 2019, 104, 103374. [Google Scholar] [CrossRef]

- Yang, J.; Fan, J.; Kong, B.; Cai, C.S.; Chen, K. Theory and Application of New Automated Concrete Curing System. J. Build. Eng. 2018, 17, 125–134. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Q.; Chen, H. Properties of High-Volume Limestone Powder Concrete under Standard Curing and Steam-Curing Conditions. Powder Technol. 2016, 301, 16–25. [Google Scholar] [CrossRef]

- Hamzah, S.; Aprianti, E. The Effect of Supplementary Cementitious Material Using Thermal Method. In Sustainable Future for Human Security; Springer Nature: Berlin, Germany, 2017; ISBN 9789811054334. [Google Scholar]

- Velay-Lizancos, M.; Martinez-Lage, I.; Azenha, M.; Vázquez-Burgo, P. Influence of Temperature in the Evolution of Compressive Strength and in Its Correlations with UPV in Eco-Concretes with Recycled Materials. Constr. Build. Mater. 2016, 124, 276–286. [Google Scholar] [CrossRef]

- Jiang, P.; Jiang, L.; Zha, J.; Song, Z. Influence of Temperature History on Chloride Diffusion in High Volume Fly Ash Concrete. Constr. Build. Mater. 2017, 144, 677–685. [Google Scholar] [CrossRef]

- Wang, M.; Xie, Y.; Long, G.; Ma, C.; Zeng, X. Microhardness Characteristics of High-Strength Cement Paste and Interfacial Transition Zone at Different Curing Regimes. Constr. Build. Mater. 2019, 221, 151–162. [Google Scholar] [CrossRef]

- Murugesan, T.; Vidjeapriya, R.; Bahurudeen, A. Reuse of Silica Rich Sugarcane Bagasse Ash in Concrete and Influence of Different Curing on the Performance of Concrete. Silicon 2021, 14, 3069–3080. [Google Scholar] [CrossRef]

- Rajasekar, A.; Arunachalam, K.; Kottaisamy, M.; Saraswathy, V. Durability Characteristics of Ultra High Strength Concrete with Treated Sugarcane Bagasse Ash. Constr. Build. Mater. 2018, 171, 350–356. [Google Scholar] [CrossRef]

- Snellings, R.; Mertens, G.; Elsen, J. Supplementary Cementitious Materials. Rev. Mineral Geochem. 2012, 74, 211–278. [Google Scholar] [CrossRef]

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C188; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C311; Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Scrivener, K.L.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; Taylor and Francis Ltd.: Abingdon, UK, 2016. [Google Scholar]

- Doebelin, N.; Kleeberg, R. Profex: A Graphical User Interface for the Rietveld Refinement Program BGMN. J. Appl. Crystallogr. 2015, 48, 1573–1580. [Google Scholar] [CrossRef] [PubMed]

- ASTM C349-18; Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure). ASTM International: West Conshohocken, PA, USA, 2018.

- U.S. Geological Survey. Mineral Commodity Summaries 2023; U.S. Geological Survey: Reston, VA, USA, 2023. [CrossRef]

- American Water Works Association. Raftelis Financial Consulting 2021 Water and Wastewater Rate Survey; American Water Works Association: Denver, CO, USA, 2021. [Google Scholar]

- Kosmatka, S.H.; Wilson, M.L. Design and Control of Concrete Mixtures, 16th ed.; Portland Cement Association: Skokie, IL, USA, 2016. [Google Scholar]

- Kim, T.; Olek, J. Effects of Sample Preparation and Interpretation of Thermogravimetric Curves on Calcium Hydroxide in Hydrated Pastes and Mortars. Transp. Res. Rec. J. Transp. Res. Board 2012, 2290, 10–18. [Google Scholar] [CrossRef]

- Yousuf, S.; Shafigh, P.; Ibrahim, Z.; Hashim, H.; Panjehpour, M. Crossover Effect in Cement-Based Materials: A Review. Appl. Sci. 2019, 9, 2776. [Google Scholar] [CrossRef]

- Boxman, S.; Stanley, B.F. Analysis of MSW Landfill Tipping Fees—2020; Environmental Research & Education Foundation: Raleigh, NC, USA, 2021. [Google Scholar]

- Arce, G.A.; Hassan, M.M.; Gutierrez-Wing, M.; Barbato, M.; Louisiana State University (Baton Rouge, La.); Transportation Consortium of South-Central States (Tran-SET) University Transportation Center for Region 6. Use of Bagasse Ash as a Concrete Additive for Road Pavement Applications; Transportation Consortium of South-Central States: Washington, DC, USA, 2019. [Google Scholar] [CrossRef]

- Ro, J.W.; Cunningham, P.R.; Miller, S.A.; Kendall, A.; Harvey, J. Technical, Economic, and Environmental Feasibility of Rice Hull Ash from Electricity Generation as a Mineral Additive to Concrete. Sci. Rep. 2024, 14, 9158. [Google Scholar] [CrossRef]

| Component | Reference | 10% SCBA | 20% SCBA | 30% SCBA |

|---|---|---|---|---|

| Cement (kg) | 486.39 | 437.75 | 389.12 | 340.48 |

| SCBA (kg) | 0.00 | 48.64 | 97.28 | 145.92 |

| Sand (SSD) (kg) | 1459.18 | 1459.18 | 1459.18 | 1459.18 |

| w/b | 0.50 | 0.50 | 0.50 | 0.50 |

| Water (kg) | 243.20 | 243.20 | 243.20 | 243.20 |

| Compound | Cost (USD) | Source [43,44] |

|---|---|---|

| Cement | 130.00/ton | US Geological Survey, 2023 |

| Natural aggregate | 11.00/ton | US Geological Survey, 2023 |

| Water | 1.25/ton | EPA WaterSense, 2021 |

| SCBA | 30/ton | See Results and Discussion |

| Compound | SCBA | OPC Type-I | SCBA [4,5] Mean (Min.–Max.) | OPC Type-I [45] Mean (Min.–Max.) | Fly Ash Type-C [2,45] | Fly Ash Type-F [2,45] | Slag Cement [2,45] | Silica Fume [2,45] |

|---|---|---|---|---|---|---|---|---|

| (%) | ||||||||

| Al2O3 | 13.85 | 5.08 | 5.37 (1.33–15.00) | 5.1 (4.40–5.70) | 18.0 | 23.0 | 12.0 | 0.4 |

| CaO | 9.98 | 64.60 | 3.54 (0.51–16.06) | 63.3 (60.7–64.6) | 21.0 | 5.0 | 40.0 | 1.6 |

| Fe2O3 | 8.57 | 2.68 | 3.69 (0.60–10.80) | 2.5 (1.3–3.6) | 6.0 | 11.0 | 1.0 | 0.4 |

| K2O | 1.39 | 0.75 | 2.68 (0.36–12.80) | Combined with Na2O | 0.7 | 2.0 | 0.4 | 2.2 |

| MgO | 2.07 | 2.77 | 1.36 (0.10–6.68) | 2.3 (0.8–3.3) | - | - | - | - |

| Mn2O3 | 1.25 | 0.02 | 0.16 (0.05–1.23) | - | - | - | - | - |

| Na2O | 0.51 | 0.11 | 0.35 (0.02–1.49) | 0.62 (0.3–1.0) | 5.8 | 1.0 | 0.3 | 0.5 |

| P2O5 | 0.21 | 0.10 | 1.05 (0.19–6.12) | - | - | - | - | - |

| SiO2 | 54.97 | 21.38 | 63.57 (22.95–85.17) | 19.8 (18.8–20.6) | 35.0 | 52.0 | 35.0 | 90.0 |

| SO3 | 0.93 | 3.24 | 0.51 (0.03–4.38) | 3.3 (2.5–4.1) | 4.1 | 0.8 | 2.0 | 0.4 |

| SrO | 0.16 | 0.03 | - | - | - | - | - | - |

| TiO2 | 1.60 | 0.29 | 0.58 (0.08–3.68) | - | - | - | - | - |

| SiO2 + Al2O3 + Fe2O3 | 77.39 | 29.14 | 74.83 (27.20–91.92) | 27.4 | 59.0 | 86.0 | 48.0 | 90.8 |

| Relative density | 2.16 | 3.12 | 2.12 (1.85–2.47) | 3.15 | 2.65 | 2.38 | 2.94 | 2.40 |

| LOI | 13.76–16.55 | 2.48 | 7.04 (0.40–59.20) | 0.0–3.3 | 0.3–3.5 | 0.2–7.2 | 1.0 | 0.0–2.8 |

| Calcium Hydroxide (%) | ||

|---|---|---|

| 21 °C | Reference | 23.83 |

| 10% | 20.83 | |

| 20% | 18.79 | |

| 45 °C | Reference | 27.74 |

| 10% | 23.23 | |

| 20% | 18.91 | |

| SCBA Replacement | Cement | SCBA | Sand | Water | Cost of Mixture | |

|---|---|---|---|---|---|---|

| (%) | (metric ton) | (per m3) | (Δ$) | |||

| 0 | 0.49 | 0.00 | 1.46 | 0.24 | $ 79.59 | - |

| 10 | 0.44 | 0.05 | 1.46 | 0.24 | $ 74.68 | −6.16% |

| 20 | 0.39 | 0.10 | 1.46 | 0.24 | $ 69.78 | −12.32% |

| 30 | 0.34 | 0.15 | 1.46 | 0.24 | $ 64.88 | −18.48% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Francioso, V.; Lemos-Micolta, E.D.; Elgaali, H.H.; Moro, C.; Rojas-Manzano, M.A.; Velay-Lizancos, M. Valorization of Sugarcane Bagasse Ash as an Alternative SCM: Effect of Particle Size, Temperature-Crossover Effect Mitigation & Cost Analysis. Sustainability 2024, 16, 9370. https://doi.org/10.3390/su16219370

Francioso V, Lemos-Micolta ED, Elgaali HH, Moro C, Rojas-Manzano MA, Velay-Lizancos M. Valorization of Sugarcane Bagasse Ash as an Alternative SCM: Effect of Particle Size, Temperature-Crossover Effect Mitigation & Cost Analysis. Sustainability. 2024; 16(21):9370. https://doi.org/10.3390/su16219370

Chicago/Turabian StyleFrancioso, Vito, Erika D. Lemos-Micolta, Husam H. Elgaali, Carlos Moro, Manuel Alejandro Rojas-Manzano, and Mirian Velay-Lizancos. 2024. "Valorization of Sugarcane Bagasse Ash as an Alternative SCM: Effect of Particle Size, Temperature-Crossover Effect Mitigation & Cost Analysis" Sustainability 16, no. 21: 9370. https://doi.org/10.3390/su16219370

APA StyleFrancioso, V., Lemos-Micolta, E. D., Elgaali, H. H., Moro, C., Rojas-Manzano, M. A., & Velay-Lizancos, M. (2024). Valorization of Sugarcane Bagasse Ash as an Alternative SCM: Effect of Particle Size, Temperature-Crossover Effect Mitigation & Cost Analysis. Sustainability, 16(21), 9370. https://doi.org/10.3390/su16219370