Abstract

Sustainable construction (SC) has become a primary objective of the building and construction industry due to the growing demand for reduced environmental impacts and more efficient resource use. Simultaneously, lean construction (LC), which focuses on minimizing waste and maximizing productivity, offers an opportunity to achieve greater sustainability in the construction process. This study explores the integration of LC and SC through a systematic literature review, employing VOSviewer software for quantitative analysis alongside qualitative analysis in conjunction with a comprehensive literature review. The findings reveal substantial synergies between LC and SC, including cost savings, waste reduction, and enhanced safety. However, challenges such as cost conflicts, environmental trade-offs, and worker welfare concerns act as barriers to effective integration. To address these challenges, this study proposes leveraging dynamic capabilities (DCs)—such as change management, organizational learning, organizational flexibility, and continuous improvement and innovation—as strategies for the successful integration of LC and SC. These insights contribute to academic research and industry practice, providing a practical framework for integrating LC and SC to improve sustainability and efficiency in construction projects.

1. Introduction

The construction industry is widely regarded as a high resource-consuming sector that generates significant waste [1]. It profoundly impacts regional economies, natural environments, and human well-being. If the reduction and elimination of waste are not prioritized, resources will continue to be depleted, rendering processes and operations unsustainable. In light of the push for clean production and resource conservation, the construction industry urgently requires more effective management approaches to adapt to the sustainable development needs of society. As such, there is both potential and a pressing need for the construction sector to adopt sustainable development practices.

Lean construction (LC) originated from lean manufacturing, with Koskela [2] introducing it in 1992 to improve project efficiency by minimizing waste and maximizing value. He proposed that the construction process can be analyzed as a production process through three perspectives, transformation, flow, and value creation, forming the basis of the ‘TFV theory’ for lean construction implementation (transformation, flow, value generation) [3,4]. The following year, Glenn Ballard proposed the Last Planner System (LPS) [5], which has been continuously improved and is now an important implementation tool for lean construction. In addition, methods such as just-in-time (JIT), 5S, virtual design construction (VDC), and concurrent engineering (CE) are also key lean construction tools [6]. Over time, LC has been applied to various construction projects, where it has proven effective in reducing waste, enhancing productivity, and promoting cost-efficiency [7,8].

On the other hand, sustainable construction (SC) emerged as a response to growing environmental concerns. Green buildings are also known as eco-buildings, sustainable buildings, energy-efficient buildings, etc. [9]. Kibert [10] defined green building as ‘(sustainable) construction as the practice of creating and operating a healthy built environment based on resource efficiency and ecological principles’. SC aims to reduce the environmental impact of construction by adopting eco-friendly practices, such as resource efficiency, waste reduction, and the use of sustainable materials [11,12]. As the world becomes more sensitive and concerned about global climate change and sustainable development, which fully integrates building design and sustainability goals in a healthier way that protects ecosystems and human health [13], the construction industry is actively promoting the construction of more green buildings.

The synergy between LC and SC is primarily driven by their shared focus on reducing waste and improving efficiency [14,15]. LC’s waste-reduction practices align well with the sustainability objectives of SC, which seek to minimize environmental degradation and optimize resource usage [16]. Exploring ways to combine LC and SC not only addresses the limitations of each approach but also better coordinates their simultaneous implementation, mitigating potential conflicts during execution. This will help the construction industry to maintain its competitiveness in terms of economic efficiency and at the same time realize the sustainable development of the environment and society.

While there are many benefits to integrating LC and SC, there are no studies that discuss the drivers or implementation dilemmas of integrating LC and SC as a whole. These articles have yet to provide a complete analysis of the relationship between LC and SC from the perspective of LC and SC integration. Furthermore, there is a lack of a specific methodology or strategy framework to improve or enhance the integration of LC and SC. In addition, although dynamic capability (DC) has been shown to improve lean principles and sustainable performance [17,18], it has never been applied to strengthen the link between LC and SC in the construction field.

Therefore, the main objective of this study is to comprehensively explore the relationship between LC and SC from the perspective of LC and SC integration, integrate existing implementation dilemmas, and find new opportunities and new methods to mitigate the conflicts and contradictions between the two based on the dilemmas. The specific objectives are: (1) To comprehensively identify the interactions that drive LC and SC integration. (2) Investigate the conceptual conflicts and potential challenges involved in the integration of LC and SC. (3) To propose the use of DC to overcome the challenges of LC–SC integration based on the identified dilemmas. (4) Propose a strategic framework for effective integration of LC and SC with DC participation that guides organizations on how to realize SC from a DC perspective using LC principles.

This study systematically analyses the convergence of LC and SC, revealing their synergies and challenges, thus making new contributions. Although LC and SC have traditionally been viewed as two separate fields, this study highlights their complementary strengths, such as cost savings, waste reduction, and improved safety. In particular, the introduction of DC as a strategy to address integration challenges is a key innovation. By focusing on change management, organizational learning, organizational flexibility, and continual improvement and innovation, this study provides a practical framework for businesses to effectively integrate LC and SC, laying the groundwork for academia and industry to adopt construction practices that are more sustainable and efficient, whilst taking into account economic, environmental and social objectives.

2. Literature Review

2.1. Integration of Lean Construction and Sustainable Construction

In the context of the growing global focus on the Sustainable Development Goals, scholars have increasingly explored the integration of LC and SC. Topics covered include, but are not limited to, the benefits of integrating LC and SC, incentives for integrating LC and SC [14,19,20,21], difficulties encountered in integrating LC and SC [14,22], and the combination of the two with other technologies (BIM [20,23], Six Sigma [22], etc.). Scholars have also examined the integration of lean and sustainable principles in various project types, including multifamily projects [24], small buildings [25], high-rise residential projects [26,27,28], condominium projects [29], road infrastructure [30], and so on. As well as the integration of LC and SC combinations into the different life cycles of buildings, from the design phase [27,31], the construction phase [15], the use phase [32] up to the dismantling and recycling phase [31].

Some authors have developed integration matrices to explore the interconnections between LC and SC [23,26,33,34,35], highlighting the benefits of combining these two approaches. These advantages include waste reduction, value maximization, collaboration, supply chain integration, continuous improvement, focus on people, resource management, reduction in environmental impacts, improvement in health and safety conditions, quality management, reduction in costs and lead times, improvement in community well-being, transparency, and reliability [14,15,26,36,37].

Existing practices in LC–SC integration have demonstrated clear benefits, such as waste reduction, cost savings, and productivity improvements [38,39]. Lean tools, like LPS and Value Stream Mapping (VSM), have been effective in streamlining workflows and minimizing resource use. Furthermore, the integration of technologies, like Building Information Modeling (BIM), has enhanced planning and coordination, contributing to both lean and sustainable outcomes [40].

While there are clear synergies between LC and SC, scholars have also identified significant challenges in their integration. The additional initial cost of the project, the difficulty of providing expertise, the reluctance of contractors to adopt additional requirements, the challenge of establishing a high level of teamwork, and the absence or ineffectiveness of government incentives were cited as challenges that hindered the integration of LC with SC [14,41].

LC traditionally emphasizes economic efficiency, often focusing on cost savings and process standardization. This focus can sometimes conflict with SC’s objectives, which require context-specific adaptations, particularly regarding environmental and social outcomes [42,43]. Some critics argue that applying LC in projects focused on sustainability may overlook key environmental concerns, such as emissions or resource depletion [44]. Moreover, LC’s emphasis on efficiency and speed can lead to increased stress on construction workers, raising concerns about social sustainability [45]. This criticism highlights the need for a balanced approach that integrates SC’s focus on environmental and social sustainability with LC’s economic efficiency and waste-reduction principles [46].

These articles have not yet provided a complete analysis of the relationship between LC and SC from the perspective of LC and SC integration, i.e., apart from the obvious synergies, the ambivalent relationship between LC and SC has only been mentioned by very few articles. Beyond the obvious synergies, very few articles mention the ambivalent relationship between LC and SC, and there is no further discussion of relationships outside of this synergistic ambivalence. On the other hand, even if contradictions in the integration process of LC and SC are identified, there are no specific methods or strategies to improve or enhance them.

2.2. Dynamic Capabilities as a Response to Solutions

The static and unchanging implementation of LC is likely to result in negative sustainable performance outcomes, and Mohaghegh et al. [47] suggest that this occurs because lean management practices themselves do not always positively lead to sustainable results. Therefore, to maintain competitiveness in a dynamic environment, organizations must continuously develop their DCs [46].

DC, as proposed by Teece et al. [48], dictates how enterprises can attain and sustain competitive advantages. The microfoundations of DC involve the ability to perceive, seize, and reconfigure organizational resources and capacities to attain sustainable competitive advantages. They enable companies to continually renew operational capabilities and adapt to long-term environmental changes.

There are many scholars who claim that lean practices with the help of DC can contribute to the sustainable business performance of an organization [6,46,47]. For instance, Mohaghegh found that DC serves as the mechanism by which lean management promotes sustainable performance, as demonstrated in a study of the Italian manufacturing industry [47]. Gutierrez et al. identified DC microfoundations as key enablers for companies to implement lean practices that drive higher levels of process innovation, emphasizing the crucial role of lean culture [49]. Ndrecaj et al. argue that integrating the DC microfoundation with Lean Six Sigma not only allows organizations to identify improvement opportunities but also to act on them efficiently and effectively, ultimately leading to sustainable performance optimization across all aspects of the business [17].

Because lean practices are often considered as zero-order capabilities [50]—delivering short-term benefits—rigid implementation in dynamic environments may not produce sustainable results. DCs, regarded as ‘higher-order’ capabilities, are designed to continuously update existing practices and facilitate the seamless integration of LC and SC. DCs enhance the integration, learning, and transformation of Lean knowledge, resources and competences, ultimately increasing the efficiency of lean transformations and improving the effectiveness of lean practices at the operational level [18]. In this sense, DCs offer a pathway for organizations to transition lean principles from static tools into adaptive systems that better align with long-term sustainability goals.

Consequently, mastering the DC relevant to integrating LC with SC is essential for construction companies to achieve sustainable outcomes. Although a limited number of scholars have recognized that DC can help organizations leverage lean principles to enhance sustainable performance, existing research primarily focuses on the manufacturing and supply chain sectors, with little to no mention of the construction industry. In the context of LC and SC, the role of DC has received relatively little attention.

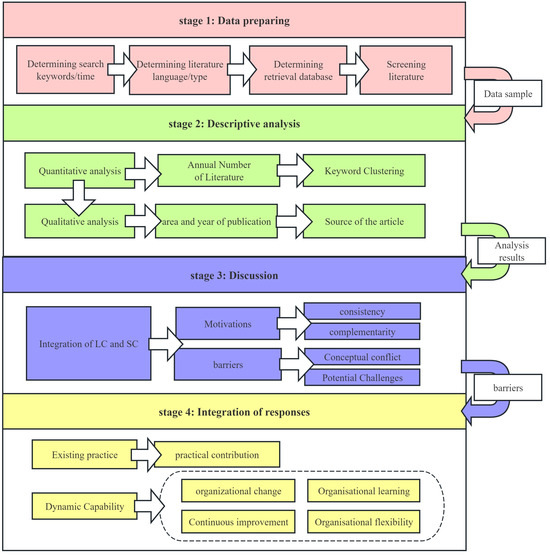

3. Materials and Methods

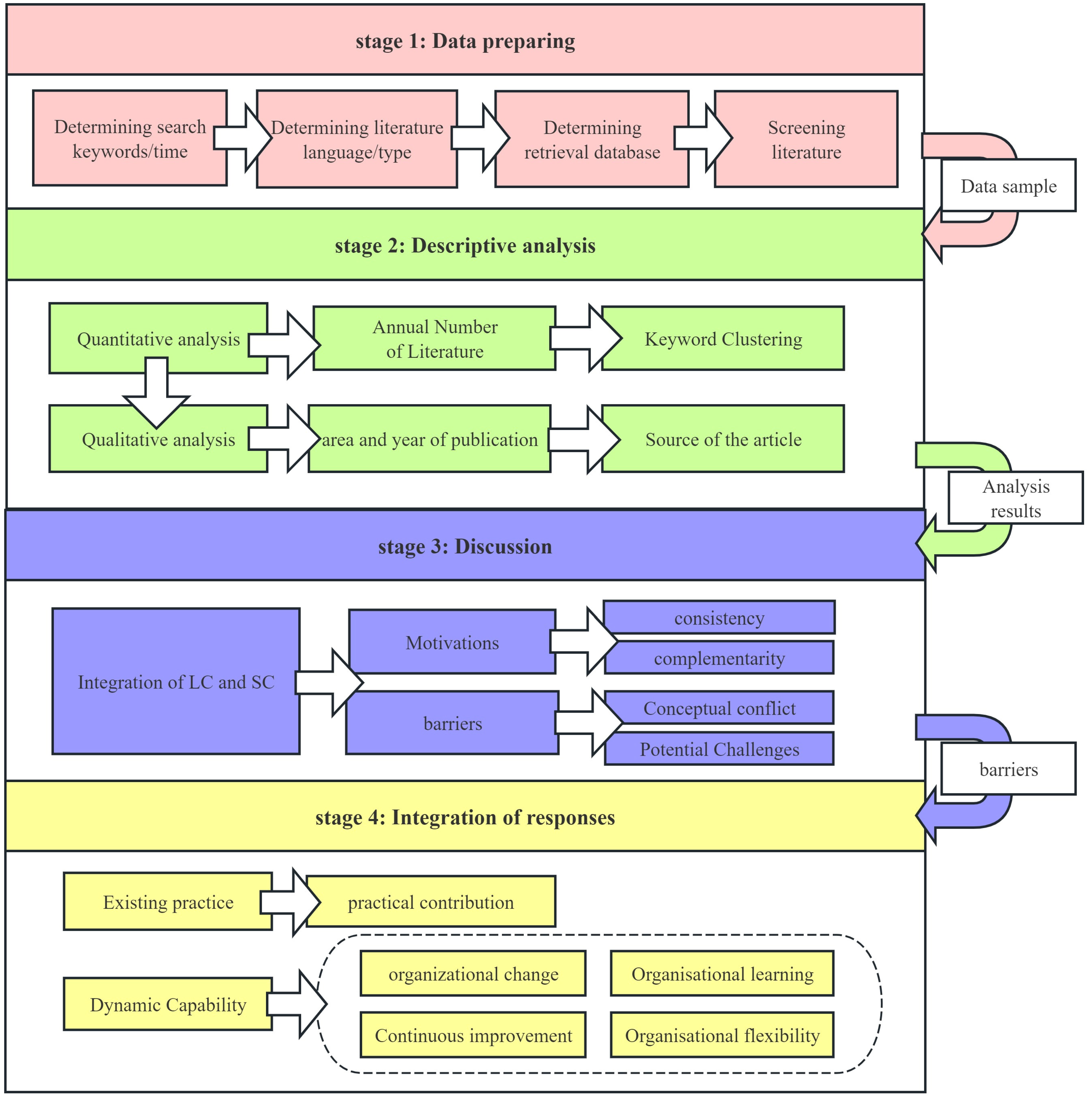

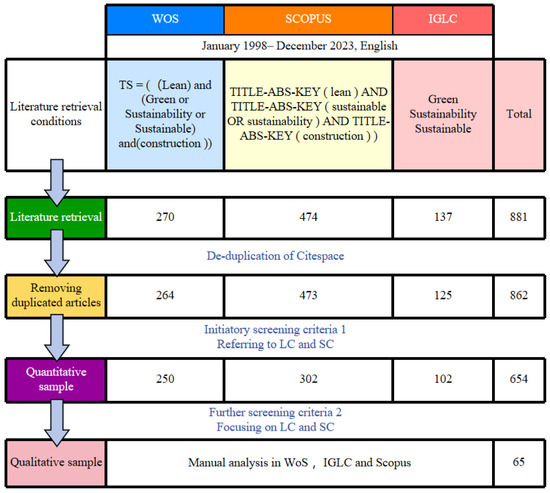

This study utilizes a four-stage research framework, as shown in Figure 1. A mixed-methods approach, combining both quantitative and qualitative methods, was employed. This combination helps in obtaining a comprehensive understanding of the publications on the integration of LC and SC and stimulates potential research areas.

Figure 1.

Research framework of the article.

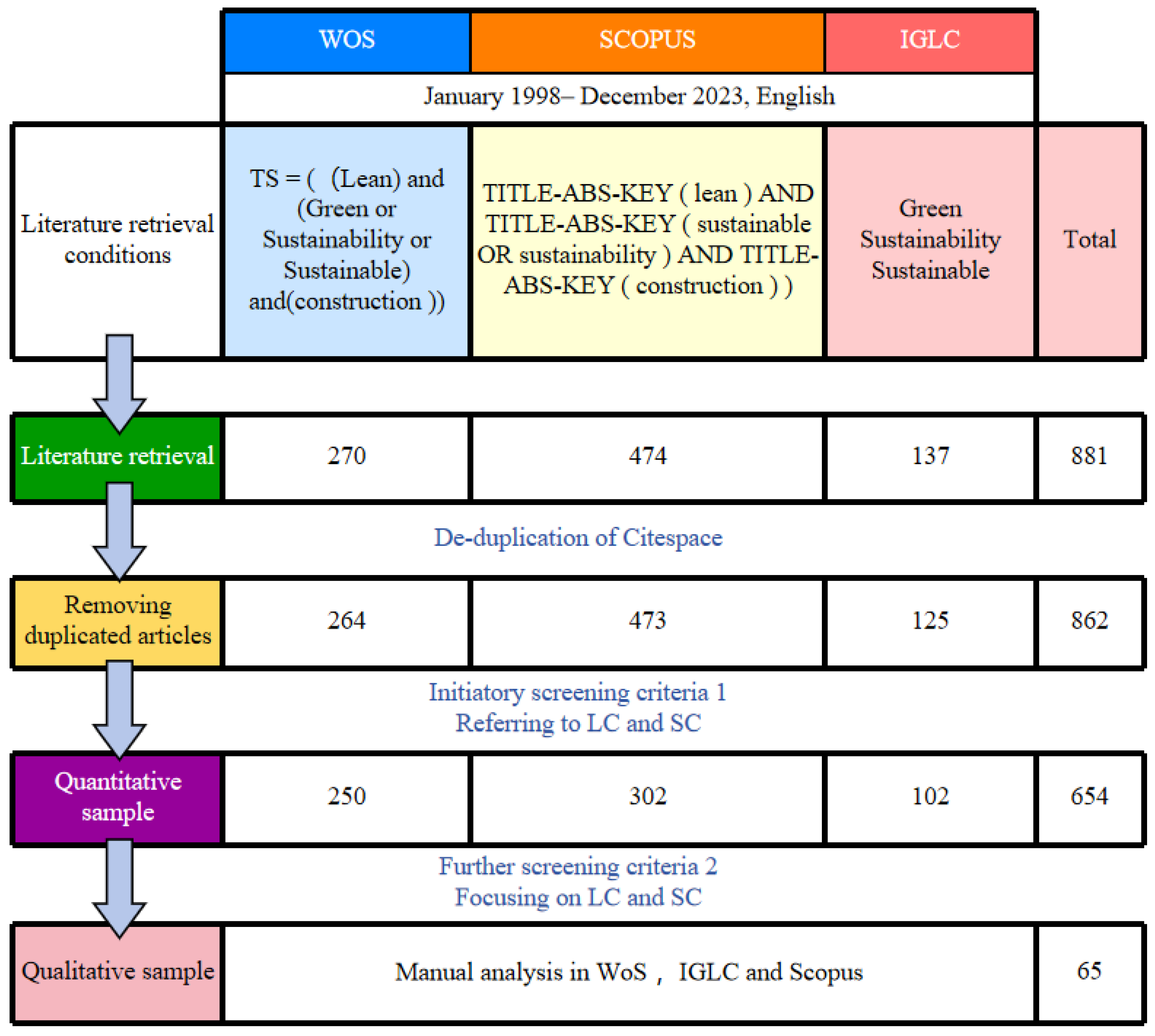

Web of Science (WoS) and Scopus are both authoritative databases, and in order to ensure that the data are as comprehensive as possible, this study utilized literature from both databases to complement each other. Figure 2 shows the literature search conditions for the WoS and Scopus databases. Additionally, the International Group for Lean Construction (IGLC) is a globally recognized authority on LC, consisting of professionals and researchers in the field. However, the WoS database does not include IGLC conference papers, and some are missing from the Scopus database; therefore, we selected conference papers from the IGLC official website (http://iglc.net/Papers, accessed on 14 June 2024) as a supplement.

Figure 2.

Processing of literature data.

Literature acquisition and processing consisted of four steps, initially, by focusing on the subject and field, the selected keywords were “lean”, “green”, “sustainability”, “sustainable”, and “construction”. Articles completed between January 1998 and December 2023 were studied. This choice was based on Lauri Koskela’s 1998 IGLC article that first combined LC and sustainability. The types of literature selected include journal articles, conference papers, and reviews written in English.

The search was performed on WoS, Scoupus, and IGLC, and the keywords searched are shown in Figure 2. A total of 270 articles were found in the WoS core collection, 474 in Scopus, and 137 in IGLC. After ensuring that these articles met the initiatory screening criteria 1 (referring to LC and SC) using citespace’s document de-duplication function, 250 documents were retained by WoS, 473 by Scopus, and 102 by IGLC.

Subsequently, a total of 862 articles underwent two rounds of screening to obtain a sample of literature for quantitative and qualitative analysis. In the fourth step, after screening articles related to LC and SC integration, 654 articles were selected for quantitative analysis using VOSviewer. Literature data in ‘ris’ form downloaded from Scoupus and IGLC were converted uniformly into ‘txt’ form downloaded from WoS using Citespace, and then bibliographic data were used to create keyword maps on Vosviewer. For the more cluttered and unorganized keyword co-occurrence maps generated, we used Pajek5.19 software to process them so that they are clustered according to color.

Finally, given the limited information provided by the quantitative literature, a ‘snowballing’ approach was used to select high-quality literature for detailed qualitative analysis. In more detail, this involved using a reverse snowballing method based on a quantitative study of the literature sample to identify earlier relevant studies by consulting the bibliography, and a forward snowballing method using a citation tool to locate articles that had recently cited key papers. This iterative process extends the literature base and provides a comprehensive analysis of both basic and recent research.

Ultimately, 65 quantitative samples were collected, and the process followed the following principles for inclusion or exclusion from the literature:

- Priority will be given to high-quality studies with in-depth analyses, methodological rigor, and comprehensive data. Based on the quantitative sample, representative articles, such as highly cited or recently published articles, will be selected from publications in leading journals in the LC and SC directions.

- Include studies that represent a variety of viewpoints and research methods (case studies, empirical studies, theoretical frameworks) to provide a broad understanding of the topic.

- Articles retrieved based on the “snowballing” method have historical threads linking them together to show the development of the research.

- To ensure that screening criterion 2 is met (representative articles where the research theme is essentially centered on the combination of LC and SC).

4. Results

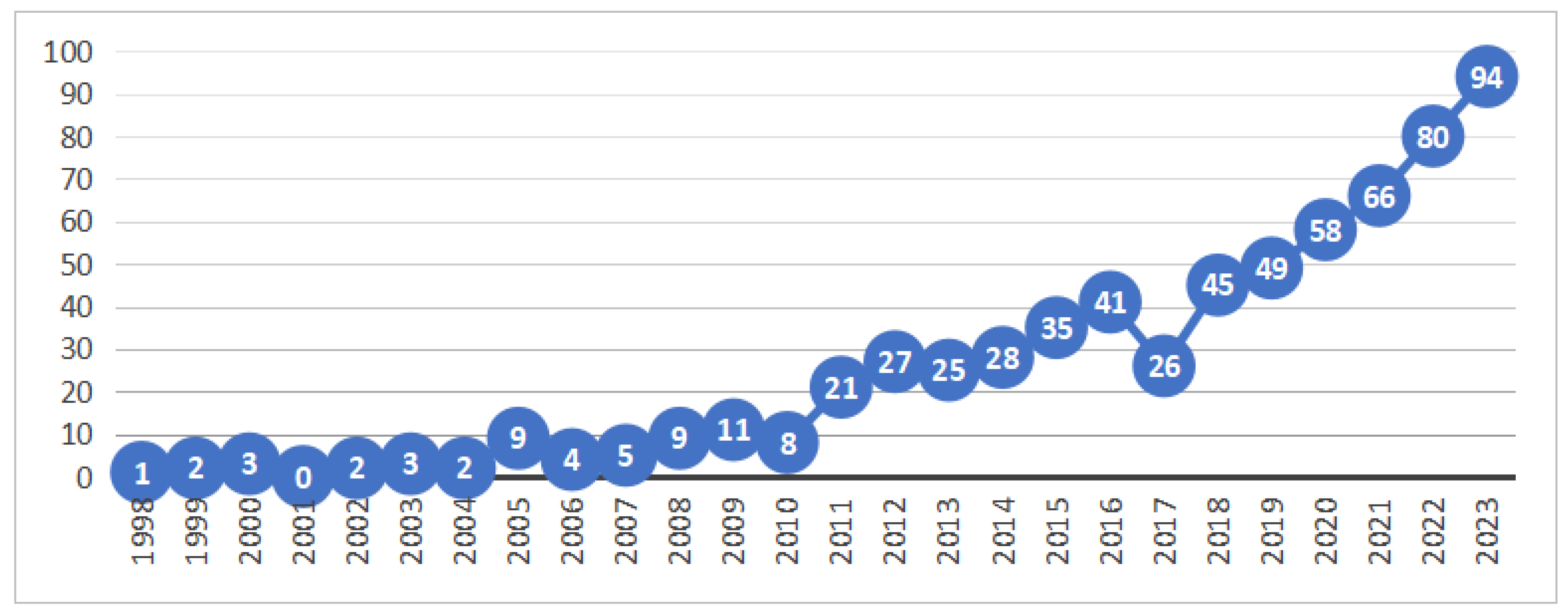

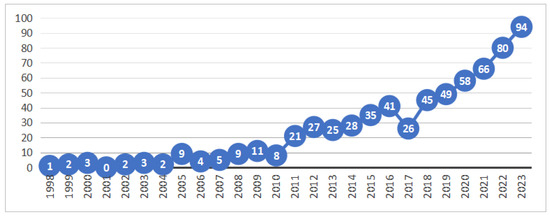

In this chapter, the 654 articles resulting from the search were quantitatively analyzed, and the results derived from analyzing the year of publication and keyword clustering of the literature in the quantitative sample are as follows: Figure 3 summarizes the annual publication of articles related to LC and SC since 1998 in chronological order. The integration of LC and SC has seen significant growth in research over the years, with distinct phases of development. From 1998 to 2009, research was limited due to LC and SC being emerging concepts, and the construction industry’s primary focus on cost and speed over sustainability. Between 2010 and 2014, interest grew as global attention to climate change and sustainability increased and lean practices began expanding in construction. From 2015 to 2019, the publication rate accelerated, driven by international sustainability goals, like the UN’s 2030 Agenda, advancements in technology (e.g., BIM), and more stringent environmental policies. The period from 2020 to 2023 saw a surge in research, largely due to the climate crisis, the post-pandemic need for efficiency, and the push for carbon neutrality. As global environmental pressures and efficiency demands grow, research in LC–SC integration is expected to continue expanding, particularly with new technologies and stricter sustainability regulations.

Figure 3.

Annual Number of Literature Issued.

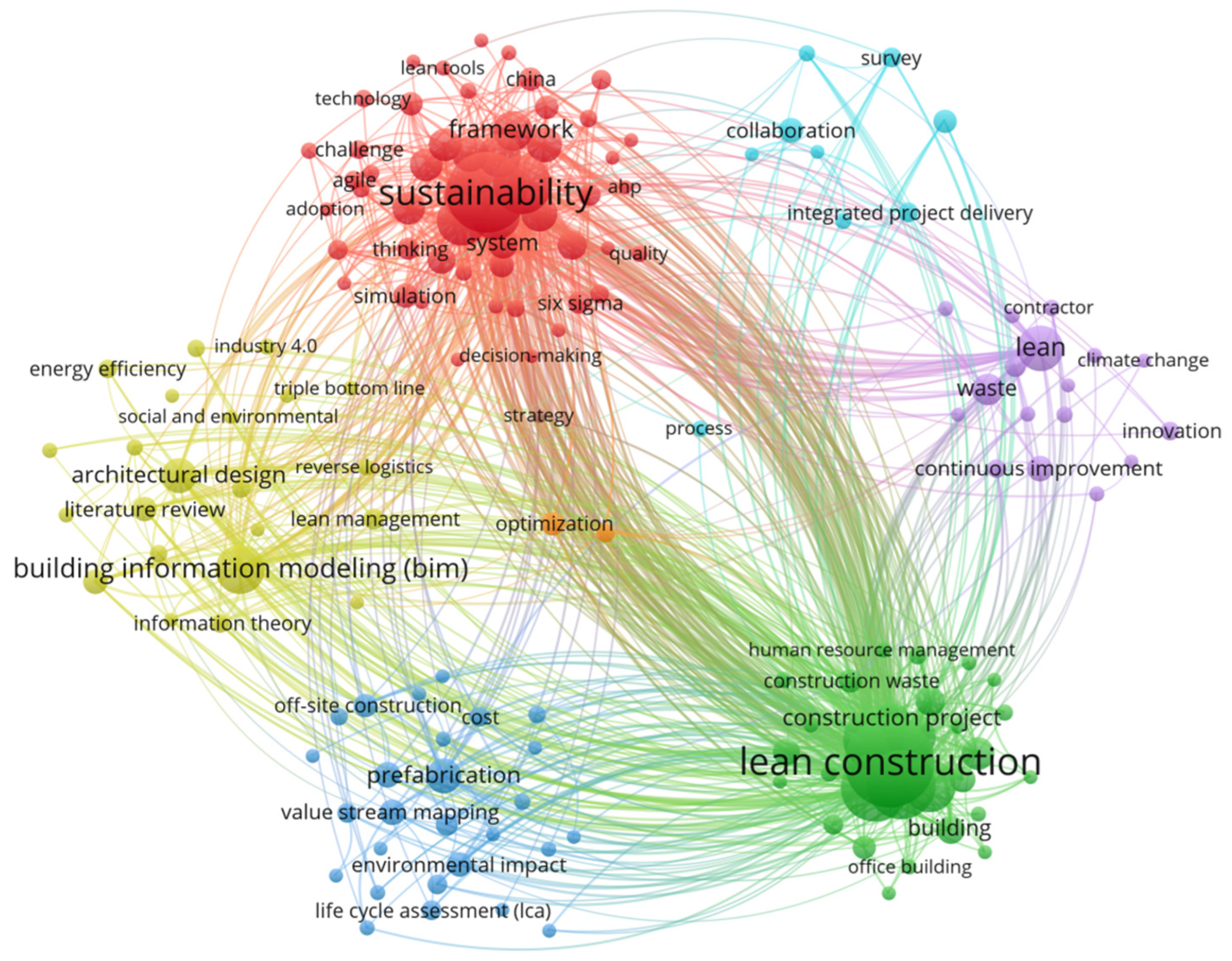

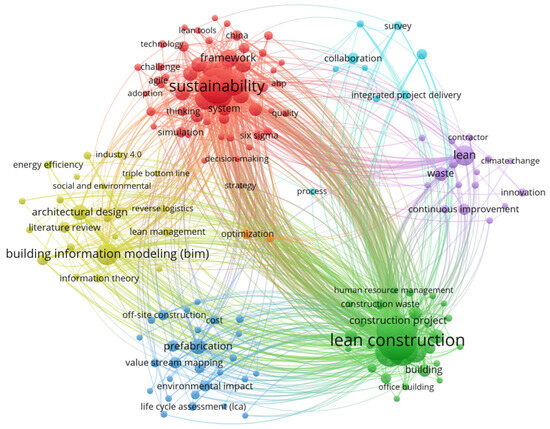

Figure 4 shows the visualization results of keyword clustering. Several keywords—lean construction, sustainability, sustainable development, construction industry, sustainable construction—have the largest nodes, which align with the focus of this study and support the reliability of the data collected. The clustering results, as shown in Figure 4, categorize the keywords into seven groups:

Figure 4.

Keyword clustering.

- (a)

- Red cluster model (sustainability): This is the largest cluster, with keywords like “sustainability”, “framework”, and “six sigma”. It represents research focused on sustainability frameworks, quality management systems, and decision-making processes. The connection to LC is evident through terms like “lean tools”, reflecting a strong focus on integrating sustainability into construction processes. Keywords such as “technology” and “agile” suggest a focus on innovation and flexibility in adopting sustainable practices;

- (b)

- Yellow cluster model (building information modeling (bim)): This cluster highlights the significant role that BIM plays in LC and SC. Keywords like “architectural design”, “energy efficiency”, and “information theory” emphasize BIM’s role in improving design coordination, energy performance, and data management in construction projects. The presence of terms like “industry 4.0” and “reverse logistics” indicates the intersection of advanced technologies and SC techniques;

- (c)

- Green cluster (lean construction): The keywords “lean construction”, “construction project”, and “human resource management” indicate that this cluster focuses on the practical application of LC principles. It addresses project management, waste reduction, and workforce optimization. The connection with “construction waste” and “building” indicates that lean principles are closely tied to minimizing waste and improving efficiency across all aspects of construction projects;

- (d)

- Teal cluster model (integrated project delivery): The presence of “IPD” and “collaboration” in this cluster indicates a focus on teamwork and collaborative approaches in construction projects. Integrated Project Delivery promotes a more unified approach to construction, aligning well with both LC and SC by fostering better communication, reducing rework, and ensuring projects meet both lean and sustainability objectives;

- (e)

- Blue cluster (prefabrication): This renamed cluster includes keywords like “prefabrication”, “off-site construction”, “cost”, and “environmental impact”. It emphasizes the growing interest in prefabrication and modular construction techniques, which align well with lean principles by reducing on-site waste, improving productivity, and optimizing resource use. The presence of “life cycle assessment (LCA)” underscores the importance of evaluating the environmental benefits of these techniques over the entire building lifecycle;

- (f)

- Purple cluster model (lean): This cluster appears to consolidate general lean principles and tools. Keywords like “lean” and “continuous improvement” show that this group focuses on the broader application of lean techniques across various sectors, not just construction. This cluster could include studies that explore how LC methods have been adapted from manufacturing to construction.

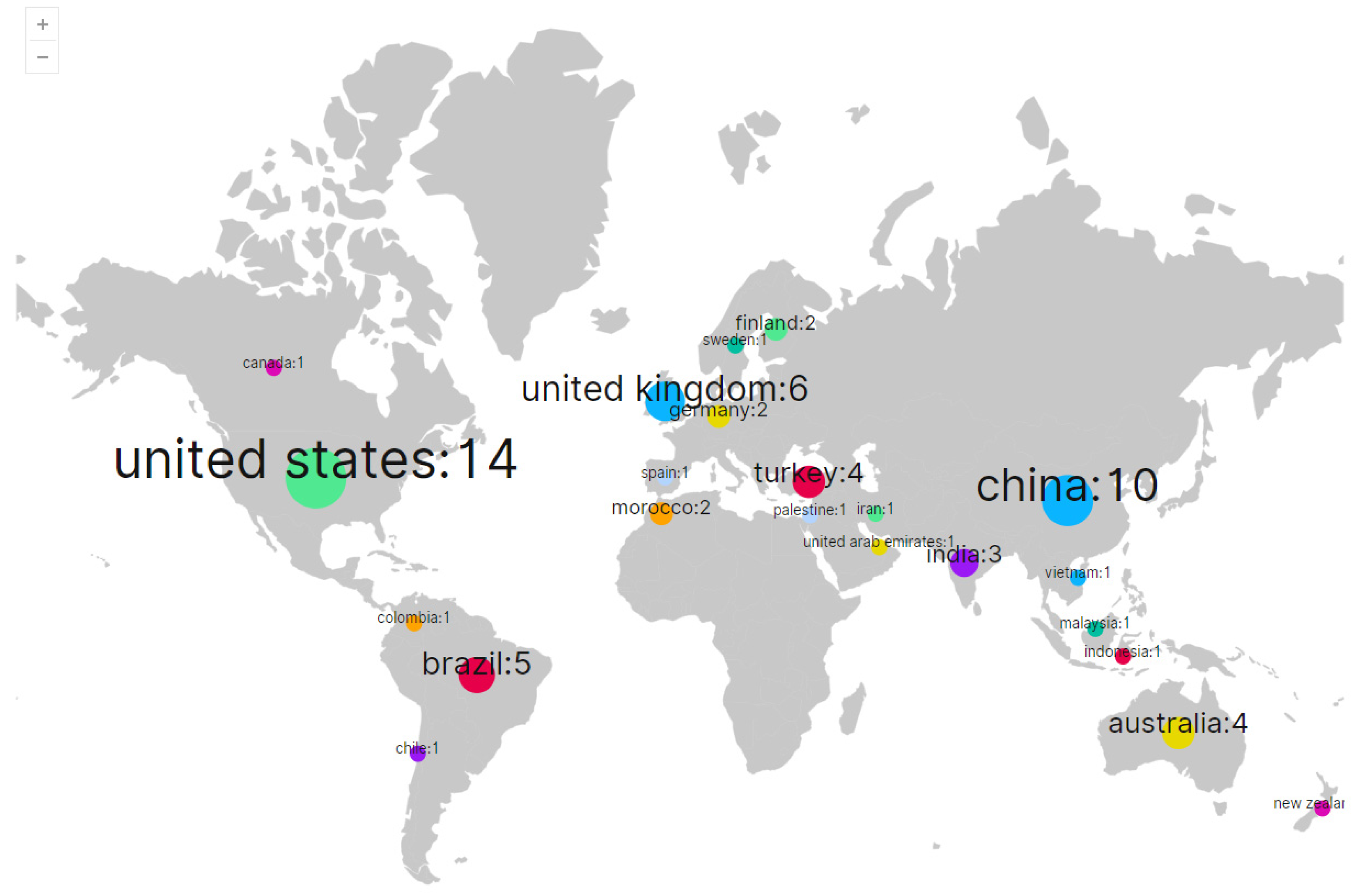

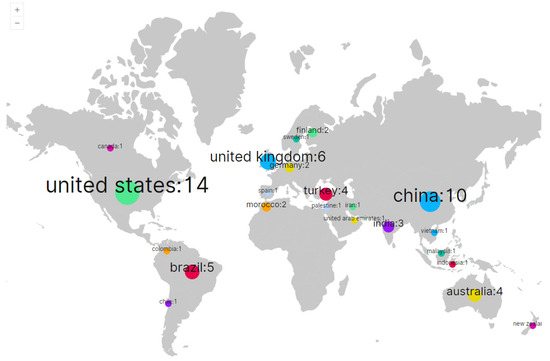

Based on the results of the previous quantitative analyses, an in-depth qualitative analysis was conducted on a sample of 65 articles focusing on the integration of LC and SC. These articles were rigorously selected according to the review principles. Figure 5 shows the geographical distribution of articles integrating LC and SC. Asia leads globally with 23 publications in this field, reflecting significant research activity in recent years. Additionally, 22% of all articles on this topic originate from North America, followed by 20% from Europe. The following is a detailed analysis of the content of these publications.

Figure 5.

Geographical distribution of the qualitative sample.

Tables S1, S2 and S3 summarize, from the TBL perspective, how lean tools improve the economic, environmental, and social aspects of SC, respectively. Tables S1–S3 can be found as appendices in the “Supplementary Material” section.

The application of LC tools can significantly enhance the economic sustainability of projects. Cost, quality, and time have been identified as three key performance indicators for achieving economic sustainability in construction [51], and LC tools can effectively reduce costs, improve quality, decrease variability, shorten delivery times, increase productivity, reduce rework, and enhance customer confidence and market reach. As seen in Table S1, LPS, VSM, and prefabrication are the most commonly applied lean tools. LPS is primarily used to reduce variability, as decreasing variability is one of the principles of LC and a hindrance in SC processes. Changes in planning not only compromise the delivery of SC projects but delays in the project also represent a form of waste [52]. Salem et al. [53] demonstrated that using LPS in road construction and maintenance projects can help reduce waste and emissions by speeding up work processes and thereby reducing project duration. Although prefabricated construction has higher initial costs, it reduces total project costs throughout the construction cycle by applying modular and lean manufacturing of prefabricated components: its time efficiency, higher quality, and management efficiency also reduce the indirect construction costs of prefabricated buildings [54]. Additionally, the high quality and durability of prefabrication help minimize operational costs [55], as well as social pollution fees and ecosystem restoration costs.

According to Table S2, lean tools and principles enhance environmental sustainability in several ways: reducing emissions, decreasing energy consumption, saving water, minimizing waste, enhancing waste recycling and processing, minimizing the project’s impact on the external environment, reducing material consumption, and increasing material utilization rates. Among these, waste reduction is the most frequently applied lean practice, as it is a core principle of LC [2]. LC minimizes material waste and maximizes resource efficiency by shortening construction processes and mitigating negative environmental impacts [14]. Energy reduction is another key aspect optimized by LC, with LC-implemented buildings regarded as one of the most effective methods to mitigate environmental impacts and energy consumption during construction [56]. Additionally, many studies link lean tools with Life Cycle Assessment [57], as LCA helps quantify the outcomes of lean technologies to determine whether initial sustainability goals have been met. The combination of the two can assist in the analysis of material, energy, and information flows within companies, as well as in the formulation of new SC strategies [58], enhancing economic performance while also focusing on environmental performance. VSM is the most widely used lean tool in studies analyzing the environmental impacts of construction processes. This is because it can identify non-value-added activities in material manufacturing, transportation, and construction sites, ensuring improved process performance and providing detailed visualization of lifecycle processes to streamline planning [59].

The literature also shows that lean tools promote social sustainability by improving safety, employee psychological health and satisfaction, and community welfare and cooperation. Table S3 highlights that many lean tools are applied to enhance worker safety and workplace conditions. VSM, 5S, and prefabrication are the most frequently used tools in terms of social sustainability.

5. Discussion

5.1. Drivers for Integrating Lean Construction with Sustainable Construction

Sustainable development is defined as the principle of meeting present needs while ensuring the capacity to meet future needs [60]. Building on this definition, Elkington integrated the three key aspects of sustainability—economic, environmental, and social—into the framework known as the Triple Bottom Line (TBL). Therefore, this article explores the current state of LC and sustainability research through the lens of the TBL, categorizing SC into economic, environmental, and social aspects for further discussion.

The TBL framework, which evaluates project outcomes across economic, environmental, and social dimensions, provides a comprehensive approach to integrating LC and SC [61]. In practice, the TBL requires construction firms to balance cost efficiency with environmental stewardship and social well-being. While LC excels at addressing the economic dimension, SC focuses more on the environmental and social aspects of sustainability.

Expanding on the TBL, recent studies suggest that LC can be adapted to better address social sustainability goals by enhancing worker conditions, safety, and well-being [32]. For instance, the implementation of LC tools, such as Kaizen and 5S, not only reduces waste but also improves workplace safety and efficiency, contributing to the social dimension of sustainability [36]. This integration of LC and SC, framed through the TBL, offers a balanced approach to sustainability, ensuring that economic efficiency does not undermine environmental or social outcomes.

To thoroughly identify the relationship between LC and SC, the article categorizes the factors driving their integration into synergistic and complementary through a comprehensive literature review. Synergies refer to areas where LC and SC share common goals and methods, promoting mutual benefits and enhancements; complementarities, on the other hand, reflect differences between LC and SC, but they can compensate for each other, forming a more comprehensive and integrated solution. Table 1 demonstrates the driving forces in the integration process of LC and SC as summarized by the study.

Table 1.

Drivers of the LC and SC integration.

5.1.1. Economic Aspects of Lean Construction and Sustainable Construction

Economic sustainability in construction refers to maintaining efficient, cost-effective operations that ensure profitability while minimizing resource consumption and waste across the project lifecycle. It focuses on optimizing construction time, managing project variability, and making cost-efficient decisions during the early design phase, all of which are critical for controlling expenses and enhancing financial performance. LC and SC share common goals that support economic sustainability. LC aims to meet customer needs regarding speed, cost, and quality [2], aligning closely with SC objectives. LC optimizes processes and resource utilization to enhance product quality, while SC emphasizes environmentally friendly materials and energy-saving measures to improve building quality and longevity. While environmental performance often dominates discussions of sustainability, measures such as optimizing natural lighting, improving ventilation, ensuring indoor comfort, and extending building lifespans also align with LC’s focus on customer satisfaction [14]. Additionally, both LC and SC prioritize waste reduction, contributing to economic sustainability by cutting costs and waste throughout a building’s lifecycle, thus enhancing profitability [62].

LC and SC complement one another in areas such as initial costs, delivery time, variability, and early design stages. LC methods can offset the traditionally high costs associated with SC, particularly in material selection and early design phases. While seeking LEED certification is valuable in the long run, it can initially inflate project timelines and costs due to documentation and certification procedures [39]. However, LC techniques that improve construction efficiency and productivity can help offset these costs [11], making SC more financially viable, particularly for small companies [63]. For example, a study by Lapinski et al. [39] found that a LEED Gold-certified building utilizing LC incurred no additional costs compared to traditional facilities.

LC also addresses SC’s challenges in construction time. SC often demands more time for design and material selection to meet environmental standards, which can hinder implementation [64,65]. However, LC’s emphasis on delivery time, supported by tools like the LPS, can mitigate these delays by streamlining processes and reducing work-in-progress [66].

Additionally, the complexity of SC requires LC to manage project variability. SC’s complexity, driven by sustainability standards and innovative materials, often leads to project variability [67]. LC principles, particularly variability reduction, are key to addressing these challenges, with tools like the LPS playing a significant role [5].

Furthermore, SC’s focus on early design enhances LC practices. While research often focuses on using LC to achieve sustainable benefits [43], integrating sustainable concepts also enriches LC. LC applications typically concentrate on construction processes, often neglecting early project stages and creating disconnects between design and construction [68]. SC’s emphasis on building design, especially concerning sustainable materials and technologies, fosters comprehensive coordination throughout the project lifecycle [69].

5.1.2. Environmental Aspects of Lean Construction and Sustainable Construction

LC and SC share a common focus on reducing waste. The direct purpose of sustainability principles is to mitigate the environmental impact of human activities, whereas the goal of lean is to eliminate non-value-adding activities, indirectly reducing their environmental impact [70]. Currently, lean and sustainable strategies are often seen as compatible initiatives. Verrier et al. [16] discussed the synergistic effect between lean and sustainable waste; Pampanelli et al. [58] argue that lean and sustainable strategies must be integrated into a comprehensive approach to be implemented simultaneously, thereby fully leveraging their cooperative effects. However, some argue that a more practical approach is to combine lean and sustainable by leveraging the connections between these two concepts to maximize their synergies [14], rather than merging them into a third approach.

SC and LC also complement each other environmentally. Firstly, the integration of SC with LC compensates for the lack of universal measurement standards in LC. LC focuses more on workflow improvements without a universal standard for measuring final performance outcomes [69], whereas the LCA method in the SC field provides a detailed way to assess environmental performance, making it more intuitive to evaluate the results of reforms in building projects.

Second, the LC and SC definitions of waste complement each other. Traditionally, these two concepts have defined waste differently; SC focuses only on environmental waste, as well as material waste, and has not focused on waste in terms of time and manpower, whereas the seven major types of waste (transport, waiting, overproduction, defects, inventories, motion, and redundant processing [71]) of lean production do not explicitly include environmental waste, with only the production waste generated during construction considered related to environmental waste [44].

Thirdly, SC focuses on environmental impacts that LC might overlook. Research on lean delivery systems primarily focuses on process improvements, reducing delivery times, and minimizing waste. These studies rarely address their often-neglected impacts on the environmental life cycle [72]. As a result, LC exhibits blind spots regarding environmental risks and life cycle impacts. Eliminating environmental waste is a focus of sustainability. Including environmental waste in the list of production waste categories encourages the simultaneous assessment of production and environmental variables [44]. Moreover, in terms of product recycling, lean practices do not prioritize themselves with the disposal and recycling of products at the end of their life cycle, whereas sustainability considers the impacts of building use and the disposal and recycling of materials in forms of reuse or recycling [73].

5.1.3. Social Aspects of Lean Construction and Sustainable Construction

In the social domain, safety is a primary concern for both LC and SC. From a lean perspective, unsafe practices in projects create inefficiencies, causing non-value-adding incidents within the production system and contributing to waste [74]. Therefore, both lean and sustainable construction share the common goal of minimizing risks and creating safer work environments in terms of ensuring personnel safety.

LC and SC align when it comes to enhancing corporate image. The purpose of introducing sustainable concepts in construction companies is to enhance their image by becoming green, environmentally friendly businesses [75], and some construction companies achieve this through zero or low incident rates [76]. Thus, it is also evident from existing surveys that one of the benefits of combining sustainability and LC is the improvement in the corporate image [77].

Both LC and SC emphasize the development of “people”. SC encourages the use of environmentally friendly materials, reduces emissions of harmful substances, and provides good ventilation and lighting conditions to ensure the physical and mental health of workers and users. The LC culture model focuses on people-centric principles, human development, and human dynamics. For example, ref. [78] proposed a lean labor management framework that provides workers with stable housing and humanized facilities and services, and creates a sanitary and safe living and site environment, also increasing workers’ comfort and well-being.

Although social aspects receive less attention compared to other areas, LC and SC still demonstrate significant complementary roles. During the construction process, LC can mitigate the risks increased by implementing SC. Although one of the goals of SC is safety, the LEED rating system rarely prioritizes it, particularly in terms of worker health and safety. Studies have found that SC projects, represented by LEED, are associated with increased basic safety risks [79] because SC construction processes are complex, cover a wide range, and lack corresponding quantified standards. Rework, frequent maintenance, or the additional effort required to complete tasks can increase the overall safety risks associated with construction and maintenance operations. LC has significant advantages in improving working conditions and protecting worker safety. Some tools, such as 5S and daily huddle meetings, substantially improve workplace conditions and enhance worker safety awareness [53].

LC facilitates the dissemination of technology and knowledge needed for SC. In the process of implementing SC, the lack of training and education is a common barrier [80]. In some remote areas or developing countries, the technical equipment needed for SC may not be scarce, and local worker training may be relatively limited. Adopting lean principles can help teams better engage in knowledge creation, sharing, and personnel training [81].

5.2. The Dilemma of Combining Lean Construction and Sustainable Construction

The reasons for integrating LC and SC have been outlined from economic, environmental, and social perspectives. However, LC and SC also inherently face conceptual contradictions and goal-oriented conflicts, as well as common application challenges. By addressing conflicts between LC and SC, the integration of these two approaches can foster a more sustainable construction process.

5.2.1. Conceptual Conflict Between Lean Construction and Sustainable Construction

Originally, LC and SC were two distinct research fields, which naturally led to isolated research within each domain. The literature review reveals conflicts indicating that certain aspects of LC and SC are at odds, and adopting the methodology of one may adversely affect the other. Table 2 demonstrates the conceptual conflicts between LC and SC.

Table 2.

Conceptual conflict between LC and SC.

From an economic perspective, SC increases project costs, which conflicts with LC’s primary goal of reducing costs. SC projects often lead to higher initial costs [63], as they demand close interdisciplinary collaboration, complex design analysis, and the use of ecological building materials. These materials, which are often locally manufactured and non-traditional, tend to be high-performance materials that are more expensive, with production costs exceeding those of conventional construction materials. An example of LC–SC integration can be seen in a hospital construction project in Brazil, where LC practices such as VSM improved production efficiency but required adjustments to meet sustainability targets for energy use and material efficiency [82]. This demonstrates the practical challenges of balancing economic efficiency with environmental goals, highlighting the need for frameworks that address both priorities.

There is also a difference in standardization. LC encourages standardization and uniformity, where suppliers and partners must follow the same methods and requirements to ensure the efficiency of the entire supply chain and improve production efficiency. This shifts suppliers towards a production-oriented approach, reducing customer choices and raising the communication costs between suppliers and partners, potentially limiting cooperation with some potential suppliers. The best techniques and methods for a specific project vary depending on geographic location, regional energy, community characteristics, stakeholder priorities, and many other variables [83]. SC demands customized design and adaptive adjustments according to the building’s characteristics and environmental conditions to meet ecological requirements. Compared to traditional construction projects, the uncertainty of SC increases, which may conflict with the standardization ethos of LC.

Environmentally, while many studies show that lean practices enhance project environmental sustainability, there are also reports of conflicts between lean and sustainable practices. LC does not always directly reduce energy consumption and emissions, and some production processes may reduce time and costs but fail to significantly improve environmental waste (energy consumption and emissions) and may even exacerbate it. For example, studies show that using lean tools like JIT in the supply of prefabricated components results in frequent deliveries, as this reduces inventory and material buffering at production and construction sites, saving space and material handling costs [84]. However, Kim et al. [85] came to the same conclusion in their study of a JIT delivery project of prefabricated steel bars in a high-rise flat project in South Korea, but they also claimed that transporting prefabricated components to the construction site would consume more energy and emit more air pollutants.

Socially, LC has been accused of potentially impacting workers’ psychological safety. Although studies suggest that construction workers feel psychologically safer in LC projects compared to traditional projects [86]; the focus on performance in lean implementation may lead to greater stress for employees [87]. Lean methods often rely on management’s dominance over labor, and while the rhetoric of flexibility, quality, and teamwork is appealing, critics argue that it translates into control, exploitation, and surveillance in practice [42]. This contradicts the goals of social sustainability, where achieving value is sometimes prioritized over reducing waste [87].

5.2.2. Potential Challenges to Integrating

The challenges of integrating LC and SC in this study can be summarized in terms of management, change awareness, economics, customers, communication, government, knowledge, training, and technology. In order to maximize the benefits of such integration, these challenges must be addressed and practical solutions developed through further targeted research and collaboration between experts in both fields. Table 3 shows the collected potential challenges in the integration of LC with SC.

Table 3.

Potential challenges gathered from the literature.

From the common challenges identified, it is clear that multiple factors contribute to the dilemmas faced by LC and SC and their integration. Much of the literature highlights economic, communication, and knowledge-related reasons, aligning with the findings of Adhi and Muslim [30] and Tafazzoli et al. [14]. The summarized challenges offer a basis for proposing targeted solutions in the subsequent sections.

5.3. Dynamic Capabilities in the Integration of Lean Construction and Sustainable Construction

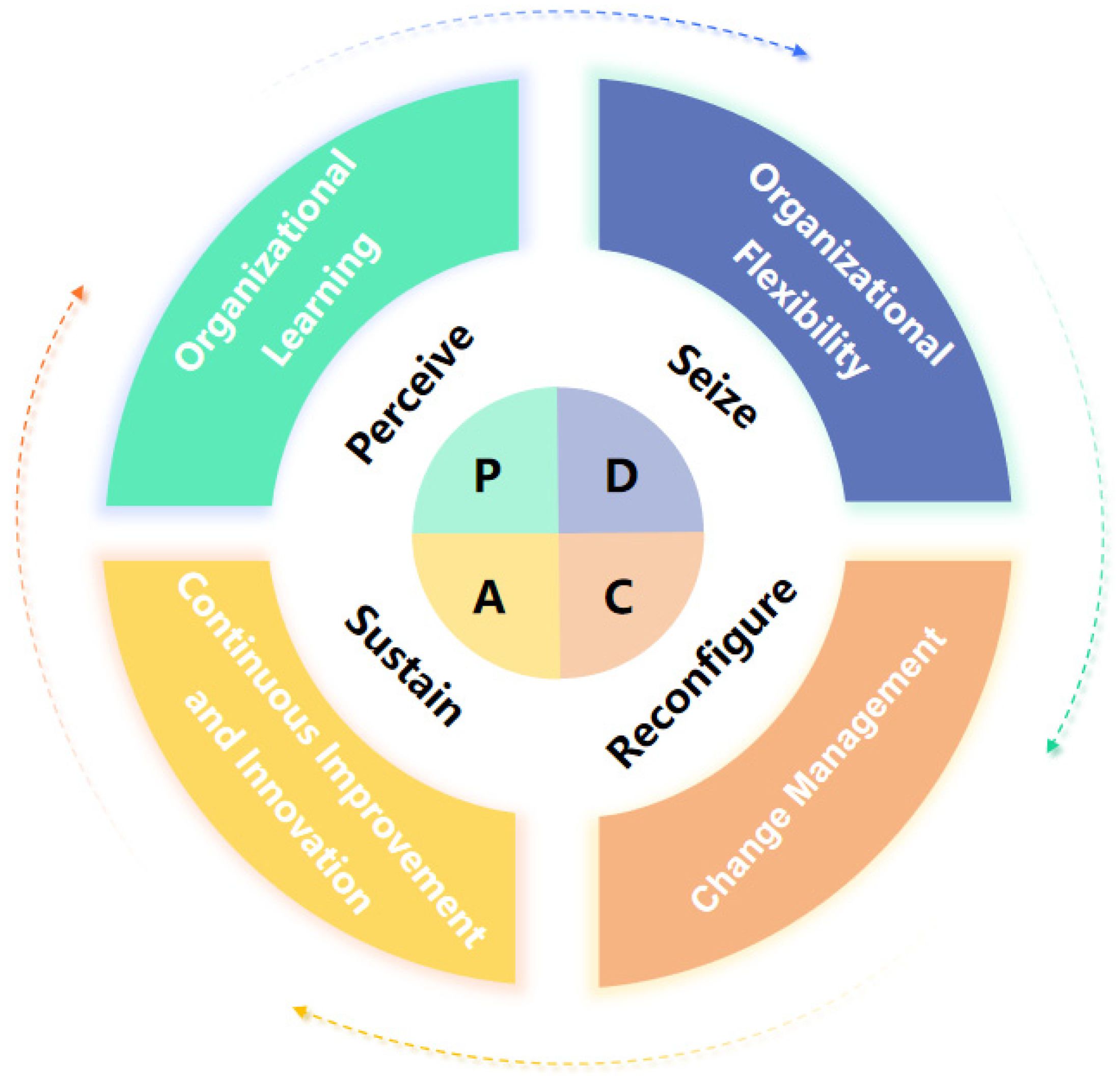

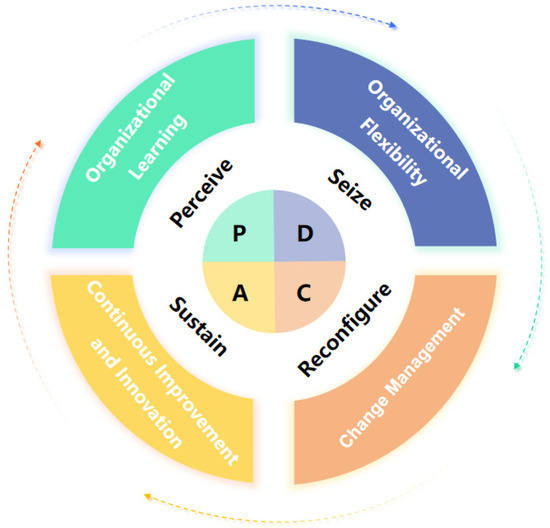

By understanding the drivers and challenges identified in the literature, this paper proposes leveraging DC to enhance the integration of LC and SC at the enterprise level. Building on the micro-foundations (perceive, seize, and reconfigure) of DC, this study extends the application of DC theory by incorporating ‘sustain’, as proposed by Mishra et al. [97] to extend the DC theory application by incorporating ‘sustain’. From a DC perspective, ‘perceive’ refers to the ability of business managers to identify opportunities for improving a project’s sustainable performance through lean thinking. ‘Seize’ represents the ability of lean construction teams to design and refine operational methods to reduce environmental pollution and enhance both performance and well-being. ‘Reconfigure’ involves realigning technical structures, skills, and knowledge to fully utilize LC. ‘Sustain’ refers to the ability to regularly monitor outcomes and continuously seek improvements and innovations.

5.3.1. Dynamic Capabilities Help to Ameliorate Dilemma

In the context of the integration of LC and SC, this paper refines the four DCs into organizational learning, organizational flexibility, change management, and continuous improvement and innovation. The study not only conceptualizes these capabilities but also creates a comprehensive framework illustrating the integration of LC principles with DC concepts, as shown in Figure 6.

Figure 6.

Application of DC in LC.

Organizational learning involves recognizing and interpreting changes in the environment or within the organization. This capability allows the organization to perceive opportunities and threats by continuously updating its knowledge and learning from past experiences. It helps in identifying areas for improvement and innovation, aligning with the “Perceive” stage, where the organization detects new possibilities and anticipates necessary changes. It aids in reducing rework through informed decision-making, facilitates sustainable transformation to overcome resistance to change [98], and promotes technical training. It also helps manage cost, pollution, and new technology adaptation by continuously updating the organization’s knowledge base.

Organizational flexibility, or agility, refers to an organization’s capacity to swiftly adapt to new or evolving environments, seize opportunities for competitive advantage, and navigate sudden changes in the business landscape [99]. It is a critical driver for survival and success in turbulent settings, requiring enterprises to balance lean and sustainable objectives across varying environmental conditions [100]. It promotes employee engagement by encouraging their participation in proposing innovative ideas, supports rapid decision-making to foster collaboration with clients, and allows for flexibility in supplier selection through innovation. Maintaining high levels of flexibility is essential for enhancing project performance in construction, especially given the complexity of projects under sustainability goals [101]. This flexibility also reduces employee stress and expands supplier options, mitigating one of the key challenges of LC—limited supplier choices.

Change management plays a critical role in reconfiguring and restructuring existing processes, roles, and systems within an organization. Organizational change focuses on ensuring clear communication and setting defined goals to foster employee support and enthusiasm for change. It involves the fundamental ability to reconfigure resources within the micro-foundations of DC. Senior management plays a pivotal role in influencing the acceptance of changes, while clear strategies align communication efforts, improving the supply chain and advocating for supportive government policies. Given that both LC and SC often necessitate changes in organizational structures and cultures, organizational change management encompasses the capacity to effectively guide and support employees in adapting to new work methods and values.

Continuous improvement is considered a DC, or a method that can develop into a DC [102]. Continual improvement is an ongoing cycle, and thus, it is regarded as highly adaptable to reconfiguration to continually update practices according to the daily changing demands [47]. Change management is essential for reconfiguring and restructuring existing processes, roles, and systems within an organization. Due to the high specialization and flexibility of construction projects, it is particularly suited for implementing continuous improvement processes, which helps enhance the organization’s ability to make quick and cohesive process changes [103]. Moreover, continuous improvement enhances a company’s innovation capability, positioning innovation as an opportunity-focused DC and a crucial component of overall dynamic capabilities [104]. Innovation is a “necessary condition” for sustainability [105] because of its importance in saving resources, improving management efficiency, increasing project reliability, and improving project sustainability [106].

Based on the above analyses and the dilemma of LC–SC integration mentioned in Section 5.2, Table 4 explains how the four DC dimensions presented in the article contribute to the conceptual conflicts and potential challenges of co-implementation between LC and SC.

Table 4.

Lean SC-related DCs for resolving existing dilemmas and conflicts.

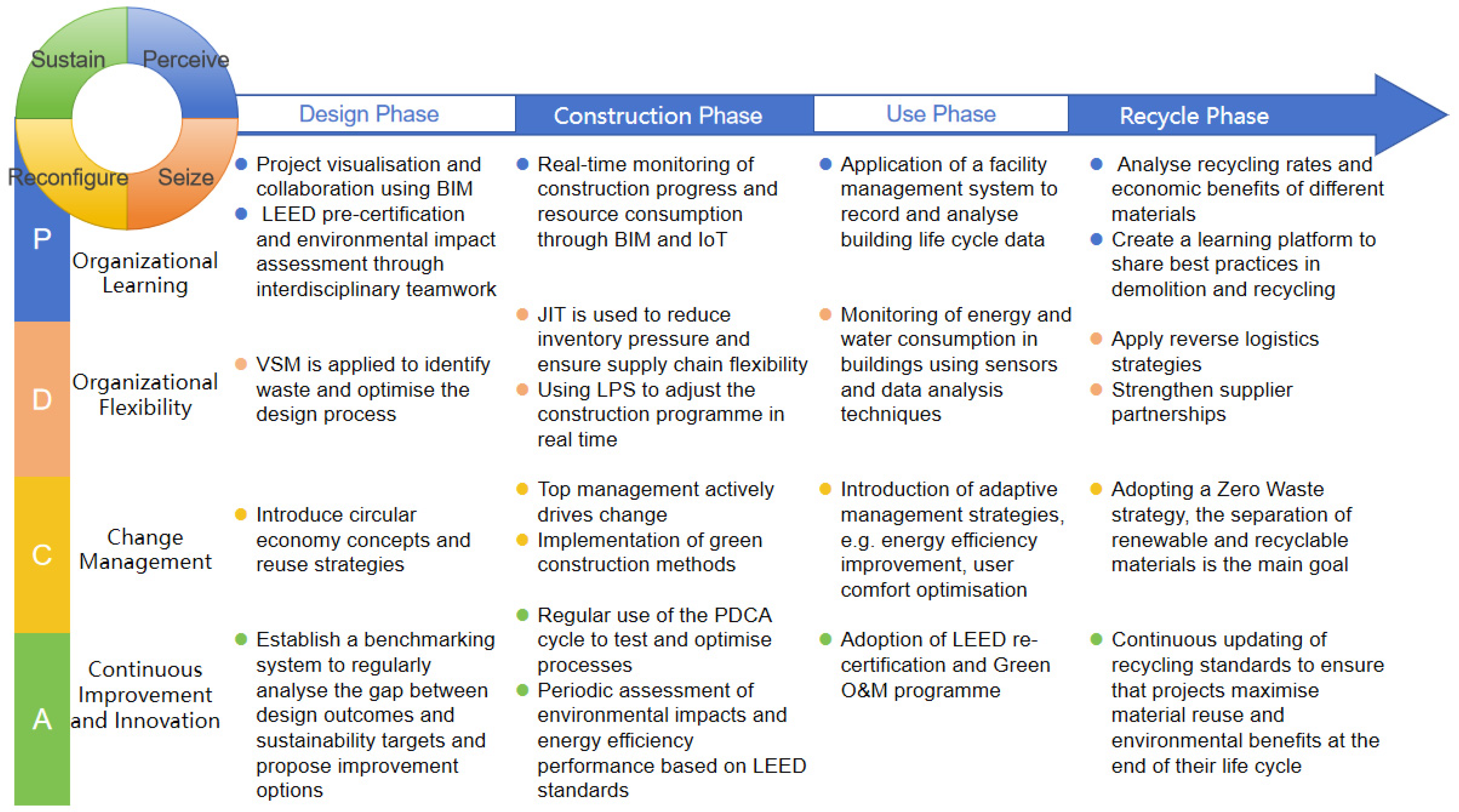

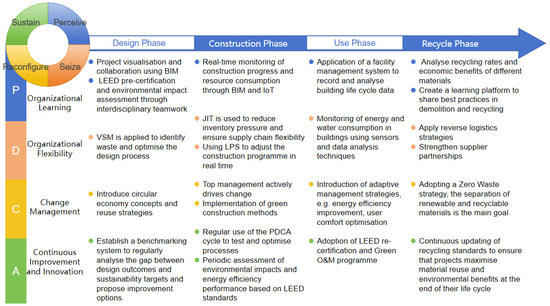

5.3.2. Dynamic Capability-Based Framework for Full Life Cycle Integration of LC and SC Buildings

In conjunction with Figure 7, a strategic framework for the application of DC to the integration of LC and SC was developed. It can be seen that in the developed framework, the building life cycle is divided into four phases based on the literature review, i.e., the design phase, the construction phase, the use phase, and the recycling phase. At each stage, the strategy for LC and SC integration is proposed using the concept of DC, and the four DCs form a cycle at each stage for continuous improvement in the project.

Figure 7.

A Strategic Framework for LC and SC Integration with DC Application.

6. Conclusions

This study makes several important theoretical contributions to the integration of LC and SC. Firstly, it provides a comprehensive framework for examining the relationship between LC and SC, moving beyond the often-discussed synergies and conflicts to highlight their complementary aspects. Through a thorough literature review, the study categorizes the drivers of LC and SC integration as either synergistic or complementary. The findings show strong synergies in areas such as quality, customer centricity, cost savings, waste reduction, personnel safety, corporate image enhancement, and employee satisfaction. In terms of complementary effects, LC and SC contribute to initial cost reduction, shortened lead times, reduced variability, early design improvements, common metrics, waste definitions, environmental impact mitigation, product recycling, worker safety, and employee training.

Secondly, this study systematically identifies the challenges involved in integrating LC and SC, focusing on both conceptual contradictions and potential implementation challenges. Conceptual contradictions arise in areas such as cost, standardization, environmental impact, and employee pressure, while implementation challenges are related to costs, communication gaps, and knowledge barriers.

By summarizing the integration dilemmas of LC and SC, this study also introduces DC as a solution. It demonstrates how the four DC dimensions—organizational learning, organizational flexibility, change management, and continuous improvement and innovation—can address these dilemmas, thereby promoting a closer integration of sustainability and lean practices.

Lastly, this research proposes a strategic framework for the application of DC to the integration of LC and SC. A structured approach is provided for construction companies to develop the capabilities required for LC and SC integration. This theoretical model not only enhances academic understanding but also offers a practical foundation for future research, driving sustainable outcomes in the construction industry.

However, it is important to acknowledge the limitations of this research. Despite efforts to manually filter relevant literature, some important articles may have been overlooked due to reliance on specific databases (WoS, Scopus, and IGLC), which may not cover all relevant publications. The snowballing method used in qualitative analysis, though effective in expanding the literature base, may introduce biases by emphasizing highly cited or recent studies, potentially underrepresenting less-cited but significant works, particularly in niche areas. Additionally, biases may have arisen from the use of specific keywords such as “lean”, “green”, “sustainability”, and “construction”, which could exclude relevant articles that use alternative terminology. Future research could mitigate these limitations by using a broader range of databases, expanding search terms, and employing advanced literature analysis software for a more exhaustive review.

As LC–SC integration is still rare among companies, future research could focus on empirical studies involving specific companies to understand the implementation challenges and details. This approach could yield concrete, actionable recommendations for practitioners, supporting the effective integration of LC and SC. While this study suggests that enhancing DC can facilitate LC–SC integration, future work should conduct empirical investigations to examine the actual impact of DC on this integration and explore additional DC dimensions to strengthen the theoretical framework and offer further practical guidance.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su16219387/s1, Table S1: lean tools to improve the economic aspects of SC, Table S2: lean tools to improve the environment aspects of SC and Table S3: lean tools to improve the social aspects of SC.

Author Contributions

Conceptualization, Y.C. and D.Q.; formal analysis, D.Q.; investigation, D.Q.; data curation, D.Q. and X.C.; writing—original draft preparation, Y.C. and D.Q.; writing—review and editing, Y.C., D.Q. and X.C.; supervision, Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Fujian Province, grant number 2022J05191.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xu, G.; Wang, W. China’s energy consumption in construction and building sectors: An outlook to 2100. Energy 2020, 195, 117045. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Stanford University Stanford: Stanford, CA, USA, 1992; Volume 72. [Google Scholar]

- Koskela, L.; Vrijhoef, R. The Prevalent Theory of Construction a Hindrance for Innovation. In Proceedings of the 8th Annual Conference of the International Group for Lean Construction, Brighton, UK, 17–19 July 2000. [Google Scholar]

- Innella, F.; Arashpour, M.; Bai, Y. Lean Methodologies and Techniques for Modular Construction: Chronological and Critical Review. J. Constr. Eng. Manag. 2019, 145, 04019076. [Google Scholar] [CrossRef]

- Ballard, G.; Howell, G. Implementing lean construction: Stabilizing work flow. Lean Constr. 1994, 2, 105–114. [Google Scholar]

- Babalola, O.; Ibem, E.O.; Ezema, I.C. Implementation of lean practices in the construction industry: A systematic review. Build. Environ. 2019, 148, 34–43. [Google Scholar] [CrossRef]

- Huovila, P.; Koskela, L. Contribution of the Principles of Lean Construction to Meet the Challenges of Sustainable Development. In Proceedings of the 6th Annual Conference of the International Group for Lean Construction, Guarujá, Brazil, 13–15 August 1998. [Google Scholar]

- Bae, J.; Kim, Y. Sustainable value on construction projects and lean construction. J. Green Build. 2008, 3, 155–167. [Google Scholar] [CrossRef]

- Li, Y.; Yang, L.; He, B.; Zhao, D. Green building in China: Needs great promotion. Sustain. Cities Soc. 2014, 11, 1–6. [Google Scholar] [CrossRef]

- Kibert, C.J. Establishing principles and a model for sustainable construction. In Proceedings of the First International Conference on Sustainable Construction, Tampa, FL, USA, 6–9 November 1994. [Google Scholar]

- Degani, C.M.; Cardoso, F.F. Environmental Performance and Lean Construction Concepts—Can We Talk About a Clean Construction. In Proceedings of the 10th Annual Conference of the International Group for Lean Construction, Gramado, Brazil, 6–8 August 2002. [Google Scholar]

- Kibert, C.J. Sustainable Construction: Green Building Design and Delivery; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Darko, A.; Chan, A.P.C. Review of Barriers to Green Building Adoption. Sustain. Dev. 2017, 25, 167–179. [Google Scholar] [CrossRef]

- Tafazzoli, M.; Mousavi, E.; Kermanshachi, S. Opportunities and Challenges of Green-Lean: An Integrated System for Sustainable Construction. Sustainability 2020, 12, 4460. [Google Scholar] [CrossRef]

- Carvajal-Arango, D.; Bahamón-Jaramillo, S.; Aristizábal-Monsalve, P.; Vásquez-Hernández, A.; Botero, L.F.B. Relationships between lean and sustainable construction: Positive impacts of lean practices over sustainability during construction phase. J. Clean. Prod. 2019, 234, 1322–1337. [Google Scholar] [CrossRef]

- Verrier, B.; Rose, B.; Caillaud, E. Lean and Green strategy: The Lean and Green House and maturity deployment model. J. Clean. Prod. 2016, 116, 150–156. [Google Scholar] [CrossRef]

- Ndrecaj, V.; Mohamed Hashim, M.A.; Mason-Jones, R.; Ndou, V.; Tlemsani, I. Exploring Lean Six Sigma as Dynamic Capability to Enable Sustainable Performance Optimisation in Times of Uncertainty. Sustainability 2023, 15, 16542. [Google Scholar] [CrossRef]

- Liu, C.-C.; Wang, M.; Niu, Z.; Mo, X. Moderating effect of dynamic capabilities on the relationship between lean practices and operational performance. Int. J. Lean Six Sigma, 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Jagannathan, M.; Kamma, R.C.; Renganaidu, V.; Ramalingam, S. Enablers for Sustainable Lean Construction in India. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 18–22 July 2018; pp. 910–922. [Google Scholar]

- Prasad, K.V.; Vasugi, V. Readiness Factors for Sustainable Lean Transformation of Construction Organizations. Sustainability 2023, 15, 6433. [Google Scholar] [CrossRef]

- Hussain, K.; He, Z.; Ahmad, N.; Iqbal, M.; Nazneen, S. Mapping Green, Lean, Six Sigma enablers through the lens of a construction sector: An emerging economy’s perspective. J. Environ. Plann. Manag. 2023, 66, 779–812. [Google Scholar] [CrossRef]

- Hussain, K.; He, Z.; Ahmad, N.; Iqbal, M.; Taskheer Mumtaz, S.M. Green, lean, Six Sigma barriers at a glance: A case from the construction sector of Pakistan. Build. Environ. 2019, 161, 106225. [Google Scholar] [CrossRef]

- Saieg, P.; Sotelino, E.D.; Nascimento, D.; Caiado, R.G.G. Interactions of Building Information Modeling, Lean and Sustainability on the Architectural, Engineering and Construction industry: A systematic review. J. Clean. Prod. 2018, 174, 788–806. [Google Scholar] [CrossRef]

- Gusmao Brissi, S.; Debs, L. Principles for adopting offsite construction in design and construction companies focused on multifamily projects in the USA. Eng. Constr. Archit. Manag. 2023; ahead-of-print. [Google Scholar] [CrossRef]

- Koranda, C.; Chong, W.K.; Kim, C.; Chou, J.-S.; Kim, C. An investigation of the applicability of sustainability and lean concepts to small construction projects. KSCE J. Civ. Eng. 2012, 16, 699–707. [Google Scholar] [CrossRef]

- Khanapure, V.U.; Shastri, S.S. A sustainable–lean implementation methodology: A catalyst for sustainability enhancement of high-rise residential projects. Eng. Constr. Archit. Manag. 2024, 31, 2585–2603. [Google Scholar] [CrossRef]

- Lam, E.W.M.; Chan, A.P.C.; Olawumi, T.O.; Wong, I.; Kazeem, K.O. Critical factors that influence lean premise design implementation: A case of Hong Kong high-rise buildings. Archit. Eng. Des. Manag. 2024, 1–17. [Google Scholar] [CrossRef]

- Lam, E.W.M.; Chan, A.P.C.; Olawumi, T.O.; Wong, I.; Kazeem, K.O. Facilitators and benefits of implementing lean premise design: A case of Hong Kong high-rise buildings. J. Build. Eng. 2023, 80, 108013. [Google Scholar] [CrossRef]

- Sutantio, A.; Anwar, N.; Wiguna, I.P.A.; Suryani, E. Developing a model of sustainable construction for condominium projects in developing countries; case of Indonesia. GEOMATE J. 2022, 23, 85–94. [Google Scholar] [CrossRef]

- Adhi, A.B.; Muslim, F. Development of Stakeholder Engagement Strategies to Improve Sustainable Construction Implementation Based on Lean Construction Principles in Indonesia. Sustainability 2023, 15, 6053. [Google Scholar] [CrossRef]

- Hei, S.; Zhang, H.; Luo, S.; Zhang, R.; Zhou, C.; Cong, M.; Ye, H. Implementing BIM and Lean Construction Methods for the Improved Performance of a Construction Project at the Disassembly and Reuse Stage: A Case Study in Dezhou, China. Sustainability 2024, 16, 656. [Google Scholar] [CrossRef]

- Francis, A.; Thomas, A. Exploring the relationship between lean construction and environmental sustainability: A review of existing literature to decipher broader dimensions. J. Clean. Prod. 2020, 252, 119913. [Google Scholar] [CrossRef]

- Aslam, M.; Gao, Z.; Smith, G. Development of Lean Approaching Sustainability Tools (LAST) matrix for achieving integrated lean and sustainable construction. Constr. Econ. Build. 2021, 21, 176–197. [Google Scholar] [CrossRef]

- Hasan, S.; Işık, Z.; Demirdöğen, G. Evaluating the Contribution of Lean Construction to Achieving Sustainable Development Goals. Sustainability 2024, 16, 3502. [Google Scholar] [CrossRef]

- De Carvalho, A.C.V.; Granja, A.D.; Da Silva, V.G. A Systematic Literature Review on Integrative Lean and Sustainability Synergies over a Building’s Lifecycle. Sustainability 2017, 9, 1156. [Google Scholar] [CrossRef]

- Nahmens, I.; Ikuma, L.H. Effects of lean construction on sustainability of modular homebuilding. J. Arch. Eng. 2012, 18, 155–163. [Google Scholar] [CrossRef]

- De Carvalho, B.S.; Scheer, S. Analysis and assessment for lean construction adoption: The DOLC tool. In Proceedings of the IGLC 2017—25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017; pp. 429–435. [Google Scholar]

- Salem, O.; Solomon, J.; Genaidy, A.; Luegring, M. Site implementation and assessment of lean construction techniques. Lean Constr. J. 2005, 2, 1–21. [Google Scholar] [CrossRef]

- Lapinski, A.R.; Horman, M.J.; Riley, D.R. Lean processes for sustainable project delivery. J. Constr. Eng. Manag. 2006, 132, 1083–1091. [Google Scholar] [CrossRef]

- Heigermoser, D.; García de Soto, B.; Abbott, E.L.S.; Chua, D.K.H. BIM-based Last Planner System tool for improving construction project management. Autom. Constr. 2019, 104, 246–254. [Google Scholar] [CrossRef]

- Aristizábal-Monsalve, P.; Vásquez-Hernández, A.; Botero Botero, L.F. Perceptions on the processes of sustainable rating systems and their combined application with Lean construction. J. Build. Eng. 2022, 46, 103627. [Google Scholar] [CrossRef]

- Green, S.D. The Dark Side of Lean Construction: Exploitation and Ideology. In Proceedings of the 7th Annual Conference of the International Group for Lean Construction, Berkeley, CA, USA, 26–28 July 1999; pp. 21–32. [Google Scholar]

- Wu, P.; Wang, X. A critical review of the factors affecting the success of using lean to achieve green benefits. In Proceedings of the IGLC 2016–24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016; pp. 33–42. [Google Scholar]

- Golzarpoor, H.; González, V.; Shahbazpour, M.; O’Sullivan, M. An input-output simulation model for assessing production and environmental waste in construction. J. Clean. Prod. 2017, 143, 1094–1104. [Google Scholar] [CrossRef]

- Karakhan, A.; Gambatese, J.; Rajendran, S. Application of choosing by advantages decision-making system to select fall-protection measures. In Proceedings of the IGLC 2016—24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016; pp. 33–42. [Google Scholar]

- Rathore, H.; Jakhar, S.K.; Bhattacharya, A.; Madhumitha, E. Examining the mediating role of innovative capabilities in the interplay between lean processes and sustainable performance. Int. J. Prod. Econ. 2020, 219, 497–508. [Google Scholar] [CrossRef]

- Mohaghegh, M.; Blasi, S.; Größler, A. Dynamic capabilities linking lean practices and sustainable business performance. J. Clean. Prod. 2021, 322, 129073. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Gutierrez, L.; Lameijer, B.A.; Anand, G.; Antony, J.; Sunder, M.V. Beyond efficiency: The role of lean practices and cultures in developing dynamic capabilities microfoundations. Int. J. Oper. Prod. Manag. 2022, 42, 506–536. [Google Scholar] [CrossRef]

- Teece, D.J. The Foundations of Enterprise Performance: Dynamic and Ordinary Capabilities in an (Economic) Theory of Firms. Acad. Manag. Perspect. 2014, 28, 328–352. [Google Scholar] [CrossRef]

- Perera, B.A.K.S.; Perera, C.S.R.; Jayalath, C. Contractor’s Perspective on Key Performance Indicators of Cost Control in Asian, Middle Eastern, and European Construction Projects. Int. J. Constr. Educ. Res. 2022, 18, 217–233. [Google Scholar] [CrossRef]

- Khanh, H.D.; Kim, S.Y. A survey on production planning system in construction projects based on Last Planner System. KSCE J. Civ. Eng. 2016, 20, 1–11. [Google Scholar] [CrossRef]

- Salem, O.; Pirzadeh, S.; Ghorai, S.; Abdel-Rahim, A. Reducing Environmental, Economic, and Social Impacts of Work-Zones by Implementing Lean Construction Techniques. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 145–155. [Google Scholar]

- Zhou, J.; Li, Y.; Ren, D. Quantitative study on external benefits of prefabricated buildings: From perspectives of economy, environment, and society. Sustain. Cities Soc. 2022, 86, 104132. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Sustainable construction aspects of using prefabrication in dense urban environment: A Hong Kong case study. Constr. Manag. Econ. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- de Oliveira Rezende, M.; Saade, M.R.M.; Nunes, A.O.; da Silva, V.G.; Moris, V.A.S.; Silva, D.A.L. A Lean and Green approach for the eco-efficiency assessment on construction sites: Description and case study. Clean Technol. Environ. Policy 2022, 24, 1535–1552. [Google Scholar] [CrossRef]

- Pampanelli, A.B.; Found, P.; Bernardes, A.M. A Lean & Green Model for a production cell. J. Clean. Prod. 2014, 85, 19–30. [Google Scholar] [CrossRef]

- Rabnawaz Ahmed, R.; Zhang, X. Multi-layer value stream assessment of the reverse logistics network for inert construction waste management. Resour. Conserv. Recycl. 2021, 170, 105574. [Google Scholar] [CrossRef]

- Cassen, R. Our Common Future: Report of the World Commission on Environment and Development; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Pan, W.; Pan, M. Rethinking lean synergistically in practice for construction industry improvements. Eng. Constr. Archit. Manag. 2023, 30, 2669–2690. [Google Scholar] [CrossRef]

- Saggin, A.B.; Valente, C.P.; Mourão, C.A.M.A.; Cabral, A.E.B. Comparing Investments in Sustainability with Cost Reduction from Waste Due to Lean Construction. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 28–31 July 2015; pp. 223–230. [Google Scholar]

- Shi, Q.; Zuo, J.; Huang, R.; Huang, J.; Pullen, S. Identifying the critical factors for green construction—An empirical study in China. Habitat Int. 2013, 40, 1–8. [Google Scholar] [CrossRef]

- Yin, B.C.L.; Laing, R.; Leon, M.; Mabon, L. An evaluation of sustainable construction perceptions and practices in Singapore. Sustain. Cities Soc. 2018, 39, 613–620. [Google Scholar] [CrossRef]

- Issa, U.H. Implementation of lean construction techniques for minimizing the risks effect on project construction time. Alex. Eng. J. 2013, 52, 697–704. [Google Scholar] [CrossRef]

- Ochoa, J.J. Reducing plan variations in delivering sustainable building projects. J. Clean. Prod. 2014, 85, 276–288. [Google Scholar] [CrossRef]

- Marhani, M.A.; Jaapar, A.; Bari, N.A.A.; Zawawi, M. Sustainability Through Lean Construction Approach: A Literature Review. Procedia Soc. Behav. Sci. 2013, 101, 90–99. [Google Scholar] [CrossRef]

- Weinheimer, N.; Schmalz, S.; Müller, D. Green Building and Lean Management: Synergies and Conflicts. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017; pp. 911–918. [Google Scholar]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green supply chain management in China: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity Press: New York, NY, USA, 1988. [Google Scholar]

- Chen, Y. Study on the application of lean construction supply chain management in EPC project. Appl. Mech. Mater. 2012, 201-202, 1207–1212. [Google Scholar] [CrossRef]

- Dües, C.M.; Tan, K.H.; Lim, M. Green as the new Lean: How to use Lean practices as a catalyst to greening your supply chain. J. Clean. Prod. 2013, 40, 93–100. [Google Scholar] [CrossRef]

- Antillon, E.I.; Alarcon, L.F.; Hallowell, M.R.; Molenaar, K.R. A Research Synthesis on the Interface Between Lean Construction and Safety Management. In Proceedings of the 19th Annual Conference of the International Group for Lean Construction, Lima, Peru, 13–15 July 2011. [Google Scholar]

- Tokbolat, S.; Karaca, F.; Durdyev, S.; Calay, R.K. Construction professionals’ perspectives on drivers and barriers of sustainable construction. Environ. Dev. Sustain. 2020, 22, 4361–4378. [Google Scholar] [CrossRef]

- Chileshe, N.; Dzisi, E. Benefits and barriers of construction health and safety management (HSM). J. Eng. Des. Technol. 2012, 10, 276–298. [Google Scholar] [CrossRef]

- Ogunbiyi, O.; Oladapo, A.; Goulding, J. An empirical study of the impact of lean construction techniques on sustainable construction in the UK. Constr. Innov. 2014, 14, 88–107. [Google Scholar] [CrossRef]

- Jiang, L.; Zhong, H.; Chen, J.; Cheng, J.; Chen, S.; Gong, Z.; Lun, Z.; Zhang, J.; Su, Z. Study on the construction workforce management based on lean construction in the context of COVID-19. Eng. Constr. Archit. Manag. 2023, 30, 3310–3329. [Google Scholar] [CrossRef]

- Karakhan, A.A.; Gambatese, J.A. Identification, Quantification, and Classification of Potential Safety Risk for Sustainable Construction in the United States. J. Constr. Eng. Manag. 2017, 143, 04017018. [Google Scholar] [CrossRef]

- Gou, Z.; Lau, S.S.-Y.; Prasad, D. Market Readiness and Policy Implications for Green Buildings: Case Study from Hong Kong. J. Green Build. 2013, 8, 162–173. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, X. Role of Lean Tools in Supporting Knowledge Creation and Performance in Lean Construction. Procedia Eng. 2016, 145, 1267–1274. [Google Scholar] [CrossRef]

- Rosenbaum, S.; Toledo, M.; González, V. Improving environmental and production performance in construction projects using value-stream mapping: Case study. J. Constr. Eng. Manag. 2014, 140, 04013045. [Google Scholar] [CrossRef]

- Ismael, D.; Shealy, T. Sustainable Construction Risk Perceptions in the Kuwaiti Construction Industry. Sustainability 2018, 10, 1854. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E. Sustainable Construction Supply Chains through Synchronized Production Planning and Control in Engineer-to-Order Enterprises. Sustainability 2017, 9, 1888. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Bae, J. Assessing the Environmental Impacts of a Lean Supply System: Case Study of High-Rise Condominium Construction in Korea. J. Arch. Eng. 2010, 16, 144–150. [Google Scholar] [CrossRef]

- Demirkesen, S.; Sadikoglu, E.; Jayamanne, E. Assessing psychological safety in lean construction projects in the united states. Constr. Econ. Build. 2021, 21, 159–175. [Google Scholar] [CrossRef]

- Vrijhoef, R.; Koskela, L. Revisiting the Three Peculiarities of Production in Construction. In Proceedings of the 13th Annual Conference of the International Group for Lean Construction, Sydney, Australia, 19–21 July 2005; pp. 19–27. [Google Scholar]

- Pham, H.; Kim, S.-Y.; Luu, T.-V. Managerial perceptions on barriers to sustainable construction in developing countries: Vietnam case. Environ. Dev. Sustain. 2020, 22, 2979–3003. [Google Scholar] [CrossRef]

- Tezel, A.; Koskela, L.; Aziz, Z. Lean thinking in the highways construction sector: Motivation, implementation and barriers. Prod. Plan. Control 2018, 29, 247–269. [Google Scholar] [CrossRef]

- Rita, R.P.; Saputra, A.; Ahmad, J.S.M. Stakeholders’ Barriers to Green Building Project at Universitas Gadjah Mada Indonesia. GEOMATE J. 2023, 25, 107–114. [Google Scholar] [CrossRef]

- Hwang, B.-G.; Shan, M.; Lye, J.-M. Adoption of sustainable construction for small contractors: Major barriers and best solutions. Clean Technol. Environ. Policy 2018, 20, 2223–2237. [Google Scholar] [CrossRef]

- Jain, M.S.; Sudarsan, J.S.; Parija, P.P. Managing construction and demolition waste using lean tools to achieve environmental sustainability: An Indian perspective. Environ. Sci. Pollut. Res. 2023, 30, 57188–57200. [Google Scholar] [CrossRef] [PubMed]

- Al-Aomar, R. Analysis of lean construction practices at Abu Dhabi construction industry. Lean Constr. J. 2012, 2012, 105–121. [Google Scholar]

- Moradi, S.; Sormunen, P. Integrating lean construction with BIM and sustainability: A comparative study of challenges, enablers, techniques, and benefits. Constr. Innov. 2023, 24, 188–203. [Google Scholar] [CrossRef]

- Serpell, A.; Kort, J.; Vera, S. Awareness, actions, drivers and barriers of sustainable construction in Chile. Technol. Econ. Dev. Econ. 2013, 19, 272–288. [Google Scholar] [CrossRef]

- Fathalizadeh, A.; Hosseini, M.R.; Vaezzadeh, S.S.; Edwards, D.J.; Martek, I.; Shooshtarian, S. Barriers to sustainable construction project management: The case of Iran. Smart Sustain. Built Environ. 2022, 11, 717–739. [Google Scholar] [CrossRef]

- Mishra, J.L.; Chiwenga, K.D.; Mishra, N.; Choudhary, S. Extending dynamic capabilities towards lean thinking in humanitarian supply chains. Prod. Plan. Control 2022, 33, 655–675. [Google Scholar] [CrossRef]

- Opoku, A.; Ahmed, V.; Ofori, G. Realising the sustainable development goals through organisational learning and efficient resource management in construction. Resour. Conserv. Recycl. 2022, 184, 106427. [Google Scholar] [CrossRef]

- Irannejad, N.; Shirouyehzad, H.; Shahin, A. Providing a Framework for Performance Evaluation of Organizations in Successfully Implementing TQM, Based on Knowledge Management Approach and Organizational Agility. Complexity 2023, 2023, 1857596. [Google Scholar] [CrossRef]

- Sun, J.; Sarfraz, M.; Turi, J.A.; Ivascu, L. Organizational Agility and Sustainable Manufacturing Practices in the Context of Emerging Economy: A Mediated Moderation Model. Processes 2022, 10, 2567. [Google Scholar] [CrossRef]

- Zhang, J.; Ouyang, Y.; Philbin, S.P.; Zhao, X.; Ballesteros-Pérez, P.; Li, H. Green dynamic capability of construction enterprises: Role of the business model and green production. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2920–2940. [Google Scholar] [CrossRef]

- Anand, G.; Ward, P.T.; Tatikonda, M.V.; Schilling, D.A. Dynamic capabilities through continuous improvement infrastructure. J. Oper. Manag. 2009, 27, 444–461. [Google Scholar] [CrossRef]

- Kohlbacher, M. The Impact of Dynamic Capabilities through Continuous Improvement on Innovation: The Role of Business Process Orientation. Knowl. Process Manag. 2013, 20, 71–76. [Google Scholar] [CrossRef]

- Strønen, F.; Hoholm, T.; Kværner, K.J.; Støme, L.N. Dynamic capabilities and innovation capabilities: The case of the ‘Innovation Clinic’. J. Entrep. Manag. Innov. 2017, 13, 89–116. [Google Scholar] [CrossRef]

- Adamczyk, S.; Hansen, E.G.; Reichwald, R. Measuring sustainability by environmental innovativeness: Results from action research at a multinational corporation in Germany. In Proceedings of the International Conference and Doctoral Consortium on Evaluation Metrics of Corporate Social and Environmental Responsibility, Lyon, France, 8–10 June 2009. [Google Scholar]

- Gu, N.; London, K. Understanding and facilitating BIM adoption in the AEC industry. Autom. Constr. 2010, 19, 988–999. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).