Systematic Review of Battery Life Cycle Management: A Framework for European Regulation Compliance

Abstract

1. Introduction

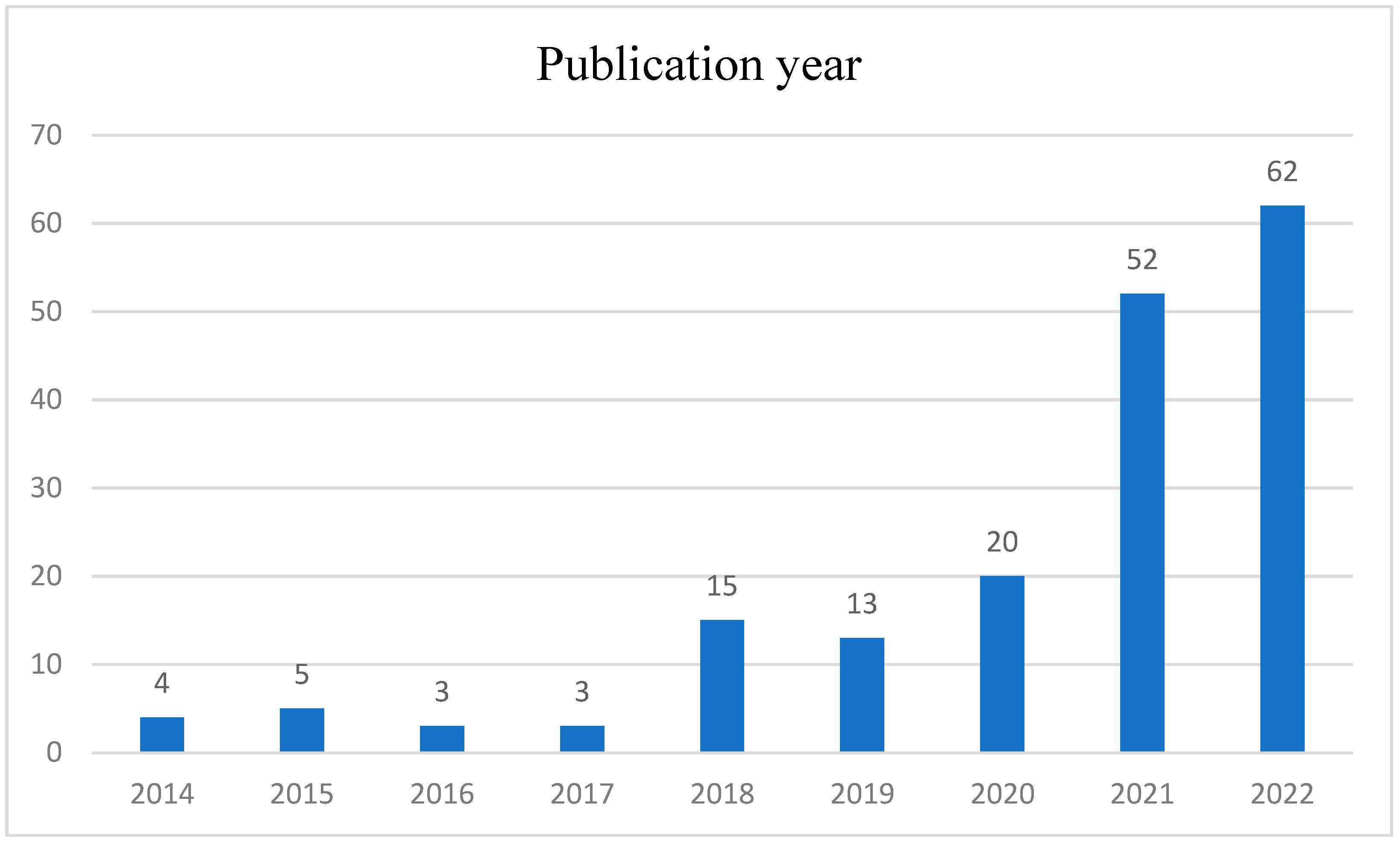

2. Materials and Methods

- Removal of duplicates identified both automatically by Rayyan and manually. At the end of the process, there were 13,145 papers left.

- Exclusion of papers through the platform’s AI and manual operations based on the interpolation of keywords, which brought the number of papers to 2302.

- Analysis of the remaining papers based on titles and abstracts and manual exclusion.

- Paper retrieval.

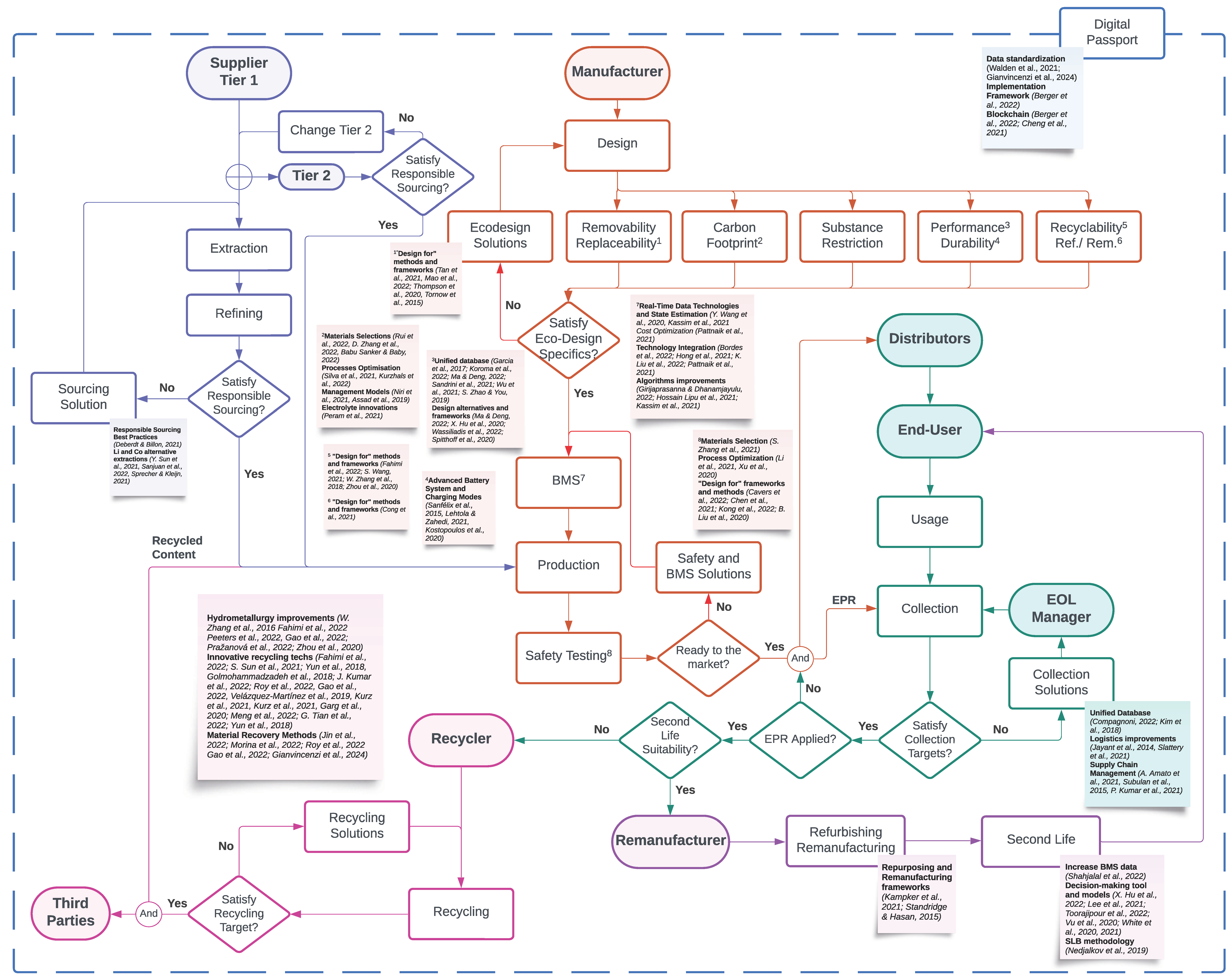

3. Results

3.1. Extraction Phase

3.2. Manufacturing Phase

3.3. Use Phase

3.4. Collection Phase

3.5. Recycling Phase

3.6. Second-Life Phase

3.7. Transversal Phase

4. Life Cycle Management Framework

4.1. Extraction Phase Management

4.2. Manufacturing Phase Management

4.3. Use and Collecting Phase Management

4.4. Remanufacturing, Refurbishing, and Second-Life Management

4.5. Recycling Phase Management

4.6. Battery Passport Management

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Masias, A.; Marcicki, J.; Paxton, W.A. Opportunities and Challenges of Lithium Ion Batteries in Automotive Applications. ACS Energy Lett. 2021, 6, 621–630. [Google Scholar] [CrossRef]

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A Review on Battery Market Trends, Second-Life Reuse, and Recycling. Sustain. Chem. 2021, 2, 167–205. [Google Scholar] [CrossRef]

- Global Market Insights. Battery Electric Vehicle Market Size, By Vehicle (Electric Cars, Electric Buses, Electric Trucks, Electric Motorcycles & Scooters, E-bikes), By Battery Type (SLA, Li-ion, NiMH), COVID-19 Impact Analysis, Regional Outlook, Growth Potential, Competitive Mar. 2022. Available online: https://www.wgsn.com/content/search/reports/?searchId=5595121#/Burberry%2520flagship%2520stores (accessed on 13 November 2024).

- Snowdon, N.; Rai, A.; Schiavon, A.; Sharp, D.; Currie, J.; Chen, T.; Zhang, J. Battery Metals Watch: The end of the beginning (Issue May 2022). 2022. Available online: https://www.goldmansachs.com/pdfs/insights/pages/gs-research/battery-metals-watch-the-end-of-the-beginning/report.pdf (accessed on 13 November 2024).

- Dühnen, S.; Betz, J.; Kolek, M.; Schmuch, R.; Winter, M.; Placke, T. Toward Green Battery Cells: Perspective on Materials and Technologies. Small Methods 2020, 4, 2000039. [Google Scholar] [CrossRef]

- Zanoletti, A.; Carena, E.; Ferrara, C.; Bontempi, E. A Review of Lithium-Ion Battery Recycling: Technologies, Sustainability, and Open Issues. Batteries 2024, 10, 38. [Google Scholar] [CrossRef]

- Gebhardt, M.; Beck, J.; Kopyto, M.; Spieske, A. Determining requirements and challenges for a sustainable and circular electric vehicle battery supply chain: A mixed-methods approach. Sustain. Prod. Consum. 2022, 33, 203–217. [Google Scholar] [CrossRef]

- Gianvincenzi, M.; Marconi, M.; Mosconi, E.M.; Tola, F. Eco-design Framework for a Battery Sustainable Lifecycle Management. In Design Tools and Methods in Industrial Engineering III. ADM 2023. Lecture Notes in Mechanical Engineering; Carfagni, M., Furferi, R., Di Stefano, P., Governi, L., Gherardini, F., Eds.; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- World Economic Forum; Global Battery Alliance. A Vision for a Sustainable Battery Value Chain in 2030. 10–11 September 2019. Available online: https://www3.weforum.org/docs/WEF_A_Vision_for_a_Sustainable_Battery_Value_Chain_in_2030_Report.pdf (accessed on 13 November 2024).

- Dai, Q.; Kelly, J.C.; Gaines, L.; Wang, M. Life cycle analysis of lithium-ion batteries for automotive applications. Batteries 2019, 5, 48. [Google Scholar] [CrossRef]

- Brückner, L.; Frank, J.; Elwert, T. Industrial recycling of lithium-ion batteries—A critical review of metallurgical process routes. Metals 2020, 10, 1107. [Google Scholar] [CrossRef]

- Toorajipour, R.; Chirumalla, K.; Parida, V.; Johansson, G.; Dahlquist, E.; Wallin, F. Preconditions of Circular Business Model Innovation for the Electric Vehicle Battery Second Life: An Ecosystem Perspective. In Proceedings of the 10th Swedish Production Symposium, SPS 2022, Skövde, Sweden, 26–29 April 2022; Volume 21, pp. 279–291. [Google Scholar] [CrossRef]

- Feng, T.; Guo, W.; Li, Q.; Meng, Z.; Liang, W. Life cycle assessment of lithium nickel cobalt manganese oxide batteries and lithium iron phosphate batteries for electric vehicles in China. J. Energy Storage 2022, 52, 104767. [Google Scholar] [CrossRef]

- Mao, J.; Ye, C.; Zhang, S.; Xie, F.; Zeng, R.; Davey, K.; Guo, Z.; Qiao, S. Toward practical lithium-ion battery recycling: Adding value, tackling circularity and recycling-oriented design. Energy Environ. Sci. 2022, 15, 2732–2752. [Google Scholar] [CrossRef]

- European Commission. Green Deal Industrial Plan for the Net-Zero Age. COM (2023) 62 Final. 2023. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52023DC0062 (accessed on 13 November 2024).

- European Parliament and Council of the European Union. Regulation (EU) No 2023/1542 of the European Parliament and of the Council on Batteries and Waste Batteries. 2023. Available online: https://eur-lex.europa.eu/eli/reg/2023/1542/oj (accessed on 13 November 2024).

- European Commission. A New Circular Economy Action Plan–For a Cleaner and More Competitive Europe. COM (2020) 98 Final. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0098 (accessed on 13 November 2024).

- Mengist, W.; Soromessa, T.; Legese, G. Method for conducting systematic literature review and meta-analysis for environmental science research. Methodsx 2020, 7, 100777. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The SAGE Handbook of Organizational Research Methods; Sage Publications Ltd.: Thousand Oaks, CA, USA, 2009; p. 776. [Google Scholar]

- Pellegrini, M.; Marsili, F. Evaluating software tools to conduct systematic reviews: A feature analysis and user survey. Form@ Re-Open J. Per Form. Rete 2021, 21, 124–140. [Google Scholar] [CrossRef]

- Weil, M.; Ziemann, S.; Peters, J. The Issue of Metal Resources in Li-Ion Batteries for Electric Vehicles. In Behaviour of Lithium-Ion Batteries in Electric Vehicles; Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2018; pp. 59–74. [Google Scholar] [CrossRef]

- Hodgkinson, J.H.; Smith, M.H. Climate change and sustainability as drivers for the next mining and metals boom: The need for climate-smart mining and recycling. Resour. Policy 2021, 74, 101205. [Google Scholar] [CrossRef]

- Khalil, A.; Mohammed, S.; Hashaikeh, R.; Hilal, N. Lithium recovery from brine: Recent developments and challenges. Desalination 2022, 528, 115611. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Q.; Wang, Y.; Yun, R.; Xiang, X. Recent advances in magnesium/lithium separation and lithium extraction technologies from salt lake brine. Sep. Purif. Technol. 2021, 256, 117807. [Google Scholar] [CrossRef]

- Sanjuan, B.; Gourcerol, B.; Millot, R.; Rettenmaier, D.; Jeandel, E.; Rombaut, A. Lithium-rich geothermal brines in Europe: An update about geochemical characteristics and implications for potential Li resources. Geothermics 2022, 101, 102385. [Google Scholar] [CrossRef]

- Wall, A. Competitiveness of direct mineral extraction from geothermal brines. In Proceedings of theGeothermal Resources Council 2019 Annual Meeting–Geothermal: Green Energy for the Long Run, GRC 2019, Palm Springs, CA, USA, 15–18 September 2019; Volume 43, pp. 854–859. [Google Scholar]

- Rachidi, N.R.; Nwaila, G.T.; Zhang, S.E.; Bourdeau, J.E.; Ghorbani, Y. Assessing cobalt supply sustainability through production forecasting and implications for green energy policies. Resour. Policy 2021, 74, 102423. [Google Scholar] [CrossRef]

- Earl, C.; Shah, I.H.; Cook, S.; Cheeseman, C.R. Environmental Sustainability and Supply Resilience of Cobalt. Sustainability 2022, 14, 4124. [Google Scholar] [CrossRef]

- Nkulu, C.B.L.; Casas, L.; Haufroid, V.; De Putter, T.; Saenen, N.D.; Kayembe-Kitenge, T.; Obadia, P.M.; Mukoma, D.K.W.; Ilunga, J.-M.L.; Nawrot, T.S.; et al. Sustainability of artisanal mining of cobalt in DR Congo. Nat. Sustain. 2018, 1, 495–504. [Google Scholar] [CrossRef]

- Sprecher, B.; Kleijn, R. Tackling material constraints on the exponential growth of the energy transition. One Earth 2021, 4, 335–338. [Google Scholar] [CrossRef]

- Alvarenga, R.; Préat, N.; Duhayon, C.; Dewulf, J. Prospective life cycle assessment of metal commodities obtained from deep-sea polymetallic nodules. J. Clean. Prod. 2021, 330, 129884. [Google Scholar] [CrossRef]

- Golroudbary, S.R.; Makarava, I.; Kraslawski, A.; Repo, E. Global environmental cost of using rare earth elements in green energy technologies. Sci. Total. Environ. 2022, 832, 155022. [Google Scholar] [CrossRef] [PubMed]

- Navarro, J.; Zhao, F. Life-cycle assessment of the production of rare-earth elements for energy applications: A review. Front. Energy Res. 2014, 2, 45. [Google Scholar] [CrossRef]

- Schreiber, A.; Marx, J.; Zapp, P. Life Cycle Assessment studies of rare earths production–Findings from a systematic review. Sci. Total. Environ. 2021, 791, 148257. [Google Scholar] [CrossRef] [PubMed]

- Deberdt, R.; Le Billon, P. Conflict minerals and battery materials supply chains: A mapping review of responsible sourcing initiatives. Extr. Ind. Soc. 2021, 8, 100935. [Google Scholar] [CrossRef]

- Deberdt, R. The Democratic Republic of the Congo (DRC)’s response to artisanal cobalt mining: The Entreprise Générale du Cobalt (EGC). Extr. Ind. Soc. 2021, 8, 101013. [Google Scholar] [CrossRef]

- Mancini, L.; Eslava, N.A.; Traverso, M.; Mathieux, F. Assessing impacts of responsible sourcing initiatives for cobalt: Insights from a case study. Resour. Policy 2021, 71, 102015. [Google Scholar] [CrossRef]

- Liu, W.; Agusdinata, D.B.; Eakin, H.; Romero, H. Sustainable minerals extraction for electric vehicles: A pilot study of consumers’ perceptions of impacts. Resour. Policy 2022, 75, 102523. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, A.; Verma, S.; Paul, A.R.; Jain, A.; Haque, N. Life Cycle Assessment Based Environmental Footprint of a Battery Recycling Process. Int. Conf. Intell. Manuf. Energy Sustain. 2022, 265, 115–123. [Google Scholar] [CrossRef]

- Melchor-Martínez, E.M.; Macias-Garbett, R.; Malacara-Becerra, A.; Iqbal, H.M.; Sosa-Hernández, J.E.; Parra-Saldívar, R. Environmental impact of emerging contaminants from battery waste: A mini review. Case Stud. Chem. Environ. Eng. 2021, 3, 100104. [Google Scholar] [CrossRef]

- Recknagel, S.; Radant, H.; Kohlmeyer, R. Survey of mercury, cadmium and lead content of household batteries. Waste Manag. 2014, 34, 156–161. [Google Scholar] [CrossRef]

- Ellingsen, L.A.-W.; Hung, C.R.; Strømman, A.H. Identifying key assumptions and differences in life cycle assessment studies of lithium-ion traction batteries with focus on greenhouse gas emissions. Transp. Res. Part D Transp. Environ. 2017, 55, 82–90. [Google Scholar] [CrossRef]

- Niri, M.F.; Liu, K.; Apachitei, G.; Ramirez, L.R.; Lain, M.; Widanage, D.; Marco, J. Machine learning for optimised and clean Li-ion battery manufacturing: Revealing the dependency between electrode and cell characteristics. J. Clean. Prod. 2021, 324, 129272. [Google Scholar] [CrossRef]

- Silva, G.V.; Thomitzek, M.; Abraham, T.; Herrmann, C. Bottleneck reduction strategies for energy efficiency in the battery manufacturing. Procedia CIRP 2021, 104, 1017–1022. [Google Scholar] [CrossRef]

- Assad, F.; Alkan, B.; Chinnathai, M.; Ahmad, M.; Rushforth, E.; Harrison, R. A framework to predict energy related key performance indicators of manufacturing systems at early design phase. Procedia CIRP 2019, 81, 145–150. [Google Scholar] [CrossRef]

- Lander, L.; Kallitsis, E.; Hales, A.; Edge, J.S.; Korre, A.; Offer, G. Cost and carbon footprint reduction of electric vehicle lithium-ion batteries through efficient thermal management. Appl. Energy 2021, 289, 116737. [Google Scholar] [CrossRef]

- Sanker, S.B.; Baby, R. Phase change material based thermal management of lithium ion batteries: A review on thermal performance of various thermal conductivity enhancers. J. Energy Storage 2022, 50, 104606. [Google Scholar] [CrossRef]

- Rui, X.; Geng, Y.; Zhuang, M.; Xiao, S.; Sun, X. Emergy-based environmental accounting of graphite anode material production. J. Clean. Prod. 2022, 339, 130705. [Google Scholar] [CrossRef]

- Kurzhals, P.; Riewald, F.; Bianchini, M.; Ahmed, S.; Kern, A.M.; Walther, F.; Sommer, H.; Volz, K.; Janek, J. Deeper Understanding of the Lithiation Reaction during the Synthesis of LiNiO2 Towards an Increased Production Throughput. J. Electrochem. Soc. 2022, 169, 050526. [Google Scholar] [CrossRef]

- Zhang, D.; Cao, J.; Gu, C.; Zhang, X.; Insin, N.; Wang, S.; Pattananuwat, P.; Zeng, Z.; Qin, J. Rational design of fly ash-based composites for sustainable lithium-ion battery anodes. Electrochimica Acta 2022, 410, 140035. [Google Scholar] [CrossRef]

- Mostert, C.; Ostrander, B.; Bringezu, S.; Kneiske, T.M. Comparing electrical energy storage technologies regarding their material and carbon footprint. Energies 2018, 11, 3386. [Google Scholar] [CrossRef]

- Peram, S.R.; Lokesh, H.; Kosaraju, S.; Murthy, K.; Jagadish, M. Reduction of acid mist emission in formation process of Automotive lead acid battery manufacturing industry by means of an electrolyte additive. Mater. Today Proc. 2021, 46, 8275–8282. [Google Scholar] [CrossRef]

- Dunn, J.; Kendall, A.; Slattery, M. Electric vehicle lithium-ion battery recycled content standards for the US—Targets, costs, and environmental impacts. Resour. Conserv. Recycl. 2022, 185, 106488. [Google Scholar] [CrossRef]

- Abdelbaky, M.; Peeters, J.R.; Dewulf, W. On the influence of second use, future battery technologies, and battery lifetime on the maximum recycled content of future electric vehicle batteries in Europe. Waste Manag. 2021, 125, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Daigo, I.; Panasiuk, D.; Dunuwila, P.; Hamada, K.; Hoshino, T. Impact of recycling effect in comparative life cycle assessment for materials selection—A case study of light-weighting vehicles. J. Clean. Prod. 2022, 349, 131317. [Google Scholar] [CrossRef]

- Woidasky, J.; Cetinkaya, E. Use pattern relevance for laptop repair and product lifetime. J. Clean. Prod. 2020, 288, 125425. [Google Scholar] [CrossRef]

- Liu, K.; Wang, Y.; Lai, X. Key Stages for Battery Full-Lifespan Management. In Data Science-Based Full-Lifespan Management of Lithium-Ion Battery; Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2022; pp. 27–47. [Google Scholar] [CrossRef]

- Tan, J.; Wang, Q.; Chen, S.; Li, Z.; Sun, J.; Liu, W.; Yang, W.; Xiang, X.; Sun, X.; Duan, X. Recycling-oriented cathode materials design for lithium-ion batteries: Elegant structures versus complicated compositions. Energy Storage Mater. 2021, 41, 380–394. [Google Scholar] [CrossRef]

- Thompson, D.L.; Hartley, J.M.; Lambert, S.M.; Shiref, M.; Harper, G.D.J.; Kendrick, E.; Anderson, P.; Ryder, K.S.; Gaines, L.; Abbott, A.P. The importance of design in lithium ion battery recycling—A critical review. Green Chem. 2020, 22, 7585–7603. [Google Scholar] [CrossRef]

- Tornow, A.; Andrew, S.; Dietrich, F.; Dröder, K. Impact of multi-material components on the assembly and disassembly of traction batteries. Procedia CIRP 2015, 29, 792–797. [Google Scholar] [CrossRef]

- Zhang, S.; Li, S.; Lu, Y. Designing safer lithium-based batteries with nonflammable electrolytes: A review. eScience 2021, 1, 163–177. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Shang, R.; Cheng, C.; Cheng, Y.; Xing, J.; Wei, Z.; Zhao, Y. Recent advances in lithium-ion battery separators with reversible/irreversible thermal shutdown capability. Energy Storage Mater. 2021, 43, 143–157. [Google Scholar] [CrossRef]

- Zhong, S.; Yuan, B.; Guang, Z.; Chen, D.; Li, Q.; Dong, L.; Ji, Y.; Dong, Y.; Han, J.; He, W. Recent progress in thin separators for upgraded lithium ion batteries. Energy Storage Mater. 2021, 41, 805–841. [Google Scholar] [CrossRef]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Liu, B.; Jia, Y.; Yuan, C.; Wang, L.; Gao, X.; Yin, S.; Xu, J. Safety issues and mechanisms of lithium-ion battery cell upon mechanical abusive loading: A review. Energy Storage Mater. 2020, 24, 85–112. [Google Scholar] [CrossRef]

- Xu, J.; Ma, J.; Zhao, X.; Chen, H.; Xu, B.; Wu, X. Detection technology for battery safety in electric vehicles: A review. Energies 2020, 13, 4636. [Google Scholar] [CrossRef]

- Xiong, R.; Ma, S.; Li, H.; Sun, F.; Li, J. Toward a safer battery management system: A critical review on diagnosis and prognosis of battery short circuit. iScience 2020, 23, 101010. [Google Scholar] [CrossRef]

- Cavers, H.; Molaiyan, P.; Abdollahifar, M.; Lassi, U.; Kwade, A. Perspectives on improving the safety and sustainability of high voltage lithium-ion batteries through the electrolyte and separator region. Adv. Energy Mater. 2022, 12, 2200147. [Google Scholar] [CrossRef]

- Kong, X.; Lu, L.; Yuan, Y.; Sun, Y.; Feng, X.; Yang, H.; Zhang, F.; Zhang, J.; Liu, X.; Han, X.; et al. Foreign matter defect battery and sudden spontaneous combustion. eTransportation 2022, 12, 100170. [Google Scholar] [CrossRef]

- Kirkels, A.F.; Bleker, J.; Romijn, H.A. Ready for the Road? A Socio-Technical Investigation of Fire Safety Improvement Options for Lithium-Ion Traction Batteries. Energies 2022, 15, 3323. [Google Scholar] [CrossRef]

- Longchamps, R.S.; Yang, X.-G.; Wang, C.-Y. Fundamental Insights into Battery Thermal Management and Safety. ACS Energy Lett. 2022, 7, 1103–1111. [Google Scholar] [CrossRef]

- Altarabichi, M.G.; Fan, Y.; Pashami, S.; Mashhadi, P.S.; Nowaczyk, S. Extracting invariant features for predicting state of health of batteries in hybrid energy buses. In Proceedings of the IEEE Data Science and Advanced Analytics (DSAA) 2021, Porto, Portugal, 6–9 October 2021; p. 9564184. [Google Scholar] [CrossRef]

- Cai, Z.; Mendoza, S.; Goodman, J.; Mcgann, J.; Han, B.; Sanchez, H.; Spray, R. The Influence of Cycling, Temperature, and Electrode Gapping on the Safety of Prismatic Lithium-Ion Batteries. J. Electrochem. Soc. 2020, 167, 160515. [Google Scholar] [CrossRef]

- Shafique, M.; Luo, X. Environmental life cycle assessment of battery electric vehicles from the current and future energy mix perspective. J. Environ. Manag. 2022, 303, 114050. [Google Scholar] [CrossRef] [PubMed]

- Garcia, J.; Millet, D.; Tonnelier, P.; Richet, S.; Chenouard, R. A novel approach for global environmental performance evaluation of electric batteries for hybrid vehicles. J. Clean. Prod. 2017, 156, 406–417. [Google Scholar] [CrossRef]

- Dik, A.; Omer, S.; Boukhanouf, R. Electric Vehicles: V2G for Rapid, Safe, and Green EV Penetration. Energies 2022, 15, 803. [Google Scholar] [CrossRef]

- Dhanasekar, R.; Vijayaraja, L.; Kaushik, V.N.; Prasanth, S.; Poornesh, C.K.; Ragunathan, A. An Overview of EV Batteries and Study Analysis on Charging Methodology. In Proceedings of the 12th International Conference on Computing Communication and Informatics, Haikou, China, 4–7 November 2022; p. 9740935. [Google Scholar] [CrossRef]

- Landi, D.; Marconi, M.; Pietroni, G. Comparative life cycle assessment of two different battery technologies: Lithium iron phosphate and sodium-sulfur. Procedia CIRP 2022, 105, 482–488. [Google Scholar] [CrossRef]

- Quan, J.; Zhao, S.; Song, D.; Wang, T.; He, W.; Li, G. Comparative life cycle assessment of LFP and NCM batteries including the secondary use and different recycling technologies. Sci. Total. Environ. 2022, 819, 153105. [Google Scholar] [CrossRef]

- Zhao, S.; You, F. Comparative Life-Cycle Assessment of Li-Ion Batteries through Process-Based and Integrated Hybrid Approaches. ACS Sustain. Chem. Eng. 2019, 7, 5082–5094. [Google Scholar] [CrossRef]

- Ma, R.; Deng, Y. The electrochemical model coupled parameterized life cycle assessment for the optimized design of EV battery pack. Int. J. Life Cycle Assess. 2022, 27, 267–280. [Google Scholar] [CrossRef]

- Sandrini, G.; Có, B.; Tomasoni, G.; Gadola, M.; Chindamo, D. The Environmental Performance of Traction Batteries for Electric Vehicles from a Life Cycle Perspective. Sci. J. Riga Tech. Univ. Environ. Clim. Technol. 2021, 25, 700–716. [Google Scholar] [CrossRef]

- Wu, H.; Hu, Y.; Yu, Y.; Huang, K.; Wang, L. The environmental footprint of electric vehicle battery packs during the production and use phases with different functional units. Int. J. Life Cycle Assess. 2021, 26, 97–113. [Google Scholar] [CrossRef]

- Koroma, M.S.; Costa, D.; Philippot, M.; Cardellini, G.; Hosen, M.S.; Coosemans, T.; Messagie, M. Life cycle assessment of battery electric vehicles: Implications of future electricity mix and different battery end-of-life management. Sci. Total Environ. 2022, 831, 154859. [Google Scholar] [CrossRef]

- Hu, X.; Zheng, Y.; Howey, D.A.; Perez, H.; Foley, A.; Pecht, M. Battery warm-up methodologies at subzero temperatures for automotive applications: Recent advances and perspectives. Prog. Energy Combust. Sci. 2020, 77, 100806. [Google Scholar] [CrossRef]

- Sanfélix, J.; Messagie, M.; Omar, N.; Van Mierlo, J.; Hennige, V. Environmental performance of advanced hybrid energy storage systems for electric vehicle applications. Appl. Energy 2015, 137, 925–930. [Google Scholar] [CrossRef]

- Spitthoff, L.; Lamb, J.J.; Pollet, B.G.; Burheim, O.S. Lifetime expectancy of lithium-ion batteries. In Micro-Optics and Energy; Springer: Berlin/Heidelberg, Germany, 2020; pp. 157–180. [Google Scholar] [CrossRef]

- Wassiliadis, N.; Steinsträter, M.; Schreiber, M.; Rosner, P.; Nicoletti, L.; Schmid, F.; Ank, M.; Teichert, O.; Wildfeuer, L.; Schneider, J.; et al. Quantifying the state of the art of electric powertrains in battery electric vehicles: Range, efficiency, and lifetime from component to system level of the Volkswagen ID.3. eTransportation 2022, 12, 100167. [Google Scholar] [CrossRef]

- Lehtola, T.A.; Zahedi, A. Electric Vehicle Battery Cell Cycle Aging in Vehicle to Grid Operations: A Review. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 423–437. [Google Scholar] [CrossRef]

- Kostopoulos, E.D.; Spyropoulos, G.C.; Kaldellis, J.K. Real-world study for the optimal charging of electric vehicles. Energy Rep. 2020, 6, 418–426. [Google Scholar] [CrossRef]

- Davidson, A.J.; Binks, S.P.; Gediga, J. Lead industry life cycle studies: Environmental impact and life cycle assessment of lead battery and architectural sheet production. Int. J. Life Cycle Assess. 2016, 21, 1624–1636. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, L.; Hua, H.; Liu, X.; Wu, H.; Yuan, Z. Assessment of end-of-life electric vehicle batteries in China: Future scenarios and economic benefits. Waste Manag. 2021, 135, 70–78. [Google Scholar] [CrossRef]

- Standridge, C.R.; Hasan, M.M. Post-vehicle-application lithium–ion battery remanufacturing, repurposing and recycling capacity: Modeling and analysis. J. Ind. Eng. Manag. 2015, 8, 823–839. [Google Scholar] [CrossRef]

- Kim, H.; Jang, Y.-C.; Hwang, Y.; Ko, Y.; Yun, H. End-of-life batteries management and material flow analysis in South Korea. Front. Environ. Sci. Eng. 2018, 12, 3. [Google Scholar] [CrossRef]

- Jayant, A.; Gupta, P.; Garg, S. Reverse logistics network design for spent batteries: A simulation study. Int. J. Logist. Syst. Manag. 2014, 18, 343. [Google Scholar] [CrossRef]

- Slattery, M.; Dunn, J.; Kendall, A. Transportation of electric vehicle lithium-ion batteries at end-of-life: A literature review. Resour. Conserv. Recycl. 2021, 174, 105755. [Google Scholar] [CrossRef]

- Turner, J.M.; Nugent, L.M. Charging up Battery Recycling Policies: Extended Producer Responsibility for Single-Use Batteries in the European Union, Canada, and the United States. J. Ind. Ecol. 2016, 20, 1148–1158. [Google Scholar] [CrossRef]

- Zan, X.; Zhang, D. Analysis on the Optimal Recycling Path of Chinese Lead-Acid Battery under the Extended Producer Responsibility System. Sustainability 2022, 14, 4950. [Google Scholar] [CrossRef]

- Lin, S.-S.; Chiu, K.-H. An evaluation of recycling schemes for waste dry batteries—A simulation approach. J. Clean. Prod. 2015, 93, 330–338. [Google Scholar] [CrossRef]

- Compagnoni, M. Is Extended Producer Responsibility living up to expectations? A systematic literature review focusing on electronic waste. J. Clean. Prod. 2022, 367, 133101. [Google Scholar] [CrossRef]

- Tian, X.; Wu, Y.; Hou, P.; Liang, S.; Qu, S.; Xu, M.; Zuo, T. Environmental impact and economic assessment of secondary lead production: Comparison of main spent lead-acid battery recycling processes in China. J. Clean. Prod. 2017, 144, 142–148. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, J.; Wu, X.; Hu, Y.; Yu, W.; Wang, J.; Dong, J.; Li, M.; Liang, S.; Hu, J.; et al. A critical review on secondary lead recycling technology and its prospect. Renew. Sustain. Energy Rev. 2016, 61, 108–122. [Google Scholar] [CrossRef]

- Gao, S.-J.; Liu, W.-F.; Fu, D.-J.; Liu, X.-G. Research progress on recovering the components of spent Li-ion batteries. Xinxing Tan Cailiao/New Carbon Mater. 2022, 37, 435–460. [Google Scholar] [CrossRef]

- Jin, S.; Mu, D.; Lu, Z.; Li, R.; Liu, Z.; Wang, Y.; Tian, S.; Dai, C. A comprehensive review on the recycling of spent lithium-ion batteries: Urgent status and technology advances. J. Clean. Prod. 2022, 340, 130535. [Google Scholar] [CrossRef]

- Pražanová, A.; Knap, V.; Stroe, D.-I. Literature Review, Recycling of Lithium-Ion Batteries from Electric Vehicles, Part I: Recycling Technology. Energies 2022, 15, 1086. [Google Scholar] [CrossRef]

- Gianvincenzi, M.; Mosconi, E.M.; Marconi, M.; Tola, F. Battery Waste Management in Europe: Black Mass Hazardousness and Recycling Strategies in the Light of an Evolving Competitive Regulation. Recycling 2024, 9, 13. [Google Scholar] [CrossRef]

- Tian, G.; Yuan, G.; Aleksandrov, A.; Zhang, T.; Li, Z.; Fathollahi-Fard, A.M.; Ivanov, M. Recycling of spent Lithium-ion Batteries: A comprehensive review for identification of main challenges and future research trends. Sustain. Energy Technol. Assess. 2022, 53, 102447. [Google Scholar] [CrossRef]

- Makuza, B.; Tian, Q.; Guo, X.; Chattopadhyay, K.; Yu, D. Pyrometallurgical options for recycling spent lithium-ion batteries: A comprehensive review. J. Power Sources 2021, 491, 229622. [Google Scholar] [CrossRef]

- Billy, E.; Joulié, M.; Laucournet, R.; Boulineau, A.; De Vito, E.; Meyer, D. Dissolution Mechanisms of LiNi1/3Mn1/3Co1/3O2 Positive Electrode Material from Lithium-Ion Batteries in Acid Solution. ACS Appl. Mater. Interfaces 2018, 10, 16424–16435. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.C.-Y.; Sui, P.-C.; Zhang, J. A review of recycling spent lithium-ion battery cathode materials using hydro-metallurgical treatments. J. Energy Storage 2021, 35, 102217. [Google Scholar] [CrossRef]

- Fahimi, A.; Ducoli, S.; Federici, S.; Ye, G.; Mousa, E.; Frontera, P.; Bontempi, E. Evaluation of the sustainability of technologies to recycle spent lithium-ion batteries, based on embodied energy and carbon footprint. J. Clean. Prod. 2022, 338, 130493. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, B.; Shen, M.; Wu, Y.; Qu, S.; Hu, Y.; Feng, Y. Environmental impact assessment of second life and recycling for LiFePO4 power batteries in China. J. Environ. Manag. 2022, 314, 115083. [Google Scholar] [CrossRef]

- Tao, Y.; Rahn, C.D.; Archer, L.A.; You, F. Second life and recycling: Energy and environmental sustainability perspectives for high-performance lithium-ion batteries. Sci. Adv. 2021, 7, eabi7633. [Google Scholar] [CrossRef]

- Peeters, N.; Binnemans, K.; Riaño, S. Recovery of cobalt from lithium-ion battery cathode material by combining solvoleaching and solvent extraction. Green Chem. 2022, 24, 2839–2852. [Google Scholar] [CrossRef]

- Kumar, J.; Neiber, R.R.; Park, J.; Soomro, R.A.; Greene, G.W.; Mazari, S.A.; Seo, H.Y.; Lee, J.H.; Shon, M.; Chang, D.W.; et al. Recent progress in sustainable recycling of LiFePO4-type lithium-ion batteries: Strategies for highly selective lithium recovery. Chem. Eng. J. 2022, 431, 133993. [Google Scholar] [CrossRef]

- Roy, J.J.; Rarotra, S.; Krikstolaityte, V.; Zhuoran, K.W.; Cindy, Y.D.; Tan, X.Y.; Carboni, M.; Meyer, D.; Yan, Q.; Srinivasan, M. Green Recycling Methods to Treat Lithium-Ion Batteries E-Waste: A Circular Approach to Sustainability. Adv. Mater. 2022, 34, 2103346. [Google Scholar] [CrossRef] [PubMed]

- Golmohammadzadeh, R.; Faraji, F.; Rashchi, F. Recovery of lithium and cobalt from spent lithium ion batteries (LIBs) using organic acids as leaching reagents: A review. Resour. Conserv. Recycl. 2018, 136, 418–435. [Google Scholar] [CrossRef]

- Morina, R.; Callegari, D.; Merli, D.; Alberti, G.; Mustarelli, P.; Quartarone, E. Cathode Active Material Recycling from Spent Lithium Batteries: A Green (Circular) Approach Based on Deep Eutectic Solvents. ChemSusChem 2022, 15, e202102080. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.-F.; Yang, D.; Du, T.; Gong, H.; Luo, W.-B. The Current Process for the Recycling of Spent Lithium Ion Batteries. Front. Chem. 2020, 8, 44. [Google Scholar] [CrossRef] [PubMed]

- Velázquez-Martínez, O.; Valio, J.; Santasalo-Aarnio, A.; Reuter, M.; Serna-Guerrero, R. A critical review of lithium-ion battery recycling processes from a circular economy perspective. Batteries 2019, 5, 68. [Google Scholar] [CrossRef]

- Kurz, L.; Faryadras, M.; Klugius, I.; Reichert, F.; Scheibe, A.; Schmidt, M.; Wörner, R. Global warming potential of a new waterjet-based recycling process for cathode materials of lithium-ion batteries. Batteries 2021, 7, 29. [Google Scholar] [CrossRef]

- Wolf, A.; Flegler, A.; Prieschl, J.; Stuebinger, T.; Witt, W.; Seiser, F.; Vinnay, T.; Sinn, T.; Gleiß, M.; Nirschl, H.; et al. Centrifugation based separation of lithium iron phosphate (LFP) and carbon black for lithium-ion battery recycling. Chem. Eng. Process.-Process. Intensif. 2021, 160, 108310. [Google Scholar] [CrossRef]

- Perez-Antolin, D.; Irastorza, C.; Gonzalez, S.; Moreno, R.; García-Quismondo, E.; Palma, J.; Lado, J.J.; Ventosa, E. Regenerative electrochemical ion pumping cell based on semi-solid electrodes for sustainable Li recovery. Desalination 2022, 533, 115764. [Google Scholar] [CrossRef]

- Yu, D.; Huang, Z.; Makuza, B.; Guo, X.; Tian, Q. Pretreatment options for the recycling of spent lithium-ion batteries: A comprehensive review. Miner. Eng. 2021, 173, 107218. [Google Scholar] [CrossRef]

- Garg, A.; Zhou, L.; Zheng, J.; Gao, L. Qualitative framework based on intelligent robotics for safe and efficient disassembly of battery modules for recycling purposes. In Proceedings of the International Conference on Sustainable Energy and Green Technology 2019, SEGT 2019, Bangkok, Thailand, 11–14 December 2019; IOP Publishing: Bristol, UK, 2020; Volume 463. [Google Scholar]

- Meng, K.; Xu, G.; Peng, X.; Youcef-Toumi, K.; Li, J. Intelligent disassembly of electric-vehicle batteries: A forward-looking overview. Resour. Conserv. Recycl. 2022, 182, 106207. [Google Scholar] [CrossRef]

- Dos Santos, C.S.; Alves, J.C.; da Silva, S.P.; Evangelista Sita, L.; da Silva PR, C.; de Almeida, L.C.; Scarminio, J. A closed-loop process to recover Li and Co compounds and to resynthesize LiCoO2 from spent mobile phone batteries. J. Hazard. Mater. 2019, 362, 458–466. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Jin, C.; He, W.; Li, G.; Zhu, H.; Huang, J. Management status of waste lithium-ion batteries in China and a complete closed-circuit recycling process. Sci. Total. Environ. 2021, 776, 145913. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Xu, C.; He, W.; Li, G.; Huang, J. A review on management of spent lithium ion batteries and strategy for resource recycling of all components from them. Waste Manag. Res. 2018, 36, 99–112. [Google Scholar] [CrossRef] [PubMed]

- Assefi, M.; Maroufi, S.; Yamauchi, Y.; Sahajwalla, V. Pyrometallurgical recycling of Li-ion, Ni–Cd and Ni–MH batteries: A minireview. Curr. Opin. Green Sustain. Chem. 2020, 24, 26–31. [Google Scholar] [CrossRef]

- Assefi, M.; Maroufi, S.; Mayyas, M.; Sahajwalla, V. Recycling of Ni-Cd batteries by selective isolation and hydro-thermal synthesis of porous NiO nanocuboid. J. Environ. Chem. Eng. 2018, 6, 4671–4675. [Google Scholar] [CrossRef]

- Yao, Y.; Farac, N.F.; Azimi, G. Supercritical Fluid Extraction of Rare Earth Elements from Nickel Metal Hydride Battery. ACS Sustain. Chem. Eng. 2018, 6, 1417–1426. [Google Scholar] [CrossRef]

- Sadeghi, S.M.; Jesus, J.; Soares, H.M. A critical updated review of the hydrometallurgical routes for recycling zinc and manganese from spent zinc-based batteries. Waste Manag. 2020, 113, 342–350. [Google Scholar] [CrossRef]

- Cong, L.; Liu, W.; Kong, S.; Li, H.; Deng, Y.; Ma, H. End-of-Use Management of Spent Lithium-Ion Batteries From Sustainability Perspective: A Review. J. Manuf. Sci. Eng. 2021, 143, 100801. [Google Scholar] [CrossRef]

- Foster, M.; Isely, P.; Standridge, C.R.; Hasan, M. Feasibility assessment of remanufacturing, repurposing, and recycling of end of vehicle application lithium-ion batteries. J. Ind. Eng. Manag. 2014, 7, 698–715. [Google Scholar] [CrossRef]

- Kampker, A.; Wessel, S.; Fiedler, F.; Maltoni, F. Battery pack remanufacturing process up to cell level with sorting and repurposing of battery cells. J. Remanufacturing 2021, 11, 1–23. [Google Scholar] [CrossRef]

- Huster, S.; Glöser-Chahoud, S.; Rosenberg, S.; Schultmann, F. A simulation model for assessing the potential of re-manufacturing electric vehicle batteries as spare parts. J. Clean. Prod. 2022, 363, 132225. [Google Scholar] [CrossRef]

- Casals, L.C.; Barbero, M.; Corchero, C. Reused second life batteries for aggregated demand response services. J. Clean. Prod. 2019, 212, 99–109. [Google Scholar] [CrossRef]

- Shahjalal, M.; Roy, P.K.; Shams, T.; Fly, A.; Chowdhury, J.I.; Ahmed, M.R.; Liu, K. A review on second-life of Li-ion batteries: Prospects, challenges, and issues. Energy 2022, 241, 122881. [Google Scholar] [CrossRef]

- Vu, F.; Rahic, M.; Chirumalla, K. Exploring second life applications for electric vehicle batteries. In SPS2020: Advances in Transdisciplinary Engineering; Säfsten, K., Elgh, F., Eds.; IOS Press: Amsterdam, The Netherlands, 2020; Volume 13, pp. 273–284. [Google Scholar] [CrossRef]

- Hu, X.; Deng, X.; Wang, F.; Deng, Z.; Lin, X.; Teodorescu, R.; Pecht, M.G. A Review of Second-Life Lithium-Ion Batteries for Stationary Energy Storage Applications. Proc. IEEE 2022, 110, 735–753. [Google Scholar] [CrossRef]

- Lee, J.W.; Haram, M.H.S.M.; Ramasamy, G.; Thiagarajah, S.P.; Ngu, E.E.; Lee, Y.H. Technical feasibility and economics of repurposed electric vehicles batteries for power peak shaving. J. Energy Storage 2021, 40, 102752. [Google Scholar] [CrossRef]

- Silvestri, L.; De Santis, M.; Bella, G. A Preliminary Techno-Economic and Environmental Performance Analysis of Using Second-Life EV Batteries in an Industrial Application. In Proceedings of the 6th International Conference on Green Energy and Applications, ICGEA 2022, Singapore, 4–6 March 2022; pp. 99–102. [Google Scholar]

- Obrecht, M.; Singh, R.; Zorman, T. Conceptualizing a new circular economy feature–storing renewable electricity in batteries beyond EV end-of-life: The case of Slovenia. Int. J. Prod. Perform. Manag. 2021, 71, 896–911. [Google Scholar] [CrossRef]

- Ioakimidis, C.S.; Murillo-Marrodán, A.; Bagheri, A.; Thomas, D.; Genikomsakis, K.N. Life cycle assessment of a lithium iron phosphate (LFP) electric vehicle battery in second life application scenarios. Sustainability 2019, 11, 2527. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Ferraro, M.; Cellura, M. Energy and environmental benefits of circular economy strategies: The case study of reusing used batteries from electric vehicles. J. Energy Storage 2019, 25, 100845. [Google Scholar] [CrossRef]

- Hu, S.; Sun, H.; Peng, F.; Zhou, W.; Cao, W.; Su, A.; Chen, X.; Sun, M. Optimization strategy for economic power dispatch utilizing retired EV batteries as flexible loads. Energies 2018, 11, 1657. [Google Scholar] [CrossRef]

- Horesh, N.; Quinn, C.; Wang, H.; Zane, R.; Ferry, M.; Tong, S.; Quinn, J.C. Driving to the future of energy storage: Techno-economic analysis of a novel method to recondition second life electric vehicle batteries. Appl. Energy 2021, 295, 117007. [Google Scholar] [CrossRef]

- Lacap, J.; Park, J.W.; Beslow, L. Development and Demonstration of Microgrid System Utilizing Second-Life Electric Vehicle Batteries. J. Energy Storage 2021, 41, 102837. [Google Scholar] [CrossRef]

- White, C.; Thompson, B.; Swan, L.G. Repurposed electric vehicle battery performance in second-life electricity grid frequency regulation service. J. Energy Storage 2020, 28, 101278. [Google Scholar] [CrossRef]

- White, C.; Thompson, B.; Swan, L.G. Comparative performance study of electric vehicle batteries repurposed for electricity grid energy arbitrage. Appl. Energy 2021, 288, 116637. [Google Scholar] [CrossRef]

- Nedjalkov, A.; Meyer, J.; Göken, H.; Reimer, M.V.; Schade, W. Blueprint and implementation of rural stand-alone power grids with second-life lithium ion vehicle traction battery systems for resilient energy supply of tropical or remote regions. Materials 2019, 12, 2642. [Google Scholar] [CrossRef] [PubMed]

- Reinhardt, R.; Christodoulou, I.; Gassmann, O.; Nair, G.G. Sustainable business model archetypes for the electric vehicle battery second use industry: Towards a conceptual framework. J. Clean. Prod. 2020, 254, 120022. [Google Scholar] [CrossRef]

- Huang, J.; Boles, S.T.; Tarascon, J.-M. Sensing as the key to battery lifetime and sustainability. Nat. Sustain. 2022, 5, 194–204. [Google Scholar] [CrossRef]

- Pattnaik, M.; Badoni, M.; Yogeshtatte; Singh, H.P. Analysis of electric vehicle battery system. In Proceedings of the 4th International Conference on Recent Developments in Control, Automation and Power Engineering, RDCAPE 2021, Noida, India, 7–8 October 2021; pp. 540–543. [Google Scholar]

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Xu, R.; Li, M.; Chen, Z. A comprehensive review of battery modeling and state estimation approaches for advanced battery management systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Liu, K.; Wei, Z.; Zhang, C.; Shang, Y.; Teodorescu, R.; Han, Q.-L. Towards Long Lifetime Battery: AI-Based Manu-facturing and Management. IEEE/CAA J. Autom. Sin. 2022, 9, 1139–1165. [Google Scholar] [CrossRef]

- Bordes, A.; Danilov, D.; Desprez, P.; Lecocq, A.; Marlair, G.; Truchot, B.; Dahmani, M.; Siret, C.; Laurent, S.; Herreyre, S.; et al. A holistic contribution to fast innovation in electric vehicles: An overview of the DEMOBASE research project. eTransportation 2021, 11, 100144. [Google Scholar] [CrossRef]

- Hossain, M.; Haque, M.; Arif, M. Kalman filtering techniques for the online model parameters and state of charge estimation of the Li-ion batteries: A comparative analysis. J. Energy Storage 2022, 51, 104174. [Google Scholar] [CrossRef]

- Kassim MR, M.; Jamil WA, W.; Sabri, R.M. State-of-Charge (SOC) and State-of-Health (SOH) Estimation Methods in Battery Management Systems for Electric Vehicles. In Proceedings of the 2021 IEEE International Conference on Computing, ICOCO 2021, Virtual, 17–19 November 2021; pp. 91–96. [Google Scholar]

- Girijaprasanna, T.; Dhanamjayulu, C. A Review on Different State of Battery Charge Estimation Techniques and Management Systems for EV Applications. Electronics 2022, 11, 1795. [Google Scholar] [CrossRef]

- Lipu, M.H.; Hannan, M.; Karim, T.F.; Hussain, A.; Saad, M.H.M.; Ayob, A.; Miah, S.; Mahlia, T.I. Intelligent algorithms and control strategies for battery management system in electric vehicles: Progress, challenges and future outlook. J. Clean. Prod. 2021, 292, 126044. [Google Scholar] [CrossRef]

- Wang, W.; Wang, J.; Tian, J.; Lu, J.; Xiong, R. Application of Digital Twin in Smart Battery Management Systems. Chin. J. Mech. Eng. (Engl. Ed.) 2021, 34, 57. [Google Scholar] [CrossRef]

- Lamoureux, C.; Gong, Z.; Nasr, M.; Assadi, S.A.; Gupta, K.; Galatro, D.; Tayyara, O.; da Silva, C.; Amon, C.; Trescases, O. Electrochemical Impedance Spectroscopy Based Power-Mix Control Strategy for Improved Lifetime Performance in Second-Life Battery Systems. In Proceedings of the 35th Annual IEEE Applied Power Electronics Conference and Exposition, APEC 2020, New Orleans, LA, USA, 15–19 March 2020; pp. 3444–3451. [Google Scholar]

- Basia, A.; Simeu-Abazi, Z.; Gascard, E.; Zwolinski, P. First step towards the development of a prognosis health management (PHM) system for Li-ion batteries: An FMMEA based approach. In Proceedings of the 29th European Safety and Reliability Conference, ESREL 2019, Hannover, Germany, 22–26 September 2019; pp. 1194–1200. [Google Scholar]

- D’Arpino, M.; Cancian, M.; Systems, D.; Division, C. Lifetime optimization for a grid-friendly dc fast charge station with second life batteries. In Proceedings of the ASME 2019 Dynamic Systems and Control Conference, DSCC 2019, Park City, Utah, 8–11 October 2019; p. 3. [Google Scholar]

- Hong, J.; Wang, Z.; Chen, W.; Wang, L.; Lin, P.; Qu, C. Online accurate state of health estimation for battery systems on real-world electric vehicles with variable driving conditions considered. J. Clean. Prod. 2021, 294, 125814. [Google Scholar] [CrossRef]

- Tete, P.R.; Gupta, M.M.; Joshi, S.S. Developments in battery thermal management systems for electric vehicles: A technical review. J. Energy Storage 2021, 35, 102255. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; Van Heyst, B. A comprehensive review on a passive (phase change materials) and an active (thermoelectric cooler) battery thermal management system and their limitations. J. Power Sources 2018, 401, 224–237. [Google Scholar] [CrossRef]

- Zare, P.; Perera, N.; Lahr, J.; Hasan, R. Solid-liquid phase change materials for the battery thermal management systems in electric vehicles and hybrid electric vehicles—A systematic review. J. Energy Storage 2022, 52, 105026. [Google Scholar] [CrossRef]

- Al Qubeissi, M.; Almshahy, A.; Mahmoud, A.; Al-Asadi, M.T.; Shah, R.M.R.A. Modelling of battery thermal management: A new concept of cooling using fuel. Fuel 2022, 310, 122403. [Google Scholar] [CrossRef]

- Gianvincenzi, M.; Marconi, M.; Mosconi, E.M.; Tola, F. A Standardized Data Model for the Battery Passport: Paving the Way for Sustainable Battery Management. Procedia CIRP 2024, 122, 103–108. [Google Scholar] [CrossRef]

- Walden, J.; Steinbrecher, A.; Marinkovic, M. Digital Product Passports as Enabler of the Circular Economy. Chem. Ing. Tech. 2021, 93, 1717–1727. [Google Scholar] [CrossRef]

- Berger, K.; Schöggl, J.-P.; Baumgartner, R.J. Digital battery passports to enable circular and sustainable value chains: Conceptualization and use cases. J. Clean. Prod. 2022, 353, 131492. [Google Scholar] [CrossRef]

- Cheng, Y.; Hao, H.; Tao, S.; Zhou, Y. Traceability Management Strategy of the EV Power Battery Based on the Blockchain. Sci. Program. 2021, 2021, 1–17. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Ghadimi, P.; Raugei, M.; Wu, Y.; Heidrich, O. Challenges and recent developments in supply and value chains of electric vehicle batteries: A sustainability perspective. Resour. Conserv. Recycl. 2022, 180, 106144. [Google Scholar] [CrossRef]

- Weimer, L.; Braun, T.; Hemdt, A.V. Design of a systematic value chain for lithium-ion batteries from the raw material perspective. Resour. Policy 2019, 64, 101473. [Google Scholar] [CrossRef]

- Mayyas, A.; Steward, D.; Mann, M. The case for recycling: Overview and challenges in the material supply chain for automotive li-ion batteries. Sustain. Mater. Technol. 2019, 19, e00087. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Paul, J.; Sinha, O. Analyzing challenges for sustainable supply chain of electric vehicle batteries using a hybrid approach of Delphi and Best-Worst Method. Resour. Conserv. Recycl. 2021, 175, 105879. [Google Scholar] [CrossRef]

- Amato, A.; Birolo, M.; De Filippis, P. Challenges for sustainable lithium supply: A critical review. J. Clean. Prod. 2021, 300, 126954. [Google Scholar] [CrossRef]

- Subulan, K.; Taşan, A.S.; Baykasoğlu, A. A fuzzy goal programming model to strategic planning problem of a lead/acid battery closed-loop supply chain. J. Manuf. Syst. 2015, 37, 243–264. [Google Scholar] [CrossRef]

- Gu, X.; Zhou, L.; Huang, H.; Shi, X.; Ieromonachou, P. Electric vehicle battery secondary use under government subsidy: A closed-loop supply chain perspective. Int. J. Prod. Econ. 2021, 234, 108035. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Long, J. Capturing value from Sustainable Electric Vehicle Supply Chain and Strategic Consumer Behaviour. In Proceedings of the 2021 International Conference on Big Data and Intelligent Decision Making, BDIDM 2021, Guilin, China, 23–25 July 2021; pp. 167–170. [Google Scholar]

- Mosconi, E.M.; Silvestri, C.; Poponi, S.; Braccini, A.M. Public policy innovation in distance and on-line learning: Reflections on the Italian case. In Lecture Notes in Information Systems and Organisation; Springer: Berlin/Heidelberg, Germany, 2013; Volume 2, pp. 381–389. [Google Scholar] [CrossRef]

- Matos, C.T.; Mathieux, F.; Ciacci, L.; Lundhaug, M.C.; León, M.F.G.; Müller, D.B.; Dewulf, J.; Georgitzikis, K.; Huisman, J. Material system analysis: A novel multilayer system approach to correlate EU flows and stocks of Li-ion batteries and their raw materials. J. Ind. Ecol. 2022, 26, 1261–1276. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. MetaArXiv 2020. [Google Scholar] [CrossRef]

| Context | Intervention | Mechanism | Outcomes |

|---|---|---|---|

| Batteries need further technological developments to ensure the green energy transition. From a regulatory point of view, the European Commission has established medium–long term objectives in the new battery regulation, which is currently being approved. | Systematic Literature Review on battery sustainability in their entire life cycle, with a phase-by-phase analysis based on the objectives indicated in the new European regulation on batteries. | Translation of the objectives of the new European Regulation in terms of technological developments. Subdivision of the various steps of the life cycle according to the subdivision made by the European regulation. Analysis of the state of the art of technology and issues addressed in the regulation. | Indication of the strengths and weaknesses of scientific research on each phase of the battery life cycle in terms of technological developments and sustainability for a better orientation of future scientific research aimed at ensuring the achievement of European objectives and facilitating the green energy transition. |

| Database | Search Strings and Search Terms | Articles (#) | Research Date |

|---|---|---|---|

| Scopus | “Responsible sourcing” AND “Battery” | 9 | 19 August 2022 |

| “Sustainable mining” OR “Green mining”) AND “Battery” | 18 | 19 August 2022 | |

| “Hazardous Substances” AND “Battery” | 161 | 22 August 2022 | |

| “Carbon Footprint” OR “Process optimization” OR “Sustainable manufacturing”) AND “Battery” AND “Manufacturing” | 103 | 22 August 2022 | |

| “Recycled Content” AND “Battery” | 9 | 22 August 2022 | |

| “Design for” AND (“Sustainability” OR “Disassembly” OR “Remanufacturing” OR “Recycling”) AND “Battery” | 116 | 22 August 2022 | |

| “Safety” AND “Manufacturing” AND “Battery” | 639 | 22 August 2022 | |

| “EV battery” AND (“Use phase” OR “LCA”) AND (“Duration” OR “Performance” OR “Sustainability”) | 46 | 23 August 2022 | |

| “End of Life management” OR “EOL management” AND “Battery” | 62 | 23 August 2022 | |

| “Extended producer responsibility” AND “Battery” | 41 | 23 August 2022 | |

| “Lead Acid” AND “Battery recycling” | 131 | 23 August 2022 | |

| “lithium” AND “battery recycling” AND “Efficiency” | 93 | 23 August 2022 | |

| “Sustainable Recycling” AND “Battery” | 67 | 23 August 2022 | |

| “Refurbishment” AND “Battery” | 61 | 25 August 2022 | |

| “Second Life” AND “Battery” | 498 | 25 August 2022 | |

| “Battery Management System” AND “Sustainability” | 106 | 25 August 2022 | |

| “Digital Passport” OR “Passport” AND “Battery” | 22 | 25 August 2022 | |

| “Sustainable Supply Chain” AND “Battery” | 20 | 25 August 2022 | |

| Science Direct | “Responsible sourcing” AND “Battery” | 91 | 19 August 2022 |

| “Sustainable mining” OR “Green mining”) AND “Battery” | 1133 | 19 August 2022 | |

| “Hazardous Substances” AND “Battery” | 3102 | 22 August 2022 | |

| “Carbon Footprint” AND “Battery” AND “Manufacturing” | 2823 | 22 August 2022 | |

| “Recycled Content” AND “Battery” | 359 | 22 August 2022 | |

| (“Design for Disassembly” OR “Design for Recycling” OR “Design for Remanufacturing” OR “Design for Sustainability”) AND “Battery” | 1408 | 22 August 2022 | |

| “Safety Improvement” AND “Manufacturing” AND “Battery” | 246 | 22 August 2022 | |

| “EV battery” AND (“Use phase” OR “LCA”) AND (“Duration” OR “Performance” OR “Sustainability”) | 2042 | 23 August 2022 | |

| “End of Life management” OR “EOL management” AND “Battery” | 1918 | 23 August 2022 | |

| “Extended producer responsibility” AND “Battery” | 788 | 23 August 2022 | |

| “Lead Acid” AND “Battery recycling” | 638 | 23 August 2022 | |

| “lithium” AND “battery recycling” AND “Efficiency” | 944 | 23 August 2022 | |

| “Recycling efficiency” AND “Battery” | 630 | 23 August 2022 | |

| “Refurbishment” AND “Battery” | 2992 | 25 August 2022 | |

| “Second Life” AND “Battery” | 885 | 25 August 2022 | |

| “Battery Management System” AND “Sustainability” | 1447 | 25 August 2022 | |

| “Digital Passport” AND “Battery” | 8 | 25 August 2022 | |

| “Sustainable Supply Chain” AND “Battery” | 429 | 25 August 2022 |

| Eligibility Criteria | Decision |

|---|---|

| The chosen keywords exist at least in the title or abstract section of the paper | Inclusion |

| The paper is published in a peer-reviewed scientific journal | Inclusion |

| The paper is written in the English language | Inclusion |

| The paper studies the use of alternative materials in batteries | Exclusion |

| The paper is duplicated within the search documents | Exclusion |

| The full paper is not available or accessible | Exclusion |

| The paper was published before 2013 | Exclusion |

| Life Cycle Phase | Battery Regulation | SLR Inclusion Criteria |

|---|---|---|

| Extraction phase | Contribution to responsible sourcing; extra-territorial aspect aimed at regulating the methods of extraction and processing of raw material by operators; also valid in third countries to lower environmental and social impacts. | The paper analyzes the impacts of the raw materials present in batteries and/or proposes sustainable solutions for green mining and/or deals with the issue of responsible sourcing. |

| Manufacturing phase | Hazardous substance restriction; carbon footprint declaration (2024); battery performance classes (2026); maximum CO2 threshold (2027); declaration of recycled content of lithium (Li), cobalt (Co), lead (Pb), and nickel (Ni) (2027); growing minimum recycled content (2030, 2035); obligation of removability and replaceability; safety requirements. | The paper analyzes the impacts of or proposes innovative and sustainable solutions regarding the content of hazardous substances in batteries, the optimization of production processes, reducing the carbon footprint in the manufacturing phase, recycled content, end-of-life design, and safety issues. |

| Use Phase | Minimum performance and durability requirements. | The paper analyzes the environmental and technical performance of EVs and portable batteries, in particular their durability and efficiency. |

| Collection Phase | Growing targets of portable battery collection (2025, 2030); 100% EV batteries collected by certified operators; Extended Producer Responsibility (EPR) requirements. | The paper proposes systems to improve end-of-life management and/or analyzes Extended Producer Responsibility. |

| Recycling Phase | Growing recycling efficiency targets for lead, lithium, and other types of batteries (2025, 2030); Growing recycling recovery targets for Li, Co, copper (Cu), Pb, and Ni (2026, 2030). | The paper analyzes the current battery recycling systems, in particular those of lead–acid and lithium batteries, and proposes alternative and better solutions to optimize the recovery of materials. |

| Second-Life Phase | Requirements for repurposing and remanufacturing; reuse indicated as a priority in the waste hierarchy. | The paper analyzes the status and improvement of battery repurposing and remanufacturing processes and second-life solutions. |

| Transversal Aspects | Obligation to have a battery management system (BMS) inside EVs and industrial batteries; mandatory supply chain due diligence focusing on social and environmental impacts; ensuring the traceability of batteries through a digital passport, mandatory from 2027. | The paper analyzes BMS status and improvements and solutions for the application of the digital passport and studies the optimization of battery supply chains to make them more sustainable. |

| Phase | Regulation Topic | Total (n°) | Screened (n°) | Selected (n°) | Included (n°) |

|---|---|---|---|---|---|

| Extraction | 1251 | 397 | 31 | 21 | |

| Natural resources | 9 | 6 | |||

| Responsible sourcing | 9 | 7 | |||

| Sustainable mining | 13 | 8 | |||

| Manufacturing | 8966 | 308 | 45 | 34 | |

| Hazardous substances | 3 | 2 | |||

| Carbon footprint | 13 | 10 | |||

| Recycled content | 5 | 4 | |||

| Design for | 8 | 5 | |||

| SESS safety | 16 | 13 | |||

| Use Phase | 2088 | 288 | 28 | 21 | |

| Collection | 2809 | 460 | 9 | 8 | |

| End-of-life management | 5 | 4 | |||

| EPR | 4 | 4 | |||

| Recycling | 2503 | 108 | 48 | 38 | |

| Lead–acid recycling | 3 | 2 | |||

| Lithium recycling | 39 | 31 | |||

| Other recycling | 6 | 5 | |||

| Second Life | 5989 | 493 | 28 | 23 | |

| Repurposing/remanufacturing | 8 | 5 | |||

| Second-life applications | 20 | 18 | |||

| Transversal Phases | 479 | 248 | 36 | 32 | |

| Battery management system | 21 | 18 | |||

| Electronic exchange system and digital passport | 4 | 4 | |||

| Sustainable supply chain | 11 | 10 | |||

| Total | 24,085 | 2302 | 233 | 177 |

| Journal | n° |

|---|---|

| Journal of Cleaner Production | 19 |

| Journal of Energy Storage | 10 |

| Resources, Conservation and Recycling | 7 |

| Energies | 6 |

| Resources Policy | 6 |

| Solutions | E | M | U | C | S | R |

|---|---|---|---|---|---|---|

| Law harmonization | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Eco-design | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Actor involvement | ✓ | ✓ | ✓ | ✓ | ||

| Complete and unified databases | ✓ | ✓ | ✓ | ✓ | ||

| Intelligent and automized disassembling | ✓ | ✓ | ||||

| Cutting-edge tech integration | ✓ | ✓ | ✓ | ✓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gianvincenzi, M.; Marconi, M.; Mosconi, E.M.; Favi, C.; Tola, F. Systematic Review of Battery Life Cycle Management: A Framework for European Regulation Compliance. Sustainability 2024, 16, 10026. https://doi.org/10.3390/su162210026

Gianvincenzi M, Marconi M, Mosconi EM, Favi C, Tola F. Systematic Review of Battery Life Cycle Management: A Framework for European Regulation Compliance. Sustainability. 2024; 16(22):10026. https://doi.org/10.3390/su162210026

Chicago/Turabian StyleGianvincenzi, Mattia, Marco Marconi, Enrico Maria Mosconi, Claudio Favi, and Francesco Tola. 2024. "Systematic Review of Battery Life Cycle Management: A Framework for European Regulation Compliance" Sustainability 16, no. 22: 10026. https://doi.org/10.3390/su162210026

APA StyleGianvincenzi, M., Marconi, M., Mosconi, E. M., Favi, C., & Tola, F. (2024). Systematic Review of Battery Life Cycle Management: A Framework for European Regulation Compliance. Sustainability, 16(22), 10026. https://doi.org/10.3390/su162210026