Enhancing Construction Management Digital Twins Through Process Mining of Progress Logs

Abstract

:1. Introduction

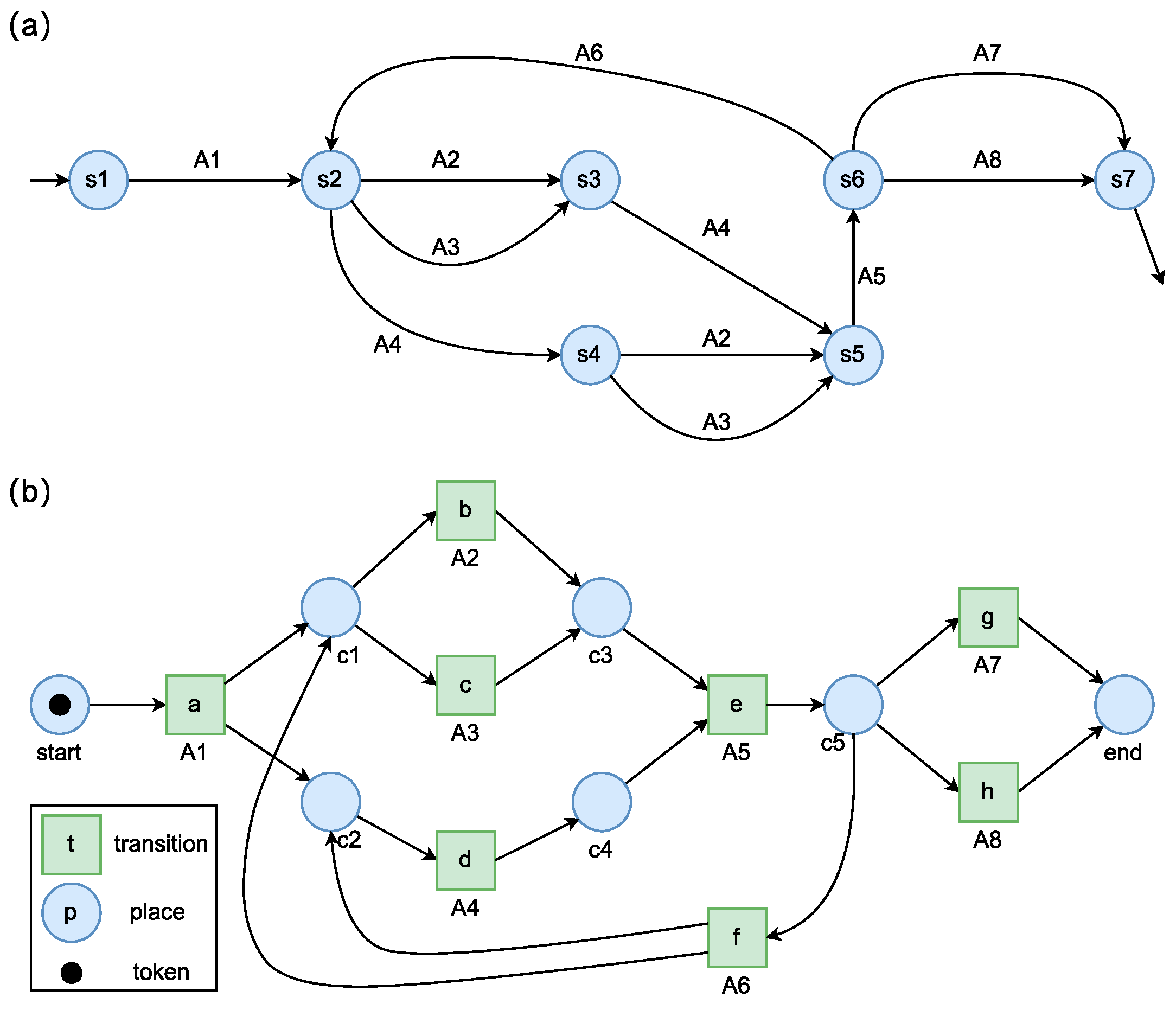

2. Preliminaries

2.1. Process Mining

2.2. The Event Log

2.3. The Process Model

2.4. Research on Process Mining in AEC

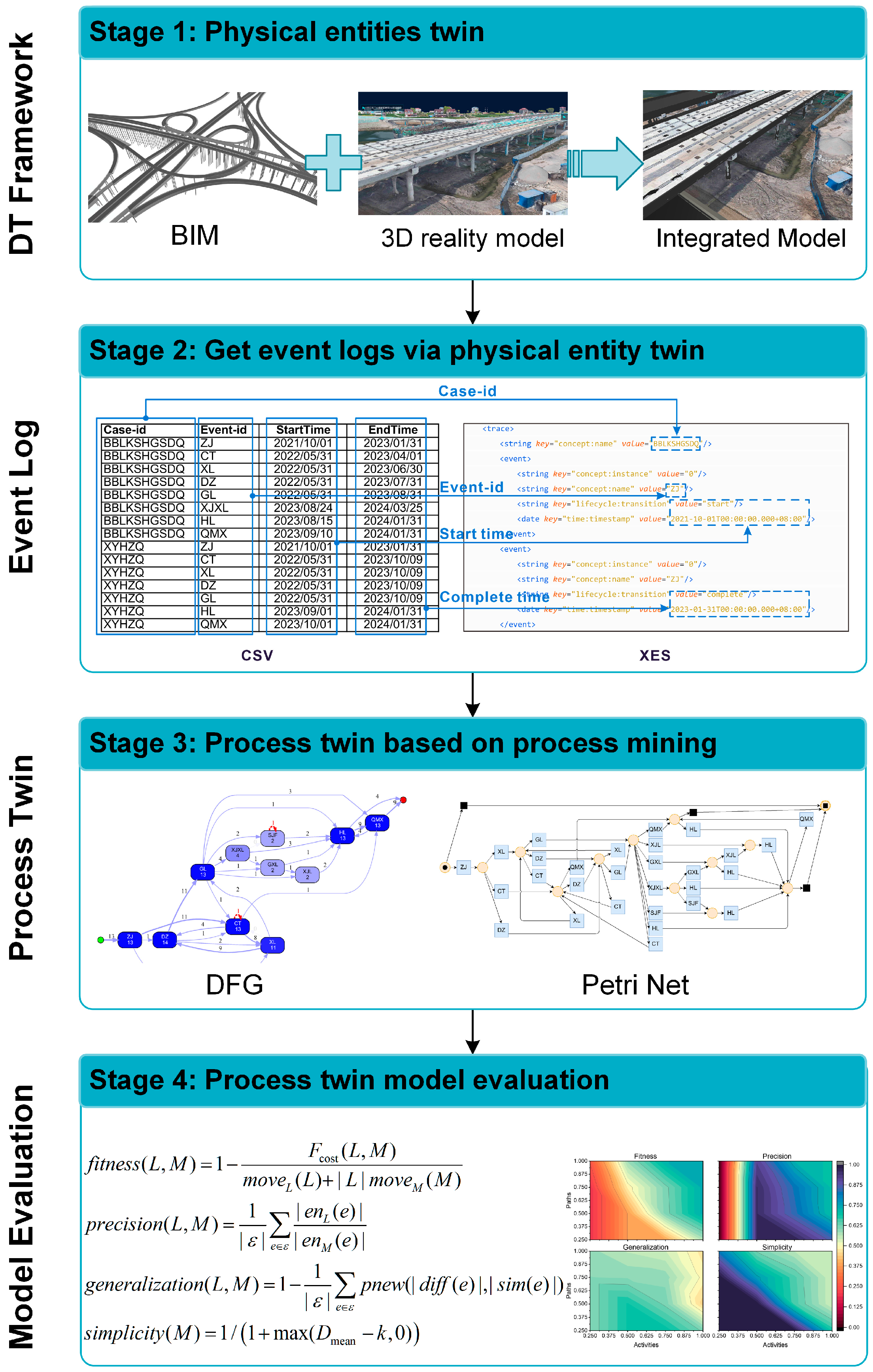

3. Methodology

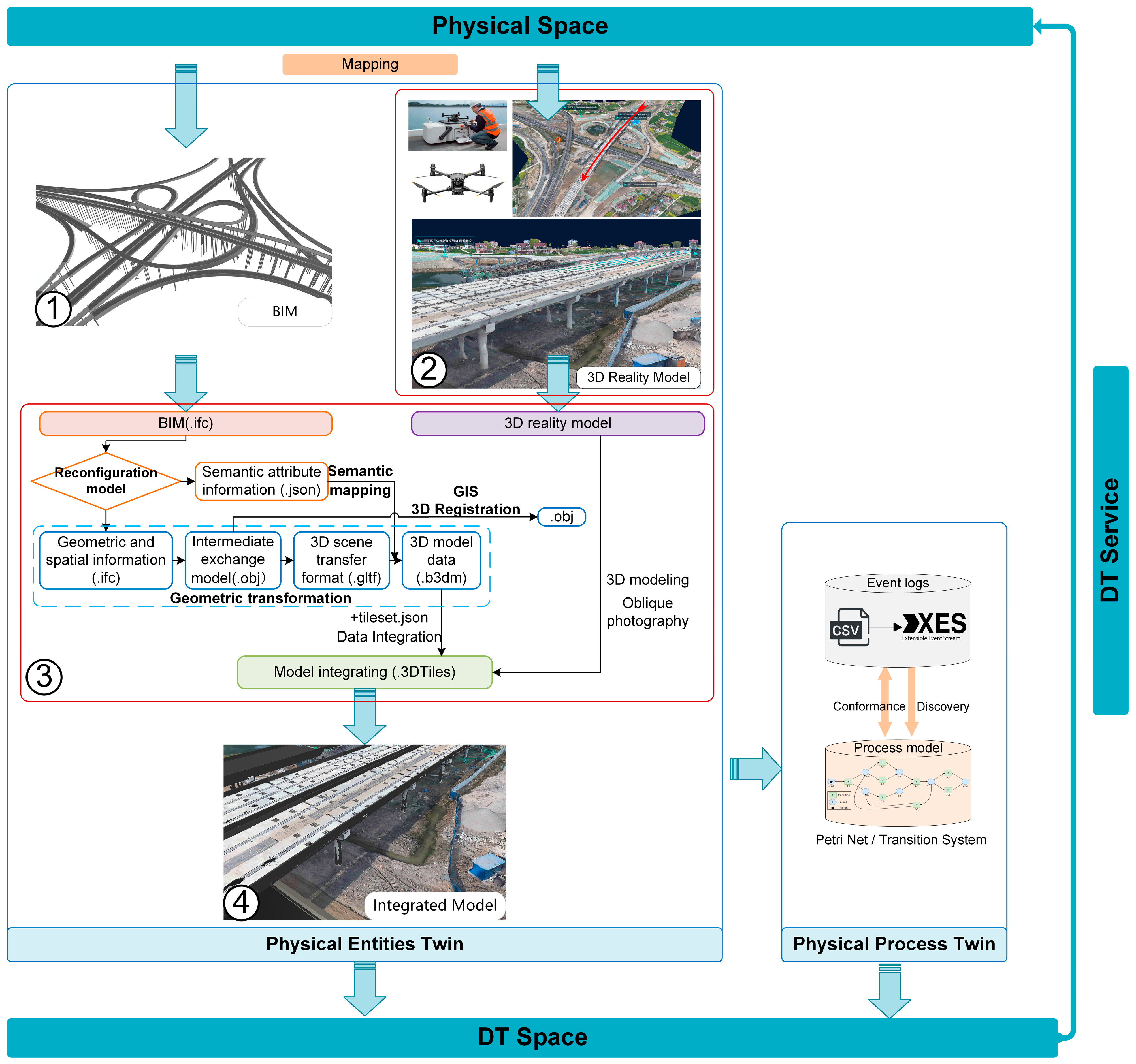

3.1. Physical Entity Twins

3.2. Process Twins

3.2.1. Event Log Acquisition

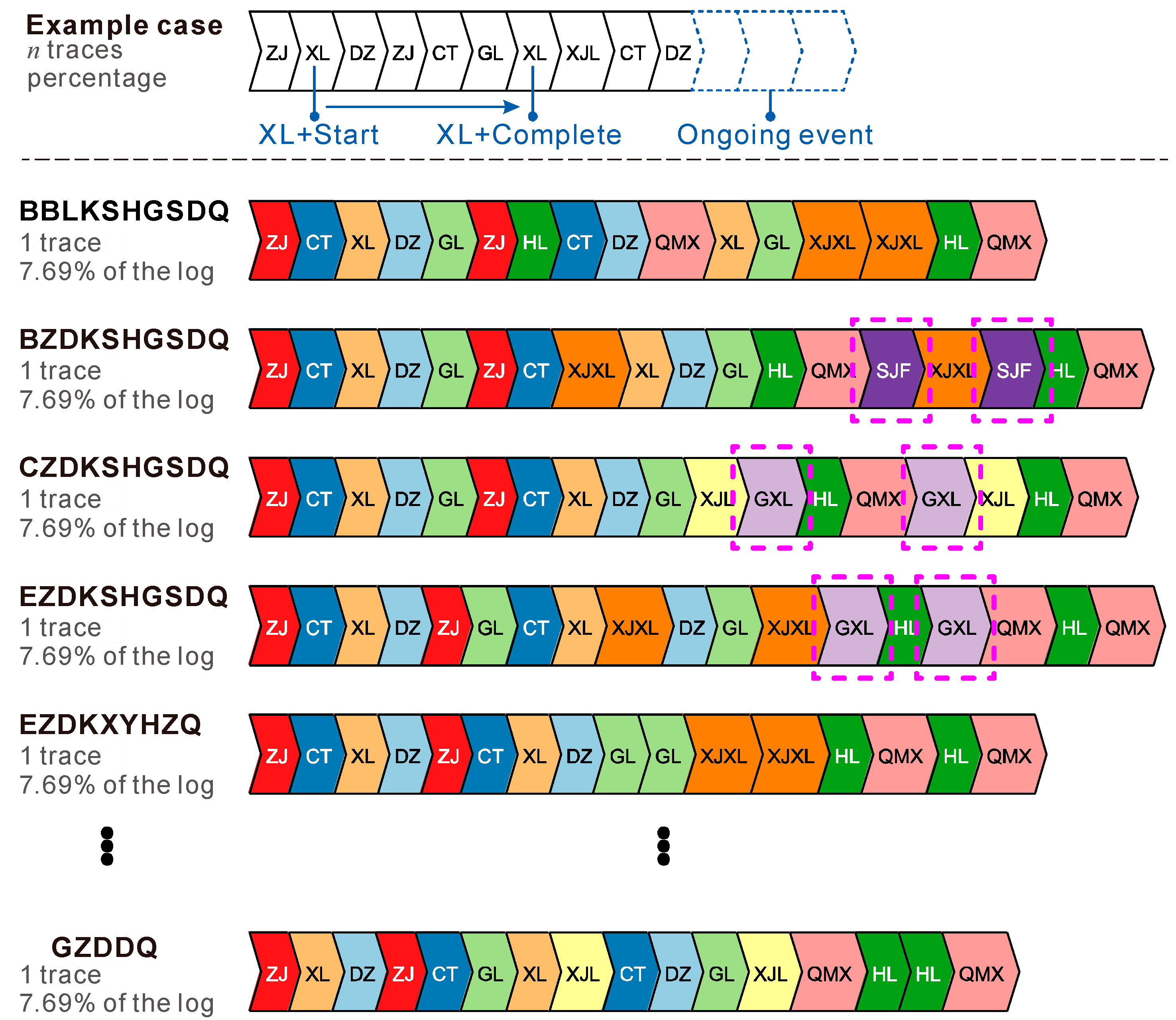

3.2.2. Event Process Variants

3.2.3. Process Twins Based on Process Mining

3.3. Process Twin Model Evaluation

4. Results

4.1. Construction Progress Log

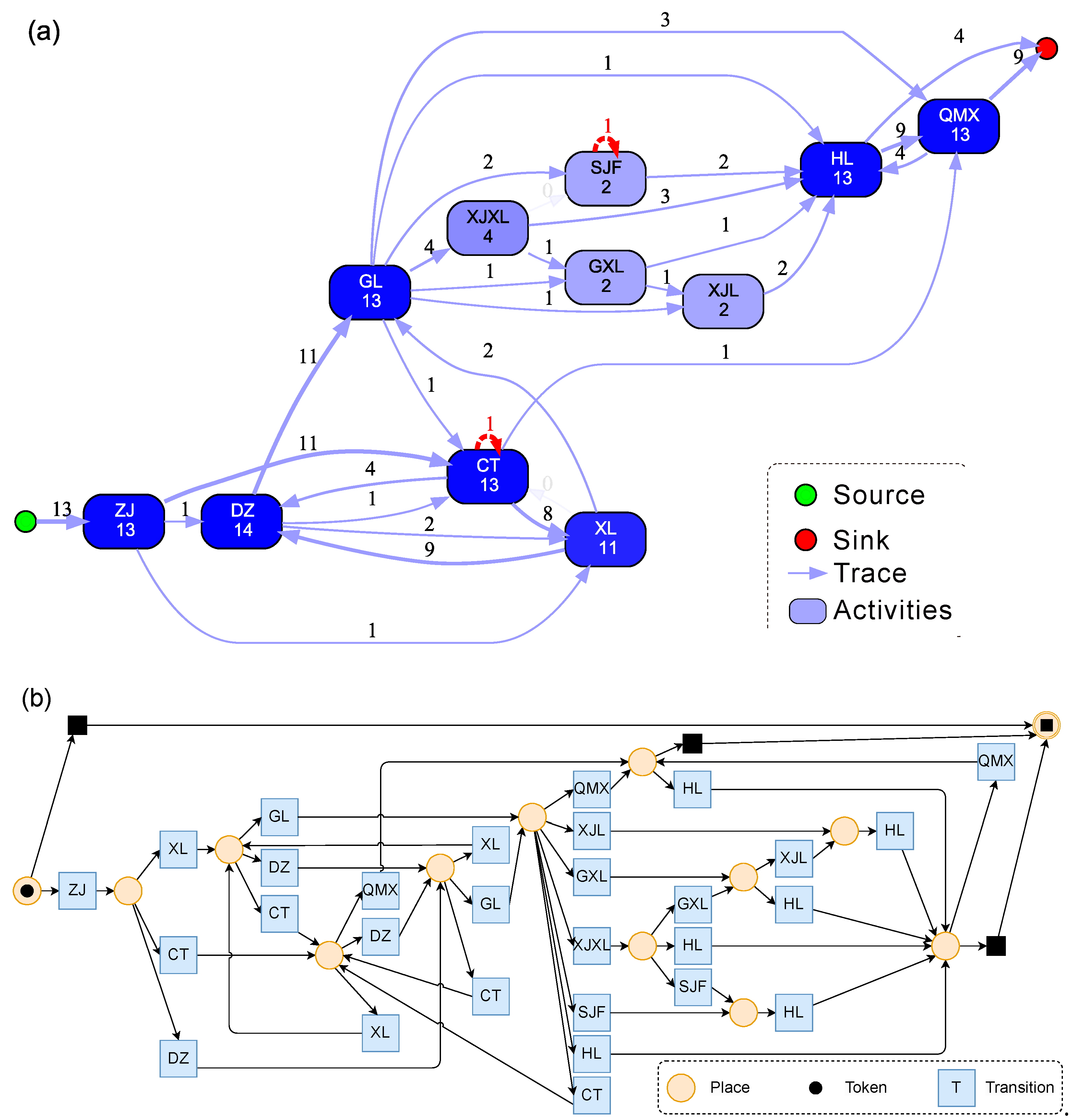

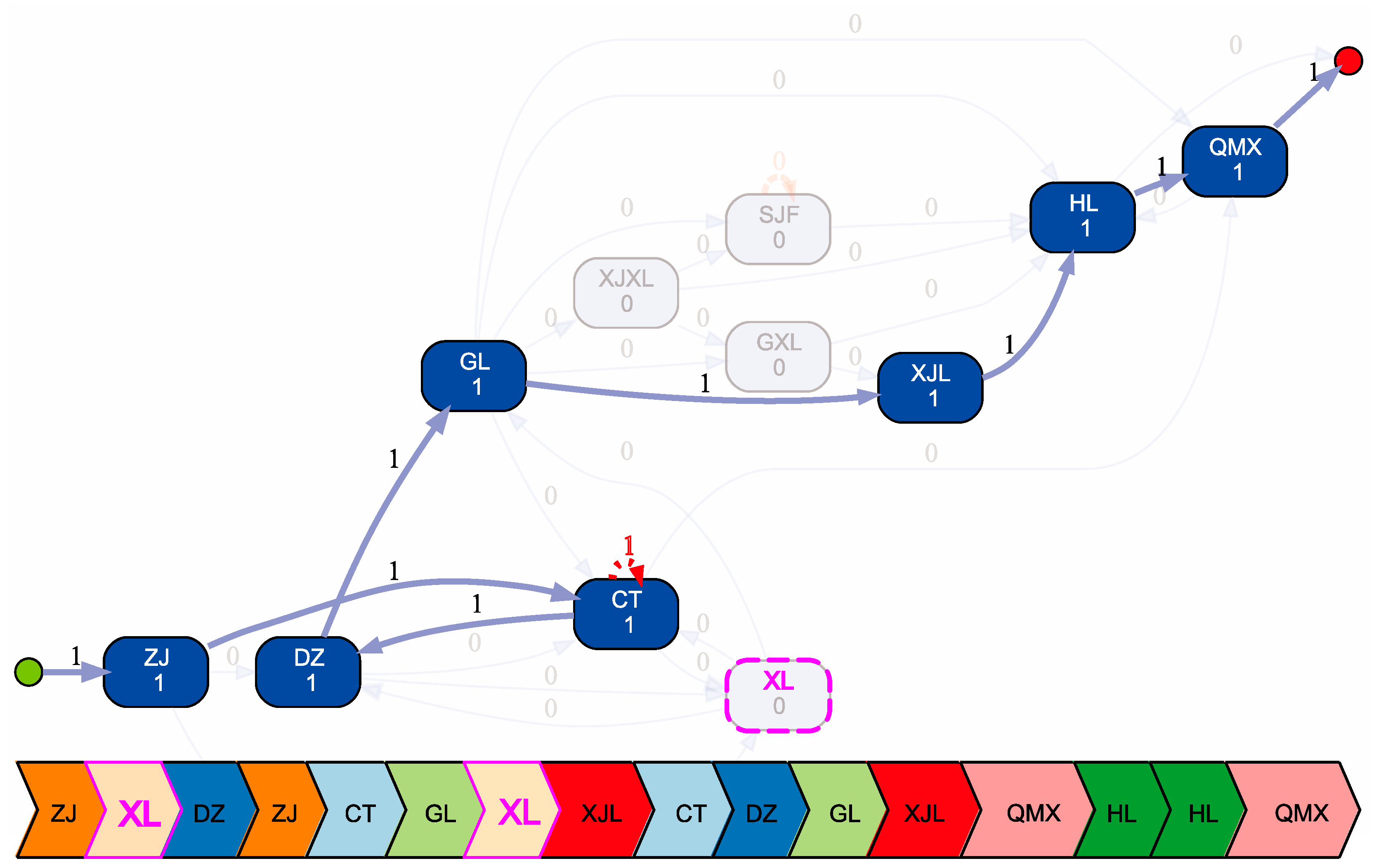

4.2. Highway Construction Process Variants

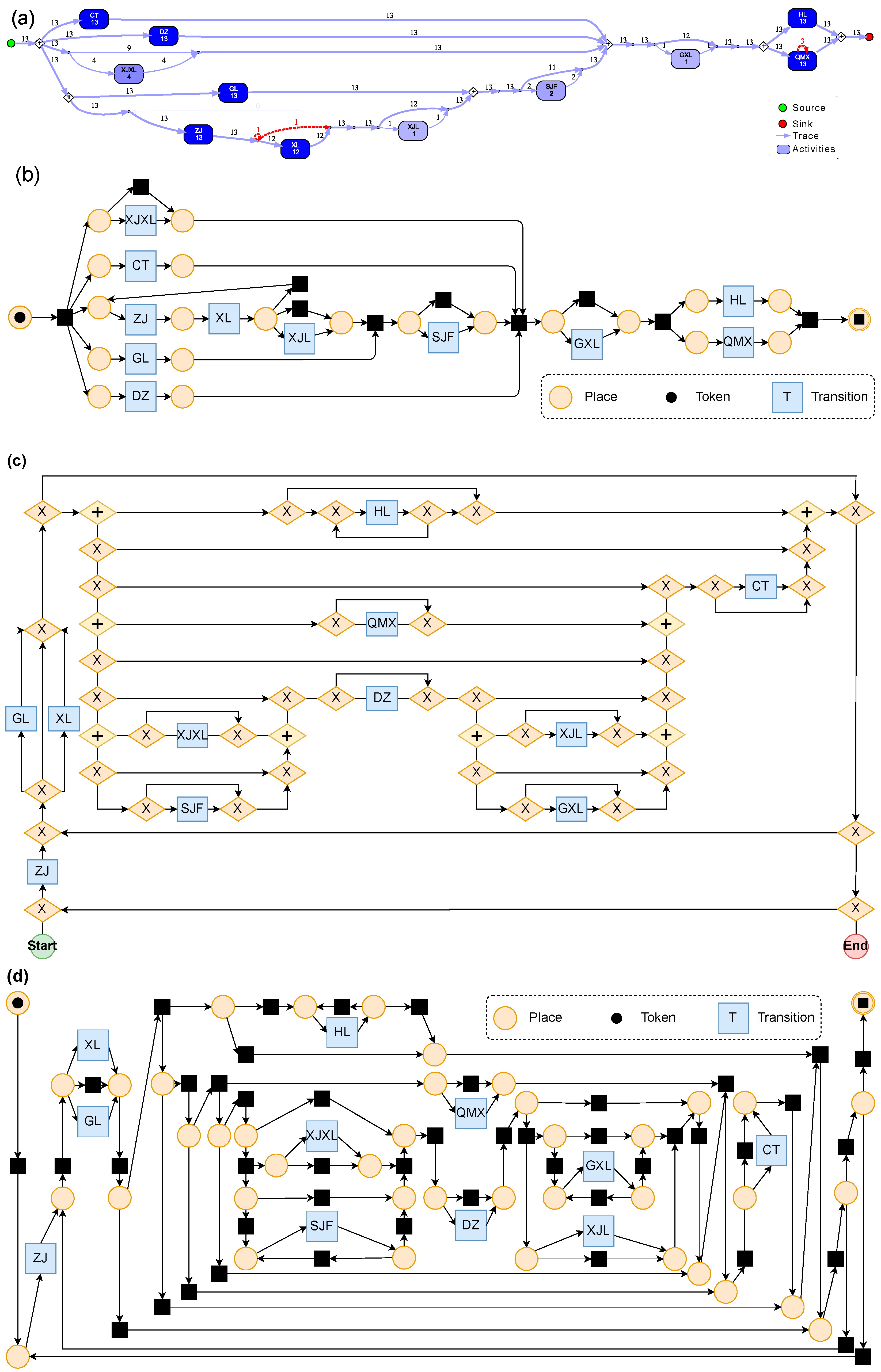

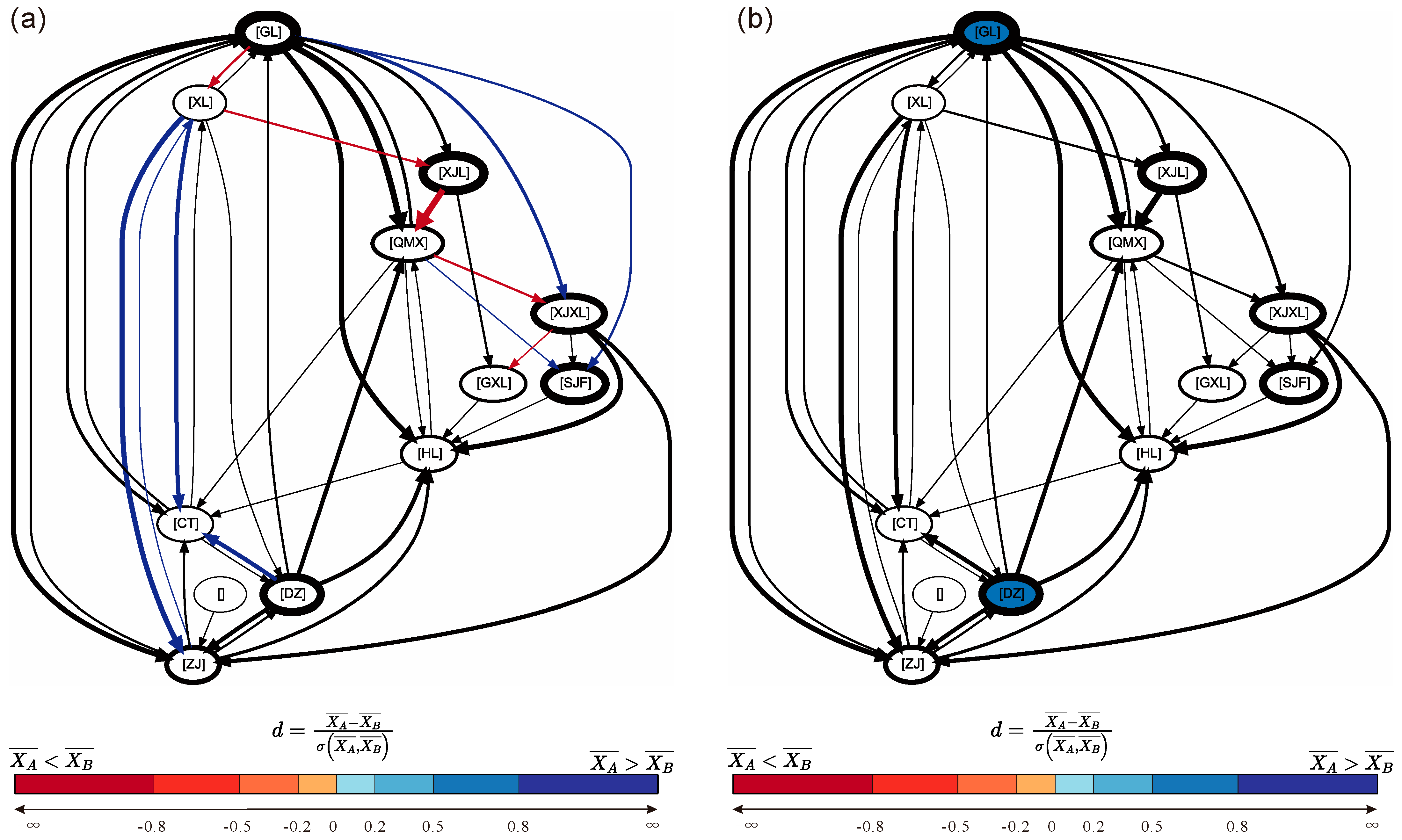

4.3. Highway Construction Process Twins

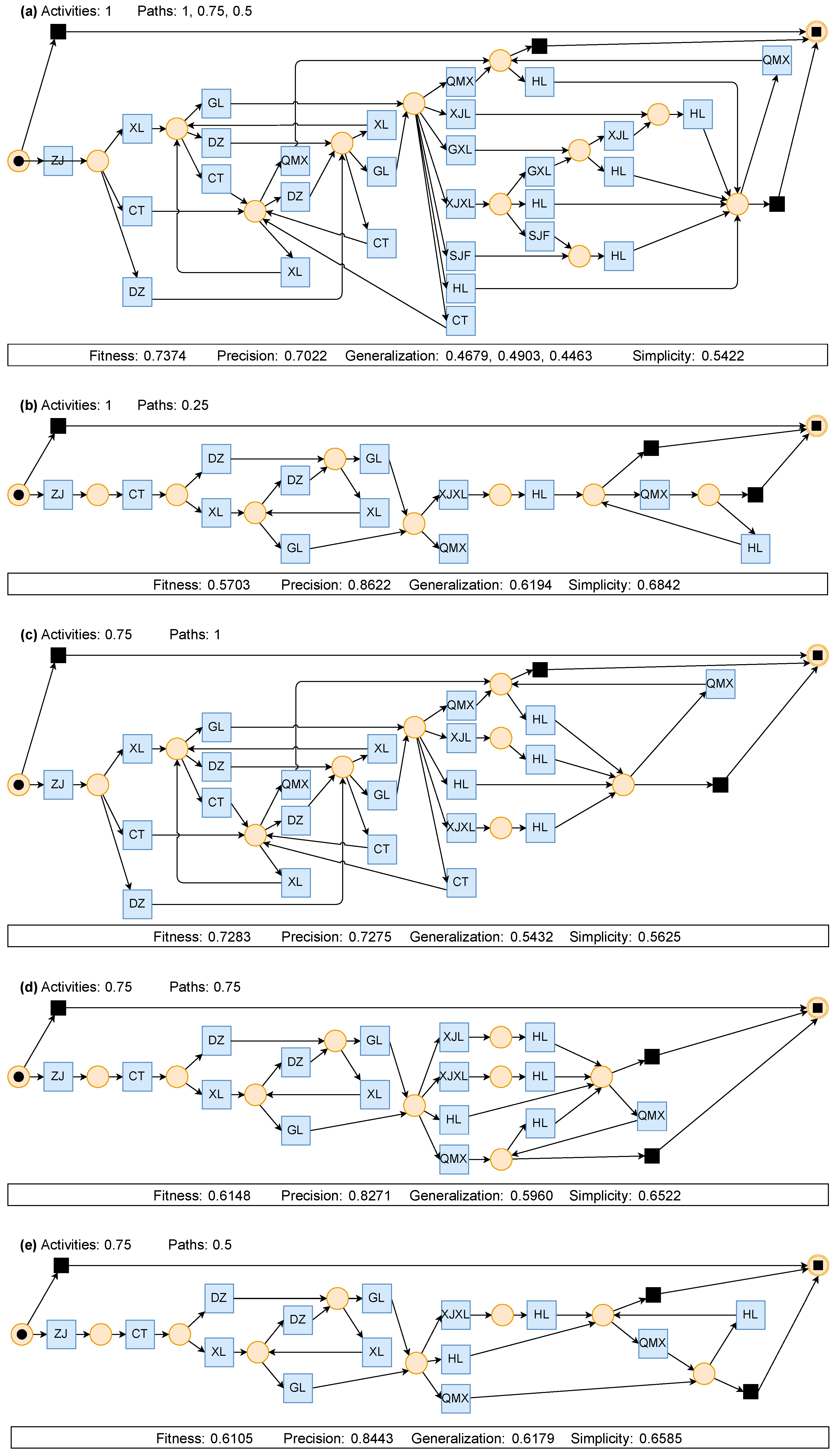

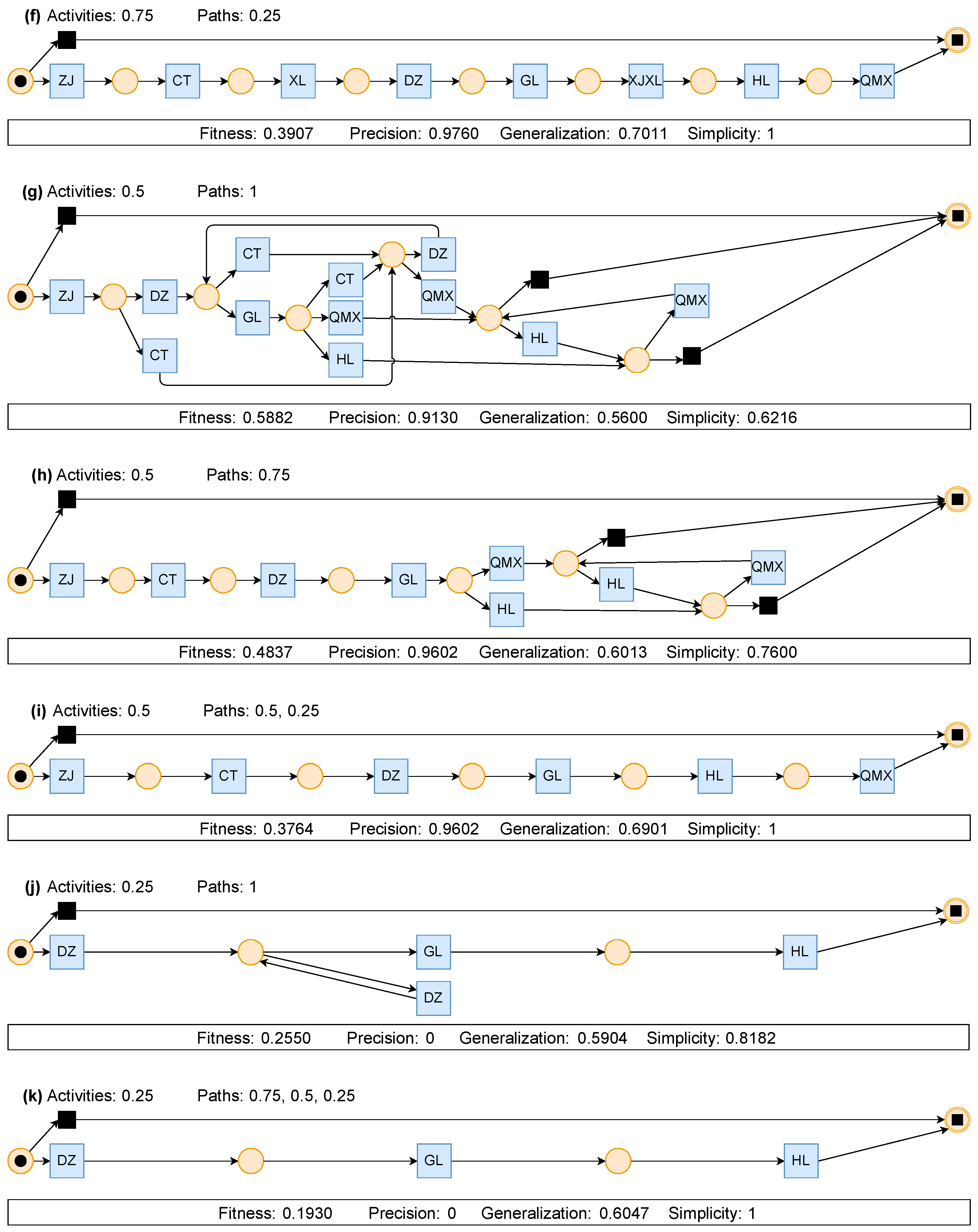

4.4. Process Twin Evaluation

5. Discussion

5.1. Construction Progress Evaluation

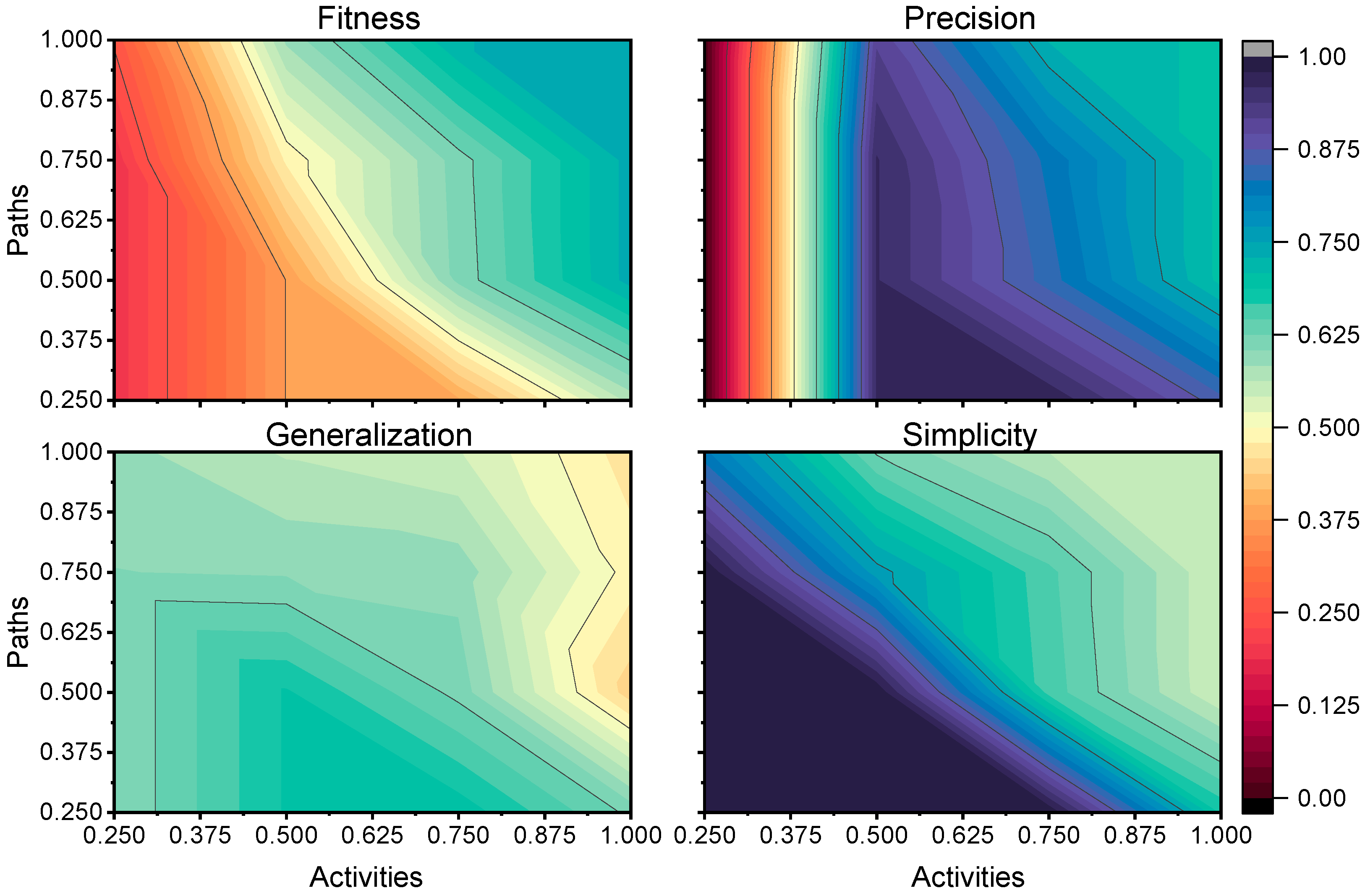

5.2. Process Model Selection

5.3. The Weighting of the Four Evaluation Indicators

5.4. Limitations and Future Research Work

6. Conclusions

- A DT model suitable for highway CM was constructed.

- Process mining was used to map the construction activities to the DT, establishing a process twin distinct from the physical entity twin and thereby addressing the deficiency of the process information in CM DTs.

- Abnormal changes in construction processes can be analyzed through process variants, enabling the early detection of potential construction risks.

- Compared with inductive mining models, the DFM more intuitively shows the relationships between construction activities and offers better interpretability. In this study, the fitness, precision, generalization, and simplicity of the DFG are: 0.74, 0.702233, 0.47, and 0.54, respectively.

- Sudden changes at various construction nodes during construction activities can affect the resource allocation planning in the subsequent multi-phase stages. Efforts should be made to reduce the number of critical nodes in key positions and lower the node degree, thereby enhancing the overall resilience of the construction process.

- The twin model based on process mining can be used to macroscopically visualize the lead-lag relationship between the actual construction process and the construction plan (i.e., the construction progress risks).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peterson, F.; Hartmann, T.; Fruchter, R.; Fischer, M. Teaching Construction Project Management with BIM Support: Experience and Lessons Learned. Autom. Constr. 2011, 20, 115–125. [Google Scholar] [CrossRef]

- Rauf, M.; Guan, Z.; Mumtaz, J.; Yue, L.; Wang, H. Digital Twin-Based Smart Manufacturing System for Project-Based Organizations: A Conceptual Framework. In Proceedings of the CIE49 Proceedings, Beijing, China, 21 October 2019; p. 281. [Google Scholar]

- Williams, C.E., Jr.; Johnson, P.W. Johnson Inadequate Design Management Compared with Unprecedented Technical Issues as Causes for Engineering Failure. J. Perform. Constr. Facil. 2015, 29, 04014031. [Google Scholar] [CrossRef]

- Woodward, J. Civil Engineering Management. Int. J. Proj. Manag. 1985, 3, 105–108. [Google Scholar] [CrossRef]

- Jin, R.; Zuo, J.; Hong, J. Scientometric Review of Articles Published in ASCE’s Journal of Construction Engineering and Management from 2000 to 2018. J. Constr. Eng. Manag. 2019, 145, 06019001. [Google Scholar] [CrossRef]

- Rauf, M.; Guan, Z.; Yue, L.; Guo, Z.; Mumtaz, J.; Ullah, S. Integrated Planning and Scheduling of Multiple Manufacturing Projects Under Resource Constraints Using Raccoon Family Optimization Algorithm. IEEE Access 2020, 8, 151279–151295. [Google Scholar] [CrossRef]

- Ding, L.; Guan, Z.; Rauf, M.; Yue, L. Multi-Policy Deep Reinforcement Learning for Multi-Objective Multiplicity Flexible Job Shop Scheduling. Swarm Evol. Comput. 2024, 87, 101550. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J.; Rauf, M.; Mumtaz, J.; Huang, S. Dynamic Scheduling of Hybrid Flow Shop Problem with Uncertain Process Time and Flexible Maintenance Using NeuroEvolution of Augmenting Topologies. IET Collab. Intell. Manuf. 2024, 6, e12119. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, J.C.P.; Chen, W.; Chen, K. Digital Twins for Construction Sites: Concepts, LoD Definition, and Applications. J. Manag. Eng. 2022, 38, 04021094. [Google Scholar] [CrossRef]

- Tan, Y.; Chen, P.; Shou, W.; Sadick, A.-M. Digital Twin-Driven Approach to Improving Energy Efficiency of Indoor Lighting Based on Computer Vision and Dynamic BIM. Energy Build. 2022, 270, 112271. [Google Scholar] [CrossRef]

- Chacón, R.; Posada, H.; Ramonell, C.; Jungmann, M.; Hartmann, T.; Khan, R.; Tomar, R. Digital Twinning of Building Construction Processes. Case Study: A Reinforced Concrete Cast-in Structure. J. Build. Eng. 2024, 84, 108522. [Google Scholar] [CrossRef]

- Speiser, K.; Teizer, J. Automatic Creation of Personalised Virtual Construction Safety Training in Digital Twins. Proc. Inst. Civ. Eng. Manag. Procure. Law 2024, 177, 173–183. [Google Scholar] [CrossRef]

- Xu, J.; Shu, X.; Qiao, P.; Li, S.; Xu, J. Developing a Digital Twin Model for Monitoring Building Structural Health by Combining a Building Information Model and a Real-Scene 3D Model. Measurement 2023, 217, 112955. [Google Scholar] [CrossRef]

- Grieves, M. Virtually Perfect: Driving Innovative and Lean Products Through Product Lifecycle Management; Space Coast Press: Melbourne, FL, USA, 2011; ISBN 978-0-9821380-0-7. [Google Scholar]

- Rosen, R.; von Wichert, G.; Lo, G.; Bettenhausen, K.D. Bettenhausen About The Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-Pap. 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication 2015. Available online: https://www.3ds.com/fileadmin/PRODUCTS-SERVICES/DELMIA/PDF/Whitepaper/DELMIA-APRISO-Digital-Twin-Whitepaper.pdf (accessed on 1 June 2024).

- Tao, F.; Qi, Q. Make More Digital Twins. Nature 2019, 573, 490–491. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Zhang, C. Advancements and Challenges of Digital Twins in Industry. Nat. Comput. Sci. 2024, 4, 169–177. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Wang, W.; Xu, K.; Song, S.; Bao, Y.; Xiang, C. From BIM to Digital Twin in BIPV: A Review of Current Knowledge. Sustain. Energy Technol. Assess. 2024, 67, 103855. [Google Scholar] [CrossRef]

- Li, T.; Li, X.; Rui, Y.; Ling, J.; Zhao, S.; Zhu, H. Digital Twin for Intelligent Tunnel Construction. Autom. Constr. 2024, 158, 105210. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital Twin and Its Implementations in the Civil Engineering Sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Pregnolato, M.; Gunner, S.; Voyagaki, E.; De Risi, R.; Carhart, N.; Gavriel, G.; Tully, P.; Tryfonas, T.; Macdonald, J.; Taylor, C. Towards Civil Engineering 4.0: Concept, Workflow and Application of Digital Twins for Existing Infrastructure. Autom. Constr. 2022, 141, 104421. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital Twin Application in the Construction Industry: A Literature Review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Song, H.; Yang, G.; Li, H.; Zhang, T.; Jiang, A. Digital Twin Enhanced BIM to Shape Full Life Cycle Digital Transformation for Bridge Engineering. Autom. Constr. 2023, 147, 104736. [Google Scholar] [CrossRef]

- Zhou, X.; Sun, K.; Wang, J.; Zhao, J.; Feng, C.; Yang, Y.; Zhou, W. Computer Vision Enabled Building Digital Twin Using Building Information Model. IEEE Trans. Ind. Inf. 2023, 19, 2684–2692. [Google Scholar] [CrossRef]

- Arsiwala, A.; Elghaish, F.; Zoher, M. Digital Twin with Machine Learning for Predictive Monitoring of CO2 Equivalent from Existing Buildings. Energy Build. 2023, 284, 112851. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. A BIM-Data Mining Integrated Digital Twin Framework for Advanced Project Management. Autom. Constr. 2021, 124, 103564. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital Twin-Enabled Anomaly Detection for Built Asset Monitoring in Operation and Maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Wang, L.; Liu, H.; Zhang, F.; Guo, L.; Chen, Z. Spatial Structure Digital Twins: Application in Intelligent Health Monitoring of Cable Dome Structures. Autom. Constr. 2024, 165, 105489. [Google Scholar] [CrossRef]

- Yang, Y.; Li, M.; Yu, C.; Zhong, R.Y. Digital Twin-Enabled Visibility and Traceability for Building Materials in on-Site Fit-out Construction. Autom. Constr. 2024, 166, 105640. [Google Scholar] [CrossRef]

- Adeagbo, M.O.; Wang, S.-M.; Ni, Y.-Q. Revamping structural health monitoring of advanced rail transit systems: A paradigmatic shift from digital shadows to digital twins. Adv. Eng. Inf. 2024, 61, 102450. [Google Scholar] [CrossRef]

- Kang, T.W.; Mo, Y. A Comprehensive Digital Twin Framework for Building Environment Monitoring with Emphasis on Real-Time Data Connectivity and Predictability. Dev. Built Environ. 2024, 17, 100309. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, Z.; Sun, Z.; Li, A.; Ni, S. A Digital Twin-Based Green Construction Management Method for Prefabricated Buildings. Digit. Twin 2023, 3, 8. [Google Scholar] [CrossRef]

- Li, X.; Tang, L.; Ling, J.; Chen, C.; Shen, Y.; Zhu, H. Digital-Twin-Enabled JIT Design of Rock Tunnel: Methodology and Application. Tunn. Undergr. Space Technol. 2023, 140, 105307. [Google Scholar] [CrossRef]

- Ye, Z.; Ye, Y.; Zhang, C.; Zhang, Z.; Li, W.; Wang, X.; Wang, L.; Wang, L. A Digital Twin Approach for Tunnel Construction Safety Early Warning and Management. Comput. Ind. 2023, 144, 103783. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Li, M.; Liu, X.; Zhong, R.Y.; Pan, W.; Huang, G.Q. Digital Twin-Enabled Real-Time Synchronization for Planning, Scheduling, and Execution in Precast on-Site Assembly. Autom. Constr. 2022, 141, 104397. [Google Scholar] [CrossRef]

- Rogage, K.; Mahamedi, E.; Brilakis, I.; Kassem, M. Beyond Digital Shadows: A Digital Twin for Monitoring Earthwork Operation in Large Infrastructure Projects. AI Civ. Eng. 2022, 1, 7. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Zhu, Q.; Guo, Y.; Zheng, W.; Zhang, L.; Wang, Q.; Zhou, R.; Ding, Y.; Wang, W.; Pirasteh, S.; et al. Multi-Level Voxel Representations for Digital Twin Models of Tunnel Geological Environment. Int. J. Appl. Earth Obs. Geoinf. 2022, 112, 102887. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.H.; Masoud, N.; Krishnan, M.S.; Li, V.C. Integrated Digital Twin and Blockchain Framework to Support Accountable Information Sharing in Construction Projects. Autom. Constr. 2021, 127, 103688. [Google Scholar] [CrossRef]

- Yu, G.; Wang, Y.; Mao, Z.; Hu, M.; Sugumaran, V.; Wang, Y.K. A Digital Twin-Based Decision Analysis Framework for Operation and Maintenance of Tunnels. Tunn. Undergr. Space Technol. 2021, 116, 104125. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a Semantic Construction Digital Twin: Directions for Future Research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Hoeber, H.; Alsem, D. Life-Cycle Information Management Using Open-Standard BIM. Eng. Constr. Archit. Manag. 2016, 23, 696–708. [Google Scholar] [CrossRef]

- Motamedi, A.; Hammad, A.; Asen, Y. Knowledge-Assisted BIM-Based Visual Analytics for Failure Root Cause Detection in Facilities Management. Autom. Constr. 2014, 43, 73–83. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Automated Process Discovery from Event Logs in BIM Construction Projects. Autom. Constr. 2021, 127, 103713. [Google Scholar] [CrossRef]

- van der Aalst, W.M.P. Process Mining: Discovery, Conformance and Enhancement of Business Processes; Springer: Berlin, Heidelberg, 2011; ISBN 978-3-642-19344-6. [Google Scholar]

- Zeng, Q. A Survey of Research Issues and Approaches on Process Mining. J. Syst. Simul. 2007, 19, 275–280. [Google Scholar]

- Kouhestani, S.; Nik-Bakht, M. IFC-Based Process Mining for Design Authoring. Autom. Constr. 2020, 112, 103069. [Google Scholar] [CrossRef]

- Leemans, S.J.J.; Poppe, E.; Wynn, M.T. Directly Follows-Based Process Mining: Exploration & a Case Study. In Proceedings of the 2019 International Conference on Process Mining (ICPM), Aachen, Germany, 24–26 June 2019; pp. 25–32. [Google Scholar]

- van der Aalst, W.M.P.; De Masellis, R.; Di Francescomarino, C.; Ghidini, C. Learning Hybrid Process Models from Events. In Proceedings of the Business Process Management, Barcelona, Spain, 10–15 September 2017; Carmona, J., Engels, G., Kumar, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 59–76. [Google Scholar]

- van Schaijk, S. Building Information Model (BIM) Based Process Mining: Enabling Knowledge Reassurance and Fact-Based Problem Discovery Within the Architecture, Engineering, Construction and Facility Management Industry. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2016. [Google Scholar]

- Yarmohammadi, S.; Pourabolghasem, R.; Castro-Lacouture, D. Mining Implicit 3D Modeling Patterns from Unstructured Temporal BIM Log Text Data. Autom. Constr. 2017, 81, 17–24. [Google Scholar] [CrossRef]

- Kouhestani, S. Integration of Building Information Modeling (BIM) and Process Mining for Design Authoring Processes. Master’s Thesis, Concordia University, Montreal, QC, Canada, 2019. [Google Scholar]

- Forcael, E.; Martínez-Rocamora, A.; Sepúlveda-Morales, J.; García-Alvarado, R.; Nope-Bernal, A.; Leighton, F. Behavior and Performance of BIM Users in a Collaborative Work Environment. Appl. Sci. 2020, 10, 2199. [Google Scholar] [CrossRef]

- Jang, S.; Lee, G. Improving BIM Authoring Process Reproducibility with Enhanced BIM Logging 2023. arXiv 2023, arXiv:2305.18032. [Google Scholar]

- Gao, W.; Wu, C.; Huang, W.; Lin, B.; Su, X. A Data Structure for Studying 3D Modeling Design Behavior Based on Event Logs. Autom. Constr. 2021, 132, 103967. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, X.; Huang, W.; Shi, S. Command2Vec: Feature Learning of 3D Modeling Behavior Sequence—A Case Study on “Spiral-Stair”. In Proceedings of the 2021 DigitalFUTURES; Yuan, P.F., Chai, H., Yan, C., Leach, N., Eds.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 45–54. [Google Scholar]

- Zhang, L.; Wen, M.; Ashuri, B. BIM Log Mining: Measuring Design Productivity. J. Comput. Civ. Eng. 2018, 32, 4017071. [Google Scholar] [CrossRef]

- Kouhestani, S.; Nik-Bakht, M. Towards Level 3 BIM Process Maps with IFC & XES Process Mining. In eWork and eBusiness in Architecture, Engineering and Construction; Karlshoj, J., Scherer, R., Eds.; CRC Press: London, UK, 2018; pp. 103–112. ISBN 978-0-429-50621-5. [Google Scholar]

- Gao, W.; Zhang, X.; He, Q.; Lin, B.; Huang, W. Command Prediction Based on Early 3D Modeling Design Logs by Deep Neural Networks. Autom. Constr. 2022, 133, 104026. [Google Scholar] [CrossRef]

- Jang, S.; Lee, G.; Shin, S.; Roh, H. Lexicon-Based Content Analysis of BIM Logs for Diverse BIM Log Mining Use Cases. Adv. Eng. Inf. 2023, 57, 102079. [Google Scholar] [CrossRef]

- Gong, Z.; Wang, Y.; Liao, S. Digitalization of construction engineering project management based on the digital twin. China Civ. Eng. J. 2024, 57, 106–128. [Google Scholar] [CrossRef]

- Wang, Y.; Liao, S.; Gong, Z.; Deng, F. Digital Twin Practice for Long Linear Engineering Management: A Case Study of Nantong Ring Expressway. In Proceedings of the 18th Conference of the Associated Research Centers for the Urban Underground Space; Wu, W., Leung, C.F., Zhou, Y., Li, X., Eds.; Springer Nature: Berlin/Heidelberg, Germany, 2024; pp. 267–272. [Google Scholar]

- Kang, J.; Deng, F.; Li, X.; Wan, F. Automatic Texture Reconstruction of 3d City Model from Oblique Images. In ISPRS—International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences; Copernicus GmbH: Göttingen, Germany, 2016; Volume XLI-B1, pp. 341–347. [Google Scholar]

- Yang, J.; Liu, L.; Lu, L.; Deng, F. Image Registration and Selection for Unmanned Aerial Vehicle Image Stitching. J. Appl. Remote Sens. 2020, 14, 46512. [Google Scholar] [CrossRef]

- Xv, J.; Deng, F. 3D Point Cloud Instance Segmentation Considering Global Shape Contour Constraints. Remote Sens. 2023, 15, 4939. [Google Scholar] [CrossRef]

- Xiao, T.; Yan, Q.; Ma, W.; Deng, F. Progressive Structure from Motion by Iteratively Prioritizing and Refining Match Pairs. Remote Sens. 2021, 13, 2340. [Google Scholar] [CrossRef]

- Deng, F.; Kang, J.; Li, P.; Wan, F. Automatic True Orthophoto Generation Based on Three-Dimensional Building Model Using Multiview Urban Aerial Images. J. Appl. Remote Sens. 2015, 9, 95087. [Google Scholar] [CrossRef]

- Verbeek, H.M.W.; Buijs, J.C.; Van Dongen, B.F.; Van Der Aalst, W.M. XES, XESame, and ProM 6. In Proceedings of the Information Systems Evolution: CAiSE Forum 2010, Hammamet, Tunisia, 7–9 June 2010; Soffer, P., Proper, E., Eds.; Springer: Berlin, Heidelberg, 2011; pp. 60–75. [Google Scholar]

- van Dongen, B.F.; de Medeiros, A.K.A.; Verbeek, H.M.W.; Weijters, A.J.M.M.; van der Aalst, W.M.P. The ProM Framework: A New Era in Process Mining Tool Support. In Proceedings of the Applications and Theory of Petri Nets 2005, Miami, FL, USA, 20–25 June 2005; Ciardo, G., Darondeau, P., Eds.; Springer: Berlin, Heidelberg, 2005; pp. 444–454. [Google Scholar]

- Leemans, S.; Poppe, E.; Wynn, M. Directly Follows-Based Process Mining: A Tool. In Proceedings of the ICPM Demo Track 2019 (CEUR Workshop Proceedings, Volume 2374); Burattin, A., van Zelst, S., Polyvyanyy, A., Eds.; Sun SITE Central Europe: Franfurt Am Main, Germany, 2019; Volume 2374, pp. 9–12. Available online: http://www.ceur-ws.org/ (accessed on 1 June 2024).

- Chapela-Campa, D.; Dumas, M.; Mucientes, M.; Lama, M. Efficient edge filtering of directly-follows graphs for process mining. Inf. Sci. 2022, 610, 830–846. [Google Scholar] [CrossRef]

- Fahland, D.; van der Aalst, W.M.P. Model Repair—Aligning Process Models to Reality. Inf. Syst. 2015, 47, 220–243. [Google Scholar] [CrossRef]

- van der Aalst, W.; Adriansyah, A.; van Dongen, B. Replaying History on Process Models for Conformance Checking and Performance Analysis. WIREs Data Min. Knowl. Discov. 2012, 2, 182–192. [Google Scholar] [CrossRef]

- Leemans, S.J.J.; Fahland, D.; van der Aalst, W.M.P. Scalable Process Discovery and Conformance Checking. Softw. Syst. Model. 2018, 17, 599–631. [Google Scholar] [CrossRef]

- Muñoz-Gama, J.; Carmona, J. A Fresh Look at Precision in Process Conformance. In Proceedings of the Business Process Management; Hull, R., Mendling, J., Tai, S., Eds.; Springer: Berlin, Heidelberg, 2010; pp. 211–226. [Google Scholar]

- Blum, F. Metrics in Process Discovery. University of Chile, Santiago, Chile, Report. 2015. pp. 1–21. Available online: https://api.semanticscholar.org/CorpusID:15882411 (accessed on 1 June 2024).

- Pm4py—Process Mining for Python. Available online: https://processintelligence.solutions/ (accessed on 24 June 2024).

- Vázquez-Barreiros, B.; Mucientes, M.; Lama, M. ProDiGen: Mining Complete, Precise and Minimal Structure Process Models with a Genetic Algorithm. Inf. Sci. 2015, 294, 315–333. [Google Scholar] [CrossRef]

- Berti, A.; van Zelst, S.; Schuster, D. PM4Py: A Process Mining Library for Python. Softw. Impacts 2023, 17, 100556. [Google Scholar] [CrossRef]

- Bolt, A.; de Leoni, M.; van der Aalst, W.M.P. Process Variant Comparison: Using Event Logs to Detect Differences in Behavior and Business Rules. Inf. Syst. 2018, 74, 53–66. [Google Scholar] [CrossRef]

- Kermani, M.A.M.A.; Seddighi, H.R.; Maghsoudi, M. Revolutionizing Process Mining: A Novel Architecture for ChatGPT Integration and Enhanced User Experience through Optimized Prompt Engineering 2024. arXiv 2024, arXiv:2405.10689. [Google Scholar]

- Colonna, J.G.; Fares, A.A.; Duarte, M.; Sousa, R. Process Mining Embeddings: Learning Vector Representations for Petri Nets. arXiv 2024, arXiv:2404.17129. [Google Scholar] [CrossRef]

- Gao, J.; Barzel, B.; Barabási, A.-L. Universal Resilience Patterns in Complex Networks. Nature 2016, 530, 307–312. [Google Scholar] [CrossRef]

| Years | References | Physical entity | Phase | Modeling technology | Twin service |

|---|---|---|---|---|---|

| 2024 | [31] | Prefabricated construction | Decoration construction | IoT, AI | Abnormal event identification |

| 2024 | [32] | Rail transit | Operation and Maintenance phase | IoT, FEM, AI | Structural health monitoring |

| 2024 | [30] | Building (Stadium Dome) | Operation and Maintenance phase | IoT | Structural health monitoring |

| 2024 | [33] | Building | Construction phase | IoT, BIM | Construction monitoring and management |

| 2024 | [21] | Tunnel | Construction phase | IoT, CV, NLP | Construction monitoring and forecasting |

| 2023 | [26] | Building | Construction phase | BIM, CV | Multi-source data fusion |

| 2023 | [27] | Building | Operation and Maintenance phase | IoT, BIM, AI | Detection and prediction |

| 2023 | [34] | Prefabricated construction | Construction phase | IoT, CV | Construction monitoring and management |

| 2023 | [35] | Tunnel | Construction phase | IoT, CV | Construction monitoring and forecasting |

| 2023 | [36] | Tunnel | Construction phase | IoT, CV | Early warning and management |

| 2022 | [37] | Prefabricated construction | Construction phase | IoT | Planning, scheduling and execution |

| 2022 | [38] | Highway | Construction phase | IoT, BIM, AI | Construction monitoring and management |

| 2022 | [39] | Tunnel | Construction phase | 3D geology | Geological information reconstruction |

| 2021 | [19] | Building | Construction phase | IoT, BIM, GIS, VR | Decision-making and supervision |

| 2021 | [40] | Building | Construction phase | IoT, BIM, Blockchain | Information sharing |

| 2021 | [41] | Tunnel | Operation and Maintenance phase | BIM, CV | Decision analysis |

| 2021 | [28] | Building | Construction phase | IoT, BIM, CV | Forecasting and Management |

| 2020 | [29] | Building Operations Assets | Operation and Maintenance phase | IFC | Abnormal event identification |

| Case-id | Event-id | Activity Name | Starting Time | Finishing Time | |

|---|---|---|---|---|---|

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋮ |

| Case-2 | Event–22 | Analyze Defect | 1 April 2024 8:10 | 1 April 2024 8:15 | |

| Case–2 | Event–23 | Repair | 1 April 2024 9:00 | 1 April 2024 9:50 | |

| Case–3 | Event–24 | Test Repair | 1 April 2024 9:55 | 1 April 2024 10:15 | |

| Case–2 | Event–25 | Archive Repair | 1 April 2024 10:30 | 1 April 2024 10:56 | |

| Case–4 | Event–26 | Register | 1 April 2024 11:27 | 1 April 2024 11:49 | |

| Case–3 | Event–27 | Repair | 1 April 2024 12:51 | 1 April 2024 13:50 | |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋮ | ⋱ |

| Case-ID | Event-ID | Start Time | Complete Time |

|---|---|---|---|

| ZXKSHGSDQ | ZJ | 1 October 2021 | 9 August 2022 |

| ZXKSHGSDQ | CT | 20 November 2021 | 24 September 2022 |

| BZDKSHGSDQ | HL | 15 February 2023 | 9 April 2024 |

| BZDKSHGSDQ | QMX | 25 February 2023 | 20 April 2024 |

| EZDKSHGSDQ | ZJ | 1 October 2021 | 30 May 2022 |

| EZDKSHGSDQ | CT | 25 October 2021 | 20 June 2022 |

| BBLKSHGSDQ | HL | 15 August 2023 | 10 May 2024 |

| BBLKSHGSDQ | QMX | 10 September 2023 | 31 May 2024 |

| XYHZQ | ZJ | 1 October 2021 | 8 June 2022 |

| XYHZQ | DZ | 31 May 2022 | 29 October 2023 |

| ⋮ | ⋮ | ⋮ | ⋮ |

| BZDKSHGSDQ | XJXL | 1 October 2022 | 29 March 2024 |

| Petri Net | Activities | Paths | Fitness | Precision | Generalization | Simplicity |

|---|---|---|---|---|---|---|

| Figure 9a | 1 | 1 | 0.737408 | 0.702233 | 0.467948 | 0.542169 |

| Figure 9a | 1 | 0.75 | 0.737408 | 0.702233 | 0.490281 | 0.542169 |

| Figure 9a | 1 | 0.5 | 0.737408 | 0.702233 | 0.446266 | 0.542169 |

| Figure 9b | 1 | 0.25 | 0.570360 | 0.862191 | 0.619425 | 0.684211 |

| Figure 9c | 0.75 | 1 | 0.728327 | 0.727506 | 0.543422 | 0.5625 |

| Figure 9d | 0.75 | 0.75 | 0.614774 | 0.827119 | 0.595957 | 0.652174 |

| Figure 9e | 0.75 | 0.5 | 0.610501 | 0.844291 | 0.617867 | 0.658537 |

| Figure 9f | 0.75 | 0.25 | 0.390720 | 0.976 | 0.701121 | 1 |

| Figure 9g | 0.5 | 1 | 0.588217 | 0.913043 | 0.559964 | 0.621622 |

| Figure 9h | 0.5 | 0.75 | 0.483745 | 0.960177 | 0.601314 | 0.76 |

| Figure 9i | 0.5 | 0.5 | 0.376374 | 0.960177 | 0.690062 | 1 |

| Figure 9i | 0.5 | 0.25 | 0.376374 | 0.960177 | 0.690062 | 1 |

| Figure 9j | 0.25 | 1 | 0.254960 | 0 | 0.590408 | 0.818182 |

| Figure 9k | 0.25 | 0.75 | 0.192995 | 0 | 0.604696 | 1 |

| Figure 9k | 0.25 | 0.5 | 0.192995 | 0 | 0.604696 | 1 |

| Figure 9k | 0.25 | 0.25 | 0.192995 | 0 | 0.604696 | 1 |

| Figure 8b | Inductive mining | 0.7148 | 0.2284 | 0.7128 | 0.7049 | |

| Figure 8c | BPMN | 1 | 0.2135 | 0.6855 | 0.6757 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liao, S.; Gong, Z.; Deng, F.; Yin, S. Enhancing Construction Management Digital Twins Through Process Mining of Progress Logs. Sustainability 2024, 16, 10064. https://doi.org/10.3390/su162210064

Wang Y, Liao S, Gong Z, Deng F, Yin S. Enhancing Construction Management Digital Twins Through Process Mining of Progress Logs. Sustainability. 2024; 16(22):10064. https://doi.org/10.3390/su162210064

Chicago/Turabian StyleWang, Yongzhi, Shaoming Liao, Zhiqun Gong, Fei Deng, and Shiyou Yin. 2024. "Enhancing Construction Management Digital Twins Through Process Mining of Progress Logs" Sustainability 16, no. 22: 10064. https://doi.org/10.3390/su162210064

APA StyleWang, Y., Liao, S., Gong, Z., Deng, F., & Yin, S. (2024). Enhancing Construction Management Digital Twins Through Process Mining of Progress Logs. Sustainability, 16(22), 10064. https://doi.org/10.3390/su162210064