A Process Analysis Framework to Adopt Intelligent Robotic Process Automation (IRPA) in Supply Chains

Abstract

1. Introduction

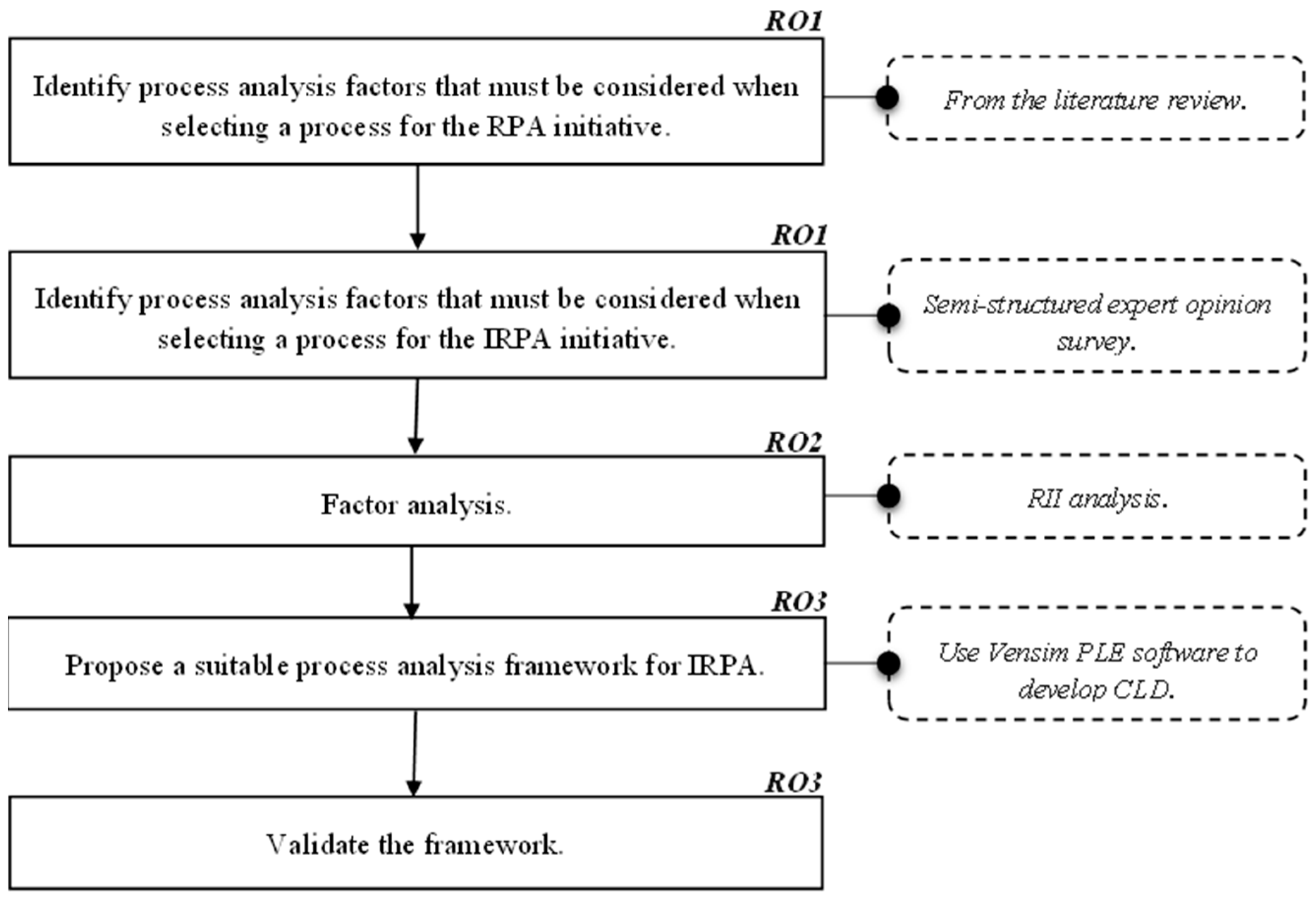

- RO1: Identify the process analysis factors that help to select the most suitable process for IRPA;

- RO2: Evaluate the contribution of process analysis factors that help to select the most suitable process for IRPA;

- RO3: Develop a suitable process analysis framework to adopt IRPA.

2. Literature Review

2.1. Robotic Process Automation (RPA)

RPA Application in Supply Chain Processes

2.2. Intelligent Robotic Process Automation (IRPA)

2.3. Process Analysis

2.3.1. Process Analysis Factors for RPA Implementations in Supply Chains

2.3.2. Process Analysis Factors for IRPA Implementations in Supply Chains

3. Methodology and Analysis

3.1. Research Objective 1: Identify the Process Analysis Factors That Help to Select the Most Suitable Process for IRPA

3.2. Research Objective 2: Evaluate the Contribution of Process Analysis Factors That Help to Select the Most Suitable Processes for IRPA

3.3. Research Objective 3: Develop a Suitable Process Analysis Framework to Adopt IRPA

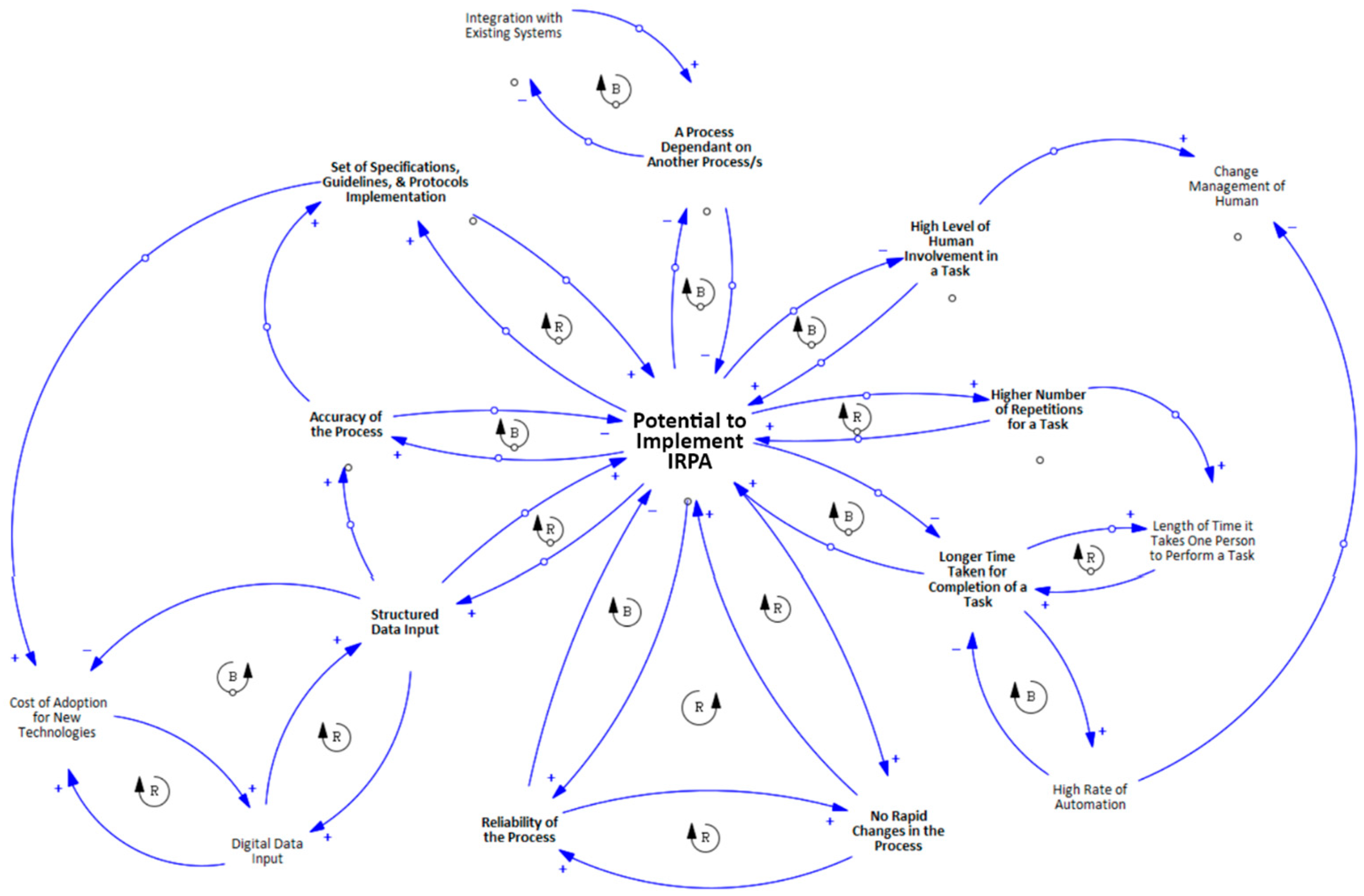

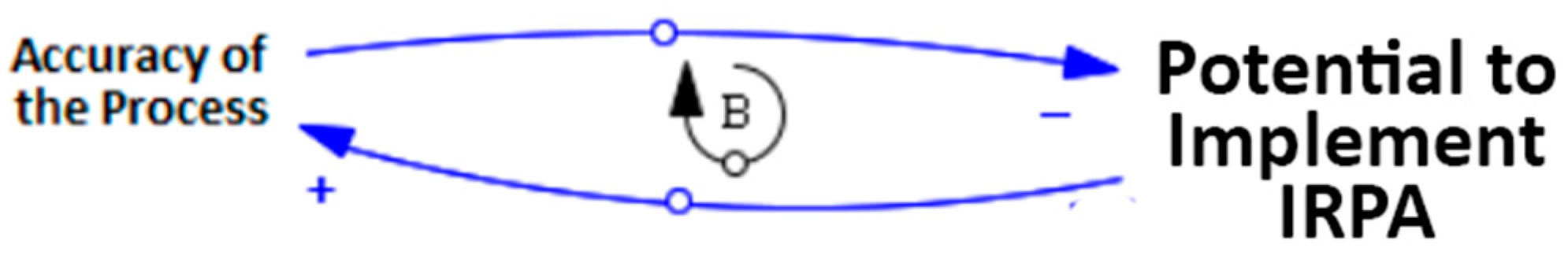

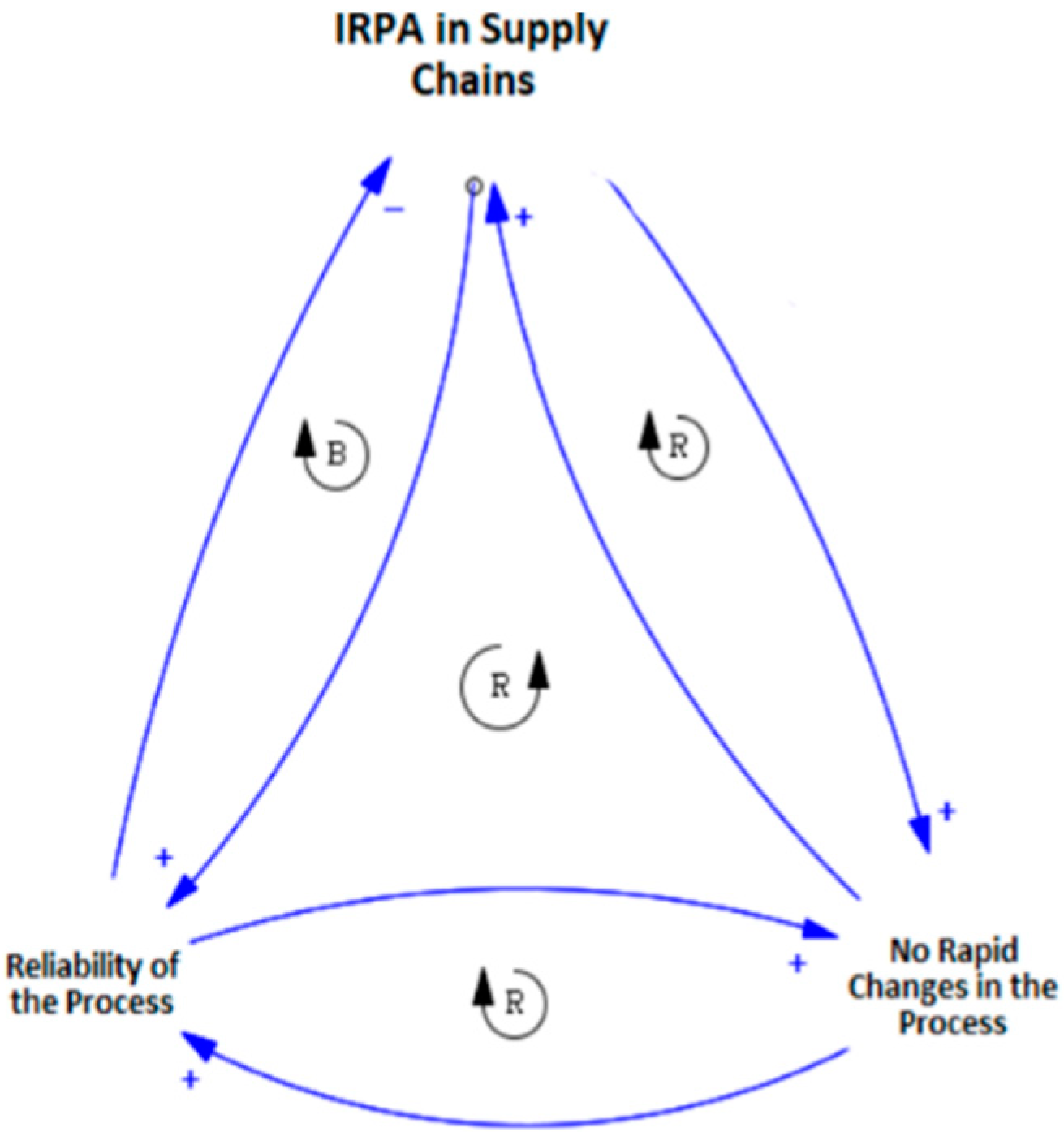

- Accuracy—When an already existing process has a higher level of accuracy, that specifically does not need to adopt IRPA. Therefore, that relationship has a negative impact. On the other hand, when there is a high potential to adopt IRPA, that helps to increase the accuracy of the processes. Therefore, that relationship has a positive impact, as represented in Figure 3.

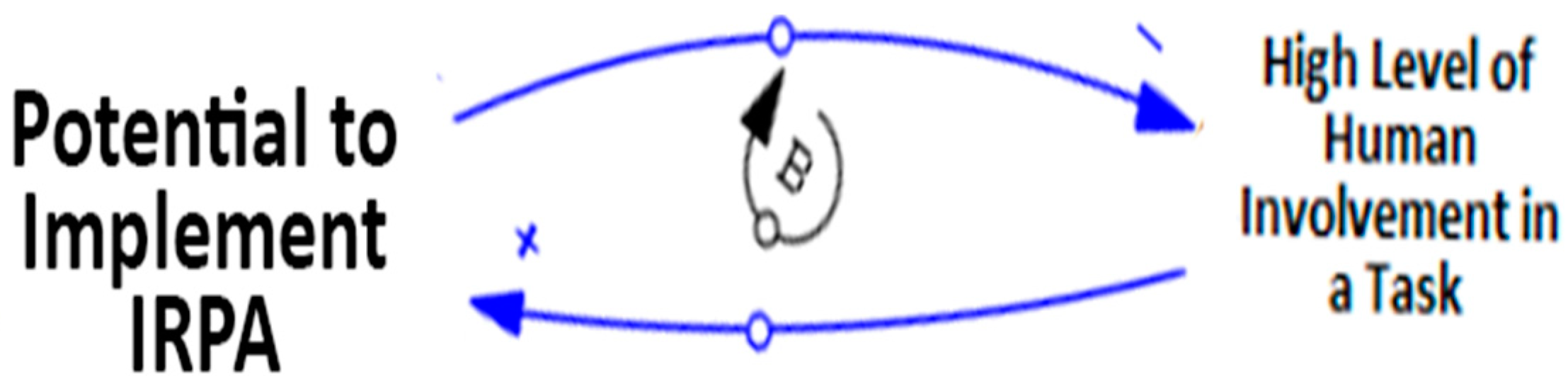

- Level of human involvement—When automating a process with a high level of human involvement, it requires to have decision-making capabilities, adopt to changing conditions, and it should reduce human errors; then, there is a higher potential to implement IRPA. Therefore, that relationship has a positive impact. On the other hand, implementing IRPA reduces human involvement in a process, since that relationship has a negative impact, as represented in Figure 4.

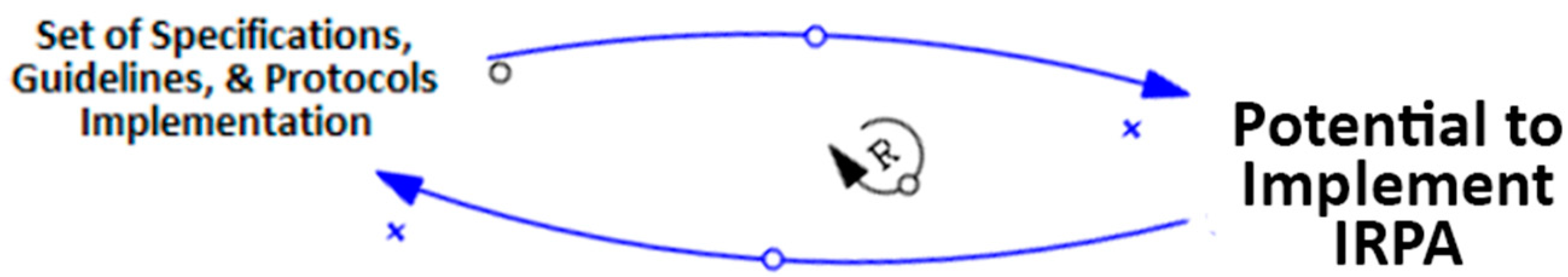

- Standardization—Standardization means the implementation of a set of specifications, guidelines, and protocols. If a process already has standardization, that increases the potential to implement IRPA and vice versa, so that both relationships have a positive impact, as represented in Figure 5.

4. Findings and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feio, I.C.L.; dos Santos, V.D. A Strategic Model and Framework for Intelligent Process Automation. Iber. Conf. Inf. Syst. Technol. Cist. 2022, 2022, 1–6. [Google Scholar] [CrossRef]

- Lee, I.; Mangalaraj, G. Big Data Analytics in Supply Chain Management: A Systematic Literature Review and Research Directions. Big Data Cogn. Comput. 2022, 6, 17. [Google Scholar] [CrossRef]

- Leshob, A.; Bourgouin, A.; Renard, L. Towards a Process Analysis Approach to Adopt Robotic Process Automation. In Proceedings of the 2018 IEEE 15th International Conference on e-Business Engineering, Xi’an, China, 12–14 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 46–53. [Google Scholar]

- Lievano-Martínez, F.A.; Fernández-Ledesma, J.D.; Burgos, D.; Branch-Bedoya, J.W.; Jimenez-Builes, J.A. Intelligent Process Automation: An Application in Manufacturing Industry. Sustainability 2022, 14, 8804. [Google Scholar] [CrossRef]

- Radke, A.M.; Dang, M.T.; Tan, W.K.A. Using robotic process automation (RPA) to enhance item master data maintenance process. Logforum 2020, 16, 129–140. [Google Scholar] [CrossRef]

- Uygun, H. Application of robotic process automation (RPA) for supply chain management, smart transportation and logistics Application of robotic process automation (RPA) for supply chain management, smart transportation and logistics. Int. J. Health Sci. 2022, 6, 11051–11063. [Google Scholar] [CrossRef]

- Keung, K.L.; Lee, C.K.M.; Ji, P. Data-driven order correlation pattern and storage location assignment in robotic mobile fulfillment and process automation system. Adv. Eng. Inform. 2021, 50, 101369. [Google Scholar] [CrossRef]

- Ferreira, D.; Rozanova, J.; Dubba, K.; Zhang, D.; Freitas, A. On the Evaluation of Intelligent Process Automation. arXiv 2020, arXiv:2001.02639. [Google Scholar]

- Axmann, B.; Harmoko, H. Robotic Process Automation: An Overview and Comparison to Other Technology in Industry 4.0. In Proceedings of the 10th International Conference “Advanced Computer Information Technologies”, Deggendorf, Germany, 16–18 September 2020; pp. 559–562. [Google Scholar] [CrossRef]

- Puica, E. How Is it a Benefit using Robotic Process Automation in Supply Chain Management? J. Supply Chain Cust. Relatsh. Manag. 2022, 2022, 221327. [Google Scholar] [CrossRef]

- Vajgel, B.; Correa, P.L.P.; Tossoli De Sousa, T.; Encinas Quille, R.V.; Bedoya, J.A.R.; De Almeida, G.M.; Filgueiras, L.V.L.; Demuner, V.R.S.; Mollica, D. Development of Intelligent Robotic Process Automation: A Utility Case Study in Brazil. IEEE Access 2021, 9, 71222–71235. [Google Scholar] [CrossRef]

- Bogue, R. Warehouse robot market boosted by Covid pandemic and technological innovations. Ind. Rob. 2022, 49, 181–186. [Google Scholar] [CrossRef]

- Flechsig, C.; Anslinger, F.; Lasch, R. Robotic Process Automation in purchasing and supply management: A multiple case study on potentials, barriers, and implementation. J. Purch. Supply Manag. 2022, 28, 100718. [Google Scholar] [CrossRef]

- Bathla, G.; Bhadane, K.; Singh, R.K.; Kumar, R.; Aluvalu, R.; Krishnamurthi, R.; Kumar, A.; Thakur, R.N.; Basheer, S. Autonomous Vehicles and Intelligent Automation: Applications, Challenges, and Opportunities. Mob. Inf. Syst. 2022, 2022, 1–36. [Google Scholar] [CrossRef]

- Chakraborti, T.; Isahagian, V.; Khalaf, R.; Khazaeni, Y.; Muthusamy, V.; Rizk, Y.; Unuvar, M. From Robotic Process Automation to Intelligent Process Automation:—Emerging Trends. Lect. Notes Bus. Inf. Process. 2020, 393 LNBIP, 215–228. [Google Scholar] [CrossRef]

- Malhotra, R. Robotic Process Automation (RPA): Integration of Robotic Process Automation Portfolio in Accessing Business Processes with Automation Maturity of Small and Medium Sized Companies to Avoid Failures. Ph.D. Thesis, Technische Hochschule Ingolstadt, Ingolstadt, Germany, 2022. [Google Scholar]

- Santos, F.; Pereira, R.; Vasconcelos, J.B. Toward robotic process automation implementation: An end-to-end perspective. Bus. Process Manag. J. 2020, 26, 405–420. [Google Scholar] [CrossRef]

- Balasundaram, S.; Venkatagiri, S. A structured approach to implementing Robotic Process Automation in HR. J. Phys. Conf. Ser. 2020, 1427, 3–11. [Google Scholar] [CrossRef]

- Gružauskas, V.; Ragavan, D. Robotic process automation for document processing: A case study of a logistics service provider. J. Manage. 2020, 36, 119–126. [Google Scholar] [CrossRef]

- Nielsen, I.E.; Piyatilake, A.; Thibbotuwawa, A.; De Silva, M.M.; Bocewicz, G.; Banaszak, Z.A. Benefits Realization of Robotic Process Automation (RPA) Initiatives in Supply Chains. IEEE Access 2023, 11, 37623–37636. [Google Scholar] [CrossRef]

- Wewerka, J.; Reichert, M. Robotic Process Automation—A Systematic Literature Review and Assessment Framework. arXiv 2020, arXiv:2012.11951. [Google Scholar]

- Hofmann, P.; Samp, C.; Urbach, N. Robotic process automation. Electron. Mark. 2020, 30, 99–106. [Google Scholar] [CrossRef]

- Sapiri, H.; Zulkepli Hew, J.; Ahmad, N.; Zainal Abidin, N.; Hawari, N.N. Introduction to System Dynamic Modelling and Vensim Software; UUM Press: Sintok, Malaysia, 2017; ISBN 9789672064084. [Google Scholar]

- Mokgohloa, K.; Kanakana-Katumba, M.G.; Maladzhi, R.W.; Xaba, S. a System Dynamics Approach To Postal Digital Transformation Dynamics: A Causal Loop Diagram (Cld) Perspective. S. Afr. J. Ind. Eng. 2022, 33, 10–31. [Google Scholar] [CrossRef]

- Elkady, G. A Decision Support Framework to Assess Grocery Retail Supply Chain Collaboration: A System Dynamics Modelling Approach. Int. J. Innov. Manag. Technol. 2014, 5, 232–238. [Google Scholar] [CrossRef]

- Salby, J. Robotic Automation Emerges as a Threat to Traditional Low-Cost Outsourcing. HfS 2012, 1–18. [Google Scholar]

- Rizk, Y.; Isahagian, V.; Boag, S.; Khazaeni, Y.; Unuvar, M.; Muthusamy, V.; Khalaf, R. A Conversational Digital Assistant for Intelligent Process Automation. Lect. Notes Bus. Inf. Process. 2020, 393 LNBIP, 85–100. [Google Scholar] [CrossRef]

- Viale, L.; Zouari, D. Impact of digitalization on procurement: The case of robotic process automation. Supply Chain. Forum Int. J. 2020, 21, 185–195. [Google Scholar] [CrossRef]

- Flechsig, C. The Impact of Intelligent Process Automation on Purchasing and Supply Management—Initial Insights from a Multiple Case Study. Lect. Notes Logist. 2021, 67–89. [Google Scholar] [CrossRef]

- Sugathadasa, R.; Rajapaksha, S. An investigation on relationship between third party logistics user and provider at FMCG industry in Sri Lanka. In Proceedings of the 17th Annual Research Symposium on Excellence in Research, Colombo, Sri Lanka, 21 September 2013. [Google Scholar]

- Zhang, Z.; Huang, Z. Design and Application of Logistics Robot based on RPA. Front. Comput. Intell. Syst. 2022, 1, 66–75. [Google Scholar] [CrossRef]

- Khan, M.G.; Ul Huda, N.; Uz Zaman, U.K. Smart Warehouse Management System: Architecture, Real-Time Implementation and Prototype Design. Machines 2022, 10, 150. [Google Scholar] [CrossRef]

- Kim, J. A Study on the Success Cases about AI RPA (Robotic Process Automation) in Manufacturing Industry. Int. J. Wirel. Mob. Commun. Ind. Syst. 2019, 6, 15–20. [Google Scholar] [CrossRef]

- Ribeiro, J.; Lima, R.; Eckhardt, T.; Paiva, S. Robotic Process Automation and Artificial Intelligence in Industry 4.0—A Literature review. Procedia Comput. Sci. 2021, 181, 51–58. [Google Scholar] [CrossRef]

- Herm, L.V.; Janiesch, C.; Reijers, H.A.; Seubert, F. From Symbolic RPA to Intelligent RPA: Challenges for Developing and Operating Intelligent Software Robots. In Proceedings of the Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer International Publishing: Berlin/Heidelberg, Germany, 2021; Volume 12875 LNCS, pp. 289–305. [Google Scholar]

- Neifer, T.; Bossauer, P.; Lawo, D.; Volkening, R.; Gadatsch, A. The Role of Marketplaces for the Transformation from Robotic Process Automation to Intelligent Process Automation. ICSBT 2022, 15–25. [Google Scholar]

- E-Fatima, K.; Khandan, R.; Hosseinian-Far, A.; Sarwar, D.; Ahmed, H.F. Adoption and Influence of Robotic Process Automation in Beef Supply Chains. Logistics 2022, 6, 48. [Google Scholar] [CrossRef]

- Gregory, S.; Singh, U.; Gray, J.; Hobbs, J. A Computer Vision Pipeline for Automatic Large-scale Inventory Tracking. In Proceedings of the ACMSE’21: Proceedings of the 2021 ACM Southeast Conference, Virtual, 15–17 April 2021; pp. 100–107. [Google Scholar]

- Jha, D.R.; Upadhyay, G.M. Novel Approach for Robotic Process Automation with Increasing Productivity and Improving Product Quality using Machine Learning. Int. J. Eng. Adv. Technol. 2021, 10, 103–109. [Google Scholar] [CrossRef]

- Hall, P.A. Systematic process analysis: When and how to use it. Eur. Manag. Rev. 2006, 3, 24–31. [Google Scholar] [CrossRef]

- Piyatilake, A.; Vitharanage, I.D.; De Silva, M.M.; Thibbotuwawa, A. Benefits Realization of Robotic Process Automation (RPA) Initiatives in Supply Chains. In Proceedings of the Research for Transport and Logistics Industry Proceedings of the 7th International Conference, Colombo, Sri Lanka, 27 August 2022; Volume 11, ISBN 9781119130536. [Google Scholar]

- Timbadia, D.H.; Jigishu Shah, P.; Sudhanvan, S.; Agrawal, S. Robotic Process Automation Through Advance Process Analysis Model. In Proceedings of the 5th International Conference on Inventive Computation Technologies, Coimbatore, India, 10 December 2019–11 January 2020; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2020; pp. 953–959. [Google Scholar]

- Syed, R.; Suriadi, S.; Adams, M.; Bandara, W.; Leemans, S.J.J.; Ouyang, C.; ter Hofstede, A.H.M.; van de Weerd, I.; Wynn, M.T.; Reijers, H.A. Robotic Process Automation: Contemporary themes and challenges. Comput. Ind. 2020, 115, 103162. [Google Scholar] [CrossRef]

- Viehhauser, J.; Doerr, M. Digging for Gold in RPA Projects—A Quantifiable Method to Identify and Prioritize Suitable RPA Process Candidates. In Proceedings of the Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2021; Volume 12751 LNCS, pp. 313–327. [Google Scholar]

- Kokina, J.; Blanchette, S. Early evidence of digital labor in accounting: Innovation with Robotic Process Automation. Int. J. Account. Inf. Syst. 2019, 35, 100431. [Google Scholar] [CrossRef]

- Wanner, J.; Hofmann, A.; Fischer, M.; Imgrund, F.; Janiesch, C.; Geyer-Klingeberg, J. Process selection in RPA projects—Towards a quantifiable method of decision making. In Proceedings of the 40th International Conference on Information Systems, Munich, Germany, 15–18 December 2019. [Google Scholar]

- Jeeva Padmini, K.V.; Perera, G.I.U.S.; Dilum Bandara, H.M.N.; Silva, R.K.O.H. A Decision Support Tool to Select Candidate Business Processes in Robotic Process Automation (RPA): An Empirical Study. In Proceedings of the Lecture Notes in Networks and Systems; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2021; Volume 173 LNNS, pp. 567–582. [Google Scholar]

- Azman, N.S.; Ramli, M.Z.; Razman, R.; Zawawi, M.H.; Ismail, I.N.; Isa, M.R. Relative importance index (RII) in ranking of quality factors on industrialised building system (IBS) projects in Malaysia. In Proceedings of the AIP Conference Proceedings, Sofia, Bulgaria, 26 February 2019; Volume 2129. [Google Scholar]

- Hossen, M.M.; Kang, S.; Kim, J. Construction schedule delay risk assessment by using combined AHP-RII methodology for an international NPP project. Nucl. Eng. Technol. 2015, 47, 362–379. [Google Scholar] [CrossRef]

- Gebrehiwet, T.; Luo, H. Analysis of Delay Impact on Construction Project Based on RII and Correlation Coefficient: Empirical Study. Procedia Eng. 2017, 196, 366–374. [Google Scholar] [CrossRef]

- Sánchez-González, L.; García, F.; Ruiz, F.; Mendling, J. A study of the effectiveness of two threshold definition techniques. IET Semin. Dig. 2012, 2012, 197–205. [Google Scholar] [CrossRef]

- Angerhofer, B.J.; Angelides, M.C. System Dynamics Modelling in supply chain management: Research review. In Proceedings of the Winter Simulation Conference Proceedings, Orlando, FL, USA, 10–13 December 2000; Volume 1, pp. 342–351. [Google Scholar]

- Lakdinu, M.; De Silva, M.M.; Balachandra, K.; Frank Perera, K.P.D. Leadership in Change Management Decisions for Successful ERP Implementation—A System Dynamics Perspective. In Proceedings of the MERCon 2022—Moratuwa Engineering Research Conference, Proceedings; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2022. [Google Scholar]

- Bottero, M.; Datola, G.; de Angelis, E. A system dynamics model and analytic network process: An integrated approach to investigate urban resilience. Land 2020, 9, 242. [Google Scholar] [CrossRef]

- Ermolaeva, A.S.; Nemtsev, V.N.; Solomatin, P.S.; Selivanova, M.A. The Analysis of Implementation of Robotic Process Automation RPA: The Experience of Russian and Foreign Companies. In Proceedings of the Lecture Notes in Networks and Systems; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2021; Volume 198, pp. 1483–1492. [Google Scholar]

- Wellmann, C.; Stierle, M.; Dunzer, S.; Matzner, M. A Framework to Evaluate the Viability of Robotic Process Automation for Business Process Activities. In Proceedings of the Lecture Notes in Business Information Processing; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2020; Volume 393 LNBIP, pp. 200–214. [Google Scholar]

- Nema, K.; Sonwaney, V. Analysis on Barriers to Implementation of RPA: An Interpretive Structural Modelling (ISM) Approach. Psychol. Educ. 2020, 57, 1958–1964. [Google Scholar]

| Requirement | RPA | IRPA |

|---|---|---|

| Data Requirements | Structured data only. Requires clean, well-organized, consistent data inputs. | Can process both structured and unstructured data. Requires AI technologies like NLP, OCR, and ML to handle diverse data. |

| Deployment and Maintenance | Faster and simpler deployment. Requires rule adjustments for updates. | More complex deployment due to AI integration. Requires continuous learning, model updates, and retraining. |

| Process Complexity | Suited for simple, repetitive, rule-based processes with clear decision trees. | Can automate simple to complex processes, including decision-making and cognitive tasks. |

| Cost and Investment | Lower initial costs and lower ongoing maintenance costs for rule adjustments. | Higher initial costs due to AI infrastructure and expertise. Long-term cost savings through adaptability and scalability. |

| Technology Requirements | Basic software for mimicking human actions. Predefined scripts and workflows. | Requires AI technologies (ML, NLP, OCR), AI model training, and advanced computing infrastructure. |

| Scalability | Limited scalability; requires manual reconfiguration for new processes. | Highly scalable. AI can generalize and adapt to new processes with minimal manual configuration. |

| Skill Requirements | Basic technical knowledge to configure and maintain rule-based automations. | Advanced AI expertise, data science, and experience with machine learning models. Multidisciplinary teams are needed. |

| Error Handling | Follows predefined rules for error handling; needs human intervention for unexpected issues. | Can handle errors dynamically using AI and make decisions based on context and past learning. |

| Infrastructure | Simple IT systems, legacy system integration, and minimal computing power required. | Requires cloud computing, AI platforms, big data environments, and significant processing power. |

| Process Analysis Factor | Description | Reference |

|---|---|---|

| Automation rate | The degree of automation within a process is considered high when there is minimal manual interaction with the software during the process. An excessive level of automation negatively influences the RPA’s effectiveness. | [3,17,40,41,42,43] |

| Complexity | The length of time it takes one person to perform an activity is referred to as the “complexity of a task” in the literature. Therefore, more difficult tasks take longer to conclude. | [3,17,40,41,42,44,45] |

| Digital data input | In addition to RPA, technologies like optical character recognition and pictures recognition are being used to make RPA bots more intelligent. Digital data input still improves the stability of automation using RPA. | [40,41,42,45,46,47] |

| Stability and maturity | A process is considered stable and mature when it demonstrates minimal or gradual changes and when its results are foreseeable. A higher level of maturity and stability is useful for the stability of automation using RPA. | [3,17,40,41,42,43,44,45,46,47] |

| Standardization | Greater standardization has a beneficial impact on the appropriateness of RPA for automation purposes. | [3,17,40,41,42,43,44,45,46,47] |

| Structured data input | Structured data helps to increase accuracy while lowering the cost of processes. Data are referred to as structured when it is saved in a defined format. The input of structured data enhance the suitability of automation using RPA. | [40,41,42,45,46,47] |

| Volume | The volume of a task is an average amount of repetitions. This makes obvious sense because RPA is routinely used to automate repetitive tasks. Enhanced volume has a favorable influence on the viability of implementing RPA for automation purposes. | [3,17,40,41,42,44,45,46,47] |

| Process Analysis Factors for IRPA | Description | Category |

|---|---|---|

| Accuracy | The accuracy of a task or a process has a huge impact on the overall output of a system. Therefore, adopting IRPA should also give a 100% accurate output for a process. | Process |

| Automation rate | The degree of automation within a process is considered high when there is minimal manual interaction with the software during the process. An excessive level of automation negatively influences the IRPA’s effectiveness. | Technology |

| Change management | Implementing IRPA involves significant changes in the way people work, including introducing new roles and responsibilities, new technologies, and new processes. Therefore, it is important to manage the change effectively to ensure that people are prepared and motivated to work with the new technology. | People |

| Complexity | The length of time it takes one person to perform an activity is referred to as the “complexity of a task” in the literature. Therefore, more difficult tasks take longer to conclude. | People |

| Cost | The cost of adopting new technologies or process improvements may be high due to the advancement of the technology. It is important to have a financially sustainable approach to adopting IRPA. | Technology |

| Dependency | When considering a particular process, look to see if that process has a relationship with any other processes. | Process |

| Digital data input | In addition to RPA, technologies like optical character recognition and picture recognition are being used to make RPA bots more intelligent. Digital data input still improves the stability of automation using IRPA. | Technology |

| Integration with existing systems | IRPA needs to be integrated with existing systems and applications to ensure it can access the data and functionality needed to perform the tasks. This includes API (Application Programming Interface) integration, middleware development, and other technical considerations. | Process |

| Level of human involvement in a task | The level of human involvement in a task means that when more people are involved in a function, the function would be more likely to be automated. | People |

| Reliability | The process should be trustworthy to apply the IRPA, which means a particular process should have long-term usage and impact on the company. On the other hand, IRPA should provide the expected outputs for that process. | Process |

| Stability and maturity | A process is considered stable and mature when it demonstrates minimal or gradual changes and when its results are foreseeable. A higher level of maturity and stability is useful for the stability of automation using IRPA. | Process |

| Standardization | Greater standardization has a beneficial impact on the appropriateness of IRPA for automation purposes. | Process |

| Structured data input | Structured data helps to increase accuracy while lowering the cost of processes. Data are referred to as structured when it is saved in a defined format. The input of structured data enhance the suitability of automation using IRPA. | Process |

| Time and Speed | When a process takes a long time to be completed by a human, it is more appropriate and beneficial to adopt IRPA. That will increase the efficiency of the process and reduce the time to complete the process. | Process |

| Volume | The volume of a task is an average amount of repetitions. This makes obvious sense because IRPA is routinely used to automate repetitive tasks. Enhanced volume has a favorable influence on the viability of implementing IRPA for automation purposes. | Process |

| Factor No. | Process Analysis Factor | RII | Factor Type |

|---|---|---|---|

| 1 | Accuracy | 0.9308 | Primary |

| 2 | Level of human involvement in a task | 0.9154 | Primary |

| 3 | Standardization | 0.9077 | Primary |

| 4 | Stability and maturity | 0.9000 | Primary |

| 5 | Structured data input | 0.8769 | Primary |

| 6 | Reliability | 0.8769 | Primary |

| 7 | Time and Speed | 0.8769 | Primary |

| 8 | Volume | 0.8615 | Primary |

| 9 | Dependency | 0.8538 | Primary |

| 10 | Digital data input | 0.8462 | Secondary |

| 11 | Integration with existing systems | 0.8385 | Secondary |

| 12 | Cost | 0.8231 | Secondary |

| 13 | Complexity | 0.7846 | Secondary |

| 14 | Change management | 0.7462 | Secondary |

| 15 | Automation rate | 0.7154 | Secondary |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waduge, S.; Sugathadasa, R.; Piyatilake, A.; Nanayakkara, S. A Process Analysis Framework to Adopt Intelligent Robotic Process Automation (IRPA) in Supply Chains. Sustainability 2024, 16, 9753. https://doi.org/10.3390/su16229753

Waduge S, Sugathadasa R, Piyatilake A, Nanayakkara S. A Process Analysis Framework to Adopt Intelligent Robotic Process Automation (IRPA) in Supply Chains. Sustainability. 2024; 16(22):9753. https://doi.org/10.3390/su16229753

Chicago/Turabian StyleWaduge, Sandali, Ranil Sugathadasa, Ashani Piyatilake, and Samudaya Nanayakkara. 2024. "A Process Analysis Framework to Adopt Intelligent Robotic Process Automation (IRPA) in Supply Chains" Sustainability 16, no. 22: 9753. https://doi.org/10.3390/su16229753

APA StyleWaduge, S., Sugathadasa, R., Piyatilake, A., & Nanayakkara, S. (2024). A Process Analysis Framework to Adopt Intelligent Robotic Process Automation (IRPA) in Supply Chains. Sustainability, 16(22), 9753. https://doi.org/10.3390/su16229753