Measurement of Synergy Management Performance in Prefabricated Building Project Supply Chain

Abstract

1. Introduction

2. Literature Review

2.1. Prefabricated Building Project Supply Chain

2.2. Synergy in Prefabricated Building Project Supply Chains

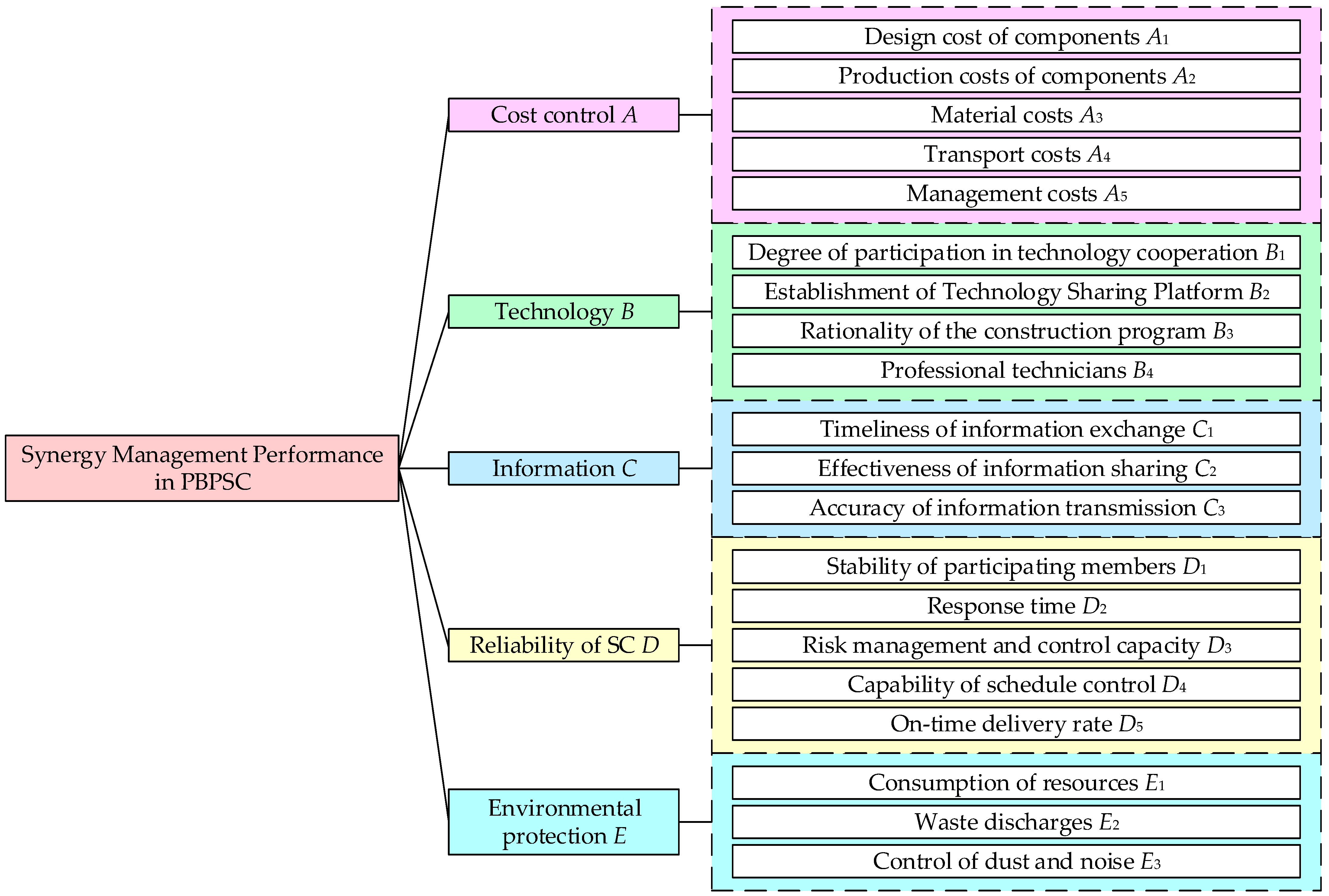

3. Measurement Index System

3.1. Identification of Influencing Factors

3.2. Establishment of the Measurement Index System

3.2.1. Cost Control

3.2.2. Technology

3.2.3. Information

3.2.4. Reliability of SCs

3.2.5. Environmental Protection

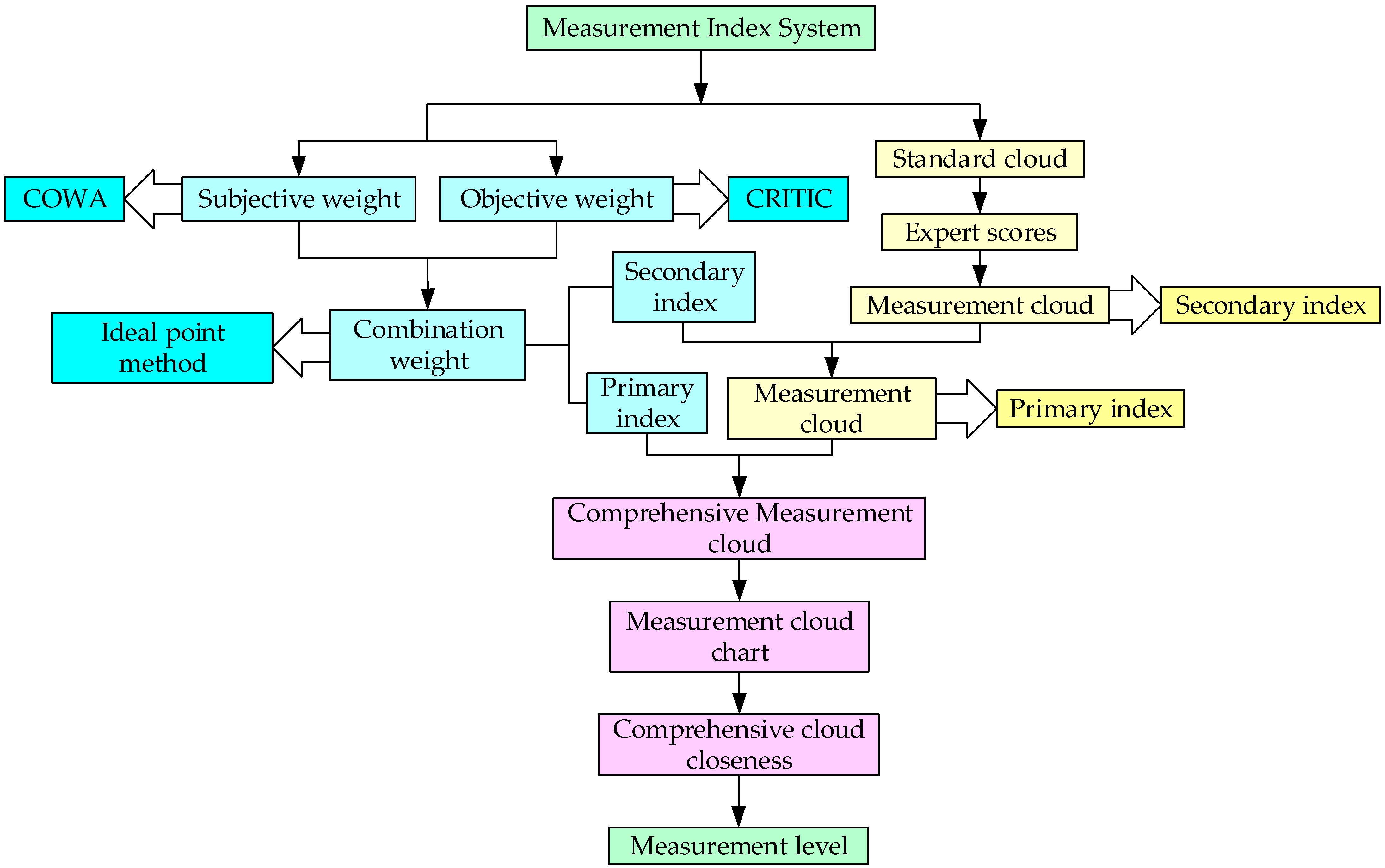

4. Methodology

4.1. Index Weights

4.1.1. Subjective Weights

4.1.2. Objective Weights

4.1.3. Combination Weights

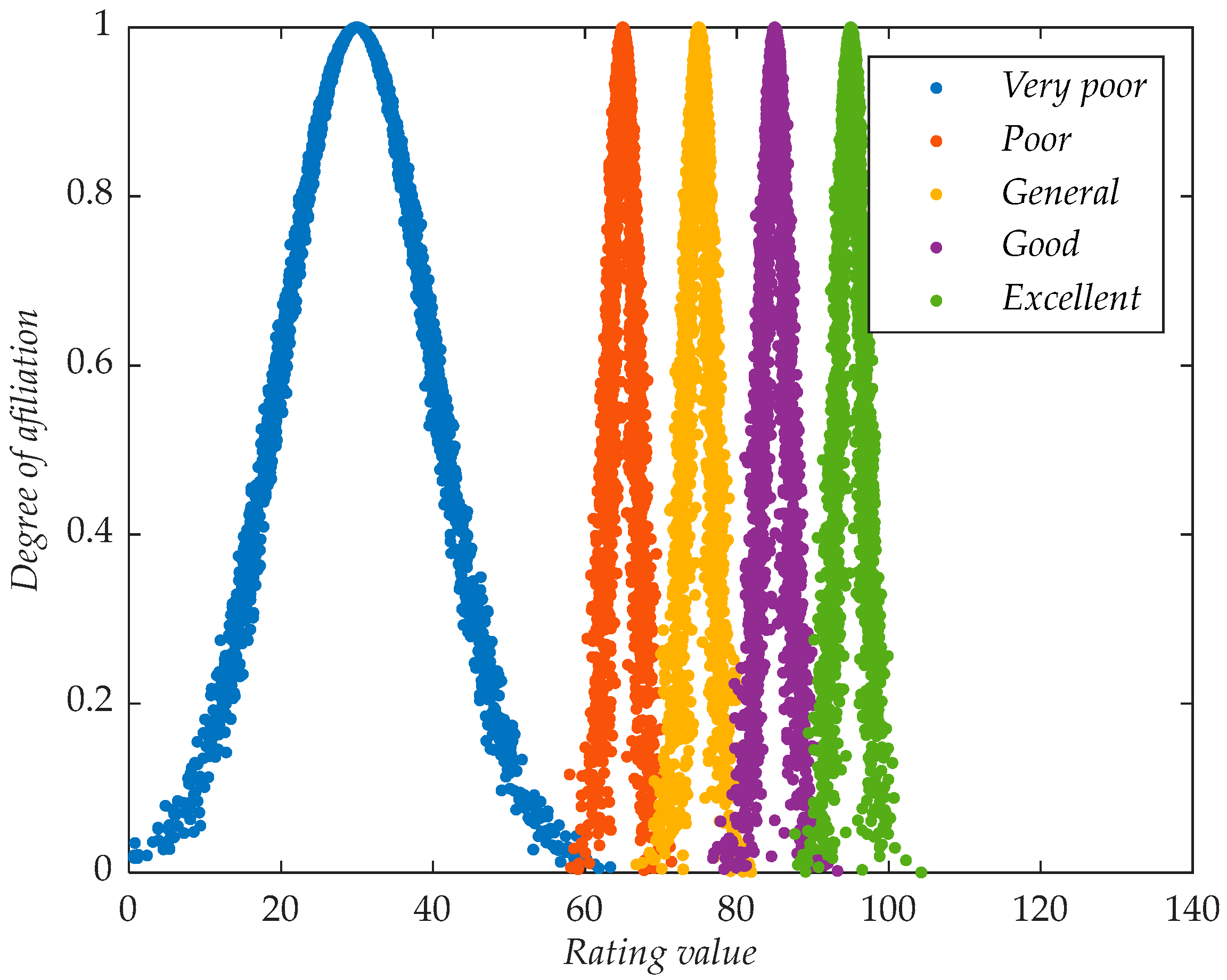

4.2. Cloud Model

4.2.1. Definition

4.2.2. Standard Measurement Cloud

4.2.3. Measurement Cloud of Indexes

5. Case Applications

5.1. Calculation of Measurement Index Weights

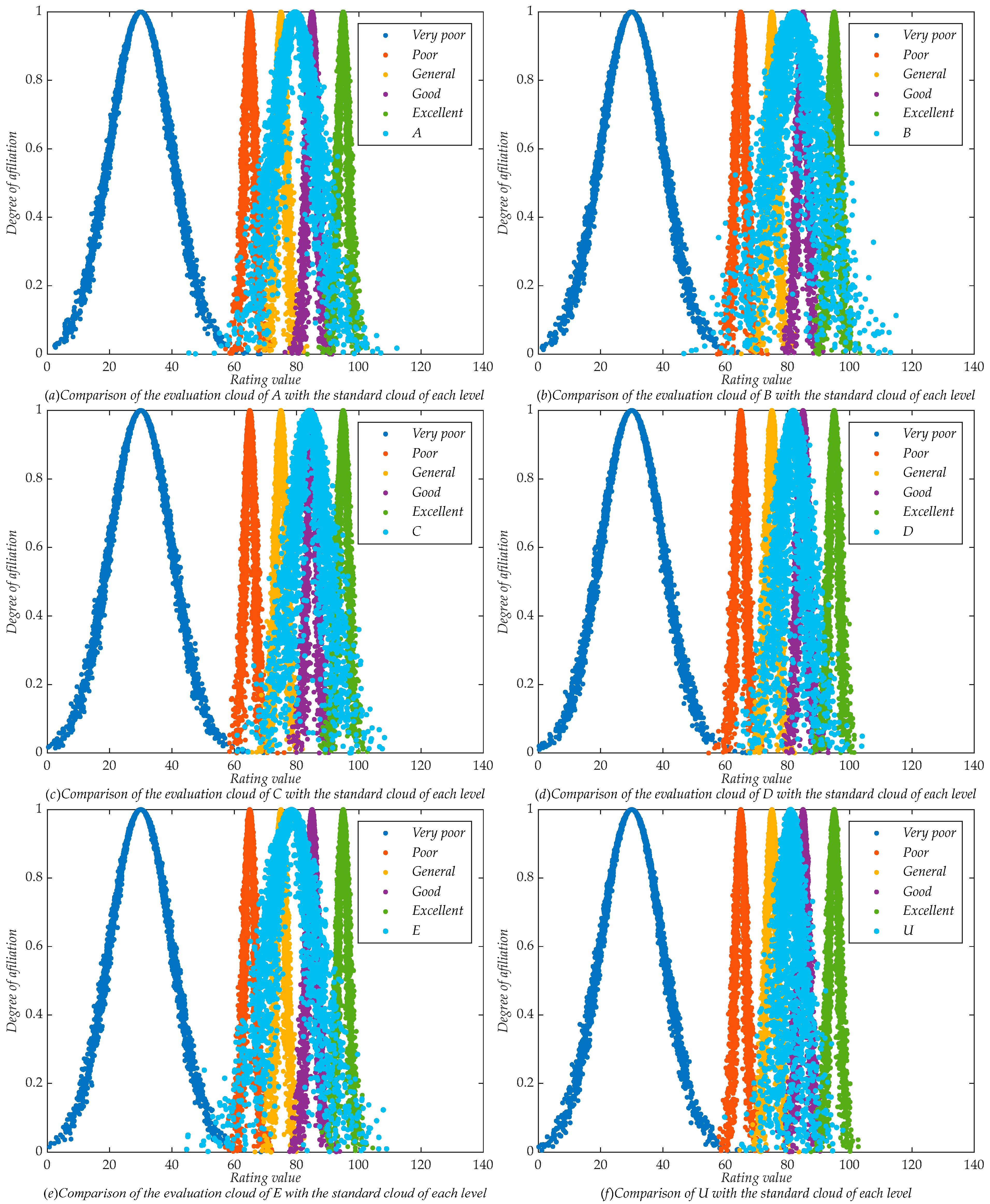

5.2. Calculation of Measurement Cloud

5.3. Determination of Performance Levels

5.4. Results and Discussion

5.4.1. Analysis of Measurement Results

5.4.2. Sensitivity Analysis

5.4.3. Suggestion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, D.; Huang, G.; Zhu, S.; Chen, L.; Wang, J. How to Peak Carbon Emissions of Provincial Construction Industry? Scenario Analysis of Jiangsu Province. Renew. Sustain. Energy Rev. 2021, 144, 110953. [Google Scholar] [CrossRef]

- Sun, S.; Chen, Y.; Wang, A.; Liu, X. An Evaluation Model of Carbon Emission Reduction Effect of Prefabricated Buildings Based on Cloud Model from the Perspective of Construction Supply Chain. Buildings 2022, 12, 1534. [Google Scholar] [CrossRef]

- Six Challenges in Achieving “Dual Carbon” in China. Available online: https://roll.sohu.com/a/616550542_260616 (accessed on 2 November 2024).

- Du, Q.; Yang, M.; Wang, Y.; Wang, X.; Dong, Y. Dynamic Simulation for Carbon Emission Reduction Effects of the Prefabricated Building Supply Chain under Environmental Policies. Sustain. Cities Soc. 2024, 100, 105027. [Google Scholar] [CrossRef]

- Jin, R.; Hong, J.; Zuo, J. Environmental Performance of Off-Site Constructed Facilities: A Critical Review. Energy Build. 2020, 207, 109567. [Google Scholar] [CrossRef]

- Li, X.; Xie, W.; Xu, L.; Li, L.; Jim, C.Y.; Wei, T. Holistic Life-Cycle Accounting of Carbon Emissions of Prefabricated Buildings Using LCA and BIM. Energy Build. 2022, 266, 112136. [Google Scholar] [CrossRef]

- Chang, Y.; Li, X.; Masanet, E.; Zhang, L.; Huang, Z.; Ries, R. Unlocking the Green Opportunity for Prefabricated Buildings and Construction in China. Resour. Conserv. Recycl. 2018, 139, 259–261. [Google Scholar] [CrossRef]

- Braglia, M.; Dallasega, P.; Marrazzini, L. Overall Construction Productivity: A New Lean Metric to Identify Construction Losses and Analyse Their Causes in Engineer-to-Order Construction Supply Chains. Prod. Plan. Control 2022, 33, 925–942. [Google Scholar] [CrossRef]

- Vrijhoef, R.; Koskela, L. The Four Roles of Supply Chain Management in Construction. Eur. J. Purch. Supply Manag. 2000, 6, 169–178. [Google Scholar] [CrossRef]

- Zhu, Y. Accelerate the Development of New Quality Productivity Solidly Promote High-Quality Development. Available online: https://www.gov.cn/yaowen/liebiao/202402/content_6929446.htm (accessed on 30 October 2024).

- Ye, H.; Su, Y. Research and Exploration on Promoting the Transformation and Development of the Construction Industry with New Quality Productivity. J. Eng. Manag. 2024, 38, 1–5. [Google Scholar] [CrossRef]

- An, K.; Wang, X.; Liao, X. Research on Transaction Cost of Prefabricated Buliding Supply Chain under EPC Mode. Constr. Econ. 2020, 41, 49–53. [Google Scholar] [CrossRef]

- Zhang, R.; Li, L. Research on Evolutionary Game and Simulation of Information Sharing in Prefabricated Building Supply Chain. Sustainability 2023, 15, 9885. [Google Scholar] [CrossRef]

- RezaHoseini, A.; Noori, S.; Ghannadpour, S.F. Integrated Scheduling of Suppliers and Multi-Project Activities for Green Construction Supply Chains under Uncertainty. Autom. Constr. 2021, 122, 103485. [Google Scholar] [CrossRef]

- Li, N.; Wang, H.; Mei, J. Risk Early Warning of Prefabricated Building Supply Chain Based on Cloud Matter Element Theory. J. Civ. Eng. Manag. 2020, 37, 123–129. [Google Scholar] [CrossRef]

- Goh, M.; Goh, Y.M. Lean Production Theory-Based Simulation of Modular Construction Processes. Autom. Constr. 2019, 101, 227–244. [Google Scholar] [CrossRef]

- Chen, Q.; Hall, D.M.; Adey, B.T.; Haas, C.T. Identifying Enablers for Coordination across Construction Supply Chain Processes: A Systematic Literature Review. Eng. Constr. Archit. Manag. 2021, 28, 1083–1113. [Google Scholar] [CrossRef]

- Du, J.; Wang, W.; Hu, M. SEM and Multi–Agent Simulation–Based Design Change Risk Management in Prefabricated Construction. J. Shanghai Univ. (Nat. Sci. Ed.) 2022, 28, 1038–1050. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Stanford University: Stanford, CA, USA, 1992; Volume 72. [Google Scholar]

- Yang, S.; Jiang, G. Risk Management of EPC Construction Supply Chain Based on Theory of Constraints and Set Pair Analysis. Technol. Econ. 2016, 35, 111–117. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, J.; Yuan, J. Research on Critical Factors Influencing the Resilience of Prefabricated Building Supply Chain Based on ISM. J. Civ. Eng. Manag. 2020, 37, 108–114. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.Q.P.; Kumaraswamy, M.M.; Owusu, E.K.; Saka, A.B. Modeling Supply Chain Resilience in Industrialized Construction: A Hong Kong Case. J. Constr. Eng. Manag. 2021, 147, 05021009. [Google Scholar] [CrossRef]

- Wang, Q.; Duan, H.; Shen, C.; Zhu, K. Study on the Influencing Factors of Prefabricated Building Resilient Supply Chain. Constr. Econ. 2021, 42, 79–82. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Z. Simulation Analysis of Supply Chain Resilience of Prefabricated Building Projects Based on System Dynamics. Buildings 2023, 13, 2629. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, T.; Cui, W.; Zhou, G.; Liu, H. Selecting Resilient Strategies for Cost Optimization in Prefabricated Building Supply Chains Based on the Non-Dominated Sorting Genetic Algorithm-II: Facing Diverse Disruption Scenarios. Sustainability 2024, 16, 6256. [Google Scholar] [CrossRef]

- Lin, M.; Ren, Y.; Feng, C.; Li, X. Analyzing Resilience Influencing Factors in the Prefabricated Building Supply Chain Based on SEM-SD Methodology. Sci. Rep. 2024, 14, 17393. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhang, Y.; Ouyang, H.; Song, L. Sustainability Evaluation of Prefabricated Building Supply Chain Based on Cloud Matter Element Theory. J. Civ. Eng. Manag. 2020, 37, 109–115+122. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, J.; Ye, M.; Huang, Q.; Si, X. An Evaluation of Supply Chain Performance of China’s Prefabricated Building from the Perspective of Sustainability. Sustainability 2022, 14, 1299. [Google Scholar] [CrossRef]

- Izadikhah, M.; Saen, R.F. Assessing Sustainability of Supply Chains by Chance-Constrained Two-Stage DEA Model in the Presence of Undesirable Factors. Comput. Oper. Res. 2018, 100, 343–367. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.; Zhang, Y. Exploring the Risk Propagation Mechanisms of Supply Chain for Prefabricated Building Projects. J. Build. Eng. 2023, 74, 106771. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, R.; Ren, L.; Geng, X.; Wang, X.; Lv, L. Risk Propagation Model and Simulation of an Assembled Building Supply Chain Network. Buildings 2023, 13, 981. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, S.; Guo, Y.; Duan, Y. Study on Supply Chain Risk of Prefabricated Building Based on EFA and CFA. Math. Pract. Theory 2021, 51, 286–299. [Google Scholar]

- Wu, Q.; Tian, Y. Research on Risk Factors of Prefabricated Construction Supply Chain Based on AHP-DEMATEL-ISM Model. J. Eng. Manag. 2022, 36, 29–34. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, G.; Ding, C.; Zhao, N.; Cui, B. Key Risk Factors of Prefabricated Building Supply Chain Based on Social Network Analysis. Sci. Technol. Eng. 2024, 24, 8372–8381. [Google Scholar] [CrossRef]

- Cai, Q.; Du, Y.; Wang, R. Analysis on Supply Chain Risk Factors of Prefabricated Buildings Using AHP-DEMATEL-ISM Model. Teh. Vjesn. 2023, 30, 1379–1386. [Google Scholar] [CrossRef]

- Zhu, T.; Liu, G. A Novel Hybrid Methodology to Study the Risk Management of Prefabricated Building Supply Chains: An Outlook for Sustainability. Sustainability 2022, 15, 361. [Google Scholar] [CrossRef]

- Guan, Y.; Wan, C.; Wang, W. Dual-Channel Supply Chain Coordination Considering Green and Service Inputs. Sustainability 2024, 16, 6492. [Google Scholar] [CrossRef]

- Rose-Anderssen, C.; Baldwin, J.; Ridgway, K. Communicative Interaction as an Instrument for Integration and Coordination in an Aerospace Supply Chain. J. Manag. Dev. 2010, 29, 193–209. [Google Scholar] [CrossRef]

- Akintoye, A.; McIntosh, G.; Fitzgerald, E. A Survey of Supply Chain Collaboration and Management in the UK Construction Industry. Eur. J. Purch. Supply Manag. 2000, 6, 159–168. [Google Scholar] [CrossRef]

- Toroghi Bidabadi, Z.; Hosseinalipour, M.; Hamidizadeh, M.R.; Mohebifar, A. Supply Chain Collaboration within the Iranian Construction Industry. Organ. Technol. Manag. Constr. Int. J. 2016, 8, 1437–1445. [Google Scholar] [CrossRef]

- Koolwijk, J.S.J.; Van Oel, C.J.; Wamelink, J.W.F.; Vrijhoef, R. Collaboration and Integration in Project-Based Supply Chains in the Construction Industry. J. Manag. Eng. 2018, 34, 04018001. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, Q.; Guo, Z. Knowledge Sharing in the Construction Supply Chain: Collaborative Innovation Activities and BIM Application on Innovation Performance. Eng. Constr. Archit. Manag. 2022, 29, 3439–3459. [Google Scholar] [CrossRef]

- Liu, G.; Zhu, T. Influencing Factors of Collaborative Management of Prefabricated Building Supply Chain Based on the Perspective of General Contractor Research. J. Shenyang Jianzhu Univ. (Soc. Sci.) 2022, 24, 496–502. [Google Scholar] [CrossRef]

- Mei, T.; Qin, Y.; Li, P.; Deng, Y. Influence Mechanism of Construction Supply Chain Information Collaboration Based on Structural Equation Model. Sustainability 2023, 15, 2155. [Google Scholar] [CrossRef]

- Wang, H.; Liu, H. Research on Collaborative Pricing of Prefabricated Building Supply Chain: Based on BIM-RFID Information Sharing Platform. Constr. Econ. 2020, 41, 54–59. [Google Scholar] [CrossRef]

- Evaluation Standard for Assembled Buildings (GB/T51129-2017). Available online: https://www.mohurd.gov.cn/gongkai/zc/wjk/art/2018/art_17339_234899.html (accessed on 28 November 2024).

- Opinions of the General Office of the State Council on Promoting the Sustainable and Healthy Development of the Construction Industry(000014349/2017-00040). Available online: https://www.gov.cn/zhengce/zhengceku/2017-02/24/content_5170625.htm (accessed on 28 November 2024).

- Zhang, F.; Xie, J. Risk Assessment of Assembly Construction Supply Chain Based on Cloud Model. Intell. Build. Smart City 2020, 48, 123–124. [Google Scholar] [CrossRef]

- Zhu, X.; Zhao, Z.; Yang, Y. Research on the Impact Path of the Resilience of Prefabricated Building Supply Chain on Construction Cost. Constr. Econ. 2024, 45, 55–64. [Google Scholar] [CrossRef]

- Liu, L.; Ren, X.; Dai, X. Research on Cooperative Subject Selection of Prefabricated Building Supply Chain for Dynamic Alliance. Constr. Econ. 2021, 42, 61–66. [Google Scholar] [CrossRef]

- Miao, Z.; Zhang, L. Research on the Influencing Factors of Supply Chain Risk Management of Assembly Building Based on SEM. Proj. Manag. Technol. 2023, 21, 95–98. [Google Scholar]

- Qu, F.; Yan, W.; Chen, C. Research on Construction of Coordination Performance Evaluation Index System of Prefabricated Construction Supply Chain. Constr. Econ. 2019, 40, 97–102. [Google Scholar] [CrossRef]

- Dan, W.; Jingyi, L.; Yongkun, W. Multifactor Uncertainty Analysis of Prefabricated Building Supply Chain: Qualitative Comparative Analysis. Eng. Constr. Archit. Manag. 2024, 31, 1994–2010. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, Y. On the Operation Efficiency Evaluation of the Assembled Building Supply Chain. J. Hefei Univ. 2023, 40, 71–76+113. [Google Scholar] [CrossRef]

- Li, Q.; Chen, W. Safety evaluation of prefabricated building construction based on entropy correction BWM. J. Saf. Environ. 2023, 23, 2580–2588. [Google Scholar] [CrossRef]

- He, Z.; Tian, Y. Safety Risk Factors of Prefabricated Building Construction from the Perspective of Participating Units. Sci. Technol. Eng. 2023, 23, 321–326. [Google Scholar] [CrossRef]

- Tian, X.; Hu, Q.; He, Z. Safety Risk Assessment of Hoisting Construction of Prefabricated Buildings Based on Improved Combined Weighting-dynamic Fuzzy Theory. J. Civ. Eng. Manag. 2021, 38, 187–193. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, R.; She, J. Safety performance evaluation of prefabricated building construction from perspective of three-dimensional space. J. Saf. Sci. Technol. 2022, 18, 210–217. [Google Scholar]

- Gao, J.; Zhao, W.-H.; Liu, W.-H. Evaluation of Influencing Factors on the Supply Chain of Prefabricated Buildings under Engineering Procurement Construction Model: A Case Study in China. Buildings 2024, 14, 1680. [Google Scholar] [CrossRef]

- Chen, J.; Xu, H.; Wu, M. Research on Collaborative Efficiency Evaluation of Prefabricated Building Supply Chain from Stakeholder Perspective. Constr. Technol. 2024, 16, 6–9. [Google Scholar] [CrossRef]

- Zhang, Y.; Qu, F.; Chen, C. Research on Performance Evaluation of Prefabricated Building Supply Chain Based on PCSCOR-FANP. Constr. Econ. 2021, 42, 172–176. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Mok, M.K. Schedule Risks in Prefabrication Housing Production in Hong Kong: A Social Network Analysis. J. Clean. Prod. 2016, 134, 482–494. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Ji, B. Influencing Factors of Resilience of PBSC Based on Empirical Analysis. Buildings 2021, 11, 467. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Critical Success Factors for Modular Integrated Construction Projects: A Review. Build. Res. Inf. 2020, 48, 763–784. [Google Scholar] [CrossRef]

- Hull, B. The Role of Elasticity in Supply Chain Performance. Int. J. Prod. Econ. 2005, 98, 301–314. [Google Scholar] [CrossRef]

- Deng, Q.; Huang, X.; Zou, J.; He, Y. Screening of Sustainable Supply Chain Performance Evaluation Indicators Based on the Ill-Conditioned Index Cycle Method. PLoS ONE 2024, 19, e0293038. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Wu, Z. Social Sustainable Supply Chain Performance Assessment Using Hybrid Fuzzy-AHP–DEMATEL–VIKOR: A Case Study in Manufacturing Enterprises. Env. Dev Sustain 2023, 25, 12273–12301. [Google Scholar] [CrossRef] [PubMed]

- Hsu, P.-Y.; Aurisicchio, M.; Angeloudis, P. Risk-Averse Supply Chain for Modular Construction Projects. Autom. Constr. 2019, 106, 102898. [Google Scholar] [CrossRef]

- Yager, R.R. Families of OWA Operators. Fuzzy Sets Syst. 1993, 59, 125–148. [Google Scholar] [CrossRef]

- Xu, Z. Dependent OWA Operators. In Modeling Decisions for Artificial Intelligence; Torra, V., Narukawa, Y., Valls, A., Domingo-Ferrer, J., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2006; Volume 3885, pp. 172–178. ISBN 978-3-540-32780-6. [Google Scholar]

- Duan, S.; Li, X.; Jiang, X.; Huang, X.; Yang, Y.; Du, H.; Xiao, W. Extension Cloud Model and Grey Clustering Evaluation of Enterprise Safety Management System: Based on COWA-CRITIC Combination Weighting. Sustainability 2023, 15, 15734. [Google Scholar] [CrossRef]

- Diakoulaki, D.; Mavrotas, G.; Papayannakis, L. Determining Objective Weights in Multiple Criteria Problems: The Critic Method. Comput. Oper. Res. 1995, 22, 763–770. [Google Scholar] [CrossRef]

- Liu, Q.; Liang, Y.; Liu, C.; Xue, J.; Zhang, H.; Tu, R.; Zou, X.; Liang, Y. Developing an Integrated and Collaborated Evaluation Index System for Crude Oil Supply Chains: A Case Study from China. Chem. Eng. Res. Des. 2024, 211, 405–420. [Google Scholar] [CrossRef]

- Xue, L.; Liu, B.; Zheng, Z.; Li, C.; Zhang, S.; Zhu, L.; Su, C.; Xu, C. Evaluation of Sustainable Capacity of Coal Resources Based on Extension Cloud Theory and Ideal Point Method. J. Nat. Resour. 2018, 33, 1657–1665. [Google Scholar] [CrossRef]

- Xun, Z.; Zhang, L.; Zhao, Z.; Xu, Y. Cost Risk Evaluation of Prefabricated Buildings Based on Combined Weighted Cloud Model. J. Civ. Eng. Manag. 2020, 37, 8–13. [Google Scholar] [CrossRef]

- Green Building Evaluation Standard (GB/T50378-2019). Available online: https://www.mohurd.gov.cn/gongkai/zc/wjk/art/2024/art_17339_779172.html (accessed on 3 December 2024).

- Luo, Z.; Guo, J.; Han, J.; Wang, Y. Research on the Construction Safety Risk Assessment of Prefabricated Subway Stations in China. Eng. Constr. Archit. Manag. 2024, 31, 1751–1787. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Li, L.; Lin, P.; Xu, Z.; Gao, C. Attribute Recognition Model for Risk Assessment of Water Inrush. Bull. Eng. Geol. Environ. 2019, 78, 1057–1071. [Google Scholar] [CrossRef]

- Zhao, X.; Ye, Y.; Zhou, J.; Liu, L.; Dai, W.; Wang, Q.; Hu, Y. Comprehensive Evaluation of Cultivated Land Quality and Sensitivity Analysis of Index Weight in Hilly Region of Pearl River Delta. Trans. Chin. Soc. Agric. Eng. 2017, 33, 226–235. [Google Scholar] [CrossRef]

- Lin, Y.-C. Construction 3D BIM-Based Knowledge Management System: A Case Study. J. Civ. Eng. Manag. 2014, 20, 186–200. [Google Scholar] [CrossRef]

| Category | Element | Literature Sources |

|---|---|---|

| Cost control | Design cost of components | [15,27,48,49] |

| Production costs of components | [15,27,48,49,50] | |

| Material costs | [33,48,51] | |

| Transport costs | [26,34,49,52] | |

| Management costs | [40,52,53] | |

| Technology | Degree of participation in technology cooperation | [43,53,54] |

| Establishment of Technology Sharing Platform | [22,43,45] | |

| Rationality of the construction program | [48,55,56,57,58] | |

| Professional technicians | [43,48,49,59,60] | |

| Information | Timeliness of information exchange | [44,52,61] |

| Effectiveness of information sharing | [13,15,26,33,36,44,45,52,62,63] | |

| Accuracy of information transmission | [52,59,61] | |

| Reliability of SC | Stability of participating members | [28,53,64] |

| Response time | [50,54,60,65] | |

| Risk management and control capacity | [23,28,49,50,53,59,60,63,66] | |

| Capability of schedule control | [15,32,34,54] | |

| On-time delivery rate | [15,28,50,60,67,68] | |

| Environmental protection | Consumption of resources | [2,27,28,29,66] |

| Waste discharges | [2,27,28,29,50] | |

| Control of dust and noise | [2,27,28,29] |

| Category | Profile | Number |

|---|---|---|

| Educational background | Specialized and below | 7 |

| Undergraduate | 1 | |

| Master | 1 | |

| Work units | Development organization | 6 |

| Construction unit | 1 | |

| Designing institute | 2 | |

| Working experience | 3–5 years | 1 |

| 6–10 years | 1 | |

| 11–20 years | 3 | |

| More than 20 years | 4 |

| Level | Interval | Standard Cloud |

|---|---|---|

| T1(Very poor) | [0, 60) | (30, 10, 0.5) |

| T2(Poor) | [60, 70) | (65, 1.667, 0.5) |

| T3(General) | [70, 80) | (75, 1.667, 0.5) |

| T4(Good) | [80, 90) | (85, 1.667, 0.5) |

| T5(Very good) | [90, 100] | (95, 1.667, 0.5) |

| Primary Index | Weight | Secondary Index | w1 | w2 | w3 | Relative Weight |

|---|---|---|---|---|---|---|

| A | 0.258 | A1 | 0.047 | 0.055 | 0.051 | 0.198 |

| A2 | 0.051 | 0.055 | 0.053 | 0.205 | ||

| A3 | 0.049 | 0.051 | 0.049 | 0.192 | ||

| A4 | 0.047 | 0.064 | 0.056 | 0.217 | ||

| A5 | 0.052 | 0.046 | 0.049 | 0.188 | ||

| B | 0.207 | B1 | 0.051 | 0.046 | 0.048 | 0.231 |

| B2 | 0.049 | 0.062 | 0.055 | 0.267 | ||

| B3 | 0.051 | 0.049 | 0.050 | 0.241 | ||

| B4 | 0.053 | 0.056 | 0.054 | 0.262 | ||

| C | 0.145 | C1 | 0.051 | 0.050 | 0.050 | 0.346 |

| C2 | 0.050 | 0.049 | 0.049 | 0.339 | ||

| C3 | 0.054 | 0.036 | 0.046 | 0.316 | ||

| D | 0.227 | D1 | 0.052 | 0.036 | 0.045 | 0.197 |

| D2 | 0.051 | 0.039 | 0.045 | 0.199 | ||

| D3 | 0.050 | 0.045 | 0.047 | 0.209 | ||

| D4 | 0.050 | 0.035 | 0.043 | 0.190 | ||

| D5 | 0.050 | 0.043 | 0.047 | 0.205 | ||

| E | 0.162 | E1 | 0.050 | 0.052 | 0.050 | 0.311 |

| E2 | 0.047 | 0.061 | 0.054 | 0.334 | ||

| E3 | 0.046 | 0.068 | 0.058 | 0.355 |

| Comprehensive Measurement Cloud | Primary Index | Measurement Cloud | Secondary Index | Measurement Cloud |

|---|---|---|---|---|

| U = (81.0, 2.5, 2.0) | A | (79.6, 6.8, 1.8) | A1 | (77.1, 7.1, 1.4) |

| A2 | (81.9, 7.7, 1.8) | |||

| A3 | (78.6, 4.4, 1.0) | |||

| A4 | (77.3,8.1, 3.0) | |||

| A5 | (83.6, 5.6, 1.9) | |||

| B | (82.3, 7.2, 2.5) | B1 | (82.3, 7.1, 3.1) | |

| B2 | (79.3, 8.4, 1.6) | |||

| B3 | (83.8, 5.0, 1.9) | |||

| B4 | (86.6, 7.5, 3.2) | |||

| C | (84.2, 5.3, 1.9) | C1 | (83.9, 5.1, 2.6) | |

| C2 | (82.0, 6.1, 2.4) | |||

| C3 | (86.9, 4.4, 1.1) | |||

| D | (81.8, 4.2, 1.7) | D1 | (83.4, 3.8, 1.1) | |

| D2 | (82.1, 4.3, 2.3) | |||

| D3 | (80.9, 4.0, 1.6) | |||

| D4 | (80.3, 3.8, 2.7) | |||

| D5 | (82.0, 4.7, 1.0) | |||

| E | (78.4, 7.5, 2.2) | E1 | (80.9, 6.5, 1.1) | |

| E2 | (77.3, 6.9, 2.0) | |||

| E3 | (77.1, 8.8, 3.2) |

| Index | Comprehensive Cloud Closeness | Maximum Value | Level | ||||

|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | |||

| A1 | 0.120 | 0.139 | 0.448 | 0.174 | 0.118 | 0.448 | T3(General) |

| A2 | 0.137 | 0.128 | 0.211 | 0.381 | 0.144 | 0.381 | T4(Good) |

| A3 | 0.082 | 0.159 | 0.370 | 0.242 | 0.146 | 0.370 | T3(General) |

| A4 | 0.249 | 0.102 | 0.441 | 0.128 | 0.081 | 0.441 | T3(General) |

| A5 | 0.210 | 0.119 | 0.233 | 0.310 | 0.128 | 0.310 | T4(Good) |

| A | 0.118 | 0.150 | 0.309 | 0.277 | 0.146 | 0.309 | T3(General) |

| B1 | 0.122 | 0.126 | 0.196 | 0.411 | 0.145 | 0.411 | T4(Good) |

| B2 | 0.166 | 0.138 | 0.311 | 0.253 | 0.132 | 0.311 | T3(General) |

| B3 | 0.079 | 0.112 | 0.145 | 0.532 | 0.132 | 0.532 | T4(Good) |

| B4 | 0.222 | 0.078 | 0.104 | 0.470 | 0.125 | 0.470 | T4(Good) |

| B | 0.123 | 0.126 | 0.197 | 0.410 | 0.145 | 0.410 | T4(Good) |

| C1 | 0.084 | 0.101 | 0.123 | 0.576 | 0.117 | 0.576 | T4(Good) |

| C2 | 0.103 | 0.135 | 0.215 | 0.396 | 0.152 | 0.396 | T4(Good) |

| C3 | 0.075 | 0.119 | 0.148 | 0.482 | 0.177 | 0.482 | T4(Good) |

| C | 0.079 | 0.102 | 0.125 | 0.575 | 0.118 | 0.575 | T4(Good) |

| D1 | 0.068 | 0.121 | 0.163 | 0.505 | 0.142 | 0.505 | T4(Good) |

| D2 | 0.079 | 0.139 | 0.216 | 0.408 | 0.157 | 0.408 | T4(Good) |

| D3 | 0.079 | 0.152 | 0.265 | 0.343 | 0.161 | 0.343 | T4(Good) |

| D4 | 0.077 | 0.157 | 0.289 | 0.318 | 0.160 | 0.318 | T4(Good) |

| D5 | 0.084 | 0.140 | 0.219 | 0.401 | 0.157 | 0.401 | T4(Good) |

| D | 0.078 | 0.144 | 0.230 | 0.388 | 0.159 | 0.388 | T4(Good) |

| E1 | 0.113 | 0.144 | 0.257 | 0.335 | 0.152 | 0.335 | T3(General) |

| E2 | 0.116 | 0.143 | 0.434 | 0.184 | 0.123 | 0.434 | T4(Good) |

| E3 | 0.177 | 0.125 | 0.434 | 0.160 | 0.104 | 0.434 | T4(Good) |

| E | 0.135 | 0.146 | 0.368 | 0.221 | 0.131 | 0.368 | T3(General) |

| U | 0.066 | 0.154 | 0.262 | 0.354 | 0.164 | 0.354 | T4(Good) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Feng, Z.; Luo, X. Measurement of Synergy Management Performance in Prefabricated Building Project Supply Chain. Sustainability 2024, 16, 11025. https://doi.org/10.3390/su162411025

Liu W, Feng Z, Luo X. Measurement of Synergy Management Performance in Prefabricated Building Project Supply Chain. Sustainability. 2024; 16(24):11025. https://doi.org/10.3390/su162411025

Chicago/Turabian StyleLiu, Wei, Zhongyi Feng, and Xiao Luo. 2024. "Measurement of Synergy Management Performance in Prefabricated Building Project Supply Chain" Sustainability 16, no. 24: 11025. https://doi.org/10.3390/su162411025

APA StyleLiu, W., Feng, Z., & Luo, X. (2024). Measurement of Synergy Management Performance in Prefabricated Building Project Supply Chain. Sustainability, 16(24), 11025. https://doi.org/10.3390/su162411025