Valorization of Recycled Aggregate and Copper Slag for Sustainable Concrete Mixtures: Mechanical, Physical, and Environmental Performance

Abstract

:1. Introduction

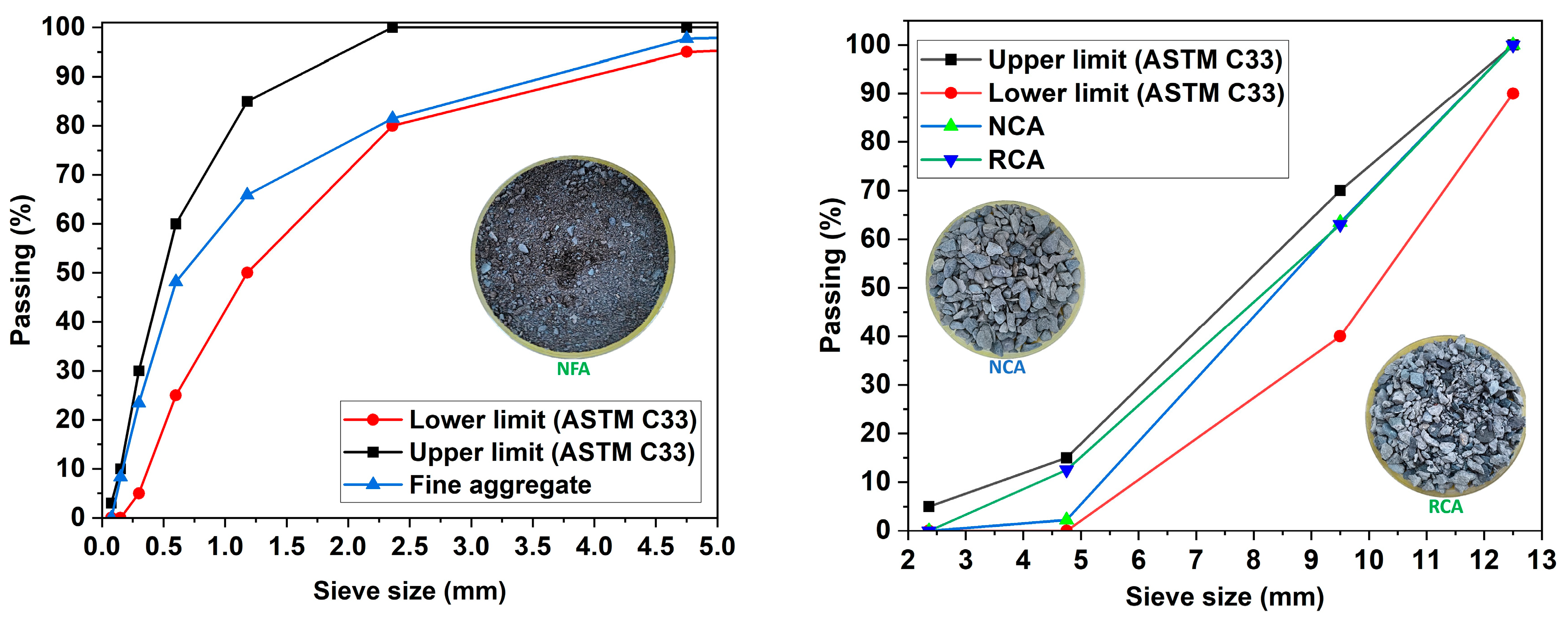

2. Materials and Methods

2.1. Concrete Mixture Designs

2.2. Experimental Methods

2.3. Carbon Footprint Analysis

3. Results

3.1. Slump Test

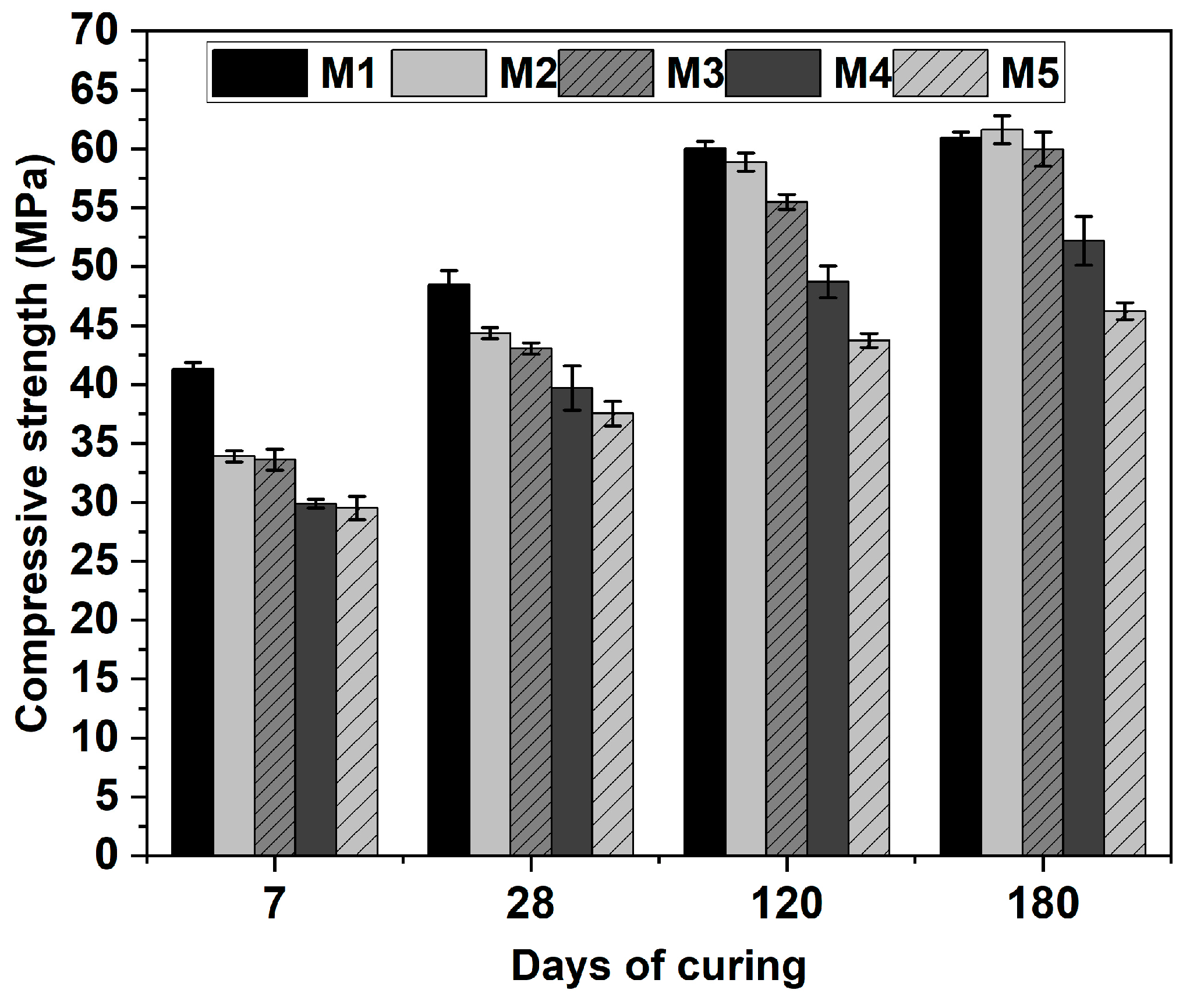

3.2. Compressive Strength

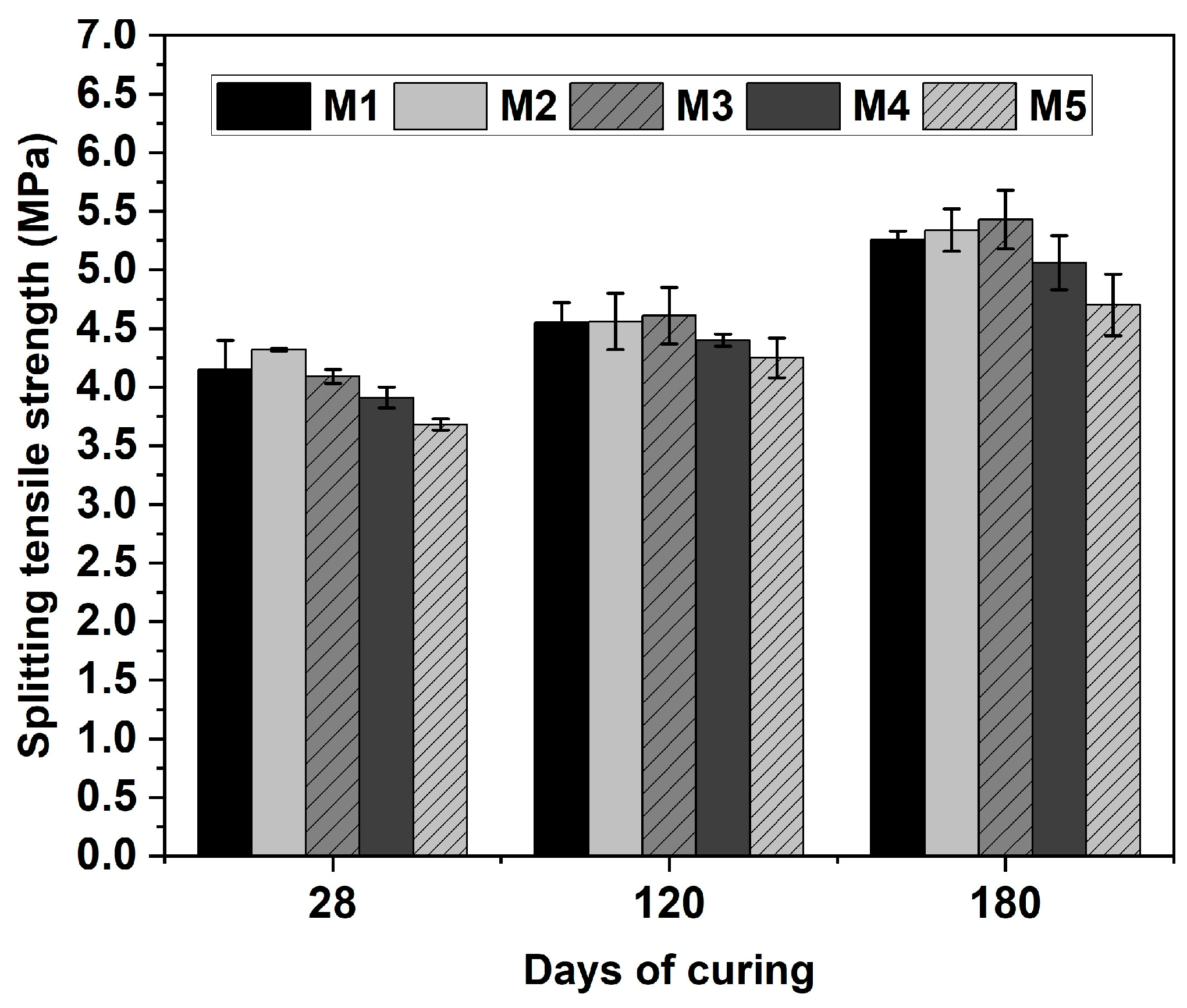

3.3. Splitting Tensile Strength

3.4. Flexural Strength

3.5. Density, Absorption, and Voids

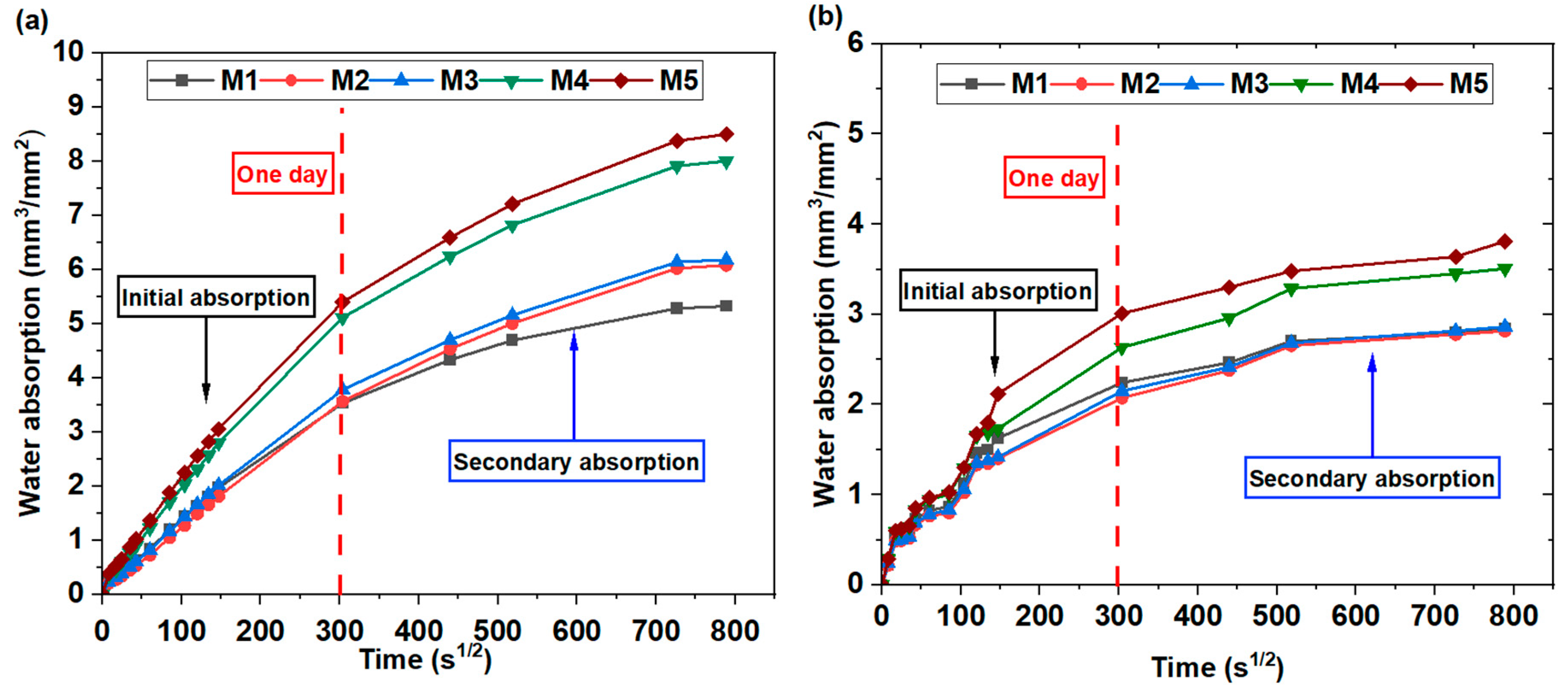

3.6. Capillary Water Absorption (Sorptivity)

3.7. Carbon Footprint Results of the Concrete Mixtures

4. Conclusions

- The replacement of 15% by vol. of OPC with CS is viable, despite the dilution effect that results in a loss of compressive strength at early ages (7 and 28 days of curing). However, at longer curing periods (120 and 180 days), the difference in compressive strength between the 100% OPC mixture (M1) and the 15% CS mixture (M2) became insignificant. Notably, at 180 days, mixture M2 achieved an average compressive strength that was slightly higher (1.2%) compared to M1.

- The favorable performances of the M2 and M3 (15% CS and 20% RCA) mixtures in terms of indirect tensile strength and flexural strength suggest potential applications in engineering contexts, such as pavements, for which concrete flexural strength performance is critical. This improvement can be explained by the increased angularity and roughness of CS and RCA, compared to OPC and NCA, respectively.

- The negative effect of RCA on the mechanical properties of concrete was most significant in terms of compressive strength performance, compared to indirect tensile and flexural strength performance. For example, after 180 days of curing, when comparing mixture M2 (15% CS and 0% RCA) with M5 (15% CS and 100% RCA), the compressive, indirect tensile, and flexural strengths decreased by 24.1%, 11.98%, and 8.05%, respectively.

- Porosity, absorption, and sorptivity were negatively affected by high RCA contents (50% and 100%) in the concrete mixtures at both the evaluated ages (28 and 180 days of curing). However, mixture M2 (15% CS and 0% RCA) exhibited 2.87% less porosity at 180 days of curing compared to the reference mixture (M1), which can be attributed to the slow pozzolanic effect of CS.

- From the EC analyses, major environmental benefits were obtained through partially replacing OPC with CS, while the substitution of NCA with RCA had a minor impact.

- The development of more sustainable concrete mixtures can be achieved with higher substitution rates of OPC with CS. However, it is essential to address the low reactivity of CS. Striking a balance between CO2 emission reduction and potential impacts on mechanical performance and durability is crucial. Additionally, future research should focus on methods to enhance the reactivity of CS in cementitious matrices, optimizing its performance as an SCM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Al2O3 | Alumina |

| CaO | Limestone |

| CDW | Construction and demolition waste |

| CO2 | Carbon dioxide |

| CS | Copper slag |

| EC | Embodied carbon |

| FA | Fly ash |

| Fe2O3 | Iron oxide |

| GGBFS | Granulated blast-furnace slag |

| ICE | Inventory of Carbon and Energy |

| ID | Identification code of concrete mixtures |

| NCA | Natural coarse aggregate |

| NFA | Natural fine aggregate |

| M1 | Concrete mixture with 100% OPC |

| M2 | Concrete mixture with 15% CS |

| M3 | Concrete mixture with 15% CS and 20% RCA |

| M4 | Concrete mixture with 15% CS and 50% RCA |

| M5 | Concrete mixture with 15% CS and 100% RCA |

| MgO | Magnesium oxide |

| ITZ | Interfacial transition zone |

| LOI | Loss on ignition |

| LCA | Life cycle assessment |

| OPC | Ordinary Portland cement |

| SCM | Supplementary cementitious material |

| SiO2 | Silica |

| RCA | Recycled coarse aggregate |

| SP | Super plasticizer |

| XRF | X-ray fluorescence |

References

- Raghuvanshi, H.; Singh, N. Fresh and Mechanical Properties of Ground Granulated Blast Furnace Slag-Based Concrete: A Review. Mater. Today Proc. 2024, 193. [Google Scholar] [CrossRef]

- Li, L.; Joseph, P.; Zhang, X.; Zhang, L. A Study of Some Relevant Properties of Concrete Incorporating Waste Ceramic Powder as a Cement Replacement Agent. J. Build. Eng. 2024, 87, 109106. [Google Scholar] [CrossRef]

- Silva, Y.F.; Burbano-Garcia, C.; Araya-Letelier, G.; González, M. Short- and Long-Term Experimental Performance of Concrete with Copper Slag: Mechanical and Physical Properties Assessment. Case Stud. Constr. Mater. 2024, 20, e03302. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, D.; Cheng, S.; Xu, X.; Zhao, C.; Wang, X.; Wu, Q.; Bai, X. Sustainable Reuse of Ceramic Waste Powder as a Supplementary Cementitious Material in Recycled Aggregate Concrete: Mechanical Properties, Durability and Microstructure Assessment. J. Build. Eng. 2022, 52, 104418. [Google Scholar] [CrossRef]

- Vintimilla, C.; Etxeberria, M.; Li, Z. Durable Structural Concrete Produced with Coarse and Fine Recycled Aggregates Using Different Cement Types. Sustainability 2023, 15, 14272. [Google Scholar] [CrossRef]

- Abellan-Garcia, J.; Fernández-Gómez, J.; Iqbal Khan, M.; Abbas, Y.M.; Pacheco-Bustos, C. ANN Approach to Evaluate the Effects of Supplementary Cementitious Materials on the Compressive Strength of Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 402, 132992. [Google Scholar] [CrossRef]

- Zhu, P.; Wang, H.; Yan, X.; Yang, L.; Zhu, L.; Liu, H. Recycled Coarse Aggregate from Parent Concrete with Supplementary Cementitious Materials under Freeze-Thaw Environment: Recyclability, Environment and Economic Evaluation. J. Build. Eng. 2024, 84, 108699. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life Cycle Assessment of Sustainable Concrete with Recycled Aggregate and Supplementary Cementitious Materials. Resour. Conserv. Recycl. 2023, 193, 106947. [Google Scholar] [CrossRef]

- Rodriguez-Morales, J.; Burciaga-Diaz, O.; Gomez-Zamorano, L.Y.; Escalante-Garcia, J.I. Transforming Construction and Demolition Waste Concrete as a Precursor in Sustainable Cementitious Materials: An Innovative Recycling Approach. Resour. Conserv. Recycl. 2024, 204, 107474. [Google Scholar] [CrossRef]

- Li, J.; Wang, T.; Du, C.; Wang, C.; Cao, F.; Su, T. Multi-Faceted Assessment of Microbial-Reinforced Recycled Brick Aggregate Concrete. Chem. Eng. J. 2024, 497, 154481. [Google Scholar] [CrossRef]

- Kalinowska-Wichrowska, K.; Kosior-Kazberuk, M.; Pawluczuk, E. The Properties of Composites with Recycled Cement Mortar Used as a Supplementary Cementitious Material. Materials 2020, 13, 64. [Google Scholar] [CrossRef] [PubMed]

- Golafshani, E.M.; Behnood, A.; Kim, T.; Ngo, T.; Kashani, A. A Framework for Low-Carbon Mix Design of Recycled Aggregate Concrete with Supplementary Cementitious Materials Using Machine Learning and Optimization Algorithms. Structures 2024, 61, 106143. [Google Scholar] [CrossRef]

- Degefa, A.B.; Park, S.; Yang, B.; Park, S. Predicting the Degree of Reaction of Supplementary Cementitious Materials in Hydrated Portland Cement. Sustainability 2023, 15, 15471. [Google Scholar] [CrossRef]

- Bouzar, B.; Mamindy-Pajany, Y. Immobilization Study of As, Cr, Mo, Pb, Sb, Se and Zn in Geopolymer Matrix: Application to Shooting Range Soil and Biomass Fly Ash. Int. J. Environ. Sci. Technol. 2023, 20, 11891–11912. [Google Scholar] [CrossRef]

- Silva, Y.F.; Delvasto, S.; Izquierdo, S.; Araya-Letelier, G. Short and Long-Term Physical and Mechanical Characterization of Self-Compacting Concrete Made with Masonry and Concrete Residue. Constr. Build. Mater. 2021, 312, 125382. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; King, D.; Ceylan, H.; Kim, S. Comparative Life Cycle Assessment of Natural and Recycled Aggregate Concrete: A Review. Sci. Total Environ. 2024, 950, 175310. [Google Scholar] [CrossRef]

- Bheel, N.; Chohan, I.M.; Ghoto, A.A.; Abbasi, S.A.; Tag-eldin, E.M.; Almujibah, H.R.; Ahmad, M.; Benjeddou, O.; Gonzalez-Lezcano, R.A. Synergistic Effect of Recycling Waste Coconut Shell Ash, Metakaolin, and Calcined Clay as Supplementary Cementitious Material on Hardened Properties and Embodied Carbon of High Strength Concrete. Case Stud. Constr. Mater. 2024, 20, e02980. [Google Scholar] [CrossRef]

- Silva, Y.F.; Lange, D.A.; Delvasto, S. Effect of Incorporation of Masonry Residue on the Properties of Self-Compacting Concretes. Constr. Build. Mater. 2019, 196, 277–283. [Google Scholar] [CrossRef]

- Silva, Y.F.; Villaquirán-Caicedo, M.; Izquierdo, S. Exploring the Potential of Alternative Materials in Concrete Mixtures: Effect of Copper Slag on Mechanical Properties and Carbonation Resistance. Materials 2023, 16, 6677. [Google Scholar] [CrossRef]

- Perera, M.A.G.P.; Ranjith, P.G. Eco-Friendly Cementitious Composites for Enhanced Strength: Emerging Trends and Innovations. J. Clean. Prod. 2024, 468, 142962. [Google Scholar] [CrossRef]

- Silva, Y.F.; Ph, D.; Delvasto, S.; Ph, D.; Valencia, W.; Ph, D.; Araya-letelier, G. Performance of Self-Compacting Concrete with Residue of Masonry and Recycled Aggregate under Sulfate Attack. J. Mater. Civ. Eng. 2024, 36, 1–12. [Google Scholar] [CrossRef]

- Görhan, G.; Bozkurt, A.M. Investigation of Properties of Mortar Containing Pyrogenic Silica-Added Supplementary Cementitious Materials. Rev. Constr. 2022, 2, 118–134. [Google Scholar] [CrossRef]

- Bouzar, B.; Mamindy-Pajany, Y. Manufacture and Characterization of Carbonated Lightweight Aggregates from Waste Paper Fly Ash. Powder Technol. 2022, 406, 117583. [Google Scholar] [CrossRef]

- Ash, F.; Pv, S.; Poyyamozhi, M.; Murugesan, B.; Narayanamoorthi, R. Sustainable Concrete Roof Tiles: Integrating Aluminium Foil. Sustainability 2024, 16, 8257. [Google Scholar] [CrossRef]

- Venkitasamy, V.; Santhanam, M.; Rao, B.P.C.; Balakrishnan, S.; Kumar, A. Mechanical and Durability Properties of Structural Grade Heavy Weight Concrete with Fly Ash and Slag. Cem. Concr. Compos. 2024, 145, 105362. [Google Scholar] [CrossRef]

- Narendra Kumar, B.; Rushikesh, M.; Akhil Kumar, A. An Experimental Study on High Strength Self-Compacting Concrete Inclusion of Zeolite and Silica Fume as a Potential Alternative Sustainable Cementitious Materials. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Chandra Sekhar, M.; Kumar, M.H.; Lova Raju, S.; Saikrishnamacharyulu, I. Influence of Metakaolin and Glass Powder on Mechanical Behaviour of Concrete. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Rosado, S.; Gullón, L.; Martínez, L.F.M.; Llamas Borrajo, J.F. Potential Uses of Copper Wastes in the Building Sector: Inertization and Added Value Solutions. Mater. Proc. 2021, 5, 5025. [Google Scholar] [CrossRef]

- Edwin, R.S.; Gruyaert, E.; De Belie, N. Valorization of Secondary Copper Slag as Aggregate and Cement Replacement in Ultra-High Performance Concrete. J. Build. Eng. 2022, 54, 104567. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Bahrpeyma, A.; Afshoon, I.; Chakkoshi, M. Protecting the Environment and Natural Resources Using Green Roller Compacted Concrete (RCC) Containing Fine and Coarse Recycled Copper Slag Aggregates. Process Saf. Environ. Prot. 2024, 186, 664–678. [Google Scholar] [CrossRef]

- Sahu, A.; Kumar, S.; Srivastava, A.K.L.; Pratap, B. Performance of Recycled Aggregate Concrete Using Copper Slag as Fine Aggregate. J. Build. Eng. 2024, 82, 108364. [Google Scholar] [CrossRef]

- Velumani, M.; Gowtham, S.; Dhananjayan, M.P.; Eniyan, G.T. Strength Assessment of Concrete with Copper Slag as Fine Aggregates. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Arunchaitanya, S.; Dey, S. Sorptivity and Rapid Chloride Ion Penetration of Self-Compacting Concrete Using Fly Ash and Copper Slag. AI Civ. Eng. 2023, 2, 4. [Google Scholar] [CrossRef]

- Li, J.; Liao, Y.; Ma, H.; Liu, Q.; Wu, Y. Review on Comprehensive Recovery Valuable Metals and Utilization of Copper Slag. J. Sustain. Metall. 2023, 9, 439–458. [Google Scholar] [CrossRef]

- He, R.; Zhang, S.; Zhang, X.; Zhang, Z.; Zhao, Y.; Ding, H. Copper Slag: The Leaching Behavior of Heavy Metals and Its Applicability as a Supplementary Cementitious Material. J. Environ. Chem. Eng. 2021, 9, 105132. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; Nithiyanantham, S. Microstructural, Mechanical, and Electrical Properties of Copper Slag Admixtured Cement Mortar. J. Build. Eng. 2020, 31, 101375. [Google Scholar] [CrossRef]

- Mirhosseini, S.R.; Fadaee, M.; Tabatabaei, R.; Fadaee, M.J. Mechanical Properties of Concrete with Sarcheshmeh Mineral Complex Copper Slag as a Part of Cementitious Materials. Constr. Build. Mater. 2017, 134, 44–49. [Google Scholar] [CrossRef]

- Moghaddas, S.A.; Nekoei, M.; Mohammadi Golafshani, E.; Nehdi, M.; Arashpour, M. Modeling Carbonation Depth of Recycled Aggregate Concrete Using Novel Automatic Regression Technique. J. Clean. Prod. 2022, 371, 133522. [Google Scholar] [CrossRef]

- Ren, X.; Yang, J.; Chen, W.; Huang, Y.; Wang, G.; Niu, J. Effect of Recycled Concrete Powder-Cement Composite Coating Modification on the Properties of Recycled Concrete Aggregate and Its Concrete. Constr. Build. Mater. 2024, 444, 137860. [Google Scholar] [CrossRef]

- Haq, M.A.U.; Xia, P.; Khan, S.; Hassam, M.; Sohaib, M.; Gong, F.; Zhao, Y. Optimal Utilization of Low-Quality Construction Waste and Industrial Byproducts in Sustainable Recycled Concrete. Constr. Build. Mater. 2024, 428, 136362. [Google Scholar] [CrossRef]

- Wang, J.; Che, Z.; Zhang, K.; Fan, Y.; Niu, D.; Guan, X. Performance of Recycled Aggregate Concrete with Supplementary Cementitious Materials (Fly Ash, GBFS, Silica Fume, and Metakaolin): Mechanical Properties, Pore Structure, and Water Absorption. Constr. Build. Mater. 2023, 368, 130455. [Google Scholar] [CrossRef]

- Wang, J.; Fan, Y.; Che, Z.; Zhang, K.; Niu, D. Study on the Durability of Eco-Friendly Recycled Aggregate Concrete with Supplementary Cementitious Materials: The Combined Action of Compound Salt Solution of MgSO4, Na2SO4, and NaCl and Dry-Wet Cycles. Constr. Build. Mater. 2023, 377, 131149. [Google Scholar] [CrossRef]

- Xia, G.; Zhao, Y. Interface Parameters of Recycled Aggregate Concrete Considering the Distribution of Old Mortar Content. Case Stud. Constr. Mater. 2024, 20, e03262. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2022; pp. 1–9.

- Barros, K.S.; Vielmo, V.S.; Moreno, B.G.; Riveros, G.; Cifuentes, G.; Bernardes, A.M. Chemical Composition Data of the Main Stages of Copper Production from Sulfide Minerals in Chile: A Review to Assist Circular Economy Studies. Minerals 2022, 12, 250. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Velázquez, S.; Bonilla, M. Evaluation of the Pozzolanic Activity of Fluid Catalytic Cracking Catalyst Residue (FC3R). Thermogravimetric Analysis Studies on FC3R-Portland Cement Pastes. Cem. Concr. Res. 2003, 33, 603–609. [Google Scholar] [CrossRef]

- Silva, Y.F.; Izquierdo, S.R.; Delvasto, S. Effect of Masonry Residue on the Hydration of Portland Cement Paste. DYNA 2019, 86, 367–377. [Google Scholar] [CrossRef]

- ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2024; pp. 1–6.

- ASTM C125; Standard Terminology Relating to Concrete and Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2021; pp. 1–9.

- ASTM C131-20; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020; Voulume 4, pp. 1–10.

- ASTM C39/C39M-18; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C496/C496M−17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–5.

- ASTM C293; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2016; pp. 1–4.

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C1585-20; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2020; pp. 1–6.

- Hammond, G.; Jones, C. Embodied Carbon, The Inventory of Carbon and Energy (Ice); University of Bath with BSRIA, ICAT: Elkridge, MD, USA, 2011. [Google Scholar]

- Luciano, A.; Altamura, P.; Baiani, S.; Cutaia, L. The Building Stock as an Urban Mine: The Case of the Circular Regeneration of Disused Buildings. Sustain. Chem. Pharm. 2023, 33, 101104. [Google Scholar] [CrossRef]

- Hernández, H.; Ossio, F.; Silva, M. Assessment of Sustainability and Efficiency Metrics in Modern Methods of Construction: A Case Study Using a Life Cycle Assessment Approach. Sustainability 2023, 15, 6267. [Google Scholar] [CrossRef]

- Edwin, R.S.; Gruyaert, E.; De Belie, N. Influence of Intensive Vacuum Mixing and Heat Treatment on Compressive Strength and Microstructure of Reactive Powder Concrete Incorporating Secondary Copper Slag as Supplementary Cementitious Material. Constr. Build. Mater. 2017, 155, 400–412. [Google Scholar] [CrossRef]

- Devi, S.C.; Khan, R.A. Effect of Graphene Oxide on Mechanical and Durability Performance of Concrete. J. Build. Eng. 2020, 27, 101007. [Google Scholar] [CrossRef]

- Belabbas, O.; Bouziadi, F.; Boulekbache, B.; Hamrat, M.; Haddi, A.; Amziane, S. Mechanical Properties of Multi-Recycled Coarse Aggregate Concrete, with Particular Emphasis on Experimental and Numerical Assessment of Shrinkage at Different Curing Temperatures. J. Build. Eng. 2024, 89, 109333. [Google Scholar] [CrossRef]

- Araos, P.; Aponte, D.; Barra, M. Ladle Furnace Slag as a New Source of Supplementary Cementitious Material: Evaluating Long-Term Performance and Environmental Impact in Portland Cement Systems. J. Build. Eng. 2024, 95, 109995. [Google Scholar] [CrossRef]

- Reddy, V.S.; Shrihari, S.; Uma, P.; Kalyan, J.P. Treated Recycled Coarse Aggregate Concrete: A New Mixture Proportioning Method Based on Packing Densities. Mater. Today Proc. 2023, 1–9. [Google Scholar] [CrossRef]

- Trento, D.; Faleschini, F.; Revilla-Cuesta, V.; Ortega-López, V. Improving the Early-Age Behavior of Concrete Containing Coarse Recycled Aggregate with Raw-Crushed Wind-Turbine Blade. J. Build. Eng. 2024, 92, 109815. [Google Scholar] [CrossRef]

- Lu, L. Optimal Replacement Ratio of Recycled Concrete Aggregate Balancing Mechanical Performance with Sustainability: A Review. Buildings 2024, 14, 2204. [Google Scholar] [CrossRef]

- Neville, A. Properties of Concrete. PEARSON: New York, NY, USA, 2003. [Google Scholar]

- Itam, Z.; Syamsir, A.; Rababah, A.Q.; Malkawi, O.; Razeman, N.A. Utilization of Mango Leaf Ash as a Supplementary Cementitious Material in Concrete. AIP Conf. Proc. 2023, 2544, 826–841. [Google Scholar] [CrossRef]

- Maharishi, A.; Singh, S.P.; Gupta, L.K. Shehnazdeep Strength and Durability Studies on Slag Cement Concrete Made with Copper Slag as Fine Aggregates. Mater. Today Proc. 2020, 38, 2639–2648. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A. A Review on Recycled Concrete Aggregates (RCA) Characteristics to Promote RCA Utilization in Developing Sustainable Recycled Aggregate Concrete (RAC). Eur. J. Environ. Civ. Eng. 2022, 26, 6505–6539. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Mechanical Properties of Recycled Aggregate Concrete Containing Ternary Blended Cementitious Materials. Int. J. Sustain. Built Environ. 2017, 6, 536–543. [Google Scholar] [CrossRef]

- Thomas, J.; Thaickavil, N.N.; Wilson, P.M. Strength and Durability of Concrete Containing Recycled Concrete Aggregates. J. Build. Eng. 2018, 19, 349–365. [Google Scholar] [CrossRef]

- Miraldo, S.; Lopes, S.; Pacheco-torgal, F.; Lopes, A. Advantages and Shortcomings of the Utilization of Recycled Wastes as Aggregates in Structural Concretes. Constr. Build. Mater. 2021, 298, 123729. [Google Scholar] [CrossRef]

- Megharani; Thejaswi, K.P.; Prakash, D. Performance of Frc With Partial Replacement of Natural Coarse Aggregate By Recycled Coarse Aggregate, Cement By Fly Ash and Natural Sand By Quarry Dust. Int. Res. J. Eng. Technol. 2008, 6, 559–564. [Google Scholar]

- Qian, R.; Lin, W.W.; Yang, C.; Zhao, R.; Ye, Z.; Kong, D.; Zhang, Y. Investigations on Carbon-Sequestration Optimization of Recycled Coarse-Aggregate and Its Effects on Concrete Performances. J. Build. Eng. 2024, 90, 109453. [Google Scholar] [CrossRef]

- Ouyang, K.; Liu, J.; Liu, S.; Song, B.; Guo, H.; Li, G.; Shi, C. Influence of Pre-Treatment Methods for Recycled Concrete Aggregate on the Performance of Recycled Concrete: A Review. Resour. Conserv. Recycl. 2023, 188, 106717. [Google Scholar] [CrossRef]

- Francioso, V.; Moro, C.; Velay-Lizancos, M. Effect of Recycled Concrete Aggregate (RCA) on Mortar’s Thermal Conductivity Susceptibility to Variations of Moisture Content and Ambient Temperature. J. Build. Eng. 2021, 43, 103208. [Google Scholar] [CrossRef]

- Alharthai, M.; Ali, T.; Qureshi, M.Z.; Ahmed, H. The Enhancement of Engineering Characteristics in Recycled Aggregates Concrete Combined Effect of Fly Ash, Silica Fume and PP Fiber. Alex. Eng. J. 2024, 95, 363–375. [Google Scholar] [CrossRef]

- Kapoor, K.; Singh, S.P.; Singh, B. Durability of Self-Compacting Concrete Made with Recycled Concrete Aggregates and Mineral Admixtures. Constr. Build. Mater. 2016, 128, 67–76. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, R.; Lu, H.; Hu, W.; Jiang, X.; Huang, B. Effect of Curing Conditions on the Strength and Durability of Air Entrained Concrete with and without Fly Ash. Clean. Mater. 2023, 7, 100170. [Google Scholar] [CrossRef]

- Haque, M.I.; Khan, R.I.; Ashraf, W.; Pendse, H. Production of Sustainable, Low-Permeable and Self-Sensing Cementitious Composites Using Biochar. Sustain. Mater. Technol. 2021, 28, e00279. [Google Scholar] [CrossRef]

- Hakeem, I.Y.; Alharthai, M.; Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Properties of Sustainable High-Strength Concrete Containing Large Quantities of Industrial Wastes, Nanosilica and Recycled Aggregates. J. Mater. Res. Technol. 2023, 24, 7444–7461. [Google Scholar] [CrossRef]

- Shi, C.; Zhao, R.; Wang, X.; Wang, W.; Ding, K. Effect of Clay Content on Concrete Properties. Case Stud. Constr. Mater. 2024, 20, e03341. [Google Scholar] [CrossRef]

- Wijayasundara, M.; Crawford, R.H.; Mendis, P. Comparative Assessment of Embodied Energy of Recycled Aggregate Concrete. J. Clean. Prod. 2017, 152, 406–419. [Google Scholar] [CrossRef]

- Bompa, D.V.; Silva, L.F.O.; Saba, M. Geoscience Frontiers Comparative Carbon Emission Assessments of Recycled and Natural Aggregate Concrete: Environmental Influence of Cement Content. Geosci. Front. 2021, 12, 101235. [Google Scholar]

- Fraj, A.B.; Idir, R. Concrete Based on Recycled Aggregates—Recycling and Environmental Analysis: A Case Study of Paris’ Region. Constr. Build. Mater. 2017, 157, 952–964. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.Y.; Le, K.N.; Butera, A.; Hao, J.L.; Wang, J. Effects of Mix Design and Functional Unit on Life Cycle Assessment of Recycled Aggregate Concrete: Evidence from CO2 Concrete. Constr. Build. Mater. 2022, 348, 128712. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejía-Arcila, J.; Mejía de Gutiérrez, R.; Martínez, E. Life Cycle Assessment (LCA) of an Alkali-Activated Binary Concrete Based on Natural Volcanic Pozzolan: A Comparative Analysis to OPC Concrete. Constr. Build. Mater. 2018, 176, 103–111. [Google Scholar] [CrossRef]

- Dacić, A.; Mester-Szabó, E.; Fenyvesi, O.; Szalay, Z. Life Cycle Assessment of Concrete Incorporating All Concrete Recycling Products. Case Stud. Constr. Mater. 2024, 21, e03910. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Xiao, J. Estimation and Minimization of Embodied Carbon of Buildings: A Review. Buildings 2017, 7, 5. [Google Scholar] [CrossRef]

- Xia, B.; Ding, T.; Xiao, J. Life Cycle Assessment of Concrete Structures with Reuse and Recycling Strategies: A Novel Framework and Case Study. Waste Manag. 2020, 105, 268–278. [Google Scholar] [CrossRef]

| Chemical Composition | CS | OPC |

|---|---|---|

| Fe2O3 | 59.15 | 3.42 |

| SiO2 | 29.15 | 25.08 |

| CaO | 2.84 | 59.15 |

| Al2O3 | 5.84 | 5.12 |

| CuO | 1.34 | - |

| SO3 | 1.15 | 2.73 |

| K2O | 1.28 | 0.77 |

| TiO2 | 0.48 | 0.28 |

| Na2O | 1.02 | 0.13 |

| PbO | 0.20 | - |

| LOI * | −5.16 | 1.99 |

| Characteristic | Standard | Aggregate | |

|---|---|---|---|

| NCA | RCA | ||

| Density (kg/m3) | ASTM C127 [50] | 2620 | 2290 |

| Water absorption (%) | ASTM C127 [50] | 1.71 | 6.83 |

| Nominal maximum size (mm) | ASTM C125 [51] | 12.7 | 12.7 |

| Abrasion resistance | ASTM C131 [52] | 14.43 | 27.98 |

| Mixtures | MIX ID | Vol. Replacement Level (%) of NCA by RCA | OPC (kg/m3) | SC (kg/m3) | Water (kg/m3) | NFA (kg/m3) | NCA (kg/m3) | RCA (kg/m3) | SP (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| Reference | M1 | 0 | 400 | 0 | 196 | 889.8 | 830.9 | 0 | 2.4 |

| 15% CS | M2 | 0 | 340 | 71.4 | 196 | 889.8 | 830.9 | 0 | 2.4 |

| 15% CS–20% RCA | M3 | 20 | 340 | 71.4 | 196 | 889.8 | 664.7 | 145.2 | 2.4 |

| 15% CS–50% RCA | M4 | 50 | 340 | 71.4 | 196 | 889.8 | 415.4 | 363.1 | 2.4 |

| 15% CS–100% RCA | M5 | 100 | 340 | 71.4 | 196 | 889.8 | 0 | 726.2 | 2.4 |

| Mixture (ID) | Water Absorption (%) | Bulk Density (kg/m3) | Voids (%) | |||

|---|---|---|---|---|---|---|

| 28 | 180 | 28 | 180 | 28 | 180 | |

| M1 | 7.77 | 5.22 | 2590 | 2616 | 17.05 | 11.28 |

| M2 | 7.93 | 5.07 | 2610 | 2639 | 17.59 | 11.17 |

| M3 | 8.76 | 5.16 | 2578 | 2619 | 18.65 | 11.43 |

| M4 | 9.63 | 6.82 | 2510 | 2543 | 19.34 | 14.16 |

| M5 | 10.46 | 7.59 | 2463 | 2480 | 19.66 | 15.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arredondo, P.W.C.; Silva, Y.F.; Araya-Letelier, G.; Hernández, H. Valorization of Recycled Aggregate and Copper Slag for Sustainable Concrete Mixtures: Mechanical, Physical, and Environmental Performance. Sustainability 2024, 16, 11239. https://doi.org/10.3390/su162411239

Arredondo PWC, Silva YF, Araya-Letelier G, Hernández H. Valorization of Recycled Aggregate and Copper Slag for Sustainable Concrete Mixtures: Mechanical, Physical, and Environmental Performance. Sustainability. 2024; 16(24):11239. https://doi.org/10.3390/su162411239

Chicago/Turabian StyleArredondo, Pamela Wendy Caballero, Yimmy Fernando Silva, Gerardo Araya-Letelier, and Héctor Hernández. 2024. "Valorization of Recycled Aggregate and Copper Slag for Sustainable Concrete Mixtures: Mechanical, Physical, and Environmental Performance" Sustainability 16, no. 24: 11239. https://doi.org/10.3390/su162411239

APA StyleArredondo, P. W. C., Silva, Y. F., Araya-Letelier, G., & Hernández, H. (2024). Valorization of Recycled Aggregate and Copper Slag for Sustainable Concrete Mixtures: Mechanical, Physical, and Environmental Performance. Sustainability, 16(24), 11239. https://doi.org/10.3390/su162411239