Abstract

Two-phase olive pomace is a byproduct of the olive-oil extraction process that is sometimes processed further to recover more oil. During pomace oil production, especially in the early stages of olive processing, odours can be produced. These odours are a serious nuisance, especially in and around the processing facilities, as well as for nearby communities. These odours can be strong and unpleasant, and they may result in various issues, including environmental concerns. Thus, in this paper, the effect of storage and drying on the composition of two-phase olive pomace was investigated. Several physicochemical and instrumental analyses were performed, and it was concluded that the structural elements of pomace are not the ones that are affected during storage and drying. Storage and drying mainly impact the oil content of pomace, leading to an acidity increase and to the production of odorous oxidation compounds. Volatile acids, methyl, and ethyl esters are released into the atmosphere, thus causing serious environmental nuisance.

1. Introduction

Olive oil is not only a source of income for Mediterranean countries, but also a centuries-old cultural value that is connected to history, culture, the environment, and the local economy. The global production of olive oil in 2021–2022 reached 3.27 million tons, but production is expected to decrease to 2.82 million tons in 2022–2023 [1]. The European Union was responsible for 70% of the global production in 2021–2022, corresponding to 2.27 million tons, while it is expected to fall to 1.39 million tons in 2022–2023 [2]. This production is mainly concentrated in Spain (58.4%), Italy (19.0%), and Greece (14.3%). Based on data from the International Olive Council (IOC) for 2010–2020, Greece produces an average of 270,000 tons per year, Italy produces 350,000 tons, and Spain produces 1,300,000 tons [3].

In Spain, intensive crops dominate, with over 200 trees per hectare, whereas in Greece, it is estimated that 70–80% of the crops are of low density with less than 200 trees per hectare [4]. Additionally, in Greece, most olive mills are small businesses, and their average production is low, only producing about 150 tons per year, while in Spain, the average production is about 700 tons per year. In Italy, the fragmentation of olive mills is greater than in Greece and more olive mills operate, with an average production of about 100–150 tons. However, Italy follows a different model compared to Greece and Spain, where it is common for growers to have small olive oil production and standardization units [5].

The main production processes are three-phase and two-phase olive mills. The latter is gaining progress due to the recent legislation. Two-phase olive mills have, as their product, olive oil and, as by-products, the two-phase pomace and a small amount of wastewater, which derives from the water used in the last stage of the clarification process [6]. The two-phase pomace is a semi-solid waste that consists of large amounts of moisture (50–75%), olive kernel, pieces of olive peel and pulp, as well as residues from leaves and pruning [7]. The waste of the two-phase pomace represents more than 80% of the raw material that is processed. Strong phytotoxic effects result from uncontrolled waste discharge into the soil. The uncontrolled discharge of waste into the soil increases hydrophobicity, causes phytotoxic effects, decreases water filtration and retention rates, and affects salinity, acidity, microbial activity, nitrogen uptake, leaching lipid concentration, and the production of phenols and organic acids [8].

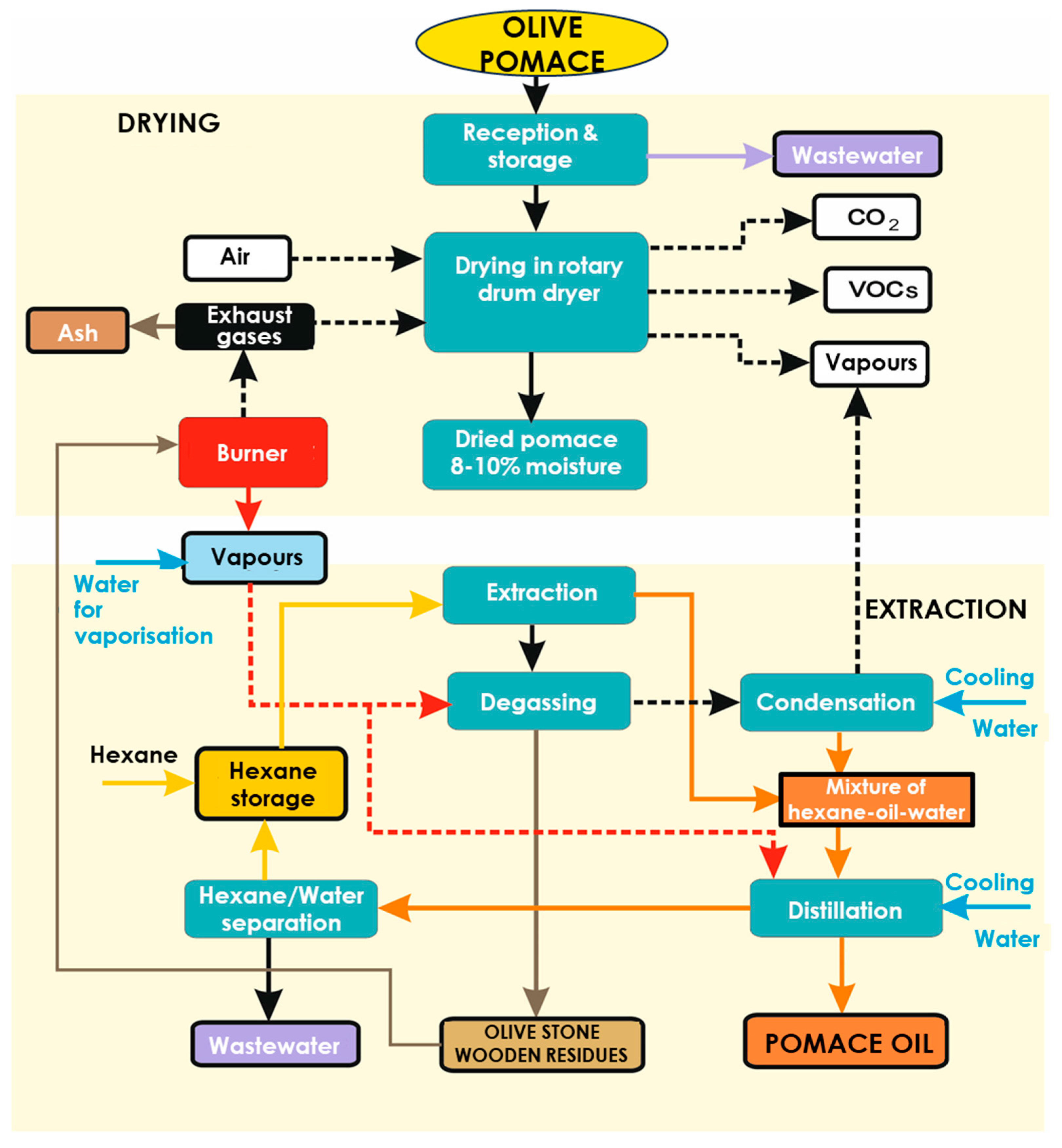

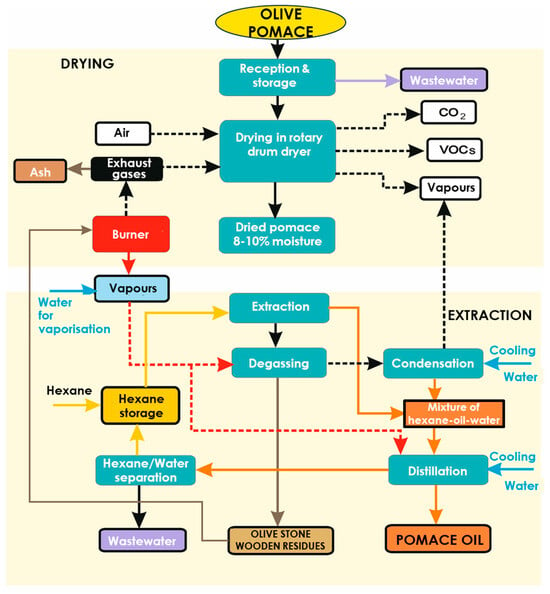

A common valorisation pathway of the two-phase pomace is the extraction of pomace oil in pomace oil plants. The production process of pomace oil is illustrated in Figure 1, including the following stages: reception and storage, drying, oil extraction, the recovery of solvent, and the degassing and management of the final products (pomace oil and olive stone wooden residue). More specifically, the olive pomace is transported from olive mills to the processing plant. Olive pomace is often dried to reduce moisture content. This can be achieved using various methods such as solar drying or industrial drying systems. A typical plant includes a drying step in a rotary drum dryer to reduce the moisture of the pomace to 8% as well as an oil extraction step. Hexane or other solvents are commonly used to extract the residual oil from the dried olive pomace. The solvent is evaporated, leaving behind olive pomace oil. Mechanical pressing can also be employed to extract oil. This method is less common in large-scale operations but is considered a more natural and environmentally friendly process. The extracted olive pomace oil undergoes refining processes in order to remove impurities and improve its quality. The oil may be fractionated to obtain different components with specific properties. The dried pomace can be used as biomass for energy production. It can be burned directly for heat, or it can be converted into pellets for use in biomass boilers or co-firing in power plants [9,10,11].

Figure 1.

Pomace oil production process.

The main environmental issue that these plants face is the emissions to the atmosphere that become a serious nuisance to the local communities. These gaseous emissions are mainly suspended particulate matter (PM), volatile organic compounds (VOCs), and flue gases that are dependent on the fuel type and quality, as well as on the combustion equipment. It has been estimated that the produced gaseous emissions from pomace oil plants are 1.4–2.45 kg VOC/tn pomace and 1.2 kg PM/tn pomace.

More specifically, odorous volatile compounds are released during the drying of the fresh olive pomace. These compounds are produced either during the process of drying or have been produced earlier (during storage) and are released during drying. The production of odours during drying can be due to the thermal decomposition of fatty components contained in the pomace oil if the drying temperature exceeds certain limits. Odorous volatile compounds are also released from the flue gases from the combustion furnace of the dryer and the steam generation section. From the combustion of olive stone wooden residues, exhaust gases are mainly produced. The CO content depends mainly on the combustion conditions rather than the fuel composition, while the SO2 content depends on the sulphur content of the fuel. The remaining compounds that were released constitute the conventional combustion products of any fuel.

Particulates from the dryer and steam generation furnaces are also produced. The particulate emissions are due to unburned particles of olive stone wooden residues (mainly in the exhaust gases of dryers) or in ash particles (mainly in the exhaust gases of steam boilers). The particle size composition of the emitted particles from dryers varies mainly between 100–500 µm, which classifies them as coarse particles, while the particles from the steam boiler are characterized by a granulometric composition 0–100 µm, classifying them as fine particles.

Additionally, water vapours are produced from the drying stage of the fresh olive pomace and the steam generation section. They are due to the induced moisture of the pomace and the moisture content of the olive stone wooden residues. Water vapour is a harmless emission but causes optical nuisance. For this reason, it is not necessary to apply any special measures to deal with it [12,13,14].

In this paper, the impact of the storage and drying of two-phase pomace on its physicochemical characteristics is investigated in view of mitigating environmental nuisance. Up to now, research has not thoroughly explored the impact of different storage conditions (e.g., duration, temperature, and atmosphere) on the physicochemical characteristics of two-phase pomace since comprehensive studies that simultaneously consider multiple physicochemical characteristics, such as moisture content, acidity, phenolic compounds, and other relevant parameters, are limited. Thus, a gap exists in understanding how the manipulation of storage and drying parameters can contribute to mitigating environmental nuisances associated with two-phase pomace. To this end, the main objective of this manuscript is to conduct a comprehensive analysis of physicochemical properties, including but not limited to moisture content, acidity, polyphenolic content, and antioxidant activity, providing a more holistic view of the changes in two-phase pomace.

2. Materials and Methods—Methodological Approach

Initially, samples of olive pomace were collected from various olive mills in Greece at different times of the oil production period (typically form late October to early February), and these were subjected to analytical physicochemical characterization so as to study the impact of the origin of the sample on the two-phase olive pomace composition.

Specifically, analyses were performed according to standard methods for the characterization of the two-phase olive pomace: pH, conductivity, moisture, total, volatile and water-soluble solids, total nitrogen, acid-insoluble residue, soluble lignin, cellulose, hemicellulose, and oil. Moisture, ash, acid-soluble and insoluble lignin, cellulose, and hemicellulose were estimated by the NREL Laboratory Analytical Protocols [15,16,17,18,19]. The Soxhlet standard method (5520E) [20] was utilized for the quantification of fats and lipids [21,22].

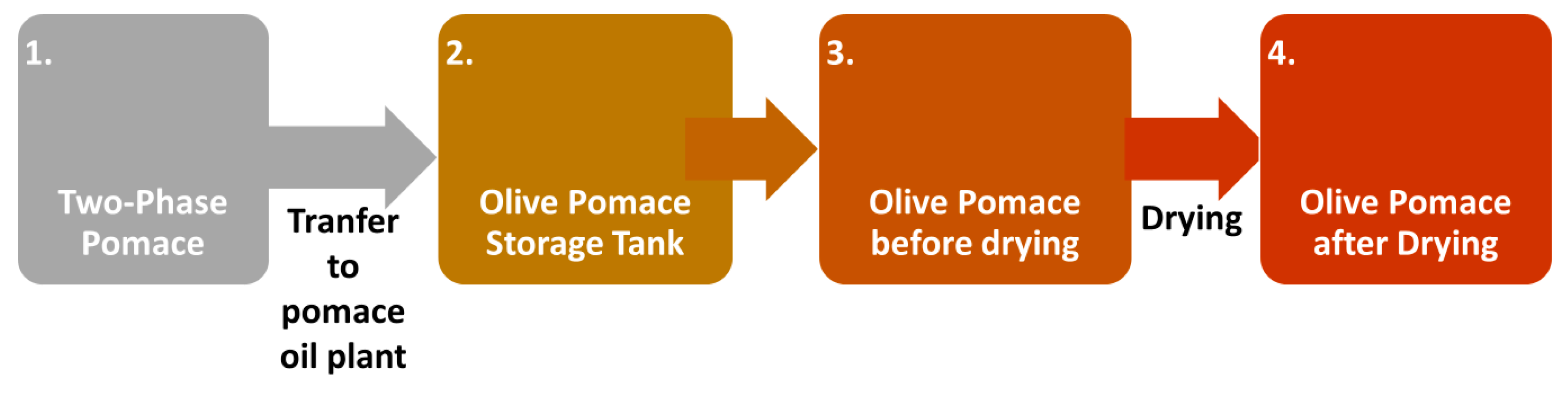

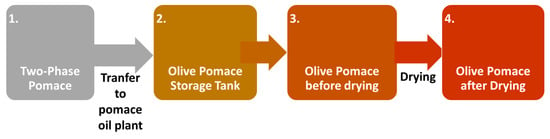

Subsequently, to study the effect of storage and drying on the composition of two-phase olive pomace under field conditions, various samples were collected from a two-phase olive mill and a pomace oil plant in Messinia, Greece, and delivered to the Unit of Environmental Science and Technology (UEST), School of Chemical Engineering, National Technical University of Athens. Figure 2 illustrates the sampling points in the value chain of pomace oil, from the production of pomace in the olive mill to the production of dried pomace.

Figure 2.

Simplified flow diagram of the sampling points in the value chain of pomace oil.

The sample taken from sampling point 1 is considered a “fresh” sample, in contrast to the sample taken from sampling point 2, which has undergone long-term storage. The sample taken from sampling point 3 results from the mixing of stored olive pomace with dry olive pomace, aiming to achieve a final moisture content of 50%. A moisture content of around 50% is necessary for the drying equipment to operate seamlessly. The sample taken from sampling point 4 is the final dry pomace.

In addition to determining the physicochemical characteristics of these samples, particle size analysis was performed via a sieve shaker analysis (Retsch Vibratory Sieve Shaker AS200 Basic, Haan, Germany). Furthermore, X-ray diffraction (XRD) analysis was performed using a Bruker D8 Advance X-ray instrument. The instrument was operated in step scan mode in steps of 0.02° 2θ over the range 10–50°.

Thermogravimetric analysis (TGA) relies on monitoring the change in the mass of a substance as a function of temperature change. More specifically, it is a dynamic combination of gravimetric analysis with oven drying. This analysis technique is applied to the analysis of solid samples, which during heating show changes in weight, due to physical or chemical phenomena. Therefore, a thermogravimetric analysis of the dry samples was carried out in a nitrogen environment, with the aim of studying the effect of thermal degradation on the components of the olive pomace. It was carried out using a Mettler Toledo TGA/DSC HT1 instrument, with the aim of exploring the effect of thermal degradation on the components of the olive pomace. A thermogravimetric analysis of fresh, ‘as received’ samples in an air environment was also performed with the same instrument, with the aim of simulating the process of drying—moisture removal. Samples were heated from 30 to 600 °C at a rate of 10 °C min−1, while the simultaneous flow of oxygen or nitrogen was regulated at 10 mL min−1. The weight of each sample’s final residue at 600 °C was measured.

Additionally, Fourier Transform Infrared Spectroscopy (FTIR) analysis was also carried out on the olive pomace samples. FTIR is a method for obtaining solid, liquid, and gaseous materials’ infrared absorption, emission, and photoconductivity spectra. FTIR was used as described by Moreno et al. [23] in order to quantify the aldehydes and ketones in the samples as well as in the oil content. An FTIR spectrometer with a TGS detector (FTIR 4200 Jasco, Tokyo, Japan) was used for the pomace. The scanning was performed from 4000 to 700 cm−1 by applying a resolution of 4 cm−1. The Jasco Spectra Manager (version 2.0) software was used to evaluate the acquired infrared spectra. Through utilizing an air background adjustment, spectra were obtained.

Pomace oil was also investigated for some qualitative characteristics (free acidity, specific extinction K232 and K270 values), with the aim of identifying changes in the organoleptic characteristics of the oil content that occurred due to the storage and fermentation progress. Free acidity (FA) and specific extinction coefficients at 232 and 270 nm (K232, K270) were estimated based on EU standards [24].

Finally, the VOC analysis was performed using a thermal desorption (Markes International Ltd., Llantrisant, Wales, UK) gas chromatography (GC-7890B, Agilent, Santa Clara, CA, USA) mass spectrometer (5977B MSD, Agilent Technologies, Santa Clara, CA, USA) system (TD-GC-MS). Chlorobenzene-d5 (Supelco, Darmstadt, Germany, concentration of 200 ppb) was previously spiked to each sample to serve as an internal standard (I.S.), as well as for the semi-quantitative approach. The PDMS HiSorb probe (Markes International Ltd., Llantrisant, Wales, UK) was used for the headspace extraction of VOCs. Then, it was inserted into an empty tube and desorbed on the TD-GC-MS system. The details of the TD-GC-MS analysis are presented in detail in Fella et al. [25].

3. Results

3.1. Two-Phase Olive Pomace Composition

The results of the analysis of the different samples of two-phase olive pomace are presented in Table 1. In addition, in this table, the mean values of the measurements of the above parameters of all samples are presented along with the corresponding literature values.

Table 1.

Two-phase olive pomace characterization.

From this Table (Table 1), it is concluded that the average value of pH is consistent with the values reported in the literature. The same applies for the average values of conductivity and total solids content. A relatively greater discrepancy is observed in the value of volatile solids (99.00 ± 0.07% vs. 83.25 ± 4.15%). In addition, the mean value for hemicellulose, acid insoluble residue, total nitrogen, and oil all fluctuate within the respective literature values. However, it is worth noting that the cellulose content of the samples of this study is much lower.

3.2. Effect of Storage and Drying on Two-Phase Olive Pomace Composition under Field Conditions

3.2.1. Evolution of Physicochemical Characteristics

Table 2 presents the evolution of the composition of the sample entering the olive pomace plant until its exit from the rotary drum dryer.

Table 2.

The composition of samples at different points in the production line of pomace oil.

A significant decrease in conductivity was observed during the storage of the fresh olive pomace. As for changes in the moisture and total solids, these are to be expected given the processes taking place. Regarding the structural elements of the solid phase, it was observed that no significant changes occurred, which is in agreement with preliminary laboratory scale experiments. However, it is worth emphasizing that there is a decrease in cellulose and hemicellulose content, which can be attributed to thermal degradation that takes place during the heat treatment of the olive pomace.

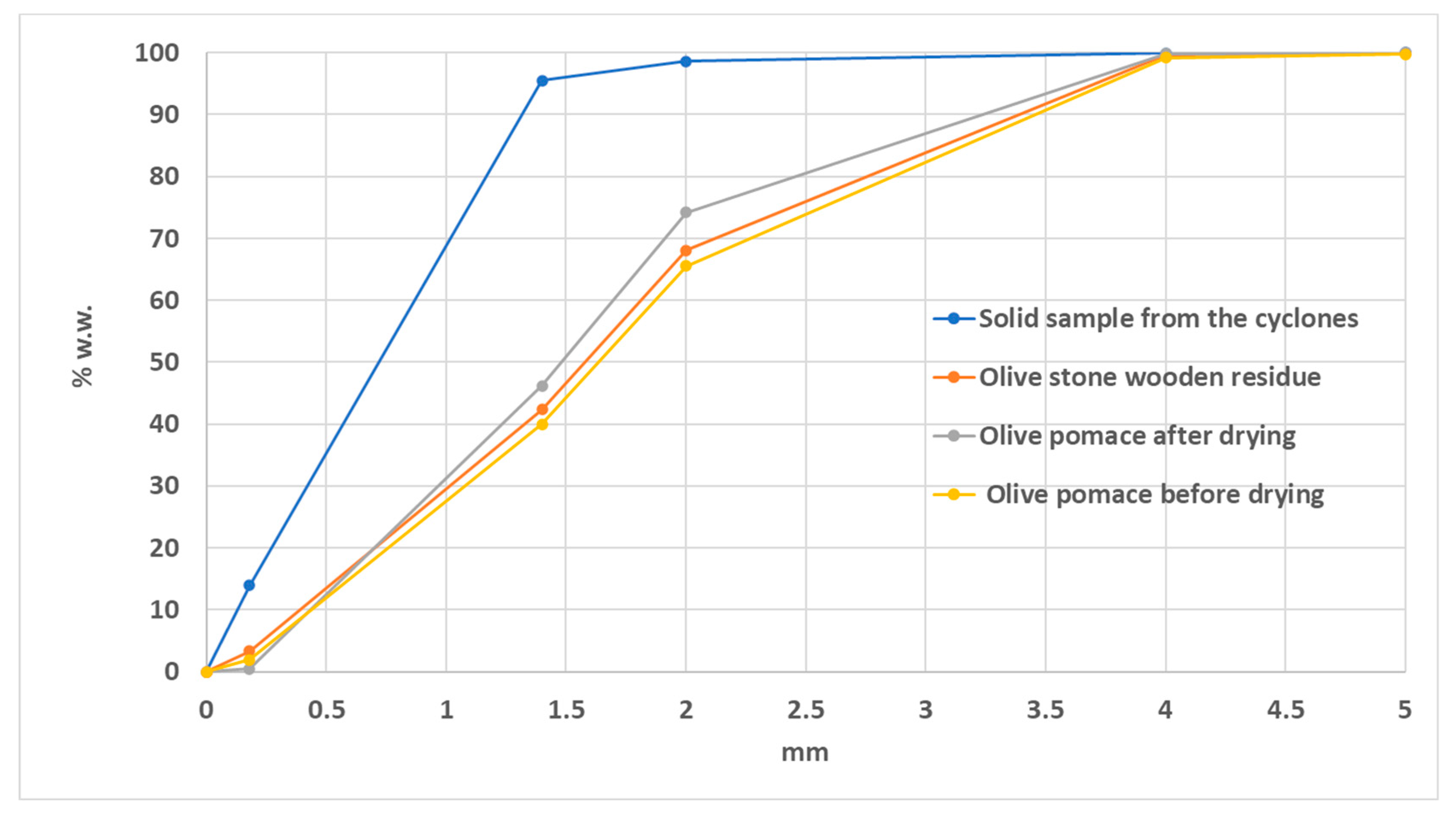

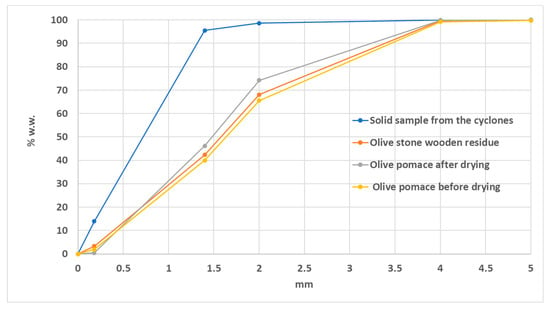

3.2.2. Particle Size Distribution

Particle size distribution analysis is used to measure the size of the particles present in a sample according to their characteristics, such as their weight or their shape, for a better understanding of their nature. Figure 3 illustrates the results from the particle size distribution analysis for the following samples:

Figure 3.

Particle size distribution of different olive pomace samples.

- Olive pomace before drying (Point 3).

- Olive pomace after drying (Point 4).

- Solid sample from the cyclones

- Olive stone wooden residue.

From this figure (Figure 3), it is observed that 90% of the granules of olive pomace before drying have a diameter of less than 3.5 mm, while the corresponding percentage for the olive pomace after drying has a diameter of 3.25 mm. This reduction is probably due to the removal of moisture. Furthermore, it is evident that small diameter particles escape and are subsequently collected in the cyclones. From the particle size distribution analysis of the olive stone wooden residue and olive pomace samples after drying, it appears that the removal of the pomace oil leads to a decrease in the diameter of the particles, as expected.

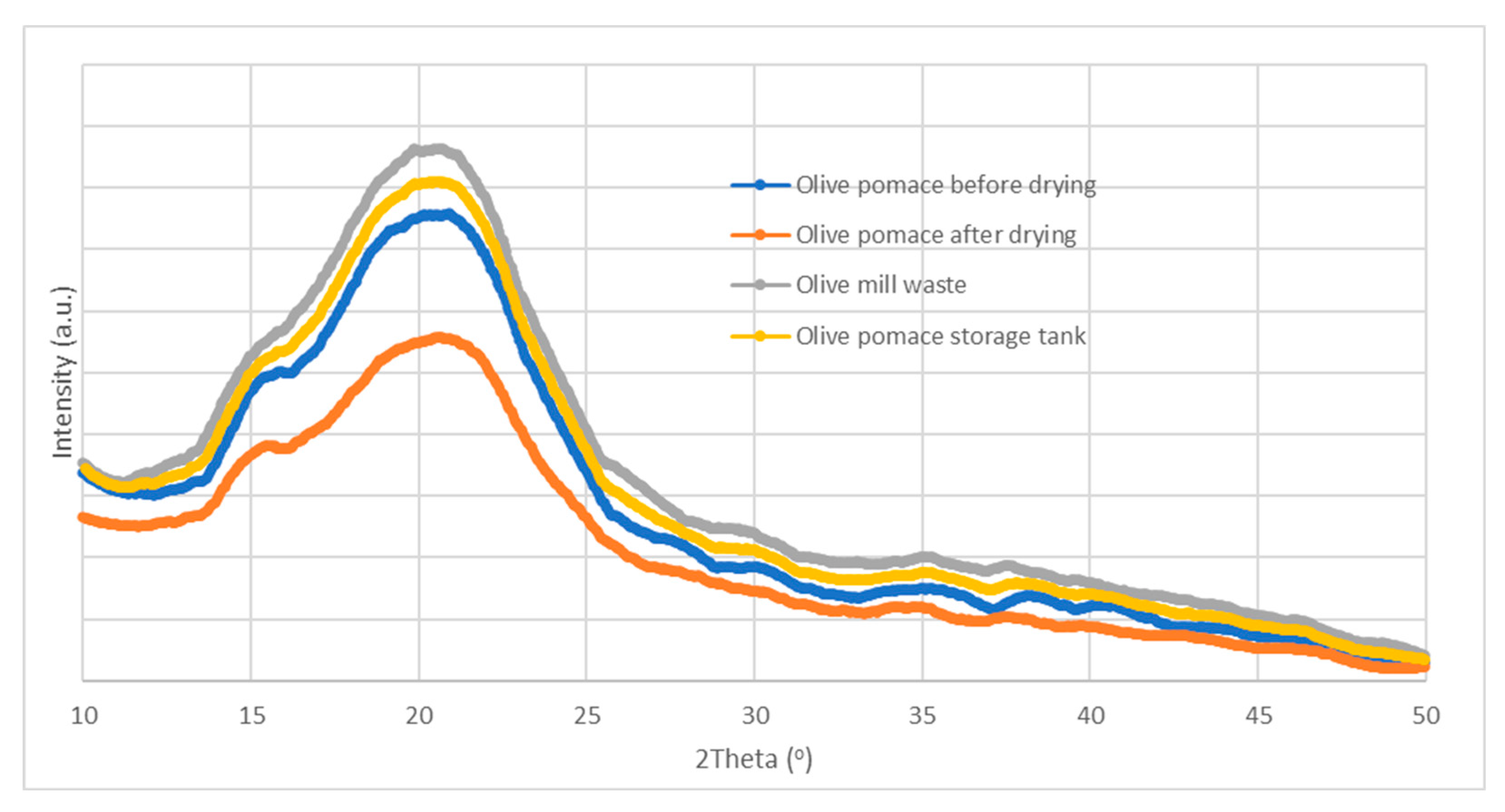

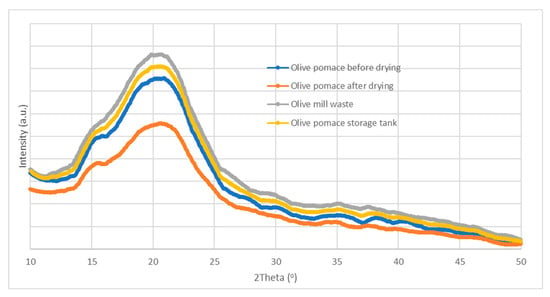

3.2.3. X-ray Diffraction Analysis

From the results of the X-ray diffraction analysis (Figure 4), the heat treatment in the dryer leads to a change in the crystallinity of the cellulose, as well as to the removal/degradation of the characteristic triglycerides of the olive oil.

Figure 4.

Schematic illustration of the results of X-ray diffraction of the samples.

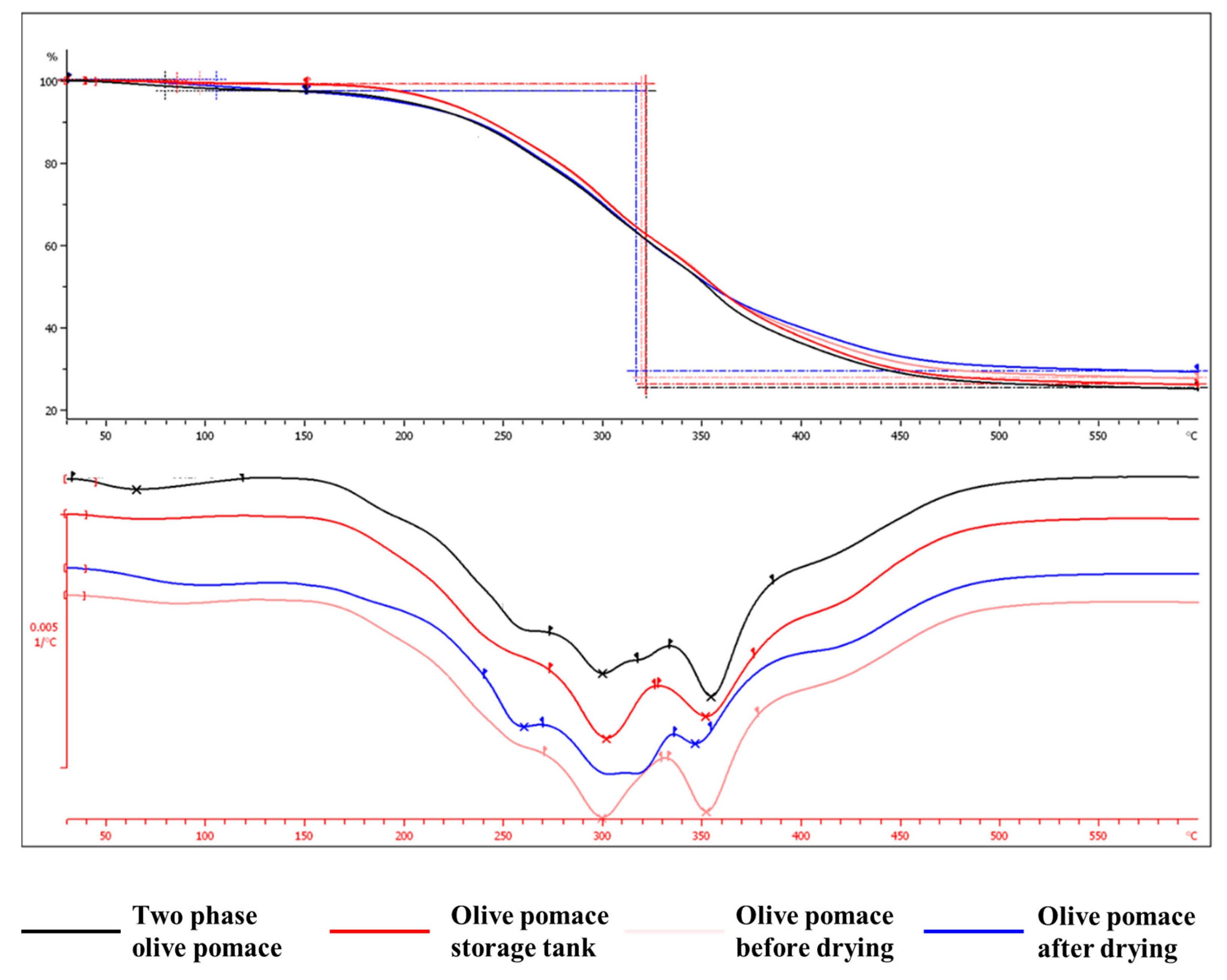

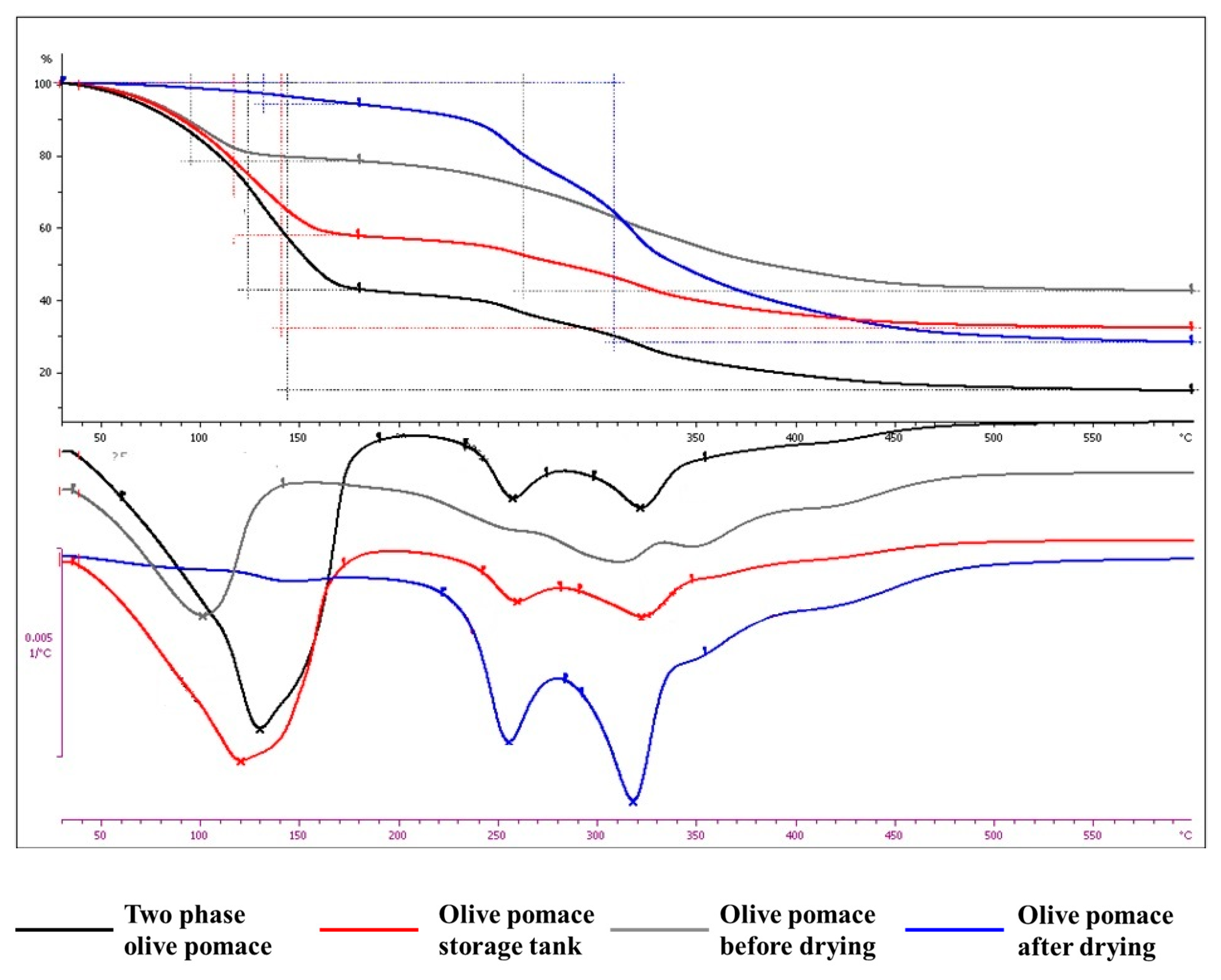

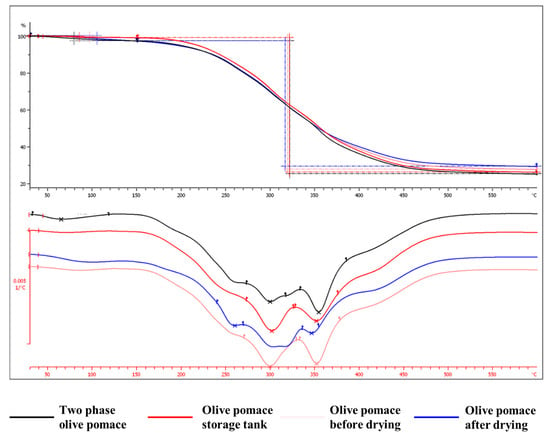

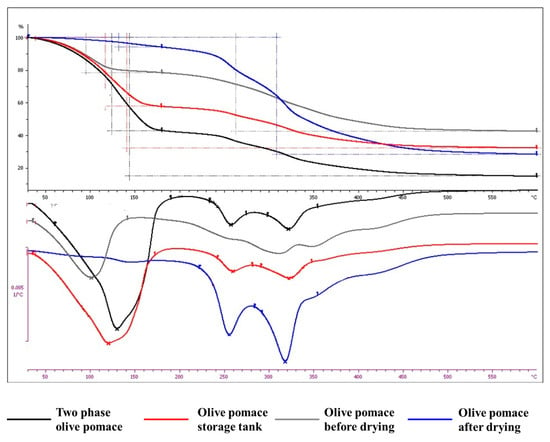

3.2.4. Thermogravimetric Analysis

The results of the thermogravimetric analysis of the dry olive pomace samples in a nitrogen environment and of the fresh olive pomace samples in an air environment are presented in Figure 5 and Figure 6, respectively.

Figure 5.

Thermogravimetric analysis of dry olive pomace samples in a nitrogen environment.

Figure 6.

Thermogravimetric analysis of the fresh olive pomace samples in an air environment.

The results from the thermogravimetric analysis tests are summarized in Table 3.

Table 3.

Thermogravimetric analysis results of olive pomace samples.

From all the above, it may be concluded that:

- The thermal degradation in the operating temperature range of the dryer is very low (0.86–2.67%).

- The weight loss of fresh, ‘as received’ samples under air flow is proportional to the moisture content.

Therefore, the nuisance (odour) of the exhaust gases of the drying process is probably due to organic compounds which are removed in very low concentrations (and cannot be illustrated in the particle size distribution analysis) and present a low odour threshold, which was investigated next.

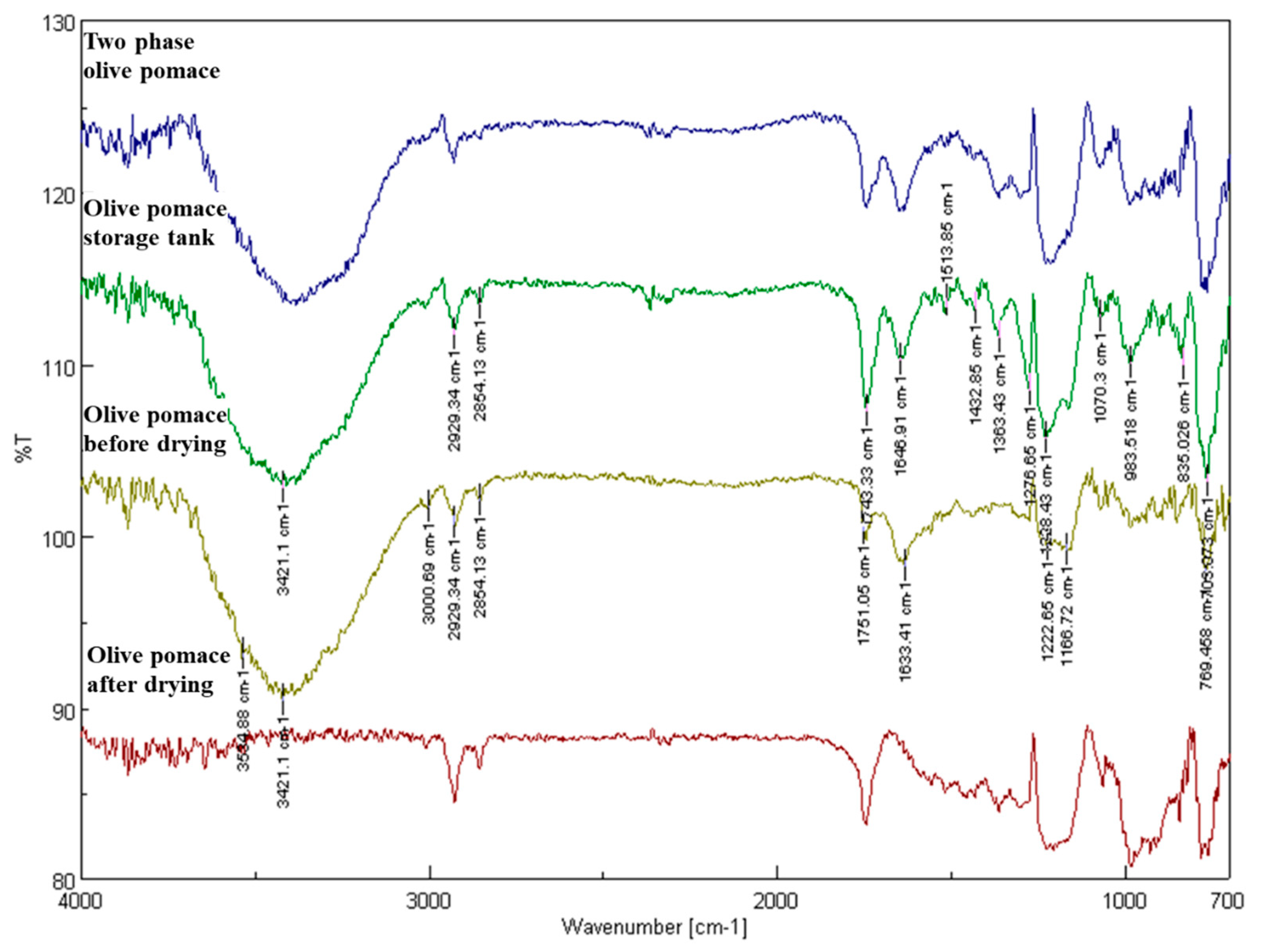

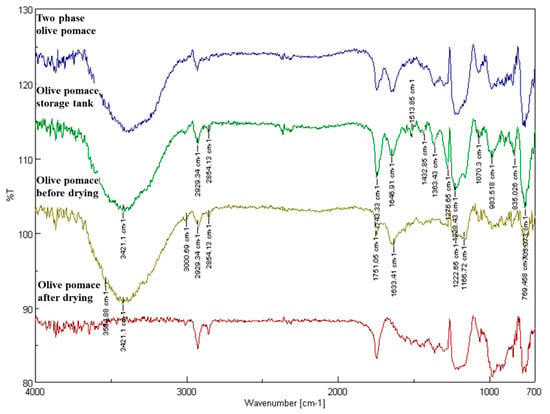

3.2.5. Analysis of Fresh, ‘As Received’ Olive Pomace Samples by Fourier Transform Infrared Spectroscopy

From the results of the FTIR analysis, according to Figure 7, it was observed that the greatest difference between the samples is found in the peak between the wavenumbers 1633–1648 cm−1. The 1664 cm−1 peak is due to the cis C=C bond. Additionally, the sample in which the respective peak does not appear is the sample after the drying process. It can thus be concluded that the oil content was auto-oxidized since oleic acid, which has a cis double bond, is the main component in olive oil.

Figure 7.

Absorption spectra of the olive pomace samples.

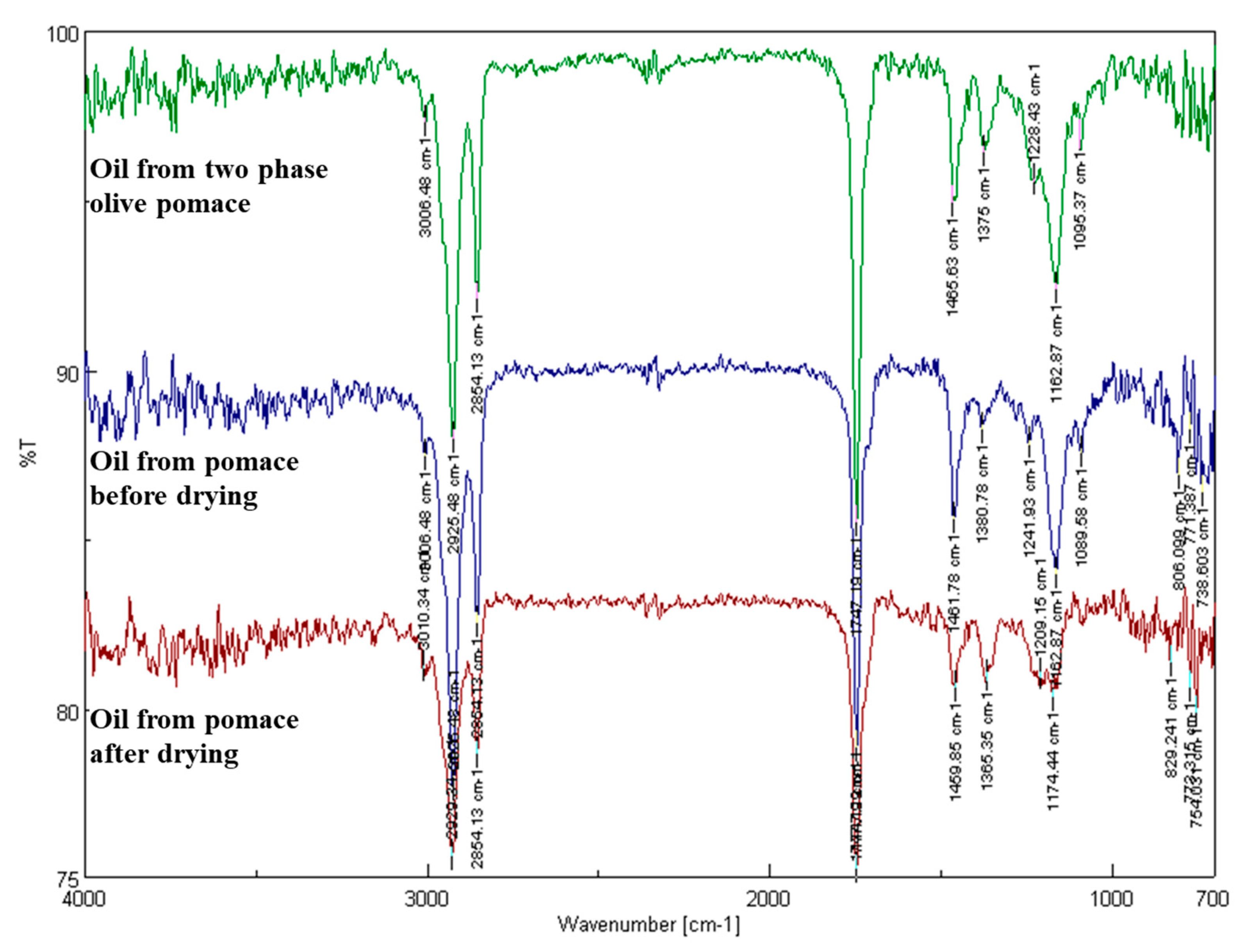

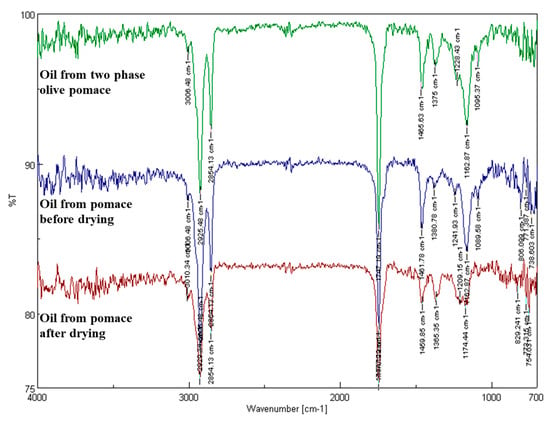

Subsequently, the recovered oils from these samples were also subjected to FTIR analysis (Figure 8).

Figure 8.

Absorption spectra of the oil content of the olive pomace samples.

In the spectra shown in Figure 8, the characteristic absorption peaks can be observed:

- at 1365.35 cm−1, corresponding to the CH2-CH2 groups and

- at 1174.44 cm−1, corresponding to the C-O bond of the ester groups,

- as well as at 1459.85 cm−1, corresponding to the group CH2-CH3.

At first sight, it seems that all samples present similar peaks. However, qualitatively, the 1465 cm−1 and 1163 cm−1 peaks appear to decrease in the oil extracted from the dried sample. Furthermore, in addition to fatty acids, it appears that triglycerides are also oxidized, as a decrease in transmittance at 1163 cm−1 is observed. The decrease in the transmittance ratio of the wavenumbers 1163 and 1377 cm−1 also indicates a change in the chemical composition of the oil.

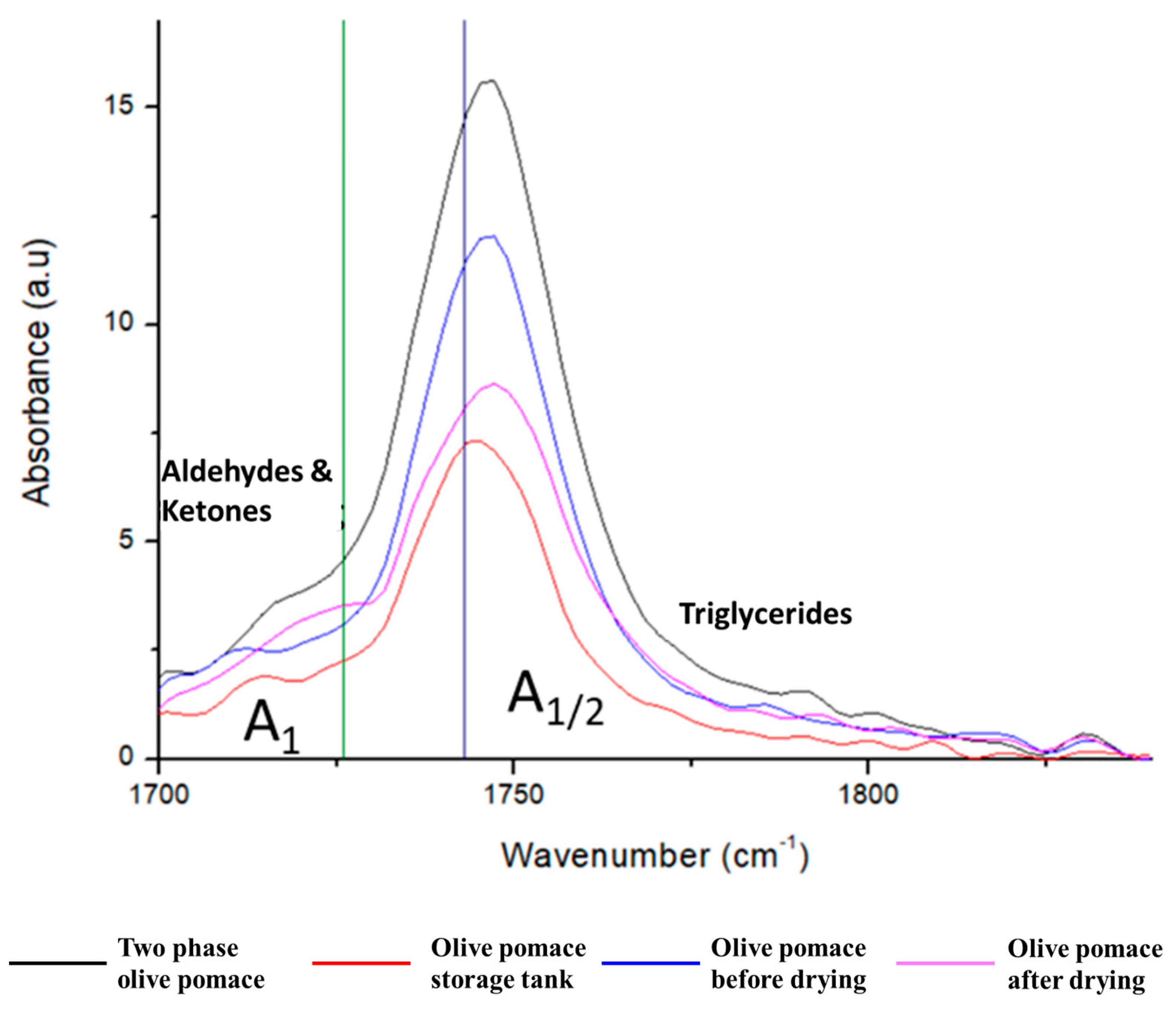

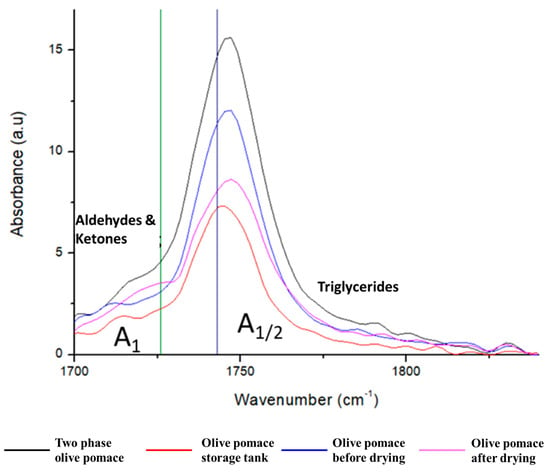

As seen in Figure 9, the triglyceride esters exhibit a prominent absorption band at 1743 cm−1 in the infrared spectrum because of the carbonyl group’s vibration. Additionally, between 1700 and 1726 cm−1, ketones and aldehydes exhibit distinctive absorption. On the other hand, the average value of aldehydes is approximately 1725 cm−1, and that of ketones is approximately 1715 cm−1. Consequently, the broadening (area) of the region between 1700–1726 cm−1 (A1) in relation to the area between 1840–1743 cm−1 (A1/2), which is proportionate only to esters, can be used to quantify the total aldehydes and ketones generated.

Figure 9.

Spectrum of the oil samples in FTIR.

The ratio A1/(A1/2), according to Moreno (1999) [23], can lead to a quantitative analysis of the aldehydes and ketones in the sample (Table 4).

Table 4.

The ratio A1/(A1/2), corresponding to the aldehydes and ketones contents of the olive pomace samples.

All the samples in the pomace oil plant showed a higher ratio than the sample entering the plant from the olive mill. This indicates a possible indication of the production of aldehydes and ketones as oxidation products.

3.2.6. Pomace Oil Acidity

Therefore, taking all of the above into account, it emerged that storage causes changes mainly in the oil content of the olive pomace, and the research was directed in this direction. One of the factors that contribute to the rapid deterioration of the olive pomace is moisture, which favours the hydrolysis of triglycerides.

In addition, the acidity of pomace oil can increase from 5 to 60% in a short period of time. This is due to the action of lipase, an enzyme which is present in the olive pomace (it comes from the olive fruit), but which is also released by the microorganisms Gliomastrix Chartarum, Aspergillus niger, Cephalosporum sp., Aspergillus glaucus, etc. These microorganisms grow on the substrate of the olive pomace and are favoured by the humidity and temperature of the olive pomace and the storage time. In addition to the acidity during the storage of the olive pomace, oxidation products (aldehydes, ketones) are also produced, which degrade the quality of the oil, as observed in the previous section.

The percentage of oleic acid in the oil indicates its acidity. Extra virgin olive oil equates to an acidity of less than 1%. In general, an olive oil’s quality deterioration and the amount of free fatty acids increase with its acidity value. Acidity increase is correlated with rancidity and oxidation, since this is related to problems faced by the olive fruit (olive fly, frozen, rotten, beaten olives, etc.); through the method of collection and storage, the olive mill facilities the possibility of mixing with previously harvested olive oil or with poor quality oils (pomace oil, etc.).

The K232 indicator, which corresponds to the radiation measured at a wavelength of 232 nm, is the known indicator of the initial stages of K232 oxidation, due to the compounds (hydroperoxides) produced in a primary oxidation step, but also to compounds (conjugated dienes) that are produced in an intermediate oxidation step. The absorption coefficient of the same radiation at a wavelength of 270 nm was also calculated (Table 5), which is the indicator of an advanced stage of oxidation, known as K270. This is likely caused by secondary oxidation products that have carbonyl groups, such as aldehydes and ketones.

Table 5.

Free acidity, coefficients K232 and K270 of oil samples from fresh two-phase olive pomace, olive pomace from the storage tank, olive pomace before and after drying, and from virgin and extra virgin olive oil.

Considering the results of Table 5, it is observed that the oil sample from the olive mill has the lowest acidity when compared to the rest of the samples. Between the samples from the storage tank and the sample before drying, no great variation is shown; however, after drying, a higher acidity value is observed. The increased acidity values are due to the higher content of the olive oil in free acids; this can be largely attributed to the fact that the olive fruit has been stored for a prolonged time. In such an occasion, the growth of microorganisms is promoted, resulting in an increased glycerides hydrolysis and ultimately in the free fatty acids production. In addition, triglycerides hydrolysis can be influenced by several factors, such as the degree of ripening, moisture, temperature, enzymes, and microorganisms. Hydrolysis is the result of the contact of triglycerides with water. Hence, high humidity has the dual impact of directly accelerating the hydrolysis process and indirectly facilitating the activity of lipolytic enzymes and microbes.

Similarly, the absorption coefficients at 232 and 270 nm show a deviation with respect to the values of virgin and extra virgin olive oil. In general, when olive fruit is kept in storage for several days before being pressed and also when olive oil is kept in improper circumstances, the value of the absorption coefficient K232 rises. The freshness of the olive oil affects the K270 absorption coefficient’s value. K270 levels are higher in ancient olive oils or in combinations including old olive oils. Furthermore, K270’s value decreases dramatically right after bottling and then rises with the age of the olive oil. Olive oil ages more quickly when exposed to sunshine or high temperatures.

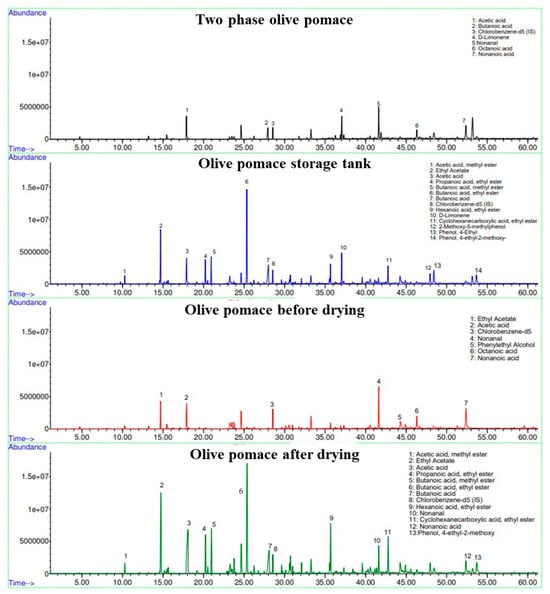

3.2.7. Analysis of Odours by TD-GC-MS

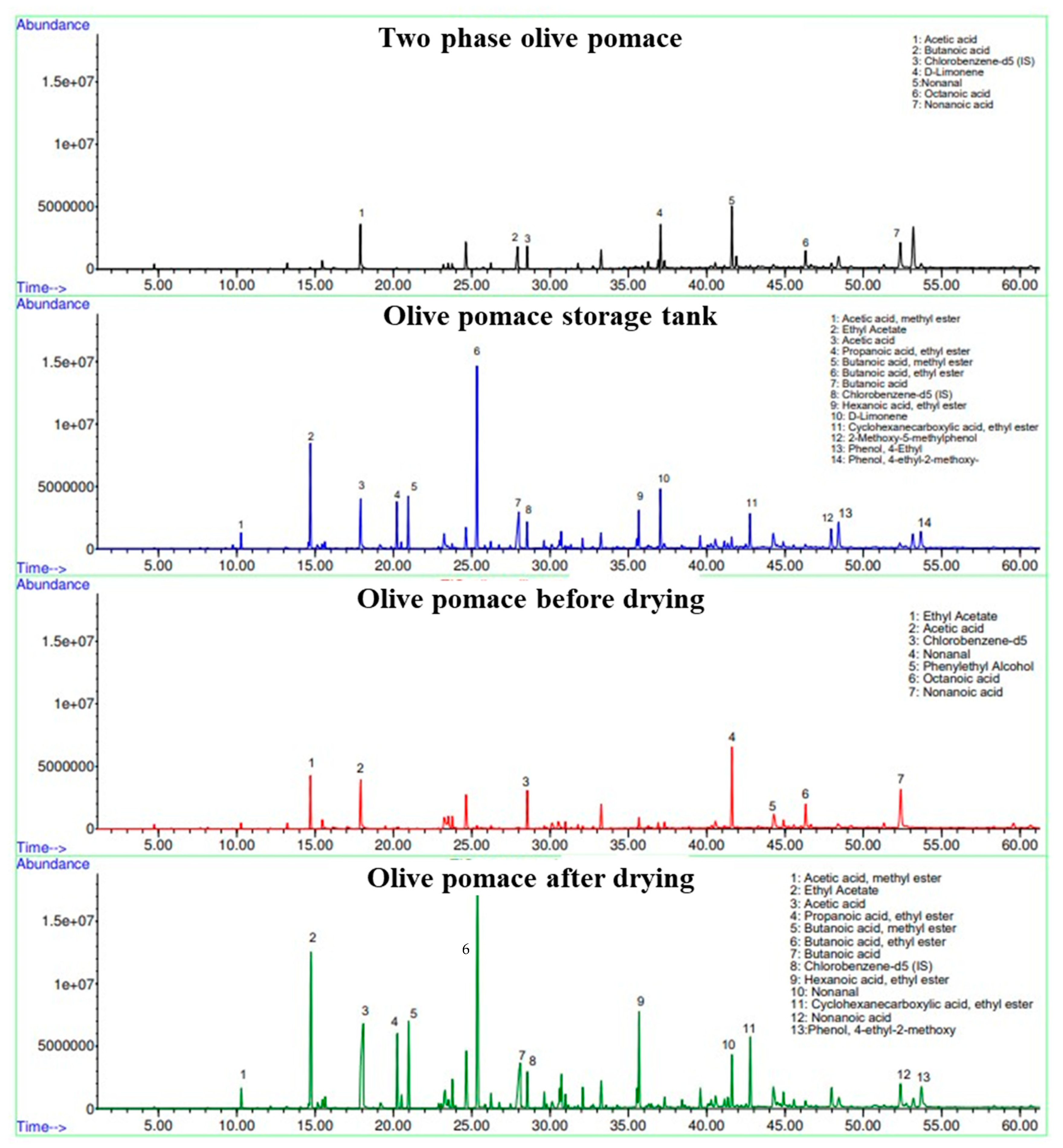

Olive pomace is a dynamic substrate that produces a plethora of VOCs, which emit unpleasant odours. These small molecules can negatively affect the aesthetics of an area, reduce property values, and lower the quality of life in a community. As a result, authorities work to prevent emissions and avoid odour complaints. VOCs are also precursors to secondary organic aerosols (SOAs) and a photochemically produced ozone. The odorous VOCs are produced due to the decomposition of olive fatty acid methyl esters as a result of various physicochemical reactions, fermentation processes, enzymatic and microbial activities, as well as the drying and storage processes. To identify and quantify the numerous VOCs present in the collected samples (and potentially escaping or having escaped during storage or drying), headspace HiSorb TD-GC-MS analysis was performed. The total ion chromatograms obtained are shown in Figure 10.

Figure 10.

Chromatograms of oil samples from fresh two-phase olive pomace, olive pomace from the storage tank, and olive pomace before and after drying.

The presented results are consistent with the previous research. Hernández et al. conducted a six-month study using sorbent tubes and TD-GC-MS to monitor the process in open reservoirs, observing an increase in aldehyde, ketone, and carboxylic acid emissions over time, as well as a decrease in fatty acid methyl esters and alkenes [32]. Another study by Hernández et al. used absorbent tubes to measure odorant components in a pilot-scale rotary dryer, identifying several frequent VOCs such as aldehydes (nonanal, furfural, and benzaldehyde), alcohols (2-furan methanol, phenol), carboxylic acids (acetic acid), and hydrocarbons (hexane, toluene, nonane, and octane) [37]. Finally, Cecchi et al. utilized headspace solid phase microextraction-GC-MS (SPME-GC-MS) in order to detect specific gaseous VOCs linked to off-Flavors, including 2-ethyl butanoate, p-cresol, 4-ethyl phenol, acetic acid, ethanol, and ethyl acetate [26]. The growth of bacteria that produce lactic acid, especially Lactobacillus pentosus, is related to the abundance of 4-ethyl phenol [38].

Various chemical classes were detected in the analysed samples. These included, among others, hydrocarbons, alcohols, ketones, esters, aldehydes, acids, phenols, and miscellaneous compounds. The short- and methyl-chained hydrocarbons such as pentane, pentane 2-methyl, pentane 3-methyl, hexane, 1-butanol 3-methyl, 1-octene, octane, and others were extracted. Small molecular weight alcohols such as ethanol, isopropyl alcohol, 2-butanol, 1-butanol, 1-hexanol, and 3-hexen-1-ol were detected next to phenylethyl alcohol. Additionally, various ketones were present including acetone, 2-butanone, 2-pentanone, 3-pentanone, 2-heptanone, and 2-nonanone. The most prevalent chemical class found was esters, with varying molecules present depending on the stage of the process. The main esters that were extracted were as follows: (a) in the olive mill waste, there were ethyl acetate, hexanoic acid ethyl ester, octanoic acid ethyl ester, and acetic acid methyl ester; (b) in the storage tank, we found butanoic acid ethyl ester, ethyl acetate, hexanoic acid ethyl ester, butanoic acid methyl ester, and cyclohexanecarboxylic acid ethyl ester; (c) before the drying process, we extracted butanoic acid ethyl ester, ethyl acetate, butanoic acid methyl ester, and propanoic acid ethyl ester; and finally (d) after drying, there were acetic acid butyl ester, cyclohexanecarboxylic acid ethyl ester, propanoic acid ethyl ester, and butanoic acid ethyl ester. Furthermore, a small number of aldehydes were also emitted, such as heptanal, 2-heptenal, octanal, nonanal, and 2-decenal. The following acids were also emitted: acetic acid, propanoic acid, butanoic acid, pentanoic acid, hexanoic acid, octanoic acid, and nonanoic acid. Finally, the phenolic compounds included 2-methoxy-5-methylphenol, phenol 2-ethylphenol, and 4-ethyl-2-methoxyphenol.

Table 6 presents the major VOCs identified and semi-quantified using headspace HiSorb TD-GC-MS analysis, based on the respective I.S. Although various oxygenated compounds were identified (e.g., alcohols, ketones, esters, and acids), only the most abundant VOCs are included in Table 6. The presence of esters, phenols, and acids is highlighted.

Table 6.

Headspace HiSorb TD-GC-MS analysis results of volatile substances of oil samples from fresh two-phase olive pomace, olive pomace from the storage tank, and olive pomace before and after drying and odour thresholds [37,39].

It is clear from Table 6 that there are noticeable differences in the levels of VOCs present during the storage and drying of two-phase olive pomace. Although these compounds are emitted in low concentrations (parts per billion to parts per trillion by volume), they escape into the atmosphere during storage and drying, leading to unpleasant consequences for the surrounding area because of their very low odour threshold.

Based on the study findings, it is critical to develop and implement strategies that will mitigate environmental nuisances that are associated with two-phase pomace, such as unpleasant odours. This could involve optimizing storage conditions or adopting technologies that reduce emissions during the storage phase.

4. Conclusions

Conclusively, from this study it was made clear that the structural elements of two-phase olive pomace, such as total and volatile solids, cellulose, hemicellulose, and acid-insoluble residue, do not change significantly during storage. In addition, the high concentration of phenolic compounds may constitute an inhibiting factor for the development of the biodegradation reactions of these components. From all the instrumental analyses during the study of the effect of storage on field samples, it was evident that during drying alterations in the crystalline structure of the cellulose are observed, as well as the removal/degradation of the triglycerides of the oil. The main alterations of the two-phase olive pomace are observed in its oil content, leading to an increase in its acidity and to the production of oxidation products (aldehydes, ketones). Finally, the storage of the olive pomace results in the progress of reactions and the production of many volatile compounds, such as acids, methyl esters, and ethyl esters, which escape into the atmosphere during the drying process. As a final conclusion, it becomes clear that the appropriate parameters for monitoring the fermentation process during the storage of the two-phase olive pomace are directly related to the physicochemical characteristics of the oil content of the two-phase olive pomace. pH, conductivity, oil acidity, volatile substances concentration, K232, and K270 could stand as the monitoring parameters for the evolution of olive pomace storage. This study enhances the scientific understanding of how different storage and drying conditions affect the physicochemical characteristics of two-phase pomace, aiding in the development of sustainable waste management strategies, and also providing insights into how the manipulation of the storage and drying parameters can be leveraged to mitigate environmental nuisances associated with two-phase pomace, such as foul odours or potential pollution. In this context, guidance may be provided to the industries involved in olive oil production on the best practices for the management of two-phase pomace, promoting environmentally friendly and economically viable solutions.

Author Contributions

Conceptualization, S.M. and E.M.B.; methodology, S.M. and E.M.B.; formal analysis, A.A., S.M. and E.M.B.; investigation, A.C. and P.F.; resources, K.M. and M.L.; writing—original draft preparation, S.M. and E.M.B.; data curation, A.A., A.C., S.M. and E.M.B.; writing—review and editing, A.A., S.M. and E.M.B.; visualization, S.M. and E.M.B.; supervision, S.M. and E.M.B.; project administration, M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Regional Development Fund of the Region of Peloponnese.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Statista. Production Volume of Olive Oil Worldwide from 2012/13 to 2022/23. Available online: https://www.statista.com/statistics/613466/olive-oil-production-volume-worldwide/ (accessed on 5 August 2023).

- Olive oil times. Europe Confirms Steep Decline in Olive Oil Production. Available online: https://www.oliveoiltimes.com/production/europe-confirms-steep-decline-in-olive-oil-production/122348 (accessed on 4 July 2023).

- International Olive Council. The World of Olive Oil. Available online: https://www.internationaloliveoil.org/the-world-of-olive-oil/ (accessed on 11 September 2023).

- Romero-Gámez, M.; Castro-Rodríguez, J.; Suárez-Rey, E.M. Optimization of olive growing practices in Spain from a life cycle assessment perspective. J. Clean. Prod. 2017, 149, 25–37. [Google Scholar] [CrossRef]

- Palazzo, A.L.; Aristone, O. Peri-urban matters. changing olive growing patterns in central Italy. Sustainability 2017, 9, 638. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; Gonzalvez, J.; Garcia, D.; Cegarra, J. Agrochemical characterisation of alperujo, a solid by-product of the two-phase centrifugation method for olive oil extraction. Bioresour. Technol. 2004, 91, 195–200. [Google Scholar] [CrossRef]

- Christoforou, E.; Fokaides, P. A review of olive mill solid wastes to energy utilization techniques. Waste Manag. 2016, 49, 346–363. [Google Scholar] [CrossRef]

- Sierra, J.; Martí, E.; Garau, M.A.; Cruañas, R. Effects of the agronomic use of olive oil mill wastewater: Field experiment. Sci. Total Environ. 2007, 378, 90–94. [Google Scholar] [CrossRef]

- Ribeiro, T.B.; Oliveira, A.L.; Costa, C.; Nunes, J.; Vicente, A.A.; Pintado, M. Total and sustainable valorisation of olive pomace using a fractionation approach. Appl. Sci. 2020, 10, 6785. [Google Scholar] [CrossRef]

- Sánchez-Sánchez, C.; González-González, A.; Cuadros-Salcedo, F.; Cuadros-Blázquez, F. Two-phase Olive mill waste: A circular economy solution to an imminent problem in Southern Europe. J. Clean. Prod. 2020, 274, 122789. [Google Scholar] [CrossRef]

- Moral, P.S.; Méndez, M.V.R. Production of pomace olive oil. Grasas y Aceites 2006, 57, 47–55. [Google Scholar]

- Deutsche Gesellschaft für Internationale Zusammenarbeit GmbH. Guidance to Develop By-Products and End-of-Waste Criteria and Proposals for Draft Legislation in Greece. 2021. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en#end-of-waste-criteria (accessed on 8 November 2023).

- De Marco, I.; Riemma, S.; Iannone, R. Global Warming Potential analysis of olive pomace processing. Chem. Eng. Trans. 2017, 57, 601–606. [Google Scholar] [CrossRef]

- Doymaz, I.; Gorel, O.; Akgun, N.A. Drying characteristics of the solid by-product of olive oil extraction. Biosyst. Eng. 2004, 88, 213–219. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Ash in Biomass. Natl. Renew. Energy Lab. (NREL) 2005, 8. Available online: https://www.nrel.gov/docs/gen/fy08/42622.pdf (accessed on 10 January 2022).

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D.L.A.P. Determination of structural carbohydrates and lignin in biomass: Laboratory Analytical Procedure (LAP) (NREL/TP-510-42618). Natl. Renew. Energy Lab. (NREL) 2012, 1617, 17. [Google Scholar]

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass. Natl. Renew. Energy Lab. (NREL) 2005, 1617, 12. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Hyman, D.; Payne, D.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, J.; Wolfe, J. Determination of total solids in biomass and total dissolved solids in liquid process samples. Natl. Renew. Energy Lab. (NREL) 2008, 3–5. Available online: https://www.nrel.gov/docs/gen/fy08/42621.pdf (accessed on 10 January 2022).

- Sluiter, J.; Sluiter, A. Summative Mass Closure: Laboratory Analytical Procedure (LAP) Review and Integration: Feedstocks; Issue Date: April 2010; Revision Date: July 2011 (Version 07-08-2011). 2010. Available online: https://www.nrel.gov/docs/gen/fy11/48087.pdf (accessed on 10 January 2022).

- OIL AND GREASE. Standard Methods For the Examination of Water and Wastewater, 23rd. Available online: https://www.standardmethods.org/ (accessed on 10 January 2022).

- Nielsen, S.S. Food Analysis Laboratory Manual; Springer: West Lafayette, IN, USA, 2017. [Google Scholar] [CrossRef]

- Hewavitharana, G.G.; Perera, D.N.; Navaratne, S.B.; Wickramasinghe, I. Extraction methods of fat from food samples and preparation of fatty acid methyl esters for gas chromatography: A review. Arab. J. Chem. 2020, 13, 6865–6875. [Google Scholar] [CrossRef]

- Moreno, M.C.M.M.; Olivares, D.M.; Lopez, F.J.A.; Martinez, V.P.; Reig, F.B. Study of the formation of carbonyl compounds in edible oils and fats by 1H-NMR and FTIR. J. Mol. Struct. 1999, 482–483, 557–561. [Google Scholar] [CrossRef]

- Frangipane, M.T.; Costantini, L.; Merendino, N.; Massantini, R. Antioxidant Profile and Sensory Analysis in Olive Oils of Different Quality Grades. Agriculture 2023, 13, 993–1006. [Google Scholar] [CrossRef]

- Fella, P.; Stylianou, M.; Agapiou, A. A green sorptive extraction method (HiSorb-TD-GC-MS) for determining the extra virgin olive oil (EVOO) aroma profile. Pure Appl. Chem. 2023, 595–610. [Google Scholar] [CrossRef]

- Cecchi, L.; Migliorini, M.; Giambanelli, E.; Cane, A.; Mulinacci, N.; Zanoni, B. Volatile Profile of Two-Phase Olive Pomace (Alperujo) by HS-SPME-GC-MS as a Key to Defining Volatile Markers of Sensory Defects Caused by Biological Phenomena in Virgin Olive Oil. J. Agric. Food Chem. 2021, 69, 5155–5166. [Google Scholar] [CrossRef]

- Morillo, J.A.; Antizar-Ladislao, B.; Monteoliva-Sánchez, M.; Ramos-Cormenzana, A.; Russell, N.J. Bioremediation and biovalorisation of olive-mill wastes. Appl. Microbiol. Biotechnol. 2009, 82, 25–39. [Google Scholar] [CrossRef]

- Doula, M.K.; Moreno-Ortego, J.L.; Tinivella, F.; Inglezakis, V.J.; Sarris, A.; Komnitsas, K. Olive mill waste: Recent advances for the sustainable development of olive oil industry. Olive Mill Waste Recent Adv. Sustain. Manag. 2017, 29–56. [Google Scholar] [CrossRef]

- González-Martínez, L.; Hernández, D.; Astudillo, C.A.; Silva, A.F.; Gabriel, D. Data extracted from olive oil mill waste exposed to ambient conditions. Data Brief 2019, 26, 104555. [Google Scholar] [CrossRef]

- Maniscalco, M.P.; Volpe, M.; Volpe, R.; Messineo, A. Promoting energy recovery from recalcitrant agro-industrial wastes through anaerobic digestion: A review on olive mill residues. AIP Conf. Proc. 2018, 2040, 140012. [Google Scholar] [CrossRef]

- Serrano, A.; Fermoso, F.G.; Rodríguez-Gutierrez, G.; Fernandez-Bolaños, J.; Borja, R. Biomethanization of olive mill solid waste after phenols recovery through low-temperature thermal pre-treatment. Waste Manag. 2017, 61, 229–235. [Google Scholar] [CrossRef]

- Hernández, D.; Astudillo, C.A.; Fernández-Palacios, E.; Cataldo, F.; Tenreiro, C. Evolution of physical-chemical parameters, D.G., microbial diversity and VOC emissions of olive oil mill waste exposed to ambient conditions in open reservoirs. Waste Manag. 2018, 79, 501–509. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, M.J.; de la Lama-Calvente, D.; Jiménez-Rodríguez, A.; Borja, R.; Rincón, B. Evolution of control parameters in biochemical methane potential tests of olive mill solid waste (OMSW), thermal pre-treated OMSW, and its co-digestion with Dunaliella salina. J. Appl. Phycol. 2021, 33, 419–429. [Google Scholar] [CrossRef]

- Mahasneh, Z.M.; Abdelnour, S.; Ebrahim, A.; Almasodi, A.G.; Moustafa, M.; Alshaharni, M.O.; Algopish, U.; Tellez-Isaias, G.; El-Hack, M.E.A. Olive oil and its derivatives for promoting performance, health, and struggling thermal stress effects on broilers. Poult. Sci. 2024, 103, 103348. [Google Scholar] [CrossRef]

- Jamrah, A.; Al-Zghoul, T.M.; Darwish, M.M. A comprehensive review of combined processes for olive mill wastewater treatments. Case Stud. Chem. Environ. Eng. 2023, 8, 100493. [Google Scholar] [CrossRef]

- Manthos, G.; Zagklis, D.; Papavasileiou, V.; Gkountou, N.A.; Saita, Z.; Zafiri, C.; Kornaros, M. High-rate upflow anaerobic sludge blanket bioreactor for the treatment of olive mill effluents: Laboratory and pilot scale systems investigation. Renew. Energy 2023, 217, 119215. [Google Scholar] [CrossRef]

- Hernández, D.; Quinteros-Lama, H.; Tenreiro, C.; Gabriel, D. Assessing concentration changes of odorant compounds in the thermal-mechanical drying phase of sediment-likewastes from olive oil extraction. Appl. Sci. 2019, 9, 519. [Google Scholar] [CrossRef]

- De Castro, A.; Asencio, E.; Ruiz-Méndez, V.; Romero, C.; Brenes, M. Production of 4-ethylphenol in alperujo by Lactobacillus pentosus. J. Sci. Food Agric. 2014, 95, 2222–2227. [Google Scholar] [CrossRef]

- Nagata, Y. Measurement of Odor Threshold by Triangle Odor Bag Method. Environ. Sci. 2003, 118, 118–127. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).