Advancing Sustainable Innovations in Mulberry Vinegar Production: A Critical Review on Non-Thermal Pre-Processing Technologies

Abstract

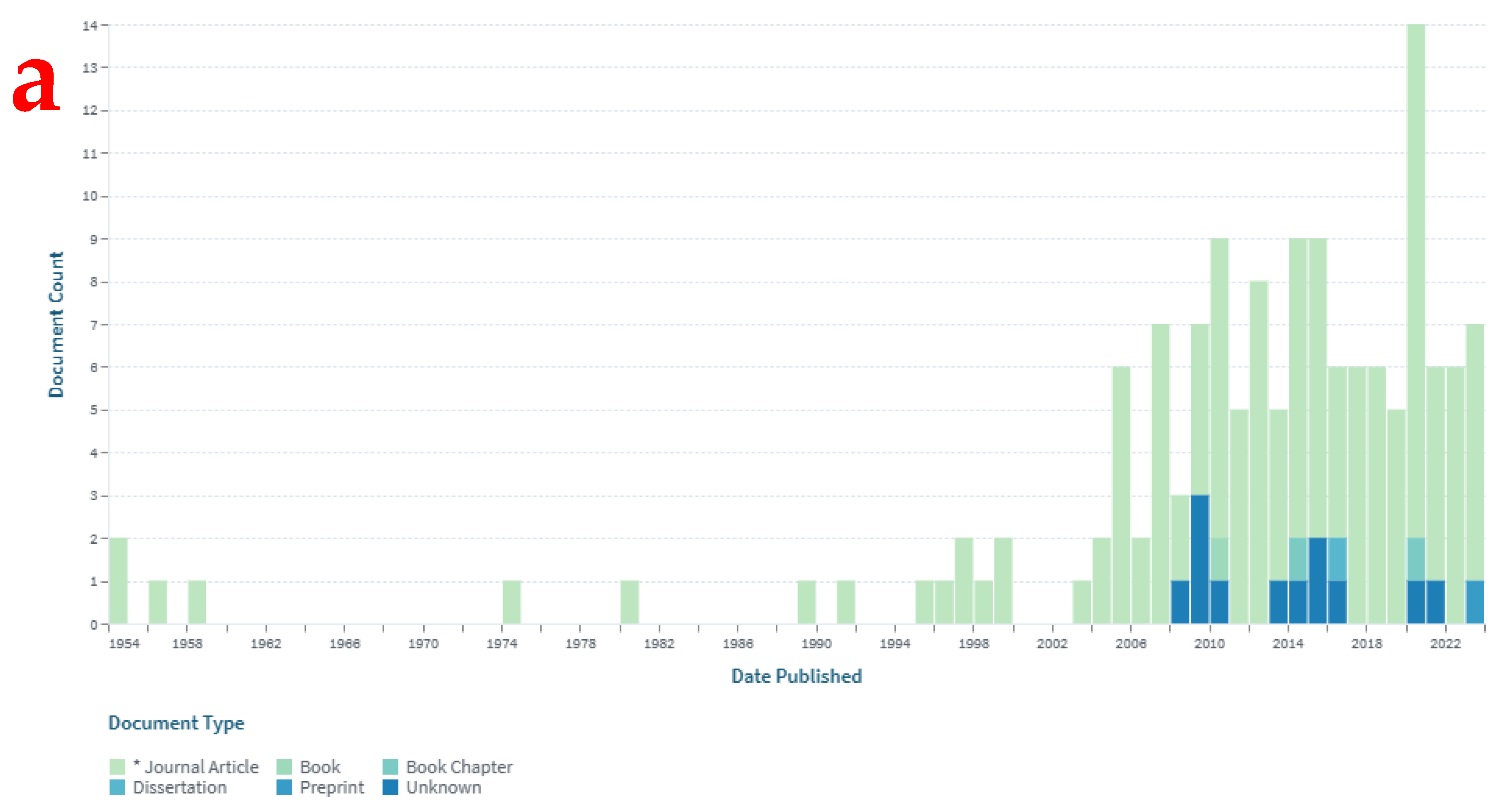

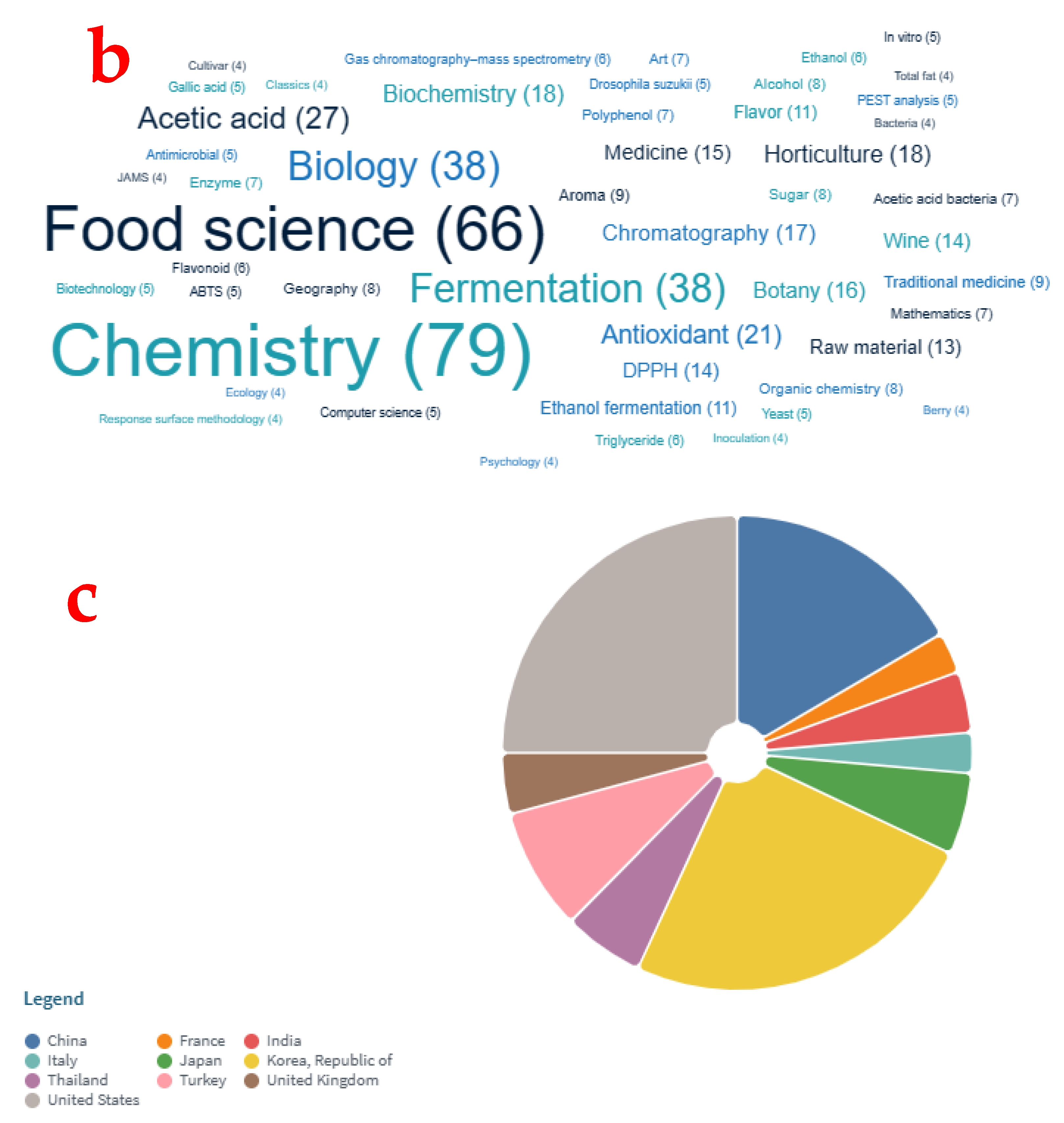

1. Introduction

2. Mulberry Vinegar Production: An Overview

3. Current Thermal Procedures in Mulberry Vinegar Production

4. Non-Thermal Pre-Processing Techniques in Mulberry Vinegar Production

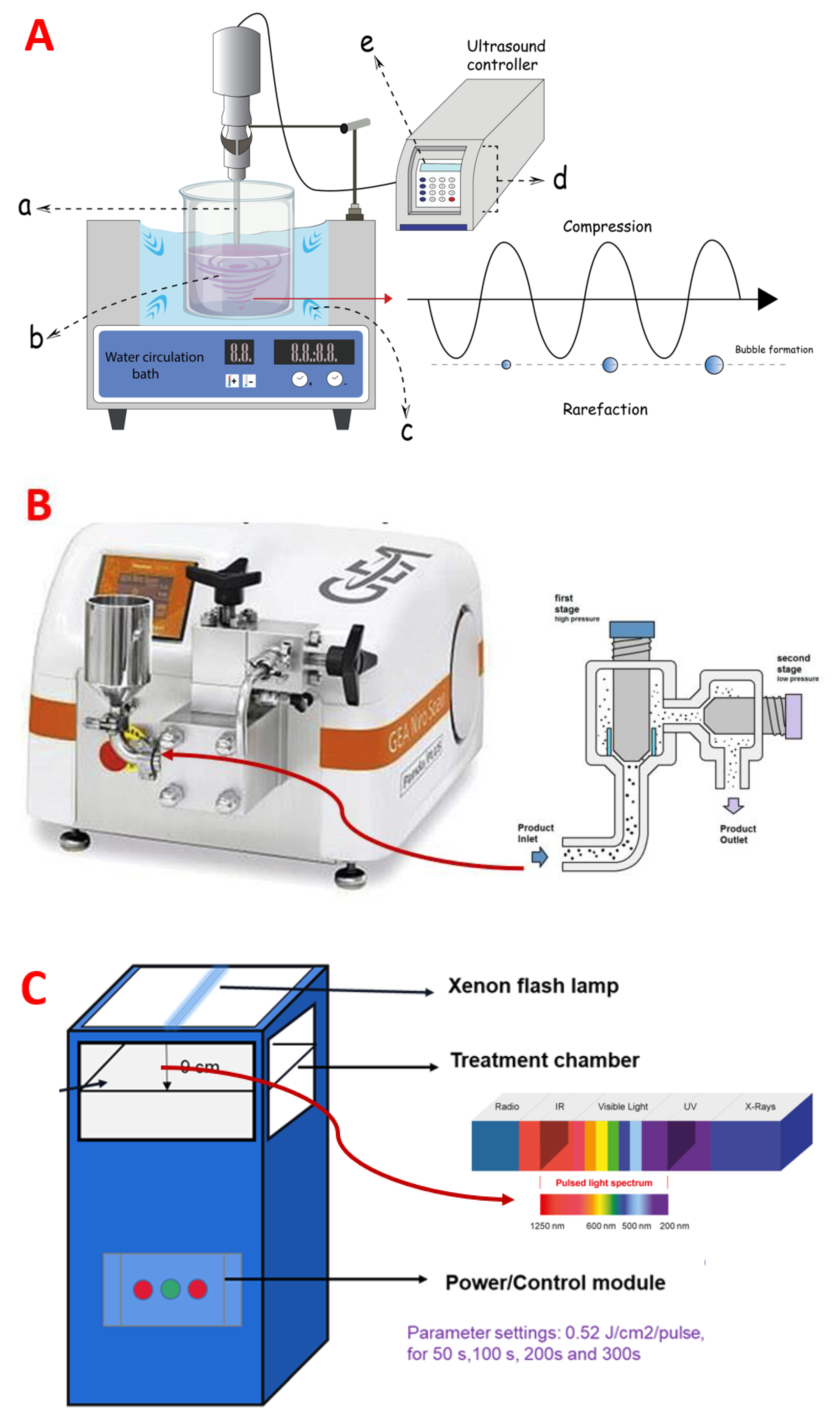

4.1. Ultrasound Technology

Ultrasonication and Ultrasonic Homogenization

4.2. Ultra-High-Pressure Homogenization

4.3. Pulsed Light Treatment

4.4. Enzymatic Pretreatment

4.5. Membrane Filtration

5. Conclusions

6. Future Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABTS•+-SA | 2,2′-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid) radical scavenging activity |

| CHM | conventional heating methods |

| DMDC | dimethyl dicarbonate |

| DPPH•-SA | 2, 2-diphenyl-1-picrylhydrazyl radical scavenging activity |

| ESI/MS | electrospray ionization–mass spectrometry |

| HHP | high hydrostatic pressure |

| HPLC | high-performance liquid chromatography |

| HS-SPME-GC–MS | headspace solid-phase microextraction gas chromatography–mass spectrometry |

| HTST | high-temperature–short-time |

| LFMJ | lactic acid-fermented mulberry juice |

| MAL | Morus alba leaves |

| MCE | mixed cellulose ester |

| MWCO | molar weight cut-off |

| NTTs | non-thermal technologies |

| OHM | ohmic heating method |

| ORAC | oxygen radical absorbance capacity |

| PEF | pulsed electric field |

| PL | pulsed light treatment |

| PME | pectin methylesterase |

| PMF | pulsed magnetic fields |

| POD | peroxidase |

| PPO | polyphenol oxidase |

| UHPH | ultra-high-pressure homogenization |

| TFC | total flavonoid content |

| TPC | total phenolic content |

References

- Zhang, H.; Ma, Z.F.; Luo, X.; Li, X. Effects of Mulberry Fruit (Morus alba L.) Consumption on Health Outcomes: A Mini-Review. Antioxidants 2018, 7, 69. [Google Scholar] [CrossRef]

- Jiang, Y.; Nie, W. Chemical properties in fruits of mulberry species from the Xinjiang province of China. Food Chem. 2015, 174, 460–466. [Google Scholar] [CrossRef]

- Can, A.; Kazankaya, A.; Orman, E.; Gundogdu, M.; Ercisli, S.; Choudhary, R.; Karunakaran, R. Sustainable Mulberry (Morus nigra L., Morus alba L. and Morus rubra L.) Production in Eastern Turkey. Sustainability 2021, 13, 13507. [Google Scholar] [CrossRef]

- Jan, B.; Parveen, R.; Zahiruddin, S.; Khan, M.C.; Mohapatra, S.; Ahmad, S. Nutritional constituents of mulberry and their potential applications in food and pharmaceuticals: A review. Saudi J. Biol. Sci. 2021, 28, 3909–3921. [Google Scholar] [CrossRef]

- Ramappa, V.K.; Srivastava, D.; Singh, P.; Kumar, U.; Kumar, D.; Gosipatala, S.B.; Saha, S.; Kumar, D.; Raj, R. Mulberries: A Promising Fruit for Phytochemicals, Nutraceuticals, and Biological Activities. Int. J. Fruit Sci. 2020, 20, S1254–S1279. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, H.; Luo, H. Uncovering the inactivation kinetics of Escherichia coli in saline by atmospheric DBD plasma using ATR FT-IR. Plasma Process. Polym. 2020, 17, 1900197. [Google Scholar] [CrossRef]

- Song, S.; Shi, J.; Duan, Y.; Wang, J.; Gao, H.; Liu, B. Distribution Characteristics and Industrialization Development of Mulberry in Mu Us Desert. Agric. For. Econ. Manag. 2022, 5, 55–62. [Google Scholar]

- Samami, R.; Seidavi, A.; Eila, N.; Moarefi, M.; Ziaja, D.J.; Lis, J.A.; Rubiu, N.G.; Cappai, M.G. Production performance and economic traits of silkworms (Bombyx mori L., 1758) fed with mulberry tree leaves (Morus alba, var. Ichinose) significantly differ according to hybrid lines. Livest. Sci. 2019, 226, 133–137. [Google Scholar] [CrossRef]

- Wang, B.; Luo, H. Effects of mulberry leaf silage on antioxidant and immunomodulatory activity and rumen bacterial community of lambs. BMC Microbiol. 2021, 21, 250. [Google Scholar] [CrossRef]

- Alipanah, M.; Abedian, Z.; Nasiri, A.; Sarjamei, F. Nutritional Effects of Three Mulberry Varieties on Silkworms in Torbat Heydarieh. J. Entomol. 2020, 2020, 6483427. [Google Scholar] [CrossRef]

- Choosung, P.; Wasusri, T.; Utto, W.; Boonyaritthongchai, P.; Wongs-Aree, C. The supply chain and its development concept of fresh mulberry fruit in Thailand: Observations in Nan Province, the largest production area. Open Agric. 2022, 7, 401–419. [Google Scholar] [CrossRef]

- Kobus-Cisowska, J.; Dziedzinski, M.; Szymanowska, D.; Szczepaniak, O.; Byczkiewicz, S.; Telichowska, A.; Szulc, P. The Effects of Morus alba L. Fortification on the Quality, Functional Properties and Sensory Attributes of Bread Stored under Refrigerated Conditions. Sustainability 2020, 12, 6691. [Google Scholar] [CrossRef]

- Rohela, G.K.; Shukla, P.; Kallur, M.; Kumar, R.; Chowdhury, S.R. Mulberry (Morus spp.): An ideal plant for sustainable development. Trees For. People 2020, 2, 100011. [Google Scholar] [CrossRef]

- Wen, P.; Hu, T.-G.; Linhardt, R.J.; Liao, S.-T.; Wu, H.; Zou, Y.-X. Mulberry: A review of bioactive compounds and advanced processing technology. Trends Food Sci. Technol. 2019, 83, 138–158. [Google Scholar] [CrossRef]

- Oktay, Y. Physicochemical and sensory properties of mulberry products: Gümüşhane pestil and köme. Turk. J. Agric. For. 2013, 37, 762–771. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhao, L. The Mulberry (Morus alba L.) Fruit—A Review of Characteristic Components and Health Benefits. J. Agric. Food Chem. 2017, 65, 10383–10394. [Google Scholar] [CrossRef]

- Dzah, C.S.; Duan, Y.; Zhang, H.; Boateng, N.A.S.; Ma, H. Latest developments in polyphenol recovery and purification from plant by-products: A review. Trends Food Sci. Technol. 2020, 99, 375–388. [Google Scholar] [CrossRef]

- Gialos, A.; Zeimpekis, V.; Madas, M.; Papageorgiou, K. Calculation and Assessment of CO2e Emissions in Road Freight Transportation: A Greek Case Study. Sustainability 2022, 14, 10724. [Google Scholar] [CrossRef]

- Mahboubi, M. Morus alba (mulberry), a natural potent compound in management of obesity. Pharmacol. Res. 2019, 146, 104341. [Google Scholar] [CrossRef]

- Feng, Y.; Liu, M.; Ouyang, Y.; Zhao, X.; Ju, Y.; Fang, Y. Comparative study of aromatic compounds in fruit wines from raspberry, strawberry, and mulberry in central Shaanxi area. Food Nutr. Res. 2015, 59, 29290. [Google Scholar] [CrossRef]

- Oza, A.D.; Dave, R.B.; Rathi, M.G.; Mane, D.V.; Shankar, P.; Boopathi, R.; Prabu, M.; Singh, H.; Copper, G.V.S.; Copper, B.; et al. Republic of Korea Intellectual Property Office (Kr) Public Patent Publication. In Proceedings of the World Congress on Engineering 2012 Vol III WCE 2012, London, UK, 4–6 July 2012; Volume 19, pp. 1–17. [Google Scholar]

- Ochando, T.; Mouret, J.R.; Humbert-Goffard, A.; Aguera, E.; Sablayrolles, J.M.; Farines, V. Comprehensive study of the dynamic interaction between SO2 and acetaldehyde during alcoholic fermentation. Food Res. Int. 2020, 136, 109607. [Google Scholar] [CrossRef]

- Sedjoah, R.A.; Ma, Y.; Xiong, M.; Yan, H. Fast monitoring total acids and total polyphenol contents in fermentation broth of mulberry vinegar using MEMS and optical fiber near-infrared spectrometers. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2021, 260, 119938. [Google Scholar] [CrossRef]

- Ekonomou, S.I.; Boziaris, I.S. Non-Thermal Methods for Ensuring the Microbiological Quality and Safety of Seafood. Appl. Sci. 2021, 11, 833. [Google Scholar] [CrossRef]

- Li, X.; Farid, M. A review on recent development in non-conventional food sterilization technologies. J. Food Eng. 2016, 182, 33–45. [Google Scholar] [CrossRef]

- Darvishi, H.; Salami, P.; Fadavi, A.; Saba, M.K. Processing kinetics, quality and thermodynamic evaluation of mulberry juice concentration process using Ohmic heating. Food Bioprod. Process. 2020, 123, 102–110. [Google Scholar] [CrossRef]

- Hardinasinta, G.; Salengke, S.; Mursalim; Muhidong, J. Evaluation of ohmic heating for sterilization of berry-like fruit juice of mulberry (Morus nigra), bignay (Antidesma bunius), and jambolana (Syzygium cumini). In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1034. [Google Scholar] [CrossRef]

- Fazaeli, M.; Hojjatpanah, G.; Emam-Djomeh, Z. Effects of heating method and conditions on the evaporation rate and quality attributes of black mulberry (Morus nigra) juice concentrate. J. Food Sci. Technol. 2013, 50, 35–43. [Google Scholar] [CrossRef]

- Hojjatpanah, G.; Emam-Djomeh, Z.; Ashtari, A.K.; Mirsaeedghazi, H.; Omid, M. Evaluation of the fouling phenomenon in the membrane clarification of black mulberry juice. Int. J. Food Sci. Technol. 2011, 46, 1538–1544. [Google Scholar] [CrossRef]

- Hojjatpanah, G.; Fazaeli, M.; Emam-Djomeh, Z. Effects of heating method and conditions on the quality attributes of black mulberry (Morus nigra) juice concentrate. Int. J. Food Sci. Technol. 2011, 46, 956–962. [Google Scholar] [CrossRef]

- Fazaeli, M.; Yousefi, S.; Emam-Djomeh, Z. Investigation on the effects of microwave and conventional heating methods on the phytochemicals of pomegranate (Punica granatum L.) and black mulberry juices. Food Res. Int. 2013, 50, 568–573. [Google Scholar] [CrossRef]

- Dincer, C.; Tontul, I.; Topuz, A. A comparative study of black mulberry juice concentrates by thermal evaporation and osmotic distillation as influenced by storage. Innov. Food Sci. Emerg. Technol. 2016, 38, 57–64. [Google Scholar] [CrossRef]

- Chottamom, P.; Kongmanee, R.; Manklang, C.; Soponronnarit, S. Effect of Osmotic Treatment on Drying Kinetics and Antioxidant Properties of Dried Mulberry. Dry. Technol. 2012, 30, 80–87. [Google Scholar] [CrossRef]

- Ongaratto, R.S.; Menezes, L.; Borges, C.P.; Laranjeira da Cunha Lage, P. Osmotic distillation applying potassium pyrophosphate as brine. J. Food Eng. 2018, 228, 69–78. [Google Scholar] [CrossRef]

- Hii, C.L.; Tan, C.H.; Woo, M.W. Special Issue “Recent Advances in Thermal Food Processing Technologies”. Processes 2023, 11, 288. [Google Scholar] [CrossRef]

- Allai, F.M.; Azad, Z.R.A.A.; Mir, N.A.; Gul, K. Recent advances in non-thermal processing technologies for enhancing shelf life and improving food safety. Appl. Food Res. 2023, 3, 100258. [Google Scholar] [CrossRef]

- Chacha, J.S.; Zhang, L.; Ofoedu, C.E.; Suleiman, R.A.; Dotto, J.M.; Roobab, U.; Agunbiade, A.O.; Duguma, H.T.; Mkojera, B.T.; Hossaini, S.M.; et al. Revisiting Non-Thermal Food Processing and Preservation Methods-Action Mechanisms, Pros and Cons: A Technological Update (2016–2021). Foods 2021, 10, 1430. [Google Scholar] [CrossRef] [PubMed]

- Jadhav, H.B.; Annapure, U.S.; Deshmukh, R.R. Non-thermal Technologies for Food Processing. Front. Nutr. 2021, 8, 657090. [Google Scholar] [CrossRef] [PubMed]

- Arshad, R.N.; Abdul-Malek, Z.; Munir, A.; Buntat, Z.; Ahmad, M.H.; Jusoh, Y.M.M.; Bekhit, A.E.; Roobab, U.; Manzoor, M.F.; Aadil, R.M. Electrical systems for pulsed electric field applications in the food industry: An engineering perspective. Trends Food Sci. Technol. 2020, 104, 1–13. [Google Scholar] [CrossRef]

- Ranjha, M.M.A.N.; Kanwal, R.; Shafique, B.; Arshad, R.N.; Irfan, S.; Kieliszek, M.; Kowalczewski, P.L.; Irfan, M.; Khalid, M.Z.; Roobab, U.; et al. A Critical Review on Pulsed Electric Field: A Novel Technology for the Extraction of Phytoconstituents. Molecules 2021, 26, 4893. [Google Scholar] [CrossRef] [PubMed]

- Arshad, R.N.; Abdul-Malek, Z.; Roobab, U.; Munir, M.A.; Naderipour, A.; Qureshi, M.I.; Bekhit, A.E.; Liu, Z.; Aadil, R.M. Pulsed electric field: A potential alternative towards a sustainable food processing. Trends Food Sci. Technol. 2021, 111, 43–54. [Google Scholar] [CrossRef]

- Pan, Y.; Cheng, J.; Sun, D. Cold Plasma-Mediated Treatments for Shelf Life Extension of Fresh Produce: A Review of Recent Research Developments. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1312–1326. [Google Scholar] [CrossRef]

- Yang, N.; Huang, K.; Lyu, C.; Wang, J. Pulsed electric field technology in the manufacturing processes of wine, beer, and rice wine: A review. Food Control 2016, 61, 28–38. [Google Scholar] [CrossRef]

- Artíguez, M.L.; de Marañón, I.M. Inactivation of spores and vegetative cells of Bacillus subtilis and Geobacillus stearothermophilus by pulsed light. Innov. Food Sci. Emerg. Technol. 2015, 28, 52–58. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Xiao, Y.; Peng, Y.; He, J.; Chen, C.; Xiao, D.; Yin, Y.; Li, F. Mulberry leaf powder regulates antioxidative capacity and lipid metabolism in finishing pigs. Anim. Nutr. 2021, 7, 421–429. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Sun, L.; Dong, K.; Wang, G.; Luo, P.; Tang, D.; Huang, Q. Mulberry fruit powder enhanced the antioxidant capacity and gel properties of hammered minced beef: Oxidation degree, rheological, and structure. LWT 2022, 154, 112648. [Google Scholar] [CrossRef]

- Nguyen, C.L.; Nguyen, H.V.H. Ultrasonic Effects on the Quality of Mulberry Juice. Beverages 2018, 4, 56. [Google Scholar] [CrossRef]

- Kwaw, E.; Ma, Y.; Tchabo, W.; Apaliya, M.T.; Sackey, A.S.; Wu, M.; Xiao, L. Effect of pulsed light treatment on the phytochemical, volatile, and sensorial attributes of lactic-acid-fermented mulberry juice. Int. J. Food Prop. 2018, 21, 213–228. [Google Scholar] [CrossRef]

- Tchabo, W.; Ma, Y.; Kwaw, E.; Zhang, H.; Xiao, L.; Apaliya, M.T. Statistical interpretation of chromatic indicators in correlation to phytochemical profile of a sulfur dioxide-free mulberry (Morus nigra) wine submitted to non-thermal maturation processes. Food Chem. 2018, 239, 470–477. [Google Scholar] [CrossRef] [PubMed]

- Pahontu, A.M.; Stefan, D.S.; Chiriac, F.L.; Calinescu, I.; Dancila, A.M.; Stefan, M. Enhanced Degradation of Bisphenol A via Ultrasound, Assisted by Chemical Treatment. Sustainability 2023, 15, 14058. [Google Scholar] [CrossRef]

- Onyeaka, H.; Miri, T.; Hart, A.; Anumudu, C.; Nwabor, O.F. Application of Ultrasound Technology in Food Processing with emphasis on bacterial spores. Food Rev. Int. 2021, 39, 3663–3675. [Google Scholar] [CrossRef]

- Boateng, I.D.; Kumar, R.; Daubert, C.R.; Flint-Garcia, S.; Mustapha, A.; Kuehnel, L.; Agliata, J.; Li, Q.; Wan, C.; Somavat, P. Sonoprocessing improves phenolics profile, antioxidant capacity, structure, and product qualities of purple corn pericarp extract. Ultrason. Sonochem. 2023, 95, 106418. [Google Scholar] [CrossRef]

- Patrignani, F.; Siroli, L.; Braschi, G.; Lanciotti, R. Combined use of natural antimicrobial based nanoemulsions and ultra high pressure homogenization to increase safety and shelf-life of apple juice. Food Control 2020, 111, 107051. [Google Scholar] [CrossRef]

- Li, F.; Boateng, I.D.; Chen, S.; Yang, X.; Soetanto, D.A.; Liu, W. Pulsed light irradiation improves degradation of ginkgolic acids and retainment of ginkgo flavonoids and terpene trilactones in Ginkgo biloba leaves. Ind. Crops Prod. 2023, 204, 117297. [Google Scholar] [CrossRef]

- Krakowska-Sieprawska, A.; Rafinska, K.; Walczak-Skierska, J.; Buszewski, B. The Influence of Plant Material Enzymatic Hydrolysis and Extraction Conditions on the Polyphenolic Profiles and Antioxidant Activity of Extracts: A Green and Efficient Approach. Molecules 2020, 25, 2074. [Google Scholar] [CrossRef]

- Zhang, W.; Shen, Y.; Li, Z.; Xie, X.; Gong, E.S.; Tian, J.; Si, X.; Wang, Y.; Gao, N.; Shu, C.; et al. Effects of high hydrostatic pressure and thermal processing on anthocyanin content, polyphenol oxidase and β-glucosidase activities, color, and antioxidant activities of blueberry (Vaccinium Spp.) puree. Food Chem. 2021, 342, 128564. [Google Scholar] [CrossRef]

- Engmann, F.N.; Ma, Y.; Tchabo, W.; Ma, H. Ultrasonication Treatment Effect on Anthocyanins, Color, Microorganisms and Enzyme Inactivation of Mulberry (Moraceae nigra) Juice. J. Food Process. Preserv. 2014, 39, 854–862. [Google Scholar] [CrossRef]

- Manzoor, M.F.; Xu, B.; Khan, S.; Shukat, R.; Ahmad, A.; Imran, M.; Rehman, A.; Karrar, E.; Aadil, R.M.; Sameh, A.; et al. Impact of high-intensity thermosonication treatment on spinach juice: Bioactive compounds, rheological, microbial, and enzymatic activities. Ultrason. Sonochem. 2021, 78, 105740. [Google Scholar] [CrossRef]

- Abdulstar, A.R.; Altemimi, A.B.; Al-Hilphy, A.R. Exploring the Power of Thermosonication: A Comprehensive Review of Its Applications and Impact in the Food Industry. Foods 2023, 12, 1459. [Google Scholar] [CrossRef]

- Zabot, G.L.; Viganó, J.; Silva, E.K. Low-Frequency Ultrasound Coupled with High-Pressure Technologies: Impact of Hybridized Techniques on the Recovery of Phytochemical Compounds. Molecules 2021, 26, 5117. [Google Scholar] [CrossRef]

- Sauceda-Gálvez, J.N.; Roca-Couso, R.; Martinez-Garcia, M.; Hernández-Herrero, M.M.; Gervilla, R.; Roig-Sagués, A.X. Inactivation of ascospores of Talaromyces macrosporus and Neosartorya spinosa by UV-C, UHPH and their combination in clarified apple juice. Food Control 2019, 98, 120–125. [Google Scholar] [CrossRef]

- de Moraes Melhem, L.C.; Rosario, D.K.A.D.; Monteiro, M.L.G.; Conte-Junior, C.A. High-Pressure Processing and Natural Antimicrobials Combined Treatments on Bacterial Inactivation in Cured Meat. Sustainability 2022, 14, 10503. [Google Scholar] [CrossRef]

- Tian, H.; Liu, C. Preserving Raw Oysters with High Hydrostatic Pressure and Irradiation Technology. Sustainability 2023, 15, 14557. [Google Scholar] [CrossRef]

- Morata, A.; Loira, I.; Vejarano, R.; González, C.; Callejo, M.J.; Suárez-Lepe, J.A. Emerging preservation technologies in grapes for winemaking. Trends Food Sci. Technol. 2017, 67, 36–43. [Google Scholar] [CrossRef]

- Yu, Y.; Xu, Y.; Wu, J.; Xiao, G.; Fu, M.; Zhang, Y. Effect of ultra-high pressure homogenisation processing on phenolic compounds, antioxidant capacity and anti-glucosidase of mulberry juice. Food Chem. 2014, 153, 114–120. [Google Scholar] [CrossRef]

- Yu, Y.; Wu, J.; Xu, Y.; Xiao, G.; Zou, B. Effect of High Pressure Homogenization and Dimethyl Dicarbonate (DMDC) on Microbial and Physicochemical Qualities of Mulberry Juice. J. Food Sci. 2016, 81, M702–M708. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Du, B.L.; Cui, Z.W.; Xu, L.P.; Li, C.Y. Effects of high hydrostatic pressure and thermal processing on bioactive compounds, antioxidant activity, and volatile profile of mulberry juice. Food Sci. Technol. Int. 2017, 23, 119–127. [Google Scholar] [CrossRef] [PubMed]

- Es-sbata, I.; Castro, R.; Durán-Guerrero, E.; Zouhair, R.; Astola, A. Production of prickly pear (Opuntia ficus-indica) vinegar in submerged culture using Acetobacter malorum and Gluconobacter oxydans: Study of volatile and polyphenolic composition. J. Food Compos. Anal. 2022, 112, 104699. [Google Scholar] [CrossRef]

- Engmann, F.N.; Ma, Y.; Ying, X.; Qing, Y. Investigating the Effect of High Hydrostatic Pressure Processing on Anthocyanins Composition of Mulberry (Morus moraceae) Juice. Czech J. Food Sci. 2013, 31, 72–80. [Google Scholar] [CrossRef]

- Nabi, B.G.; Mukhtar, K.; Arshad, R.N.; Radicetti, E.; Tedeschi, P.; Shahbaz, M.U.; Walayat, N.; Nawaz, A.; Inam-Ur-Raheem, M.; Aadil, R.M. High-Pressure Processing for Sustainable Food Supply. Sustainability 2021, 13, 13908. [Google Scholar] [CrossRef]

- Oms-Oliu, G.; Martín-Belloso, O.; Soliva-Fortuny, R. Pulsed Light Treatments for Food Preservation. A Review. Food Bioprocess Technol. 2008, 3, 13–23. [Google Scholar] [CrossRef]

- Sarika, K.; Bindu, J. An overview of non-thermal preservation techniques in food. Agric. Food Sci. 2018, 1996, 99–108. [Google Scholar]

- Palgan, I.; Caminiti, I.M.; Muñoz, A.; Noci, F.; Whyte, P.; Morgan, D.J.; Cronin, D.A.; Lyng, J.G. Effectiveness of High Intensity Light Pulses (HILP) treatments for the control of Escherichia coli and Listeria innocua in apple juice, orange juice and milk. Food Microbiol. 2011, 28, 14–20. [Google Scholar] [CrossRef] [PubMed]

- Kwaw, E.; Ma, Y.; Tchabo, W.; Apaliya, M.T.; Sackey, A.S.; Wu, M.; Xiao, L. Impact of ultrasonication and pulsed light treatments on phenolics concentration and antioxidant activities of lactic-acid-fermented mulberry juice. LWT 2018, 92, 61–66. [Google Scholar] [CrossRef]

- Perreault, V.; Gouin, N.; Bérubé, A.; Villeneuve, W.; Pouliot, Y.; Doyen, A. Effect of Pectinolytic Enzyme Pretreatment on the Clarification of Cranberry Juice by Ultrafiltration. Membranes 2021, 14, 55. [Google Scholar] [CrossRef] [PubMed]

- Velasco, D.; Senit, J.J.; De la Torre, I.; Santos, T.M.; Yustos, P.; Santos, V.E.; Ladero, M. Optimization of the Enzymatic Saccharification Process of Milled Orange Wastes. Fermentation 2017, 3, 37. [Google Scholar] [CrossRef]

- Nguyen, C.; Nguyen, H. The Quality of Mulberry Juice as Affected by Enzyme Treatments. Beverages 2018, 4, 41. [Google Scholar] [CrossRef]

- Sun, T.; Powers, J.R.; Tang, J. Effect of enzymatic macerate treatment on rutin content, antioxidant activity, yield, and physical properties of asparagus juice. J. Food Sci. 2007, 72, S267–S271. [Google Scholar] [CrossRef]

- Oszmianski, J.; Wojdylo, A.; Kolniak, J. Effect of pectinase treatment on extraction of antioxidant phenols from pomace, for the production of puree-enriched cloudy apple juices. Food Chem. 2011, 127, 623–631. [Google Scholar] [CrossRef] [PubMed]

- Padayachee, A.; Netzel, G.; Netzel, M.; Day, L.; Zabaras, D.; Mikkelsen, D.; Gidley, M.J. Binding of polyphenols to plant cell wall analogues—Part 2: Phenolic acids. Food Chem. 2012, 135, 2287–2292. [Google Scholar] [CrossRef]

- Qadir, R.; Anwar, F.; Gilani, M.A.; Zahoor, S.; ur Rehman, M.M.; Mustaqeem, M. RSM/ANN based optimized recovery of phenolics from mulberry leaves by enzyme-assisted extraction. Czech J. Food Sci. 2019, 37, 99–105. [Google Scholar] [CrossRef]

- Yang, N.; Zhang, N.; Jin, Y.; Jin, Z.; Xu, X. Development of a fluidic system for efficient extraction of mulberry leaves polysaccharide using induced electric fields. Sep. Purif. Technol. 2017, 172, 318–325. [Google Scholar] [CrossRef]

- Loizzo, M.R.; Sicari, V.; Tundis, R.; Leporini, M.; Falco, T.; Calabrò, V. The Influence of Ultrafiltration of Citrus limon L. Burm. cv Femminello Comune Juice on Its Chemical Composition and Antioxidant and Hypoglycemic Properties. Antioxidants 2019, 8, 23. [Google Scholar] [CrossRef] [PubMed]

- Cosio, M.S.; Pellicanò, A.; Gardana, C.; Fuenmayor, C.A. Debittering of Grape Juice by Electrospun Nylon Nanofibrous Membranes: Impact of Filtration on Physicochemical, Functional, and Sensory Properties. Polymers 2023, 15, 192. [Google Scholar] [CrossRef] [PubMed]

- Quezada, C.; Estay, H.; Cassano, A.; Troncoso, E.; Ruby-Figueroa, R. Prediction of Permeate Flux in Ultrafiltration Processes: A Review of Modeling Approaches. Membranes 2021, 11, 368. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Yan, H.; Li, W.; Zhao, J.; Ming, J. A Comparative Study of the Effects of Ultrafiltration Membranes and Storage on Phytochemical and Color Properties of Mulberry Juice. J. Food Sci. 2019, 84, 3565–3572. [Google Scholar] [CrossRef]

- Xiong, Q.M.; Liu, J.; Liu, M.; Shen, C.H.; Yu, X.C.; Wu, C.D.; Huang, J.; Zhou, R.Q.; Jin, Y. Fouling analysis and permeate quality evaluation of mulberry wine in microfiltration process. RSC Adv. 2020, 10, 655–665. [Google Scholar] [CrossRef]

| Non-Thermal Technologies | Treatment Conditions | Effects and Outcomes | Key Findings | References |

|---|---|---|---|---|

| Ultrasonication | Operating frequencies: 20–500 MHz | Bioactive compound extraction | Enhancement of bioactive compound extraction | [51] |

| Optimal conditions for LAFMJ (low-temperature ultrasonic-assisted fermentation of mulberry juice) | Cellular breakdown and efficiency improvement | Study on LAFMJ: sonication at 24 kHz, 10 min, and 60 W increased a* (redness) and ΔE (total color difference) values Improved phytochemical properties of fermented juice | [48] | |

| Optimal conditions for ultrasonic treatment vs. pressing on juice yield and quality: 45 °C for 60 min | Impact on color and phytochemical properties Comparison of ultrasonic treatment vs. pressing alone | Ultrasonic treatment (UT) vs. pressing alone: extraction yield from UT increased total soluble solids (8.7%), titratable acidity (39.3%), L-Ascorbic acid content (94.3%), total phenolic content (174.1%), total anthocyanin content (156.9%), antioxidant capacity (40.7%) | [47] | |

| Ultra-high-pressure homogenization | UHPH | Inactivation of microorganisms Bioactive compounds and antioxidant activity | Impact on molds (M. circinelloides) Elevated levels of TPC and α-glucosidase inhibitory activity | [66] |

| HPH and DMDC (HPH passes at 200 MPa or the addition of 250 mg/L DMDC) | Total plate count and α-glucosidase inhibitory activity | Reduction in microbial counts (log CFU/mL) Specific levels of bioactive compounds (resveratrol 24.20 µg/mL) and antioxidant activity (oxygen radical absorbance capacity 481.68 µmol TE/mL) | [66] | |

| HPH: 500 MPa for 10 min | Total phenolic content (TPC) Total flavonoid content (TFC) | Maintenance of TPC and TFC levels (4.27 mg GAE/mL and 7.25 mg RE/mL, respectively) | [67] | |

| HHP: 200, 400, and 600 MPa for 20 min | Volatile compound concentrations Anthocyanin detection and composition | Enhancement of volatile compound concentrations (alcohols, aldehydes, and ketones) Detection of new anthocyanins under HHP treatment at different pressure levels | [68] | |

| Pulsed light treatment | UT (ultrasonic treatment) and PL (pulsed light treatment) | Microbial load reduction | Viable microbial count: 1.02 ± 0.04 log10 CFU/mL | [48] |

| parameters: 1.213 Jcm−2pulse−1, 360 μs, 3 Hz, 4 s | Extended shelf life (6 months at 5 °C) | |||

| Enzymatic pretreatment | Enzymes used: kemzyme dry-plus, natuzyme, zympex-014 Incubation periods (60 to 240 min), enzyme concentration (5%), pH (8.5), temperature (70 °C), duration (45 min) | Comparison of MAL extract yield from enzymes: zympex-014 vs. natuzyme vs. kemzyme dry-plus | Extraction yield at different time intervals: Pectinex Ultra SP-L (60–180 min): 84.3% to 87.1% Viscozyme L (60–180 min): 82.3% to 83.4% Beyond 180 min: 84.9 ± 0.19% Common maximum extraction yield: 30.00 g/100 g | [81] |

| Membrane filtration techniques | MF (microfiltration) and UF (ultrafiltration) | Particle permeation and Rf values: | Initial polyphenol content: 809 mg per 100 mL juice | [29] |

| Membrane: MCE (mixed cellulose ester) | MF pore size 0.1 µm to MF pore size 0.22 µm | Polyphenol content after membrane clarification: 396.3 mg per 100 mL juice | [29] | |

| Pore sizes investigated: 0.1 µm, 0.22 µm, 0.025 µm | UF pore size 0.025 µm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boasiako, T.A.; Boateng, I.D.; Ekumah, J.-N.; Johnson, N.A.N.; Appiagyei, J.; Murtaza, M.S.; Mubeen, B.; Ma, Y. Advancing Sustainable Innovations in Mulberry Vinegar Production: A Critical Review on Non-Thermal Pre-Processing Technologies. Sustainability 2024, 16, 1185. https://doi.org/10.3390/su16031185

Boasiako TA, Boateng ID, Ekumah J-N, Johnson NAN, Appiagyei J, Murtaza MS, Mubeen B, Ma Y. Advancing Sustainable Innovations in Mulberry Vinegar Production: A Critical Review on Non-Thermal Pre-Processing Technologies. Sustainability. 2024; 16(3):1185. https://doi.org/10.3390/su16031185

Chicago/Turabian StyleBoasiako, Turkson Antwi, Isaac Duah Boateng, John-Nelson Ekumah, Nana Adwoa Nkuma Johnson, Jeffrey Appiagyei, Mian Shamas Murtaza, Bismillah Mubeen, and Yongkun Ma. 2024. "Advancing Sustainable Innovations in Mulberry Vinegar Production: A Critical Review on Non-Thermal Pre-Processing Technologies" Sustainability 16, no. 3: 1185. https://doi.org/10.3390/su16031185

APA StyleBoasiako, T. A., Boateng, I. D., Ekumah, J.-N., Johnson, N. A. N., Appiagyei, J., Murtaza, M. S., Mubeen, B., & Ma, Y. (2024). Advancing Sustainable Innovations in Mulberry Vinegar Production: A Critical Review on Non-Thermal Pre-Processing Technologies. Sustainability, 16(3), 1185. https://doi.org/10.3390/su16031185