3.1. Life Cycle Assessment

The Bibliometric Map generated based on a density visualization of research trends over 20 years (2003–2023) is shown in

Figure 4.

According to the result presented in

Figure 4, in 2003, the main focus of studies on WTP sludge treatment was the adsorption of phosphorus and other elements, while in 2013, adsorption mechanisms and the development of reuse strategies were the main focus. In 2023, energy recovery and carbon footprint reduction were the main focus of WTP sludge treatment. Balbinoti et al. [

1] state that there is an effort by industries to minimize the impact generated by the treatment of industrial waters, especially regarding the search for the use of biocoagulants, such as tannin-based coagulants. Pratibha and Fahad [

4] investigated

Moringa oleifera as vegetable coagulants in the treatment of wastewater from the dairy industry and slaughterhouses, respectively, and reported 90% removal of color and turbidity, while obtaining a reduction of 64% in chemical oxygen demand. In summary, the search for best practices in the industrial water treatment process has intensified in the last 20 years, as shown in

Figure 4.

The amount and properties of WTP sludge are specific to each location, which is dependent on different factors such as seasonal changes in raw water quality, treatment process technology, and chemical use [

29]. The silica (SiO

2) accounts for a significant part of the sludge composition, which comes mainly from the raw water, followed by aluminum oxide (Al

2O

3)) and Iron oxide (Fe

2O

3) from the coagulants used in the WTP [

30].

The proportions of (Al

2O

3) and (Fe

2O

3) are directly related to the dose and type of coagulants used in the WTP. Aluminum-based and iron-based coagulants are the most popular chemicals used for coagulation and flocculation processes [

31]. The metallic coagulant’s popularity is due to their comparatively low cost, high availability, and high efficiency in removing water turbidity and color [

32].

Aluminum sulphate [Al

2(SO

4)

3] and aluminum chloride (AlCl

3) are the most common metallic coagulants, which are used in water and wastewater treatment [

33]. Aluminum content varies greatly among WTP sludges, which accounts for approximately 16% of the mass composition on average [

34]. Other major components of WTP sludges are calcium (Ca), silicon dioxide (SiO

22−), iron (Fe), chloride (Cl

−), sulfate (SiO

42−), and humic acids.

In addition, other oxides such as calcium oxide (CaO), magnesium oxide (MgO), sodium oxide (Na

2O), potassium oxide (K

2O), and phosphate (P

2O

5), as well as some trace metals, can be found in the WTP sludge. The main physical characteristics and chemical composition of WTP sludge are summarized in

Table 4 and

Table 5, respectively.

The adequate use of water in the Brazilian semi-arid region is a key water security strategy as around 27 million people use water from this region for domestic consumption (

Figure 3). The physical-climatic conditions that prevail in the Brazilian semi-arid region require more commitment and greater rationality in the management of natural resources, mainly water. As a result, industries need to act more efficiently in water resource preservation and use.

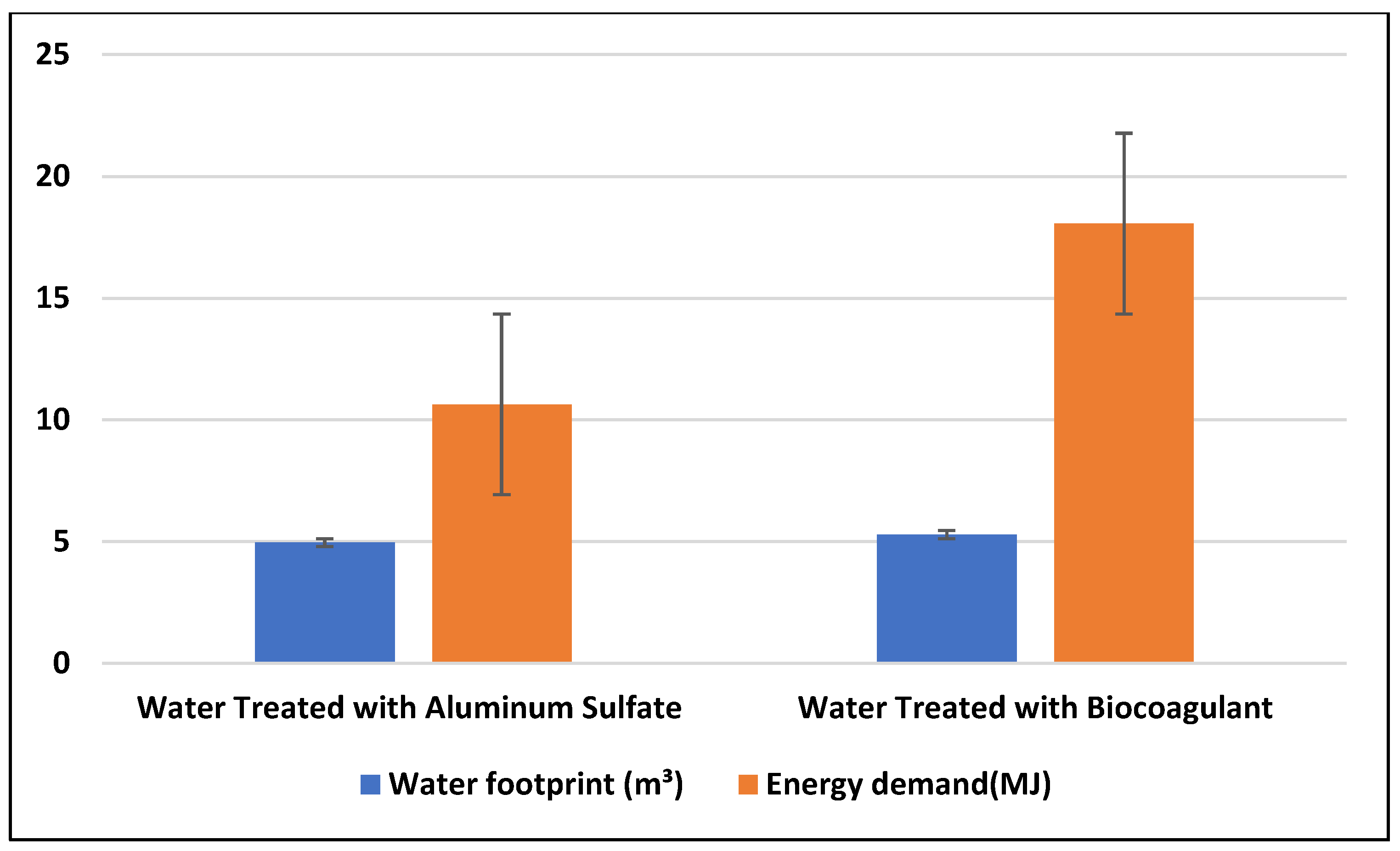

Figure 5 presents the water footprint and energy demand of 1 m

3 of water treated in the industry with aluminum sulfate and a tannin-based biocoagulant.

The biocoagulant had a larger water footprint than aluminum sulfate due to the plant’s cultivation stage, which takes an average of seven years to reach the cutting size. As the cultivation of

Acacia mearnsii does not have a mechanical irrigation system (only rainwater and groundwater are used), the water footprint includes the remaining water used in the product’s life cycle. Another contribution to the water footprint was the production of biocoagulant, which requires 0.87 m

3 per kg of biocoagulant (

Table 2). In this regard, to make the biocoagulant more ecological, it is necessary to rationalize the use of water in its production.

Table 6 presents the CED by energy source for water treatment with the biocoagulant and aluminum sulfate in the refinery’s water supply chain.

The energy demand shown in

Figure 6 points to the advantage of treating industrial water with aluminum sulfate, with an impact 31% lower than the treatment using biocoagulant.

Table 6 shows the high demand of non-renewable fossil energy for treatment with biocoagulant due to the large demand for fossil fuels to drive machines (chainsaws, tractors, cutting machines, and scrapers) in the

Acacia mearnsii cultivation stage. Regarding the WTP, for every 50 m

3 of water treated, 1 m

3 of sludge is generated.

Figure 6 presents a comparison of the environmental impacts resulting from water treatment with biocoagulant and aluminum sulfate.

In

Figure 6, a greater impact on water treatment is noted with aluminum sulfate in several categories, except for eutrophication and land use. For the biocoagulant, the carbon footprint category was influenced mainly by the use of non-renewable energy; however, it is possible to observe that there is carbon dioxide sequestration from the atmosphere during the cultivation of Black Acacia, which is an environmental benefit. The carbon footprint of the water treatment with the biocoagulant is lower than that with aluminum sulfate.

For the acidification category, an environmental profile with less impact on the use of the biocoagulant is perceived. Regarding the delivery process of the aluminum sulfate coagulant, a large energy demand is noted for the use of transport and movement of machinery, making this contribution directly related to air emissions from the burning of diesel. Another factor to be considered is the demand for non-renewable energy in some stages of aluminum sulfate production, such as coal and natural gas, which intensified the impacts related to the use of aluminum sulfate. However, the cultivation of black wattle, as well as transport between the transformation processes, required a high use of diesel in its stages, however, in smaller quantities than aluminum sulfate.

For the eutrophication category, the use of biocoagulants has a greater potential impact. The impacts of this category are mainly related to the release of nutrients into the water, as well as emissions from the burning of fuel and the use of non-renewable energy of fossil origin. Furthermore, there is also a contribution attributed to the use of fertilizers in the Black Acacia cultivation stage, which includes long-term emissions into groundwater.

The human toxicity category presented a disadvantage for the use of aluminum sulfate in relation to the biocoagulant, as it is an inorganic product with high contaminant potential when it is released into the water bodies from sludge disposal. The difference between the human toxicity results was 93%, which shows that the use of aluminum sulfate in water treatment processes is an environmental concern. WTPs that use aluminum sulfate as a coagulating agent are quite widespread among companies worldwide. However, if there is no adequate destination for sludge generated through this process, the risk of contamination of nearby water sources is quite high. It is important to highlight that the disposal of sludge generated in water bodies causes a significant change in the physical and chemical properties of the aquatic ecosystems, which can significantly affect biological activity.

For the particulate matter category, the result of the environmental performance of sludge generated with aluminum sulfate presents the worst scenario in relation to the biocoagulant. It is worth mentioning that the particles suspended in the air due to these processes have different diameters, and for this category, only particles with a size smaller than or equivalent to 2.5 μm were considered due to their highest impact potential for respiratory system effects.

Water treatment with the biocoagulant has a greater environmental impact in terms of land use compared to that with aluminum sulfate. The cultivation of Black Acacia, which is the basic raw material for the manufacture of the biocoagulant, demands more land use in relation to the production of aluminum sulfate.

The aluminum sulfate scenario indicated that the greatest contribution within the category of abiotic depletion is the use of electricity, followed by the use of chemical agents involved in the water treatment process.

Water treatment using aluminum sulfate as a coagulating agent for industrial use is quite widespread among companies. If there is no adequate disposal for sludge generated from this process, the risk of contamination of nearby water sources is quite high [

10]. The WTP analyzed does not have water source conservation programs, does not fully treat the sludge, and also does not have full control over the amount of waste generated. All sludge generated is sent to a lake at the industrial unit itself or recycled in the water treatment process.

3.2. Cost Analysis

The average operating costs of water treatment are presented in

Table 7. These costs are based on internal reports from the oil refinery, as well as data from the aluminum sulfate and biocoagulant production sector. The costs do not include fixed costs for personnel, maintenance, and laboratory analyses due to the complexity of collecting these data and the confidentiality imposed by the refinery.

The costs associated with managing sludge generated in water treatment have significant implications for long-term economic viability. Sludge, a common byproduct of this process, requires careful consideration regarding collection, transportation, processing, and final disposal. The determination of economic viability is directly influenced by the costs associated with these stages. The choice of disposal techniques, such as landfills, controlled incineration, co-processing, or agricultural reuse, impacts operational costs and compliance with environmental standards.

Investing in advanced sludge treatment technologies, while potentially involving higher initial costs, can result in reduced operational expenses and the production of higher-quality sludge. Additionally, strategies that allow for resource recovery, such as biogas production through anaerobic digestion, can not only mitigate costs but also generate additional revenue.

Choosing waste management methods that balance operational efficiency, environmental compliance, and economic considerations contributes to long-term financial sustainability in water treatment. This approach not only meets regulatory requirements but also minimizes environmental impacts, ensuring effective and economical sludge management.

With the results shown in

Table 8, it was identified that more than 65% of treatment costs are due to the use of electricity and that the water pumping stage is the stage that contributes the most to this electricity consumption. Therefore, it is necessary to optimize the use of electricity within the water supply system to improve the environmental performance.

It is also shown in

Table 8 that the price of aluminum sulfate is one-eighth that of the biocoagulant. However, as pointed out in the study, a major problem found in the use of aluminum sulfate as a coagulating agent in water treatment is the appropriate disposal of the sludge generated from metal-based coagulants, which is classified as hazardous waste and must be properly disposed of. However, this disposal has high costs associated with it, which often leads to improper disposal. The sludge generated from water treatment with the biocoagulant is not contaminated with heavy metals, which simplifies its handling for a circular economy practice.

From an economic point of view, aluminum sulfate, although widely used as a coagulant in water treatment, can present significant costs associated with its processing, transportation, and, mainly, the management of waste resulting from the treatment. This waste often involves specialized disposal methods, contributing to additional operational costs.

On the other hand, the biocoagulant, as a more sustainable alternative, may initially have slightly higher production and implementation costs, but offers long-term benefits. Its natural and biodegradable origin can reduce costs associated with waste management since the biocoagulant can be more easily integrated into environmental processes.

Therefore, the destination of the sludge generated from biocoagulants tends to be more economically viable than the sludge generated from the use of aluminum sulfate, in addition to being a source of income when valued in circular economy proposals (

Figure 7).

3.3. Circular Economy

The industrial water supply presents challenges in its life cycle, which range from the water treatment process to the final disposal of the sludge generated in the WTP [

2]. This management must involve innovation throughout the value chain to reduce waste generation, recycle waste, and eliminate waste disposal in landfills. Therefore, after diagnosing the environmental impact of the sludge generated at the WTP, a proposal for a circular economy in sludge management was made (

Figure 8).

Innovative applications for using WTP sludge have been recognized for their notable performance in mitigating pollution, standing out as efficient adsorbents of polluting substances [

55]. This approach was not only revealed as an effective strategy to face environmental challenges but also represents a practical and promising example of water sustainability, promoting harmony between environmental preservation and advanced water treatment processes. An effective toxin-reduction practice using WTP sludge is the agricultural application of the sludge as an organic fertilizer, those from coagulants with iron compounds [

55]. Sludge contains nutrients such as phosphorus and potassium (

Table 5) and organic matter that benefit agricultural soils.

The controlled application of treated sludge to agricultural areas not only provides an adequate way of disposing of waste but also contributes to the reduction in pollutants in water bodies [

21]. The nutrients present in the sludge support soil fertility, reducing the need for synthetic chemical fertilizers. This, in turn, decreases the emission of nutrients to nearby water bodies, which is a common source of water pollution. Furthermore, applying sludge to the soil can increase the water retention capacity and improve the soil structure, reducing the risk of erosion. However, it is essential to ensure adequate application and monitoring practices to avoid negative environmental impacts, ensuring the safety and effectiveness of this pollutant-reduction proposal [

21].

Studies such as Akamatsu (2017) [

55] investigated applications of sludge as a raw material for the manufacture of bricks and cement. WTP sludge, when treated properly, can be incorporated into various construction materials, offering economic and environmental benefits. A common application is the use of sludge as an additive in the production of bricks and blocks. Treated sludge can be mixed with clay and other components during the brickmaking process, which reduces the amount of waste going to landfills and also transmits improved properties to construction materials. Furthermore, the presence of minerals in WTP sludge strengthens bricks, making them more durable. This practice not only provides an environmentally friendly alternative to waste management but also reduces the demand for natural resources traditionally used in the production of construction materials. However, it is crucial to ensure that the sludge incorporation in products is carried out safely, meeting regulatory standards [

55].

Using WTP sludge is a practice that aims to optimize resources, promote sustainability, and reduce environmental impact. A common approach involves sludge use as an integral part of advanced water treatment systems [

21]. The main aspects of this practice are as follows:

Enhanced Coagulation and Flocculation: Adequate coagulant dose in WTP based on monitoring solids concentration in water supports environmental and economic optimization water treatment.

Bioremediation and Biological Filtration: WTP sludge can also be applied in bioremediation systems. Microorganisms present in sludge can contribute to the degradation of organic pollutants, promoting a more natural and sustainable approach to sludge management.

Biogas Production: In some cases, WTP sludge can be used in the production of biogas through anaerobic processes. The biogas generated can be used as a source of renewable energy to power part of the operations of the water treatment system itself.

Nutrient Recycling: WTP sludge often contains valuable nutrients such as phosphorus and potassium. Their reintroduction into the biomass production system can be planned to recover these nutrients, contributing to the overall efficiency of the water supply system.

Dehydration and Thermal Drying: In some cases, WTP sludge may be subjected to dehydration and thermal drying processes to transform it into a more stable material suitable for use as fertilizer or in other processes outside of the water treatment sector.

Coagulant recovery: WTP sludge coagulant reuse, generally metallic salts, contributes to resource efficiency, reduces operational costs, and minimizes the amount of waste generated.

Use in Construction: Treated WTP sludge can be used in construction for the production of bricks, blocks, or landfill material. It is important to ensure that the sludge meets necessary safety and quality standards.

Metal Recovery: In some cases, WTP sludge may contain valuable metals. Chemical or biological extraction processes can be applied to recover these metals, allowing for reuse or recycling.

Composting: If the WTP sludge is organic, it can be composted to produce organic fertilizer. Sludge mixes with suitable composting material such as vegetable scraps, straw, or sawdust allow the composting process to take place. The end product can be used as fertilizer in agricultural areas.

Implementing these practices requires compliance with environmental regulations, water quality standards, and public health to ensure the safety and effectiveness of the WTP sludge valorization in the circular economy.

Figure 8 shows the destination options of the sludge generated at WTPs through the Circular Economy (CE) model.

The Circular Economy (CE) has become a promoted model to be adopted in environmental management, mainly in the water supply and sewage management sectors [

56]. Water utilities consider CE approaches to manage their resources, which aim to eliminate waste [

56]. Geissdoerfer et al. [

57] affirmed that the CE concept is an alternative option to the conventional “Take-Make-Dispose” concept of the linear economy model. An essential aspect of the CE is to keep resources within the economy as long as possible so that a product or its material descendants are continuously reused to create added value [

56]. However, due to the scarcity of landfills and increasingly strict environmental regulations, discarding WTP sludge in landfills is becoming more expensive and less desirable [

35,

58]. As such, there is a pressing need to develop more sustainable sludge management practices, including material reuse, recycling, and recovery [

56].

The choice of the reuse technique depends on the sludge composition, local regulations, environmental conditions, and acceptable practices in the specific region. It is crucial to conduct laboratory analyses to understand the sludge composition before deciding on the best approach for its use. Additionally, it is important to follow environmental and safety guidelines to ensure responsible use.