Assessing the Physical and Environmental Aspects of Greenhouse Cultivation: A Comprehensive Review of Conventional and Hydroponic Methods

Abstract

:1. Introduction

2. Literature Review

2.1. Life Cycle Assessment (LCA)

2.2. Types of Cultivation in Greenhouses

2.2.1. Conventional Cultivation

| Items | Energy Equivalent (MJ unit−1) | References |

|---|---|---|

| Human labor (h) | 1.96 | [68,69,70] |

| Diesel fuel (L) | 56.31 | [71] |

| Electricity (kwh) | 11.93 | [67,72] |

| Transportation (tone.km) | 3.05 | [73] |

| Chemical pesticides (kg) | 101.2 | [74] |

| Chemical fertilizer (kg) | - | |

| Nitrogen | 78.1 | [75] |

| Phosphate | 17.4 | [75] |

| Potassium | 13.7 | [76] |

| Micronutrients (kg) | 120 | [77] |

| Manure (kg) | 0.3 | [78] |

| Water (m3) | 1.02 | [75] |

| Natural gas (m3) | 49.5 | [79] |

| Machinery (kg) | 62.7 | |

| Nylon (kg) | 17.91 | [80] |

| Steel (kg) | 27.73 | [81] |

| Plastic general (kg) | 90 | |

| Cucumber (kg) | 0.8 | [82] |

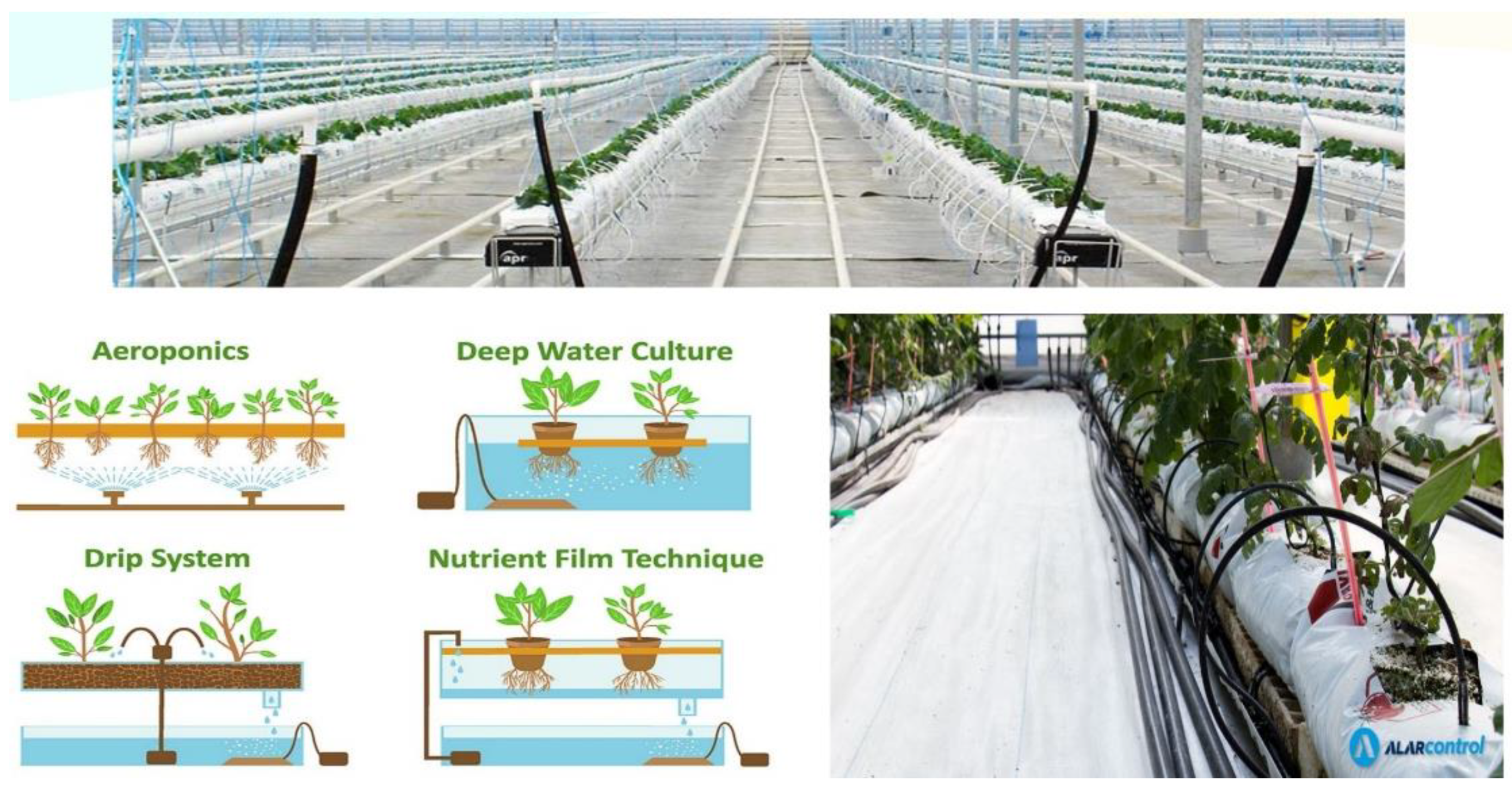

2.2.2. Hydroponic Cultivation

2.3. All the Inputs in the Greenhouse

2.3.1. Structure

| References | Structural Shapes | Picture | Properties | Advantages | Disadvantages |

|---|---|---|---|---|---|

| [116] | Lean-to greenhouse |  | Suitable for the side of a building; One or two rows at 12 ft | Close to the water and electricity facilities of the building; Lower cost of materials; Needs a small space; Fewer support requirements for the roof | Limited space for plant growth; Lack of exposure to sufficient light; Difficulty controlling the temperature due to the sides of the wall |

| [117] | Ridge and furrow greenhouse |  | It has a structure similar to the A-frame structure that drains extra snow and rain; It is cheap to make and can be made with only basic materials; Very little use of wooden and plastic covers | Sufficient space for plant growth; Energy saving and automation; Increasing the life of the structure by discharging excess snow and rain | Needs a large piece of land to set up; High setup cost |

| [118] | Even span greenhouse |  | This design is suitable for a backyard; It can increase the size; Sufficient sunlight penetration due to the high transparent coating surface | Flexible design in the size of the structure; Suitable for carrying many plants; An ideal structure that maintains temperature uniformity; Additional snow and rain drainage due to the A-shaped roof | Expensive setup cost; Needs a dedicated heating system |

| [119] | Gothic arch greenhouse |  | Flexible in the size of the greenhouse structure; The pointed roof of the greenhouse eliminates the use of trusses in its structure | No need for trusses; Easy drainage of snow and rain; Can be made in different sizes | Compared to other types of greenhouses, it requires more materials for construction; Air circulation to the corners is difficult |

| [100] | Uneven span greenhouse |  | One of the roofs of the structure is longer than the other; Suitable for hilly areas that receive more light from the sun | Penetration of more sunlight into the greenhouse; It prevents the wind; Strong and durable structure | Not suitable for flat areas |

2.3.2. Temperature and Fuel

2.3.3. Light

2.3.4. Carbon Dioxide

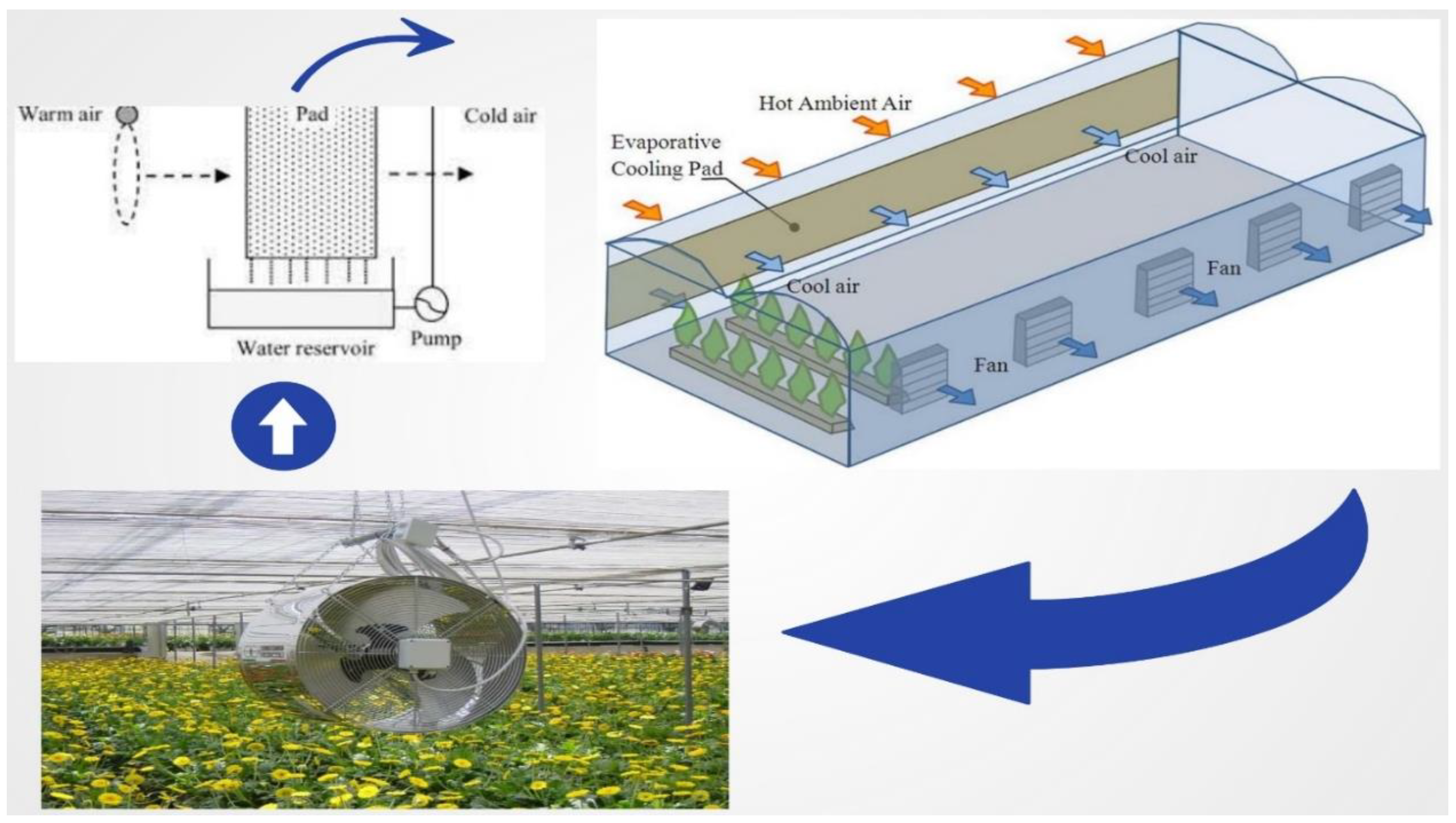

2.3.5. Water and Humidity

2.3.6. Electricity

2.3.7. Human Labor

2.3.8. Machinery

2.3.9. Fertilizer and Pesticides

2.3.10. Energy Indicators

3. Conclusions

4. Future Suggestions

- Expanding hydroponic cultivation using renewable energy is suggested to reduce the initial investment and energy consumption according to the environmental conditions.

- Farmers are advised to develop hydroponic cultivation techniques to produce high-quality products, profit more, and reduce energy losses.

- Researchers in agriculture and environmental science should conduct further research on energy-efficient and eco-friendly techniques for conventional greenhouse and hydroponic farming.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baddadi, S.; Bouadila, S.; Ghorbel, W.; Guizani, A. Autonomous greenhouse microclimate through hydroponic design and refurbished thermal energy by phase change material. J. Clean. Prod. 2019, 211, 360–379. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Maestre-Valero, J.F.; Gallego-Elvira, B.; Marín-Membrive, P.; Terrero, P.; Martínez-Alvarez, V. Recycling drainage effluents using reverse osmosis powered by photovoltaic solar energy in hydroponic tomato production: Environmental footprint analysis. J. Environ. Manag. 2021, 297, 113326. [Google Scholar] [CrossRef]

- Sims, R.; Flammini, A.; Puri, M.; Bracco, S. Opportunities for Agri-Food Chains to Become Energy-Smart; FAO: Rome, Italy; USAID: Washington, DC, USA, 2015. [Google Scholar]

- Pittelkow, C.M.; Liang, X.; Linquist, B.A.; van Groenigen, K.J.; Lee, J.; Lundy, M.E.; van Gestel, N.; Six, J.; Venterea, R.T.; van Kessel, C. Productivity limits and potentials of the principles of conservation agriculture. Nature 2015, 517, 365–368. [Google Scholar] [CrossRef]

- Panwar, N.; Kaushik, S.; Kothari, S. Solar greenhouse an option for renewable and sustainable farming. Renew. Sustain. Energy Rev. 2011, 15, 3934–3945. [Google Scholar] [CrossRef]

- Allardyce, C.S.; Fankhauser, C.; Zakeeruddin, S.M.; Grätzel, M.; Dyson, P.J. The influence of greenhouse-integrated photovoltaics on crop production. Sol. Energy 2017, 155, 517–522. [Google Scholar] [CrossRef]

- Vadiee, A.; Martin, V. Energy management in horticultural applications through the closed greenhouse concept, state of the art. Renew. Sustain. Energy Rev. 2012, 16, 5087–5100. [Google Scholar] [CrossRef]

- Castro, A.J.; López-Rodríguez, M.D.; Giagnocavo, C.; Gimenez, M.; Céspedes, L.; La Calle, A.; Gallardo, M.; Pumares, P.; Cabello, J.; Rodríguez, E.; et al. Six Collective Challenges for Sustainability of Almería Greenhouse Horticulture. Int. J. Environ. Res. Public Health 2019, 16, 4097. [Google Scholar] [CrossRef]

- Hesampour, R.; Taki, M.; Fathi, R.; Hassani, M.; Halog, A. Energy-economic-environmental cycle evaluation comparing two polyethylene and polycarbonate plastic greenhouses in cucumber production (from production to packaging and distribution). Sci. Total Environ. 2022, 828, 154232. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Shariati, H.M.; Rafiee, S.; Mousazadeh, H. Comparison of energy consumption and GHG emissions of open field and greenhouse strawberry production. Renew. Sustain. Energy Rev. 2014, 29, 316–324. [Google Scholar] [CrossRef]

- Esen, M.; Yuksel, T. Experimental evaluation of using various renewable energy sources for heating a greenhouse. Energy Build. 2013, 65, 340–351. [Google Scholar] [CrossRef]

- Jain, D.; Tiwari, G.N. Modeling and optimal design of evaporative cooling system in controlled environment greenhouse. Energy Convers. Manag. 2002, 43, 2235–2250. [Google Scholar] [CrossRef]

- Savvas, D.; Gianquinto, G.; Tuzel, Y.; Gruda, N. Soilless culture. Good Agric. Pract. Greenh. Veg. Crop. 2013, 303, 303–354. [Google Scholar]

- Barbosa, G.L.; Gadelha, F.D.; Kublik, N.; Proctor, A.; Reichelm, L.; Weissinger, E.; Wohlleb, G.M.; Halden, R.U. Comparison of Land, Water, and Energy Requirements of Lettuce Grown Using Hydroponic vs. Conventional Agricultural Methods. Int. J. Environ. Res. Public Health 2015, 12, 6879. [Google Scholar] [CrossRef]

- Killebrew, K.; Wolff, H. Environmental Impacts of Agricultural Technologies EPAR Brief No. 65. Available online: https://econ.washington.edu/sites/econ/files/old-site-uploads/2014/06/2010-Environmental-Impacts-of-Ag-Technologies.pdf (accessed on 17 March 2011).

- Stanghellini, C.; Kempkes, F.L.K.; Knies, P. Enhancing Environmental Quality in Agricultural Systems; International Society for Horticultural Science (ISHS): Leuven, Belgium, 2003; pp. 277–283. [Google Scholar]

- Ezzahoui, I.; Abdelouahid, R.A.; Taji, K.; Marzak, A. Hydroponic and Aquaponic Farming: Comparative Study Based on Internet of things IoT technologies. Procedia Comput. Sci. 2021, 191, 499–504. [Google Scholar] [CrossRef]

- Sharma, N.; Acharya, S.; Kumar, K.; Singh, N.; Chaurasia, O. Hydroponics as an advanced technique for vegetable production: An overview. J. Soil Water Conserv. 2019, 17, 364–371. [Google Scholar] [CrossRef]

- Gentry, M. Local heat, local food: Integrating vertical hydroponic farming with district heating in Sweden. Energy 2019, 174, 191–197. [Google Scholar] [CrossRef]

- Bakhtar, N.; Chhabria, V.; Chougle, I.; Vidhrani, H.; Hande, R. IoT based Hydroponic Farm. In Proceedings of the 2018 International Conference on Smart Systems and Inventive Technology (ICSSIT), Tirunelveli, India, 13–14 December 2018; pp. 205–209. [Google Scholar]

- Leal, L.Y.d.C.; Souza, E.R.d.; Santos Júnior, J.A.; Dos Santos, M.A. Comparison of soil and hydroponic cultivation systems for spinach irrigated with brackish water. Sci. Hortic. 2020, 274, 109616. [Google Scholar] [CrossRef]

- Qadir, M.; Quillérou, E.; Nangia, V.; Murtaza, D.G.; Singh, M.; Thomas, R.; Drechsel, P.; Noble, A. Economics of salt-induced land degradation and restoration. Nat. Resour. Forum 2014, 38, 282–295. [Google Scholar] [CrossRef]

- Chatzigianni, M.; Ntatsi, G.; Theodorou, M.; Stamatakis, A.; Livieratos, I.; Rouphael, Y.; Savvas, D. Functional Quality, Mineral Composition and Biomass Production in Hydroponic Spiny Chicory (Cichorium spinosum L.) Are Modulated Interactively by Ecotype, Salinity and Nitrogen Supply. Front. Plant Sci. 2019, 10, 1040. [Google Scholar] [CrossRef]

- Sahin, U.; Ekinci, M.; Ors, S.; Turan, M.; Yildiz, S.; Yildirim, E. Effects of individual and combined effects of salinity and drought on physiological, nutritional and biochemical properties of cabbage (Brassica oleracea var. capitata). Sci. Hortic. 2018, 240, 196–204. [Google Scholar] [CrossRef]

- Duarte, H.H.F.; Souza, E.R.d. Soil water potentials and Capsicum annuum L. under salinity. Rev. Bras. De Ciência Do Solo 2016, 40, 1–11. [Google Scholar]

- Atzori, G.; Mancuso, S.; Masi, E. Seawater potential use in soilless culture: A review. Sci. Hortic. 2019, 249, 199–207. [Google Scholar] [CrossRef]

- Achour, Y.; Ouammi, A.; Zejli, D. Technological progresses in modern sustainable greenhouses cultivation as the path towards precision agriculture. Renew. Sustain. Energy Rev. 2021, 147, 111251. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Omid, M.; Yousefi, M.; Movahedi, M. Modeling of energy consumption and GHG (greenhouse gas) emissions in wheat production in Esfahan province of Iran using artificial neural networks. Energy 2013, 52, 333–338. [Google Scholar] [CrossRef]

- Menten, F.; Chèze, B.; Patouillard, L.; Bouvart, F. A review of LCA greenhouse gas emissions results for advanced biofuels: The use of meta-regression analysis. Renew. Sustain. Energy Rev. 2013, 26, 108–134. [Google Scholar] [CrossRef]

- Wowra, K.; Zeller, V.; Schebek, L. Nitrogen in Life Cycle Assessment (LCA) of agricultural crop production systems: Comparative analysis of regionalization approaches. Sci. Total Envivon. 2021, 763, 143009. [Google Scholar] [CrossRef] [PubMed]

- Hosseini-Fashami, F.; Motevali, A.; Nabavi-Pelesaraei, A.; Hashemi, S.J.; Chau, K.-w. Energy-Life cycle assessment on applying solar technologies for greenhouse strawberry production. Renew. Sustain. Energy Rev. 2019, 116, 109411. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Rafiee, S.; Mohtasebi, S.; Hosseinzadeh-Bandbafha, H.; Chau, K. Energy consumption enhancement and environmental life cycle assessment in paddy production using optimization techniques. J. Clean. Prod. 2017, 162, 571–586. [Google Scholar] [CrossRef]

- Ghasemi-Mobtaker, H.; Sharifi, M.; Taherzadeh-Shalmaei, N.; Afrasiabi, S. A new method for green forage production: Energy use efficiency and environmental sustainability. J. Clean. Prod. 2022, 363, 132562. [Google Scholar] [CrossRef]

- Martin, E.; Chester, M.; Vergara, S. Attributional and Consequential Life-cycle Assessment in Biofuels: A Review of Recent Literature in the Context of System Boundaries. Curr. Sustain./Renew. Energy Rep. 2015, 2, 82–89. [Google Scholar] [CrossRef]

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy efficient operation and modeling for greenhouses: A literature review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- Bamber, N.; Turner, I.; Dutta, B.; Heidari, M.; Pelletier, N. Consequential Life Cycle Assessment of Grain and Oilseed Crops: Review and Recommendations. Sustainability 2023, 15, 6201. [Google Scholar] [CrossRef]

- Peter, C.; Helming, K.; Nendel, C. Do greenhouse gas emission calculations from energy crop cultivation reflect actual agricultural management practices?–A review of carbon footprint calculators. Renew. Sustain. Energy Rev. 2017, 67, 461–476. [Google Scholar] [CrossRef]

- Borghino, N.; Corson, M.; Nitschelm, L.; Wilfart, A.; Fleuet, J.; Moraine, M.; Breland, T.A.; Lescoat, P.; Godinot, O. Contribution of LCA to decision making: A scenario analysis in territorial agricultural production systems. J. Environ. Manag. 2021, 287, 112288. [Google Scholar] [CrossRef] [PubMed]

- ISO/DIS 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2022.

- Hertwich, E. Understanding the Climate Mitigation Benefits of Product Systems: Comment on “Using Attributional Life Cycle Assessment to Estimate Climate-Change Mitigation…”. J. Ind. Ecol. 2014, 18, 464–465. [Google Scholar] [CrossRef]

- Soussana, J.-F. Research priorities for sustainable agri-food systems and LCA. J. Clean. Prod. 2014, 73, 19–23. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Gallego-Elvira, B.; Álvarez, V.; Maestre, J. Life cycle assessment of fruit and vegetable production in the Region of Murcia (south-east Spain) and evaluation of impact mitigation practices. J. Clean. Prod. 2020, 265, 121656. [Google Scholar] [CrossRef]

- Gunady, M.; Biswas, W.; Solah, V.; James, A. Evaluating the global warming potential of the fresh produce supply chain for strawberries, romaine/cos lettuces (Lactuca sativa), and button mushrooms (Agaricus bisporus) in Western Australia using life cycle assessment (LCA). J. Clean. Prod. 2012, 28, 81–87. [Google Scholar] [CrossRef]

- Zarei, M.J.; Kazemi, N.; Marzban, A. Life cycle environmental impacts of cucumber and tomato production in open-field and greenhouse. J. Saudi Soc. Agric. Sci. 2019, 18, 249–255. [Google Scholar] [CrossRef]

- Clune, S.; Crossin, E.; Verghese, K. Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef]

- Dias, G.M.; Ayer, N.W.; Khosla, S.; Van Acker, R.; Young, S.B.; Whitney, S.; Hendricks, P. Life cycle perspectives on the sustainability of Ontario greenhouse tomato production: Benchmarking and improvement opportunities. J. Clean. Prod. 2017, 140, 831–839. [Google Scholar] [CrossRef]

- Wang, X.; Liu, B.; Wu, G.; Sun, Y.; Guo, X.; Jin, Z.; Xu, W.; Zhao, Y.; Zhang, F.; Zou, C.; et al. Environmental costs and mitigation potential in plastic-greenhouse pepper production system in China: A life cycle assessment. Agric. Syst. 2018, 167, 186–194. [Google Scholar] [CrossRef]

- Zhang, H.; Burr, J.; Zhao, F. A comparative life cycle assessment (LCA) of lighting technologies for greenhouse crop production. J. Clean. Prod. 2017, 140, 705–713. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G. Life cycle analysis of organic tomato production and supply in Sweden. J. Clean. Prod. 2018, 196, 635–643. [Google Scholar] [CrossRef]

- PRe Sustainability B.V., PRe Sustainability. 2020. Available online: www.pre-sustainability.com (accessed on 21 February 2020).

- Yano, A.; Cossu, M. Energy sustainable greenhouse crop cultivation using photovoltaic technologies. Renew. Sustain. Energy Rev. 2019, 109, 116–137. [Google Scholar] [CrossRef]

- Hanan, J. Greenhouses: Advanced Technology for Protected Horticulture; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Achour, Y.; Ouammi, A.; Zejli, D.; Sayadi, S. Supervisory Model Predictive Control for Optimal Operation of a Greenhouse Indoor Environment Coping With Food-Energy-Water Nexus. IEEE Access 2020, 8, 211562–211575. [Google Scholar] [CrossRef]

- Su, Y.; Yu, Q.; Zeng, L. Parameter self-tuning pid control for greenhouse climate control problem. IEEE Access 2020, 8, 186157–186171. [Google Scholar] [CrossRef]

- Majid, M.; Khan, J.N.; Shah, Q.M.A.; Masoodi, K.Z.; Afroza, B.; Parvaze, S. Evaluation of hydroponic systems for the cultivation of Lettuce (Lactuca sativa L., var. Longifolia) and comparison with protected soil-based cultivation. Agric. Water Manag. 2021, 245, 106572. [Google Scholar] [CrossRef]

- Lambin, E. Global land availability: Malthus versus Ricardo. Glob. Food Secur. 2012, 1, 83–87. [Google Scholar] [CrossRef]

- Lal, R. Restoring Soil Quality to Mitigate Soil Degradation. Sustainability 2015, 7, 5875–5895. [Google Scholar] [CrossRef]

- Lehman, R.; Cambardella, C.; Stott, D.; Acosta-Martinez, V.; Manter, D.; Buyer, J.; Maul, J.; Smith, J.; Collins, H.; Halvorson, J.; et al. Understanding and Enhancing Soil Biological Health: The Solution for Reversing Soil Degradation. Sustainability 2015, 7, 988–1027. [Google Scholar] [CrossRef]

- Taki, M.; Rohani, A.; Rahmati-Joneidabad, M. Solar thermal simulation and applications in greenhouse. Inf. Process. Agric. 2018, 5, 83–113. [Google Scholar] [CrossRef]

- Vadiee, A.; Yaghoubi, M.; Sardella, M.; Farjam, P. Energy analysis of fuel cell system for commercial greenhouse application—A feasibility study. Energy Convers. Manag. 2014, 89, 925–932. [Google Scholar] [CrossRef]

- Mohammadi, A.; Omid, M. Economical analysis and relation between energy inputs and yield of greenhouse cucumber production in Iran. Appl. Energy 2010, 87, 191–196. [Google Scholar] [CrossRef]

- Vadiee, A.; Yaghoubi, M. Enviro-economic assessment of energy conservation methods in commercial greenhouses in Iran. Outlook Agric. 2016, 45, 47–53. [Google Scholar] [CrossRef]

- Hoang, A.; Pham, V.V.; Nguyen, X.P. Integrating renewable sources into energy system for smart city as a sagacious strategy towards clean and sustainable process. J. Clean. Prod. 2021, 305, 127161. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Yan, P.; Zhang, Q.; Shuai, X.; Pan, J.; Zhang, W.; Shi, J.; Wang, M.; Chen, X.; Cui, Z. Interaction between plant density and nitrogen management strategy in improving maize grain yield and nitrogen use efficiency on the North China Plain. J. Agric. Sci. 2015, 154, 978–988. [Google Scholar] [CrossRef]

- Ghasemi Mobtaker, H.; Mostashari-Rad, F.; Saber, Z.; Chau, K.; Nabavi-Pelesaraei, A. Application of photovoltaic system to modify energy use, environmental damages and cumulative exergy demand of two irrigation systems-A case study: Barley production of Iran. Renew. Energy 2020, 160, 1316–1334. [Google Scholar] [CrossRef]

- Hesampour, R.; Hassani, M.; Hanafiah, M.; Heidarbeigi, K. Technical Efficiency, Sensitivity Analysis and Economic Assessment applying Data Envelopment Analysis approach: A Case Study of Date Production in Khuzestan State of Iran. J. Saudi Soc. Agric. Sci. 2021, 21, 197–207. [Google Scholar] [CrossRef]

- Hesampour, R.; Bastani, A.; Heidarbeigi, K. Environmental assessment of date (Phoenix Doctylifera) production in Iran by life cycle assessment. Inf. Process. Agric. 2018, 5, 388–393. [Google Scholar] [CrossRef]

- Salehi, M.; Ebrahimi, R.; Maleki, A.; Ghasemi Mobtaker, H. An assessment of energy modeling and input costs for greenhouse button mushroom production in Iran. J. Clean. Prod. 2014, 64, 377–383. [Google Scholar] [CrossRef]

- Payandeh, Z.; Jahanbakhshi, A.; Mesri Gundoshmian, T.; Clark, S. Improving Energy Efficiency of Barley Production Using Joint Data Envelopment Analysis (DEA) and Life Cycle Assessment (LCA): Evaluation of Greenhouse Gas Emissions and Optimization Approach. Sustainability 2021, 13, 6082. [Google Scholar] [CrossRef]

- Ghasemi Mobtaker, H.; Kaab, A.; Rafiee, S. Application of life cycle analysis to assess environmental sustainability of wheat cultivation in the west of Iran. Energy 2019, 193, 116768. [Google Scholar] [CrossRef]

- Younesi, A.; Javadi, A.; Rahmati, M. Determining energy efficiency indicators in fish farming. In Proceedings of the 30th International Conference on New Approaches in Alborz Province, Energy Conservation, Tehran, Iran, 21 April 2014. [Google Scholar]

- Taki, M.; Soheili-Fard, F.; Rohani, A.; Chen, G.; Yildizhan, H. Life cycle assessment to compare the environmental impacts of different wheat production systems. J. Clean. Prod. 2018, 197, 195–207. [Google Scholar] [CrossRef]

- Kaab, A.; Sharifi, M.; Hossein, M.; Nabavi-Pelesaraei, A.; Chau, K. Use of optimization techniques for energy use efficiency and environmental life cycle assessment modification in sugarcane production. Energy 2019, 181, 1298–1320. [Google Scholar] [CrossRef]

- Kitani, O.; Jungbluth, T.; Peart, R.M.; Ramdani, A. CIGR Handbook of Agricultural Engineering, Volume 5: Energy and Biomass Engineering; American Society of Agricultural Engineers: Saint Joseph, MI, USA, 1999. [Google Scholar]

- Kizilaslan, H. Input–output energy analysis of cherries production in Tokat Province of Turkey. Appl. Energy 2009, 86, 1354–1358. [Google Scholar] [CrossRef]

- Naderi, S.; Dehkordi, A.; Taki, M. Energy and environmental evaluation of greenhouse bell pepper production with life cycle assessment approach. Environ. Sustain. Indic. 2019, 3–4, 100011. [Google Scholar] [CrossRef]

- Elhami, B.; Nejad, G.; Soheilifard, F. Energy and Environmental Indices through Life Cycle Assessment of Raisin Production: A Case Study (Kohgiluyeh and Boyer-Ahmad Province, Iran). Renew. Energy 2019, 141, 507–515. [Google Scholar] [CrossRef]

- Kitani, O. CIGR Handbook of Agricultural Engineering, Volume V Energy and Biomass Engineering; Chapter 1 Natural Energy and Biomass, Part 1.3 Biomass Resources; American Society of Agricultural Engineers: Saint Joseph, MI, USA, 1999. [Google Scholar]

- Canakci, M.; Akinci, I. Energy use pattern analyses of greenhouse vegetable production. Energy 2006, 31, 1243–1256. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Omid, M.; Mousazadeh, H.; Clark, S. Environmental impact assessment of tomato and cucumber cultivation in greenhouses using life cycle assessment and adaptive neuro-fuzzy inference system. J. Clean. Prod. 2014, 73, 183–192. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; Hernández, J.C.; Baeza, E.; Pérez-Parra, J.; Muñoz, P.; Montero, J. LCA of a tomato crop in a multi-Tunnel greenhouse in Almeria. Int. J. Life Cycle Assess. 2012, 17, 863–875. [Google Scholar] [CrossRef]

- Bojacá, C.; Wyckhuys, K.; Schrevens, E. Life cycle assessment of Colombian greenhouse tomato production based on farmer-level survey data. J. Clean. Prod. 2014, 69, 26–33. [Google Scholar] [CrossRef]

- Nicholson, S.R.; Rorrer, N.A.; Carpenter, A.C.; Beckham, G.T. Manufacturing energy and greenhouse gas emissions associated with plastics consumption. Joule 2021, 5, 673–686. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, J.; Ren, Y. Demand side management of energy consumption in a photovoltaic integrated greenhouse. Int. J. Electr. Power Energy Syst. 2022, 134, 107433. [Google Scholar] [CrossRef]

- Taki, M.; Ajabshirchi, Y.; Ranjbar, F.; Rohani, A.; Matloobi, M. Modeling and experimental validation of heat transfer and energy consumption in an innovative greenhouse structure. Inf. Process. Agric. 2016, 3, 157–174. [Google Scholar] [CrossRef]

- Hayashi, A.; Homma, T.; Akimoto, K. The potential contribution of food wastage reductions driven by information technology on reductions of energy consumption and greenhouse gas emissions in Japan. Environ. Chall. 2022, 8, 100588. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D.; Fang, Y. Methodologies of control strategies for improving energy efficiency in agricultural greenhouses. J. Clean. Prod. 2020, 274, 122695. [Google Scholar] [CrossRef]

- Khammayom, N.; Maruyama, N.; Chaichana, C.; Hirota, M. Impact of environmental factors on energy balance of greenhouse for strawberry cultivation. Case Stud. Therm. Eng. 2022, 33, 101945. [Google Scholar] [CrossRef]

- Alinejad, T.; Yaghoubi, M.; Vadiee, A. Thermo-environomic assessment of an integrated greenhouse with an adjustable solar photovoltaic blind system. Renew. Energy 2020, 156, 1–13. [Google Scholar] [CrossRef]

- Ndukwu, M.C.; Ikechukwu-Edeh, C.E.; Nwakuba, N.R.; Okosa, I.; Horsefall, I.T.; Orji, F.N. Nanomaterials application in greenhouse structures, crop processing machinery, packaging materials and agro-biomass conversion. Mater. Sci. Energy Technol. 2020, 3, 690–699. [Google Scholar] [CrossRef]

- Khudoyberdiev, A.; Ahmad, S.; Ullah, I.; Kim, D. An optimization scheme based on fuzzy logic control for efficient energy consumption in hydroponics environment. Energies 2020, 13, 289. [Google Scholar] [CrossRef]

- Savvas, D. Hydroponics: A modern technology supporting the application of integrated crop management in greenhouse. J. Food Agric. Environ. 2003, 1, 80–86. [Google Scholar] [CrossRef]

- Eigenbrod, C.; Gruda, N. Urban vegetable for food security in cities. A review. Agron. Sustain. Dev. 2015, 35, 483–498. [Google Scholar] [CrossRef]

- Hayden, A. Aeroponic and Hydroponic Systems for Medicinal Herb, Rhizome, and Root Crops. HortScience 2006, 41, 536–538. [Google Scholar] [CrossRef]

- Tomasi, N.; Pinton, R.; Dalla Costa, L.; Cortella, G.; Terzano, R.; Mimmo, T.; Scampicchio, M.; Cesco, S. New ‘solutions’ for floating cultivation system of ready-to-eat salad: A review. Trends Food Sci. Technol. 2015, 46, 267–276. [Google Scholar] [CrossRef]

- Schmilewski, G. Growing medium constituents used in the EU. Acta Hortic. 2009, 819, 33–46. [Google Scholar] [CrossRef]

- Lee, S.; Lee, J. Beneficial bacteria and fungi in hydroponic systems: Types and characteristics of hydroponic food production methods. Sci. Hortic. 2015, 195, 206–215. [Google Scholar] [CrossRef]

- Shabani, E. Improving the growth, P uptake and quality characteristics of ‘Lollo Rosso’ lettuce in the nutrient solution by Bacillus subtilis in different phosphorus concentrations. J. Plant. Nutr. 2023, 46, 971–983. [Google Scholar] [CrossRef]

- Shabani, E.; Alemzadeh Ansari, N.; Fayezizadeh, M.R. Plant growth bio-stimulants of seaweed extract (Sargasum boveanum): Implications towards sustainable production of cucumber. Yuz. Yıl Univ. J. Agric. Sci. 2023, 33, 478–490. [Google Scholar] [CrossRef]

- Gashgari, R.; Alharbi, K.; Mughrbil, K.; Jan, A.; Glolam, A. Comparison between Growing Plants in Hydroponic System and Soil Based System. In Proceedings of the 4th World Congress on Mechanical, Chemical, and Material Engineering (MCM’18), Madrid, Spain, 16–18 August 2018. [Google Scholar]

- Liebman-Pelaez, M.; Kongoletos, J.; Norford, L.K.; Reinhart, C. Validation of a building energy model of a hydroponic container farm and its application in urban design. Energy Build. 2021, 250, 111192. [Google Scholar] [CrossRef]

- Martinez-Mate, M.A.; Martin-Gorriz, B.; Martínez-Alvarez, V.; Soto-García, M.; Maestre-Valero, J.F. Hydroponic system and desalinated seawater as an alternative farm-productive proposal in water scarcity areas: Energy and greenhouse gas emissions analysis of lettuce production in southeast Spain. J. Clean. Prod. 2018, 172, 1298–1310. [Google Scholar] [CrossRef]

- Zangeneh, M.; Omid, M.; Akram, A. A comparative study on energy use and cost analysis of potato production under different farming technologies in Hamadan province of Iran. Energy 2010, 35, 2927–2933. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Abdi, R.; Rafiee, S.; Ghasemi Mobtaker, H. Optimization of energy required and greenhouse gas emissions analysis for orange producers using data envelopment analysis approach. J. Clean. Prod. 2013, 65, 311–317. [Google Scholar] [CrossRef]

- Ghasemi Mobtaker, H.; Taki, M.; Salehi, M.; Zarei shahamat, E. Application of non–Parametric method to improve energy productivity and CO2 emission for barley production in Iran. Agric. Eng. Int. CIGR J. 2014, 15, 84–93. [Google Scholar]

- Ozkan, B.; Akcaoz, H.; Fert, C. Energy input–output analysis in Turkish agriculture. Renew. Energy 2004, 29, 39–51. [Google Scholar] [CrossRef]

- Fazaeli, H.; Golmohammadi, H.; Tabatabayee, S.; Asghari-Tabrizi, M. Productivity and Nutritive Value of Barley Green Fodder Yield in Hydroponic System. World Appl. Sci. J. 2012, 16, 1–12. [Google Scholar]

- Nabavi-Pelesaraei, A.; Azadi, H.; Passel, S.; Saber, Z.; Hosseini-Fashami, F.; Mostashari-Rad, F.; Ghasemi Mobtaker, H. Prospects of solar systems in production chain of sunflower oil using cold press method with concentrating energy and life cycle assessment. Energy 2021, 223, 120117. [Google Scholar] [CrossRef]

- Bronchart, F.; De Paepe, M.; Dewulf, J.; Schrevens, E.; Demeyer, P. Thermodynamics of greenhouse systems for the northern latitudes: Analysis evaluation and prospects for primary energy saving. J. Environ. Manag. 2013, 119C, 121–133. [Google Scholar] [CrossRef]

- Giacomelli, G.A. Engineering principles impacting high-tunnel environments. HortTechnology 2009, 19, 30–33. [Google Scholar] [CrossRef]

- Peet, M.M.; Welles, G. Greenhouse tomato production. Tomatoes 2005, 257–304. [Google Scholar] [CrossRef]

- Rohimi, R.; Woaswi, W.; Awang, R.; Rizman, Z.; Mohamed, T.D.M. Design and Prototype Development of Automated Greenhouse with Arduino and (IoT) Application. J. Adv. Sci. 2019, 28, 437–446. [Google Scholar]

- Cellura, M.; Longo, S.; Mistretta, M. Life Cycle Assessment (LCA) of protected crops: An Italian case study. J. Clean. Prod. 2012, 28, 56–62. [Google Scholar] [CrossRef]

- Verrier, B.; Rose, B.; Caillaud, E. Lean and Green strategy: The Lean and Green House and maturity deployment model. J. Clean. Prod. 2016, 116, 150–156. [Google Scholar] [CrossRef]

- Mushtaq, R.; Kumar, A.; Sharma, M. Achievements in Rootstock Breeding for Temperature Fruit Crops. Chapter of Advances in Horticultural Crops. 2018, pp. 59–77. Available online: www.weserbooks.com (accessed on 27 September 2023).

- Kwon, K.-s.; Kim, D.-w.; Kim, R.; Ha, T.; Lee, I.B. Evaluation of wind pressure coefficients of single-span greenhouses built on reclaimed coastal land using a large-sized wind tunnel. Biosyst. Eng. 2016, 141, 58–81. [Google Scholar] [CrossRef]

- Waller, R.; Kacira, M.; Magadley, E.; Teitel, M.; Yehia, I. Evaluating the Performance of Flexible, Semi-Transparent Large-Area Organic Photovoltaic Arrays Deployed on a Greenhouse. AgriEngineering 2022, 4, 969–992. [Google Scholar] [CrossRef]

- Canakci, M.; Emekli, N.Y.; Bilgin, S.; Caglayan, N. Heating requirement and its costs in greenhouse structures: A case study for Mediterranean region of Turkey. Renew. Sustain. Energy Rev. 2013, 24, 483–490. [Google Scholar] [CrossRef]

- Rocamora, M.; Tripanagnostopoulos, Y. Aspects of PV/T solar system application for ventilation needs in greenhouses, International Symposium on Greenhouse Cooling. Acta Hortic. 2006, 719, 239–246. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Lin, W.D. Advanced applications of solar energy in agricultural greenhouses. Renew. Sustain. Energy Rev. 2016, 54, 989–1001. [Google Scholar] [CrossRef]

- Wang, T.; Wu, G.; Chen, J.; Cui, P.; Chen, Z.; Yan, Y.; Zhang, Y.; Li, M.; Niu, D.; Li, B. Integration of solar technology to modern greenhouse in China: Current status, challenges and prospect. Renew. Sustain. Energy Rev. 2017, 70, 1178–1188. [Google Scholar] [CrossRef]

- Singh, M.C.; Singh, J.; Pandey, S.; Mahay, D.; Srivastava, V. Factors affecting the performance of greenhouse cucumber cultivation—A review. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 2304–2323. [Google Scholar] [CrossRef]

- Martzopoulou, A.; Vafiadis, D.; Fragos, V.P. Energy gain in passive solar greenhouses due to CO2 enrichment. Energies 2020, 13, 1242. [Google Scholar] [CrossRef]

- Barbaresi, A.; Maioli, V.; Bovo, M.; Tinti, F.; Torreggiani, D.; Tassinari, P. Application of basket geothermal heat exchangers for sustainable greenhouse cultivation. Renew. Sustain. Energy Rev. 2020, 129, 109928. [Google Scholar] [CrossRef]

- Firfiris, V.; Fragos, V.; Kotsopoulos, T.; Nikita-Martzopoulou, C. Energy and environmental analysis of an innovative greenhouse structure towards frost prevention and heating needs conservation. Sustain. Energy Technol. Assess. 2020, 40, 100750. [Google Scholar] [CrossRef]

- Huang, L.; Deng, L.; Li, A.; Gao, R.; Zhang, L.; Lei, W. A novel approach for solar greenhouse air temperature and heating load prediction based on Laplace transform. J. Build. Eng. 2021, 44, 102682. [Google Scholar] [CrossRef]

- Chai, L.; Ma, C.; Ni, J.-Q. Performance evaluation of ground source heat pump system for greenhouse heating in northern China. Biosyst. Eng. 2012, 111, 107–117. [Google Scholar] [CrossRef]

- Yang, S.-H.; Rhee, J.Y. Utilization and performance evaluation of a surplus air heat pump system for greenhouse cooling and heating. Appl. Energy 2013, 105, 244–251. [Google Scholar] [CrossRef]

- Tong, Y.; Kozai, T.; Nishioka, N.; Ohyama, K. Reductions in energy consumption and CO2 emissions for greenhouses heated with heat pumps. Appl. Eng. Agric. 2012, 28, 401–406. [Google Scholar] [CrossRef]

- Iwasaki, Y.; Aizawa, M.; Yoshida, C.; Takaichi, M. Developing a new energy-saving, photosynthesis-promoting environmental control system for greenhouse production based on a heat pump with a heat storage system. J. Agric. Meteorol. 2013, 69, 81–92. [Google Scholar] [CrossRef]

- Baeza, E.; Stanghellini, C.; Castilla, N. Protected cultivation in Europe. Acta Hortic. 2013, 987, 11–28. [Google Scholar] [CrossRef]

- Vadiee, A.; Martin, V. Energy management strategies for commercial greenhouses. Appl. Energy 2014, 114, 880–888. [Google Scholar] [CrossRef]

- Vadiee, A.; Martin, V. Thermal energy storage strategies for effective closed greenhouse design. Appl. Energy 2013, 109, 337–343. [Google Scholar] [CrossRef]

- Wahid, A.; Gelani, S.; Ashraf, M.; Foolad, M.R. Heat tolerance in plants: An overview. Environ. Exp. Bot. 2007, 61, 199–223. [Google Scholar] [CrossRef]

- Baille, A.; Kittas, C.; Katsoulas, N. Influence of whitening on greenhouse microclimate and crop energy partitioning. Agric. For. Meteorol. 2001, 107, 293–306. [Google Scholar] [CrossRef]

- Mashonjowa, E.; Ronsse, F.; Mhizha, T.; Milford, J.; Lemeur, R.; Pieters, J. The effects of whitening and dust accumulation on the microclimate and canopy behaviour of rose plants (Rosa hybrida) in a greenhouse in Zimbabwe. Sol. Energy 2010, 84, 10–23. [Google Scholar] [CrossRef]

- Ahemd, H.A.; Al-Faraj, A.A.; Abdel-Ghany, A.M. Shading greenhouses to improve the microclimate, energy and water saving in hot regions: A review. Sci. Hortic. 2016, 201, 36–45. [Google Scholar] [CrossRef]

- Kittas, C.; Karamanis, M.; Katsoulas, N. Air temperature regime in a forced ventilated greenhouse with rose crop. Energy Build. 2005, 37, 807–812. [Google Scholar] [CrossRef]

- Santamouris, M.; Balaras, C.A.; Dascalaki, E.; Vallindras, M. Passive solar agricultural greenhouses: A worldwide classification and evaluation of technologies and systems used for heating purposes. Sol. Energy 1994, 53, 411–426. [Google Scholar] [CrossRef]

- Taghavifar, H.; Mardani, A. Energy consumption analysis of wheat production in West Azarbayjan utilizing life cycle assessment (LCA). Renew. Energy 2015, 74, 208–213. [Google Scholar] [CrossRef]

- Franco-Salas, A.; Valera, D.; Peña, A. Energy Efficiency in Greenhouse Evaporative Cooling Techniques: Cooling Boxes versus Cellulose Pads. Energies 2014, 7, 1427–1447. [Google Scholar] [CrossRef]

- Kwak, M.J.; Je, S.M.; Cheng, H.C.; Seo, S.M.; Park, J.H.; Baek, S.G.; Khaine, I.; Lee, T.; Jang, J.; Li, Y. Night light-adaptation strategies for photosynthetic apparatus in yellow-poplar (Liriodendron tulipifera L.) exposed to artificial night lighting. Forests 2018, 9, 74. [Google Scholar] [CrossRef]

- Hemming, S.; de Zwart, H.; Swinkels, G.; Janssen, H. Development of electricity producing greenhouses-two case studies, International Symposium on New Technologies for Environment Control, Energy-Saving and Crop Production in Greenhouse and Plant. Acta Hortic. 2013, 1037, 129–136. [Google Scholar]

- Larcher, W. Plant Physiological Ecology; Springer: Berlin/Heidelberg, Germany, 1995. [Google Scholar]

- Ahamed, M.S.; Sultan, M.; Shamshiri, R.; Mostafizar, R.; Aleem, M.; Balasundram, S. Present Status and Challenges of Fodder Production in Controlled Environments: A Review. Smart Agric. Technol. 2022, 3, 100080. [Google Scholar] [CrossRef]

- Wang, C.; Du, J.; Liu, Y.; Chow, D. A climate-based analysis of photosynthetically active radiation availability in large-scale greenhouses across China. J. Clean. Prod. 2021, 315, 127901. [Google Scholar] [CrossRef]

- Rahman, M.; Vasiliev, M.; Alameh, K. LED Illumination Spectrum Manipulation for Increasing the Yield of Sweet Basil (Ocimum basilicum L.). Plants 2021, 10, 344. [Google Scholar] [CrossRef]

- Hao, X.; Guo, X.; Lanoue, J.; Zhang, Y.; Cao, R.; Zheng, J.; Little, C.; Leonardos, E.; Kholsa, S.; Grodzinski, B.; et al. A review on smart application of supplemental lighting in greenhouse fruiting vegetable production. Acta Hortic. 2018, 1227, 499–506. [Google Scholar] [CrossRef]

- Pinho, P.; Hytonen, T.; Rantanen, M.; Elomaa, P.; Halonen, L. Dynamic control of supplemental lighting intensity in a greenhouse environment. Light. Res. Technol. 2013, 45, 295–304. [Google Scholar] [CrossRef]

- Singh, D.; Basu, C.; Wollweber, M.; Roth, B. LEDs for Energy Efficient Greenhouse Lighting. Renew. Sustain. Energy Rev. 2014, 49, 139–147. [Google Scholar] [CrossRef]

- Leontovich, V.; Bobro, M. Technology of continuous growing of hydroponic fodder. Russ. Agric. Sci. 2007, 33, 239–241. [Google Scholar] [CrossRef]

- Shafiq, I.; Hussain, S.; Raza, M.; Iqbal, N.; Asghar, M.; Raza, A.; Yuan-Fang, F.; Mumtaz, M.; Shoaib, M.; Ansar, M.; et al. Crop photosynthetic response to light quality and light intensity. J. Integr. Agric. 2020, 19, 2–21. [Google Scholar] [CrossRef]

- Yang, F.; Huang, S.; Gao, R.; Weiguo, L.; Yong, T.; Wang, X.; Wu, X.; Yang, W. Growth of soybean seedlings in relay strip intercropping systems in relation to light quantity and red: Far-red ratio. Field Crop. Res. 2014, 155, 245–253. [Google Scholar] [CrossRef]

- El-Deeba, M.; El-Awady, M.; Hegazi, M.; Abdel-Azeem, F.; El-Bourdiny, M. Engineering factors affecting hydroponics grass- fodder production. Misr J. Agric. Eng. 2009, 26, 1647–1666. [Google Scholar] [CrossRef]

- Ngilah, E.; Tsan, F.; Yap, B. Photoperiod and light spectrum effects on growth, pigment and ascorbic acid content of Lactuca sativa cv. Fire Red under controlled growth environment. Int. Food Res. J. 2018, 25, 1300–1308. [Google Scholar]

- He, F.; Zeng, L.; Li, D.; Ren, Z. Study of LED Array Fill Light Based on Parallel Particle Swarm Optimization in Greenhouse Planting. Inf. Process. Agric. 2018, 6, 73–80. [Google Scholar] [CrossRef]

- Clausen, A.; Maersk-Moeller, H.; Sørensen, J.; Jørgensen, B.; Kjaer, K.; Ottosen, C.-O. Integrating Commercial Greenhouses in the Smart Grid with Demand Response based Control of Supplemental Lighting. In Proceedings of the 2015 International Conference on Industrial Technology and Management Science, Tianjin, China, 27–28 March 2015. [Google Scholar] [CrossRef]

- Stanghellini, C.; Incrocci, L.; Gázquez, J.C.; Dimauro, B. Carbon dioxide concentration in Mediterranean greenhouses: How much lost production? In Proceedings of the International Symposium on High Technology for Greenhouse System Management: Greensys2007, Naples, Italy, 4 October 2007; Volume 801, pp. 1541–1550. [Google Scholar]

- Li, Y.L.; Stanghellini, C.; Challa, H. Effect of electrical conductivity and transpiration on production of greenhouse tomato (Lycopersicon esculentum L.). Sci. Hortic. 2001, 88, 11–29. [Google Scholar] [CrossRef]

- Bot, G.; Van De Braak, N.; Challa, H.; Hemming, S.; Rieswijk, T.; Van Straten, G.; Verlodt, I. The solar greenhouse: State of the art in energy saving and sustainable energy supply. Acta Hortic. 2005, 691, 501. [Google Scholar] [CrossRef]

- Teitel, M.; Montero, J.; Baeza, E. Greenhouse design: Concepts and trends. In Proceedings of the International Symposium on Advanced Technologies and Management Towards Sustainable Greenhouse Ecosystems: Greensys2011, Athens, Greece, 5–10 June 2010; Volume 952, pp. 605–620. [Google Scholar]

- Garcıa, J.; De la Plaza, S.; Navas, L.; Benavente, R.; Luna, L. Evaluation of the feasibility of alternative energy sources for greenhouse heating. J. Agric. Eng. Res. 1998, 69, 107–114. [Google Scholar] [CrossRef]

- Lin, D.; Zhang, L.; Xia, X. Model predictive control of a Venlo-type greenhouse system considering electrical energy, water and carbon dioxide consumption. Appl. Energy 2021, 298, 117163. [Google Scholar] [CrossRef]

- Kläring, H.P.; Hauschild, C.; Heißner, A.; Bar-Yosef, B. Model-based control of CO2 concentration in greenhouses at ambient levels increases cucumber yield. Agric. For. Meteorol. 2007, 143, 208–216. [Google Scholar] [CrossRef]

- Vox, G.; Teitel, M.; Pardossi, A.; Minuto, A.; Tinivella, F.; Schettini, E. Sustainable Greenhouse Systems. In Book chapter of Sustainable Agriculture: Technology, Planning and Management; Rios, A.S.e.I., Ed.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2010; pp. 1–79. ISBN 978-1-60876-269-9. [Google Scholar]

- Baille, A. Trends in greenhouse technology for improved climate control in mild winter climates. Acta Hortic. 2001, 559, 161–168. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Rafiee, S.; Mohtasebi, S.S.; Hosseinzadeh-Bandbafha, H.; Chau, K.-w. Comprehensive model of energy, environmental impacts and economic in rice milling factories by coupling adaptive neuro-fuzzy inference system and life cycle assessment. J. Clean. Prod. 2019, 217, 742–756. [Google Scholar] [CrossRef]

- Khanali, M.; Mousavi, S.A.; Sharifi, M.; Keyhani Nasab, F.; Chau, K.-w. Life cycle assessment of canola edible oil production in Iran: A case study in Isfahan province. J. Clean. Prod. 2018, 196, 714–725. [Google Scholar] [CrossRef]

- Energy, I.M.o. Energy Balance Report. Available online: https://www.iea.org/data-and-statistics/data-product/world-energy-balances (accessed on 2 December 2018).

- Eggleston, H.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2006. Available online: https://www.ipcc.ch/site/assets/uploads/2019/12/19R_V0_01_Overview.pdf (accessed on 27 September 2023).

- Berge, B. The Ecology of Building Materials; Elsevier: Oxford, UK, 2009. [Google Scholar]

- Hammond, G.; Jones, C. Inventory of Carbon & Energy: ICE; Sustainable Energy Research Team, Department of Mechanical Engineering, University of Bath: Bath, UK; BSRIA, iCAT: Bracknell, UK, 2008; Volume 5, ISBN 13: 9780860227038. [Google Scholar]

- Lal, R. Carbon emission from farm operations. Environ. Int. 2004, 30, 981–990. [Google Scholar] [CrossRef] [PubMed]

- St Clair, S.B.; Lynch, J.P. The opening of Pandora’s Box: Climate change impacts on soil fertility and crop nutrition in developing countries. Plant Soil 2010, 335, 101–115. [Google Scholar] [CrossRef]

- Dhawan, V. Water and agriculture in India. Background Paper for the South Asia Expert Panel during the Global Forum for Food and Agriculture; 2017. OAV German Asia-Pacific Business Association. Available online: http://www.sciepub.com/reference/312086 (accessed on 27 September 2023).

- Bhanja, S.; Mukherjee, A.; Rodell, M. Groundwater of South Asia; Springer: Berlin, Germany, 2018. [Google Scholar]

- Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A review on hydroponics and the technologies associated for medium-and small-scale operations. Agriculture 2022, 12, 646. [Google Scholar] [CrossRef]

- Papadakis, G.; Briassoulis, D.; Scarascia Mugnozza, G.; Vox, G.; Feuilloley, P.; Stoffers, J.A. Review Paper (SE—Structures and Environment): Radiometric and Thermal Properties of, and Testing Methods for, Greenhouse Covering Materials. J. Agric. Eng. Res. 2000, 77, 7–38. [Google Scholar] [CrossRef]

- Tewolde, F.; Takagaki, M.; Oshio, T.; Maruo, T.; Kozai, T.; Kikuchi, Y. Environmental impact of tomato production under different hydroponic systems. In Proceedings of the XXIX International Horticultural Congress on Horticulture: Sustaining Lives, Livelihoods and Landscapes (IHC2014), Brisbane, Australia, 17–22 August 2014; Volume 1112, pp. 267–271. Available online: https://www.actahort.org/books/1125/ (accessed on 27 September 2023).

- Campen, J.; Kempkes, F.; Bot, G. Mechanically controlled moisture removal from greenhouses. Biosyst. Eng. 2009, 102, 424–432. [Google Scholar] [CrossRef]

- Ozkan, B.; Fert, C.; Karadeniz, C. Energy and cost analysis for greenhouse and open-field grape production. Energy 2007, 32, 1500–1504. [Google Scholar] [CrossRef]

- Ohyama, K.; Takagaki, M.; Kurasaka, H. Urban horticulture: Its significance to environmental conservation. Sustain. Sci. 2008, 3, 241–247. [Google Scholar] [CrossRef]

- Omid, M.; Ghojabeige, F.; Delshad, M.; Ahmadi, H. Energy use pattern and benchmarking of selected greenhouses in Iran using data envelopment analysis. Energy Convers. Manag. 2011, 52, 153–162. [Google Scholar] [CrossRef]

- Taki, M.; Yildizhan, H. Evaluation the sustainable energy applications for fruit and vegetable productions processes; Case study: Greenhouse cucumber production. J. Clean. Prod. 2018, 199, 164–172. [Google Scholar] [CrossRef]

- Katzin, D.; Marcelis, L.F.M.; Mourik, S. Energy savings in greenhouses by transition from high-pressure sodium to LED lighting. Appl. Energy 2021, 281, 116019. [Google Scholar] [CrossRef]

- Hassani, M.; Kabiesz, P.; Hesampour, R.; Mirzaei, S.; Bartnicka, J. Prevalence of Musculoskeletal Disorders, Working Conditions, and Related Risk Factors in the Meat Processing Industry: Comparative Analysis of Iran-Poland. Work 2021, 74, 309–325. [Google Scholar] [CrossRef] [PubMed]

- Hassani, M.; Hesampour, R.; Bartnicka, J.; Monjezi, N.; Mirzaei, S. Evaluation of Working Conditions, Work Postures, Musculoskeletal Disorders and Low Back Pain among Sugar Production Workers. Work 2021, 73, 273–289. [Google Scholar] [CrossRef] [PubMed]

- Kiani, F.; Randazzo, G.; Yelmen, I.; Seyyedabbasi, A.; Nematzadeh, S.; Anka, F.A.; Erenel, F.; Zontul, M.; Lanza, S.; Muzirafuti, A. A smart and mechanized agricultural application: From cultivation to harvest. Appl. Sci. 2022, 12, 6021. [Google Scholar] [CrossRef]

- Stanghellini, C.; Kempkes, F.; Knies, P. Enhancing environmental quality in agricultural systems. Acta Hortic. 2003, 609, 277–283. [Google Scholar] [CrossRef]

- Pérez-Alonso, J.; Pérez-García, M.; Pasamontes-Romera, M.; Callejón-Ferre, A. Performance analysis and neural modelling of a greenhouse integrated photovoltaic system. Renew. Sustain. Energy Rev. 2012, 16, 4675–4685. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Espi, E. PLastic Films for Agricultural Applications. J. Plast. Film Sheeting 2006, 22, 85–102. [Google Scholar] [CrossRef]

- Giacomelli, G.; Roberts, W. Greenhouse Covering Systems. HortTechnology 1993, 3, 50–58. [Google Scholar] [CrossRef]

- Gao, L.-H.; Qu, M.; Ren, H.-Z.; Sui, X.-L.; Chen, Q.-Y.; Zhang, Z.-X. Structure, function, application, and ecological benefit of a single-slope, energy-efficient solar greenhouse in China. HortTechnology 2010, 20, 626–631. [Google Scholar] [CrossRef]

- Tong, G.; Christopher, D.M.; Li, T.; Wang, T. Passive solar energy utilization: A review of cross-section building parameter selection for Chinese solar greenhouses. Renew. Sustain. Energy Rev. 2013, 26, 540–548. [Google Scholar] [CrossRef]

- Yano, A.; Furue, A.; Kadowaki, M.; Tanaka, T.; Hiraki, E.; Miyamoto, M.; Ishizu, F.; Noda, S. Electrical energy generated by photovoltaic modules mounted inside the roof of a north–South oriented greenhouse. Biosyst. Eng. 2009, 103, 228–238. [Google Scholar] [CrossRef]

- Fitz-Rodríguez, E.; Kubota, C.; Giacomelli, G.A.; Tignor, M.E.; Wilson, S.B.; McMahon, M. Dynamic modeling and simulation of greenhouse environments under several scenarios: A web-based application. Comput. Electron. Agric. 2010, 70, 105–116. [Google Scholar] [CrossRef]

- Ihoume, I.; Tadili, R.; Arbaoui, N.; Bazgaou, A.; Idrissi, A.; Benchrifa, M.; Fatnassi, H. Performance study of a sustainable solar heating system based on a copper coil water to air heat exchanger for greenhouse heating. Sol. Energy 2022, 232, 128–138. [Google Scholar] [CrossRef]

| Open field cultivation | Greenhouse Cultivation |

| Large cultivation area is needed | Optimal use of water |

| The need for natural minerals | Off-season cultivation |

| Hard weed removal | Higher yield and nutrient content |

| Water wastage | Control of environmental conditions |

| Refs. | Titles | Purpose and Review | Results |

|---|---|---|---|

| [35] | Energy-efficient operation and modeling for greenhouses: A literature review | Existing strategies in energy efficiency control operations; Advanced simulations of greenhouse energy | The result showed that the cost and precision of sensors restrict the adoption of optimal controls by growers. |

| [85] | Manufacturing energy and greenhouse gas emissions associated with plastics consumption | Comparison of energy supply chain requirements; Greenhouse gas emissions caused by plastic production technologies; Development of bioplastic production technologies | The results indicated that commodity polymers, with a global consumption of 1 MMT per year, cause 3.2 quadrillion Btutus of energy and 104 MMT CO2e of GHG emissions annually in the US alone. |

| [86] | Demand side management of energy consumption in a photovoltaic integrated greenhouse | Analysis of activities in greenhouse production and electrical equipment performance; Particle swarm optimization scheme; Analysis of the energy consumption program in the greenhouse | The results showed that the optimization plan is useful for directing production activities in greenhouses and building photovoltaic integrated greenhouse systems. |

| [87] | Modeling and experimental validation of heat transfer and energy consumption in an innovative greenhouse structure | Modeling and experimental evaluation of heat and mass transfer functions in a solar greenhouse with a thermal screen | The results revealed that implementing a thermal screen could decrease both the final cost and air pollution. |

| [88] | The potential contribution of food wastage reductions driven by information technology on reductions of energy consumption and greenhouse gas emissions in Japan | Analysis of the effects of food waste; Reducing energy consumption; Reducing greenhouse gas emissions | The results showed that the reduction of GHG emissions would be between 5.6 to 7.8 million tons of CO2-eq per year. |

| [89] | Methodologies of control strategies for improving energy efficiency in agricultural greenhouses | Systematic review of control strategies to improve energy efficiency in greenhouses (especially low-energy greenhouses) | The results showed that 60% of the selected articles on greenhouse climate management consider temperature and humidity as controlled parameters. |

| [9] | Energy-economic-environmental cycle evaluation comparing two polyethylene and polycarbonate plastic greenhouses in cucumber production (from production to packaging and distribution) | Investigation of energy flow, economic benefit, and environmental effects in cucumber greenhouse cultivation; Measurement with two methods of LCA and Cumulative Exergy Demand (CExD) considering different greenhouse structures | The LCA results showed that the main environmental impacts come from direct emissions due to input consumption (air: carbon dioxide (CO2), and nitrogen oxides (NOx); soil: mercury (Hg), copper (Cu), and lead (Pb)) and indirect emissions induced by the production of chemical fertilizers, greenhouse structures, and chemical pesticides. |

| [90] | Impact of environmental factors on the energy balance of greenhouse for strawberry cultivation | Effects of solar greenhouses on strawberry cultivation in temperate regions; Energy required to heat the greenhouse; Experimental investigation of ambient temperature, solar radiation, and relative humidity | The result showed that passive solar heating may not suffice in cold regions with extended cloudy weather, requiring additional gas or electricity-based heating systems. |

| [91] | Thermo-environomic assessment of an integrated greenhouse with an adjustable solar photovoltaic blind system | Energy plus modeling as a greenhouse reference in rose cultivation; Validation of the developed greenhouse model with experimental site measurements; Investigating ambient temperature in the greenhouse with a photovoltaic system | The results showed that covering 19.2% of the roof can reduce natural gas consumption, electricity demand, and CO2 emission by 3.57%, 45.5%, and 30.56 kgm−2 annually, without affecting plant canopy illumination levels. |

| [92] | Nanomaterials application in greenhouse structures, crop processing machinery, packaging materials, and agro-biomass conversion | Application of nanomaterials in agricultural products; Investigating nanotechnology in climate control and photosynthesis of plants in the greenhouse | The reviewed work indicated that nanotechnology has the potential to enhance agricultural production. |

| [52] | Energy-sustainable greenhouse crop cultivation using photovoltaic technologies | Examining the important aspects of greenhouse cultivation and the electricity required; Studying state-of-the-art photovoltaic systems in the greenhouse and their shading effects on plants; A vision for sustainable greenhouses with photovoltaic technologies | The results showed that solar cells can be used in greenhouses to generate electricity, but the shading from photovoltaic panels can impact plants below. |

| Refs. | Titles | Purpose and Review | Results |

|---|---|---|---|

| [2] | Recycling drainage effluents using reverse osmosis powered by photovoltaic solar energy in hydroponic tomato production: Environmental footprint analysis | Measuring the environmental benefits and trade-offs of reverse osmosis integration; Recycling of greenhouse drainage effluents using photovoltaic solar system; Comparison of the environmental footprint of tomato production in two types of conventional and hydroponic cultivation; Comparison of three independent sources of irrigation | The results showed that using brackish groundwater as a substitute for desalinated seawater can reduce the global warming footprint by 27%. |

| [17] | Hydroponic and Aquaponic Farming: Comparative Study Based on Internet of things IoT technologies | Comparison of hydroponic and aquaponic cultivation systems; Using the automatic technology of the Internet of Things (IoT) | The results showed that implementing a depth-camera module in the system offered an advantage, and a mobile application to maintain the ecological balance of the environment. |

| [103] | Validation of a building energy model of a hydroponic container farm and its application in urban design | Validation of Energy Plus model in container hydroponic culture; Continuation of experiments for nine months and data collection; Studying energy consumption and its optimization | The results showed that stakeholders can reliably predict annual container farm energy use by representing plant–air interactions within EnergyPlus. |

| [1] | Autonomous greenhouse microclimate through hydroponic design and refurbished thermal energy by phase change material | Evaluation of the microclimate of hydroponic greenhouse cultivation without heating; Hydroponic design evaluation; Comparison of environmental conditions inside the greenhouse during the day and night | The results showed that hydroponic greenhouses offer better conditions than conventional ones, with temperatures above 18 °C and a humidity range of 20–35% during the day. |

| [104] | Hydroponic system and desalinated seawater as an alternative farm-productive | Comparison of energy consumption of lettuce production in two types of conventional and hydroponic greenhouse cultivation; Investigating the amount and emission of greenhouse gases; Comparison of different percentages of desalinated seawater for irrigation | The results showed that desalinated seawater with hydroponic systems can sustain agriculture but relies heavily on energy. |

| [21] | Comparison of soil and hydroponic cultivation systems for spinach irrigated with brackish water | Measurement of differences in the water status of spinach plants; Using brackish water to grow plants in covered soil, non-covered soil, and hydroponic cultivation system; Investigating the leaf water and osmosis potential of the product and also its regulation | The results showed that the spinach plant adjusts to salinity with adaptive strategies by increasing osmotic adjustment and leaf succulence, reducing leaf water potential. Sodium concentration in leaves and fresh weight are highest in hydroponic cultivation, especially with brackish water. |

| [56] | Evaluation of hydroponic systems for the cultivation of Lettuce (Lactuca sativa L., var. Longifolia) and comparison with protected soil-based cultivation | Investigating the suitability of hydroponic cultivation of lettuce in replacing greenhouse soil-based cultivation; Study of two hydroponic techniques including deep-water culture and nutrient film technique and compare them with conventional greenhouse cultivation; Using Tukey’s test to investigate crop performance, water consumption and economy | The results indicated that hydroponic techniques outperformed soil-based systems with a higher yield, simplicity, ease of operation, economic feasibility, and nutritionally superior produce. |

| [33] | A new method for green forage production: Energy use efficiency and Environmental sustainability | Evaluating energy and water consumption in hydroponic fodder production; Study of environmental indicators | The results showed that despite the many benefits of hydroponic fodder on livestock nutrition, its greenhouse cultivation imposes many adverse environmental effects. |

| Items (unit) | Energy Equivalent (MJ unit−1) | References |

|---|---|---|

| Human labor (hr) | 1.96 | [70] |

| Stationary equipment (kg yr) | 9 | [80] |

| Natural gas (m3) | 49.5 | [80] |

| Nitrogen fertilizer (kg) | 66.14 | [105] |

| Pesticides (kg) | 199 | [106] |

| Electricity (kWh) | 11.93 | [107] |

| Seed (kg) | 14.7 | [108] |

| Hydroponic Fodder Yield (kg) | 1.66 | [109] |

| Inputs | Diesel Fuel (kg MJ−1) | Natural Gas (kg (m3)−1) | Human Labor (kg. man-h−1) | Electricity (kg. kwh−1) |

|---|---|---|---|---|

| CO2 emissions to air | 74.5 | 0.0133 | 0.07 | 0.58 |

| Environmental Impact | Unit | Method 1 | Method 2 | ||

|---|---|---|---|---|---|

| Characterization | Normalization | Characterization | Normalization | ||

| Global warming | Kg CO2 eq | 888.55 | 3.44 × 10−9 | 1983.43 | 7.7 × 10−9 |

| Inputs | CO2 Gas Emissions | Unit | Sources |

|---|---|---|---|

| Diesel | 0.07 | kg CO2eq MJ−1 | [171] |

| Electricity | 0.210 | kg CO2eq kWh−1 | |

| Machinery and irrigation systems | - | ||

| PVC sheet | 5.7 | kg CO2eq m2 | [172] |

| Steel | 1.76 | kg CO2eq m2 | [173] |

| PE | 2.2 | kg CO2eq m2 | [172] |

| PVC | 3.0 | kg CO2eq m2 | [172] |

| Copper | 6 | kg CO2eq m2 | [172] |

| Fertilizers | [174] | ||

| N | 1.3 | kg CO2eq kg−1 N | - |

| P2O2 | 0.2 | kg CO2eq kg−1P2O5 | - |

| K2O | 0.15 | kg CO2eq kg−1K2O | - |

| Pesticides | [174] | ||

| Fungicides | 3.9 | kg CO2eq kg−1 | - |

| Insecticides | 5.1 | kg CO2eq kg−1 | - |

| Herbicides | 6.3 | kg CO2eq kg−1 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farvardin, M.; Taki, M.; Gorjian, S.; Shabani, E.; Sosa-Savedra, J.C. Assessing the Physical and Environmental Aspects of Greenhouse Cultivation: A Comprehensive Review of Conventional and Hydroponic Methods. Sustainability 2024, 16, 1273. https://doi.org/10.3390/su16031273

Farvardin M, Taki M, Gorjian S, Shabani E, Sosa-Savedra JC. Assessing the Physical and Environmental Aspects of Greenhouse Cultivation: A Comprehensive Review of Conventional and Hydroponic Methods. Sustainability. 2024; 16(3):1273. https://doi.org/10.3390/su16031273

Chicago/Turabian StyleFarvardin, Mahrokh, Morteza Taki, Shiva Gorjian, Edris Shabani, and Julio C. Sosa-Savedra. 2024. "Assessing the Physical and Environmental Aspects of Greenhouse Cultivation: A Comprehensive Review of Conventional and Hydroponic Methods" Sustainability 16, no. 3: 1273. https://doi.org/10.3390/su16031273

APA StyleFarvardin, M., Taki, M., Gorjian, S., Shabani, E., & Sosa-Savedra, J. C. (2024). Assessing the Physical and Environmental Aspects of Greenhouse Cultivation: A Comprehensive Review of Conventional and Hydroponic Methods. Sustainability, 16(3), 1273. https://doi.org/10.3390/su16031273