Abstract

This paper develops a technology for manufacturing a biocomposite using post-production wood waste as filler, but also as an alternative material that can substitute traditional composites. Three types of post-production wood waste, i.e., ash wood chips, oak chips and medium-density wood fiberboard (MDF), were used in this study. Three different biocomposites were produced for each of these materials, differing in the content of waste to polymer. The biodegradable and compostable bioplastic Mater-Bi (CF05S) was obtained using the pioneering proprietary technologies of Novamont company using starches, cellulose, vegetable oils and their combinations. Mater-Bi was used as the matrix of the composite, which, due to its chemical composition, allows the production of fully biodegradable composites. The physicochemical properties, such as static tensile, impact, water absorption and hardness, were investigated. The results provide the basis for a detailed analysis of the properties of the biocomposites and made it possible to accurately determine their properties. The results show that the optimal solution is the Mater-Bi biocomposite with 20 wt.% oak filler content, which shows the most favorable adhesion strength and water absorption. The research conducted here is in the context of issues related to sustainability and a circular economy, through waste management, as well as through the production of biodegradable construction products.

1. Introduction

The contemporary materials industry, including recycling, are sectors of the economy that hold an important role. In recent years, increasing importance has been attached to sustainability, minimizing the carbon footprint and protecting the environment. In this perspective, biomaterials are gaining popularity as solutions that combine innovation, efficiency and minimal environmental impact [1,2,3].

The recycling and recovery of materials are important aspects of the concept of biomaterials. They are designed to be recyclable and reusable. Recycling processes for biomaterials include the segregating, shredding and processing of waste materials to produce regranulates that can be used to manufacture new products. In this way, biomaterials contribute to reducing waste and maximizing the use of raw materials [2,4].

Biocomposites are materials that combine two or more components, a polymer matrix and the reinforcement of natural origins. The polymer matrix can be a biopolymer or a traditional polymer, while reinforcement can derive from natural fibers, and plant particles such as cellulose, lignin, starch, flax fibers or bamboo. Biocomposites with natural fillers combine the characteristics of both materials while linking the properties of plastics, such as flexibility and moldability, with the benefits of natural filler, such as strength, low product weight and biodegradability [5,6]. The classification of biocomposites could be based on the type of matrix, reinforcement types, production method or application [5,7].

Biocomposites have found applications in various scientific fields and industries. In the automotive industry, they are used as lightweight structural materials that help reduce the vehicle weight and emissions. In the construction industry, the materials are used as finishing, insulation and construction materials that offer excellent thermal insulation, strength and durability. In food and disposable packaging, they are replacing traditional plastics, minimizing environmental impact [6,8]. Figure 1 shows examples of where biocomposites can be used in the automotive industry as a covering element (Figure 1a) and the construction industry, as interior components made of WPC composite (Figure 1b).

Figure 1.

Examples of biocomposite applications in (a) the automotive industry and (b) the construction industry.

Another important aspect of biocomposites is in reducing raw material consumption. The use of nature-based components, such as cellulose or lignin, reduces dependency on traditional petrochemical raw materials. In addition, biocomposites can be produced from agricultural or industrial wastes, which contributes to their efficient management and reduces the amount of waste generated. The mechanical properties of biocomposites are also important in terms of their applications. Thanks to reinforcements of natural origin, for example, plant fibers, biocomposites can achieve high strength and stiffness. Therefore, biomaterials are appealing to the automotive, aerospace or construction industries, where lightweight and durable materials are crucial [1,2,3,4].

The ecological aspects of wood waste provide an opportunity for its effective use as a filler for the development of a biocomposite, also providing an opportunity for the management of this type of waste. Large amounts of waste in the form of wood chips in companies’ warehouses are due to restrictions on burning this waste in furnaces by stricter environmental standards aimed at reducing the pollution generated in the combustion process. The use of wood waste as fillers for biocomposites carries the potential to reduce waste. In addition, wood fibers have a beneficial effect on the strength properties of biocomposites [9,10,11,12,13,14,15].

Wood chip-filled biocomposites are advanced materials that combine the advantages of natural plant raw materials with sophisticated technology. These materials are an alternative to the traditional composites used in the automotive industry and offer several environmental and technical benefits. They are lightweight, low-density and have a positive impact on the environment due to the use of renewable raw materials. In addition, the materials can exhibit good mechanical properties, such as tensile strength and impact strength [15,16,17].

The application of wood chip filler biocomposites in vehicle interior components represents an innovative step in the automotive industry. The materials combine environmental and technical benefits, offering an alternative to traditional composites. Biocomposites mainly consist of a polymer matrix and a filler in the form of wood chips, extracted from wood waste, which are used mainly in vehicle interior components [18,19].

Dashboards made from these materials are not only aesthetically appealing but also lightweight and durable, resulting in a modern cabin appearance. Additionally, door panels made from biocomposites not only reduce the weight of the vehicle but can also improve driving comfort by reducing noise and vibration. Car seats made with biocomposites are especially used in the construction of upholstery support components, combining comfort with a sustainable manufacturing approach. In addition, biocomposites can be used in a variety of interior trim elements, such as moldings, decorative details and storage compartment covers, giving the vehicle’s interior a unique design. As another application example, biocomposites can be used for pushbuttons, lighting elements or other trim details, which contributes to the attractive appearance of controls in the vehicle cabin. The introduction of these innovative materials into the automotive industry not only responds to the growing consumer expectations for sustainable production but also represents an important step toward a green future for the automotive industry [18,19,20,21,22,23,24,25].

The need to develop sustainable manufacturing materials has grown into a pressing social need in recent years. However, the transition to sustainable materials from conventional fossil fuel-based materials, which are deeply rooted and well accustomed to in industry, is proceeding at a slow rate. Therefore, further development and research into natural materials as well as biocomposites is a very important aspect [26,27].

This study aims to develop a technology to produce biocomposites using post-production wood waste as fillers, which will provide a way to manage waste from wood processing companies. The study envisages obtaining an alternative biocomposite, using natural materials, that could replace traditional composites.

2. Materials and Methods

2.1. Material Processing

To manufacture the biocomposites, Novamont’s Mater-Bi CF05S biodegradable plastic was used as the matrix, while three different post-production wastes, i.e., wood waste from pure oak and pure ash wood as well as MDF, were used as the filler. Table 1 shows the different compositions and designations of the composites.

Table 1.

Symbols and materials composition.

Mater-bi is derived from renewable agricultural raw materials and non-genetically modified starch. Mater-Bi is a commercially available thermoplastic composed of starch and polyethylene-vinyl alcohol (PEVOH), manufactured by Novamont. This material is biodegradable and compostable in soil, freshwater and saltwater. Mater-Bi shows a density of about 1.25 and a molecular weight > 10,000 g/mol [28,29].

The natural post-production wood waste used in the production of biocomposites was ash wood and oak. For ash wood, the density is 0.80 g/cm3 and the moisture content is 10%, while the density of oak is about 0.95 g/cm3, with its moisture content at 10%.

Medium-density fiberboard (MDF) is produced primarily from wood waste. MDF is a wood-based composite, with wood fibers as its main component. It is produced by molding to create a board of specific dimensions and with processing at a high temperature and pressure. The fibers are joined by adhesives containing compounds such as phenol, resorcinol, cresol and formaldehyde, or amino compounds such as urea and melamine. MDF, in its composition, contains up to 9 wt.% of adhesives and additives. The density of MDF is about 850 [30].

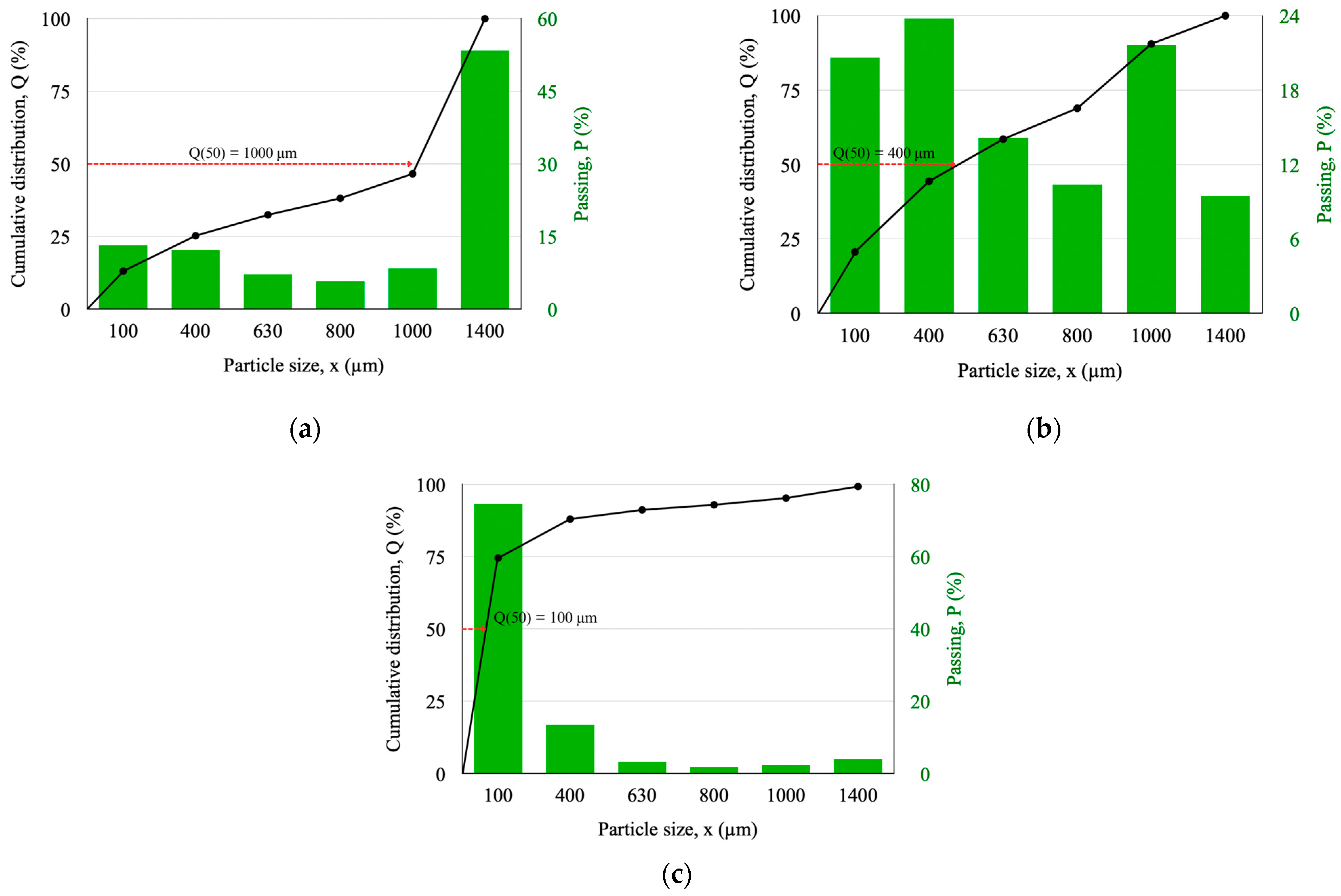

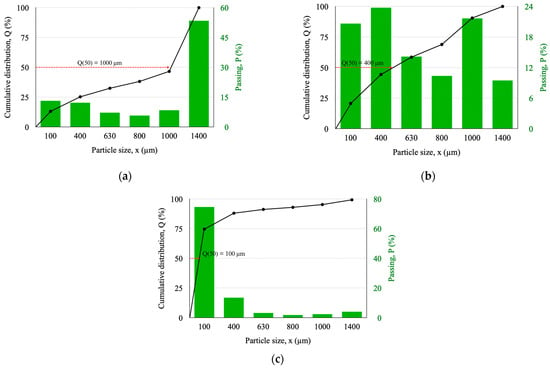

The materials that constitute the fillers were created by wood processing. To standardize the fractions, the materials were ground using a Shini SG-1411-CE-X knife mill (Shini Plastics Technologies Inc., Taipei, Taiwan). Sieve analysis was then performed using a Vibratory Sieve Shaker Fritsch ANALYSETTE 3 120 Pro apparatus (Idar-Oberstein, Germany). Sieve sizes of 1400 μm, 1000 μm, 800 μm, 630 μm, 400 μm and 100 μm were used for the test. The test time was 3 min with an interval of 5 s, while the amplitude was equal to 1 mm. Figure 1 shows the results of the sieve analysis of the tested fillers.

Figure 2 graphically shows the mass fractional shares (P) in the form of a histogram, while the cumulative distribution curve (Q) is illustrated with a line graph. In the case of ash wood chips (Figure 2a), the 1400 μm fraction makes up the largest part of the sample, accounting for about 73%. The median of the distribution can also be determined from the graph. For ash wood chip filler, 50% of the sample’s weight is made up of fractions equal to or smaller than 1000 μm. From Figure 2b, which shows the results of the sieve analysis of oak chips, it can be seen that the fractions of 100 μm, 400 μm and 1000 μm show the largest share. Half of the sample weight is accounted for by fractions equal to or smaller than 400 μm. Figure 2c illustrates the results obtained for MDF dust. Based on the data obtained, it was determined that 75% of the fractions were particles with a dimension of 100 μm and the median weight of the sample was 100 μm.

Figure 2.

Distribution curve of cumulative fraction (Q) and percentage fraction (P) of fillers used in the study: (a) ash wood, (b) oak and (c) MDF.

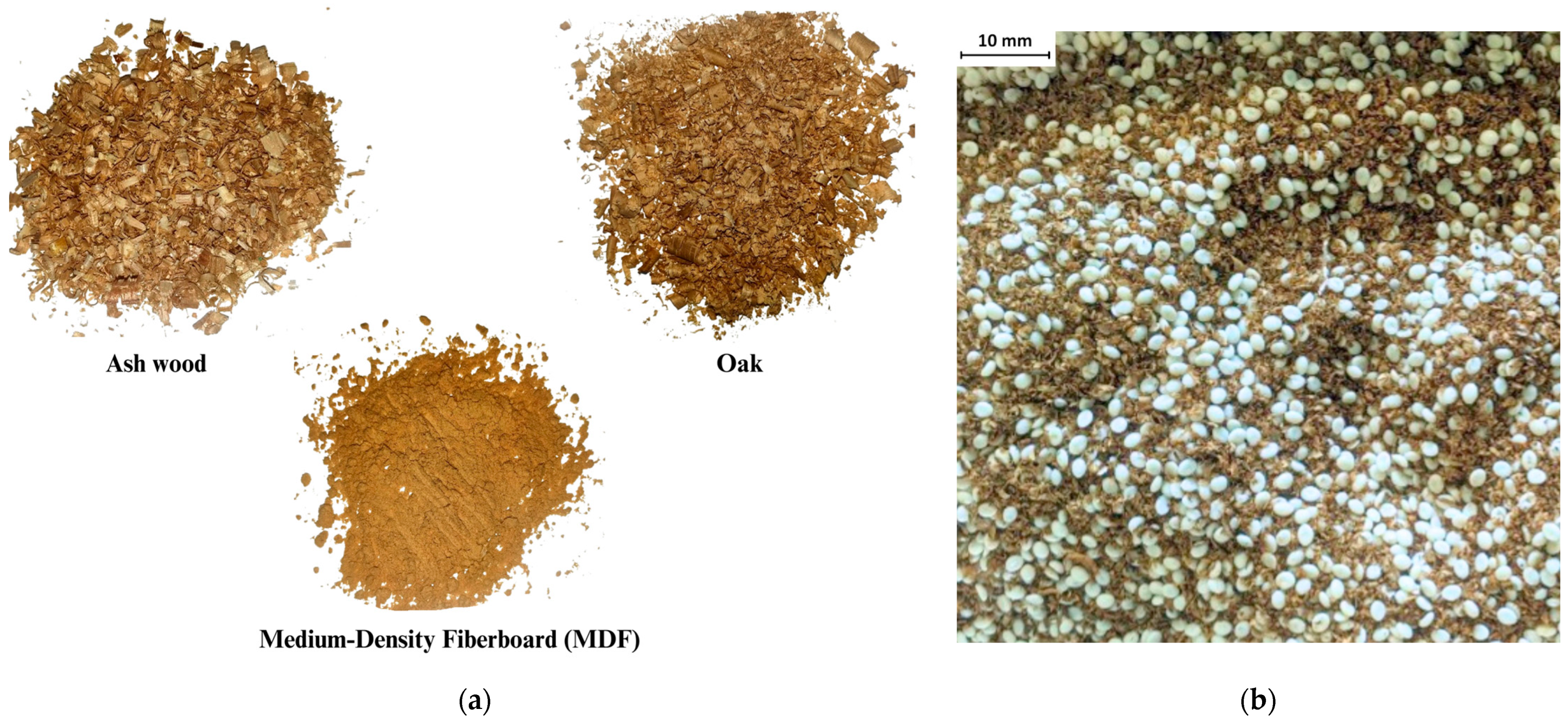

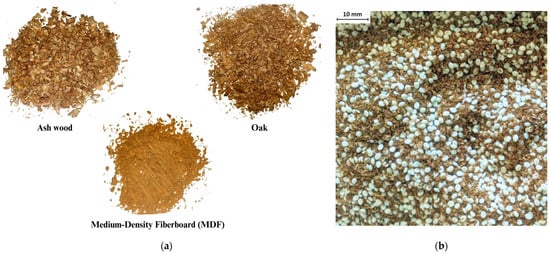

The fillers were then soaked in a two percent sodium hydroxide (NaOH) solution to change the surface properties. This change was implemented to improve the adhesion of the filler with Mater-Bi. The solution was boiled using an electric stirrer, and the soaking lasted two hours. The fillers were dried for 24 h at 80 °C, while the Mater-Bi was dried for 24 h at 70 °C using a laboratory dryer (Binder, Holzgerlingen, Germany). Then, depending on the composite, appropriate amounts of matrix and filler were mixed. Figure 3 shows the post-production wood waste used (Figure 3a) and an example of a Marte-Bi with filler blend (Figure 3b).

Figure 3.

Post-production wood waste (a); Mater-Bi with filler blend (b).

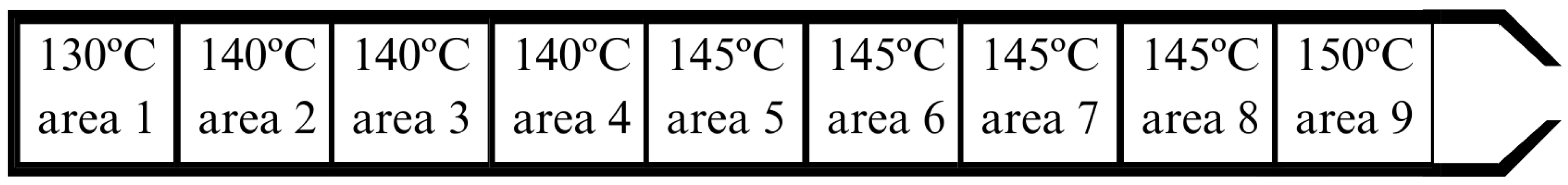

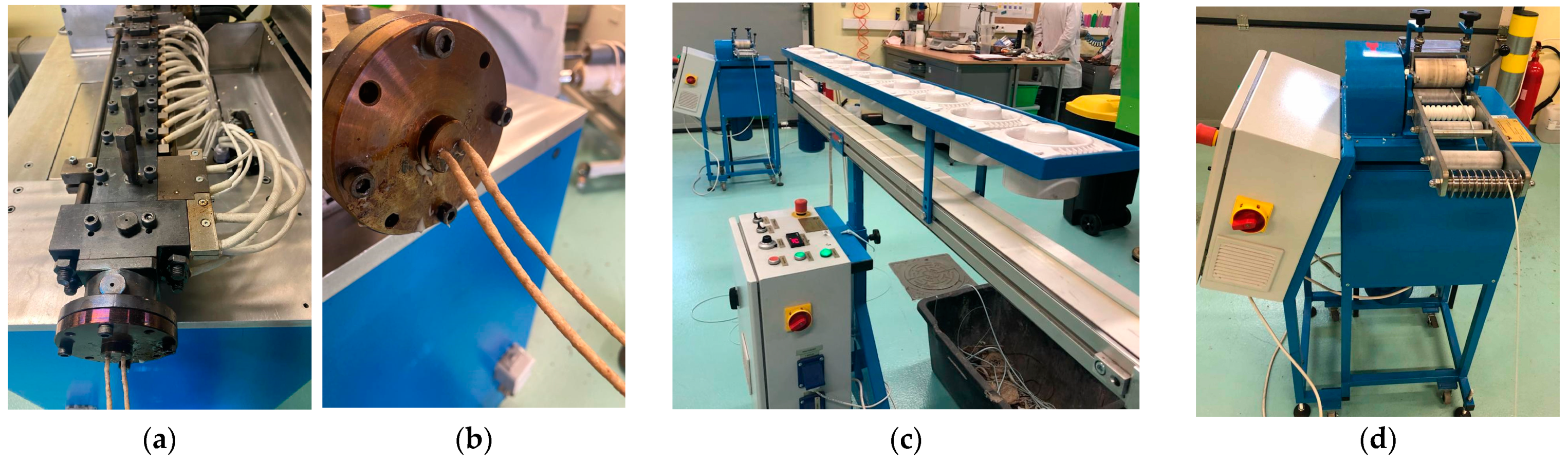

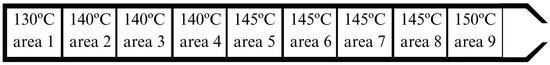

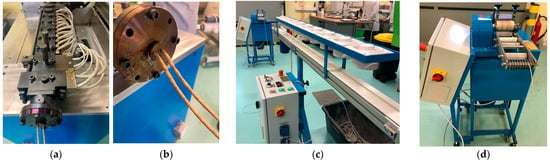

A twin-screw extruder (Zamak, Skawina, Poland) was used to produce pellets, along with a line designed to cool the extrudate and a pelletizing device. Figure 4 shows the temperature scheme of the various zones during the biocomposite extrusion process. The process resulted in granules with a fraction size of 3–5 mm. The components of the regranulate production line are shown in the Figure 5.

Figure 4.

Process parameters of Mater-Bi biocomposites extrusion.

Figure 5.

Components of the regranulate production line: a twin-screw extruder (a), extrudate in the form of a rode (b), air cooling system (c) and granulator (d).

2.2. Sample Preparation

From the prepared biocomposites, standardized shapes (150 mm × 10 mm × 4 mm) were made by injection molding technology for the evaluation of the mechanical properties and structure, following the ISO 527-2 standard [31]. An Engel Victory 50 injection molding machine was used for their manufacture. The parameters of the biocomposite injection molding process are shown in Table 2.

Table 2.

Process parameters for injection molding of biocomposites.

2.3. Characterization of Composites

2.3.1. Density

The density of the composites was determined by the hydrostatic method according to ISO1183-1:2013 [32] using AXIS AD200 balance (Gdansk, Poland). The test was carried out at 20 °C with distilled water with a density of 1 g/cm3. The measurement was performed for five samples from each series.

2.3.2. Water Absorption

The water absorption test was carried out following PN-EN ISO 62:2008 [33]. Before determining their initial weight, all samples were subjected to drying. Then, the materials were placed in distilled water at 25 °C for 24 h. After the immersion time, the samples were removed from the water, dried and weighed to the nearest 0.001 g. The amount of water absorbed by the biocomposites was calculated according to Equation (1):

where —the mass of the sample before immersion in water [g] and —the mass of the sample after removal from water [g]

2.3.3. Mechanical Properties

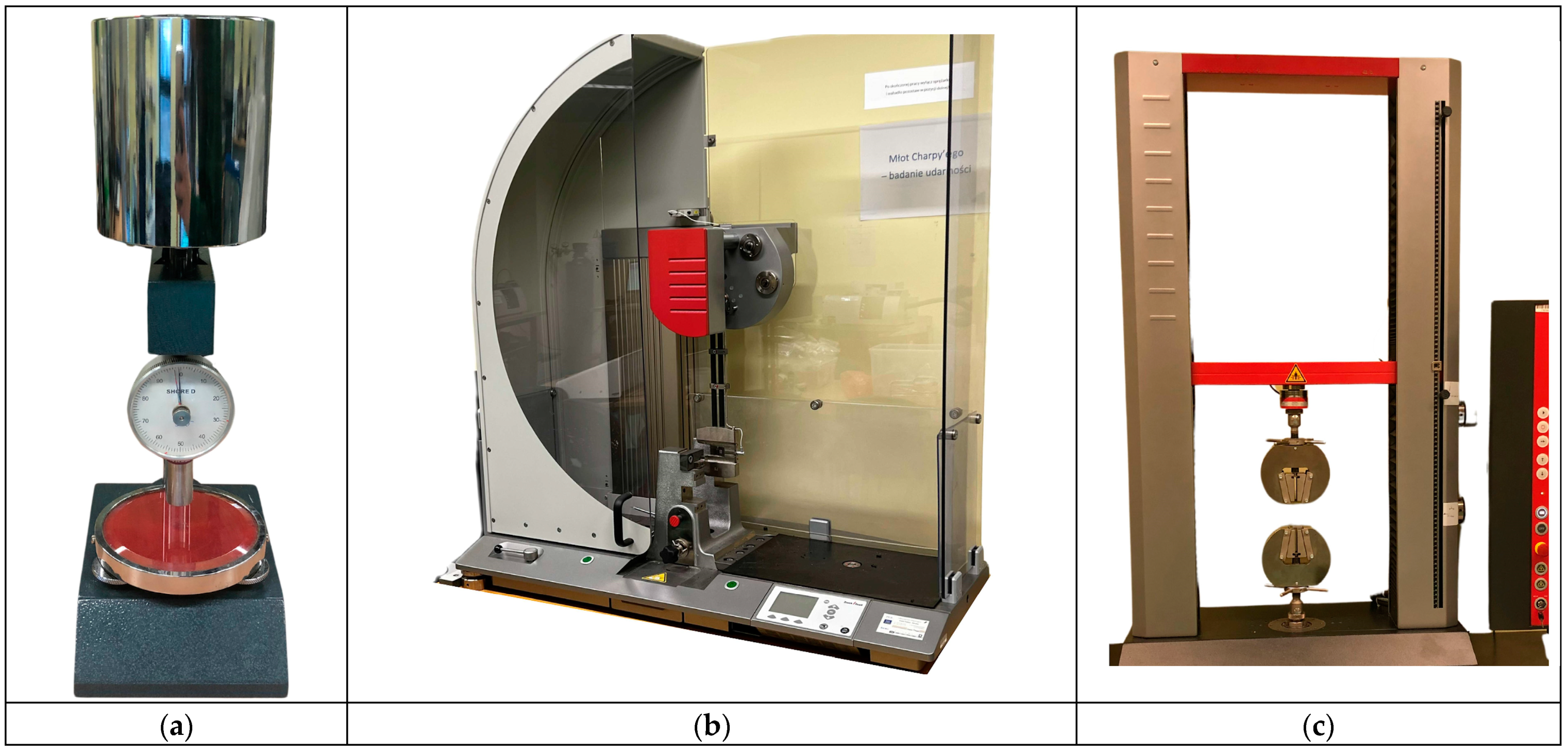

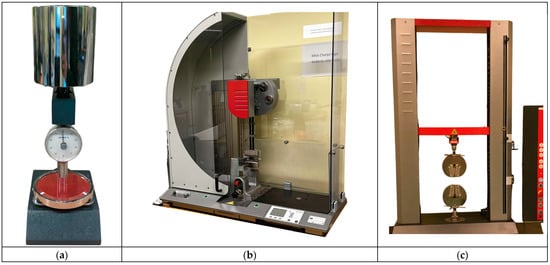

Mechanical properties, such as static tensile, impact and hardness of pure Mater-Bi and biocomposites, were assessed. Figure 6 shows the equipment that was used to conduct the tests.

Figure 6.

Equipment used to determine mechanical properties: Shore hardness tester (a), Charpy hammer (b) and universal testing strength machine (c).

The hardness of the composites was determined using a SAUTER Shore hardness tester on the D scale (Figure 6a), following the PN EN ISO 868 standard [34]. Five measurements were taken on both sides of the sample of each type of biocomposite.

The impact test was carried out using the Charpy method by PN EN ISO 179 [35]. Five measurements were made for each biocomposite. The test was carried out using a Zwick Roel Charpy hammer (Figure 6b), HIT25P (Ulm, Germany). The test was carried out at room temperature.

The tensile properties of the produced biocomposites with different filler content were evaluated by static tensile test. The test was performed by PN EN ISO 527-2 [31]. The measurement was carried out at a tensile speed of 50 mm/min, at ambient temperature using a Zwick Roel Z010 (Figure 6c) universal strength machine (Ulm, Germany). For each type of material, five measurements were taken. The obtained stress–strain strength curves for the composites were the basis for determining the mechanical characteristics, i.e., tensile modulus, tensile strength, tensile at break and elongation at break.

2.3.4. Microscopic Evaluation of Structure

The breakthrough structure of the biocomposites was evaluated using an OPTA-TECH SK-series stereoscopic microscope with a microscope camera for image capture processing and measurements.

3. Results and Discussion

3.1. Density Determination and Water Absorption Results

Table 3 illustrates the results of the density determination and water absorption of the obtained materials The values shown are the mean values of five measurements along with the standard deviation.

Table 3.

Density and water absorption of materials.

The results show that the density of the biocomposites increases with the increase in the filler content in the mixture. Regardless of the type of filler used, the density value increases compared to unmodified Mater-Bi. Comparing the results obtained for MB1 and MB2 biocomposites, it can be assumed that the density of the biocomposites is influenced by the density of the filler used, i.e., oak shows a 10 wt.% higher density in the fresh-cut state compared to ash wood. Therefore, it can be seen that biocomposite M1, which is filled with oak chips, shows a higher density compared to M2, which contains ash wood chips. The highest density value of 1.294 was obtained for a biocomposite containing 80 wt.% Mater-bi and 20 wt.% filler in the form of oak chips.

It can be seen that, as the filler content increases, the water absorption of the biocomposites increases. The MB3 composite containing 20 wt.% MDF dust has the highest water absorption of 3.75%, while the MB2/5 material filled with oak chips has the lowest water absorption of 2.22%. Comparing MB1-MB3 composites, it can be noted that composites containing oak chip filler (MB2) show a lower water absorption value compared to composites filled with MDF dust (MB3) or ash wood chips (MB1). It can also be noted that an increase in the content of the filler does not cause a sharp increase in water absorption compared to other tested fillers. An important feature of composites that contain natural fillers is that they exhibit the lowest possible water absorption. Therefore, products manufactured from the materials in question will have higher dimensional stability.

3.2. Mechanical Properties of the Composites

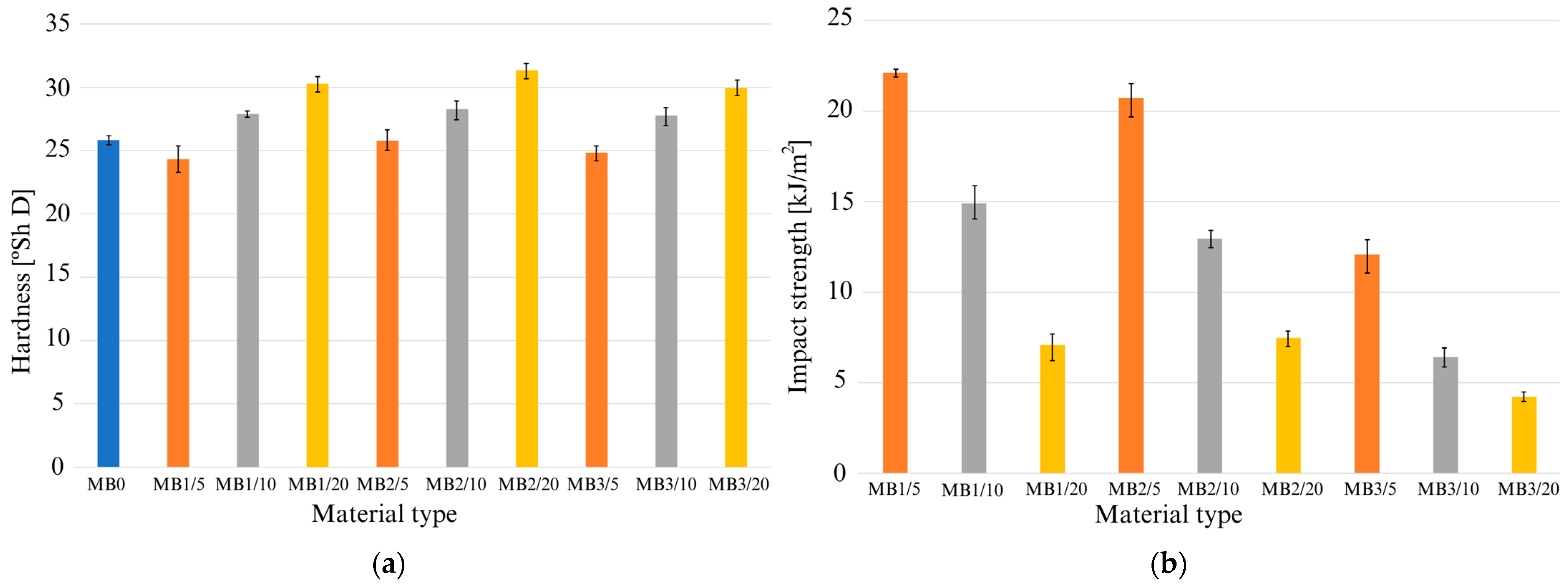

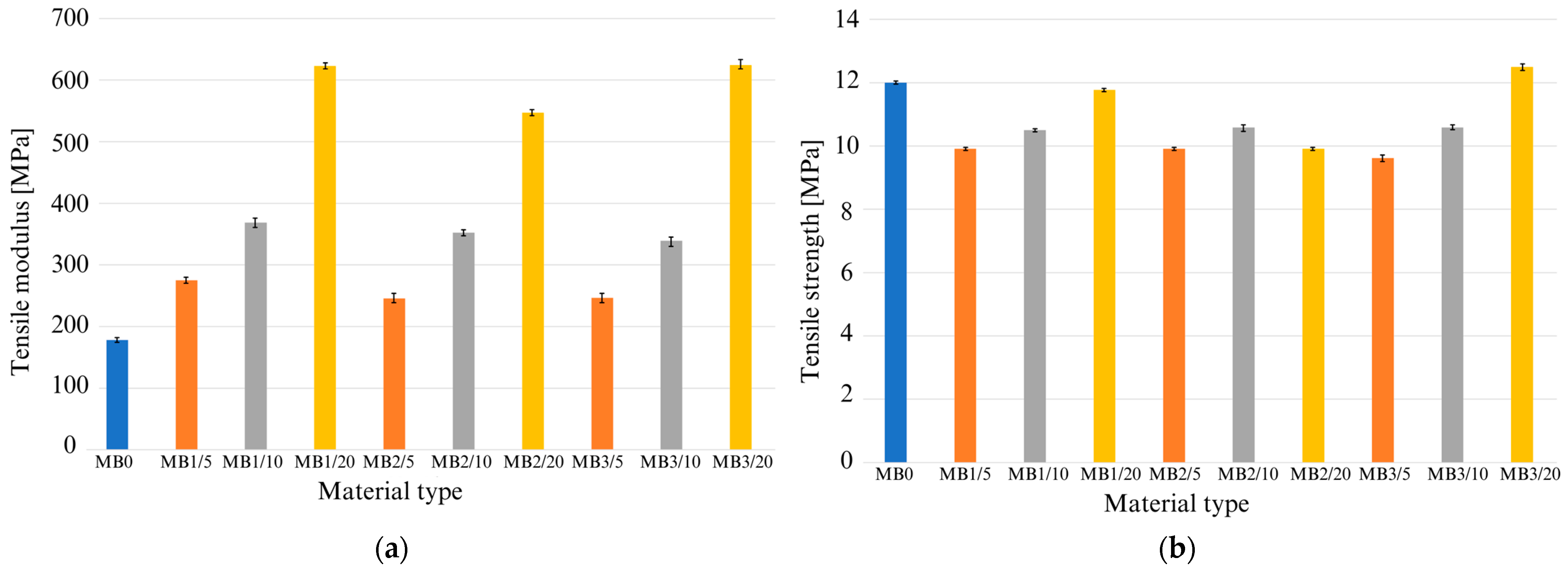

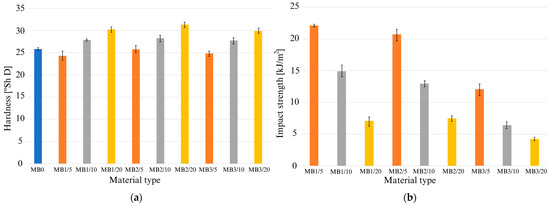

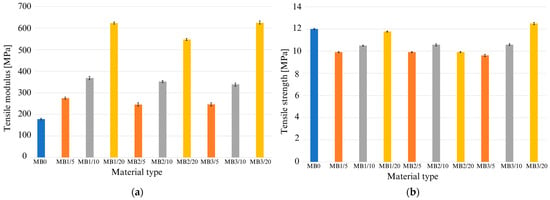

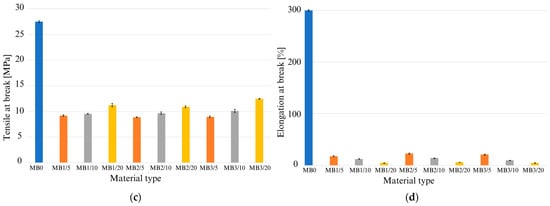

Figure 7 and Figure 8 show the results of the mechanical properties of the tested composites. The measurement results shown are the average values obtained from five measurements along with the standard deviation. The MB0 material was not included in the impact test because it is too flexible and did not fracture during the measurement but was slightly deformed.

Figure 7.

Mechanical properties of biomaterials: (a) hardness and (b) impact strength. Color indication: blue—pure Mater-Bi, orange—biocomposites containing 5 wt.% filler; gray—biocomposites containing 10 wt.% filler; yellow—biocomposites containing 20 wt.% filler.

Figure 8.

Mechanical properties of biomaterials: (a) tensile modulus, (b) tensile strength, (c) tensile at break and (d) elongation at break. Color indication: blue—pure Mater-Bi, orange—biocomposites containing 5 wt.% filler; gray—biocomposites containing 10 wt.% filler; yellow—biocomposites containing 20 wt.% filler.

Figure 7a shows the hardness results of the tested biocomposites. Based on the results, it can be concluded that MB2 composites containing filler in the form of oak chips show the highest hardness compared to the other samples. Biocomposites for which 5 wt.% filler was used to show lower hardness values compared to pure Mater-Bi, as well as the other composites. The highest hardness value of approx. 31°Sh D is shown by the MB2/20 composite containing 20 wt.% oak chips. Comparing the results of the composites containing 10 wt.% and 20 wt.% filler, it can be concluded that the composite containing 10 wt.% filler shows higher hardness values by about 12%.

A comparison of the impact strength values of the tested composites is shown in Figure 7b. It can be seen that, as the filler percentage increases, the impact strength of the biocomposites decreases. The highest value of 22.13 is shown by biocomposite MB1/5 containing 5 wt.% filler in the form of ash wood chips. Composites containing ash wood chips show slightly higher impact strength values compared to composites containing oak chips, while composites containing MDF dust show lower values compared to the other composites analyzed. The lowest impact strength of 4.22 shows MB3/20 composite containing 20 wt.% MDF dust. This means that, as the filler in the composite increases, the resistance to brittle fracture decreases, i.e., the material is more resistant to dynamic loading.

Figure 8a illustrates the Young’s modulus values of MB0-MB4 materials. From the results, it can be seen that the addition of 5 wt.% filler to Mater-Bi results in an increase in the tensile modulus of about 45% for all tested biocomposites and, in the case of mixtures containing 20 wt.% filler, the increase reaches 250% for the biocomposite containing ash wood and MDF dust chips, and 200% for C4 with oak chips. The MB0 material containing only Mater-Bi has a Young’s modulus of about 180 MPa, while biocomposites with fillers show a modulus ranging from 550 MPa to 640 MPa. The modulus is 300% higher for biocomposites compared to unmodified Mater-Bi.

A comparison of tensile strength values for the tested materials is shown in Figure 8b. The highest tensile strength value of 12.5 MPa was obtained for the MB3/20 composite containing 20 wt.% MDF dust in its composition. Comparing MB1 and MB2 materials in relation to MB0, it can be concluded that the introduction of filler decreases the tensile strength value compared to pure Mater-Bi, while, as the filler content increases, the tensile strength increases by about 7%.

Figure 8c compares the obtained values of tensile strength at the break for the MB0-MB3 composites tested. Based on the results, it can be concluded that the introduction of filler results in an increase in the values of tensile strength at break. Composites containing 5 wt.% and 10 wt.% filler show similar values of about 10 MPa, while, in comparison with composites filled in 20 wt.%, an increase in the tensile at break value of about 18% can be observed. The highest tensile strength at break value is shown by the MB3/20 composite containing 20 wt.% MDF dust.

A comparison of the values of elongation at break for the tested blends is shown in Figure 8d. Based on the results, it can be concluded that the introduction of filler results in a sharp decrease in the values of the elongation at break of the biocomposites, amounting to about 95%, compared to pure Mater-Bi. The highest value of elongation at break for filler-containing materials, amounting to 22.8%, is shown by biocomposite MB2/5 containing 5 wt.% oak chips in its composition. The results also show that, as the amount of filler in the composite increases, the value of elongation at break decreases. Comparing each group of tested biocomposites, it can be seen that the composites containing oak chips (MB2) show a higher value compared to composites for which filler in the form of ash wood chips (MB1) or MDF dust (MB3) was used. The lowest value of elongation at break, which was about 4.68%, was obtained for the MB3/20 composite containing 20 wt.% MDF dust.

3.3. Microscopic Surface Morphology Analysis

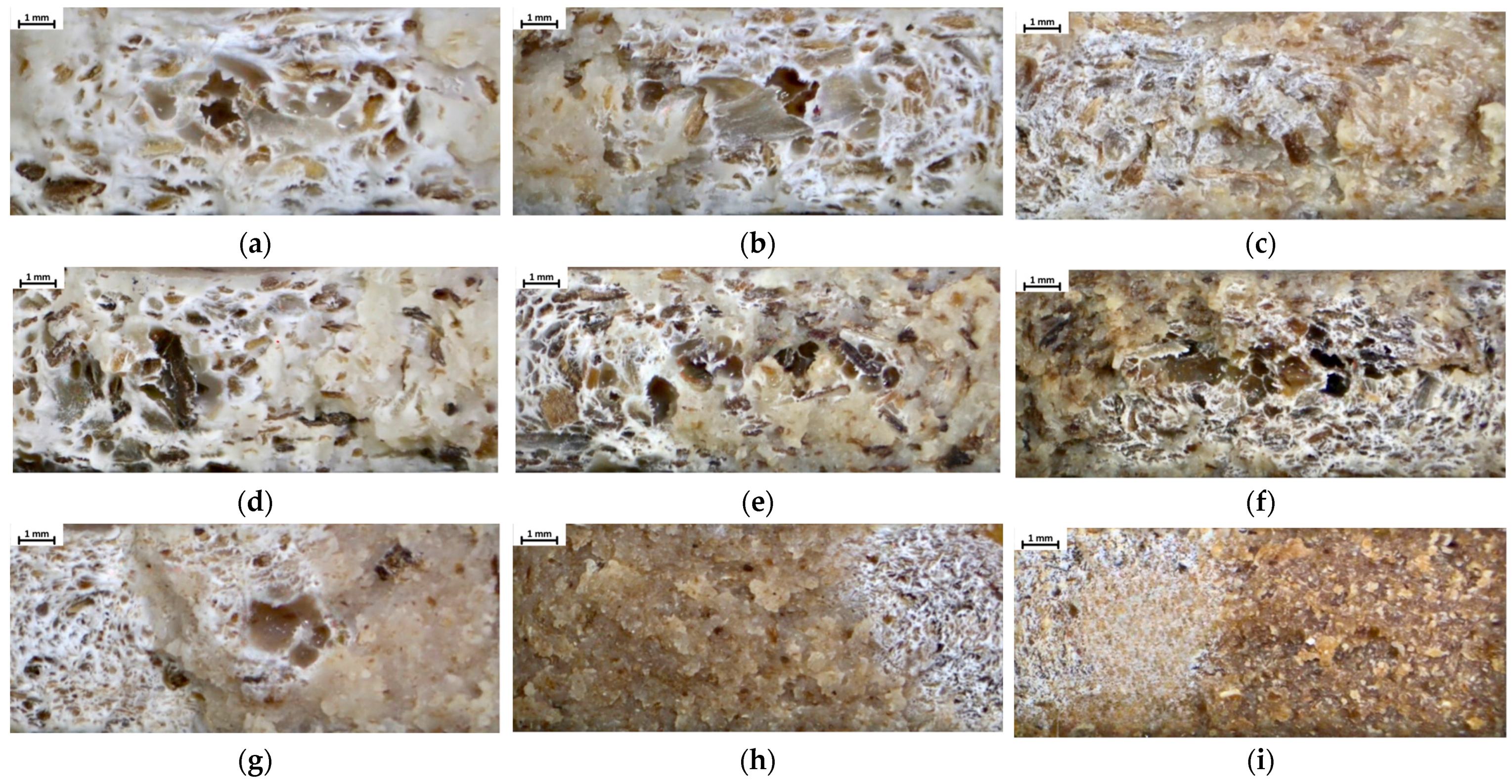

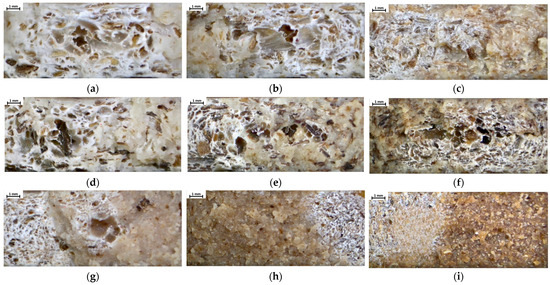

Figure 9 shows microscopic images of the surface morphology of the fracture surfaces of MB1-MB3 biocomposites with different amounts of filler, obtained by static tensile testing of the tested materials.

Figure 9.

Microscopic images of biocomposites: (a) MB1/5, (b) MB1/10, (c) MB1/20, (d) MB2/5, (e) MB2/10, (f) MB2/20, (g) MB3/5, (h) MB3/10 and (i) MB3/20.

Figure 9 shows microscopic images of the fractures obtained during the static tensile test of the MB0-MB3 biocomposites. Based on the results, it can be concluded that the composites containing filler in the form of MDF dust are distinguished by the most homogeneous structure compared to the other tested materials. From Figure 9g–i, it can be seen that fine particles of MDF filler are visible, and are uniformly dispersed throughout the volume.

Microscopic analysis showed that, in the case of oak (Figure 9a–c) and ash wood (Figure 9d–f), which exhibit a fraction with larger particles, their use results in a less homogeneous material structure. In the case of these fillers, one can also notice the presence of more free spaces in the structure, which can contribute to a decrease in strength properties. Biocomposites containing 20 wt.% filler, compared to other materials, show a smaller amount, as well as smaller free spaces in the structure. This may be due to the higher proportion of sodium hydroxide (NaOH) in the structure, with which oak, ash wood and MDF wood waste were soaked. The use of the chemical compound increases the adhesion between the Mater-Bi matrix and the wood waste filler.

4. Conclusions

The present study aimed to develop a method of managing natural wood waste from wood processing plants. Biocomposites in the Mater-Bi matrix modified with wood fillers were manufactured from the collected waste.

Based on the results obtained, the mechanical properties of the produced biocomposites were determined and compared. As the percentage of filler in the biocomposite increases, the Young’s modulus increases. This is a desirable characteristic; due to its higher value, it is more difficult to deform the material. In the case of impact strength, the analysis showed that increasing the amount of filler has no positive effect. A higher content of wood waste causes a decrease in the resistance of the biocomposite to brittle fracture. The impact strength between the lowest and highest percentage of filler was halved. Hardness, on the other hand, increased with higher amounts of filler, resulting in an improvement in the material’s resistance to deformation by up to 20 wt.% when comparing it to an unmodified material containing only Mater-Bi. Hardness is also affected by the type of filler used. Biocomposites containing oak and ash wood chips show higher hardness values compared to MDF materials.

The highest density is exhibited by biocomposites containing 20 wt.% by weight of filler in the structure. The density value of the biocomposite is also affected by the type of filler used and its density. Of the wood waste used, oak has the highest density compared to ash wood and MDF. This is reflected in the results obtained for the biocomposites, i.e., materials containing oak chips show a higher density compared to the other materials.

The microscopic results of the biocomposites showed the distribution of wood waste chips in the structure. The most homogeneous structure, containing the smallest amount, as well as the smallest free spaces, were obtained for biocomposites containing 20% by weight of filler.

Based on the analysis of the results obtained for the tested biocomposites, it can be concluded that the optimal solution for the management of natural wood waste is the production of a biocomposite with a matrix of Mater-Bi and 20 wt.% filler content. These composites are characterized by a homogeneous structure and favorable mechanical properties. The most favorable properties were obtained for a Mater-Bi biocomposite filled with 20 wt.% oak chips. This material, compared to the others, is characterized by increased strength and low water absorption, so that the products produced from it will be rigid and resistant to dynamic deformation.

Author Contributions

Conceptualization, D.C.-K.; Methodology, D.C.-K., D.W. and K.G.; Software, W.K.; Validation, M.P. and W.K.; Formal analysis, D.C.-K. and D.O.; Investigation, D.W., K.G. and W.K.; Resources, K.G. and W.K.; Data curation, D.C.-K. and M.P.; Writing—original draft, D.W. and K.G.; Visualization, W.K.; Supervision, D.O. and M.P. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the Polish Ministry of Science and Higher Education as a part of research subsidy, project number: 614/SBAD/4820.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ibrahim, S.; Riahi, O.; Said, S.M.; Sabri, M.F.M.; Rozali, S. Biopolymers from Crop Plants. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- MacGregor, E.A. Biopolymers. In Encyclopedia of Physical Science and Technology, 3rd ed.; Academic Press: Cambridge, MA, USA, 2003; pp. 207–245. [Google Scholar] [CrossRef]

- Christian, S.J. 5—Natural fibre-reinforced noncementitious composites (biocomposites). In Nonconventional and Vernacular Construction Materials; Woodhead Publishing: Sawston, UK, 2016; pp. 111–126. [Google Scholar] [CrossRef]

- Biological Recycling of Biodegradable Plastics. Available online: https://www.biocycle.net/biological-recycling-biodegradable-plastics/ (accessed on 29 August 2023).

- Ferrari, F.; Striani, R.; Fico, D.; Alam, M.M.; Greco, A.; Esposito Corcione, C. An Overview on Wood Waste Valorization as Biopolymers and Biocomposites: Definition, Classification, Production, Properties and Applications. Polymers 2022, 14, 5519. [Google Scholar] [CrossRef] [PubMed]

- Tanase-Opedal, M.; Espinosa, E.; Rodríguez, A.; Chinga-Carrasco, G. Lignin: A Biopolymer from Forestry Biomass for Biocomposites and 3D Printing. Materials 2019, 12, 3006. [Google Scholar] [CrossRef] [PubMed]

- Bertini, F.; Canetti, M.; Cacciamani, A.; Elegir, G.; Orlandi, M.; Zoia, L. Effect of Ligno-Derivatives on Thermal Properties and Degradation Behavior of Poly(3-Hydroxybutyrate)-Based Biocomposites. Polym. Degrad. Stab. 2012, 97, 1979–1987. [Google Scholar] [CrossRef]

- Kompozyty.net. Biocomposites—An Overview. Available online: https://kompozyty.net/biokompozyty-przeglad/ (accessed on 14 December 2023).

- H Gołuch-Góreczna, R.; Urbaniak, M.; Błędzki, A.K. Biocomposites properties based on natural cork agglomerate manufactured by the vacuum bag method. Przetwórstwo Tworzyw 2017, 23, 527–534. [Google Scholar]

- Zahid Rayaz Khan, M.; Srivastava, S.K. Development, Characterization and Application Potential of Bio-Composites: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 404, 12028. [Google Scholar] [CrossRef]

- Sztorch, B.; Brząkalski, D.; Pakuła, D.; Frydrych, M.; Špitalský, Z.; Przekop, R.E. Natural and Synthetic Polymer Fillers for Applications in 3D Printing—FDM Technology Area. Solids 2022, 3, 508–548. [Google Scholar] [CrossRef]

- Kaczmar, J.W.; Pach, J.; Kozłowski, R. Application of natural fibers as the fillers for polymer composites. Polimery 2006, 51, 722–726. [Google Scholar] [CrossRef][Green Version]

- Fejdyś, M.; Łandwijt, M. Technical fibres reinforcing the composite material. Tech. Wyr. Włókiennicze 2010, 18, 12–22. [Google Scholar]

- Włodarczyk-Fligier, A.; Polok-Rubiniec, M.; Chmielnicki, B. Polimers compoistes with natural filler. Przetwórstwo Tworzyw 2018, 24, 50–57. [Google Scholar]

- Zajchowski, S.; Ryszkowska, J. Wood-polymer composites—General characteristics and their preparation from waste materials. Polimery 2009, 54, 737–746. [Google Scholar] [CrossRef][Green Version]

- Alam, M.A.; Sapuan, S.M.; Ya, H.H.; Hussain, P.B.; Azeem, M.; Ilyas, R.A. Application of biocomposites in automotive components: A review. In Biocomposite and Synthetic Composites for Automotive Applications; Woodhead Publishing: Sawston, UK, 2021; pp. 1–17. [Google Scholar]

- Spasowka, E. Sustainable biopolymer composites biocompatibility, self-healing, modeling, repair and recyclability. Polimery 2022, 67, 47–49. [Google Scholar]

- Bajwa, D.S.; Bhattacharjee, S. Current progress, trends and challenges in the application of biofiber composites by automotive industry. J. Nat. Fibers 2016, 13, 660–669. [Google Scholar]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X.H. Review of the applications of biocomposites in the automotive industry. Polym. Compos. 2017, 38, 2553–2569. [Google Scholar] [CrossRef]

- Njuguna, J.; Wambua, P.; Pielichowski, K.; Kayvantash, K. Natural fibre-reinforced polymer composites and nanocomposites for automotive applications. In Cellulose Fibers: Bio- and Nano-Polymer Composites: Green Chemistry and Technology; Springer: Berlin/Heidelberg, Germany, 2011; pp. 661–700. [Google Scholar]

- Loureiro, N.C.; Esteves, J.L. Green composites in automotive interior parts: A solution using cellulosic fibers. In Green Composites for Automotive Applications; Woodhead Publishing: Sawston, UK, 2019; pp. 81–97. [Google Scholar]

- Kim, Y.K.; Chalivendra, V. Natural fibre composites (NFCs) for construction and automotive industries. In Handbook of Natural Fibres; Woodhead Publishing: Sawston, UK, 2020; pp. 469–498. [Google Scholar]

- WPC Wall Panels. Available online: https://www.hosungdeck.com/wpc-industry-trends/elevate-space-wpc-wall-panels/ (accessed on 16 December 2023).

- Andrzejewski, J.; Barczewski, M.; Czarnecka-Komorowska, D.; Rydzkowski, T.; Gawdzińska, K.; Thakur, V.K. Manufacturing and characterization of sustainable and recyclable wood-polypropylene biocomposites: Multiprocessing-properties-structure relationships. Ind. Crops Prod. 2024, 207, 117710. [Google Scholar] [CrossRef]

- Chmielnicki, B.; Jurczyk, S. WPC composites as an alternative to the products of wood. Przetwórstwo Tworzyw 2013, 19, 477–484. [Google Scholar]

- Venkataravanappa, R.Y.; Lakshmikanthan, A.; Kapilan, N.; Chandrashekarappa, M.P.G.; Der, O.; Ercetin, A. Physico-Mechanical Property Evaluation and Morphology Study of Moisture-Treated Hemp–Banana Natural-Fiber-Reinforced Green Composites. J. Compos. Sci. 2023, 7, 266. [Google Scholar] [CrossRef]

- Manu, T.; Nazmi, A.R.; Shahri, B.; Emerson, N.; Huber, T. Biocomposites: A review of materials and perception. Mater. Today Commun. 2022, 31, 103308. [Google Scholar] [CrossRef]

- Characteristics of Mater-Bi. Available online: https://www.novamont.com/eng/mater-bi (accessed on 14 December 2023).

- Knitter, M.; Czarnecka-Komorowska, D.; Czaja-Jagielska, N.; Szymanowska-Powałowska, D. Manufacturing and properties of biodegradable composites based on thermoplastic starch/polyethylene-vinyl alcohol and silver particles. In Advances in Manufacturing II: Volume 4—Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2019; pp. 610–624. [Google Scholar]

- Zdziobek, P.; Worek, J.; Jodłowski, G. The problem of dioxins formed during processes of uncontrolled waste incineration. In Współczesne Problemy Ochrony Środowiska i Energetyki; Katedra Technologii i Urządzeń Zagospodarowania Odpadów: Gliwice, Poland, 2019; pp. 81–92. [Google Scholar]

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/05/60/56046.html (accessed on 2 February 2024).

- ISO 1183-1:2013; Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pyknometer Method and Titration Method. ISO: Geneva, Switzerland, 2013. Available online: https://www.iso.org/standard/27790.html (accessed on 1 February 2024).

- ISO 62:2008; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008. Available online: https://www.iso.org/standard/41672.html (accessed on 1 February 2024).

- ISO 868:2003; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). ISO: Geneva, Switzerland, 2003. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/03/48/34804.html (accessed on 1 February 2024).

- ISO 179-2:2020; Plastics Determination of Charpy Impact Properties, Part 2: Instrumented Impact Test. ISO: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/75825.html (accessed on 1 February 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).