Valorisation of Seafood Side-Streams through the Design of New Holistic Value Chains: WaSeaBi Project

Abstract

:1. Introduction

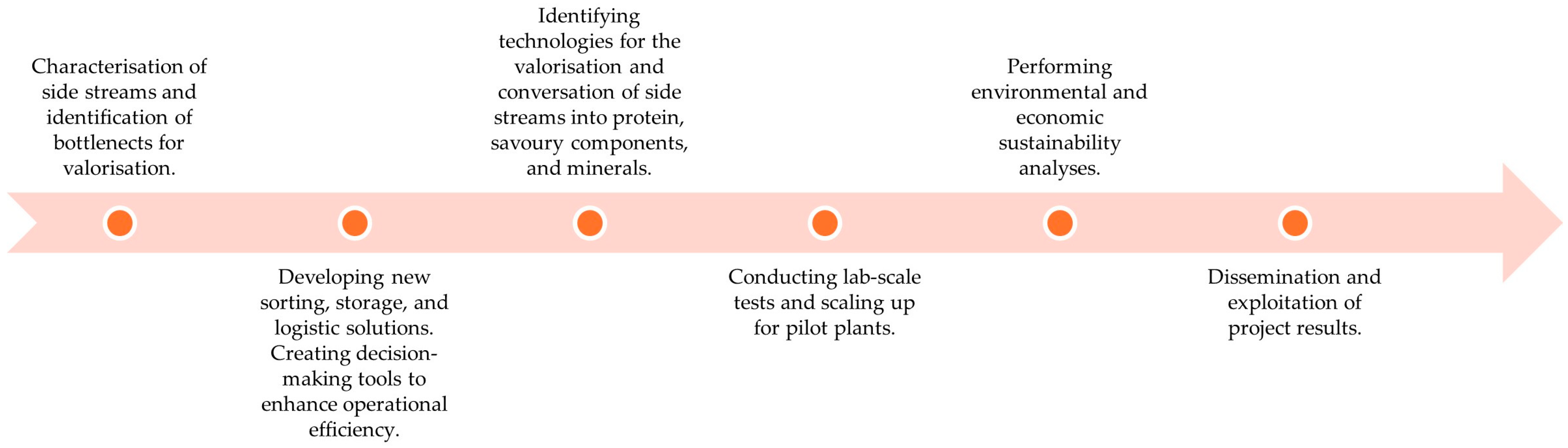

2. Project Overview

2.1. Description of the Project

2.2. Project Goals

- Identifying bottlenecks that hinder the exploitation of side-streams;

- Developing improved sorting and storage technologies, decision-making tools, and guidelines for optimal utilisation of aquatic side-streams;

- Developing innovative processes to produce new ingredients from high-quality side-streams, thereby offering more high-quality side-streams;

- Quantifying the environmental and economic sustainability performance of the studied value chains;

- Maximising the influence of the project results by disseminating the results.

3. Project Approach

3.1. Identification of Hurdles and Bottlenecks to Valorise Seafood Side-Streams

- To chemically describe and characterise side-streams from fisheries, aquaculture, aquatic processing industries, and fisheries’ by-catches.

- To identify prevailing challenges obstructing the implementation of valorisation solutions within participating firms.

- To delineate consumer awareness and discern their reservations and incentives regarding the use of side-stream ingredients in food manufacturing.

3.2. Characterisation of Selected Seafood Side-Streams

4. Results and Findings

4.1. Optimising the Possibilities to Use Fish Side-Streams by Sorting and Antioxidant Treatments

4.2. Summary of the Selected Valorisation Technologies

4.2.1. pH-Shift Processing

4.2.2. Flocculation

4.2.3. Membrane Concentration

4.2.4. Enzymatic Hydrolysis

4.3. Implementation of the Technologies in Pilot-Scale Experiments

4.4. Environmental Sustainability of the Selected Technologies

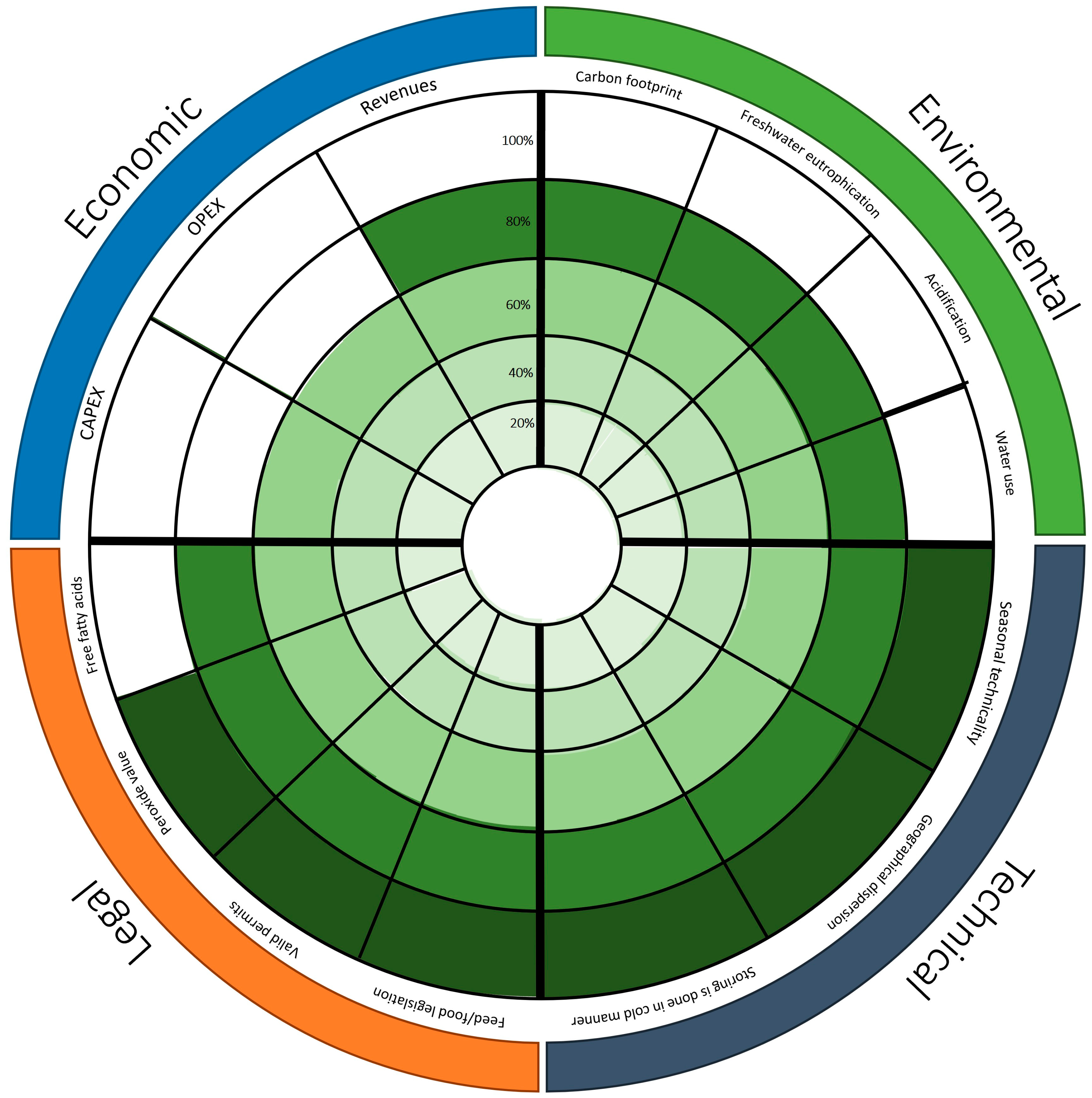

4.5. Decision-Making Tools

4.5.1. Tool to Select the Most Appropriate Valorisation Strategy

4.5.2. Value Chain Navigator Tool

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. The State of World Fisheries and Aquaculture 2022. Towards Blue Transformation; FAO: Rome, Italy, 2022. [Google Scholar] [CrossRef]

- Cooney, R.; de Sousa, D.B.; Fernández-Ríos, A.; Mellett, S.; Rowan, N.; Morse, A.P.; Hayes, M.; Laso, J.; Regueiro, L.; Wan, A.H.L.; et al. A Circular Economy Framework for Seafood Waste Valorisation to Meet Challenges and Opportunities for Intensive Production and Sustainability. J. Clean. Prod. 2023, 392, 136283. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Schulte, H.; Pleissner, D.; Schönfelder, S.; Kvangarsnes, K.; Dauksas, E.; Rustad, T.; Cropotova, J.; Heinz, V.; Smetana, S. Transformation of Seafood Side-Streams and Residuals into Valuable Products. Foods 2023, 12, 422. [Google Scholar] [CrossRef]

- Naseem, S.; Imam, A.; Rayadurga, A.S.; Ray, A.; Suman, S.K. Trends in Fisheries Waste Utilization: A Valuable Resource of Nutrients and Valorized Products for the Food Industry. Crit. Rev. Food Sci. Nutr. 2023, 1–21. [Google Scholar] [CrossRef]

- Coppola, D.; Lauritano, C.; Palma Esposito, F.; Riccio, G.; Rizzo, C.; de Pascale, D. Fish Waste: From Problem to Valuable Resource. Mar. Drugs 2021, 19, 116. [Google Scholar] [CrossRef]

- Caruso, G. Fishery Wastes and By-Products: A Resource to Be Valorised. J. Fish. Sci. 2015, 9, 80–83. [Google Scholar]

- Arvanitoyannis, I.S.; Kassaveti, A. Fish Industry Waste: Treatments, Environmental Impacts, Current and Potential Uses. Int. J. Food Sci. Technol. 2008, 43, 726–745. [Google Scholar] [CrossRef]

- Kim, S.-K.; Mendis, E. Bioactive Compounds from Marine Processing Byproducts—A Review. Food Res. Int. 2006, 39, 383–393. [Google Scholar] [CrossRef]

- Campanati, C.; Willer, D.; Schubert, J.; Aldridge, D.C. Sustainable Intensification of Aquaculture through Nutrient Recycling and Circular Economies: More Fish, Less Waste, Blue Growth. Rev. Fish. Sci. Aquac. 2022, 30, 143–169. [Google Scholar] [CrossRef]

- Erasmus, V.N.; Kadhila, T.; Gabriel, N.N.; Thyberg, K.L.; Ilungu, S.; Machado, T. Assessment and Quantification of Namibian Seafood Waste Production. Ocean Coast. Manag. 2021, 199, 105402. [Google Scholar] [CrossRef]

- Caruso, G.; Floris, R.; Serangeli, C.; Di Paola, L. Fishery Wastes as a Yet Undiscovered Treasure from the Sea: Biomolecules Sources, Extraction Methods and Valorization. Mar. Drugs 2020, 18, 622. [Google Scholar] [CrossRef] [PubMed]

- Ozogul, F.; Cagalj, M.; Šimat, V.; Ozogul, Y.; Tkaczewska, J.; Hassoun, A.; Kaddour, A.A.; Kuley, E.; Rathod, N.B.; Phadke, G.G. Recent Developments in Valorisation of Bioactive Ingredients in Discard/Seafood Processing by-Products. Trends Food Sci. Technol. 2021, 116, 559–582. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Bao, H.N.D.; Dang, H.T.T.; Tómasson, T.; Arason, S.; Gudjónsdóttir, M. Protein Recovery of Tra Catfish (Pangasius hypophthalmus) Protein-Rich Side-streams by the pH-Shift Method. Foods 2022, 11, 1531. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Forghani, B.; Abdollahi, M.; Undeland, I. Five Cuts from Herring (Clupea Harengus): Comparison of Nutritional and Chemical Composition between Co-Product Fractions and Fillets. Food Chem. X 2022, 16, 100488. [Google Scholar] [CrossRef]

- Wu, H.; Forghani, B.; Abdollahi, M.; Undeland, I. Lipid Oxidation in Sorted Herring (Clupea Harengus) Filleting Co-Products from Two Seasons and Its Relationship to Composition. Food Chem. 2022, 373, 131523. [Google Scholar] [CrossRef]

- Wu, H.; Axelsson, J.; Kuhlin, M.; Fristedt, R.; Undeland, I. Pilot-Scale Antioxidant Dipping of Herring (Clupea Harengus) Co-Products to Allow Their Upgrading to a High-Quality Mince for Food Production. ACS Sustain. Chem. Eng. 2023, 11, 4727–4737. [Google Scholar] [CrossRef]

- Wu, H.; Forghani, B.; Sajib, M.; Undeland, I. A Recyclable Dipping Strategy to Stabilize Herring (Clupea Harengus) Co-Products During Ice Storage. Food Bioprocess Technol. 2021, 14, 2207–2218. [Google Scholar] [CrossRef]

- Abdollahi, M.; Wu, H.; Undeland, I. Impact of Processing Technology on Macro- and Micronutrient Profile of Protein-Enriched Products from Fish Backbones. Foods 2021, 10, 950. [Google Scholar] [CrossRef]

- Sørensen, A.-D.M.; Wu, H.; Hyldig, G.; Bøknæs, N.; Mejlholm, O.; Undeland, I.; Jacobsen, C. Oxidative Stability of Side-Streams from Cod Filleting—Effect of Antioxidant Dipping and Low-Temperature Storage. Mar. Drugs 2023, 21, 591. [Google Scholar] [CrossRef]

- Surasani, V.K.R. Acid and alkaline solubilization (pH shift) process: A better approach for the utilization of fish processing waste and by-products. Environ. Sci. Pollut. Res. 2018, 25, 18345–18363. [Google Scholar] [CrossRef]

- van Berlo, E.; Undeland, I.; Abdollahi, M. Physicochemical and Functional Properties of Protein Isolated from Herring Co-Products; Effects of Catching Season, Pre-Sorting, and Co-Product Combination. Food Chem. 2023, 398, 133947. [Google Scholar] [CrossRef]

- Santschi, M.V.; Undeland, I.; Abdollahi, M. Ultrasound-aided pH-shift processing for resource-smart valorization of salmon and herring side streams. Ultrason. Sonochem. 2023, 99, 106539. [Google Scholar] [CrossRef]

- Forghani, B.; Sørensen, A.-D.M.; Johannesson, J.; Svendsen, T.C.; Undeland, I. Flocculation and Flotation to Recover Protein-Enriched Biomasses from Shrimp Boiling and Peeling Process Waters: A Case Study. ACS Sustain. Chem. Eng. 2020, 8, 9660–9668. [Google Scholar] [CrossRef]

- Forghani, B.; Mihnea, M.; Svendsen, T.C.; Undeland, I. Protein and Long-Chain n-3 Polyunsaturated Fatty Acids Recovered from Herring Brines upon Flocculation and Flotation—A Case Study. ACS Sustain. Chem. Eng. 2023, 11, 6523–6534. [Google Scholar] [CrossRef]

- Coque, J.; Jacobsen, C.; Forghani, B.; Meyer, A.; Jakobsen, G.; Sloth, J.J.; Sørensen, A.-D.M. Recovery of Nutrients from Cod Processing Waters. Mar. Drugs 2023, 21, 558. [Google Scholar] [CrossRef]

- Gutierrez, M.; San Martin, D.; Ibarruri, J.; Foti, G.; Bald, C.; Goienetxea, N.; Zufia, J.; Iñarra, B. Recovery of savoury compounds from mussel cooking side stream as circular economy solution. Environ. Chall. 2024, 14, 100840. [Google Scholar] [CrossRef]

- Jauregi, P.; Alvarez-Ossorio, C.; Bald, C.; Ibarruri, J.; Iñarra, B.; San Martin, D.; Zufia, J. Chapter 7—Enzymatic Processes for the Production of Food Ingredients from Food Processing by-Products. In Value-Addition in Food Products and Processing Through Enzyme Technology; Kuddus, M., Aguilar, C.N., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 83–100. ISBN 978-0-323-89929-1. [Google Scholar]

- Iñarra, B.; Bald, C.; Gutierrez, M.; San Martin, D.; Zufía, J.; Ibarruri, J. Production of Bioactive Peptides from Hake By-Catches: Optimization and Scale-Up of Enzymatic Hydrolysis Process. Mar. Drugs 2023, 21, 552. [Google Scholar] [CrossRef]

- Shimada, K.; Fujikawa, K.; Yahara, K.; Namkamura, T. Antioxidative properties of Xanthan gum on the autooxidation of soyabean oil in cyclodextrin emulsion. J. Agric. Food Chem. 1992, 40, 945–948. [Google Scholar] [CrossRef]

- Brodkorb, A.; Egger, L.; Alminger, M.; Alvito, P.; Assunção, R.; Ballance, S.; Bohn, T.; Bourlieu-Lacanal, C.; Boutrou, R.; Carrière, F.; et al. INFOGEST Static in Vitro Simulation of Gastrointestinal Food Digestion. Nat. Protoc. 2019, 14, 991–1014. [Google Scholar] [CrossRef]

- ISO 14040; Environmental management—Life cycle assessment—Principles and framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental management—Life cycle assessment—Requirements and guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

| Species | Side-Stream | Protein (g/100 g Wet Weight) | Fat (g/100 g Wet Weight) | Dry Matter (g/100 g Wet Weight) | Ash (g/100 g Wet Weight) | Peroxide Value (PV) (µmol Peroxide/kg Wet Weight) | TBARS (µmol TBARS/kg Wet Weight) | Chloride (g/100 g Wet Weight) |

|---|---|---|---|---|---|---|---|---|

| Herring (Clupea harengus) n = 3–5 | All parts * | 11.39–14.95 | 3.07–17.85 | 22.97–33.30 | 2.69–5.75 | 20.50–113.42 | 7.34–28.46 | |

| Without guts | 17.57 ± 0.63 | 9.31 ± 0.48 | 27.77 ± 0.87 | 4.03± 0.17 | 30.00 ± 1.25 | 4.00 ± 0.32 | ||

| Cod (Gadus morhua) n = 6 | Backbones | 15.30 ± 0.67 | 1.25 ± 0.08 | 23.20 ± 1.83 | 6.07 ± 0.31 | 1.45 ± 0.26 | 5.87 ± 3.68 | |

| Head | 13.64 ± 0.56 | 5.60 ± 0.46 | 23.36 ± 1.63 | 4.23 ± 0.44 | 25.98 ± 4.15 | 64.63 ± 13.00 | ||

| Viscera | 10.26 ± 0.68 | 22.5 ± 5.07 | 34.93 ± 5.28 | 0.98 ± 0.17 | 0.37 ± 0.07 | 54.15 ± 17.04 | ||

| Salmon (Salmo salar) n = 2 and 4 | Head | 14.73 ± 1.69 | 21.64 ± 1.28 | 38.91 ± 1.13 | 3.83 ± 0.48 | |||

| Skins | 18.87 ± 6.58 | 22.37 ± 6.82 | 51.99 ± 2.15 | 1.14 ± 0.22 | ||||

| Trimmings | 14.72 ± 2.10 | 29.62 ± 5.67 | 46.37 ± 3.49 | 1.34 ± 0.48 | ||||

| Backbones (place a) | 18.52 ± 7.63 | 24.21 ± 1.13 | 48.78 ± 1.73 | 7.55 ± 0.34 | ||||

| Backbones (place b) | 14.55 ± 0.39 | 21.88 ± 0.05 | 42.05 ± 0.11 | 11.93 ± 0.19 | ||||

| Hake, (Merluccius merluccius) n = 3 | Whole fish | 15.91 ± 0.57 | 0.85 ± 0.08 | 20.17 ± 0.39 | 3.05 ± 0.22 | |||

| Mussel n = 4 | Shells | 4.87 ± 1.77 | ND | 94.0 ± 0.9 | 93.0 ± 2.0 | 0.16 ± 0.01 |

| Species | Side-Stream | Protein (g/100 g Wet Weight) | Fat (g/100 g Wet Weight) | Dry Matter (g/100 g Wet Weight) | Ash (g/100 g Wet Weight) | Peroxide Value (PV) (µmol Peroxide/kg Wet Weight) | TBARS (µmol TBARS/kg Wet Weight) | Ionic Strength (NaCl Equivalent, %) | Salt (g/ 100 g Wet Weight) | Salinity (Chloride g/L) |

|---|---|---|---|---|---|---|---|---|---|---|

| Herring (Clupea harengus) n = 3–7 | Refrigerated sea water | 0.05–0.3 | 0.3–0.5 | 1.1–2.5 | - | - | - | 2.9 ± 0.0 | ||

| Filleting water | 0.19–0.39 | 0.08–0.15 | 0.4 ± 0.0 | - | - | - | 0.09 ± 0.00 | |||

| Storage water | 0.10–0.58 | 0.2–0.3 | 2.8–3.8 | - | - | - | - | |||

| 3% salting brine | 0.5–1.3 | 0.3–0.4 | 3.4–4.7 | - | 260 ± 31.5 | 64.4 ± 4.6 | 1.9 ± 0.0 | |||

| 5% salting brine | 0.5–1.2 | 0.8–4.4 | 5.8–6.2 | - | 1063 ± 98.2 | 50.1 ± 1.4 | 3.7 ± 0.1 | |||

| 13% salting brine | 0.72–1.4 | 0.3 ± 0.0 | 5.0–8.4 | - | 497 ± 45.8 | 40.0 ± 3.3 | 9.2 ± 0.5 | |||

| Cod (Gadus morhua) n = 27 | Process water | 0.02–1.71 | 0.08–26.8 | 0.02–25.0 | ||||||

| Mussel n = 3 | Cooking water | 0.65 ± 0.09 | ND | 4.26 ± 0.75 | 1.75 ± 0.07 | 13.4 ± 1.9 |

| Technology | Description | Side-Stream | Technical Performance | Key Takeaways |

|---|---|---|---|---|

| pH-shift | Solubilisation of muscle proteins in low and high pH environments. Investigated impacts of sorting, combination, harvest season, and stabilisation on protein isolation yield and quality from cod and herring side-streams. | Herring frame | Seasonal variation affects processing, with spring catch yielding proteins with better gel-forming capacity. Sorting is essential. Herring frame most promising for value addition. | Sorting and adapting processing conditions are crucial. Pre-dipping with rosemary extracts highly recommended for stable protein isolates, mitigating lipid oxidation during storage. |

| Enzymatic hydrolysis | Side-streams with adequate food-grade handling were hydrolysed in pilot-scale experiments with different enzymes and process conditions focusing the production of savoury compounds or bioactive peptides. | Salmon and cod side-streams (for savoury compounds) Undersized hake (by-catch, for bioactive peptides) | Savoury compounds with adequate organoleptic characteristics and high content of free glutamic acid (up to 40 mg/g hydrolysate). Bioactive peptides with antioxidant and antihypertensive capacity (e.g., for DPPH an IC50 range of 2.25–2.60 mg/mL for cod hydrolysates). Protein and mineral rich powder with bioaccessible calcium and magnesium. | Commercial products for food and nutraceutical application can be obtained from side-stream hydrolysis. |

| Membrane concentration | Nanofiltration membranes were used to concentrate protein from effluent. At the same time, a permeate with low organic load was obtained. | Mussel cooking water | Production of protein concentrate with savoury characteristics. Reduction of 90% of effluent volume and organic load, allowing its reuse in some processes (such as cleaning). | Membrane technologies are a key element for the valorisation of liquid side-streams with a double-purpose biomolecule recovery and reduction of environmental impact. |

| Flocculation with centrifugation | Flocculation with food grade flocculants was used to recover proteins and/or phosphate. | Herring liquid side-streams or process waters generated during production of salted cod | In lab-scale experiments, up to 90% of proteins from herring salt brines and ca. 50% of the proteins and phosphorus from the cod processing waters were recovered. In non-optimised pilot-scale trials, 35% protein yield was obtained from herring process waters, and the recovered biomass had 33% dry matter and nearly 20% protein (wet weight basis). | Flocculation enables the recovery of proteins and phosphorous from liquid side-streams, thus lowering the organic and chemical load of the effluent water. Use of the recovered protein and phosphorous in, e.g., foods or feeds may be possible. |

| Technology | Opportunities | Challenges |

|---|---|---|

| pH-shift | The higher yield leads to a reduction in the need for utilities and thus a reduction in environmental impact. | As sodium hydroxide and hydrochloric acid are products with a high environmental impact, chemical consumption is the largest contributor in this value chain. |

| Enzymatic hydrolysis | The recovery of fish oils as a side-stream in this technology is a compensatory effect that minimises the environmental burdens. | Total electricity consumption is the primary driver of the environmental impacts. Moreover, the use of enzymes contributes to environmental burden, as enzyme production has a high environmental impact. |

| Membrane concentration | The limited use of chemicals in this value chain minimises its potential environmental impacts. Furthermore, the ability to reuse wastewater will lead to a reduction in the environmental burden. | Results highlight the substantial energy consumption due to the technical characteristics of filtration process, primarily driven by the electricity used during nanofiltration and diafiltration stages. |

| Flocculation with centrifugation | The selection of suitable flocculant plays a critical role; therefore, environmental impact can be reduced by choosing appropriate flocculants. | The selection of the most suitable flocculants and separation equipment in this value chain is critical to the environmental impact. Additionally, the utilisation of electricity during the separation stage has a substantial impact. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cadena, E.; Kocak, O.; Dewulf, J.; Iñarra, B.; Bald, C.; Gutierrez, M.; San Martin, D.; Ibarruri, J.; Sørensen, A.-D.M.; Hyldig, G.; et al. Valorisation of Seafood Side-Streams through the Design of New Holistic Value Chains: WaSeaBi Project. Sustainability 2024, 16, 1846. https://doi.org/10.3390/su16051846

Cadena E, Kocak O, Dewulf J, Iñarra B, Bald C, Gutierrez M, San Martin D, Ibarruri J, Sørensen A-DM, Hyldig G, et al. Valorisation of Seafood Side-Streams through the Design of New Holistic Value Chains: WaSeaBi Project. Sustainability. 2024; 16(5):1846. https://doi.org/10.3390/su16051846

Chicago/Turabian StyleCadena, Erasmo, Ozan Kocak, Jo Dewulf, Bruno Iñarra, Carlos Bald, Monica Gutierrez, David San Martin, Jone Ibarruri, Ann-Dorit Moltke Sørensen, Grethe Hyldig, and et al. 2024. "Valorisation of Seafood Side-Streams through the Design of New Holistic Value Chains: WaSeaBi Project" Sustainability 16, no. 5: 1846. https://doi.org/10.3390/su16051846