Analyzing the Optimization of Unloading Gas Extraction Drilling Arrangement Based on Stress Distribution in the Protected Layer

Abstract

:1. Introduction

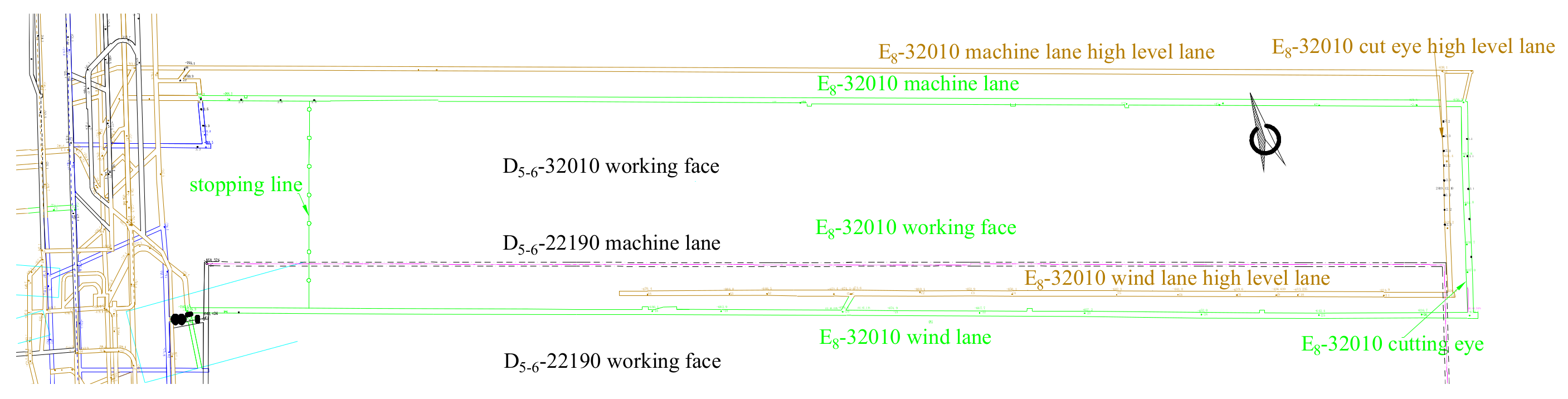

2. Geological Profile

3. Numerical Simulation Studies

3.1. Principles of Numerical Simulation

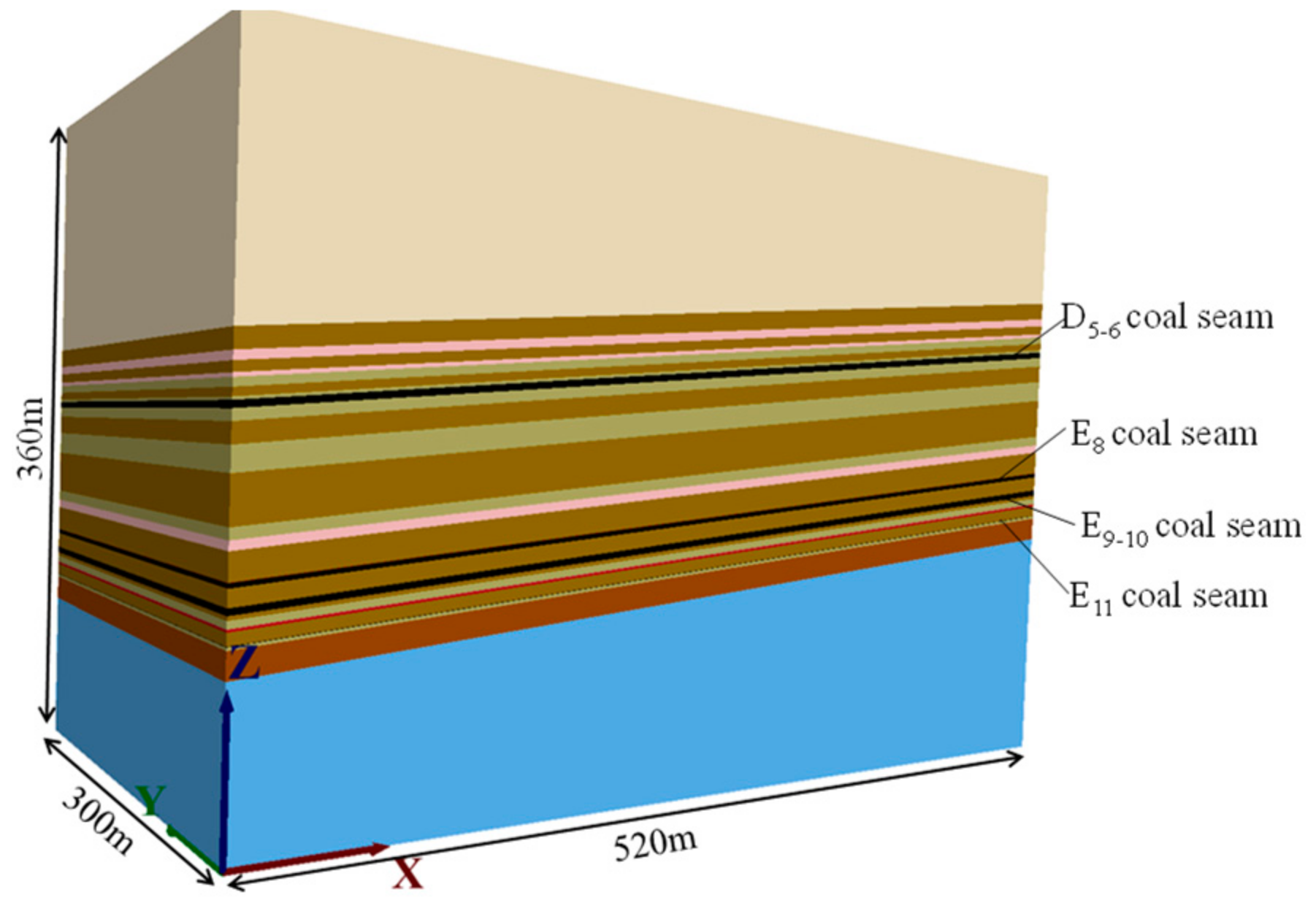

3.2. Model Building

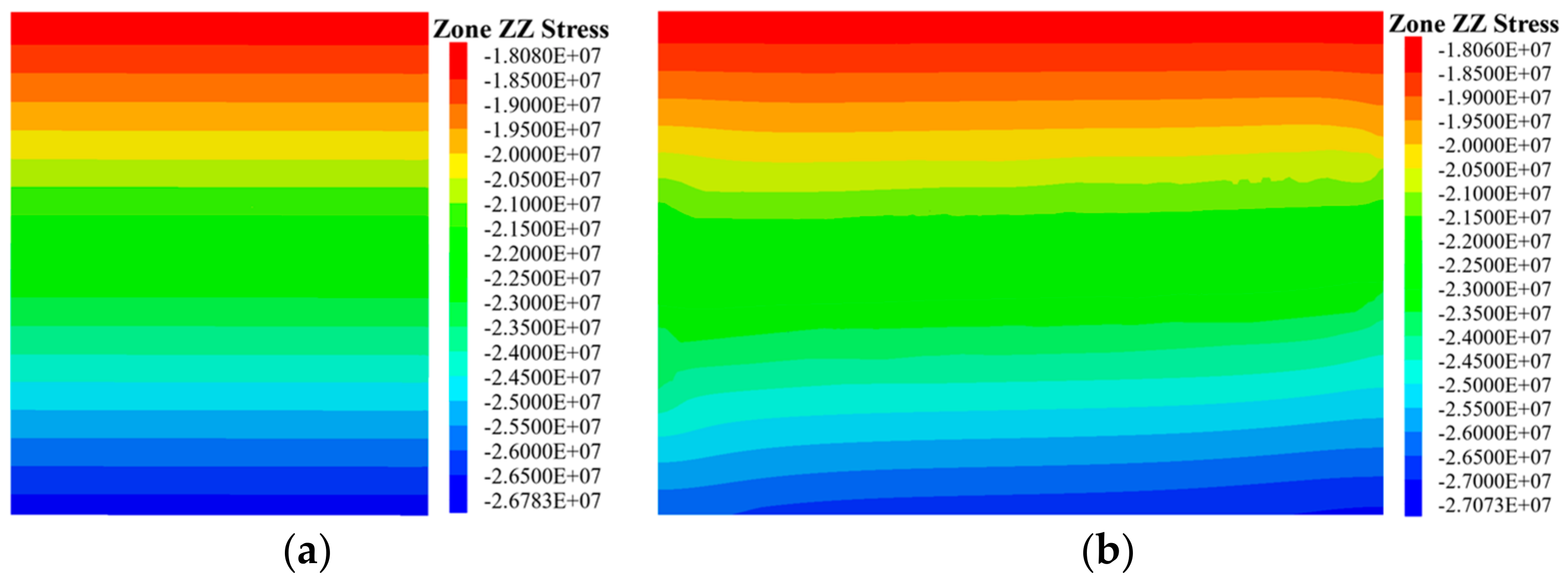

3.3. Initial Geostress Equilibrium

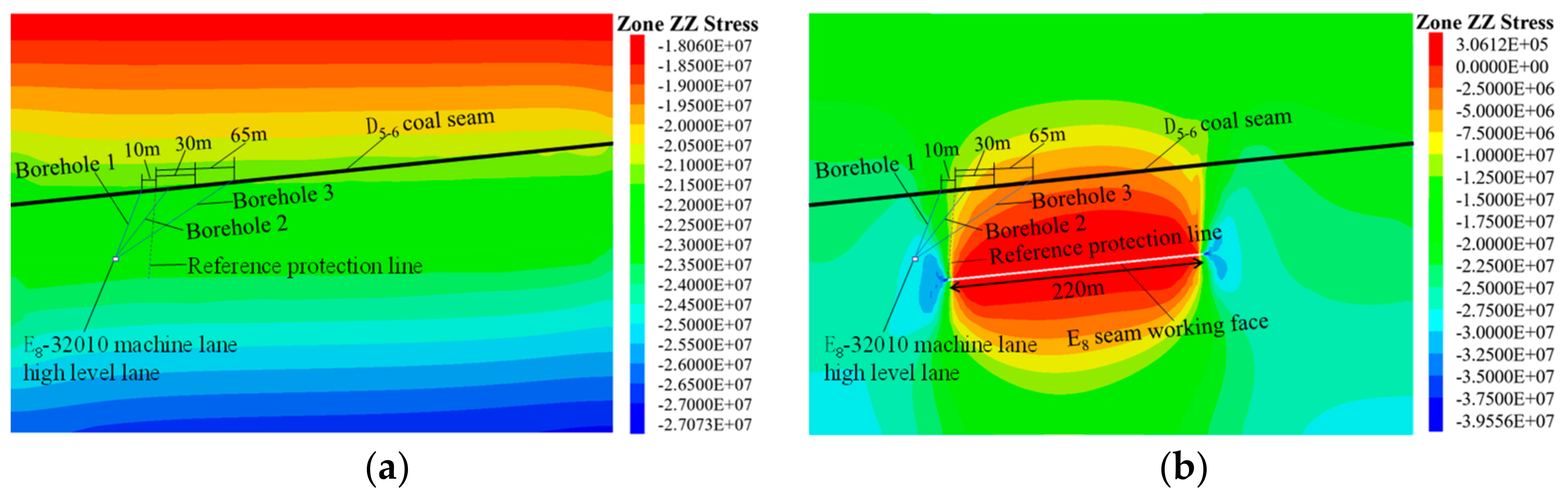

4. Coal Body Stress Distribution

4.1. Stress Distribution in Modeled Profiles

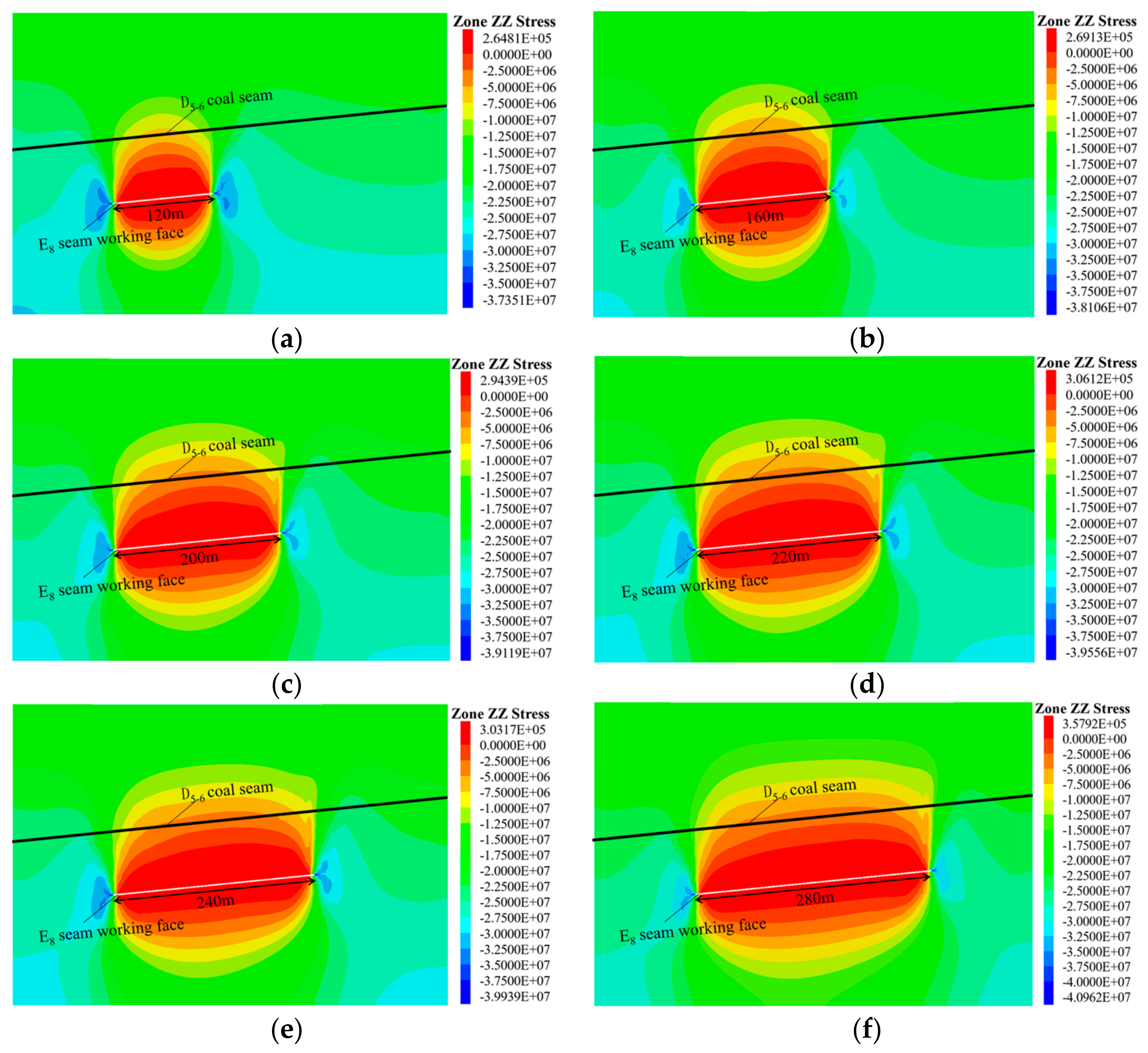

4.2. Stress Evolution in the Protected Layer

5. Protected Layer Gas Extraction

5.1. Arrangement of Extraction Drill Holes

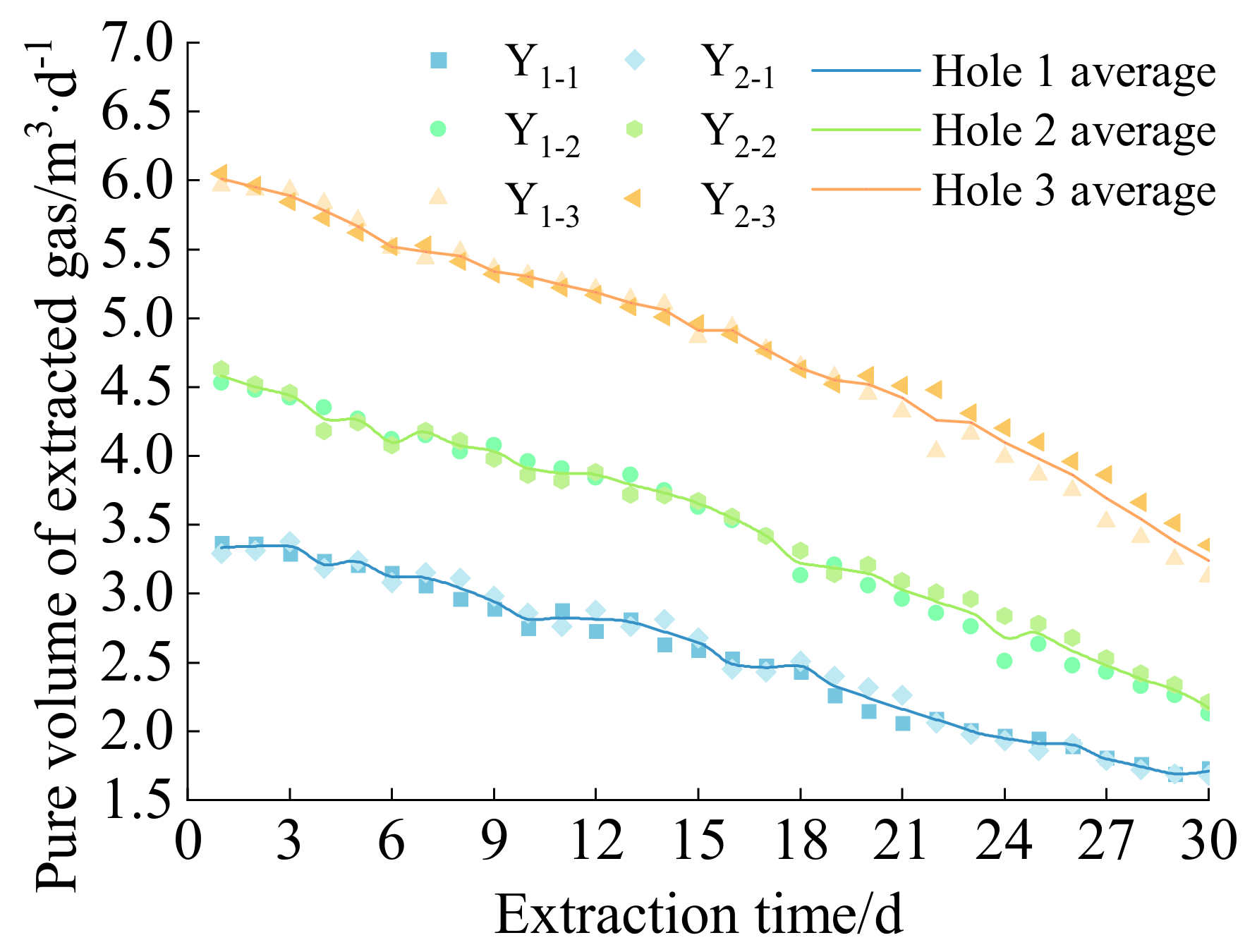

5.2. Analysis of Pre−Sampling Effects

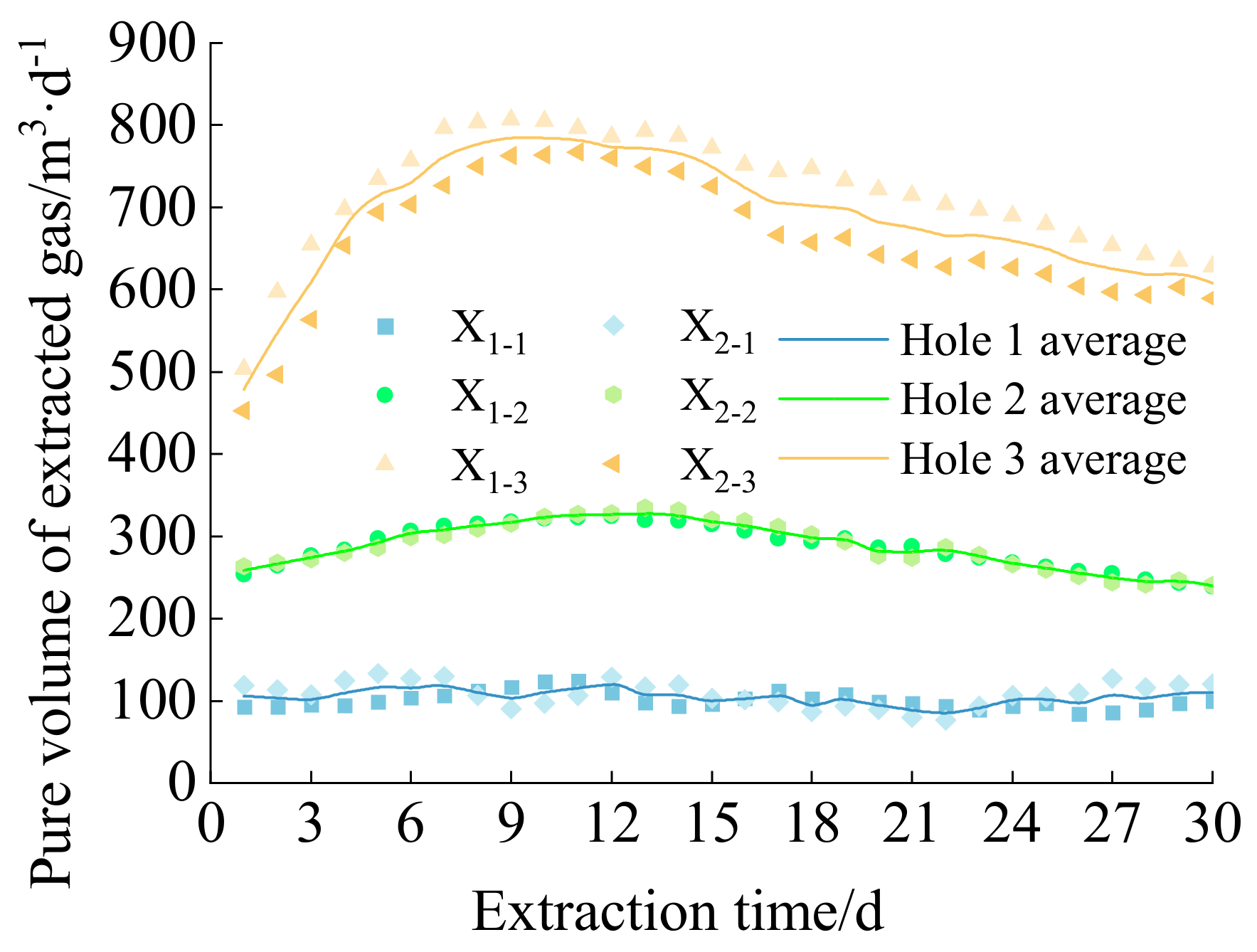

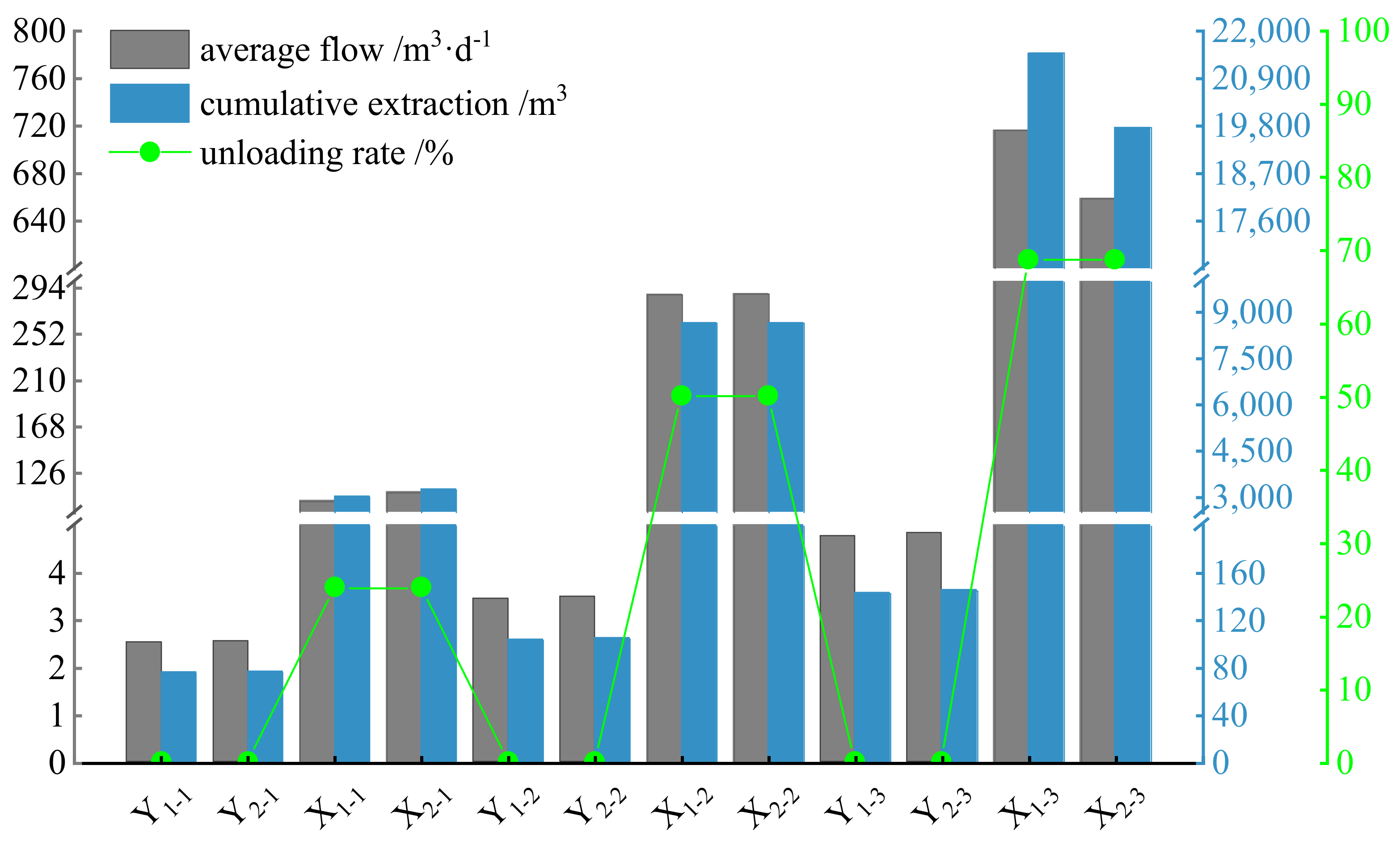

5.3. Pressure Relief Pumping Effect Analysis

5.4. Analyzing the Effect of Depressurization and Penetration Enhancement

6. Conclusions

- (i)

- When mining the E8 coal seam, with the increase in tendency length, the unloading degree and unloading range of the protected layer are increasing, the stress increase in the deep D5-6 coal seam is larger than that of the shallow D5-6 coal seam, and the tendency direction can be divided into stress elevation area, unloading area, and stress elevation area from the shallow zone to the deep zone; moreover, the minimum stresses are all less than 40% of the original stresses.

- (ii)

- After excavation, the vertical stresses at the final hole locations of the No. 1, No. 2, and No. 3 drill holes were 16.42 MPa, 10.74 MPa, and 6.72 MPa, respectively, and the pure amount of gas extracted by unloading increased significantly, whereas, the higher the unloading rate, the greater the increase in the amount of extraction, and the unloaded drill holes extracted 19.77–21.31 times, 41.62–41.68 times, and 68.68–74.66 times, respectively, the pure amount of gas extracted by the corresponding pre−pumping drill holes. Moreover, the lower the vertical stress at the final hole location, the higher the gas extraction efficiency.

- (iii)

- The amount of coal liberated by the No. 3 unpressurized extraction borehole for 30 d continuously is 5430.58–5903.31 t, which is 138.43–148.18 times as much as that of the No. 3 pre−pressurized extraction borehole, and 6.09–7.14 and 2.28–2.49 times as much as that of the No. 1 and No. 2 unpressurized extraction boreholes, respectively. The lower the vertical stress at the location of the final borehole is, the higher the protection efficiency of the boreholes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, L. Strategic thinking of simultaneous exploitation of coal and gas in deep mining. China Coal Soc. 2016, 41, 1–6. [Google Scholar]

- Xie, H.; Ju, Y.; Ren, S.; Gao, F.; Liu, J.; Zhu, Y. Theoretical and technological exploration of deep in situfluidized coal mining. Front. Energy. 2019, 13, 603–611. [Google Scholar] [CrossRef]

- Zhou, A.; Wang, K.; Fan, L.; Kiryaeva, T. Gas-solid coupling laws for deep high-gas coal seams. Int. J. Min. Sci. Technol. 2017, 27, 675–679. [Google Scholar] [CrossRef]

- Xie, H. Research review of the state key research development program of China:Deep rock mechanics and min-ing theory. China Coal Soc. 2019, 44, 1283–1305. [Google Scholar]

- Wang, E.; Zhang, G.; Zhang, C.; Li, Z. Research progress and prospect on theory andtechnology for coal and gas outburst control and protection in China. China Coal Soc. 2022, 47, 297–322. [Google Scholar]

- Zhang, C.; Tu, S.; Chen, M.; Zhang, L. Pressure-relief and methane production performance of pressure relief gas extraction technology in the longwall mining. J. Geophys. 2017, 14, 77–89. [Google Scholar] [CrossRef]

- Peng, X.; Qi, L.; Wang, Z.; Zhou, X.; Hua, C. Study on overburden movement deformationand roof breakage law of under-protective steeply inclined coal seam mining. Sustainability 2022, 14, 10068. [Google Scholar] [CrossRef]

- Tu, Q.; Cheng, Y. Stress evolution and coal seam deformation through the mining of a remote upper protective laye. Energy Sources Part. A. 2019, 41, 338–348. [Google Scholar]

- Cheng, X.; Zhao, G.; Li, Y.; Meng, X.; Tu, Q.; Huang, S.; Qin, Z. Mining-induced pressure-relief mechanism of coal-rock mass for different protective layer mining modes. Adv. Mater. Sci. Eng. 2021, 2021, 3598541. [Google Scholar] [CrossRef]

- Cheng, X.; Zhao, G.; Li, Y.; Meng, X.; Tu, Q. Key technologies and engineering practices for soft-rock protective seam mining. Int. J. Min. Sci. Technol. 2020, 30, 889–899. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Z.; Chen, D.; Liu, Q.; Chu, P.; Shu, L.; Ullah, B.; Wen, Z. Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf. Sci. 2020, 129, 104800. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.; Li, M.; Wang, C. A gas seepage modeling study for mitigating gas accumulation risk in upper protective coal seam mining process. Geofluids 2018, 2018, 8127207. [Google Scholar] [CrossRef]

- Li, W.; Cheng, Y.; Guo, P.; An, F.; Chen, M. The evolution of permeability and gas composition during remote protective longwall mining and stress-relief gas drainage: A case study of the underground Haishiwan Coal Mine. Geosci. J. 2014, 18, 427–437. [Google Scholar] [CrossRef]

- Cheng, H.; Dong, Y.; Li, X.; Chen, H. The dynamic evolution analysis of gas seepage field during the mining process of protective layer. Therm. Sci. 2019, 23 Pt. 3, 1371–1378. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, Y. The elimination of coal and gas outburst disasters by long distance lower protective seam mining combined with stress-relief gas extraction in the Huaibei coal mine area. J. Nat. Gas. Sci. Eng. 2015, 27, 346–353. [Google Scholar] [CrossRef]

- Cao, Z.; He, X.; Wang, E.; Kong, B. Protection scope and gas extraction of the low-protective layer in a thin coal seam: Lessons from the DaHe coalfield, China. Geosci. J. 2018, 22, 487–499. [Google Scholar] [CrossRef]

- Niu, X.; Shi, B.; Zhang, Z.; Zhang, Y. Stress distribution and gas concentration evolution during protective coal seam mining. Adv. Civ. Eng. 2021, 2021, 6644142. [Google Scholar] [CrossRef]

- He, X.; Yang, K.; Han, P.; Liu, W.; Zhang, Z.; Wu, H. Permeability enhancement and gas drainage effect in deep high gassy coal seams via long-distance pressure relief mining: A case study. Adv. Civ. Eng. 2021, 2021, 6637052. [Google Scholar] [CrossRef]

- Wang, L.; Chen, X.; Wang, Z.; Xu, S.; Xu, Q. Extending the protection range in protective seam mining under the influence of gas drainage. J. South. Afr. Inst. Min. Metall. 2020, 120, 211–220. [Google Scholar] [CrossRef]

- Fan, Z.; Fan, G.; Zhang, D. Representation of mining permeability and borehole layout optimization for efficient methane drainage. Energy Rep. 2021, 7, 3911–3921. [Google Scholar] [CrossRef]

- Xie, G.; Li, X.; Cai, J.; Wang, S.; Feng, C. Evolution of fissures and pressure discharge of gas caused by mining of the upper protective layer of a coal seam. Sci. Rep. 2023, 13, 2561. [Google Scholar] [CrossRef]

- Dang, J.; Tu, M.; Zhang, X.; Bu, Q. Analysis of the influence of upper protective layer mining on the effect of pressure relief and protection of coal and rock masses between the lower overburden layers. Adv. Civ. Eng. 2021, 2021, 8682156. [Google Scholar] [CrossRef]

- Fang, S.; Liang, B.; Sun, W.; Qin, M.; Shi, Z.; Hao, J. Study on stress evolution law of upper coal seam in long-distance advance mining of lower coal seam. Energy Sci. Eng. 2023, 11, 1753–1769. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, C.; Liang, N. Gas permeability evolution mechanism and comprehensive gas drainage technology for thin coal seam mining. Energies 2017, 10, 1382. [Google Scholar] [CrossRef]

- Xue, J.; Xiao, J.; Du, X.; Shi, Y. Current situation and development trend of pressure-relief gas extraction in theprotective layer mining in coal mines in China. Coal Geol. Explor. 2023, 51, 50–61. [Google Scholar]

- Yuan, Z.; Jiang, Z.; Li, S.; Zhao, J.; Huang, F. Numerical Assessment on Unloading Disturbance and Gas Extraction in Remote Distance Protective Layer Mining. Geofluids 2022, 2022, 3679384. [Google Scholar] [CrossRef]

- He, A.; Fu, H.; Huo, B.; Fan, C. Permeability enhancement of coal seam by lower protective layer mining for gas outburst prevention. Shock. Vib. 2020, 2020, 8878873. [Google Scholar] [CrossRef]

- Zhang, H.; Wen, Z.; Yao, B.; Chen, X. Numerical simulation on stress evolution and deformation of overlying coal seam in lower protective layer mining. Alex. Eng. J. 2020, 59, 3623–3633. [Google Scholar] [CrossRef]

- Hou, P.; Xue, Y.; Gao, F.; Wang, S.; Jiao, X.; Zhu, C. Numerical evaluation on stress and permeability evolution of overlying coal seams for gas drainage and gas disaster elimination in protective layer mining. Mining Metall. Explor. 2022, 39, 1027–1043. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Z.; Xu, S.; Zhou, W.; Wu, J. A field investigation of the deformation of protected coal and its application for CBM extraction in the Qinglong coalmine in China. J. Nat. Gas. Sci. Eng. 2015, 27, 367–373. [Google Scholar] [CrossRef]

- Yao, B.; Ma, Q.; Wei, J.; Ma, J.; Cai, D. Effect of protective coal seam mining and gas extraction on gas transport in a coal seam. Int. J. Min. Sci. Technol. 2016, 26, 637–643. [Google Scholar] [CrossRef]

- AQ 1050–2008; Technical Criterion of Protective Coal Seam Exploitation. Standards Press of China: Beijing, China, 2008.

- Xi, J.; Wang, Z.; Chen, D.; Chen, J. Study on time–space characteristics of gas drainage in advanced self-pressure-relief area of the stope. Energy Sci. Eng. 2023, 11, 1311–1324. [Google Scholar]

- Jiang, W.; Zhao, L.; Cheng, B. Variation characteristics of coal rock layer and gas extraction law of surface well under mining pressure relief. Arab. J. Geosci. 2021, 14, 298. [Google Scholar] [CrossRef]

| Lithology | Density /kg.m−3 | Bulk Modulus /Pa | Shear Modulus /Pa | Tensile Strength/Pa | Cohesion /Pa | Frictional Angle/° |

|---|---|---|---|---|---|---|

| Overlying rock | 2500 | 9.67 × 109 | 7.64 × 109 | 5.68 × 106 | 5.71 × 106 | 46 |

| Sandy mudstone | 2480 | 6.41 × 109 | 5.32 × 109 | 1.23 × 106 | 1.97 × 106 | 35 |

| Fine sandstones | 2850 | 8.42 × 109 | 6.15 × 109 | 2.73 × 106 | 2.65 × 106 | 40 |

| Mudstone | 2450 | 5.74 × 109 | 3.31 × 109 | 1.02 × 106 | 1.61 × 106 | 32 |

| D5-6 coal seam | 1430 | 1.46 × 109 | 1.11 × 109 | 0.64 × 106 | 0.93 × 106 | 28 |

| Carbonaceous Mudstone | 2450 | 5.63 × 109 | 4.98 × 109 | 1.66 × 106 | 1.78 × 106 | 35 |

| E8 coal seam | 1490 | 2.06 × 109 | 1.46 × 109 | 1.51 × 106 | 1.08 × 106 | 30 |

| E9-10 coal seam | 1450 | 1.86 × 109 | 1.35 × 109 | 1.42 × 106 | 0.99 × 106 | 30 |

| Siltstone | 2550 | 7.43 × 109 | 6.24 × 109 | 1.65 × 106 | 2.17 × 106 | 38 |

| E11 coal seam | 1460 | 1.88 × 109 | 1.40 × 109 | 1.45 × 106 | 1.02 × 106 | 30 |

| Medium sandstone | 2600 | 8.97 × 109 | 7.15 × 109 | 3.71 × 106 | 3.65 × 106 | 40 |

| deep rock layer | 2500 | 9.67 × 109 | 7.64 × 109 | 5.68 × 106 | 5.71 × 106 | 46 |

| Borehole Name | Borehole Position | Elevation Angle/° | Borehole Length/m | Coal Length/m |

|---|---|---|---|---|

| Y1−1 | G28 point is 8 m away | 65 | 59.2 | 3.8 |

| Y1−2 | G28 point is 18 m away | 41 | 85.3 | 5.9 |

| Y1−3 | G28 point is 28 m away | 32 | 115.4 | 7.7 |

| Y2−1 | G28 point is 38 m away | 65 | 60.1 | 4.0 |

| Y2−2 | G28 point is 48 m away | 41 | 84.9 | 5.8 |

| Y2−3 | G28 point is 58 m away | 32 | 114.8 | 7.9 |

| X1−1 | G30 point is 5 m away | 65 | 59.3 | 3.9 |

| X1−2 | G30 point is 15 m away | 41 | 84.9 | 5.9 |

| X1−3 | G30 point is 25 m away | 32 | 115.2 | 8.0 |

| X2−1 | G30 point is 35 m away | 65 | 59.6 | 3.8 |

| X2−2 | G30 point is 45 m away | 41 | 85.7 | 5.7 |

| X2−3 | G30 point is 55 m away | 32 | 114.6 | 7.8 |

| Borehole Number | Vertical Stress /MPa | Extraction Method | 30 d Cumulative Extraction/m3 | Liberated Coal/t | Ratio of Liberated Coal Volume | Ratio of Borehole 3 to Other Boreholes |

|---|---|---|---|---|---|---|

| 1# | 21.58 | pre−extraction | 75.73–76.46 | 20.80–21.01 | 39.73–42.42 | 261.02–281.04 |

| 16.42 | unloading pump | 3008.93–3243.55 | 826.63–891.09 | 6.09–7.14 | ||

| 2# | 21.56 | pre−extraction | 103.08–104.54 | 28.32–28.72 | 82.77–83.82 | 191.77–205.55 |

| 10.74 | unloading pump | 8640.26–8652.73 | 2373.70–2377.12 | 2.28–2.49 | ||

| 3# | 21.53 | pre−extraction | 142.80–145.01 | 39.23–39.84 | 138.43–148.18 | 138.43–148.18 |

| 6.72 | unloading pump | 19,767.30–21,488.06 | 5430.58–5903.31 | − |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, J.; Chen, X.; Li, S.; Bi, R.; Chen, Z. Analyzing the Optimization of Unloading Gas Extraction Drilling Arrangement Based on Stress Distribution in the Protected Layer. Sustainability 2024, 16, 2133. https://doi.org/10.3390/su16052133

Xiao J, Chen X, Li S, Bi R, Chen Z. Analyzing the Optimization of Unloading Gas Extraction Drilling Arrangement Based on Stress Distribution in the Protected Layer. Sustainability. 2024; 16(5):2133. https://doi.org/10.3390/su16052133

Chicago/Turabian StyleXiao, Jian, Xuexi Chen, Shugang Li, Ruiqing Bi, and Zhiheng Chen. 2024. "Analyzing the Optimization of Unloading Gas Extraction Drilling Arrangement Based on Stress Distribution in the Protected Layer" Sustainability 16, no. 5: 2133. https://doi.org/10.3390/su16052133

APA StyleXiao, J., Chen, X., Li, S., Bi, R., & Chen, Z. (2024). Analyzing the Optimization of Unloading Gas Extraction Drilling Arrangement Based on Stress Distribution in the Protected Layer. Sustainability, 16(5), 2133. https://doi.org/10.3390/su16052133