Utilization of Nano Silica and Plantain Leaf Ash for Improving Strength Properties of Expansive Soil

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Expansive Soil

2.1.2. Nano Silica

2.1.3. Plantain Leaf Ash

| Parameters | Value | Standard |

|---|---|---|

| Liquid Limit (%) | 74 | ASTM D4318 [25] |

| Plastic Limit (%) | 39 | ASTM D4318 [25] |

| Plastic Index (%) | 35 | ASTM D4318 [25] |

| Soil Classification (USCS) | CH | ASTM D2487 [30] |

| Unconfined Compressive Strength (MPa) | 0.68 | ASTM D2166 [31] |

| Swelling Potential (%) | 72 | ASTM D4546 [32] |

| Specific Gravity (Gs) | 2.68 | ASTM D854 [33] |

| Optimum Moisture Content (OMC) (%) | 27.4 | ASTM D1557 [34] |

| Maximum Dry Density (g/cm3) | 1.2 | ASTM D1557 [34] |

| Parameters | Percentage (%) |

|---|---|

| Mineralogical Composition % | |

| Quartz | 46.1 |

| Montmorillonite | 34.7 |

| Kaolinite | 11.4 |

| Feldspar | 3.1 |

| Other | 4.7 |

| Chemical Composition % | |

| SiO2 | 59.34 |

| Al2O3 | 23.42 |

| FeO | 9.31 |

| CaO | 3.07 |

| MgO | 1.94 |

| TiO2 | 1.78 |

| K2O | 0.71 |

| Na2O + P2O5 | 0.43 |

| Parameters | Values |

|---|---|

| Color | White |

| Form | Powder |

| Surface Area | 200 (m2/g) |

| Refractive Index | 1.46 (lit.) |

| Average Particle Size | 200–300 (nm) |

| Density | 2.31 (b/cu.ft) |

| Parameters | Percentage (%) |

|---|---|

| CaO | 47.31 |

| SiO2 | 17.54 |

| K2O | 16.92 |

| Al2O3 | 4.08 |

| Fe2O3 | 3.87 |

| P2O5 | 3.14 |

| SO3 | 2.69 |

| MgO | 1.47 |

| LOI | 0.28 |

| Others | 2.70 |

2.2. Preparation of Soil Samples

2.3. Test Methods

2.3.1. Compaction Test

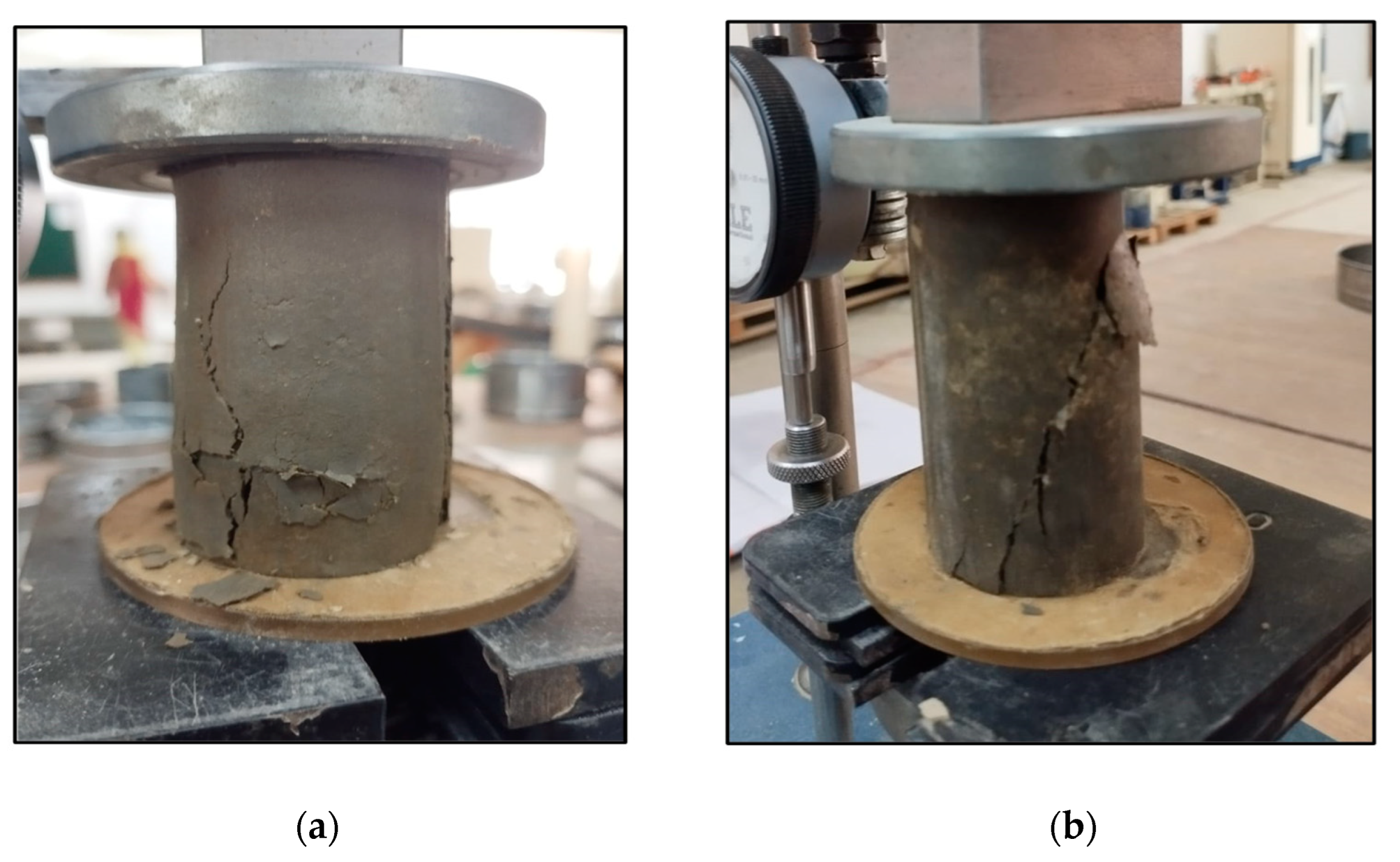

2.3.2. UCS Test

2.3.3. Direct Shear Test

2.3.4. CBR Test

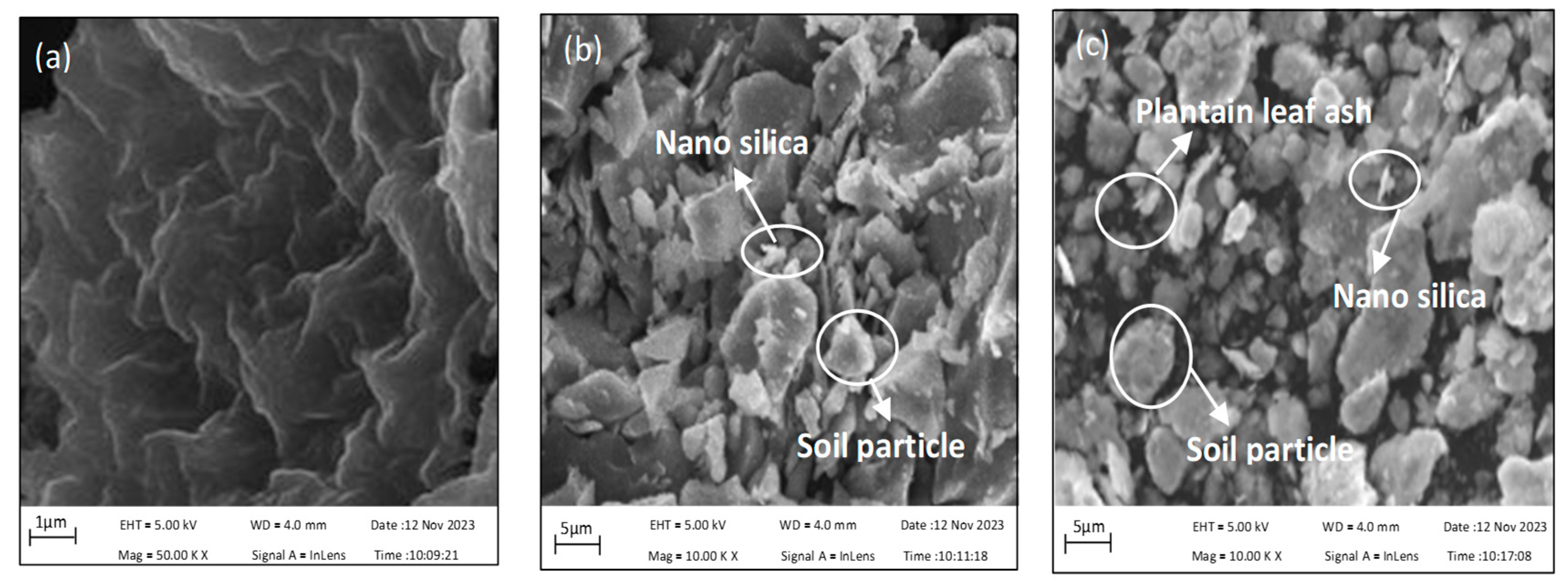

2.3.5. SEM Test

3. Results and Discussion

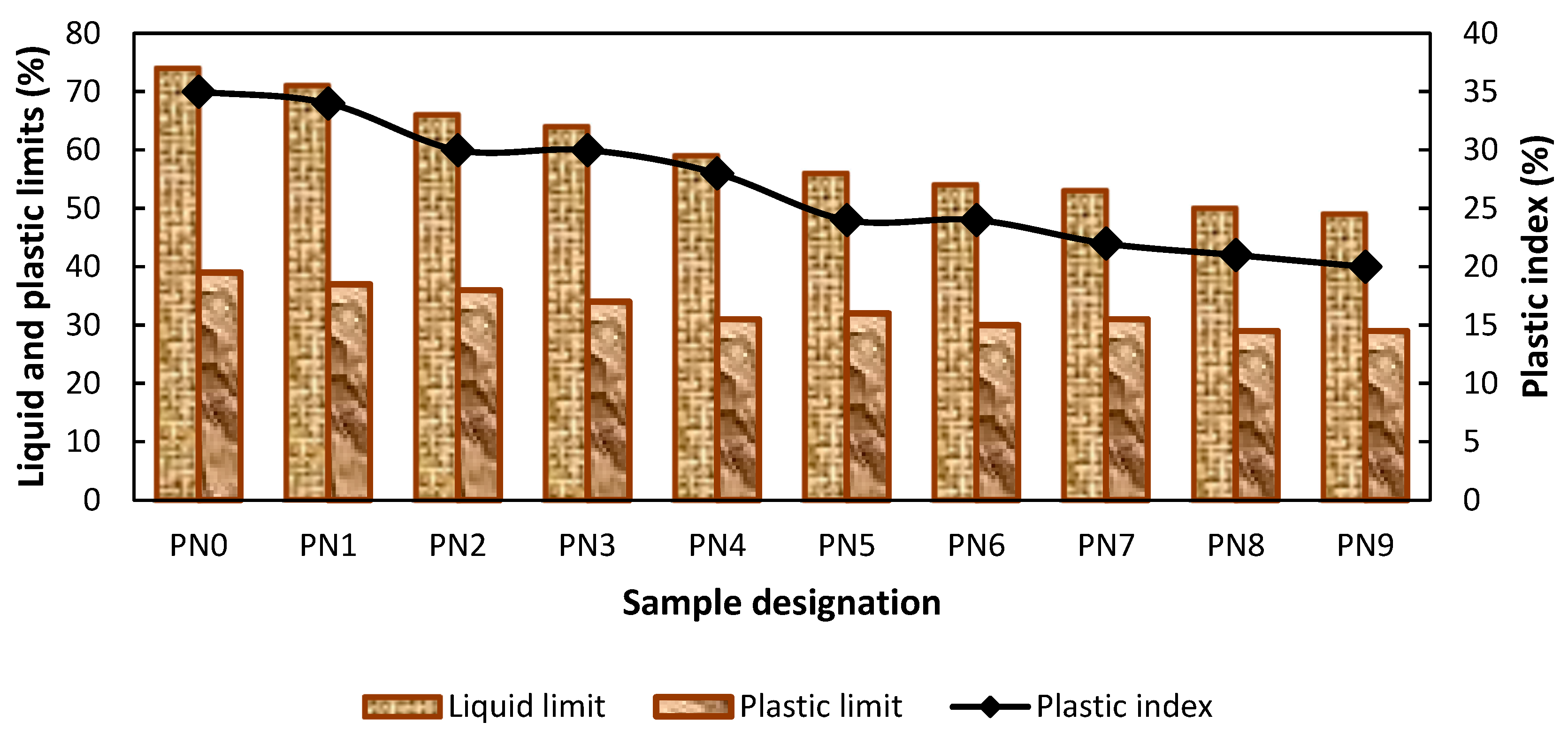

3.1. Effect of Nano Silica and Plantain Leaf Ash on Atterberg Limits

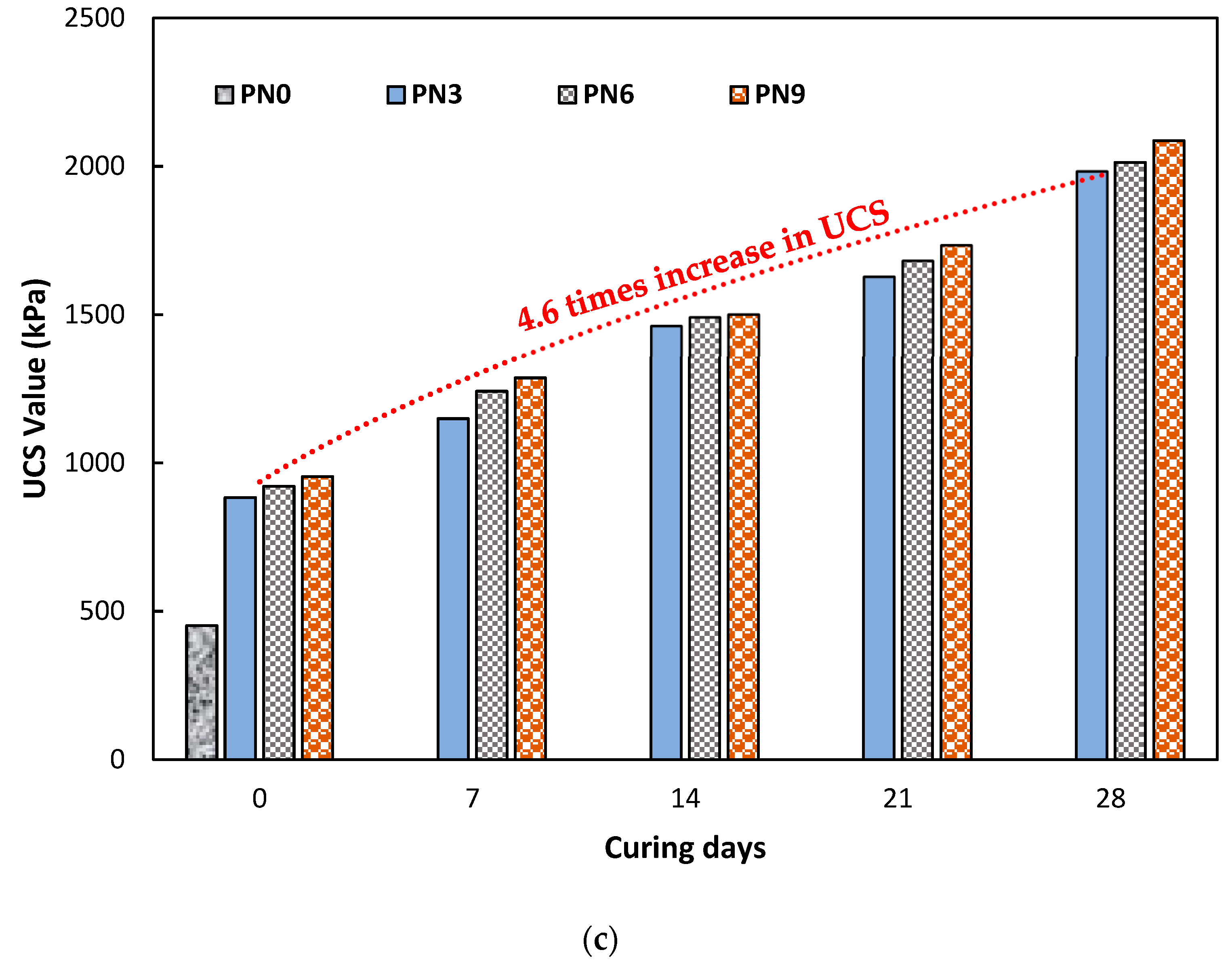

3.2. Effect of Nano Silica and Plantain Leaf Ash on UCS

3.3. Effect of Nano Silica and Plantain Leaf Ash on Shear Strength Parameters

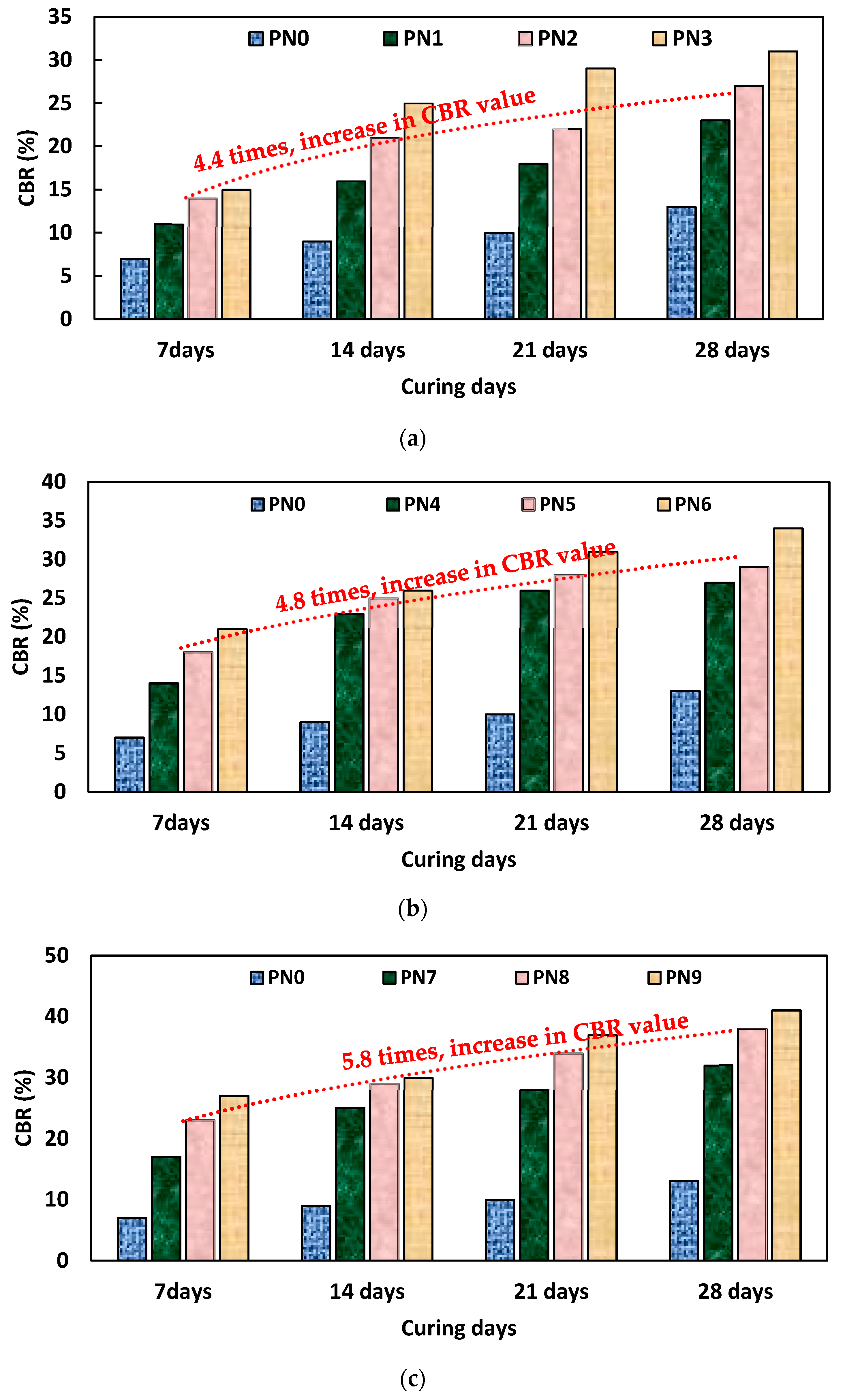

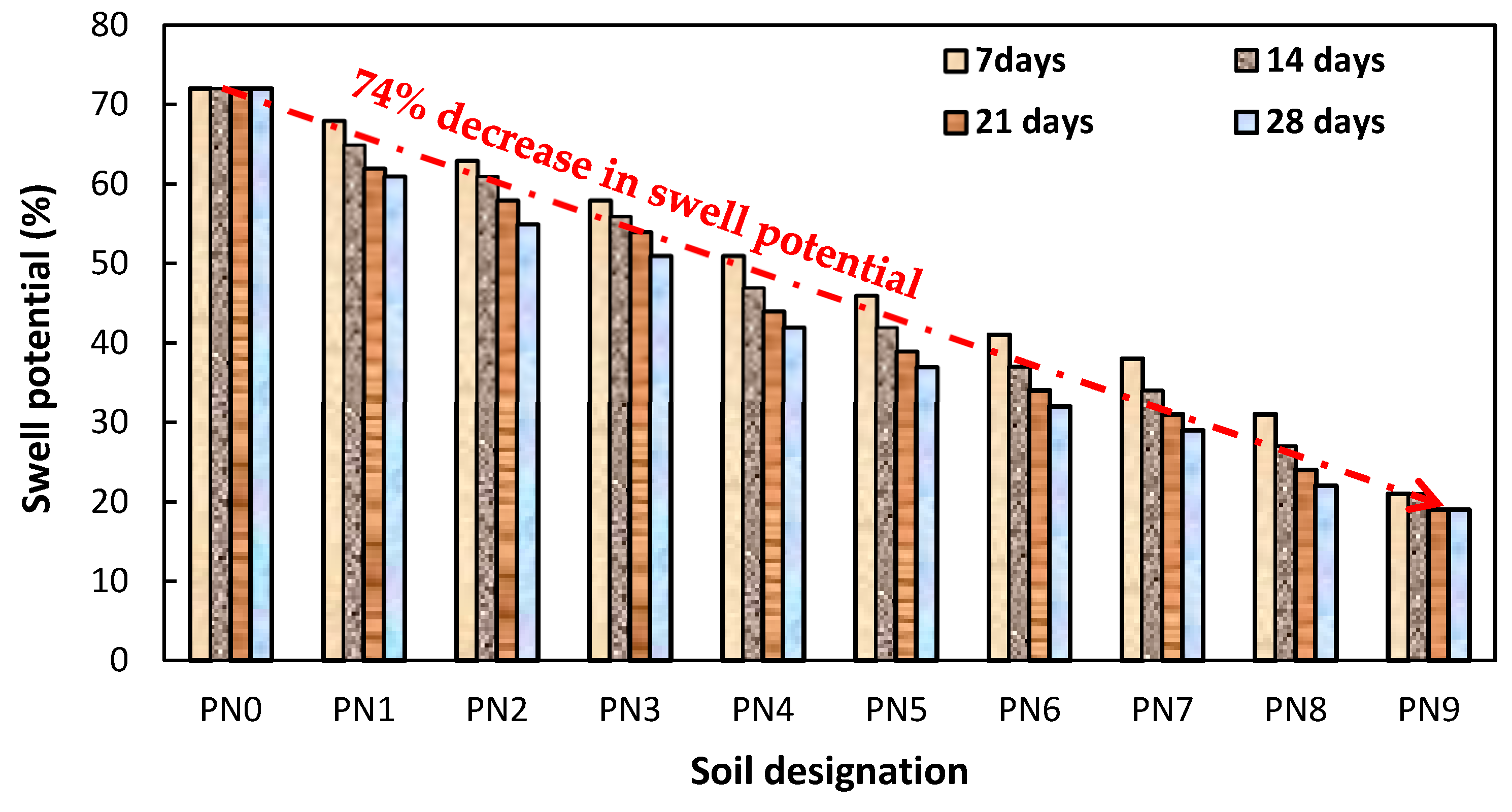

3.4. Effect of Nano Silica and Plantain Leaf Ash on CBR

3.5. Effect of Nano Silica and Plantain Leaf Ash on Microstructure Analysis

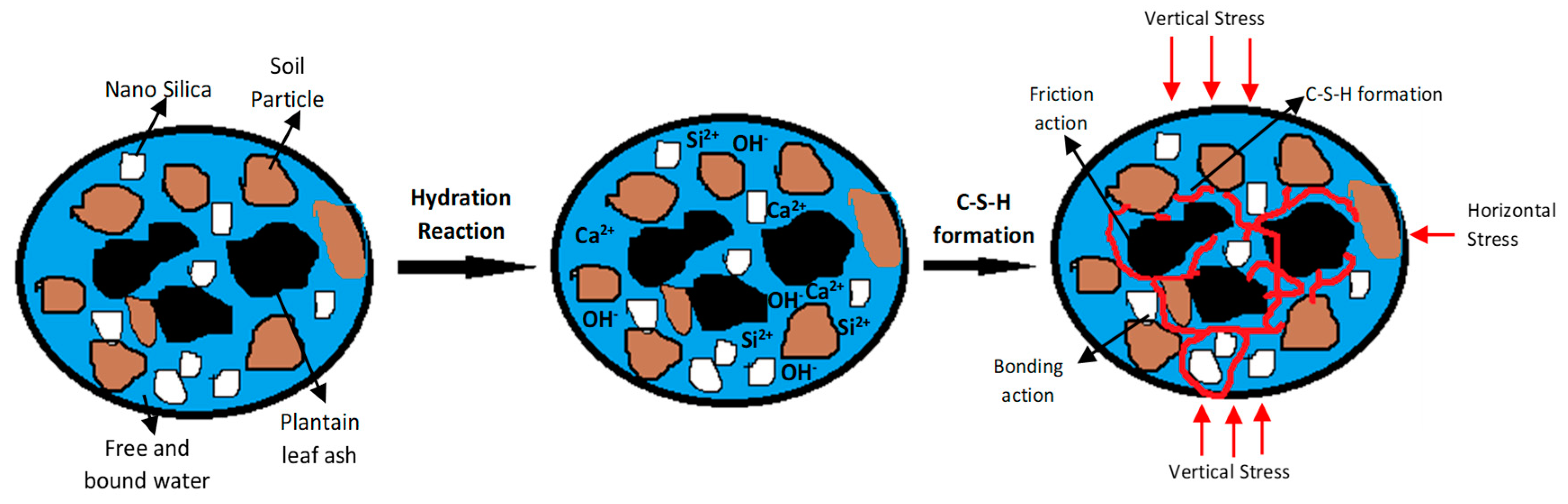

4. Interaction Mechanism between Soil, Plantain Leaf Ash, and Nano Silica

5. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, F.H. Foundations on Expansive Soils; Elsevier: Amsterdam, The Netherlands, 2012; Volume 12. [Google Scholar]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Ghavami, S.; Naseri, H.; Jahanbakhsh, H.; Nejad, F.M. The impacts of nano-SiO2 and silica fume on cement kiln dust treated soil as a sustainable cement-free stabilizer. Constr. Build. Mater. 2021, 285, 122918. [Google Scholar] [CrossRef]

- Ezema, N.; Adinna, B.; Anayo, C. Effect of sugarcane bagasse ash and plantain leaf ash on geotechnical properties of clay soil from Efab Estate, Awka, Anambra State. Niger. J. Technol. 2022, 41, 949–954. [Google Scholar] [CrossRef]

- Ijaz, N.; Dai, F.; Meng, L.; ur Rehman, Z.; Zhang, H. Integrating lignosulphonate and hydrated lime for the amelioration of expansive soil: A sustainable waste solution. J. Clean. Prod. 2020, 254, 119985. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, B.S.; Bajaj, A. Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. J. Mater. Civ. Eng. 2007, 19, 242–248. [Google Scholar] [CrossRef]

- Wijaya, W.; Ismanti, S.; Rifa’i, A. Soft Clay Improvement Using Bamboo Leaf Ash on CBR Values. J. Phys. Conf. Ser. 2020, 1625, 012007. [Google Scholar] [CrossRef]

- Khalid, B.; Alshawmar, F. Exploring the Feasibility of Using Recycled PET Strips with Palm Leaf Ash for Sustainable Soil Stabilization. Sustainability 2023, 15, 13542. [Google Scholar] [CrossRef]

- Zada, U.; Jamal, A.; Iqbal, M.; Eldin, S.M.; Almoshaogeh, M.; Bekkouche, S.R.; Almuaythir, S. Recent advances in expansive soil stabilization using admixtures: Current challenges and opportunities. Case Stud. Constr. Mater. 2023, 18, e01985. [Google Scholar] [CrossRef]

- Petry, T.M.; Little, D.N. Review of stabilization of clays and expansive soils in pavements and lightly loaded structures—History, practice, and future. J. Mater. Civ. Eng. 2002, 14, 447–460. [Google Scholar] [CrossRef]

- Luo, X.; Kong, L.; Bai, W. Effect of Superhydrophobic Nano-SiO2 on the Hydraulic Conductivity of Expansive Soil and Analysis of Its Mechanism. Appl. Sci. 2023, 13, 8198. [Google Scholar] [CrossRef]

- Ghasabkolaei, N.; Choobbasti, A.J.; Roshan, N.; Ghasemi, S.E. Geotechnical properties of the soils modified with nanomaterials: A comprehensive review. Arch. Civ. Mech. Eng. 2017, 17, 639–650. [Google Scholar] [CrossRef]

- Mostafa, A.; Ouf, M.S.; Elgendy, M. Stabilization of subgrade pavement layer using silica fume and nano silica. Int. J. Sci. Eng. Res. 2016, 7, 573–581. [Google Scholar]

- Buazar, F. Impact of biocompatible nanosilica on green stabilization of subgrade soil. Sci. Rep. 2019, 9, 15147. [Google Scholar] [CrossRef] [PubMed]

- Awadalseed, W.; Zhang, J.; Zhao, H. Experimental Study on Nano SiO2 and Cement Modified Expansive Soil. In Proceedings of the GeoShanghai 2018 International Conference: Fundamentals of Soil Behaviours, Shanghai, China, 27–30 May 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 209–217. [Google Scholar]

- Al-Gharbawi, A.S.; Najemalden, A.M.; Fattah, M.Y. Expansive Soil Stabilization with Lime, Cement, and Silica Fume. Appl. Sci. 2022, 13, 436. [Google Scholar] [CrossRef]

- Biswas, N.; Puppala, A.J.; Chakraborty, S. Role of Nano-and Crystalline Silica to Accelerate Chemical Treatment of Problematic Soil. J. Geotech. Geoenviron. Eng. 2023, 149, 04023044. [Google Scholar] [CrossRef]

- Alshami, A.W.; Ismael, B.H.; Aswad, M.F.; Majdi, A.; Alshijlawi, M.; Aljumaily, M.M.; AlOmar, M.K.; Aidan, I.A.; Hameed, M.M. Compaction Curves and Strength of Clayey Soil Modified with Micro and Nano Silica. Materials 2022, 15, 7148. [Google Scholar] [CrossRef]

- Eissa, A.; Bassuoni, M.; Ghazy, A.; Alfaro, M. Improving the properties of soft clay using cement, slag, and nanosilica: Experimental and statistical modeling. J. Mater. Civ. Eng. 2022, 34, 04022031. [Google Scholar] [CrossRef]

- Akinwumi, I.; Onyeiwu, M.; Epelle, P.; Ajayi, V. Soil Improvement Using Blends of Coal Ash and Plantain Peel Ash as Road Pavement Layer Materials. Resources 2023, 12, 41. [Google Scholar] [CrossRef]

- Naguib, H.M.; Hou, G. Exploitation of natural and recycled biomass resources to get eco-friendly polymer. J. Polym. Environ. 2023, 31, 533–540. [Google Scholar] [CrossRef]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, R. Sub-grade characteristics of soil stabilized with agricultural waste, constructional waste, and lime. Bull. Eng. Geol. Environ. 2021, 80, 2473–2484. [Google Scholar] [CrossRef]

- Gidebo, F.A.; Yasuhara, H.; Kinoshita, N. Stabilization of expansive soil with agricultural waste additives: A review. Int. J. Geo-Eng. 2023, 14, 14. [Google Scholar] [CrossRef]

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- Mourhly, A.; Khachani, M.; Hamidi, A.E.; Kacimi, M.; Halim, M.; Arsalane, S. The synthesis and characterization of low-cost mesoporous silica SiO2 from local pumice rock. Nanomater. Nanotechnol. 2015, 5, 35. [Google Scholar] [CrossRef]

- Kho, K.; Hadinoto, K. Effects of excipient formulation on the morphology and aqueous re-dispersibility of dry-powder silica nano-aggregates. Colloids Surf. A Physicochem. Eng. Asp. 2010, 359, 71–81. [Google Scholar] [CrossRef]

- Kong, D.; Corr, D.J.; Hou, P.; Yang, Y.; Shah, S.P. Influence of colloidal silica sol on fresh properties of cement paste as compared to nano-silica powder with agglomerates in micron-scale. Cem. Concr. Compos. 2015, 63, 30–41. [Google Scholar] [CrossRef]

- Ugwu, J.; Ugwuanyi, D. Sustainability Performance of Plantain Leaf Ash and the Compressive Strength of Concrete. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Thessaloniki, Greece, 2020; p. 012112. [Google Scholar]

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM D4546; Standard Test Methods for One-Dimensional Swell or Collapse of Soils. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D854; Standard Test Methods for Specific Gravity of Soil Solids by the Water Displacement Method. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D1557; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2700 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2021.

- Wang, J.; Liu, M.; Wang, Y.; Zhou, Z.; Xu, D.; Du, P.; Cheng, X. Synergistic effects of nano-silica and fly ash on properties of cement-based composites. Constr. Build. Mater. 2020, 262, 120737. [Google Scholar] [CrossRef]

- Munda, J.; Padhi, J.; Mohanty, S. Investigation on performance of expansive soil stabilized with fly ash and nano-SiO2. Mater. Today: Proc. 2022, 67, 1268–1275. [Google Scholar] [CrossRef]

- Munawar, M.; Khan, A.H.; Rehman, Z.U.; Rahim, A.; Aziz, M.; Almuaythir, S.; El Kheir, B.S.; Haider, F. Micro to Nanolevel Stabilization of Expansive Clay Using Agro-Wastes. Adv. Civ. Eng. 2023, 2023, 2753641. [Google Scholar] [CrossRef]

- Kulanthaivel, P.; Selvakumar, S.; Soundara, B.; Kayalvizhi, V.; Bhuvaneshwari, S. Combined effect of nano-silica and randomly distributed fibers on the strength behavior of clay soil. Nanotechnol. Environ. Eng. 2022, 7, 23–34. [Google Scholar] [CrossRef]

- Ishola, K.; Olawuyi, O.; Bello, A.; Yohanna, P. Effect of plantain peel ash on the strength properties of tropical red soil. Niger. Res. J. Eng. Environ. Sci. 2019, 4, 447–459. [Google Scholar]

- ASTM D3080; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2004.

- Zumrawi, M.M.; Mohammed, L.A. Correlation of placement conditions and soil intrinsic properties with shear strength of cohesive soils. In Proceedings of the 7th Annual Conference for Postgraduate Studies and Scientific Research-Basic Sciences and Engineering Studies, Khartoum, Sudan, 20–23 February 2016. [Google Scholar]

- Smalley, I.J. Cohesion of soil particles and the intrinsic resistance of simple soil systems to wind erosion. J. Soil Sci. 1970, 21, 154–161. [Google Scholar] [CrossRef]

- Pul, S.; Ghaffari, A.; Öztekin, E.; Hüsem, M.; Demir, S. Experimental Determination of Cohesion and Internal Friction Angle on Conventional Concretes. ACI Mater. J. 2017, 114, 407. [Google Scholar] [CrossRef]

- ASTM D1883; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E2809-22; Standard Guide for Using Scanning Electron Microscopy/Energy Dispersive X-ray Spectroscopy (SEM/EDS) in Forensic Polymer Examinations. ASTM International: West Conshohocken, PA, USA, 2022.

- Jassim, N.W.; Hassan, H.A.; Mohammed, H.A.; Fattah, M.Y. Enhancement consistency and compaction characteristics of clayey soil using nano silica material. Period. Eng. Nat. Sci. 2023, 10, 77–83. [Google Scholar] [CrossRef]

- Gao, Y.; Zhou, W.; Zeng, W.; Pei, G.; Duan, K. Preparation and flexural fatigue resistance of self-compacting road concrete incorporating nano-silica particles. Constr. Build. Mater. 2021, 278, 122380. [Google Scholar] [CrossRef]

- Bahmani, S.H.; Farzadnia, N.; Asadi, A.; Huat, B.B. The effect of size and replacement content of nanosilica on strength development of cement treated residual soil. Constr. Build. Mater. 2016, 118, 294–306. [Google Scholar] [CrossRef]

- Bahmani, S.H.; Huat, B.B.; Asadi, A.; Farzadnia, N. Stabilization of residual soil using SiO2 nanoparticles and cement. Constr. Build. Mater. 2014, 64, 350–359. [Google Scholar] [CrossRef]

- Nnochiri, E.S.; Ogundipe, O.M.; Ola, S.A. Geotechnical and microstructural properties of cement-treated laterites stabilized with rice husk ash and bamboo leaf ash. Acta Polytech. 2021, 61, 722–732. [Google Scholar] [CrossRef]

- Mim, N.J.; Meraz, M.M.; Islam, M.H.; Farsangi, E.N.; Mehedi, M.T.; Arafin, S.A.K.; Shrestha, R.K. Eco-friendly and cost-effective self-compacting concrete using waste banana leaf ash. J. Build. Eng. 2023, 64, 105581. [Google Scholar] [CrossRef]

- Amin, M.; Tayeh, B.A.; Kandil, M.A.; Agwa, I.S.; Abdelmagied, M.F. Effect of rice straw ash and palm leaf ash on the properties of ultrahigh-performance concrete. Case Stud. Constr. Mater. 2022, 17, e01266. [Google Scholar] [CrossRef]

- Bello, A.A.; Ige, J.; Ibitoye, G.I. Geotechnical Properties of Lateritic Soil Stabilized with Cement-Bamboo Leaf Ash Admixture. Int. J. Appl. Eng. Res. 2014, 9, 9655–9665. [Google Scholar]

- Shahin, S.S.; Fayed, L.; Ahmad, E.H. Review of Nano Additives in Stabilization of Soil. In Proceedings of the 7th International Conference on Nano-Technology in Construction, Sharm El-Sheikh, Egypt, 27–31 March 2015; pp. 1–11. [Google Scholar]

- Kulanthaivel, P.; Soundara, B.; Velmurugan, S.; Naveenraj, V. Experimental investigation on stabilization of clay soil using nano-materials and white cement. Mater. Today Proc. 2021, 45, 507–511. [Google Scholar] [CrossRef]

- Rajabi, A.M.; Ghorashi, S.; Yeganeh, M.M. The effect of polypropylene and glass fibers on strength and failure behavior of clayey sand soil. Arab. J. Geosci. 2023, 16, 6. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Miraftab, M.; Mohamed, M.; McMahon, P. Unconfined compression strength of reinforced clays with carpet waste fibers. J. Geotech. Geoenviron. Eng. 2013, 139, 483–493. [Google Scholar] [CrossRef]

- Kalhor, A.; Ghazavi, M.; Roustaei, M. Impacts of nano-silica on physical properties and shear strength of clayey soil. Arab. J. Sci. Eng. 2022, 47, 5271–5279. [Google Scholar] [CrossRef]

- Changizi, F.; Haddad, A. Effect of nano-SiO2 on the geotechnical properties of cohesive soil. Geotech. Geol. Eng. 2016, 34, 725–733. [Google Scholar] [CrossRef]

- Cui, H.; Jin, Z.; Bao, X.; Tang, W.; Dong, B. Effect of carbon fiber and nanosilica on shear properties of silty soil and the mechanisms. Constr. Build. Mater. 2018, 189, 286–295. [Google Scholar] [CrossRef]

- Inim, I.J.; Affiah, U.E.; Eminue, O.O. Assessment of bamboo leaf ash/lime-stabilized lateritic soils as construction materials. Innov. Infrastruct. Solut. 2018, 3, 32. [Google Scholar] [CrossRef]

- Yathushan, V.; Puswewala, U.G.A. Effectiveness of Pozzolanic Leaf Ashes and Plastics on Geotechnical Characteristics. Int. J. Eng. Technol. Innov. 2022, 12, 155–166. [Google Scholar] [CrossRef]

- Maduka, E.J. Geotechnical Properties of Lateritic Soil–Bentonite Mixture Treated with Bamboo Leaf Ash; NAU Department of Civil Engineering Final Year Project & Postgraduate Portal; Nnamdi Azikiwe University: Awka, Nigeria, 2023; Volume 2. [Google Scholar]

- Ishola, K.; Olawuyi, O.; Kareem, M. Compaction Characteristics of the Lateritic Soil-Mango Leaf Ash Admixed. UNIOSUN J. Eng. Environ. Sci. 2019, 1, 96–102. [Google Scholar] [CrossRef]

- Patro, A.; Sahoo, R.R. Strength and Microstructure Evolution of Soft Soils by Using Nano-silica. In Ground Characterization and Foundations: Proceedings of Indian Geotechnical Conference 2020 Volume 1; Springer: Singapore, 2022; pp. 315–325. [Google Scholar]

- Alireza, S.G.S.; Mohammad, M.S.; Hasan, B.M. Application of nanomaterial to stabilize a weak soil. In Proceedings of the 7th Conference of the International Conference on Case Histories in Geotechnical Engineering, Chicago, IN, USA, 2 May 2013. [Google Scholar]

- Kulkarni, P.P.; Mandal, J.N. Performance assessment of stabilized soil with fly ash-nano material mixes. J. Geotech. Transp. Eng. 2017, 3, 35–46. [Google Scholar]

- Eshaghzadeh, M.; Bayat, M.; Ajalloeian, R.; Hejazi, S.M. Mechanical behavior of silty sand reinforced with nanosilica-coated ceramic fibers. J. Adhes. Sci. Technol. 2021, 35, 2664–2683. [Google Scholar] [CrossRef]

- Pham, H.; Nguyen, Q.P. Effect of silica nanoparticles on clay swelling and aqueous stability of nanoparticle dispersions. J. Nanopart. Res. 2014, 16, 2137. [Google Scholar] [CrossRef]

- Omurlu, C.; Pham, H.; Nguyen, Q. Interaction of surface-modified silica nanoparticles with clay minerals. Appl. Nanosci. 2016, 6, 1167–1173. [Google Scholar] [CrossRef]

- Ettu, L.; Mbarjiogu, S.; Arimanwa, J. Strength of blended cement sandcrete and soilcrete blocks containing cassava waste ash and plantain leaf ash. Am. J. Eng. Res. 2013, 2, 55–60. [Google Scholar]

- Ettu, L.; Ezeh, J.; Anya, U.; Arimanwa, J.; Nwachukwu, K. Strength of binary blended cement composites containing plantain leaf ash. IOSR J. Eng 2013, 3, 54–59. [Google Scholar] [CrossRef]

- Ettu, L.; Nwachukwu, K.; Arimanwa, J.; Awodiji, C.; Opara, H. Strength of Ternary Blended Cement Concrete Containing Oil Palm Bunch Ash and Plantain Leaf Ash. Int. J. Comput. Eng. Res. 2013, 3, 64–68. [Google Scholar]

- Yerima, B.P.; Van Ranst, E. Introduction to Soil Science: Soils of the Tropics; Trafford Publishing: Victoria, BC, Canada, 2005. [Google Scholar]

- Ramezanianpour, A.A.; Mortezaei, M.; Mirvalad, S. Synergic effect of nano-silica and natural pozzolans on transport and mechanical properties of blended cement mortars. J. Build. Eng. 2021, 44, 102667. [Google Scholar] [CrossRef]

- Atahu, M.K. The Effect of Coffee Husk Ash on Geotechnical Properties of Expansive Soil; Universität Rostock: Rostock, Germany, 2020. [Google Scholar]

| No. | Mixed Ratios of Samples | Designation | Soil (%) | Plantain Leaf Ash (%) | Nano Silica (%) | Total (%) | OMC (%) |

|---|---|---|---|---|---|---|---|

| 1 | Soil + 0% Plantain leaf ash + 0% Nano silica | PN0 | 100 | 0 | 0 | 100 | 27.4 |

| 2 | Soil + 5% Plantain leaf ash + 0.4% Nano silica | PN1 | 94.6 | 5 | 0.4 | 100 | 16.3 |

| 3 | Soil + 10% Plantain leaf ash + 0.4% Nano silica | PN2 | 89.6 | 10 | 0.4 | 100 | 17.1 |

| 4 | Soil + 15% Plantain leaf ash + 0.4% Nano silica | PN3 | 84.6 | 15 | 0.4 | 100 | 18.6 |

| 5 | Soil + 5% Plantain leaf ash + 0.8% Nano silica | PN4 | 94.2 | 5 | 0.8 | 100 | 21.9 |

| 6 | Soil + 10% Plantain leaf ash + 0.8% Nano silica | PN5 | 89.2 | 10 | 0.8 | 100 | 22.4 |

| 7 | Soil + 15% Plantain leaf ash + 0.8% Nano silica | PN6 | 84.2 | 15 | 0.8 | 100 | 23.7 |

| 8 | Soil + 5% Plantain leaf ash + 1.2% Nano silica | PN7 | 93.8 | 5 | 1.2 | 100 | 26.8 |

| 9 | Soil + 10% Plantain leaf ash + 1.2% Nano silica | PN8 | 88.8 | 10 | 1.2 | 100 | 28.2 |

| 10 | Soil + 15% Plantain leaf ash + 1.2% Nano silica | PN9 | 83.8 | 15 | 1.2 | 100 | 28.9 |

| Sample Designation | Nano Silica (%) | Plantain Leaf Ash (%) | Frictional Angle (°) | Cohesion (kPa) |

|---|---|---|---|---|

| PN0 | 0 | 0 | 18.7 | 13.6 |

| PN1 | 0.4 | 5 | 19.3 | 18.1 |

| PN2 | 10 | 21.1 | 24.7 | |

| PN3 | 15 | 21.9 | 26.8 | |

| PN4 | 0.8 | 5 | 22.6 | 32.5 |

| PN5 | 10 | 23.1 | 38.3 | |

| PN6 | 15 | 24.2 | 42.9 | |

| PN7 | 1.2 | 5 | 25.7 | 38.4 |

| PN8 | 10 | 28.6 | 43.7 | |

| PN9 | 15 | 29.2 | 45.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshawmar, F. Utilization of Nano Silica and Plantain Leaf Ash for Improving Strength Properties of Expansive Soil. Sustainability 2024, 16, 2157. https://doi.org/10.3390/su16052157

Alshawmar F. Utilization of Nano Silica and Plantain Leaf Ash for Improving Strength Properties of Expansive Soil. Sustainability. 2024; 16(5):2157. https://doi.org/10.3390/su16052157

Chicago/Turabian StyleAlshawmar, Fahad. 2024. "Utilization of Nano Silica and Plantain Leaf Ash for Improving Strength Properties of Expansive Soil" Sustainability 16, no. 5: 2157. https://doi.org/10.3390/su16052157

APA StyleAlshawmar, F. (2024). Utilization of Nano Silica and Plantain Leaf Ash for Improving Strength Properties of Expansive Soil. Sustainability, 16(5), 2157. https://doi.org/10.3390/su16052157