Production Decision Model for the Cement Industry in Pursuit of Carbon Neutrality: Analysis of the Impact of Carbon Tax and Carbon Credit Costs

Abstract

:1. Introduction

2. The Related References

2.1. The Related Researches for the Cement Industry

2.2. Carbon Emissions, Carbon Tax, and Carbon Trading

2.3. ESG Indicators in the Cement Industry

2.4. Activity-Based Costing and Theory of Constraints

3. Research Methods

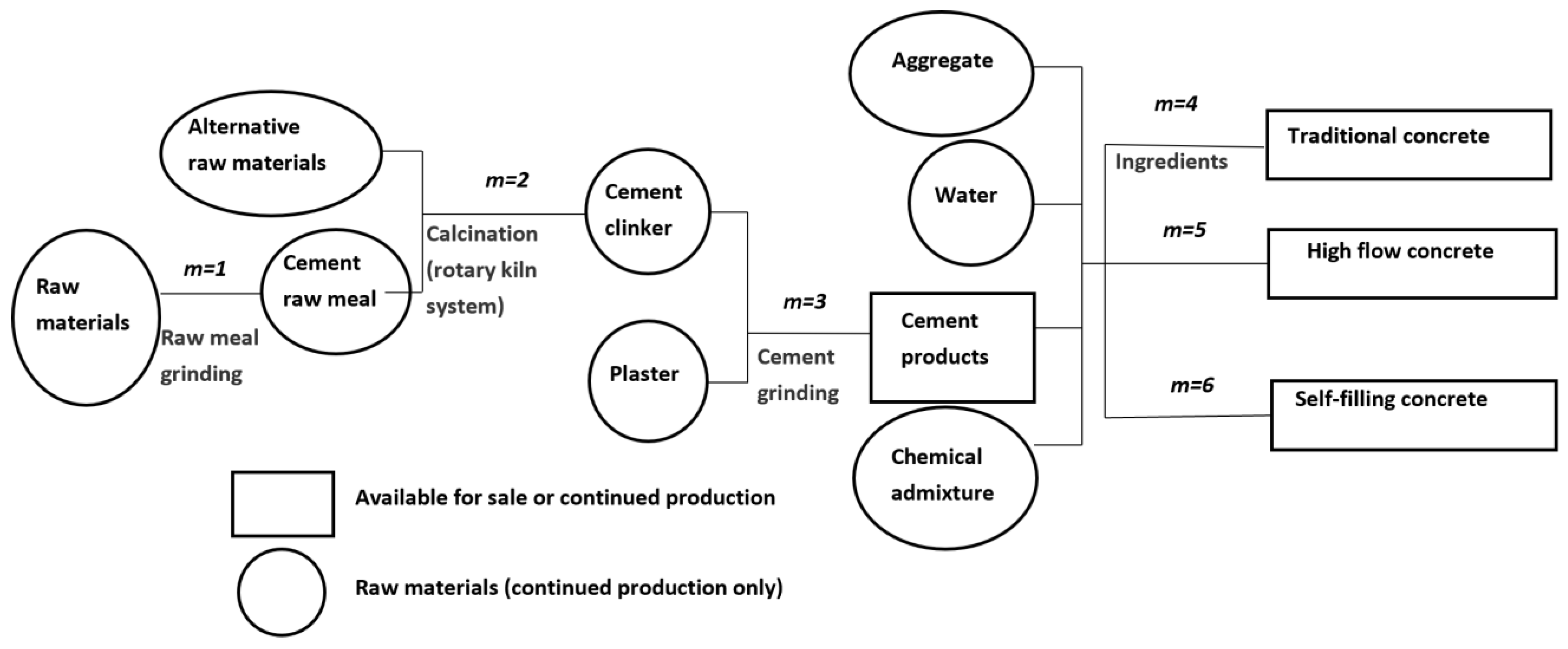

3.1. Cement Production Process and ESG Indicators

3.2. Research Assumptions

- The company primarily produces four products: Cement finished product (i = 1), Traditional concrete (i = 2), High-fluidity concrete (i = 3), and Self-compacting concrete (i = 4), with unit prices remaining constant during production.

- Seven main raw materials are used: Clinker (j = 1), Gypsum (j = 2), alternative materials (j = 3), Cement (j = 4), Aggregates (j = 5), Water (j = 6), and Pyrite (j = 7), with material costs fixed throughout production.

- Waste from other industries is incorporated as alternative materials, for instance, sludge, slag, and elements like silicon, aluminum, iron, and calcium, which are then used as raw materials. This not only aids in waste treatment but also reduces costs.

- The usage of alternative materials is considered an ESG indicator for the company, with yearly increments aiming to achieve the “Net Zero Emissions by 2050” goal.

- During production, all steps are categorized into unit-level, batch-level, and product-level operations.

- According to regulations and policies, human resources may work overtime, but wages are calculated based on overtime rates. Additionally, the utilization rates of all machinery and labor are 100%, with no idle resources, and wage rates remain constant throughout production.

- Carbon tax is levied on the production of each unit of product, thus the tax amount depends on the quantity produced.

- The cap on carbon credit trading is limited by government regulations, assumed to be unchanged in the short term, and the trading costs of carbon credits for each company are zero.

- The ratio of carbon emission reduction (CO2 in tons/binder material in tons) is progressively increased yearly to meet the “Net Zero Emissions by 2050” target.

3.3. Objective Function

3.3.1. General Formula for the Objective Function

| Maximization of profit | |

| i | Product index where i = 1 to 4. Products are: i = 1 (Finished Cement), i = 2 (Traditional Concrete), i = 3 (High Fluidity Concrete), i = 4 (Self-compacting Concrete). |

| j | Raw material index where j = 1 to 7. Raw materials are: j = 1 (Clinker), j = 2 (Gypsum), j = 3 (Alternative Materials), j = 4 (Cement), j = 5 (Aggregates), j = 6 (Water), j = 7 (Chemical Additives). |

| m | Process index where m = 1 to 6. Processes are: m = 1 (Raw Meal Grinding), m = 2 (Calcination), m = 3 (Cement Grinding), m = 4, m = 5, m = 6 (Batching). |

| t | Time period index where t = 1 to 3. |

| Unit price of the ith product for different time periods (t = 1, 2, 3). | |

| Quantity of the ith product in period t (i = 1~4; t = 1~3). | |

| Quantity of the jth raw material required for producing one unit of the ith product during the tth time period (i = 1~4; j = 1~7; t = 1~3). | |

| Total direct labor costs at points , and respectively. | |

| Non-negative variables for period t, with at most two adjacent variables being non-zero (t = 1~3). | |

| Unit batch-level cost in the mth process (m = 3~6). | |

| Resource consumption per batch for the ith product in the mth batch-level process (i = 1~4; m = 3~6). | |

| Number of batches for the ith product in the mth process during period t (i = 1~4; m = 3~6; t = 1~3). | |

| Number of batches for the ith product in the mth batch-level process (i = 1~4; m = 3~6). | |

| Unit product-level cost in the mth process (m = 3~6). | |

| Resource consumption for the ith product in the mth product-level process (i = 1~4; m = 3~6). | |

| Binary variable for period t, determining whether the ith product is produced (1 if produced, 0 otherwise) (i = 1~4; t = 1~3). | |

| Total fixed cost in period t (t = 1~3). |

3.3.2. Direct Material Cost Function

| Unit cost of the jth raw material, (j = 1~7) | |

| Quantity of the jth raw material required per unit of the ith product (i = 1~4; j = 1~7; t = 1~3) | |

| Upper limit on the available quantity of the jth raw material in period t (j = 1~7; t = 1~3) | |

| Lower limit on the available quantity of the jth raw material in period t (j = 3; t = 1~3) |

3.3.3. Direct Labor Cost Function

| Quantity of the ith product in period t, (i = 1~4; t = 1~3) | |

| Non-negative variables where at most two adjacent variables are not 0, (t = 1~3) | |

| Dummy variables (0, 1), where only one can be 1 for each period (t = 1~3) | |

| Labor hours required to produce one unit of the ith product in the mth process. | |

| The total number of labor hours under normal circumstances | |

| Maximum number of labor hours falling in the first overtime segment, as shown in Figure 2 | |

| Maximum number of labor hours in the second overtime segment, as indicated in Figure 2 |

3.3.4. Batch-Level Operational Costs

| Unit machine handling cost for the mth process | |

| Resource consumption per batch for the ith product in the mth process (i = 1~4; m = 3~6) | |

| Output per batch for the ith product in the mth process (i = 1~4; m = 3~6) | |

| Maximum available resources for the mth batch-level operation (m = 3~6) |

3.3.5. Product-Level Operational Costs

| Unit cost of product batching for the mth process | |

| Resource consumption for the ith product in the mth process (i = 1~4; m = 3~6) | |

| Dummy variable (0, 1) for period t, determining whether the ith product is produced (i = 1~4; t = 1~3) | |

| Maximum available resources for the mth product-level operation (m = 3~6) |

3.3.6. Constraints of Machine Hours

| Machine hours required to complete one unit of the ith product in the mth process (m = 1~3) | |

| Upper limit of available machine hours for the mth process (m = 1~3) |

3.4. Carbon Tax Cost Function Model

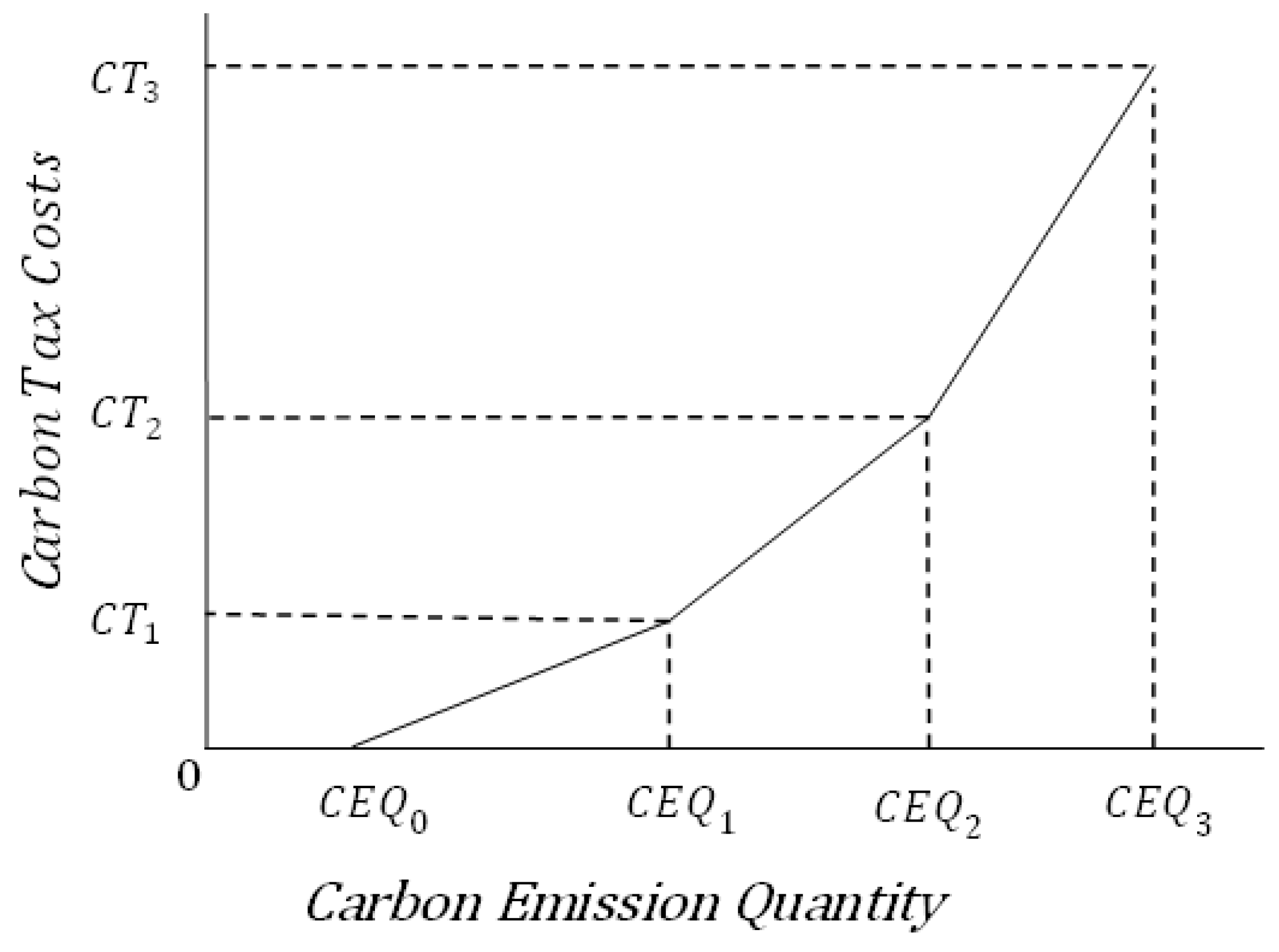

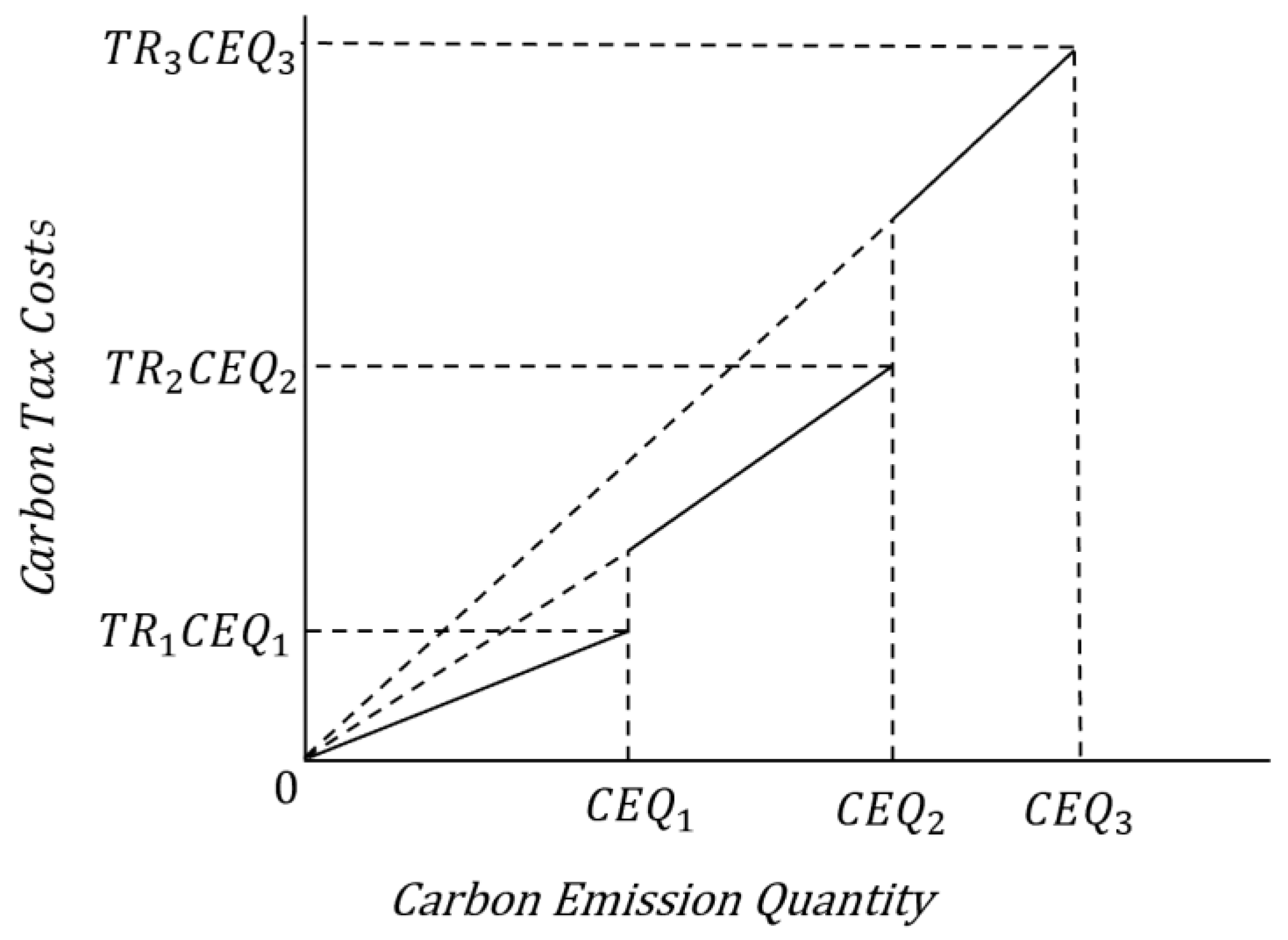

3.4.1. Model 1: Continuous Incremental Progressive Tax Rate Function for Carbon Tax

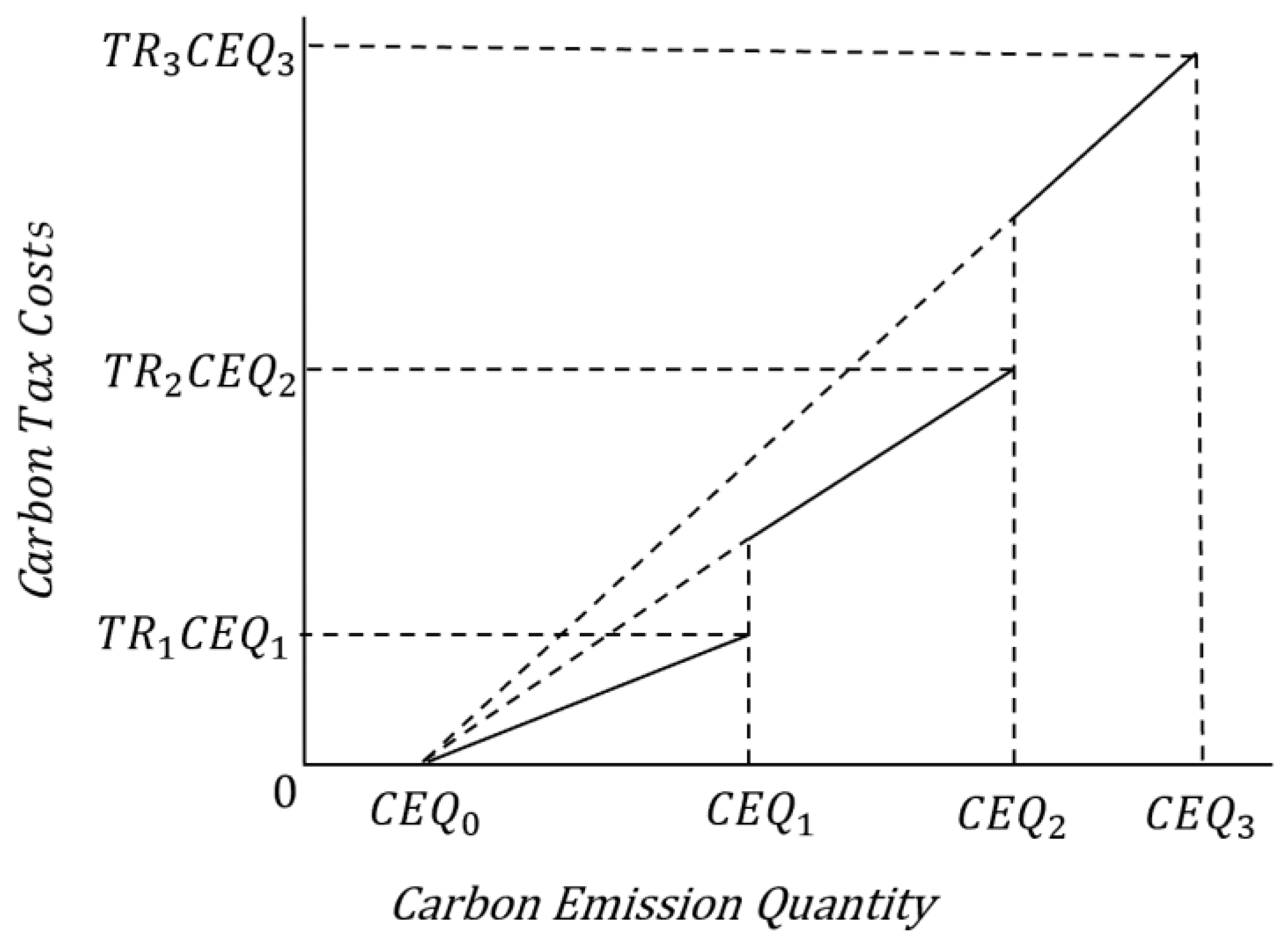

3.4.2. Model 2: Continuous Incremental Progressive Carbon Tax Function with Tax Exemption

3.4.3. Model 3: Continuous Incremental Progressive Carbon Tax Function with Carbon Trading

3.4.4. Model 4: Continuous Incremental Progressive Carbon Tax Objective Function (Including Tax Exemption and Carbon Credits)

3.4.5. Model 5: Discontinuous Incremental Progressive Carbon Tax Objective Function

3.4.6. Model 6: Discontinuous Incremental Progressive Carbon Tax Function with Tax Exemption

3.4.7. Model 7: Discontinuous Incremental Progressive Carbon Tax Objective Function with Carbon Trading

3.4.8. Model 8: Discontinuous Incremental Progressive Carbon Tax Function with Tax Exemption and Carbon Trading

4. Research Results and Analysis

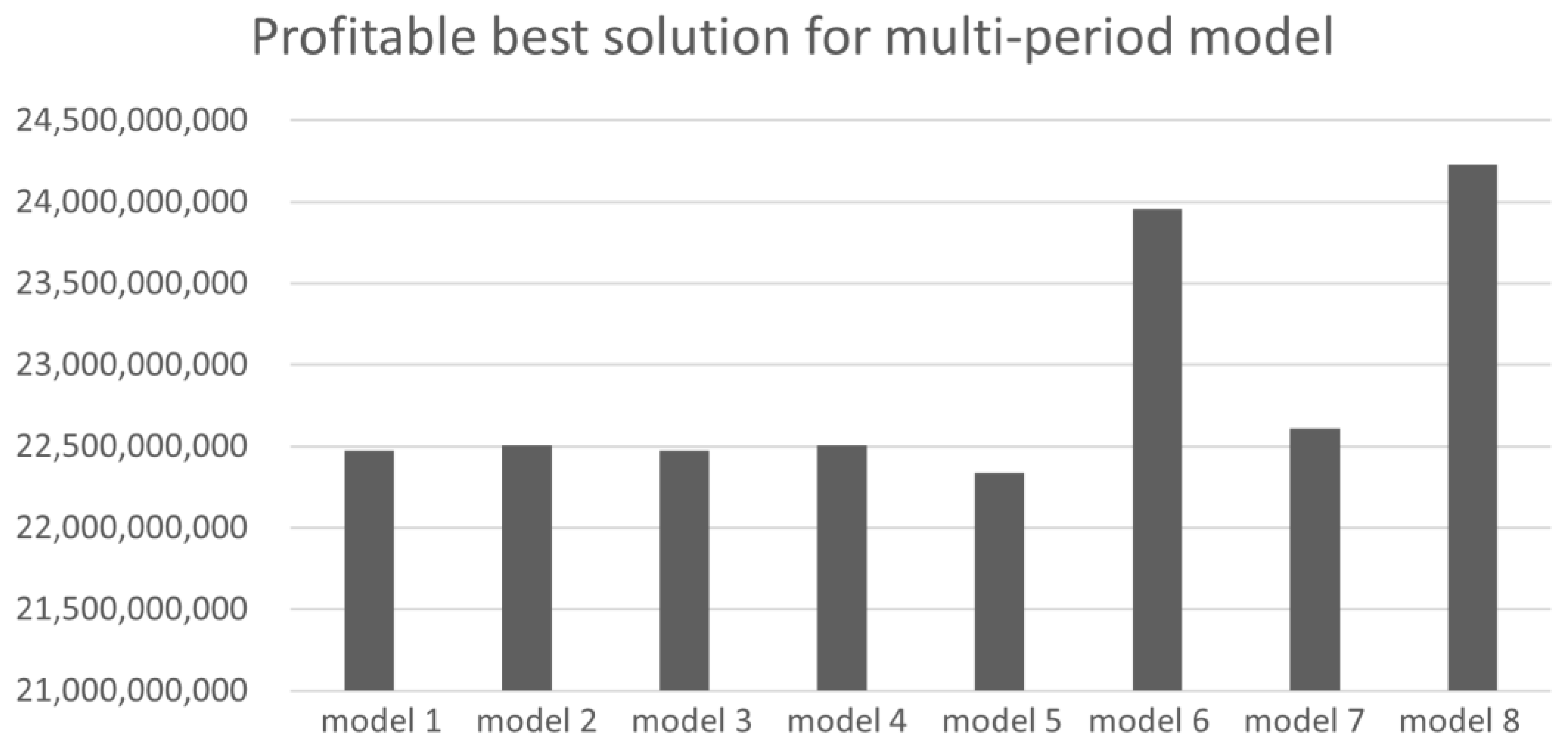

4.1. Model Comparison

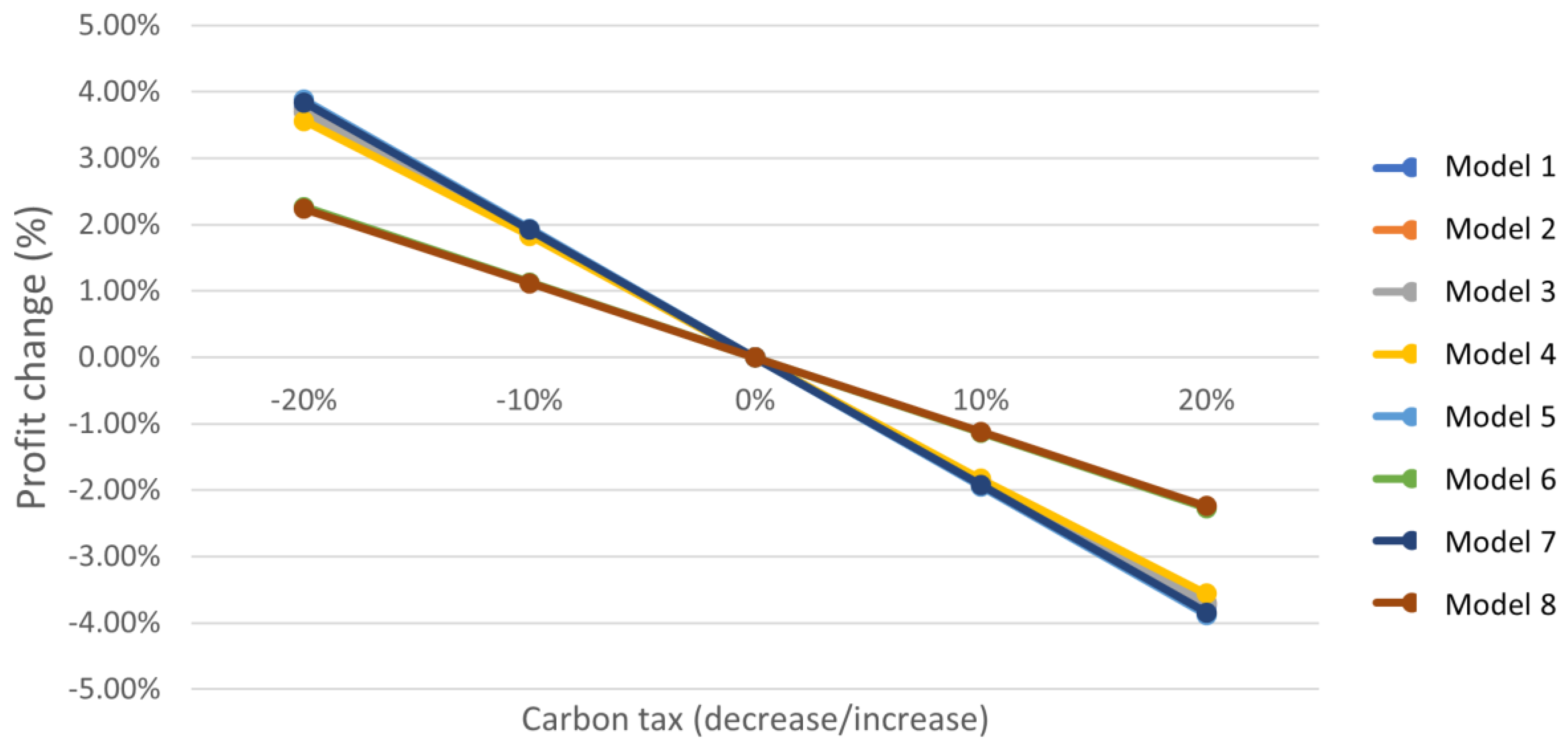

4.2. Sensitivity Analysis

5. Discussion

6. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wolniak, R.; Wyszomirski, A.; Olkiewicz, M.; Olkiewicz, A. Environmental corporate social responsibility activities in heating industry—Case study. Energies 2021, 14, 1930. [Google Scholar] [CrossRef]

- Yoon, B.; Lee, J.H.; Byun, R. Does ESG performance enhance firm value? Evidence from Korea. Sustainability 2018, 10, 3635. [Google Scholar] [CrossRef]

- Dinga, C.D.; Wen, Z. China’s green deal: Can China’s cement industry achieve carbon neutral emissions by 2060? Renew. Sustain. Energy Rev. 2022, 155, 111931. [Google Scholar] [CrossRef]

- Tesema, G.; Worrell, E. Energy efficiency improvement potentials for the cement industry in Ethiopia. Energy 2015, 93, 2042–2052. [Google Scholar] [CrossRef]

- Wang, N. Environmental Production: Use of Waste Materials in Cement Kilns in China. Master’s Thesis, Høgskolen i Telemark, Porsgrunn, Norway, 2008. [Google Scholar]

- Zhu, Q. CO2 Abatement in the Cement Industry; IEA Clean Coal Centre: 2011. Available online: https://usea.org/sites/default/files/062011_CO2%20abatement%20in%20the%20cement_ccc184.pdf (accessed on 26 February 2024).

- Watson, J.G.; Chow, J.C. Protocol for Applying and Validating Receptor Model Source Apportionment in PMEH Study Areas; Desert Research Institute: Washington, DC, USA, 2018. [Google Scholar]

- Cai, W.; Wang, C.; Chen, J.; Wang, K.; Zhang, Y.; Lu, X. Comparison of CO2 emission scenarios and mitigation opportunities in China’s five sectors in 2020. Energy Policy 2008, 36, 1181–1194. [Google Scholar] [CrossRef]

- Talaei, A.; Pier, D.; Iyer, A.V.; Ahiduzzaman, M.; Kumar, A. Assessment of long-term energy efficiency improvement and greenhouse gas emissions mitigation options for the cement industry. Energy 2019, 170, 1051–1066. [Google Scholar] [CrossRef]

- Yang, L.; Xia, H.; Zhang, X.; Yuan, S. What matters for carbon emissions in regional sectors? A China study of extended STIRPAT model. J. Clean. Prod. 2018, 180, 595–602. [Google Scholar] [CrossRef]

- Dong, C.; Dong, X.; Jiang, Q.; Dong, K.; Liu, G. What is the probability of achieving the carbon dioxide emission targets of the Paris Agreement? Evidence from the top ten emitters. Sci. Total. Environ. 2018, 622–623, 1294–1303. [Google Scholar] [CrossRef]

- Li, W.; Gao, S. Prospective on energy related carbon emissions peak integrating optimized intelligent algorithm with dry process technique application for China’s cement industry. Energy 2018, 165, 33–54. [Google Scholar] [CrossRef]

- Shen, W.; Cao, L.; Li, Q.; Zhang, W.; Wang, G.; Li, C. Quantifying CO2 emissions from China’s cement industry. Renew. Sustain. Energy Rev. 2015, 50, 1004–1012. [Google Scholar] [CrossRef]

- Obrist, M.D.; Kannan, R.; Schmidt, T.J.; Kober, T. Decarbonization pathways of the Swiss cement industry towards net zero emissions. J. Clean. Prod. 2021, 288, 125413. [Google Scholar] [CrossRef]

- Fang, D.; Zhang, X.; Yu, Q.; Jin, T.C.; Tian, L. A novel method for carbon dioxide emission forecasting based on improved Gaussian processes regression. J. Clean. Prod. 2018, 173, 143–150. [Google Scholar] [CrossRef]

- Junianto, I.; Sunardi; Sumiarsa, D. The Possibility of Achieving Zero CO2 Emission in the Indonesian Cement Industry by 2050: A Stakeholder System Dynamic Perspective. Sustainability 2023, 15, 6085. [Google Scholar] [CrossRef]

- Ofosu-Adarkwa, J.; Xie, N.; Javed, S.A. Forecasting CO2 emissions of China’s cement industry using a hybrid Verhulst-GM(1,N) model and emissions’ technical conversion. Renew. Sustain. Energy Rev. 2020, 130, 109945. [Google Scholar] [CrossRef]

- Hsieh, C.-L.; Tsai, W.-H. Sustainable Decision Model for Circular Economy towards Net Zero Emissions under Industry 4.0. Processes 2023, 11, 3412. [Google Scholar] [CrossRef]

- Tsai, W.-H.; Lu, Y.-H.; Hsieh, C.-L. Comparison of production decision-making models under carbon tax and carbon rights trading. J. Clean. Prod. 2022, 379, 134462. [Google Scholar] [CrossRef]

- Zaklan, A. Coase and Cap-and-trade: Evidence on the independence property from the European carbon market. Am. Econ. J. Econ. Policy 2023, 15, 526–558. [Google Scholar] [CrossRef]

- Peng, Z.; Lu, W.; Webster, C. If invisible carbon waste can be traded, why not visible construction waste? Establishing the construction waste trading ‘missing market’. Resour. Conserv. Recycl. 2022, 187, 106607. [Google Scholar] [CrossRef]

- Arvidsson, S.; Dumay, J. Corporate ESG reporting quantity, quality and performance: Where to now for environmental policy and practice? Bus. Strat. Environ. 2022, 31, 1091–1110. [Google Scholar] [CrossRef]

- Clément, A.; Robinot, É.; Trespeuch, L. Improving ESG scores with sustainability concepts. Sustainability 2022, 14, 13154. [Google Scholar] [CrossRef]

- Taiwan Cement Corporation. Taiwan Cement Sustainability Report. 2022. Available online: https://www.taiwancement.com/tw/esgIndex.html (accessed on 3 May 2022).

- Turney, P.B.B. Common Cents: The ABC Performance Breakthrough: How to Succeed with Activity-Based Costing; McGraw-Hill: New York, NY, USA, 2005. [Google Scholar]

- Tsai, W.H.; Lin, T.W.; Chou, W.C. Integrating Activity-Based Costing and Environmental Cost Accounting Systems: A Case Study. Int. J. Bus. Syst. Res. 2010, 4, 186. [Google Scholar] [CrossRef]

- Jasch, C. The use of Environmental Management Accounting (EMA) for identifying environmental costs. J. Clean. Prod. 2003, 11, 667–676. [Google Scholar] [CrossRef]

- Bento, N.; Gianfrate, G.; Aldy, J.E. national climate policies and corporate internal carbon pricing. Energy J. 2021, 42, 89–100. [Google Scholar] [CrossRef]

- Sánchez-Rebull, M.-V.; Niñerola, A.; Hernández-Lara, A.-B. After 30 Years, What Has Happened to Activity-Based Costing? A Systematic Literature Review. SAGE Open 2023, 13. [Google Scholar] [CrossRef]

- Al-Hashimi, A.M.; Al-Ghazal HA, A.-S. Towards corporate sustainability: Cost-benefit considerations of quantitative methods (multiple regression model) versus activity-based methods for determining indirect costs—An applied study in KDD industrial company. AIP Conf. Proc. 2023, 2776, 100005. [Google Scholar] [CrossRef]

- Al-Sayed, M.; Dugdale, D. Activity-based innovations in the UK manufacturing sector: Extent, adoption process patterns and contingency factors. Br. Account. Rev. 2016, 48, 38–58. [Google Scholar] [CrossRef]

- Cannavacciuolo, L.; Illario, M.; Ippolito, A.; Ponsiglione, C. An activity-based costing approach for detecting inefficiencies of healthcare processes. Bus. Process. Manag. J. 2015, 21, 55–79. [Google Scholar] [CrossRef]

- Demdoum, Z.; Meraghni, O.; Bekkouche, L. The Application of Green Accounting According to Activity-Based Costing for an Orientation Towards a Green Economy: Field Study. Int. J. Digit. Strat. Gov. Bus. Transform. 2021, 11, 1–15. [Google Scholar] [CrossRef]

- French, K.E.; Guzman, A.B.; Rubio, A.C.; Frenzel, J.C.; Feeley, T.W. Value based care and bundled payments: Anesthesia care costs for outpatient oncology surgery using time-driven activity-based costing. In Healthcare; Elsevier: Amsterdam, The Netherlands, 2016; Volume 4, pp. 173–180. [Google Scholar]

- Quesado, P.; Silva, R. Activity-Based Costing (ABC) and Its Implication for Open Innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 41. [Google Scholar] [CrossRef]

- AL Mashkoor, I.A.S.; Ali, J.H.; Al-Kanani, M.M. The Role of Green Activity-Based Costing in Achieving Sustainability Development: Evidence From Iraq. Int. J. Prof. Bus. Rev. 2023, 8, e01276. [Google Scholar] [CrossRef]

- Tsai, W.-H.; Chang, J.-C.; Hsieh, C.-L.; Tsaur, T.-S.; Wang, C.-W. Sustainability concept in decision-making: Carbon tax consideration for joint product mix decision. Sustainability 2016, 8, 1232. [Google Scholar] [CrossRef]

- Goldratt, E.M.; Cox, J. The Goal: A Process of Ongoing Improvement; North River Press: Great Barrington, MA, USA, 1992. [Google Scholar]

- Burange, L.G.; Yamini, S. Performance of the Indian cement industry: The competitive landscape. Artha Vijnana 2009, 51, 209. [Google Scholar] [CrossRef]

- Demirel, E.; Eskin, İ. Relation between environmental impact and financial structure of cement industry. Int. J. Energy Econ. Policy 2017, 7, 129–134. [Google Scholar]

- Panizzolo, R. Theory of constraints (TOC) production and manufacturing performance. Int. J. Ind. Eng. Manag. 2016, 7, 15–23. [Google Scholar] [CrossRef]

- Mabin, V.J.; Balderstone, S.J. The performance of the theory of constraints methodology: Analysis and discussion of successful TOC applications. Int. J. Oper. Prod. Manag. 2003, 23, 568–595. [Google Scholar] [CrossRef]

- LINGO 20: Mathematical Programming Software; Optimization Modeling Software for Linear, Nonlinear, and Integer Programming. Available online: https://www.lindo.com/index.php/ls-downloads/try-lingo (accessed on 26 February 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, W.-H.; Lin, W.-H. Production Decision Model for the Cement Industry in Pursuit of Carbon Neutrality: Analysis of the Impact of Carbon Tax and Carbon Credit Costs. Sustainability 2024, 16, 2251. https://doi.org/10.3390/su16062251

Tsai W-H, Lin W-H. Production Decision Model for the Cement Industry in Pursuit of Carbon Neutrality: Analysis of the Impact of Carbon Tax and Carbon Credit Costs. Sustainability. 2024; 16(6):2251. https://doi.org/10.3390/su16062251

Chicago/Turabian StyleTsai, Wen-Hsien, and Wei-Hong Lin. 2024. "Production Decision Model for the Cement Industry in Pursuit of Carbon Neutrality: Analysis of the Impact of Carbon Tax and Carbon Credit Costs" Sustainability 16, no. 6: 2251. https://doi.org/10.3390/su16062251

APA StyleTsai, W.-H., & Lin, W.-H. (2024). Production Decision Model for the Cement Industry in Pursuit of Carbon Neutrality: Analysis of the Impact of Carbon Tax and Carbon Credit Costs. Sustainability, 16(6), 2251. https://doi.org/10.3390/su16062251