1. Introduction

Recently, Pakistani companies have witnessed a significant increase in their enthusiasm for adopting green supply chain management (GSCM). GSCM practices prioritize worker and machine well-being at the operational level, ensuring control and planning at the process level, and implementing eco-friendly strategies and designs at the system level. Business alliances and buyers are increasingly distancing themselves from manufacturers lacking eco-friendly credentials. Research consistently supports a positive link between eco-friendly supply chain management and ecological effectiveness. As manufacturing is a globally significant industry known for rapid advancement and intense competitiveness, greening the supply chain requires considering immediate and long-term environmental repercussions. Manufacturing firms facing pressure to adopt sustainable practices contribute significantly to environmental issues. Investigating how GSCM practices affect their performance provides valuable insights into enhancing ecological sustainability. Manufacturing firms respond to institutional pressures by integrating GSCM practices. This involved implementing eco-friendly manufacturing processes, reducing waste, sourcing materials sustainably to meet environmental regulations and societal sustainability expectations, or emulating industry leaders [

1]. The adoption of GSCM practices is anticipated to enhance environmental performance, resulting in decreased carbon emissions, resource preservation, and overall sustainability. Institutional theory suggests that the relationship between GSCM practices and environmental performance may be influenced by institutional pressures [

2]. Firms under stringent environmental regulations may experience a more significant positive impact on environmental performance compared to those under weaker regulations. Similarly, firms facing strong societal sustainability expectations may be more inclined to adopt and effectively implement GSCM practices [

3].

In Ref. [

4], the authors employ institutional theory to understand how normative, mimetic, or coercive pressures drive organizational responses to societal needs. Normative pressure emanates from social norms and values. In response to heightened awareness of environmental sustainability, the fashion industry faced normative pressure to adopt eco-friendly practices [

5]. This pressure, driven by consumer demand for transparency and sustainability, prompted companies to transition to organic and recycled materials, implement energy-efficient manufacturing, and commit to ethical supply chains, thereby reducing their carbon footprint and mitigating environmental impact [

6,

7,

8]. Mimetic isomorphism is observed when organizations, faced with uncertainty, imitate successful policies or technologies others adopt [

9]. One specific case of mimetic isomorphism is observed in the adoption of total quality management (TQM) practices by organizations. During the 1980s and 1990s, many companies in various industries rushed to implement TQM principles after witnessing the success of firms like Toyota [

10]. This imitation occurred not necessarily because these companies fully understood the principles or had a pressing need for them, but because TQM was perceived as a marker of excellence and competitiveness [

5]. Coercive isomorphism results from external pressures, especially in SCM, with regulatory environments often compelling organizations to enhance environmental performance. Many oil companies operating in the Gulf of Mexico, including those not directly involved in the Deepwater Horizon incident, were forced to conform to these new regulations. Despite some companies initially resisting the changes due to concerns about increased costs and operational challenges, compliance with the stricter regulations became mandatory for obtaining drilling permits and maintaining operations in the region [

5,

11]. Managers adopting green information systems under coercive pressure demonstrate positive behaviors, reaping environmental and commercial benefits [

12]. Growing demands from government entities and environmental regulatory bodies drive organizations to prioritize environmental conservation. GSCM involves environmentally friendly manufacturing, distribution, marketing, purchasing, reverse logistics, and information systems practices [

13]. In GSCM, practices are implemented across various facets of the supply chain to minimize environmental impact and promote sustainability. Manufacturing focuses on reducing energy consumption and waste generation and utilizing eco-friendly materials and processes [

14]. Distribution strategies prioritize minimizing the environmental footprint of transportation through route optimization, alternative fuels, and efficient packaging [

2]. Green marketing highlights environmental attributes to attract eco-conscious consumers. Sustainable procurement practices in purchasing involve selecting suppliers with strong environmental credentials and considering life cycle assessments. Reverse logistics maximizes the reuse, recycling, or refurbishment of products to minimize waste [

3]. Information systems provide crucial data and analytics to support environmentally friendly decision-making, including tracking environmental performance and identifying improvement opportunities [

15]. Through these integrated efforts, GSCM aims to enhance sustainability throughout the entire supply chain. Beyond environmental compliance, organizations aim to enhance both ecological outcomes [

16] and economic outcomes [

17]. Successful GSCM implementation involves a trade-off between investing in anti-pollution equipment, which leads to high costs and lower economic productivity [

18].

Previous studies have explored the influence of GSCM across various domains, including its effects on organizational performance. These include Ref. [

19], firm performance [

20], environmental efficacy [

21], environmental consciousness [

22], as well as the challenges connected to closed-loop and reverse supply chain processes [

23], and sustainable outcomes [

24]. Contemporary academic literature has also investigated evolving trends and upcoming challenges within GSCM [

24]. Previous studies show that adherence to environmental regulations through traditional approaches does not boost competitiveness and hampers productivity [

12]. Previous studies indicate that green sourcing and ecological cooperation motivate contractors and customers to embrace eco-conscious approaches, curbing unsustainable behaviors and positively influencing the environmental outcomes of manufacturing firms. Building upon existing knowledge, this study seeks to investigate how implementing green supply chain management practices affects the performance of manufacturing firms. It also aims to consider the moderating effect of institutional pressures on their environmental impact. Ref. [

25] explored GSCM in the automotive industry, while Ref. [

26] investigated GSCM practices and their implications for environmental performance in Mexican manufacturing companies. Ref. [

27] focused on establishing GSCM in pharmaceutical companies in Indonesia, and Ref. [

28] examined factors influencing managers’ intention to adopt GSCM practices in manufacturing firms in Jordan. Meanwhile, Ref. [

29] delved into Taiwan’s electric and electronic industry, exploring the mediating role of GSCM capability. However, there is a notable gap in attention to environmental and green activities in countries like Pakistan. This research endeavors to address this gap by examining the influence of GSCM on the manufacturing sector in Pakistan and its consequential implications for the environment. Additionally, it is crucial to investigate the impact of GSCM practices in Pakistan due to the myriad challenges faced by the manufacturing sector, including energy shortages, inadequate infrastructure, bureaucratic hurdles, policy implementation issues, and limited access to finance, all of which have impeded the widespread adoption of GSCM.

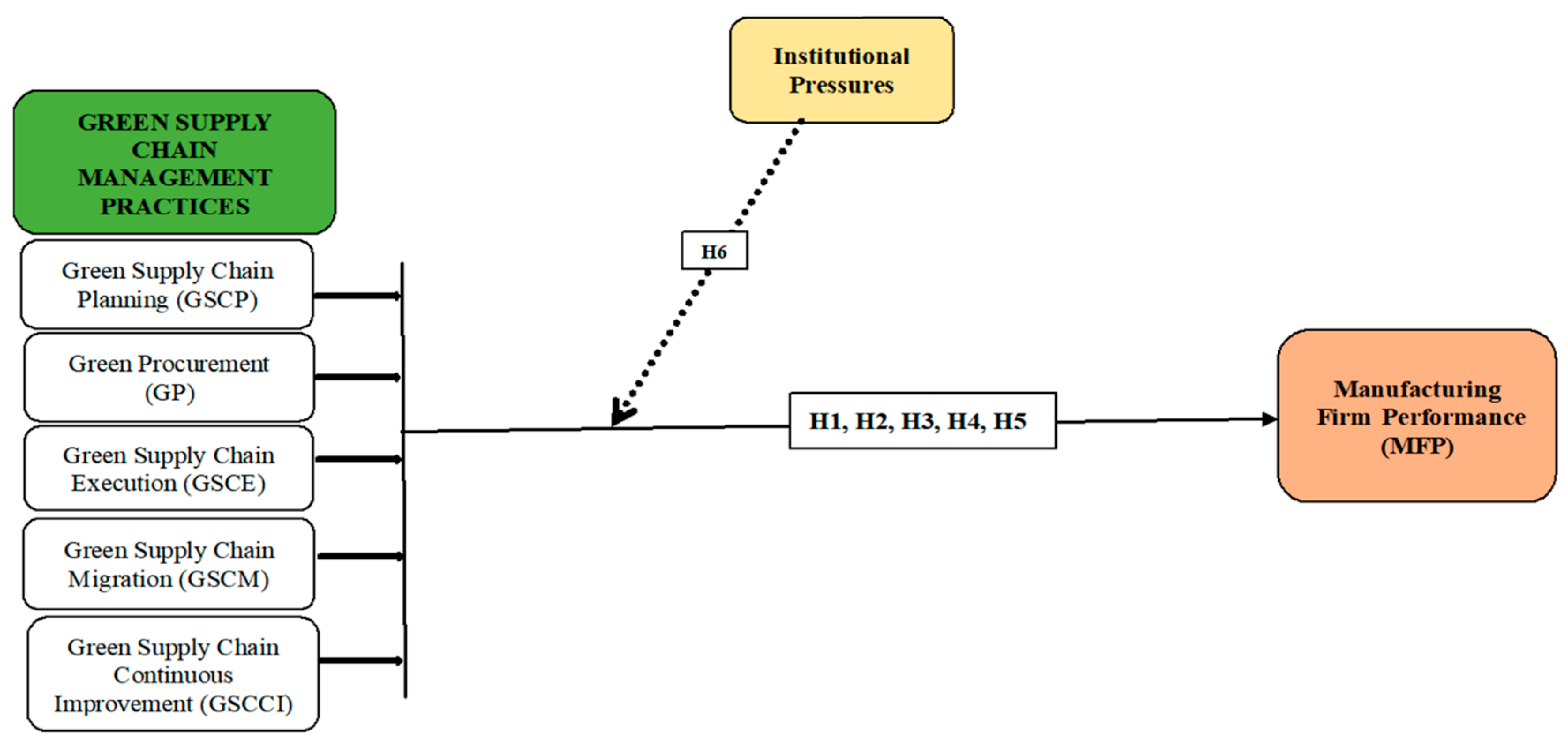

Considering the preceding information, it becomes evident that researchers have not addressed the dual aspects of GSCM practices within manufacturing firms, incorporating the moderating impact of institutional pressures in a single comprehensive study. This study contains several contributions. Firstly, it uncovers how companies align operations with regulations and achieve compliance by optimizing processes, reducing waste, and enhancing resource efficiency for cost savings. Secondly, embracing sustainable practices provides a competitive edge, as consumers and stakeholders increasingly prefer environmentally conscious businesses. Thirdly, the association of GSCM with manufacturing industry performance contributes to understanding how sustainable practices enhance a company’s reputation, attract customers, and differentiate it from competitors. Fourthly, researching this area expands our understanding of the association of GSCM with manufacturing industry outcomes, offering novel insights to guide manufacturing companies, policymakers, and stakeholders toward sustainable practices. The evidence-based insights from the research can support the formulation of policies incentivizing manufacturing firms to enhance their environmental efficiency. Finally, the contribution lies in integrating the resource-based view, triple bottom line, and institutional theory to elucidate how institutional pressures moderate the link between a firm’s RBV, sustainability TBL, and implementing GSCM practices. This comprehensive perspective reveals how external institutions impact strategic decisions and resource allocation in GSCM, extending beyond internal factors.

The primary aims of this research were as follows:

To determine how green supply chain planning relates to manufacturing firms’ environmental performance.

To determine how green procurement relates to manufacturing business’s environmental outcomes.

To determine how green supply chain execution relates to manufacturing firm environmental performance.

To determine how green supply chain migration relates to manufacturing firm environmental performance.

To find out how green supply chain continuous improvement relates to a manufacturing firm’s environmental performance.

To find out how institutional pressures moderate the relationship of GSCM with manufacturing firms’ environmental performance.

This study is significant as it addresses real-world environmental concerns and guides business practices, especially in the industrial sector, where GSCM is crucial. It highlights GSCM as a practical solution for ecological concerns in manufacturing, offering tangible strategies to reduce environmental impact across waste management, energy efficiency, pollution control, and greenhouse gas emissions. The study’s practical significance extends to examining institutional pressure as a moderator in GSCM adoption by manufacturing firms, with potential positive impacts on policy, strategy, risk management, competitiveness, resource efficiency, community relations, continuous improvement, and education within the sector. Furthermore, the study offers a comprehensive view of GSCM’s positive impact by highlighting the convergence of environmental and business advantages. In addition, the research fills a critical gap by demonstrating the effects of GSCM on the manufacturing sector and the environment, providing a holistic perspective covering air and water quality, climate impact, and various human health factors, studying institutional pressure as a moderator in GSCM adoption, contributing to advancing theories, contextualizing global perspectives, enhancing institutional theory, introducing innovative methodologies, evaluating policies, fostering interdisciplinary insights, and analyzing longitudinal trends.

Considering the moderating influence of institutional pressures, the investigation into how GSCM affects manufacturing firms is grounded in recognizing the evolving business landscape where environmental considerations are integral to success. Institutional pressures serve as catalysts, compelling manufacturing firms to adopt GSCM practices to align with regulatory requirements, gain a competitive edge, optimize resource utilization, ensure enduring sustainability, and fulfill stakeholder expectations.

3. Methodology

3.1. Study Design

This research is grounded in a quantitative approach, which includes assembling and analyzing mathematical information to understand relationships, patterns, and trends among variables [

73]. In this case, the researcher gathered measurable data on GSCM practices, manufacturing firms’ performance, and institutional pressures.

3.2. Target Participants

The survey included distributing questionnaires to key participants, like supply chain managers, operations managers, and environmental supervisors, to gather their opinions. All the steps were completed for a thorough survey of manufacturing firms in Pakistan, defining the population based on location, size, and industry. ISO 14001 standards [

74] guided the selection of diverse manufacturing categories. With a clear understanding, relevant categories were identified, and random sampling was used for participant selection. The survey instrument, a carefully designed questionnaire, was employed, and suitable participants were identified through HR departments and online platforms, ensuring a well-informed survey of Pakistan’s manufacturing landscape.

3.3. Data Collection Method

To measure respondents‘ attitudes, the study utilized a questionnaire with Likert scale questions ranging from 1 (strongly disagree) to 5 (strongly agree). This method facilitated the collection of quantitative data, which were further analyzed using statistical tools to identify patterns and trends. The primary data source was survey responses from large-scale manufacturing firms in Pakistan between July and October 2023. Large-scale manufacturing, defined by the Factories Act of 1934, includes entities with ten or more employees. Focusing on this sector provided valuable insights into the challenges and opportunities for implementing GSCM practices in industries with significant environmental impacts. While the exact number of manufacturing firms in Pakistan is not readily available, as of April 2019, 99,291 registered firms were spanning diverse sectors such as textiles, food, beverages, tobacco, and pharmaceuticals. Questionnaires, known for their effectiveness in obtaining quantitative data, played a crucial role in this research. There were three sections in the questionnaire. The first section concentrated on the participants’ backgrounds. The second half sought to obtain demographic information about the company; the final portion evaluated ideas concerning GSCM practices, the performance of manufacturing companies, environmental impact, and institutional performance. There are a total of 37 items distributed across ten constructs, outlined as follows: The GSCP construct was measured by six items; five items measured GP; GSCE was measured by five items; GSCM was measured by five items; GSCCI was measured by six items; MFP was measured by five items; and IP was measured by five items. The analysis of PLS-SEM was employed to assess the collected data.

Table 2 provides details on the origins of the measurement instruments.

3.4. Data Collection Procedure

A random sampling technique was used in the study. Random sampling involves selecting participants or cases from a population to give each population member an equal chance of being chosen for the sample. In this research, random sampling was used to select participants following a systematic series of steps. Firstly, the population was defined as comprising all large-scale manufacturing industries in Pakistan. Next, a comprehensive list of these industries was created, assigning each unique identifier, typically a numerical code. To introduce randomness, a set of random numbers was generated using a tool in a spreadsheet’s random number function. The next step involves matching these randomly generated numbers to the unique identifiers assigned to the industries. Those corresponding to the matched numbers are selected as participants in my study. Randomization software (R 4.1.2) was utilized to maintain precision and ensure the sample’s representativeness. Regular audits and validations of the sampling process are integral to monitoring and upholding the randomness of the sample throughout my study. By following these steps, the true randomness of the sampling method is guaranteed, leading to more accurate and representative results in the examination of large-scale manufacturing industries in Pakistan. The survey questionnaires were distributed to participants electronically using Google Forms, email, and WhatsApp.

Table 3 offers a comprehensive overview of the demographic and professional attributes of the participants and companies within a survey. The table is organized into distinct categories, each with relevant numerical data.

Random sampling was chosen to ensure fairness, providing each element in the population with an equal opportunity for inclusion and minimizing selection bias, ultimately leading to unbiased results. This method is conducive to statistical analysis, mainly when population details are limited. In survey research, it is essential to prevent multiple questionnaire completions by the same respondent to maintain data integrity. Transparency was maintained by assuring participants of anonymity and confidentiality, with measures in place to prevent duplicates. Participants were informed about the expected questionnaire duration (approximately 10 to 15 min), and no incentives were provided due to budget constraints. Anonymity was guaranteed through robust data security, ethical review, and the freedom for participants to discontinue their involvement without consequences, ensuring a survey experience that is voluntary and free from coercion.

Table 4 summarizes each variable’s statistics overview, including the mean, standard deviation, and sample size.

3.5. Data Quality Check Procedure

Non-response bias arises when those who do not participate in a survey differ from those who do, potentially skewing the results. Response bias manifests when participants offer inaccurate or biased responses influenced by factors such as social desirability or misunderstanding of questions. To assess non-response bias, a

t-test [

80] was conducted using SPSS Statistics 28. The findings in

Table 5 reveal minimal mean differences between the two groups. With

p-values surpassing 0.05, no statistically significant difference was observed between late and early responses. In conclusion, the

t-test results indicate the absence of substantial non-response bias in this research study.

Of the 500 distributed questionnaires, 376 were received, and 360 were deemed usable for analysis. Factors contributing to the disparity include incomplete or irrelevant responses, rendering some questionnaires unusable. Additionally, individuals who did not meet the survey criteria may have participated. However, with only 16 omitted due to incomplete or inaccurate responses, the remaining 360 fully completed forms show no missing values, ensuring data integrity.

According to [

52], when dealing with a sample size of 80 or more, a standardized score value of approximately ±3 is considered appropriate for detecting outliers. In our dataset, nine responses were identified as outliers. It is crucial to highlight that these 9 responses originated from 16 questionnaires that were improperly filled out or incomplete. These half-finished questionnaires accounted for more than 5% of missing values, so they were excluded from our analysis. Consequently, our final dataset is based on 360 fully completed and adequately filled out surveys.

Additionally, it is crucial to consider the sample size requirements for PLS-SEM, ideally exceeding 200, as established by [

81]. Our study’s sample size is 360, confirming that this criterion does not hinder the utilization of PLS-SEM. Furthermore, we leverage the substantial size of our sample and its associated statistical power, aligning with [

82]. In a sample size of 360, a loading factor of 0.55 or higher is deemed significantly meaningful. This approach reinforces the robustness of our analysis and interpretation, enhancing our research findings’ credibility.

Standard method bias potentially affects studies, particularly those involving surveys and self-report measures. It occurs when a single data collection method influences relationships among variables, leading to artificially inflated correlations. This overestimation threatens model validity [

83]. Following [

84] recommendations, we implemented procedural measures to address CMB, emphasizing participant confidentiality and anonymity to discourage disingenuous responses and minimize potential CMB.

Additionally, Harman’s single-factor test was applied, which is a method proposed by [

85], to assess the presence of Common Method Bias (CMB) in our dataset. The test results assured that CMB was not a significant issue, as the proportion of variance explained by a single factor was below 50% [

86], as indicated in

Table 6.

Furthermore, we conducted tests to examine the presence of multicollinearity by assessing Variance Inflation Factor (VIF) values. The results of these tests indicated that all VIF values for the variables were below 5, suggesting that multicollinearity was not a concern requiring attention in this study.

Cross-loading analysis examines whether the observed variables demonstrate substantial loadings on multiple latent factors simultaneously. If an item displays notable loadings on numerous factors, it is considered to have cross-loadings. We scrutinize the factor loading matrix derived from Structural Equation Modeling to conduct a cross-loading analysis. VIF and cross-loading are shown in

Table 7.

To mitigate social desirability response bias, this study utilizes anonymous questionnaires to encourage candid participant responses, alleviating concerns about potential judgment. Questions and prompts are crafted impartially, avoiding language that may influence socially desirable answers. Clear communication of confidentiality ensures participant anonymity. The study refrains from suggesting socially desirable responses, preserving data integrity. Pilot testing of survey instruments or interview protocols is also conducted to address potential issues related to social desirability bias.

3.6. Ethical Consideration

Before commencing the study, participants were informed about the research focus and potential outcomes, emphasizing voluntary participation and the freedom to withdraw without consequences. Privacy protection was prioritized through stringent measures, ensuring information access only by authorized individuals. A respectful and supportive approach was maintained, promptly addressing any concerns. Transparency included the disclosure of factors that could influence the research. Reliable research methods were employed to ensure integrity and compliance with established guidelines. Approval from oversight bodies confirmed adherence to ethical standards.

3.7. Research Design Flow Chart

A research design is a systematic and organized outline of a research project’s objectives, goals, methods, and timeline. It acts as a guide, providing a structured framework to accomplish the research objectives effectively. The study plan has been explained in chart form, as shown in

Figure 4.

4. Data Analysis and Result Interpretation

PLS, or Partial Least Squares, is a statistical method commonly used in PLS-SEM. This versatile approach combines elements from regression and factor analyses to model relationships between observed and latent variables in a dataset. There are two main types of SEM: CB-SEM and PLS-SEM. CB-SEM is suitable for theory confirmation or comparing multiple theories, while PLS-SEM is more fitting for predicting a specific construct or identifying salient factors [

87].

PLS-SEM is well-suited for exploratory research and extending existing structural theories. It is not highly constrained by sample size, making it applicable to large and small samples [

88]. In contrast, CB-SEM is more supportive of large sample sizes, with the definition of a large sample being debated. PLS-SEM is non-parametric, not assuming a normal data distribution, while CB-SEM strictly takes a normal distribution. CB-SEM requires a minimum of three measuring items per construct, whereas PLS-SEM allows constructs to be reckoned with just one or two items [

87].

In PLS-SEM, the model comprises two main mechanisms: the measurement and structural models.

The measurement model delineates connections between observed and latent variables. In contrast, the structural model delves into the relationships between latent variables, offering insights into the underlying connections within the studied phenomena. PLS-SEM’s adaptability and appropriateness for exploratory research render it a valuable tool across diverse fields, including business, social sciences, and engineering.

4.1. Reliability and Validity

Validity and reliability are pivotal in ensuring the precision and consistency of the data in quantitative research. The reliability of each variable is gauged using Cronbach’s alpha. Convergent validity, measured by AVE, evaluates the extent to which items within a construct share a common variance, indicating how accurately the items measure the construct. Both Cronbach’s alpha and AVE play crucial roles in evaluating the quality of measurement instruments and constructs in research studies. Another indicator, composite reliability, assesses internal consistency by estimating how well-observed variables represent the underlying construct.

Table 8 presents the validity and reliability of the items.

4.2. Discriminant Validity

The Fornell–Larcker criterion is a conventional approach in confirmatory factor analysis to evaluate discriminant validity. It scrutinizes each construct’s correlation and associated indicators (factor loadings). For discriminant validity to be established, the square root of the AVE for each construct should exceed the correlation between that construct and other constructs in the model [

89,

90]. The outcomes of the Discriminant Validity evaluation utilizing the Fornell–Larcker Criterion are presented in

Table 9.

HTMT is a current approach for measuring discriminant validity. It contrasts correlations among diverse constructs (heterotrait correlations) with the average correlations within the same construct (monotrait correlations). An indication of good discriminant validity is observed when heterotrait correlations are lower than monotrait correlations. The results of the heterotrait–monotrait ratio of correlation analysis are presented in

Table 10.

4.3. Fit Indices

Table 11 displays the model fit statistics for the saturated and estimated models. The saturated model reveals a SRMR of 0.064, an Unweighted Least Squares (d_ULS) value of 3.737 with a non-significant

p-value (>0.05), a Bentler Comparative Fit Index (d_G) of 8.241 with a non-significant

p-value (>0.05), a Chi-square of 7567.964, and a Normed Fit Index (NFI) of 0.906. On the other hand, the estimated model shows an SRMR of 0.093, a d_ULS of 7.757 with a non-significant

p-value (>0.05), a d_G of 8.356 with a non-significant

p-value (>0.05), a Chi-square of 7735.895, and an NFI of 0.901. The

p-values indicate the statistical significance of fit indices, with values above 0.05 suggesting satisfactory model–data fit. Lower SRMR and d_ULS values and higher NFI values indicate a better model.

4.4. Structural Model

To validate and reinforce the interpretation of results for all hypotheses, we scrutinized the significance of path coefficient estimates within the model, as illustrated in

Figure 5. We presented the outcomes in

Figure 6 and

Figure 7. To establish the relevance of a relationship,

t-values exceeding 1.96 were required for the variables. For this purpose, a non-parametric bootstrap procedure, recommended by [

87,

91], assessed the coefficients’ significance. This involved generating 5000 bootstrap samples to mitigate bias and providing corrected intervals for bootstrap confidence at a 95% confidence level following the model, as outlined by [

88]. Hypotheses were affirmed or refuted based on the confidence intervals; a predicted coefficient was considered to have a meaningful effect if its confidence interval did not include zero.

Table 12 presents the bootstrapping results for various hypotheses examining the relationships between independent variables and manufacturing firm performance (MFP). The coefficients indicate the estimated impact of each independent variable on MFP, with accompanying

t-statistics and

p-values assessing their statistical significance. The F2 values provide insights into the effect sizes, indicating the percentage of variance in the dependent variable clarified by the independent variables. Interpretation of the results suggests that all hypotheses (H1 to H6) are supported, as each coefficient is statistically significant (

p values < 0.05), and the corresponding F2 values suggest meaningful effect sizes. The F2 value of 0.231 underscores the substantive impact of GSCCI on MFP. Overall, the table delivers a complete summary of the robustness and significance of the hypothesized relationships in the regression model, with meaningful effect sizes contributing to a better understanding of the factors influencing manufacturing firm performance with a moderation effect of institutional pressures.

The R

2 values play a vital role in assessing the adequacy of the regression model, providing valuable insights into how effectively the independent variables collectively explain variations in the dependent variables. A statistical metric in predictive modeling indicates enhanced model fitness and predictive capabilities. R

2 and Q

2 values are shown in

Table 13.

4.5. Critical Analysis

The hypothesis posits a positive correlation between green supply chain planning and the environmental performance of manufacturing firms, underscoring the significance of effective planning aligned with environmental objectives. The success of this relationship is contingent upon the specific details of the planning processes. Another hypothesis suggests a positive association between green procurement and environmental performance, with the degree of implementation playing a pivotal role in impacting the overall supply chain. Green procurement involves the sourcing of eco-friendly materials. Similarly, the hypothesis proposes a positive connection between the execution of green supply chain practices and environmental performance, where success depends on the robustness of execution strategies for implementing sustainable practices throughout the supply chain. The hypothesis related to green supply chain migration proposes a positive correlation with environmental performance. The success of this relationship relies on the effectiveness and scope of migration strategies, mainly if they involve transitioning to more environmentally sustainable practices.

Additionally, a hypothesis indicates a positive relationship between continuous improvement in green supply chain practices and environmental performance. The success of this association hinges on the effectiveness of improvement mechanisms and their adaptability to evolving environmental standards. Lastly, the final hypothesis introduces the moderating effect of institutional pressures on the relationship between GSCM and environmental performance, acknowledging the influence of external factors such as regulations and societal expectations. The validity of this hypothesis depends on the strength and nature of the institutional pressures exerted.

5. Discussion

In hypothesis testing, we established a significant positive impact of GSCP on MFP. Research by [

92] supports this finding, indicating that implementing GSCP positively influences financial performance. Similarly, [

43] affirms that GSCM practices positively affect operational outcomes and ecological sustainability, suggesting that GSCP enhances supply chain efficiency and contributes to environmental sustainability. This aligns with the RBV theory, emphasizing strategic resources and capabilities that improve firm performance, including environmental practices. Studies by [

32,

93,

94] further reinforce this alignment by emphasizing the constructive correlation between GSCP and firm performance, highlighting its role in reducing the degree of negative impact on the environment.

The research exposed a significant and positive association between GP and MFP during hypothesis testing. The study by [

95] further confirmed this association, highlighting the positive influence of GP on monetary performance, notably through cost savings from resource efficiency and waste reduction. Additionally, [

96] found that firms adopting green purchasing practices experienced enhanced operational performance, cost efficiencies, and a reduced degree of negative impact on the environment. According to [

26], resource dependence theory aligns with the positive connection between green procurement and manufacturing firm performance by elucidating how supplier involvement and procurement can bolster a firm’s core competitiveness, leading to successful procurement and reducing the degree of negative impact on the environment. RDT emphasizes the importance of resources in influencing firm performance and underscores the idea that green procurement, as a strategic resource, can improve a firm’s affordability and performance [

97]. This aligns seamlessly with the observed positive relationship between GP and MFP.

The study identified a significant and positive association between GSCE and MFP during hypothesis testing. According to [

98], GSCE positively influenced ecological and financial performance by reducing energy consumption, waste, and emissions while enhancing cost savings and operational efficiency. [

91] reinforced this, emphasizing how environmental collaboration positively impacts supply chain execution, leading to improved delivery performance, cost reduction, and increased customer satisfaction to reduce the degree of negative impact on the environment. Moreover, [

48] conducted a comprehensive review of the electronics industry, stressing the importance of green logistics and transportation for environmental sustainability. Their research found that efficient transportation methods, route optimization, and low-emission vehicles positively influenced the ecological performance of electronic manufacturing.

In the process of hypothesis testing, the research uncovered a noteworthy and favorable correlation between green supply chain migration and MFP. These environmentally conscious practices also translated into enhanced economic performance, characterized by cost savings and heightened operational efficiency. Similarly, [

6] explored the effects of GSC practices on sustainable performance in the manufacturing sector, unveiling positive impacts across environmental, economic, and social dimensions. The TBL approach [

38] emerges as a guiding principle in GSCM. Encouraging a comprehensive perspective, Ref. [

99] explained that the TBL approach urges companies to evaluate and manage their supply chain activities, integrating environmental and social considerations into decision-making processes. This adoption allows companies to make informed choices, balancing ecological and social factors alongside economic considerations and reducing the degree of negative impact on the environment, as advocated by [

100]. This holistic strategy aligns with sustainability goals, ensuring supply chain decisions impact various performance dimensions. By embracing TBL principles [

101] within the context of GSCM, companies embark on a journey toward sustainable practices, harmonizing economic prosperity, environmental stewardship, and social accountability. This approach aspires to achieve a holistic balance between profitability, environmental conservation, and societal well-being.

Research by [

41] indicates that continuous improvement in GSCM positively impacts both ecological and financial performance. Ref. [

102] stresses the significance of a proactive approach in identifying and implementing eco-friendly practices throughout the supply chain. Additionally, Ref. [

103] highlights the seamless integration of green practices into continuous improvement initiatives and offers insights into successful implementation factors. Incorporating TQM [

104] principles further enhances the pursuit of constant improvement in GSCCI. TQM integrates environmental considerations into product design and supply chain practices, extending sustainability principles beyond manufacturing to service industries [

105]. GSCCI involves employees at all levels, engaging them in identifying and implementing eco-friendly practices to minimize resource use, waste, and environmental impact. This ongoing process leverages employees’ insights to drive environmental performance improvements, fostering a culture of sustainability and progress in electronic manufacturing [

106,

107].

In the context of GSCM and firm performance, institutional pressures, encompassing government, customer, and competitor influences, significantly shape the adoption of GSCM practices and subsequently impact overall performance. A study by [

108] specifically investigated the impact of these three institutional pressures on GSCM and firm performance, revealing their influential role in both environmental and economic dimensions. Furthermore, research by [

109] and other scholars explored the moderating effects of institutional pressures on emerging GSCM practices, emphasizing the influence of normative and coercive pressures on environmental performance. Similarly, institutional theory [

110] provides valuable insights into how external pressures affect organizational practices and outcomes in GSCM. Numerous studies [

49,

111,

112] have applied institutional theory to scrutinize the influence of normative and coercive institutional pressures on shaping sustainable practices within supply chains, as observed in the dairy supply chain. These pressures play a substantial role in influencing the adoption of GSCM practices, impacting environmental and economic performance [

42].

Additionally, aligned with stakeholder theory, companies are subject to influence from stakeholders advocating practices conducive to business success and survival [

72]. Strong connections with customers drive the adoption of green purchasing practices to reduce material and inventory costs and invest in streamlined production facilities. This underscores why robust pressures from occupational and legal institutions do not notably affect the impact of these practices on financial performance [

113]. The findings also highlight that environmental performance is a crucial mechanism through which GSCM enhances firms’ overall environmental performance, especially under elevated institutional pressures.

6. Conclusions

The study uncovers a positive correlation between green supply chain planning and the performance of manufacturing firms. This indicates that strategic planning for environmentally sustainable practices contributes positively to the firm’s overall performance and to reduce the degree of negative impact on the environment. The research identifies a positive relationship between green procurement practices and the performance of manufacturing firms. This implies that adopting environmentally friendly procurement processes has a beneficial impact on the overall organizational performance. The study establishes a positive association between green supply chain execution and the performance of manufacturing firms. This indicates that implementing environmentally sustainable practices throughout the supply chain positively influences firm performance and reduces the degree of negative impact on the environment. The research suggests a positive relationship between green supply chain migration practices and the performance of manufacturing firms. This indicates that transitioning towards greener supply chain practices positively contributes to organizational performance. The study demonstrates a positive association between continuous improvement in green supply chain practices and the performance of manufacturing firms. This highlights the significance of ongoing efforts to enhance environmental sustainability, positively influencing overall firm performance. The findings reveal that institutional pressures play a moderating role in the relationship between green supply chain management and the performance of manufacturing firms. This implies that the external environment, including regulatory and societal pressures, influences how GSCM practices impact organizational performance.

Manufacturing firms seeking to enhance their environmental performance should adopt a comprehensive approach that includes investing in eco-friendly technologies, collaborating with suppliers for sustainable sourcing, implementing environmental management systems (EMS) such as ISO 14001 certification, integrating life cycle assessments (LCAs) to evaluate environmental impact, and investing in green logistics and transportation. By prioritizing the adoption of renewable energy systems, energy-efficient machinery, and waste-reduction technologies, firms can minimize energy consumption, emissions, and resource usage, thereby meeting environmental regulations and reducing their carbon footprint. Collaborating with suppliers to select environmentally responsible partners, conducting regular audits, and establishing sustainable sourcing criteria addresses both normative pressures from environmentally conscious consumers and regulatory requirements. Implementing EMS frameworks and conducting LCAs facilitate monitoring, measuring, and improving environmental performance across the supply chain, aligning with societal expectations for sustainability. Additionally, optimizing transportation and logistics operations through fuel-efficient vehicles, route planning, and intermodal transportation solutions enables firms to reduce costs, comply with emissions regulations, and demonstrate commitment to sustainability, satisfying both coercive and normative pressures.

6.1. Implications of the Study

The theoretical implications of this study are multifaceted and align with several management theories, notably the RBV, Triple TBL, institutional theory, Stakeholder Theory, and dynamic capabilities theory. The positive associations identified between green supply chain planning, procurement, execution, migration, continuous improvement, and manufacturing firms’ performance resonate with RBV, emphasizing the strategic value of environmentally sustainable practices as unique resources contributing to competitive advantage. Additionally, the findings align with TBL by highlighting the holistic benefits of green practices, considering economic, environmental, and social dimensions. This research integrates institutional theory by incorporating institutional pressures and GSCM practices into a unified model, bridging previously treated independent factors. Unlike prior literature, it explores the nexus of examining GSCM practices and firm performance within the context of normative, coercive, and mimetic pressures, and the findings underscore organizations’ inherent response to these pressures for survival and competitiveness. This highlights the imperative need to scrutinize organizational actions from an institutional perspective. In response to recent literature calls, this study accentuates institutional pressures as a pivotal contingent factor shaping the relationship between GSCM practices and environmental performance, aligning with scholars such as [

40]. The positive impact of green practices on stakeholder relationships and satisfaction reflects the influence of Stakeholder Theory. Additionally, the study contributes to the dynamic capabilities theory by emphasizing the dynamic relationship between green supply chain management practices and firm performance. It suggests that firms capable of adapting and evolving their practices in response to external pressures demonstrate superior performance over time. In essence, the study integrates insights from these diverse theories to offer a comprehensive understanding of the strategic, environmental, and dynamic aspects of green supply chain management and its implications for the performance of manufacturing firms.

The study’s practical implications for business management and sustainability strategies are substantial. Manufacturing firms should strategically align their GSCM practices with normative, coercive, and mimetic institutional pressures to enhance environmental performance, ensuring compliance with regulations and societal expectations. Customizing GSCM strategies to various institutional pressures allows organizations to design practices that meet external expectations. Encouraging proactive stakeholder engagement fosters support for sustainable practices. Staying informed about evolving regulations and adapting GSCM practices is crucial, given the dynamic nature of institutional pressures. Integrating GSCM practices into overall environmental management systems ensures a holistic approach, and recognizing the moderating effect of institutional pressures enables proactive risk management. Continuous improvement and innovation in GSCM practices are emphasized, urging firms to stay ahead of evolving institutional pressures. Benchmarking against industry best practices, considering institutional pressures, enhances the effectiveness of environmental performance initiatives. Transparency in reporting is crucial for building trust, and educational programs are recommended to raise awareness among employees about the impact of institutional pressures on GSCM practices, ensuring the successful implementation of sustainable initiatives.

6.2. Limitations and Future Research

The study’s contextual limitations call for future research to enhance generalizability. Potential bias in self-reported data emphasizes the need for objective, quantitative measures in future studies. The study’s omission of exploration into industry interactions underscores the necessity for a more holistic view in future research, considering policies and technological advances. Limited stakeholder input suggests a call for future research to broaden insights, incorporating perspectives from suppliers, customers, and regulators. The absence of a dynamic view prompts the suggestion for future research to examine evolving green supply chain practices, including technical adoption, regulations, and consumer trends. Future studies should explore the social and economic impacts of GSCM practices [

40] in manufacturing, given the primary environmental focus of the study. The lack of comparisons with conventional or alternative practices indicates a need for future research to assess effectiveness through comparative analyses. Lastly, the predominantly quantitative methods suggest an opportunity for future research to incorporate qualitative approaches for a more comprehensive understanding of green supply chain implementation’s motivations, barriers, and success factors.