Investigation of Emission Inventory for Non-Road Mobile Machinery in Shandong Province: An Analysis Grounded in Real-World Activity Levels

Abstract

1. Introduction

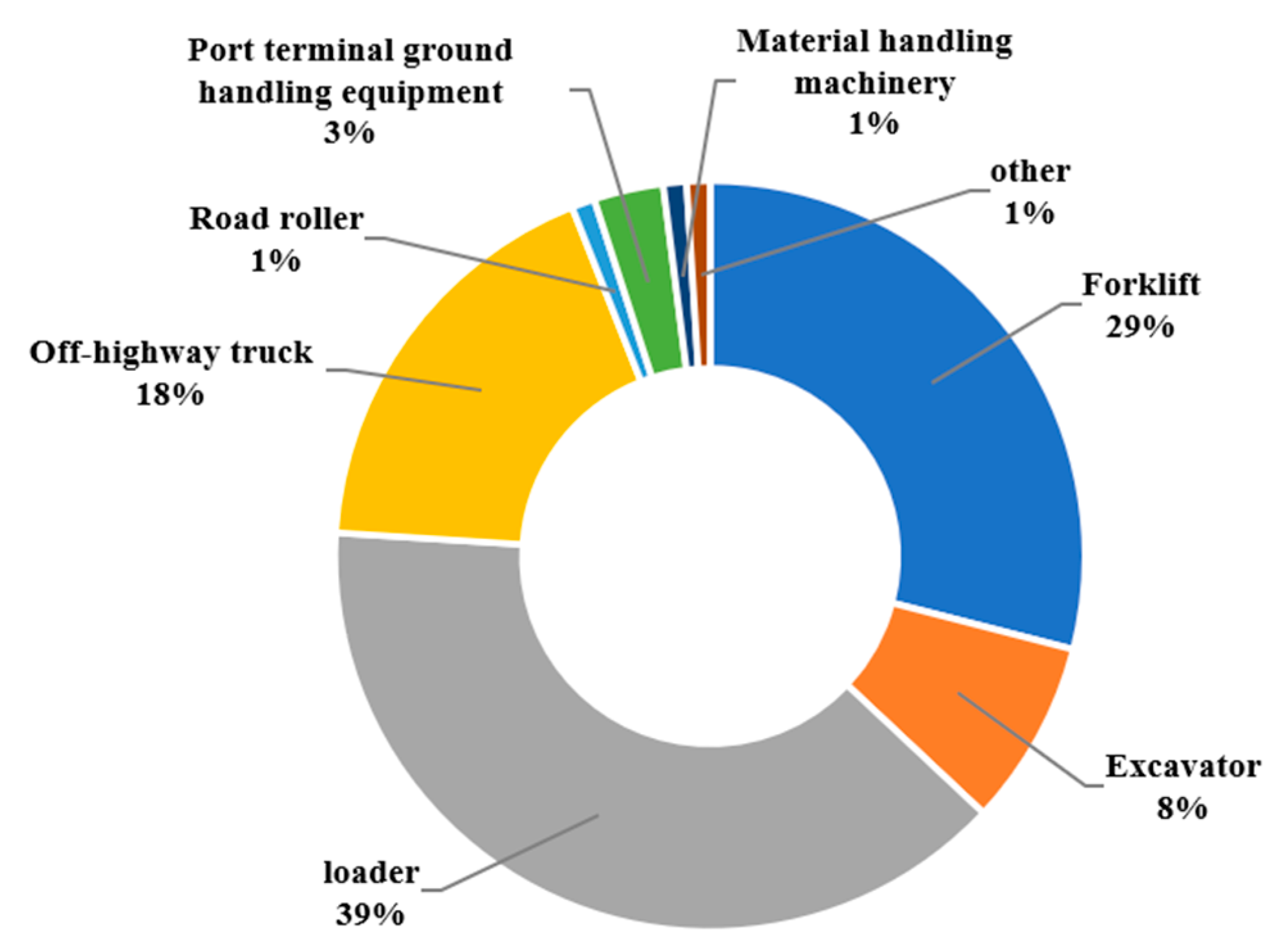

2. Materials and Methods

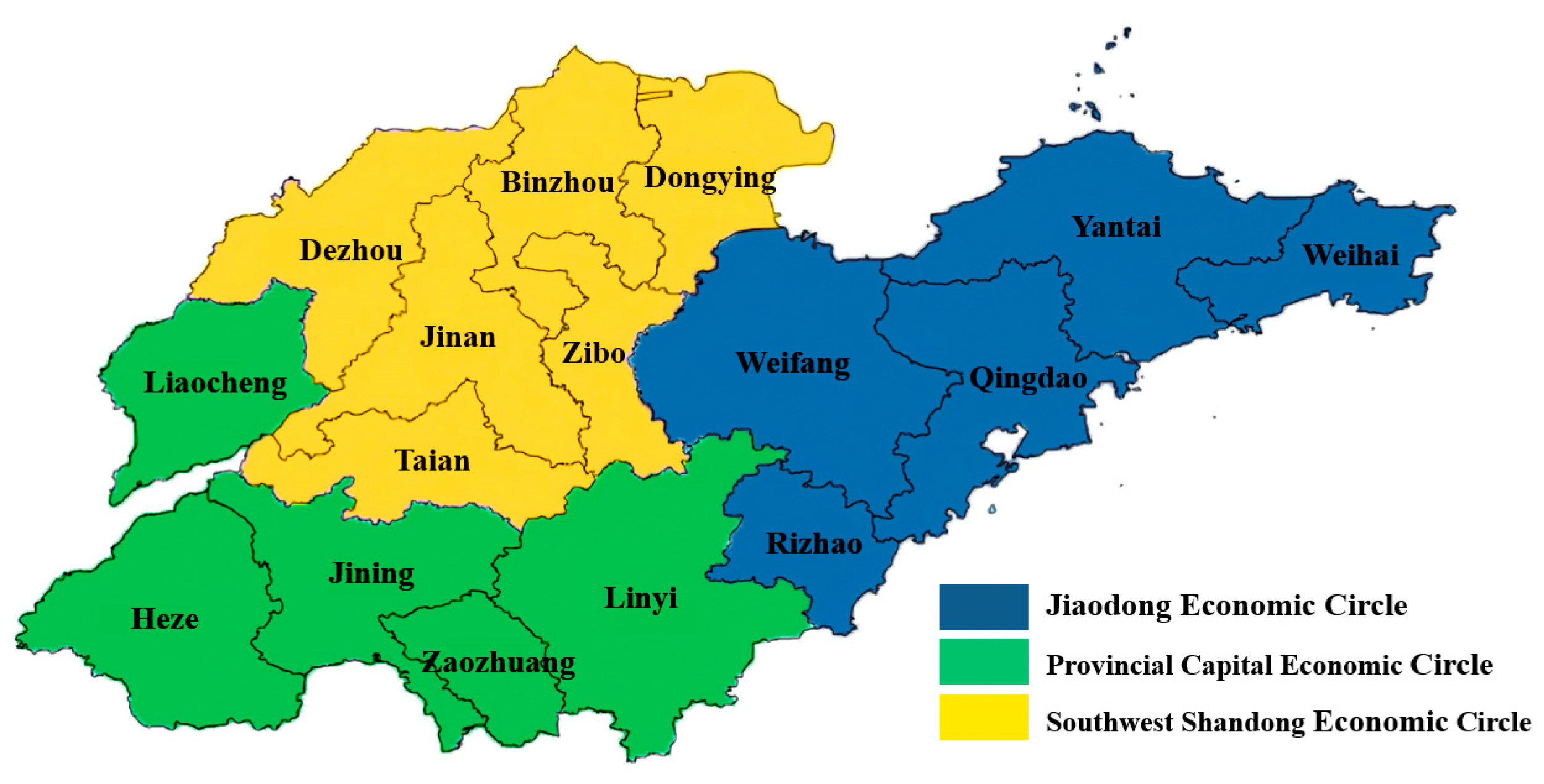

2.1. Overview of the Study Area

2.2. Data Sources

2.3. Methodology for Calculating Emission Inventories

2.4. Activity Level Data Collection and Statistical Methods

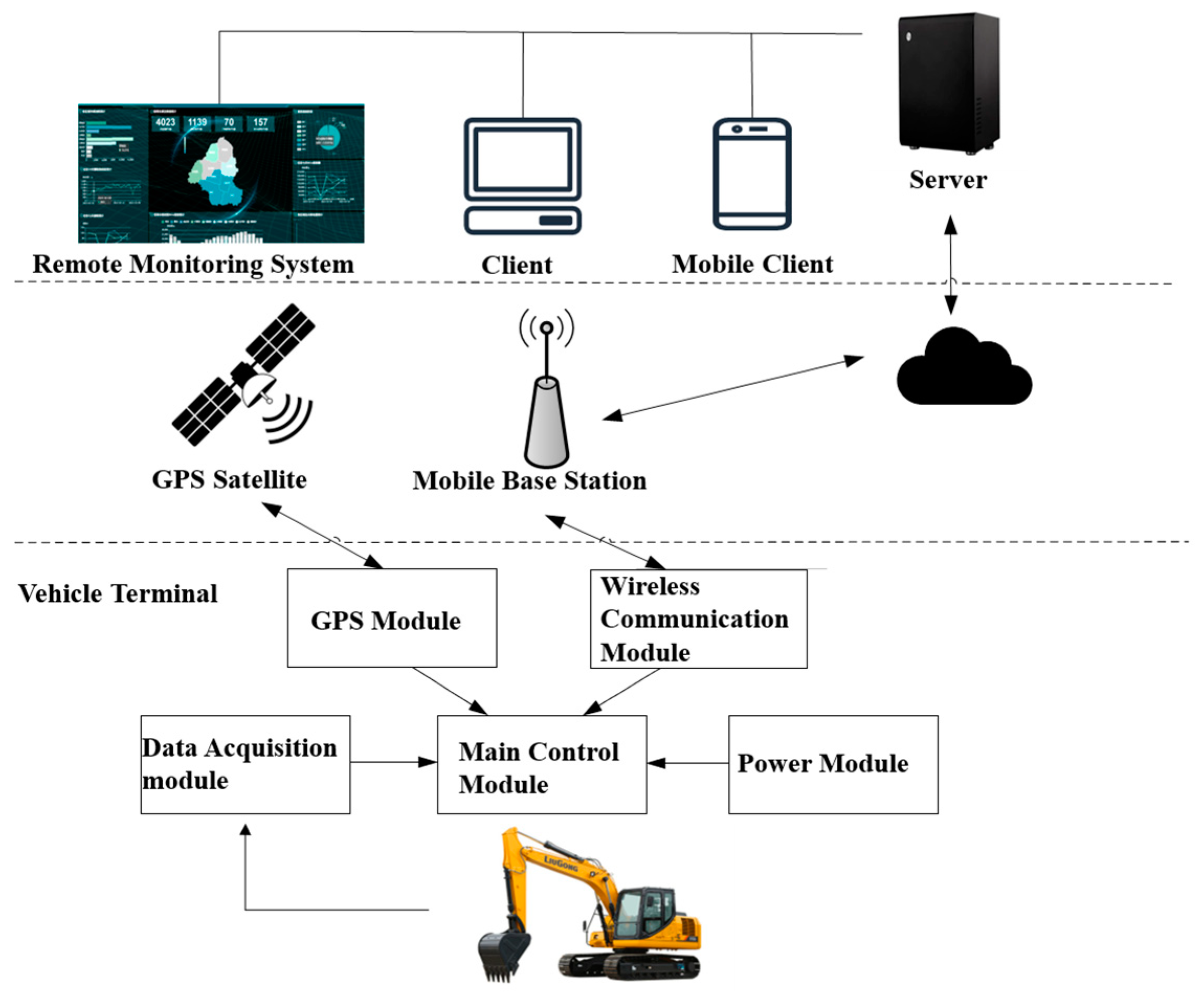

2.4.1. Remote Monitoring Management System

2.4.2. Statistical Method of the Actual Activity Level of Machinery

- Obtain the historical data of the database. Extract the required data from the database according to study year, region, machine type, etc.

- Data preprocessing. Perform data cleaning to ensure data quality and integrity, including the exclusion of missing values, duplicate values, and outliers.

- Calculate the actual activity level. For non-road mobile machinery equipped with an onboard terminal OBD, once started, it is connected to the server through wireless communication, and the mechanical data are sent to the server every 30 s. Therefore, as long as the total number of data of a non-road mobile machine on the platform is counted, the actual activity level of the machine in this period can be calculated. The specific calculation formula is as follows:where m is the total number of data of the machine in the database within a certain period.

- Data analysis. By employing big data technologies and methodologies, this study conducts statistical and trend analyses to reveal the distribution of actual activity levels. It also involves descriptive statistical analysis to characterize the overall distribution of the data.

3. Obtain the Calculation Parameters

3.1. Mechanical Activity Level

3.2. Net Mechanical Power Rating

3.3. Quantity of Stock

3.4. Selection of Other Factors

4. Results and Discussion

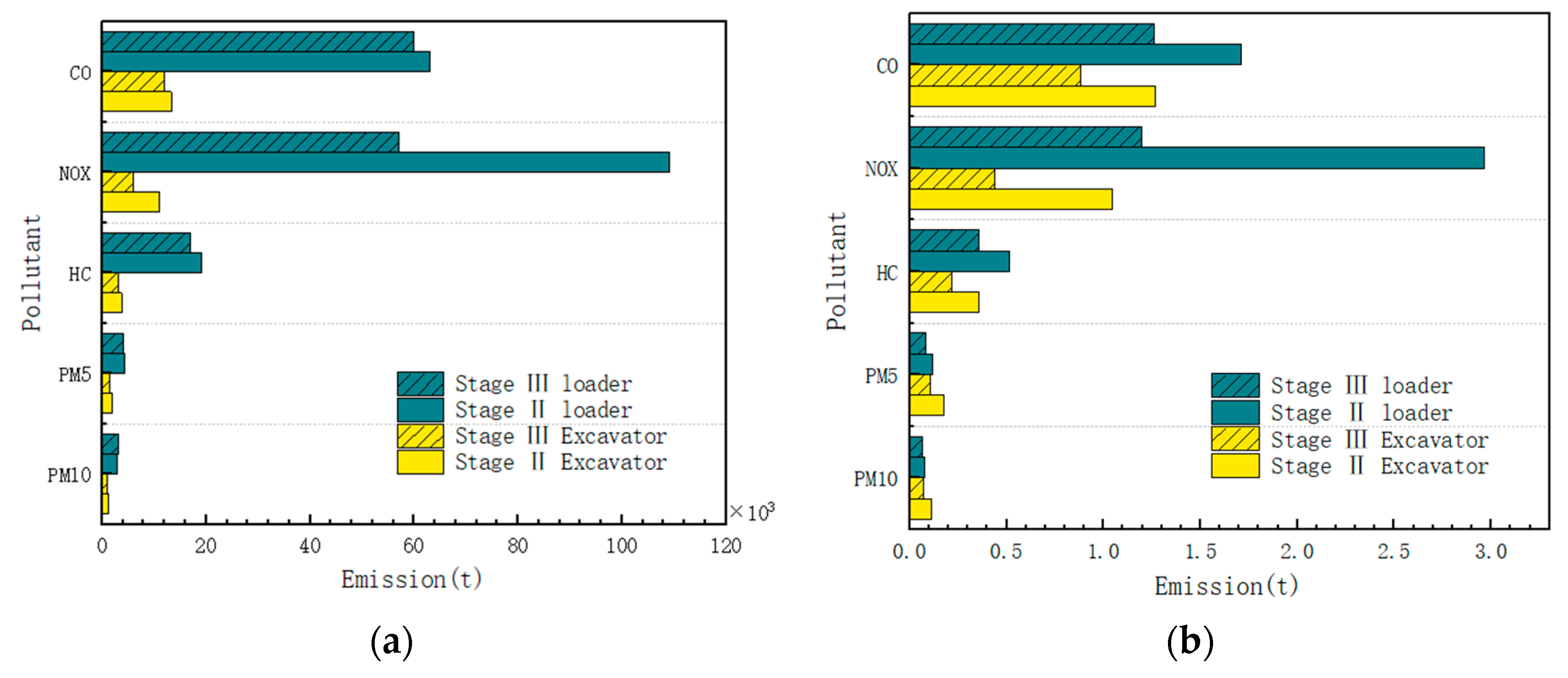

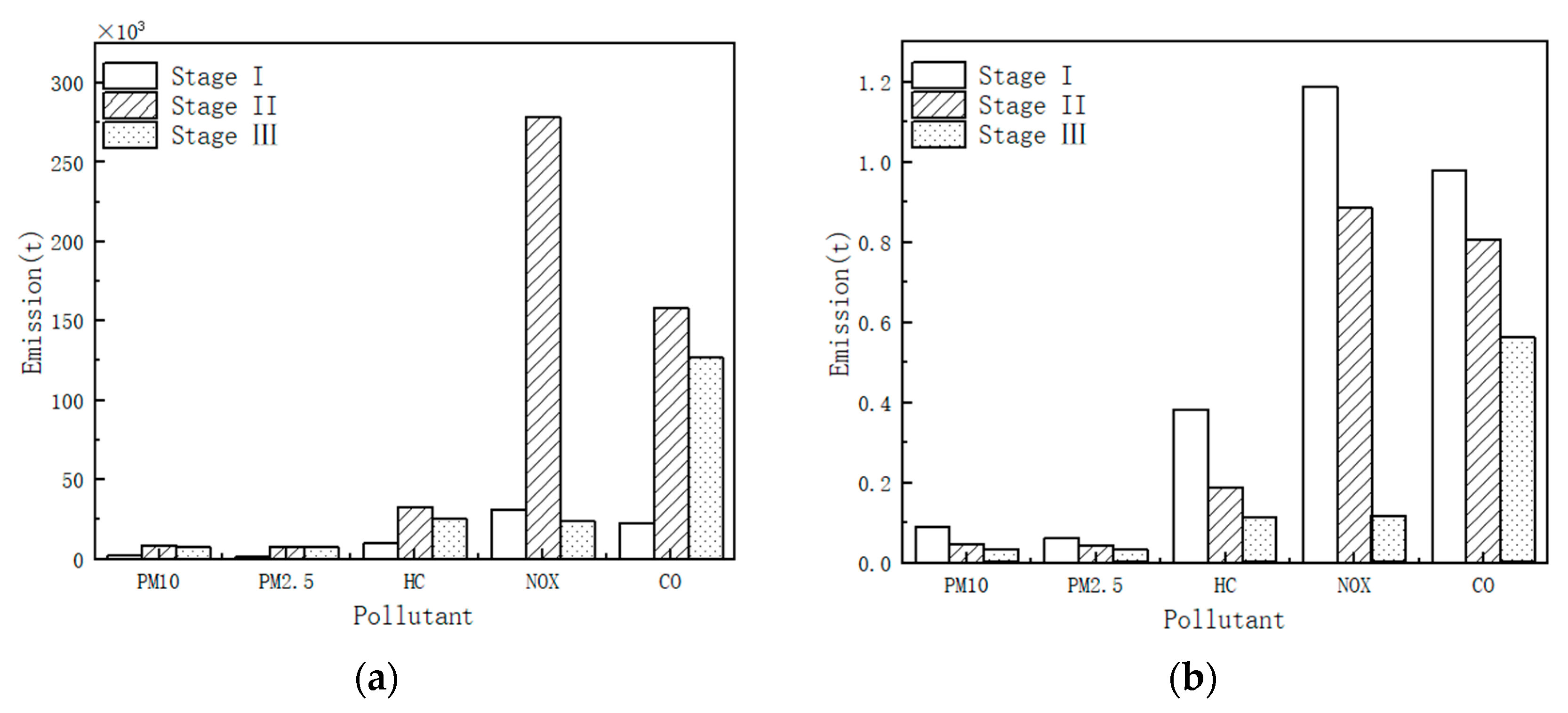

4.1. Calculation Result of Emission Inventory

4.2. Particulate Matter Emission Verification

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bie, P.; Ji, L.; Cui, H.; Li, G.; Liu, S.; Yuan, Y.; He, K.; Liu, H. A Review and Evaluation of Nonroad Diesel Mobile Machinery Emission Control in China. J. Environ. Sci. 2023, 123, 30–40. [Google Scholar] [CrossRef]

- Cui, M.; Chen, Y.; Li, C.; Yin, J.; Li, J.; Zheng, J. Parent and Methyl Polycyclic Aromatic Hydrocarbons and N-Alkanes Emitted by Construction Machinery in China. Sci. Total Environ. 2021, 775, 144759. [Google Scholar] [CrossRef]

- Wang, C.; Duan, W.; Cheng, S.; Zhang, J. Multi-Component Emission Characteristics and High-Resolution Emission Inventory of Non-Road Construction Equipment (NRCE) in China. Sci. Total Environ. 2023, 877, 162914. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, R.; Peng, S.; Zhang, X.; Mao, H.; Zhu, L.; Li, X.; Zheng, L.; Wang, Y. Study on Emission Characteristics of Non-Road Mobile Source Pollutants in Tianjin. IOP Conf. Ser. 2020, 467, 012163. [Google Scholar] [CrossRef]

- Gu, C.; Zhang, L.; Xu, Z.; Xia, S.; Wang, Y.; Li, L.; Wang, Z.; Zhao, Q.; Wang, H.; Zhao, Y. High-Resolution Regional Emission Inventory Contributes to the Evaluation of Policy Effectiveness: A Case Study in Jiangsu Province, China. Atmos. Chem. Phys. 2023, 23, 4247–4269. [Google Scholar] [CrossRef]

- Fan, W.; Chen, J.; Li, Y.; Jiang, T.; Sun, S.; Wang, G.; Liao, H.; Jiang, T.; Wu, K.; Qian, J.; et al. Study on the non-road mobile source emission inventory for Sichuan province. China Environ. Sci. 2018, 38, 4460–4468. (In Chinese) [Google Scholar]

- Huang, C.; An, J.; Jun, L. Emission Inventory and Prediction of Non-Road Machineries in the Yangtze River Delta Region, China. Huan Jing ke Xue Huanjing Kexue 2018, 39, 3965–3975. [Google Scholar]

- Gao, C.; You, H.; Ba, Q.; Liang, C. Study on a Non-road Mobile Source Emission Inventory and Scenario Prediction in Northeast China. J. Northeast. Univ. (Nat. Sci.) 2021, 42, 358–366. (In Chinese) [Google Scholar]

- Yang, L.; Zeng, W.; Zhang, Y.; Liu, Y.; Liao, C.; Gan, Y.; Deng, X. Establishment of emission inventory and spatial-temporal allocation model for air pollutant sources in the Pearl River Delta region. China Environ. Sci. 2015, 35, 3521–3534. (In Chinese) [Google Scholar]

- Shen, X.; Kong, L.; Shi, Y.; Cao, X.; Li, X.; Wu, B.; Zhang, H.; Yao, Z. Multi-Type Air Pollutant Emission Inventory of Non-Road Mobile Sources in China for the Period 1990–2017. Aerosol Air Qual. Res. 2021, 21, 210003. [Google Scholar] [CrossRef]

- Lončarević, Š.; Ilinčić, P.; Šagi, G.; Lulić, Z. Problems and Directions in Creating a National Non-Road Mobile Machinery Emission Inventory: A Critical Review. Sustainability 2022, 14, 3471. [Google Scholar] [CrossRef]

- Wu, B.; Xuan, K.; Shen, X.; Zhao, Q.; Shi, Y.; Kong, L.; Hu, J.; Li, X.; Zhang, H.; Cao, X.; et al. Non-Negligible Emissions of Black Carbon from Non-Road Construction Equipment Based on Real-World Measurements in China. Sci. Total Environ. 2022, 806, 151300. [Google Scholar] [CrossRef]

- Guo, X.; Wu, H.; Chen, D.; Ye, Z.; Shen, Y.; Liu, J.; Cheng, S. Estimation and Prediction of Pollutant Emissions from Agricultural and Construction Diesel Machinery in the Beijing-Tianjin-Hebei (BTH) Region, China☆. Environ. Pollut. 2020, 260, 113973. [Google Scholar] [CrossRef]

- Wang, C.; Duan, W.; Cheng, S.; Jiang, K. Emission Inventory and Air Quality Impact of Non-Road Construction Equipment in Different Emission Stages. Sci. Total Environ. 2024, 906, 167416. [Google Scholar] [CrossRef]

- Hou, X.; Tian, J.; Song, C.; Wang, J.; Zhao, J.; Zhang, X. Emission Inventory Research of Typical Agricultural Machinery in Beijing, China. Atmos. Environ. 2019, 216, 116903. [Google Scholar] [CrossRef]

- Li, X.; Yang, L.; Liu, Y.; Zhang, C.; Xu, X.; Mao, H.; Jin, T. Emissions of Air Pollutants from Non-Road Construction Machinery in Beijing from 2015 to 2019. Environ. Pollut. 2023, 317, 120729. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, Y.; Zhang, C.; Jin, T. Study of the Beijing construction machinery emission pollution in 2019. J. Saf. Environ. 2021, 21, 2835–2844. (In Chinese) [Google Scholar]

- Pang, K.L.; Zhang, K.S.; Ma, S.; Wang, F. Analysis of activity and its emissions trend for construction equipment in China. Huan Jing Ke Xue Huanjing Kexue 2020, 41, 1132–1142. (In Chinese) [Google Scholar]

- Sun, S. Study on Evolution of Vehicle Emissions in Shandong Province. Master’s Thesis, University of Jinan, Jinan, China, June 2017. [Google Scholar]

- Ministry of Environmental Protection. Technical Guidelines for Compilation of Emission Inventory of Air Pollutants from Non-Road Mobile Sources (Trial). 2014. Available online: https://www.mee.gov.cn/gkml/hbb/bgg/201501/W020150107594587960717.pdf (accessed on 1 December 2023).

- Wang, H.; Zhou, J.; Li, X.; Ling, Q.; Wei, H.; Gao, L.; He, Y.; Zhu, M.; Xiao, X.; Liu, Y.; et al. Review on Recent Progress in On-Line Monitoring Technology for Atmospheric Pollution Source Emissions in China. J. Environ. Sci. 2023, 123, 367–386. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Liu, X.; Cui, Y.-Y.; Shen, Y.; Wu, T.; Wu, B.; Yang, X. Characterization of Air Pollutant Emissions from Construction Machinery in Beijing and Evaluation of the Effectiveness of Control Measures Based on Information Code Registration Data. Chemosphere 2022, 303, 135064. [Google Scholar] [CrossRef]

- Yang, B.; Cui, H.; Liu, S.; Li, G. Distribution and Exhaust Smoke Characteristics of Typical Construction Machinery in Service in Jinan. Constr. Mach. Equip. 2021, 52, 108–112+13. (In Chinese) [Google Scholar]

- Liu, P.; Hu, M. Emission Inventory of Non-Road Mobile Machinery in Shenzhen. J. Shenzhen Univ. (Sci. Eng.) 2020, 38, 331–339. (In Chinese) [Google Scholar] [CrossRef]

- Wang, L. Study on Relationship among Dynamic Smoke, Filter Type Smoke Fs and Particles. Mod. Veh. Power 2016, 4, 32–35. [Google Scholar]

| Type of Machinery | Annual Use Hours | The Guide-Recommended Annual Use Hours | ||

|---|---|---|---|---|

| This Research | The Literature [18] | The Literature [7] | ||

| Forklift | 1642.8 | 2274 | 950 | 770 |

| Excavator | 2212.4 | 1983 | 1580 | 770 |

| Loader | 3618.3 | 2131 | 1261 | 770 |

| Off-highway truck | 3815.0 | - | - | 770 |

| Road roller | 2507.2 | 1983 | 617 | 770 |

| Port terminal ground handling equipment | 4321.5 | - | 2442 | 770 |

| Material handling machinery | 2760.3 | 2299 | 1826 | 770 |

| Other | 3268.2 | 3749 | - | 770 |

| Type of Machinery | Average Power | The Guide-Recommended Power |

|---|---|---|

| Forklift | 46 | 40 |

| Loader | 150 | 135 |

| Off-highway truck | 204 | 30 (other) |

| Excavator | 125 | 100 |

| Road roller | 118 | 110 |

| Port terminal ground handling equipment | 181 | 30 (other) |

| Material handling machinery | 145 | 30 (other) |

| Bulldozer | 153 | 120 |

| Asphalt pavers | 156 | 80 |

| Industrial drilling equipment | 132 | 30 (other) |

| Generator set | 180 | 88 |

| Air compressor | 152 | 30 (other) |

| Airport ground handling equipment | 18 | 30 (other) |

| Type of Machinery | Stage I and before | Stage II | Stage III | Total |

|---|---|---|---|---|

| Forklift | 15,884 | 109,044 | 140,812 | 265,740 |

| Excavator | 1537 | 10,504 | 13,579 | 25,620 |

| Loader | 5380 | 36,765 | 47,525 | 89,670 |

| Off-highway truck | 1793 | 12,255 | 15,842 | 29,890 |

| Road roller | 205 | 1401 | 1810 | 3416 |

| Port terminal ground handling equipment | 359 | 2451 | 3168 | 5978 |

| Material handling machinery | 256 | 1751 | 2263 | 4270 |

| Other | 154 | 1050 | 1358 | 2562 |

| Total | 25,568 | 175,221 | 226,357 | 427,146 |

| Emission Standard | PM10 | PM2.5 | HC | NOx | CO | |

|---|---|---|---|---|---|---|

| G < 37 kW | Stage I and before | 1.20 | 1.14 | 1.30 | 10.50 | 6.50 |

| Stage I | 1.00 | 0.95 | 1.30 | 10.50 | 6.50 | |

| Stage II | 0.95 | 0.90 | 1.30 | 7.50 | 6.50 | |

| Stage III | 0.55 | 0.52 | 1.10 | 6.00 | 5.00 | |

| 37 kW < G < 75 kW | Stage I and before | 1.00 | 0.95 | 1.30 | 10.50 | 6.50 |

| Stage I | 0.85 | 0.81 | 1.30 | 9.20 | 6.50 | |

| Stage II | 0.40 | 0.38 | 1.30 | 7.00 | 5.00 | |

| Stage III | 0.35 | 0.32 | 1.00 | 3.50 | 4.50 | |

| 75 kW < G < 130 kW | Stage I and before | 0.80 | 0.76 | 1.30 | 10.00 | 5.00 |

| Stage I | 0.70 | 0.67 | 1.30 | 9.20 | 5.00 | |

| Stage II | 0.30 | 0.29 | 1.00 | 6.00 | 5.00 | |

| Stage III | 0.25 | 0.23 | 0.80 | 2.80 | 4.50 | |

| G > 130 kW | Stage I and before | 0.70 | 0.67 | 1.30 | 10.00 | 5.00 |

| Stage I | 0.54 | 0.51 | 1.30 | 9.20 | 5.00 | |

| Stage II | 0.20 | 0.19 | 1.00 | 6.00 | 3.50 | |

| Stage III | 0.18 | 0.16 | 0.80 | 2.80 | 3.00 |

| Machinery Category | PM10 | PM2.5 | HC | NOx | CO |

|---|---|---|---|---|---|

| Forklift | 5208.1 | 4863.5 | 14,837.5 | 68,621.9 | 62,744.1 |

| Excavator | 1370.1 | 1294.1 | 4200.1 | 20,705.8 | 21,806.5 |

| Loader | 6915.7 | 6371.8 | 30,062.3 | 148,202.0 | 109,602.2 |

| Off-highway truck | 3172.3 | 2922.8 | 13,789.8 | 67,981.4 | 50,275.4 |

| Road roller | 195.4 | 184.6 | 599.1 | 2953.4 | 3110.4 |

| Port terminal ground handling equipment | 637.7 | 587.5 | 2771.9 | 13,665.0 | 10,105.9 |

| Material handling machinery | 233.1 | 214.7 | 1013.1 | 4994.5 | 3693.7 |

| Other | 188.4 | 173.6 | 819 | 4037.5 | 2985.9 |

| Total | 17,920.8 | 16,612.6 | 68,092.8 | 331,161.5 | 264,324.1 |

| Machinery Category | Exhaust Smoke (m−1) | Exhaust Flow (kg/h) | Activity Level (h) | Quantity of Stock | Particulate Matter Mass Estimated by Exhaust Smoke (t) | Inventory Estimation Quality (t) |

|---|---|---|---|---|---|---|

| Forklift | 0.55 | 282 | 1642.8 | 264,740 | 8171.6 | 5208.1 |

| Excavator | 0.23 | 782 | 2212.4 | 25,620 | 1235.0 | 1370.1 |

| Loader | 0.30 | 796 | 3618.3 | 89,670 | 9386.0 | 6915.7 |

| Off-highway truck | 0.20 | 929 | 3815.0 | 29,890 | 2566.6 | 3172.3 |

| Road roller | 0.35 | 702 | 2507.2 | 3416 | 254.9 | 195.4 |

| Port terminal ground handling equipment | 0.28 | 844 | 4321.5 | 5978 | 739.6 | 637.7 |

| Material handling machinery | 0.40 | 775 | 2760.3 | 4270 | 442.6 | 233.1 |

| Other | 0.53 | 688 | 3268.2 | 2562 | 369.9 | 188.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, N.; Cai, Y.; Ouyang, H.; Xiao, Z.; Xu, X. Investigation of Emission Inventory for Non-Road Mobile Machinery in Shandong Province: An Analysis Grounded in Real-World Activity Levels. Sustainability 2024, 16, 2292. https://doi.org/10.3390/su16062292

Zhu N, Cai Y, Ouyang H, Xiao Z, Xu X. Investigation of Emission Inventory for Non-Road Mobile Machinery in Shandong Province: An Analysis Grounded in Real-World Activity Levels. Sustainability. 2024; 16(6):2292. https://doi.org/10.3390/su16062292

Chicago/Turabian StyleZhu, Neng, Yunkai Cai, Hanxiao Ouyang, Zhe Xiao, and Xiaowei Xu. 2024. "Investigation of Emission Inventory for Non-Road Mobile Machinery in Shandong Province: An Analysis Grounded in Real-World Activity Levels" Sustainability 16, no. 6: 2292. https://doi.org/10.3390/su16062292

APA StyleZhu, N., Cai, Y., Ouyang, H., Xiao, Z., & Xu, X. (2024). Investigation of Emission Inventory for Non-Road Mobile Machinery in Shandong Province: An Analysis Grounded in Real-World Activity Levels. Sustainability, 16(6), 2292. https://doi.org/10.3390/su16062292